wheel bolts TOYOTA PROACE CITY VERSO 2021 Owners Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2021, Model line: PROACE CITY VERSO, Model: TOYOTA PROACE CITY VERSO 2021Pages: 272, PDF Size: 57.64 MB

Page 170 of 272

170

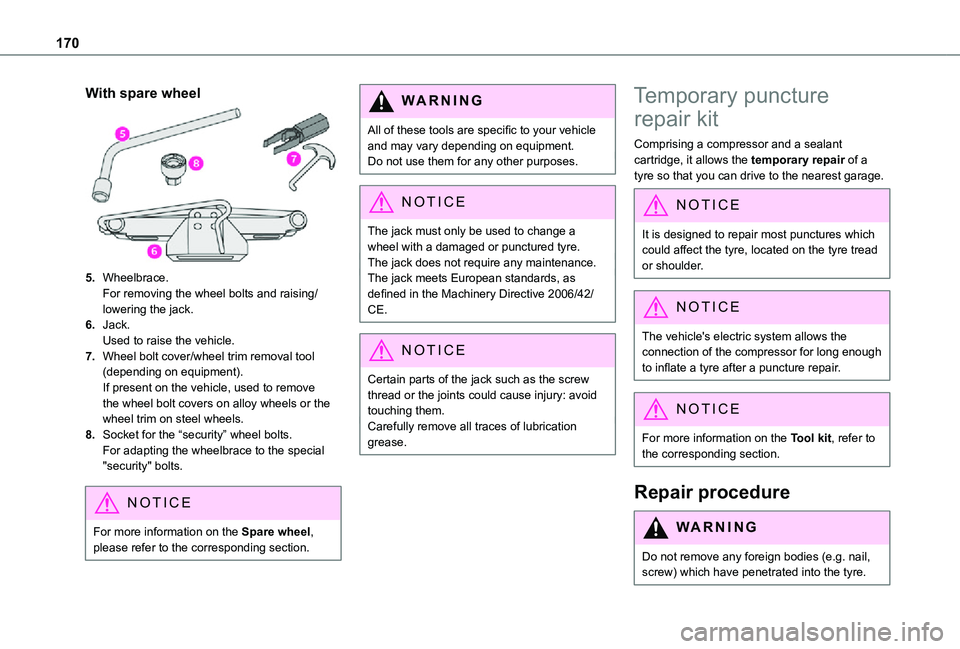

With spare wheel

5.Wheelbrace.For removing the wheel bolts and raising/lowering the jack.

6.Jack.Used to raise the vehicle.

7.Wheel bolt cover/wheel trim removal tool (depending on equipment).If present on the vehicle, used to remove the wheel bolt covers on alloy wheels or the wheel trim on steel wheels.

8.Socket for the “security” wheel bolts.For adapting the wheelbrace to the special "security" bolts.

NOTIC E

For more information on the Spare wheel, please refer to the corresponding section.

WARNI NG

All of these tools are specific to your vehicle and may vary depending on equipment.Do not use them for any other purposes.

NOTIC E

The jack must only be used to change a

wheel with a damaged or punctured tyre.The jack does not require any maintenance.The jack meets European standards, as defined in the Machinery Directive 2006/42/CE.

NOTIC E

Certain parts of the jack such as the screw thread or the joints could cause injury: avoid touching them.Carefully remove all traces of lubrication grease.

Temporary puncture

repair kit

Comprising a compressor and a sealant cartridge, it allows the temporary repair of a tyre so that you can drive to the nearest garage.

NOTIC E

It is designed to repair most punctures which

could affect the tyre, located on the tyre tread or shoulder.

NOTIC E

The vehicle's electric system allows the connection of the compressor for long enough to inflate a tyre after a puncture repair.

NOTIC E

For more information on the Tool kit, refer to the corresponding section.

Repair procedure

WARNI NG

Do not remove any foreign bodies (e.g. nail, screw) which have penetrated into the tyre.

Page 174 of 272

174

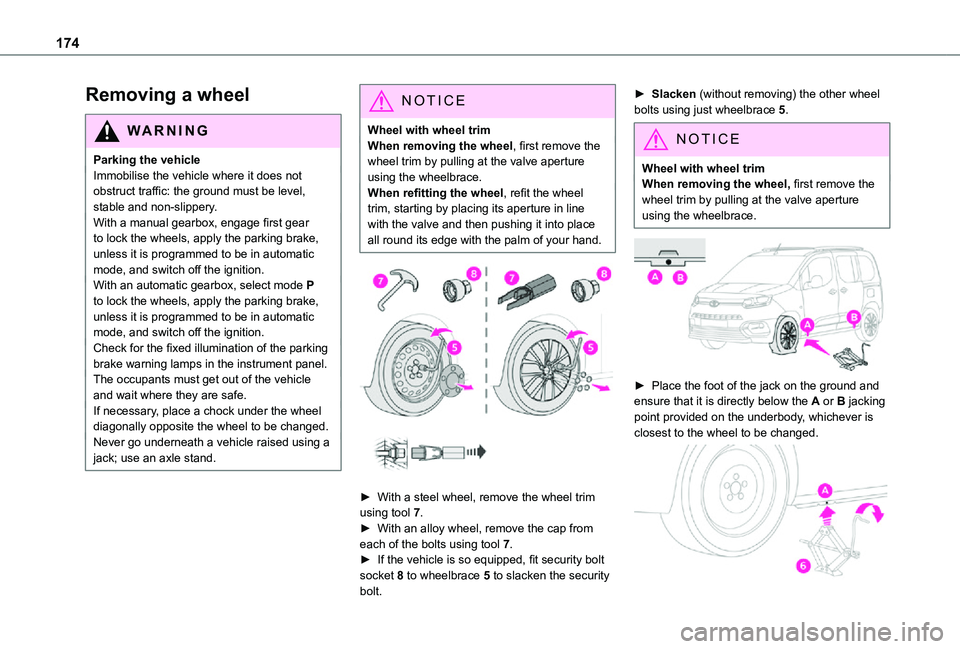

Removing a wheel

WARNI NG

Parking the vehicleImmobilise the vehicle where it does not obstruct traffic: the ground must be level, stable and non-slippery.With a manual gearbox, engage first gear to lock the wheels, apply the parking brake, unless it is programmed to be in automatic mode, and switch off the ignition.With an automatic gearbox, select mode P to lock the wheels, apply the parking brake, unless it is programmed to be in automatic mode, and switch off the ignition.Check for the fixed illumination of the parking brake warning lamps in the instrument panel.The occupants must get out of the vehicle and wait where they are safe.If necessary, place a chock under the wheel diagonally opposite the wheel to be changed.Never go underneath a vehicle raised using a

jack; use an axle stand.

NOTIC E

Wheel with wheel trimWhen removing the wheel, first remove the wheel trim by pulling at the valve aperture using the wheelbrace.When refitting the wheel, refit the wheel trim, starting by placing its aperture in line with the valve and then pushing it into place all round its edge with the palm of your hand.

► With a steel wheel, remove the wheel trim using tool 7.► With an alloy wheel, remove the cap from each of the bolts using tool 7.

► If the vehicle is so equipped, fit security bolt socket 8 to wheelbrace 5 to slacken the security bolt.

► Slacken (without removing) the other wheel bolts using just wheelbrace 5.

NOTIC E

Wheel with wheel trimWhen removing the wheel, first remove the wheel trim by pulling at the valve aperture using the wheelbrace.

► Place the foot of the jack on the ground and ensure that it is directly below the A or B jacking point provided on the underbody, whichever is closest to the wheel to be changed.

Page 175 of 272

175

In the event of a breakdown

8

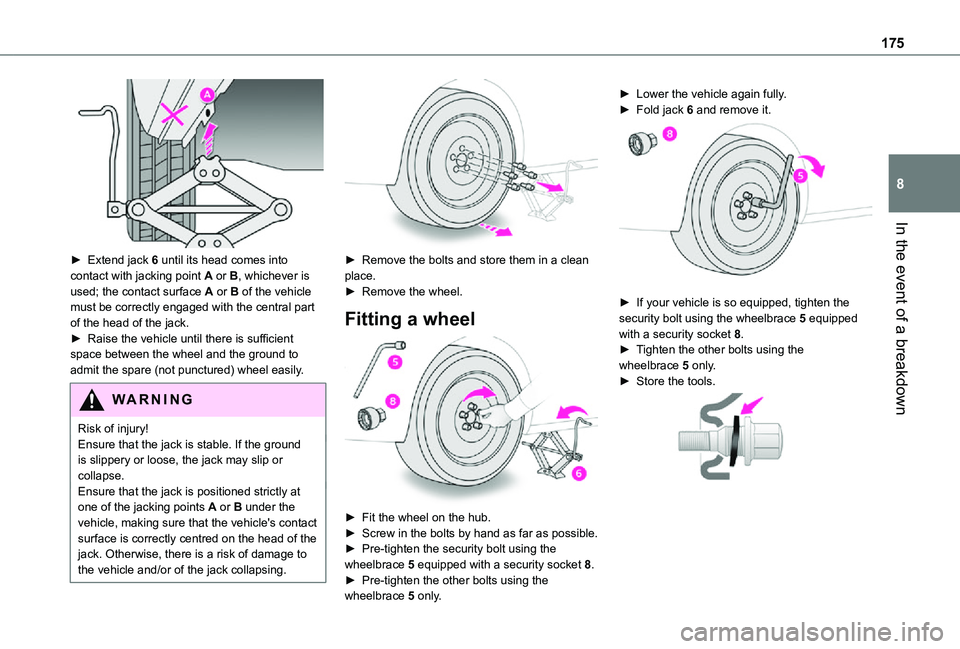

► Extend jack 6 until its head comes into contact with jacking point A or B, whichever is used; the contact surface A or B of the vehicle must be correctly engaged with the central part of the head of the jack.► Raise the vehicle until there is sufficient space between the wheel and the ground to admit the spare (not punctured) wheel easily.

WARNI NG

Risk of injury!

Ensure that the jack is stable. If the ground is slippery or loose, the jack may slip or collapse.Ensure that the jack is positioned strictly at one of the jacking points A or B under the vehicle, making sure that the vehicle's contact surface is correctly centred on the head of the jack. Otherwise, there is a risk of damage to the vehicle and/or of the jack collapsing.

► Remove the bolts and store them in a clean place.► Remove the wheel.

Fitting a wheel

► Fit the wheel on the hub.► Screw in the bolts by hand as far as possible.► Pre-tighten the security bolt using the wheelbrace 5 equipped with a security socket 8.► Pre-tighten the other bolts using the wheelbrace 5 only.

► Lower the vehicle again fully.► Fold jack 6 and remove it.

► If your vehicle is so equipped, tighten the security bolt using the wheelbrace 5 equipped with a security socket 8.► Tighten the other bolts using the wheelbrace 5 only.► Store the tools.