replace battery TOYOTA RAV4 1996 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 52 of 1632

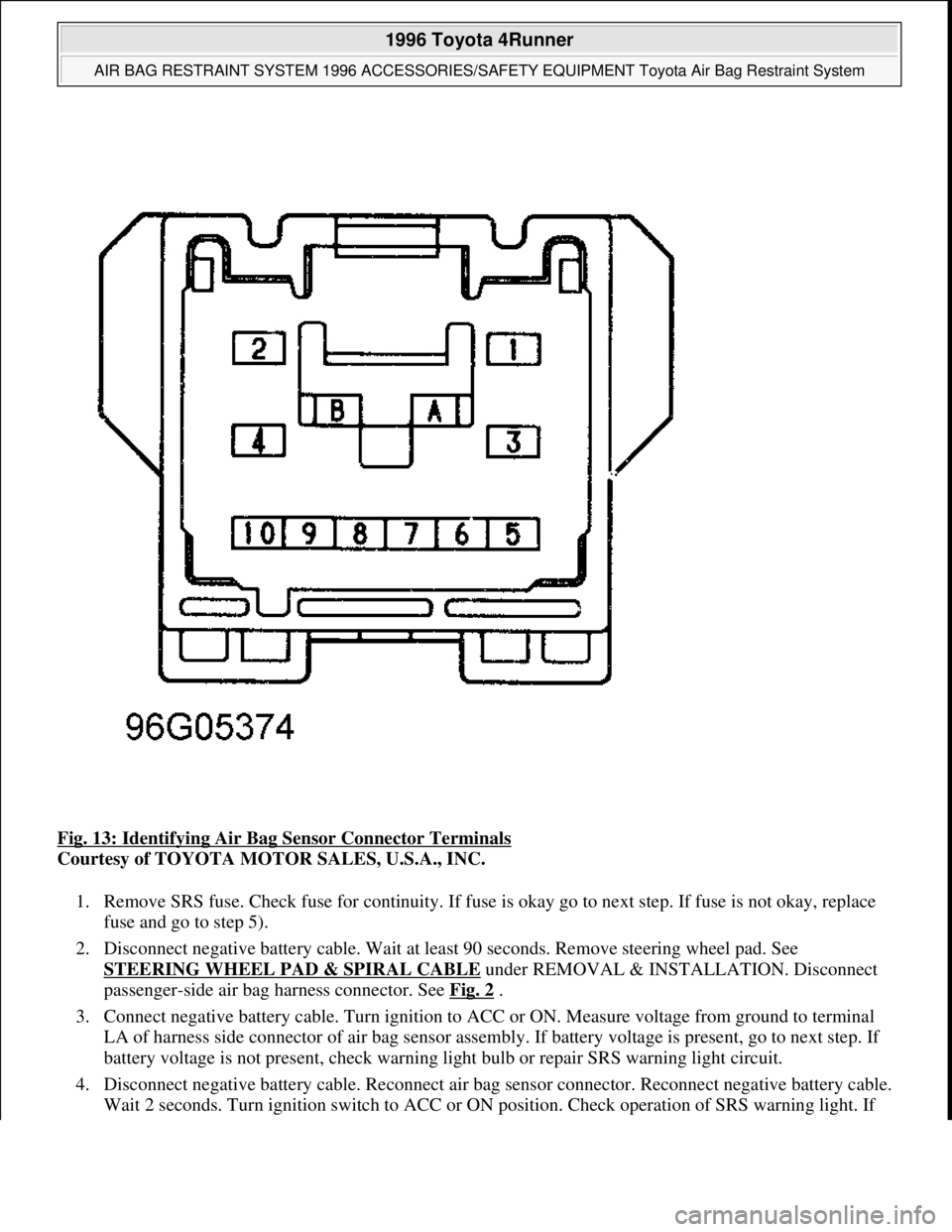

Fig. 13: Identifying Air Bag Sensor Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1. Remove SRS fuse. Check fuse for continuity. If fuse is okay go to next step. If fuse is not okay, replace

fuse and go to step 5).

2. Disconnect negative battery cable. Wait at least 90 seconds. Remove steering wheel pad. See

STEERING WHEEL PAD & SPIRAL CABLE

under REMOVAL & INSTALLATION. Disconnect

passenger-side air bag harness connector. See Fig. 2

.

3. Connect negative battery cable. Turn ignition to ACC or ON. Measure voltage from ground to terminal

LA of harness side connector of air bag sensor assembly. If battery voltage is present, go to next step. If

battery voltage is not present, check warning light bulb or repair SRS warning light circuit.

4. Disconnect negative battery cable. Reconnect air bag sensor connector. Reconnect negative battery cable.

Wait 2 seconds. Turn i

gnition switch to ACC or ON position. Check operation of SRS warning light. If

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 18 © 2005 Mitchell Repair Information Company, LLC.

Page 53 of 1632

light is okay, the malfunction is now corrected. If light is not okay, check terminal LA of air bag sensor

assembly. If terminal is okay, replace air bag sensor assembly.

5. If new fuse burns out again, check harness between SRS fuse and SRS warning light. If fuse is not burned

out check for intermittent fault. See AIR BAG WARNING LIGHT INTERMITTENT

under

DIAGNOSIS.

AIR BAG WARNING LIGHT STAYS ON WITH IGNITION OFF

Disable SRS. See DISABLING & ACTIVATING AIR BAG SYSTEM

. Disconnect air bag sensor connector

(s). Reconnect negative battery cable. If air bag warning light is off, replace air bag sensor. If air bag warning

light is still on, repair warning light circuit or AB circuit leading to DLC. See Fig. 12

.

AIR BAG WARNING LIGHT INTERMITTENT

If air bag warning light comes on intermittently, perform the following tests to simulate driving conditions:

Wiggle-test wiring harness.

Using a hair dryer, apply heat to components.

Spray water onto entire vehicle (not directly onto electrical components) to simulate humidity.

If problem cannot be found, replace all components including wiring harness.

CODE(S) NOT DISPLAYED

1. Turn ignition switch from LOCK to ACC or ON position. If air bag warning light does not come on,

repair air bag warning light circuit. If air bag warning light comes on, go to next step.

2. Turn ignition to ACC or ON. Measure voltage between terminals Tc and E1 of DLC. See Fig. 12

. If

battery voltage is present, go to step 4). If battery voltage is not present go to next step.

3. Measure voltage between body ground and terminal Tc of DLC. If battery voltage is present, repair

harness between body ground and terminal E1 of DLC. If battery voltage is not present, go to next step.

4. Turn ignition to LOCK. Disconnect negative battery cable. wait at least 90 seconds. Disconnect air bag

sensor assembly connector. Connect a jumper wire between body ground and terminal Tc from back side.

See Fig. 13

. If air bag warning light does not come on, replace air bag sensor. If air bag warning light

comes on, check wiring harness between air bag sensor and DLC.

CODE(S) CONTINUOUSLY DISPLAYED

Disable SRS. See DISABLING & ACTIVATING AIR BAG SYSTEM

. Disconnect air bag sensor connector

NOTE: Use the following procedure if code(s) are not displayed or air bag warning light

stays on when jumper wire is connected between terminals Tc and E1 of DLC

connector.

NOTE: Use the following procedure if code(s) are displayed without connecting jumper

wire between terminals Tc and E1 of DLC connector.

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 19 © 2005 Mitchell Repair Information Company, LLC.

Page 56 of 1632

3. With squib circuit connector disconnected, insert paper into female terminal, sliding it under shorting bar

spring. This lifts the spring, breaking the circuit and allowing the test procedure to be performed as

specified.

TESTING - DIAGNOSTIC

NO CODES - SOURCE VOLTAGE DROP

1. Disconnect negative battery cable. Wait at least 90 seconds. Remove steering wheel pad. See

STEERING WHEEL PAD & SPIRAL CABLE

under REMOVAL & INSTALLATION. Disconnect

passenger-side air bag harness connector, accessible through finish plate in glove box. See Fig. 2

.

Disconnect air bag sensor assembly connector.

2. Reconnect negative battery cable. Turn ignition switch to ON position. Measure voltage between ground

and terminals IG2 and ACC of air bag sensor connector. See Fig. 13

. Operate electrical components

(defogger, wiper, headlights, heater blower, etc.). If voltage is 8-14 volts, go to next step. If voltage is not

8-14 volts, check harness between battery and air bag sensor assembly and check battery and charging

system.

3. Turn ignition switch to LOCK position. Connect steering wheel pad connector. Connect passenger-side

air bag connector. Turn ignition switch to ON position. Operate electrical components as in step 2) and

check that SRS warning light goes off. If light does not go off, check diagnostic trouble code and go to

appropriate CODE under TESTING - DIAGNOSTIC. If a normal code is output, replace air bag sensor

assembly. If warning light goes off, no problem detected at this time.

CODE 11

1. Disconnect negative battery cable. Wait at least 90 seconds. Remove steering wheel pad. See

STEERING WHEEL PAD & SPIRAL CABLE

under REMOVAL & INSTALLATION. Disconnect

passenger-side air bag harness connector, accessible through finish plate in glove box. See Fig. 2

.

Disconnect air bag sensor assembly connector.

2. Measure resistance on spiral cable side of connector between spiral cable and steering wheel pad between

D+, D- and ground. If resistance is 1000 ohms or more, go to next step. If resistance is less than 1000

ohms, go to step 7).

3. Measure resistance on air ba

g sensor assembly side of connector between air bag sensor and passenger- WARNING:Paper must not be thicker than male terminal. If paper is thicker,

connector terminal may be damaged, possible resulting in system

fault.

NOTE: Use Diagnosis Check Wiring (09843-18020) when connecting jumper wire

between terminals of DLC. Spiral cable upper connector is same as steering

wheel pad (squib) connector. Spiral cable lower connector (located under

steering column) connects the harness between spiral cable and center air bag

sensor.

NOTE: During testing, if codes other than Code 11 are displayed, disregard them.

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 22 © 2005 Mitchell Repair Information Company, LLC.

Page 57 of 1632

side air bag assembly between P+, P- and ground. If resistance is 1000 ohms or more, go to next step. If

resistance is less than 1000 ohms, replace harness or connector between air bag sensor assembly and

passenger-side air bag assembly.

4. Connect connector to air bag sensor assembly. Use a jumper wire to connect D+ and D- on spiral cable

side of connector between spiral cable and steering wheel pad. Use a jumper to connect P+ and P- on air

bag sensor assembly side of connector between air bag sensor assembly and passenger-side air bag

assembly. Connect negative battery cable and wait 2 seconds. Turn ignition switch to ACC or ON

position and wait at least 20 seconds. Clear malfunction codes. Turn ignition switch to LOCK position.

Wait 20 seconds. Turn ignition switch to ACC or ON position and wait at least 20 seconds. Using

Diagnosis Wire (09843-18020), connect terminals Tc and E1 of DLC1. If DTC 11 is output, go to next

step. If DTC 11 is not output, Replace air bag sensor assembly.

5. Turn ignition switch to LOCK position. Disconnect negative battery cable. Wait 90 seconds. Connect

steering wheel pad connector. Connect negative battery cable. Wait 2 seconds. Turn ignition switch to

ACC or ON position. Wait 20 seconds. Clear malfunction codes. Turn ignition switch to LOCK position.

Wait at least 20 seconds. Turn ignition switch to ACC or ON position. Wait at least 20 seconds. Use

Diagnosis Wire (09843-18020), connect terminals Tc and E1 of DLC1. If DTC 11 is output, replace

steering wheel pad. If DTC 11 is output, go to next step.

6. Turn ignition switch to LOCK position. Disconnect negative battery cable. Wait at least 90 seconds.

Connect passenger-side air bag assembly connector. Connect negative battery cable. Wait at least 2

seconds. Turn ignition switch to ACC or ON position. Wait at least 20 seconds. Clear malfunction codes.

Turn ignition switch to LOCK position. Wait at least 20 seconds. Turn ignition switch to ACC or ON

position. Wait at least 20 seconds. Use Diagnosis Wire (09843-18020) to connect terminals Tc and E1 of

DLC1. If DTC 11 is output, replace passenger-side air bag assembly. If DTC 11 is not output, go to next

step.

7. Disconnect connector between air bag sensor assembly and spiral cable. Measure resistance between D+

on spiral cable side of connector between spiral cable and steering wheel pad and body ground. If

resistance is 1000 ohms or more, replace harness or connector between air bag sensor assembly and spiral

cable. If resistance is less than 1000 ohms, replace spiral cable.

CODE 12

1. Disconnect negative battery cable. Wait at least 90 seconds. Remove steering wheel pad. See

STEERING WHEEL PAD & SPIRAL CABLE

under REMOVAL & INSTALLATION. Disconnect

passenger-side air bag connector, accessible through finish plate inside glove box. See Fig. 2

. Disconnect

air bag sensor assembly connector

2. Check voltage between ground, D+ and D- of connector (spiral cable side) between spiral cable and

steering wheel pad. If voltage is zero volts, go to next step. If voltage is not zero volts, go to step 7).

3. Check voltage between P+, P- and ground of connector (air bag sensor assembly side) between air bag

sensor assembly and passenger-side air bag assembly. If voltage is zero volts, go to next step. If voltage is

not zero volts, replace harness or connector between air bag sensor assembly and passenger-side air bag

assembly.

4. Connect connector to air bag sensor assembly. Use jumper wire to connect D+ and D- on spiral cable side

of connector between spiral cable and steering wheel pad. Use a jumper wire to connect P+ and P- on air NOTE: During testing, if codes other than Code 12 are displayed, disregard them.

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 23 © 2005 Mitchell Repair Information Company, LLC.

Page 58 of 1632

bag sensor assembly side of connector between airbag sensor assembly and passenger-side air bag

assembly. Connect negative battery cable. Wait 2 seconds. Turn ignition switch to ACC or ON position.

Wait at least 20 seconds. Clear malfunction codes. Turn ignition switch to LOCK position. Wait at least

20 seconds. Turn ignition switch to ACC or ON position. Wait at least 20 seconds. Using Diagnosis Wire

(09843-18020) connect terminals Tc and E1 of DLC1. If DTC 12 is output, replace air bag sensor

assembly. If DTC 12 is output, go to next step.

5. Turn ignition switch to LOCK position. Disconnect negative battery cable. Wait 90 seconds. Connect

steering wheel pad connector. Connect negative battery cable. Wait 2 seconds. Turn ignition to ACC or

On. Wait at least 20 seconds. Clear malfunction codes. Turn ignition switch to LOCK position. Wait at

least 20 seconds. Turn ignition to ACC or On. Wait at least 20 seconds. Using Diagnosis Wire (09843-

18020) connect terminals Tc and E1 of DLC1. If DTC 12 is output, replace passenger-side air bag. If

DTC 12 is not output, go to next step.

6. Turn ignition switch to LOCK position. Disconnect connector between air bag sensor assembly and spiral

cable. Turn ignition ON. Measure voltage between D+ terminal on spiral cable side of connector between

spiral cable and steering wheel pad. If voltage is zero volts, replace harness or connector between air bag

sensor assembly and spiral cable. If voltage is not zero volts, replace spiral cable.

CODE 14

1. Disconnect negative battery cable. Wait at least 90 seconds. Remove steering wheel pad. See

STEERING WHEEL PAD & SPIRAL CABLE

under REMOVAL & INSTALLATION. Disconnect

passenger-side air bag connector, accessible through finish plate inside glove box. See Fig. 2

. Disconnect

air bag sensor assembly connector.

2. Use a jumper wire to connect D+ and D- on air bag sensor assembly connector. Measure resistance

between D+ and D-. If resistance is less than one ohm, go to next step. If resistance is more than one ohm,

go to step 5).

3. Connect connector to air bag sensor assembly. Using a jumper wire, connect D+ and D- on spiral cable

side of connector between spiral cable and steering wheel pad. Connect negative battery cable. Wait 2

seconds. Turn ignition switch to ACC or ON position. Wait at least 20 seconds. Clear malfunction codes.

Turn ignition switch to LOCK position. Wait at least 20 seconds. Using Diagnosis Wire (09843-18020),

connect terminals Tc and E1 of DLC1. If DTC 14 is output, replace air bag sensor assembly. If DTC 14 is

not output, go to next step.

4. Turn ignition switch to LOCK position. Disconnect negative battery cable. Wait at least 90 seconds.

Connect steering wheel pad (squib) connector. Connect negative battery cable. Wait 2 seconds. Turn

ignition switch to ACC or ON position. Wait at least 20 seconds. Clear malfunction codes. Turn ignition

switch to LOCK position. Wait at least 20 seconds. Turn ignition switch to ACC or ON position. Wait at

least 20 seconds. Using Diagnosis Wire (09843-18020), connect terminals Tc and E1 of DLC1. If DTC

14 is output, replace steering wheel pad. If DTC 14 is not output, no problem is detected at this time..

5. Disconnect connector between air bag sensor assembly and spiral cable. Measure resistance between

terminals D+ and D- on spiral cable side of connector between spiral cable and steering wheel pad. If

resistance is less than one ohm, go to next step. If resistance is more than one ohm, replace spiral cable.

6. Use a jumper wire to connect D+ and D- on air bag sensor assembly connector. Measure resistance

between D+ and D- on air bag side of connector between air bag sensor assembly and spiral cable. If NOTE: During testing, if codes other than Code 14 are displayed, disregard them.

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 24 © 2005 Mitchell Repair Information Company, LLC.

Page 59 of 1632

resistance is less than one ohm, no problem detected at this time. If resistance is more than one ohm,

replace harness or connector between air bag sensor and spiral cable.

CODE 31

1. Disconnect negative battery cable. Wait at least 90 seconds. Remove steering wheel pad. See

STEERING WHEEL PAD & SPIRAL CABLE

under REMOVAL & INSTALLATION. Disconnect

passenger-side air bag connector, accessible through finish plate inside glove box. See Fig. 2

. Disconnect

air bag sensor assembly connector.

2. Turn ignition switch to ON position. Measure voltage between terminals IG2 and ACC of air bag sensor

assembly and ground. If voltage is less than 16 Volts, go to next step. If voltage is more than 16 volts,

check battery and charging system.

3. Clear malfunction code. Turn ignition switch to LOCK position. Wait at least 20 seconds. Turn ignition

switch to ACC or ON position. Wait at least 20 seconds. Repeat these steps at least 5 times. Using

Diagnosis Wire (09843-18020), connect terminals Tc and E1 of DLC1. Check DTC. If CODE 31 is

output, replace air bag sensor assembly. If CODE 31 is not output, check for intermittent fault. See AIR

BAG WARNING LIGHT INTERMITTENT under DIAGNOSIS.

CODE 54

1. Disconnect negative battery cable. Wait at least 90 seconds. Remove steering wheel pad. See

STEERING WHEEL PAD & SPIRAL CABLE

under REMOVAL & INSTALLATION. Disconnect

passenger-side air bag connector, accessible through finish plate inside glove box. See Fig. 2

. Disconnect

air bag sensor assembly connector.

2. Using a jumper wire, connect P+ and P- of air bag sensor connector. Measure resistance between

terminals of passenger-side air bag connector. If resistance is less than one ohm, go to next step. If

resistance is more than one ohm, replace harness or connector between air bag sensor assembly and

passenger-side air bag assembly.

3. Connect connector to center air bag sensor assembly. Using a jumper wire, connect P+ and P- terminals

(on center air bag sensor assembly side of connector between center air bag sensor assembly) and

passenger-side air bag assembly. Connect negative battery cable and wait 20 seconds. Turn ignition

switch to ACC or ON position. Wait at least 20 seconds. Clear malfunction codes. Turn ignition switch to

LOCK position. Wait at least 20 seconds. Turn ignition switch to ACC or ON position. Wait for at least

20 seconds. Using Diagnosis Wire (09843-18020), check for DTC 54. If DTC 54 is output, replace air

bag sensor assembly. If DTC 54 is not output, go to next step.

4. Turn ignition switch to LOCK position. Disconnect negative battery cable. Wait at least 90 seconds.

Connect passenger-side air bag assembly connector. Connect negative battery cable. Wait 2 seconds.

Turn ignition switch to ACC or ON position. Wait at least 20 seconds. Clear malfunction codes. Turn

ignition switch to LOCK position. Wait at least 20 seconds. Turn ignition switch to ACC or ON position.

Wait at least 20 seconds. Using Diagnosis Wire (09843-18020), check for DTC 54. If DTC 54 is output,

replace passen

ger-side air bag assembly. If DTC 54 is not output, the malfunction is now normal. NOTE: During testing, if codes other than Code 14 are displayed, disregard them.

NOTE: During testing, if codes other than Code 54 are displayed, disregard them.

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 25 © 2005 Mitchell Repair Information Company, LLC.

Page 66 of 1632

may allow air bag to deploy until 90 seconds after disconnecting negative battery cable.

If vehicle was in a minor collision but air bags did not deploy, inspect all system components for any sign

of damage, and replace as necessary.

Never use air bag system components from another vehicle. Replace air bag system components with new

parts.

Remove air bag sensor assembly if repairing the vehicle requires impacting (shocking) the vehicle.

Air bag sensor assembly contains mercury. After replacement, DO NOT destroy old part. When

scrapping vehicle or replacing air bag sensor assembly, remove air bag sensor assembly and dispose of it

as toxic waste.

Never disassemble and repair air bag sensor assembly, front air bag sensors, passenger-side or driver-side

air bag modules or seat belt pretensioners.

Replace dropped, cracked, dented or otherwise damaged components.

DO NOT expose air bag sensor assembly, front air bag sensors or air bag modules directly to heat or

flame.

When diagnosing electrical circuits, use a volt/ohm meter with high impedance (10,000 ohms minimum).

Information labels are attached to air bag components. Follow all notices on labels.

After work on air bag system is complete, check AIR BAG warning light to ensure system is functioning

properly. See SYSTEM OPERATION CHECK

.

Always wear safety glasses when servicing or handling an air bag.

When placing a live air bag on a bench or other surface, always face air bag and trim cover up and away

from surface. This will reduce motion of module if it is accidentally deployed.

After deployment, air bag surface may contain deposits of sodium hydroxide, which irritates skin. Always

wear safety glasses, rubber gloves, and long-sleeved shirt during clean-up. After clean-up, wash hands

using mild soap and water.

Carry a live air bag module with trim cover (air bag) pointed away from your body to minimize injury in

case accidental deployment.

If air bag system is not fully functional for any reason, vehicle should not be driven until system is

repaired and again becomes operational. DO NOT remove bulbs, modules, sensors or other components,

or in any way disable system from operating normally. If air bag system is not functional, park vehicle

until it is repaired and functions properly.

ADJUSTMENTS

SPIRAL CABLE

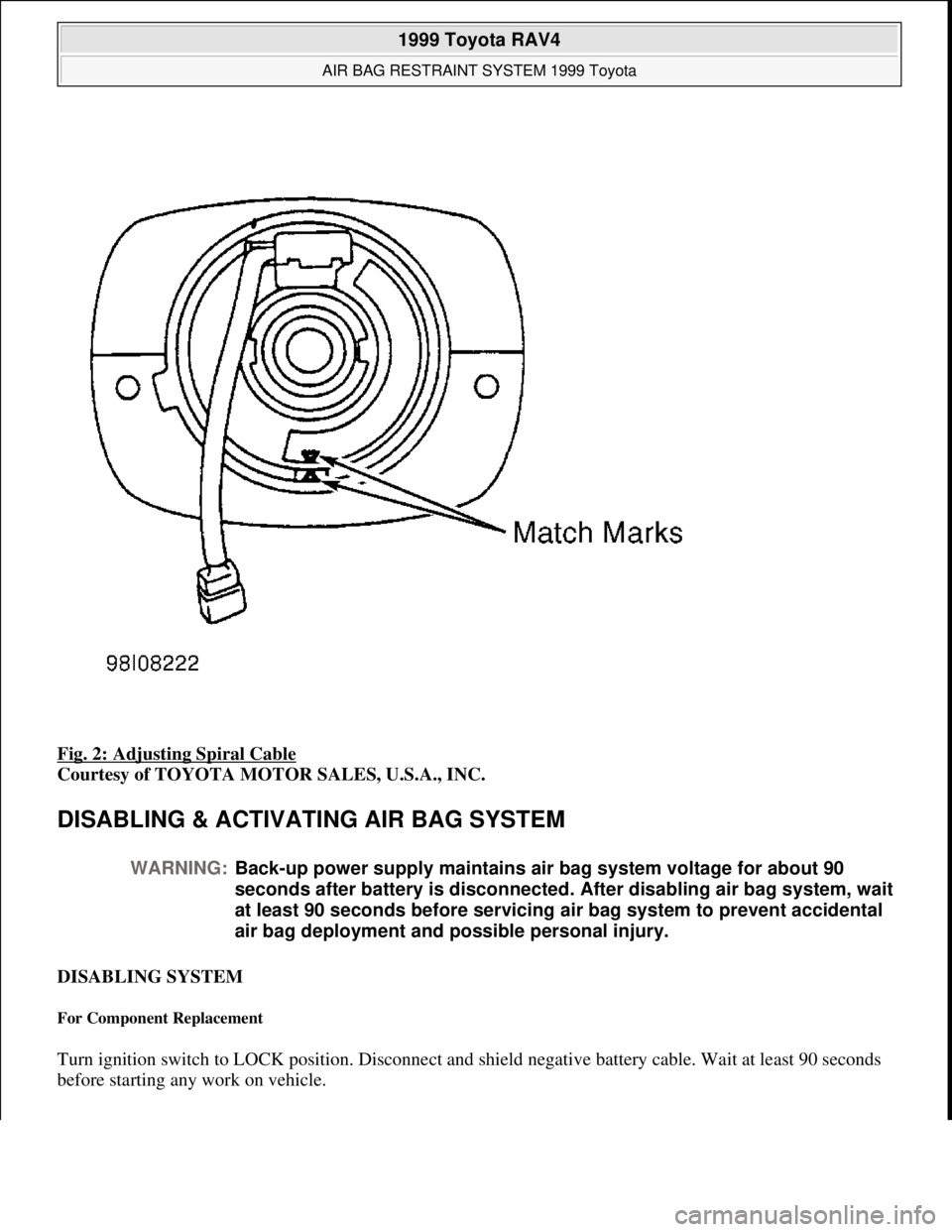

Ensure front wheels are in straight-ahead position. Turn spiral cable counterclockwise until it becomes difficult

to turn. Turn spiral cable clockwise about 2 1/2 turns to align match marks. See Fig. 2

. Install steering wheel.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:22 AMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 67 of 1632

Fig. 2: Adjusting Spiral Cable

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

DISABLING & ACTIVATING AIR BAG SYSTEM

DISABLING SYSTEM

For Component Replacement

Turn ignition switch to LOCK position. Disconnect and shield negative battery cable. Wait at least 90 seconds

before starting any work on vehicle.

WARNING:Back-up power supply maintains air bag system voltage for about 90

seconds after battery is disconnected. After disabling air bag system, wait

at least 90 seconds before servicing air bag system to prevent accidental

air bag deployment and possible personal injury.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:22 AMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 69 of 1632

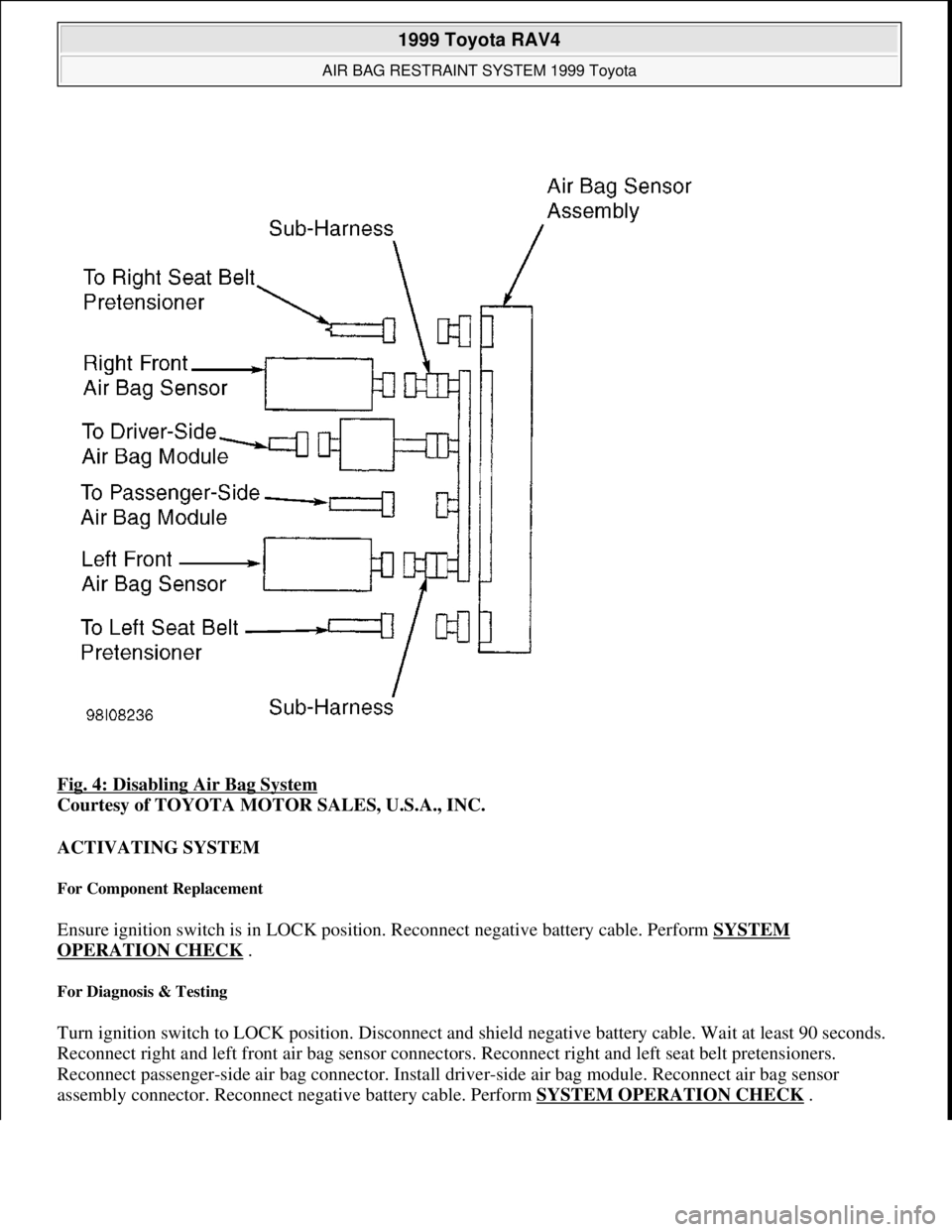

Fig. 4: Disabling Air Bag System

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

ACTIVATING SYSTEM

For Component Replacement

Ensure ignition switch is in LOCK position. Reconnect negative battery cable. Perform SYSTEM

OPERATION CHECK .

For Diagnosis & Testing

Turn ignition switch to LOCK position. Disconnect and shield negative battery cable. Wait at least 90 seconds.

Reconnect right and left front air bag sensor connectors. Reconnect right and left seat belt pretensioners.

Reconnect passenger-side air bag connector. Install driver-side air bag module. Reconnect air bag sensor

assembl

y connector. Reconnect negative battery cable. Perform SYSTEM OPERATION CHECK.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:22 AMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 76 of 1632

REMOVAL & INSTALLATION

AIR BAG SENSOR ASSEMBLY

Removal & Installation

1. Before proceeding, see SERVICE PRECAUTIONS . Air bag sensor assembly is located on the floor

inside center console box. See Fig. 10

. Turn ignition switch to LOCK position. Disconnect negative

battery cable. Wait at least 90 seconds.

2. Remove shift lever and boot. Ash tray and console box hole cover. Remove console box. Remove 4 Torx

screws retaining air bag sensor assembly. Remove air bag sensor assembly.

3. To install, reverse removal procedure. Tighten air bag sensor assembly Torx screws to specification. See

TORQUE SPECIFICATIONS

. Check AIR BAG warning light to ensure system is functioning

properl

y. See SYSTEM OPERATION CHECK. WARNING:Failure to follow service precautions may result in air bag deployment and

personal injury. See SERVICE PRECAUTIONS

. After component

replacement, check system operation. See SYSTEM OPERATION CHECK

.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:22 AMPage 13 © 2005 Mitchell Repair Information Company, LLC.