TOYOTA PRIUS 2001 Service Manual PDF

Manufacturer: TOYOTA, Model Year: 2001, Model line: PRIUS, Model: TOYOTA PRIUS 2001Pages: 1943, PDF Size: 18.26 MB

Page 71 of 1943

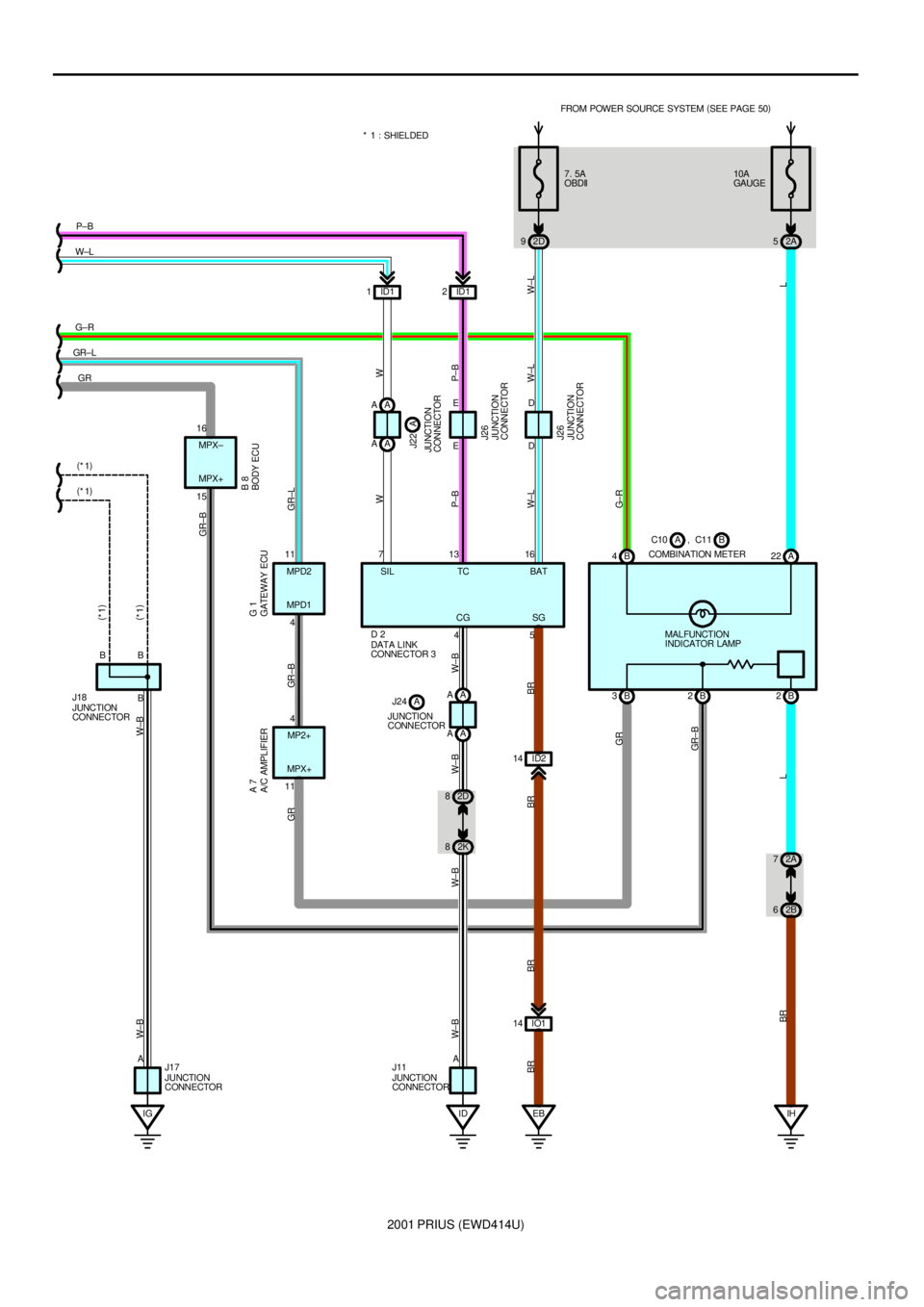

2001 PRIUS (EWD414U)

IGB 3B2 B 4 7. 5A

OBDII

2D 9

EB IO1 14ID2 14 15

B

115 4ED

4 11 16ED

BB

A71316FROM POWER SOURCE SYSTEM (

SEE PAGE 50)

JUNCTION

CONNECTOR J26 JUNCTION

CONNECTOR J26 BODY ECU B 8

A/C AMPLIFIER A 7

GATEWAY ECU G 1

DATA LINK

CONNECTOR 3 D 2

JUNCTION

CONNECTOR J18

W±L W

P±B

W±L W

P±B

W± L BR BR BR BR

GR

GR± B GR GR±B GR±L(

*1)

(

*1)

W±B W± B

G± R GR±B

GR GR± LG±R W±LP±B

(

*1) (

*1)

JUNCTION

CONNECTOR J17MPX+ MPD1 MPX+

SG CGBAT TC SIL MPD2 MPX±

MP2+

ID 2K 82D 8

W± B W± B

A

JUNCTION

CONNECTOR J11

W± B W± B

4 ID1 1ID12 * 1 : SHIELDED

COMBINATION METERB C10 , C11A10A

GAUGE

2A 5

L

A 22

MALFUNCTION

INDICATOR LAMP

B 2

IH 2A 7

2B 6

L BR

A A

A A A A

A A

JUNCTION

CONNECTORJ22 A

JUNCTION

CONNECTORJ24 A

Page 72 of 1943

2001 PRIUS (EWD414U)

ENGINE CONTROL

This system utilizes an engine control module and maintains overall control of the engine, transmission and so on. An outline

of the engine control is explained here.

1. INPUT SIGNALS

(1) Engine coolant temp. signal circuit

The engine coolant temp. sensor detects the engine coolant temp. and has a built±in thermistor with a resistance which

varies according to the engine coolant temp. thus the engine coolant temp. is input in the form of a control signal into

TERMINAL THW of the engine control module.

(2) Intake air temp. signal circuit

The intake air temp. sensor is installed in the mass air flow meter and detects the intake air temp., which is input as a

control signal into TERMINAL THA of the engine control module.

(3) Oxygen sensor signal circuit

The oxygen density in the exhaust gases is detected and input as a control signal into TERMINALS OX1A and OX1B of

the engine control module.

(4) RPM signal circuit

Camshaft position and crankshaft position are detected by the camshaft position sensor and crankshaft position sensor.

Camshaft position is input as a control signal to TERMINAL G2 of the engine control module, and engine RPM is input

into TERMINAL NE+.

(5) Throttle signal circuit

The throttle position sensor detects the throttle valve opening angle, which is input as a control signal into TERMINALS

VTA and VTA2 of the engine control module.

(6) Vehicle speed signal circuit

The vehicle speed signal from brake ECU, detects the vehicle speed and inputs a control signal into TERMINAL SPD of

the engine control module via the combination meter.

(7) Battery signal circuit

Voltage is constantly applied to TERMINAL BATT of the engine control module. When the ignition SW is turned on, the

voltage for engine control module start±up power supply is applied to TERMINAL +B of the engine control module via

EFI relay.

(8) Engine knock signal circuit

Engine knocking is detected by knock sensor and the signal is input into TERMINAL KNK1 of the engine control module

as a control signal.

2. CONTROL SYSTEM

*SFI system

The SFI system monitors the engine condition through the signals, which are input from each sensor to the engine

control module. The best fuel injection volume is decided based on this data and the program memorized by the engine

control module, and the control signal is output to TERMINALS #10, #20, #30 and #40 of the engine control module to

operate the injector. (Inject the fuel). The SFI system produces control of fuel injection operation by the engine control

module in response to the driving conditions.

*ESA system

The ESA system monitors the engine condition through the signals, which are input to the engine control module from

each sensor. The best ignition timing is detected according to this data and the memorized data in the engine control

module, and the control signal is output to TERMINALS IGT1, IGT2, IGT3 and IGT4. This signal controls the ignition coil

and igniter to provide the best ignition timing for the driving conditions.

*Fuel pump control system

The engine control module operation outputs to TERMINAL FC and controls the CIR OPN relay. Thus controls the fuel

pump drive speed in response to conditions.

3. DIAGNOSIS SYSTEM

With the diagnosis system, when there is a malfunctioning in the engine control module signal system, the malfunction

system is recorded in the memory. The malfunctioning system can then be found by reading the display (Code) of the

malfunction indicator lamp.

4. FAIL±SAFE SYSTEM

When a malfunction occurs in any system, if there is a possibility of engine trouble being caused by continued control based

on the signals from that system, the fail±safe system either controls the system by using data (Standard values) recorded in

the engine control module memory or else stops the engine.

SYSTEM OUTLINE

Page 73 of 1943

2001 PRIUS (EWD414U)

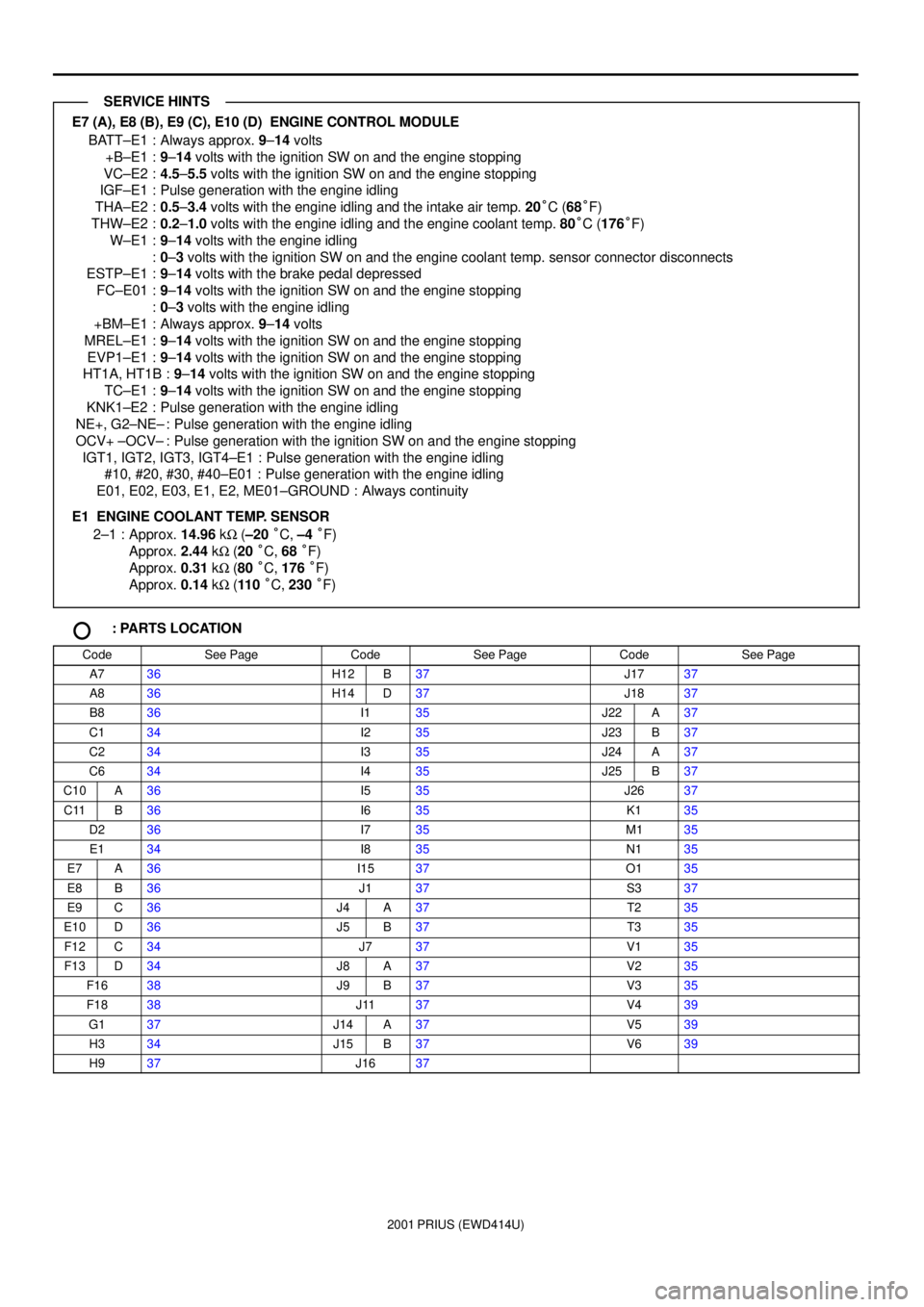

E7 (A), E8 (B), E9 (C), E10 (D) ENGINE CONTROL MODULE

BATT±E1 : Always approx. 9±14 volts

+B±E1 :9±14 volts with the ignition SW on and the engine stopping

VC±E2 :4.5±5.5 volts with the ignition SW on and the engine stopping

IGF±E1 : Pulse generation with the engine idling

THA±E2 :0.5±3.4 volts with the engine idling and the intake air temp. 20°C (68°F)

THW±E2 :0.2±1.0 volts with the engine idling and the engine coolant temp. 80°C (176°F)

W±E1 :9±14 volts with the engine idling

:0±3 volts with the ignition SW on and the engine coolant temp. sensor connector disconnects

ESTP±E1 :9±14 volts with the brake pedal depressed

FC±E01 :9±14 volts with the ignition SW on and the engine stopping

:0±3 volts with the engine idling

+BM±E1 : Always approx. 9±14 volts

MREL±E1 :9±14 volts with the ignition SW on and the engine stopping

EVP1±E1 :9±14 volts with the ignition SW on and the engine stopping

HT1A, HT1B :9±14 volts with the ignition SW on and the engine stopping

TC±E1 :9±14 volts with the ignition SW on and the engine stopping

KNK1±E2 : Pulse generation with the engine idling

NE+, G2±NE± : Pulse generation with the engine idling

OCV+ ±OCV± : Pulse generation with the ignition SW on and the engine stopping

IGT1, IGT2, IGT3, IGT4±E1 : Pulse generation with the engine idling

#10, #20, #30, #40±E01 : Pulse generation with the engine idling

E01, E02, E03, E1, E2, ME01±GROUND : Always continuity

E1 ENGINE COOLANT TEMP. SENSOR

2±1 : Approx. 14.96 kW (±20 °C, ±4 °F)

Approx. 2.44 kW (20 °C, 68 °F)

Approx. 0.31 kW (80 °C, 176 °F)

Approx. 0.14 kW (110 °C, 230 °F)

: PARTS LOCATION

CodeSee PageCodeSee PageCodeSee Page

A736H12B37J1737

A836H14D37J1837

B836I135J22A37

C134I235J23B37

C234I335J24A37

C634I435J25B37

C10A36I535J2637

C11B36I635K135

D236I735M135

E134I835N135

E7A36I1537O135

E8B36J137S337

E9C36J4A37T235

E10D36J5B37T335

F12C34J737V135

F13D34J8A37V235

F1638J9B37V335

F1838J1137V439

G137J14A37V539

H334J15B37V639

H937J1637

SERVICE HINTS

Page 74 of 1943

2001 PRIUS (EWD414U)

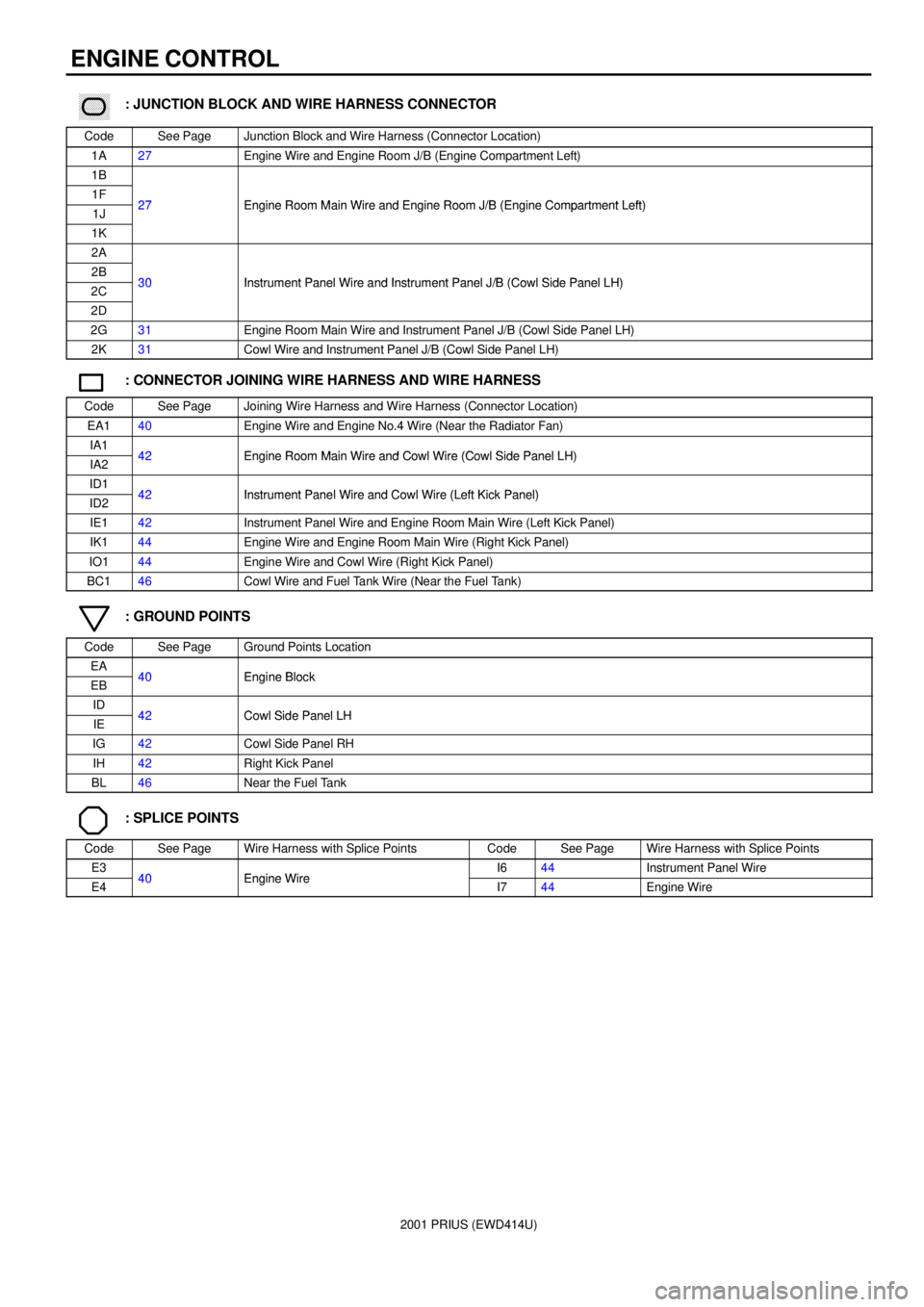

ENGINE CONTROL

������ ���: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CodeSee PageJunction Block and Wire Harness (Connector Location)

1A27Engine Wire and Engine Room J/B (Engine Compartment Left)

1B

1F27Engine Room Main Wire and Engine Room J/B (Engine Compartment Left)1J27Engine Room Main Wire and Engine Room J/B (Engine Compartment Left)

1K

2A

2B30Instrument Panel Wire and Instrument Panel J/B (Cowl Side Panel LH)2C30Instrument Panel Wire and Instrument Panel J/B (Cowl Side Panel LH)

2D

2G31Engine Room Main Wire and Instrument Panel J/B (Cowl Side Panel LH)

2K31Cowl Wire and Instrument Panel J/B (Cowl Side Panel LH)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CodeSee PageJoining Wire Harness and Wire Harness (Connector Location)

EA140Engine Wire and Engine No.4 Wire (Near the Radiator Fan)

IA142Engine Room Main Wire and Cowl Wire (Cowl Side Panel LH)IA242Engine Room Main Wire and Cowl Wire (Cowl Side Panel LH)

ID142Instrument Panel Wire and Cowl Wire (Left Kick Panel)ID242Instrument Panel Wire and Cowl Wire (Left Kick Panel)

IE142Instrument Panel Wire and Engine Room Main Wire (Left Kick Panel)

IK144Engine Wire and Engine Room Main Wire (Right Kick Panel)

IO144Engine Wire and Cowl Wire (Right Kick Panel)

BC146Cowl Wire and Fuel Tank Wire (Near the Fuel Tank)

: GROUND POINTS

CodeSee PageGround Points Location

EA40Engine BlockEB40Engine Block

ID42Cowl Side Panel LHIE42Cowl Side Panel LH

IG42Cowl Side Panel RH

IH42Right Kick Panel

BL46Near the Fuel Tank

: SPLICE POINTS

CodeSee PageWire Harness with Splice PointsCodeSee PageWire Harness with Splice Points

E340Engine WireI644Instrument Panel Wire

E440Engine WireI744Engine Wire

Page 75 of 1943

2001 PRIUS (EWD414U)

MEMO

Page 76 of 1943

2001 PRIUS (EWD414U)

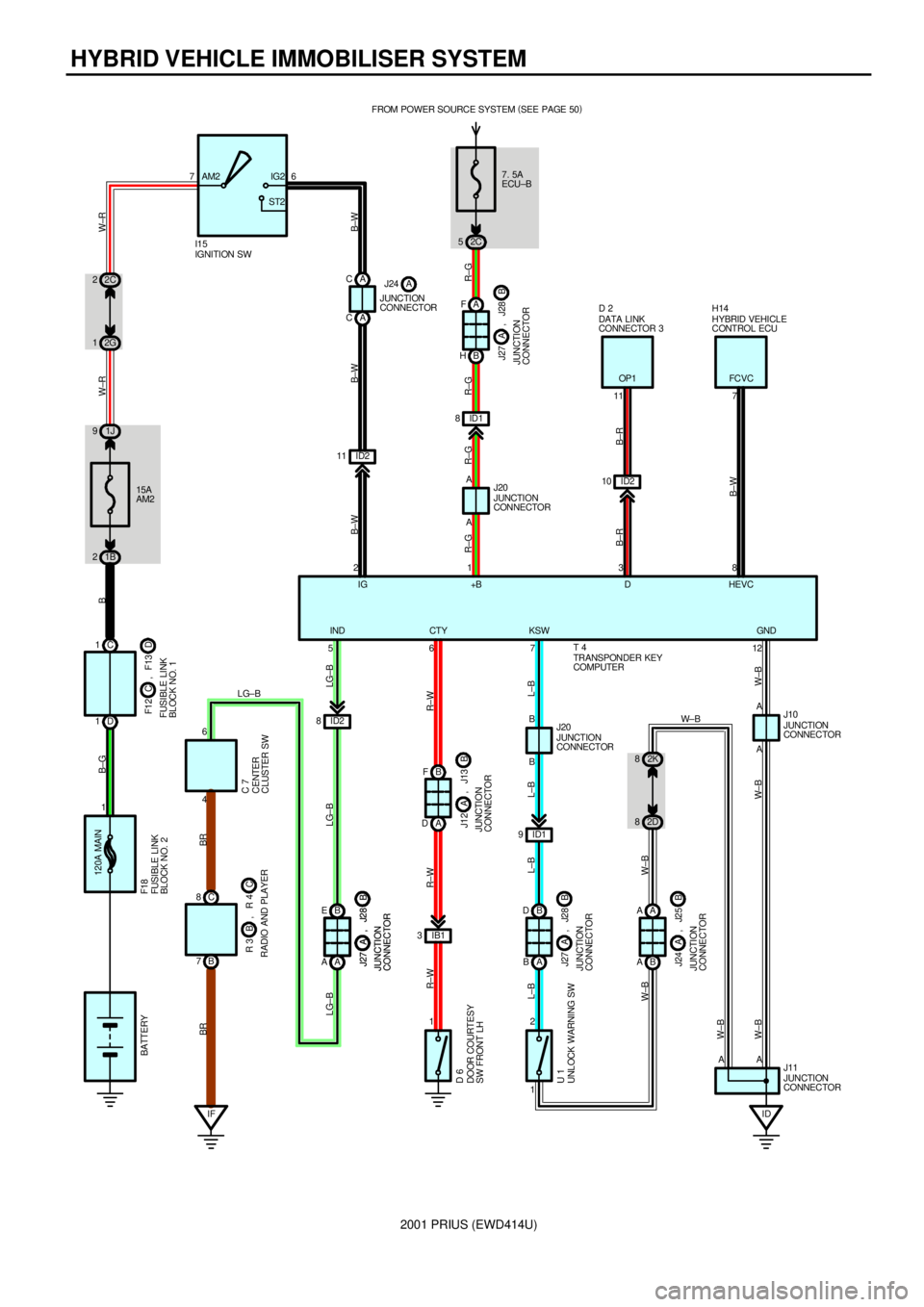

HYBRID VEHICLE IMMOBILISER SYSTEM

7. 5A

ECU±B FROM POWER SOURCE SYSTEM (

SEE PAGE 50)

2C 5

A A AA F

B H

5JUNCTION

CONNECTOR J20

JUNCTION

CONNECTOR J11 1

12

R±G R±G R±G LG±B

W±B W± B W±B

+B HEVC

IND

JUNCTION

CONNECTORB J27 A , J28

ID2 10 ID2 11 76

15A

AM2

1B 21J 92C 2

2G 1

D 1C 1

120A MAIN

1AM2 IG2

ST2

IFC 8

B 7B E

A A

JUNCTION

CONNECTORB J27 A , J28

JUNCTION

CONNECTORB J27 A , J28

B F

A D

JUNCTION

CONNECTORB J12 A , J13

B D

A B

JUNCTION

CONNECTORB J27 A , J28

A A

B A

JUNCTION

CONNECTORB J24 A , J25

ID A A

2D 8

1 2ID1 9B B

IB1 3

1 ID2 8

JUNCTION

CONNECTOR J10

JUNCTION

CONNECTOR J20

46711 7

238

6DATA LINK

CONNECTOR 3 D 2

HYBRID VEHICLE

CONTROL ECU H14

CENTER

CLUSTER SW C 7

DOOR COURTESY

SW FRONT LH D 6

UNLOCK WARNING SW U 1RADIO AND PLAYERC R 3 B , R 4FUSIBLE LINK

BLOCK NO. 1D F1 2 C , F13 BATTERYB±G B W±R W±R

B±W B±W B±W

B±R

B±WB±R R±W

L±B

W±BL±B L±B L±B

W±BR±W R±WLG±B BR BR

LG±B

2K 8

A IG D

KSW CTY

LG±B

FUSIBLE LINK

BLOCK NO. 2 F18

W±B

W± B ID1 8

R±G

IGNITION SW I15

OP1 FC VC

GND

TRANSPONDER KEY

COMPUTER T 4 A C

A CJUNCTION

CONNECTORJ24 A

Page 77 of 1943

2001 PRIUS (EWD414U)

T4 TRANSPONDER KEY COMPUTER

1±GROUND : Always approx. 12 volts

12±GROUND : Always continuity

U1 UNLOCK WARNING SW

1±2 : Closed with the ignition key in cylinder

: PARTS LOCATION

CodeSee PageCodeSee PageCodeSee Page

C736I1537J25B37

D236J1037J27A37

D638J1137J28B37

F12C34J12A37R3B37

F13D34J13B37R4C37

F1838J2037T437

H1437J24A37U137

������ ���: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CodeSee PageJunction Block and Wire Harness (Connector Location)

1B27Engine Room Main Wire and Engine Room J/B (Engine Compartment Left)1J27Engine Room Main Wire and Engine Room J/B (Engine Compartment Left)

2C30Instrument Panel Wire and Instrument Panel J/B (Cowl Side Panel LH)2D30Instrument Panel Wire and Instrument Panel J/B (Cowl Side Panel LH)

2G31Engine Room Main Wire and Instrument Panel J/B (Cowl Side Panel LH)

2K31Cowl Wire and Instrument Panel J/B (Cowl Side Panel LH)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CodeSee PageJoining Wire Harness and Wire Harness (Connector Location)

IB142Floor Wire and Cowl Wire (Cowl Side Panel LH)

ID142Instrument Panel Wire and Cowl Wire (Left Kick Panel)ID242Instrument Panel Wire and Cowl Wire (Left Kick Panel)

: GROUND POINTS

CodeSee PageGround Points Location

ID42Cowl Side Panel LH

IF42Left Kick Panel

SERVICE HINTS

Page 78 of 1943

2001 PRIUS (EWD414U)

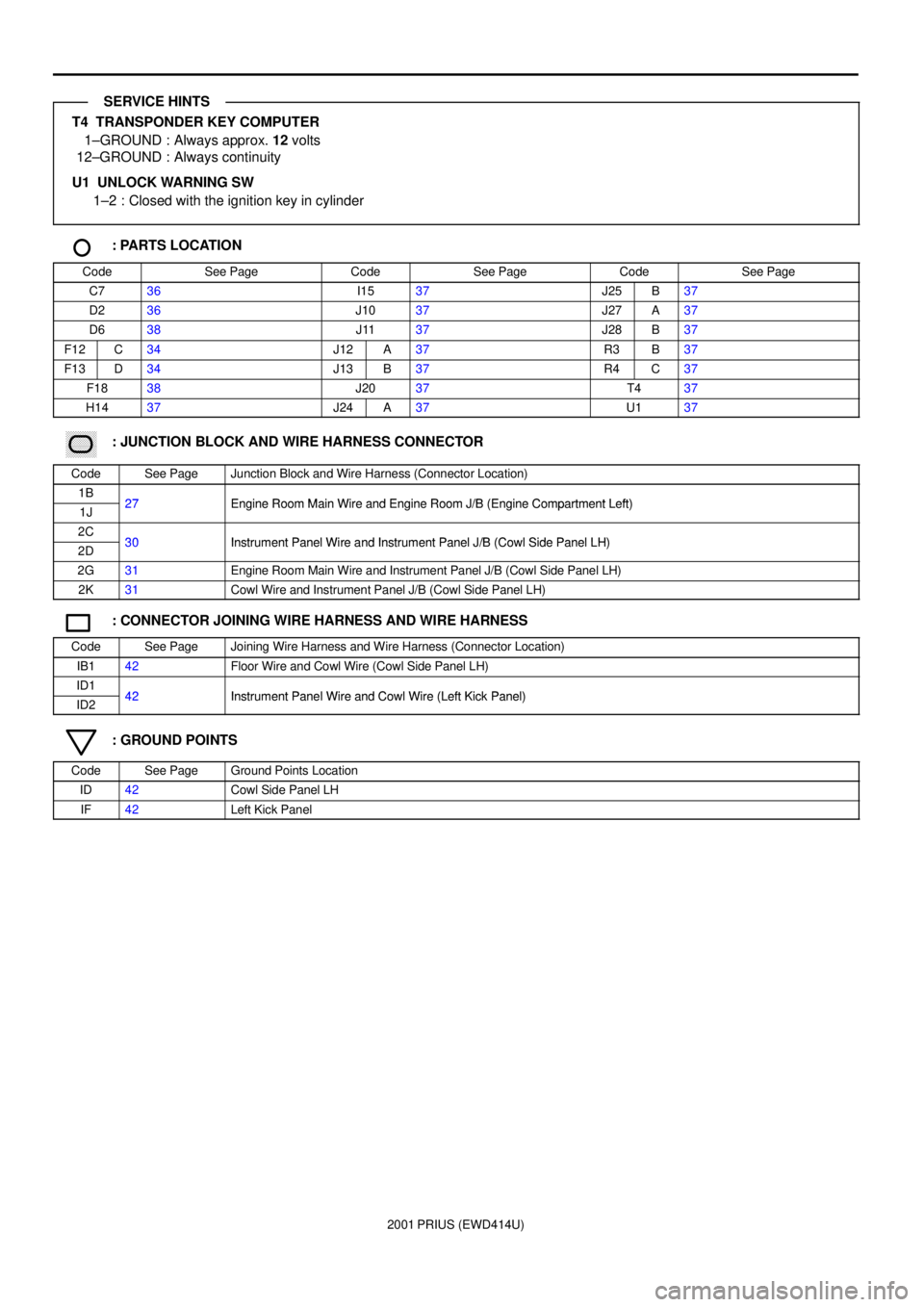

HEADLIGHT (w/ DAYTIME RUNNING LIGHT)

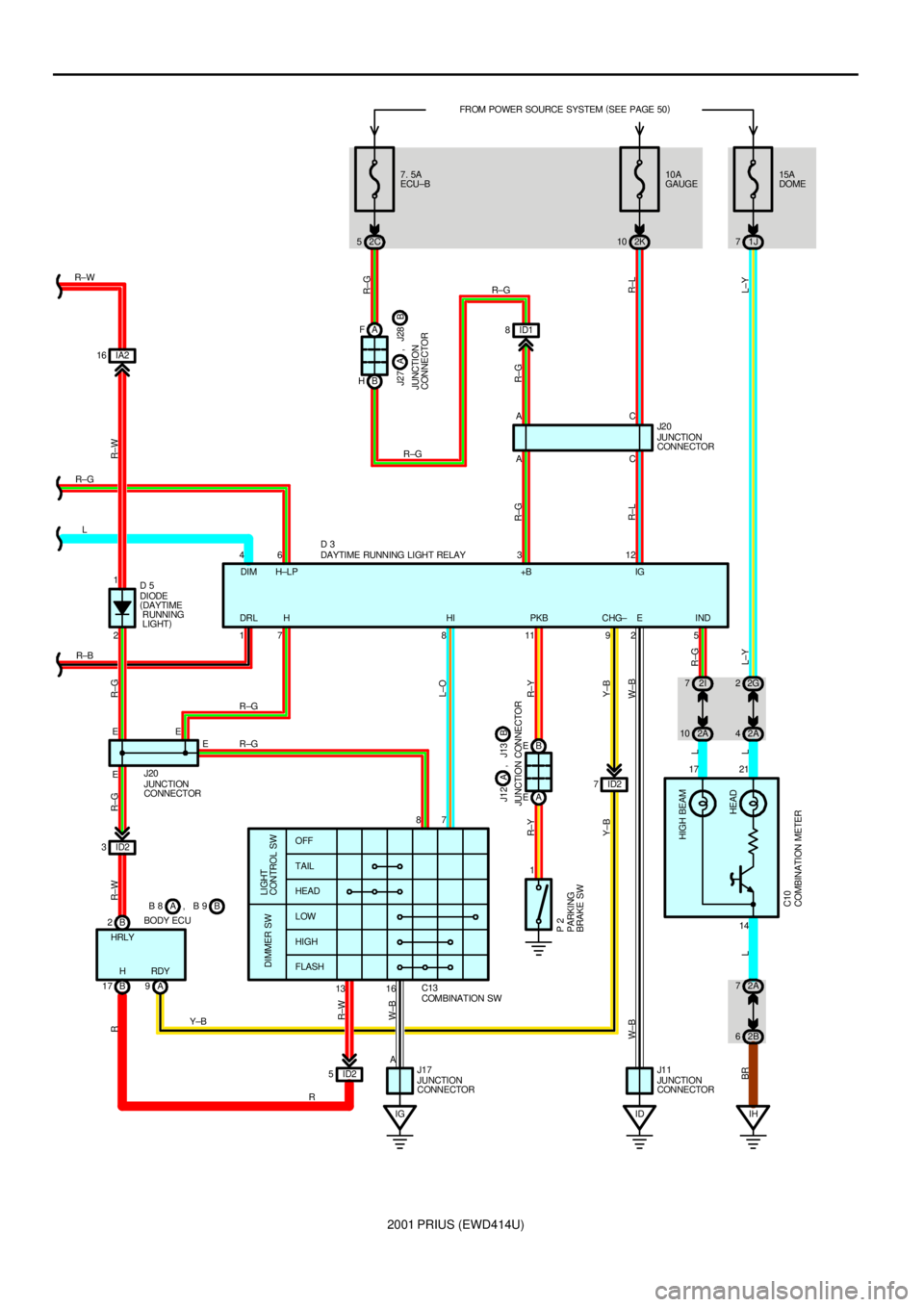

30A

HEAD FROM POWER SOURCE SYSTEM (

SEE PAGE 50)

23 14

32 14 2 1

10A

HEAD HI (

RH) 10A

HEAD HI (

LH) 10A

HEAD LO (

RH) 10A

HEAD LO (

LH)

213

213IA19 1E 5 1E 2 1F 7 1F 6313 25

33 7. 5A

DRL

33

IE 1E 31F8

IA217 IA26

JUNCTION

CONNECTOR J 1 A

G± R R±WR±YR

R±G R±G

R±W

R

W±B W±B

R±G

LR±G

L R±W

R±B R±L

R±G HEAD

RELAY

DIM

RELAYDRL

RELAY

R±B

HEADLIGHT

LH H 1

HEADLIGHT

RH H 2

R±Y G±R

2 1

E 2

R±B

Page 79 of 1943

2001 PRIUS (EWD414U)

2B 62A 7 10 2A72I

ID OFF

TAIL

HEAD

LOW

HIGH

IG ID2 510A

GAUGE FROM POWER SOURCE SYSTEM (

SEE PAGE 50)

2K 10

B E

A E

1ID2 7 7. 5A

ECU±B

2C 5

ID1 8

IA2 16

DAYTIME RUNNING LIGHT RELAY D 3

JUNCTION

CONNECTOR J20JUNCTION

CONNECTOR J2 0

JUNCTION

CONNECTOR J17

JUNCTION

CONNECTOR J1 1

PARKING

BRAKE SW P 2

COMBINATION SW C13 DIODE

(

DAYTIME

RUNNING

LIGHT) D 5 1

EE46 3 12AC

87

A17 2

E17 8 11 92 5AC

14

R±W

R±G

R±L R±G R±G

R±L R±W RR±GR±G

L±O

R±Y

Y±B

W±B

R±G L Y±B R±Y

BRW±B

L

R±BL R±G R±W

R R±G R±G

R±W

W±B

EDRL HDIM H±LP +B IG

HI PKB CHG± IND

ID2 3

13 16

JUNCTION CONNECTORB J12 A , J13

B 2

B 17 A9 BODY ECUB B 8 , B 9A

Y±BA F

B HR±G

R±G

JUNCTION

CONNECTORB J27 A , J28

E

FLASH

LIGHT

CONTROL SW DIMMER SW

15A

DOME

1J 7

HIGH BEAM

HEAD

42A 22G

LL±Y

21

COMBINATION METER C10L±Y

H RDY HRLY

IH

Page 80 of 1943

2001 PRIUS (EWD414U)

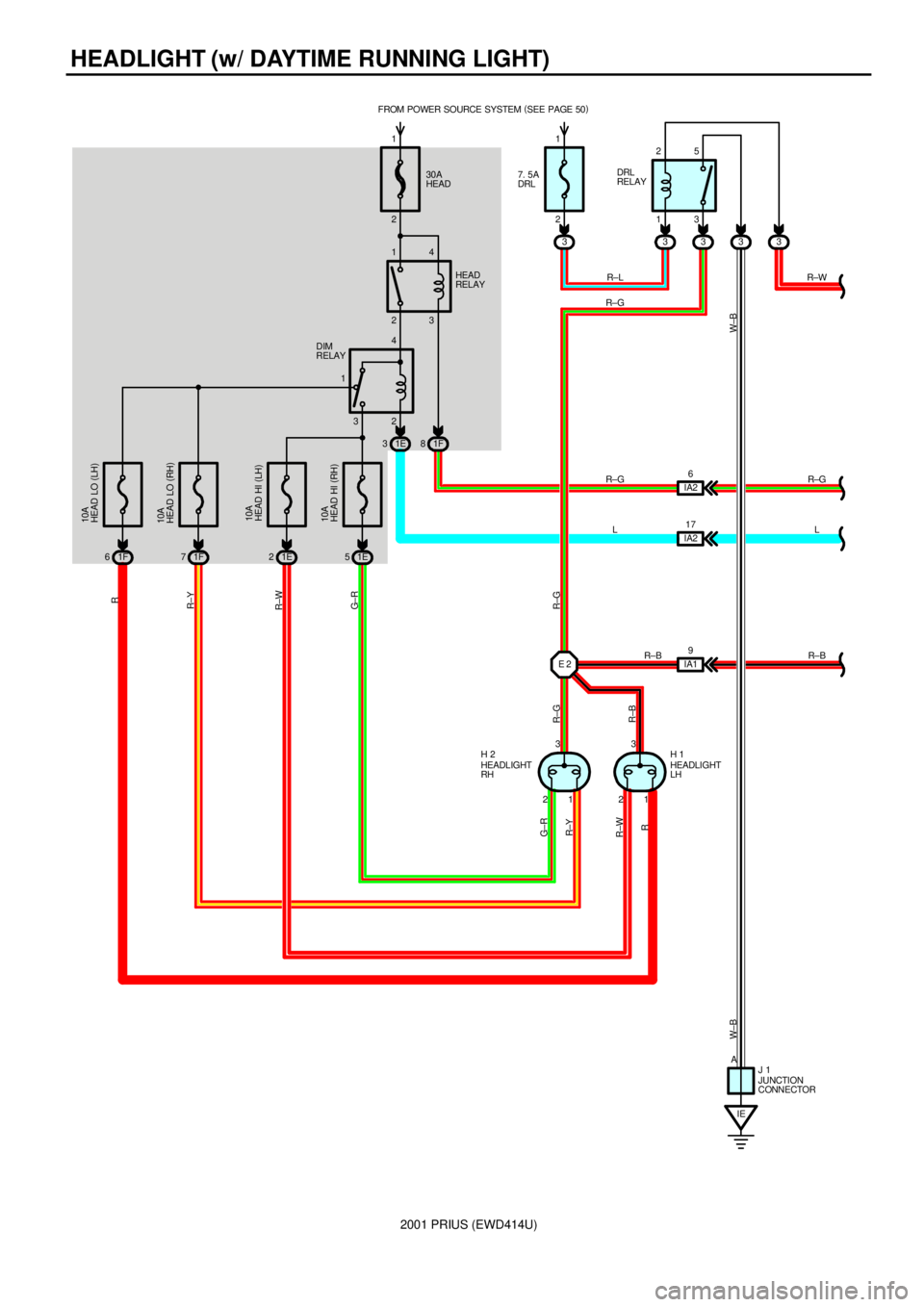

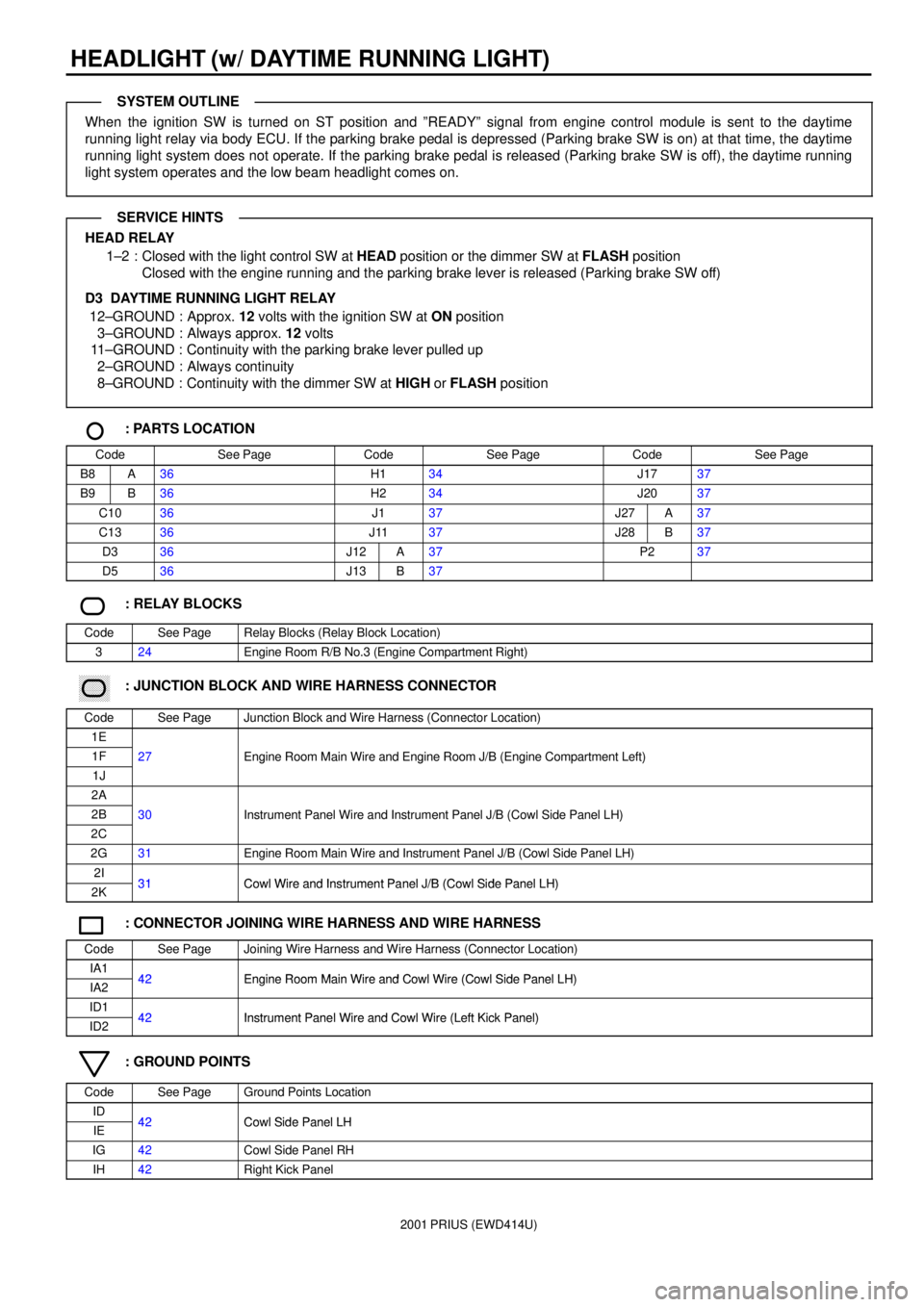

HEADLIGHT (w/ DAYTIME RUNNING LIGHT)

When the ignition SW is turned on ST position and ºREADYº signal from engine control module is sent to the daytime

running light relay via body ECU. If the parking brake pedal is depressed (Parking brake SW is on) at that time, the daytime

running light system does not operate. If the parking brake pedal is released (Parking brake SW is off), the daytime running

light system operates and the low beam headlight comes on.

HEAD RELAY

1±2 : Closed with the light control SW at HEAD position or the dimmer SW at FLASH position

Closed with the engine running and the parking brake lever is released (Parking brake SW off)

D3 DAYTIME RUNNING LIGHT RELAY

12±GROUND : Approx. 12 volts with the ignition SW at ON position

3±GROUND : Always approx. 12 volts

11±GROUND : Continuity with the parking brake lever pulled up

2±GROUND : Always continuity

8±GROUND : Continuity with the dimmer SW at HIGH or FLASH position

: PARTS LOCATION

CodeSee PageCodeSee PageCodeSee Page

B8A36H134J1737

B9B36H234J2037

C1036J137J27A37

C1336J1137J28B37

D336J12A37P237

D536J13B37

: RELAY BLOCKS

CodeSee PageRelay Blocks (Relay Block Location)

324Engine Room R/B No.3 (Engine Compartment Right)

������ ���: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CodeSee PageJunction Block and Wire Harness (Connector Location)

1E

1F27Engine Room Main Wire and Engine Room J/B (Engine Compartment Left)

1J

gg(g)

2A

2B30Instrument Panel Wire and Instrument Panel J/B (Cowl Side Panel LH)

2C

()

2G31Engine Room Main Wire and Instrument Panel J/B (Cowl Side Panel LH)

2I31Cowl Wire and Instrument Panel J/B (Cowl Side Panel LH)2K31Cowl Wire and Instrument Panel J/B (Cowl Side Panel LH)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CodeSee PageJoining Wire Harness and Wire Harness (Connector Location)

IA142Engine Room Main Wire and Cowl Wire (Cowl Side Panel LH)IA242Engine Room Main Wire and Cowl Wire (Cowl Side Panel LH)

ID142Instrument Panel Wire and Cowl Wire (Left Kick Panel)ID242Instrument Panel Wire and Cowl Wire (Left Kick Panel)

: GROUND POINTS

CodeSee PageGround Points Location

ID42Cowl Side Panel LHIE42Cowl Side Panel LH

IG42Cowl Side Panel RH

IH42Right Kick Panel

SYSTEM OUTLINE

SERVICE HINTS