Engine TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 723 of 1632

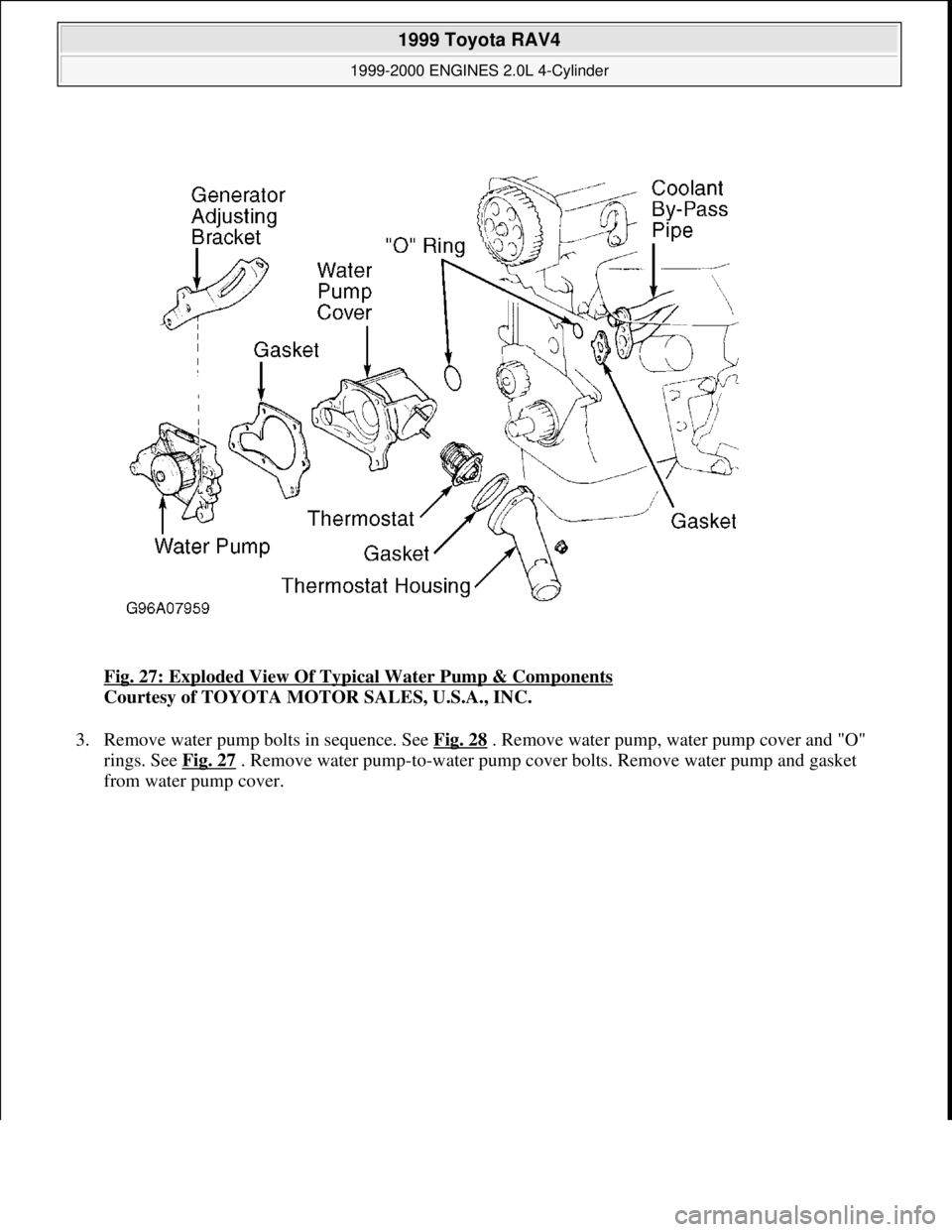

Fig. 27: Exploded View Of Typical Water Pump & Components

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3. Remove water pump bolts in sequence. See Fig. 28

. Remove water pump, water pump cover and "O"

rings. See Fig. 27

. Remove water pump-to-water pump cover bolts. Remove water pump and gasket

from water pump cover.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 40 © 2005 Mitchell Repair Information Company, LLC.

Page 724 of 1632

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 41 © 2005 Mitchell Repair Information Company, LLC.

Page 725 of 1632

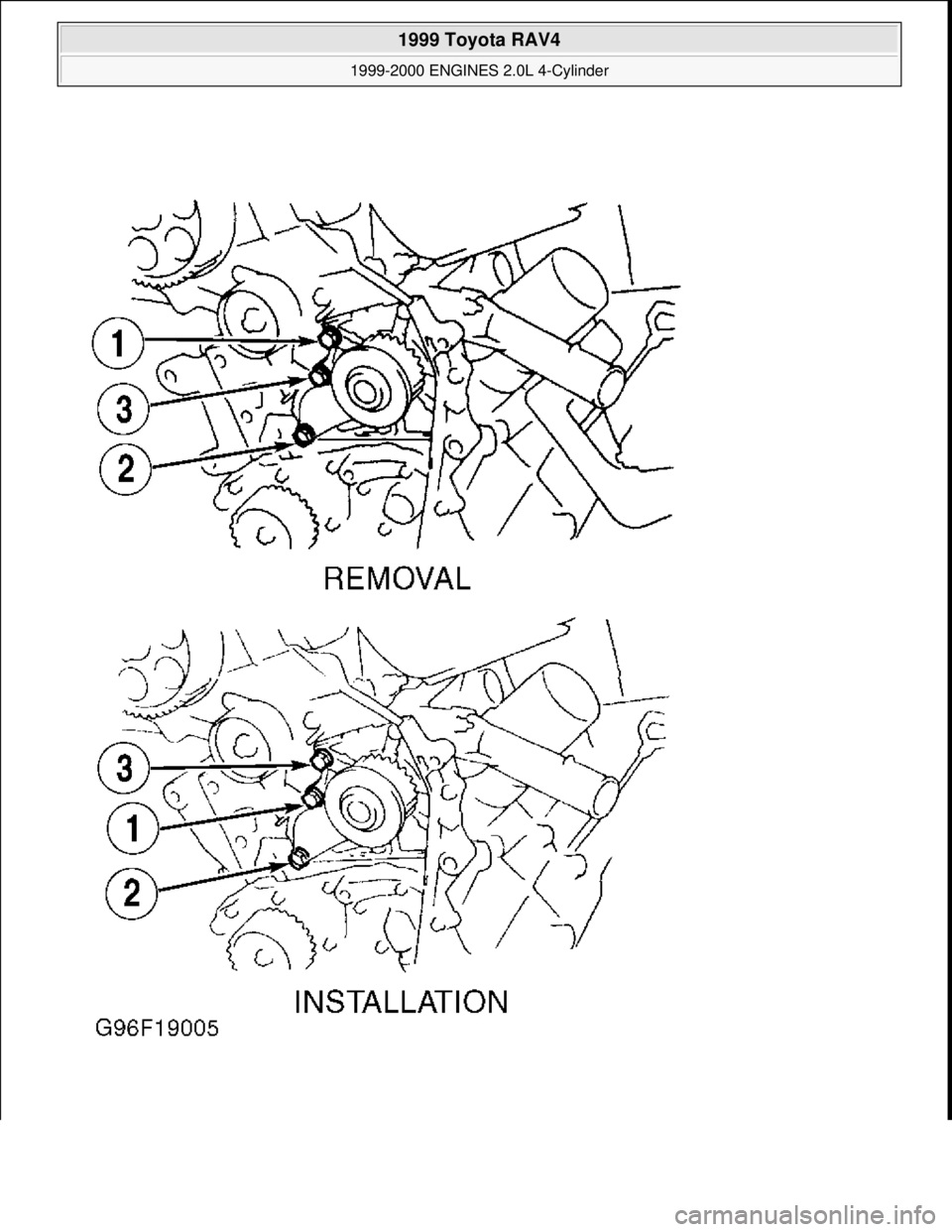

Fig. 28: Water Pump Bolt Removal & Installation Sequence

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Installation

1. To install, reverse removal procedure. Use NEW gaskets and NEW "O" rings. Apply soapy water

solution to coolant by-pass pipe "O" ring before installing water pump.

2. Tighten water pump bolts to specification in sequence. Tightening coolant by-pass pipe-to-water pump

nuts. See Fig. 28

. See TORQUE SPECIFICATIONS . To install remaining components, reverse

removal procedure. Fill cooling system.

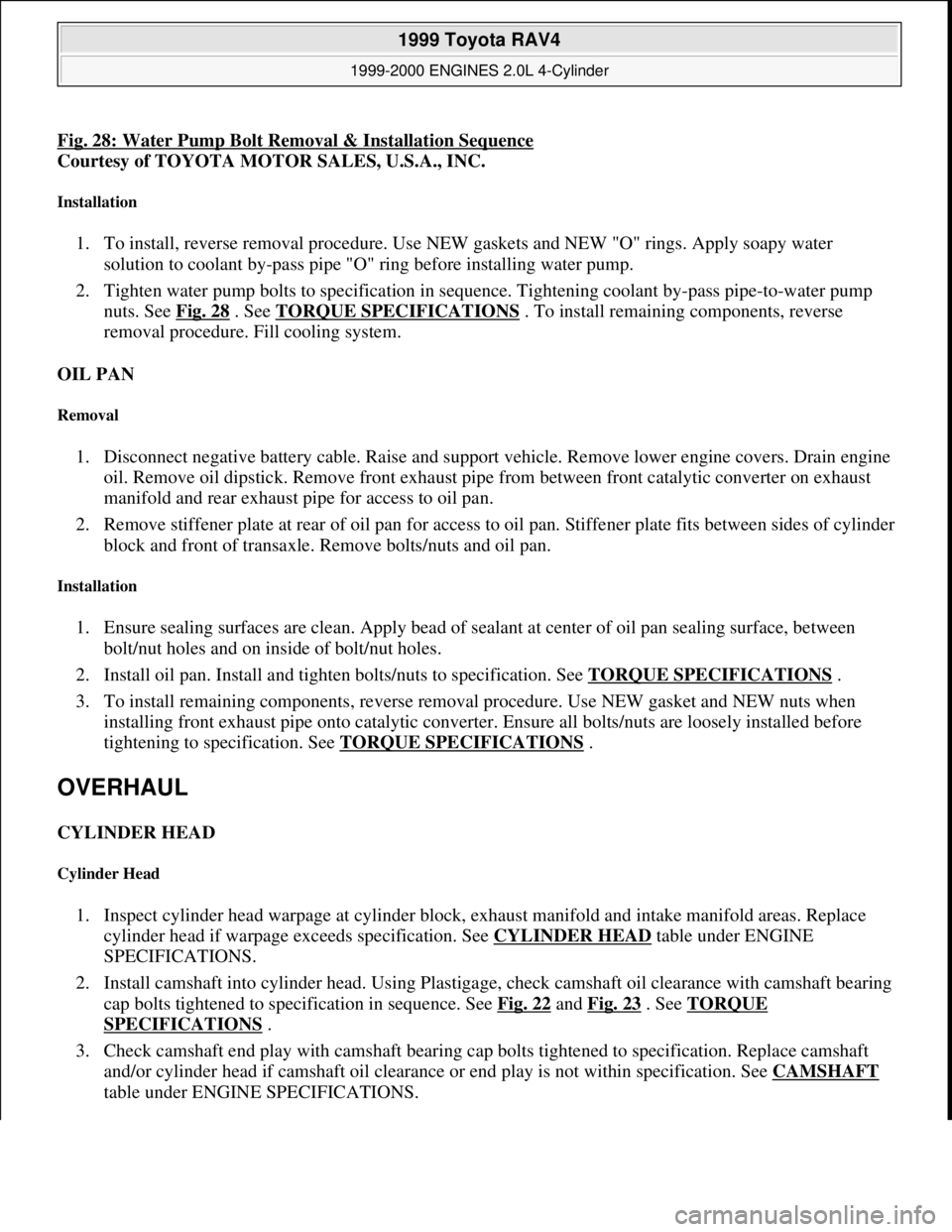

OIL PAN

Removal

1. Disconnect negative battery cable. Raise and support vehicle. Remove lower engine covers. Drain engine

oil. Remove oil dipstick. Remove front exhaust pipe from between front catalytic converter on exhaust

manifold and rear exhaust pipe for access to oil pan.

2. Remove stiffener plate at rear of oil pan for access to oil pan. Stiffener plate fits between sides of cylinder

block and front of transaxle. Remove bolts/nuts and oil pan.

Installation

1. Ensure sealing surfaces are clean. Apply bead of sealant at center of oil pan sealing surface, between

bolt/nut holes and on inside of bolt/nut holes.

2. Install oil pan. Install and tighten bolts/nuts to specification. See TORQUE SPECIFICATIONS

.

3. To install remaining components, reverse removal procedure. Use NEW gasket and NEW nuts when

installing front exhaust pipe onto catalytic converter. Ensure all bolts/nuts are loosely installed before

tightening to specification. See TORQUE SPECIFICATIONS

.

OVERHAUL

CYLINDER HEAD

Cylinder Head

1. Inspect cylinder head warpage at cylinder block, exhaust manifold and intake manifold areas. Replace

cylinder head if warpage exceeds specification. See CYLINDER HEAD

table under ENGINE

SPECIFICATIONS.

2. Install camshaft into cylinder head. Using Plastigage, check camshaft oil clearance with camshaft bearing

cap bolts tightened to specification in sequence. See Fig. 22

and Fig. 23 . See TORQUE

SPECIFICATIONS .

3. Check camshaft end play with camshaft bearing cap bolts tightened to specification. Replace camshaft

and/or cylinder head if camshaft oil clearance or end play is not within specification. See CAMSHAFT

table under ENGINE SPECIFICATIONS.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 42 © 2005 Mitchell Repair Information Company, LLC.

Page 726 of 1632

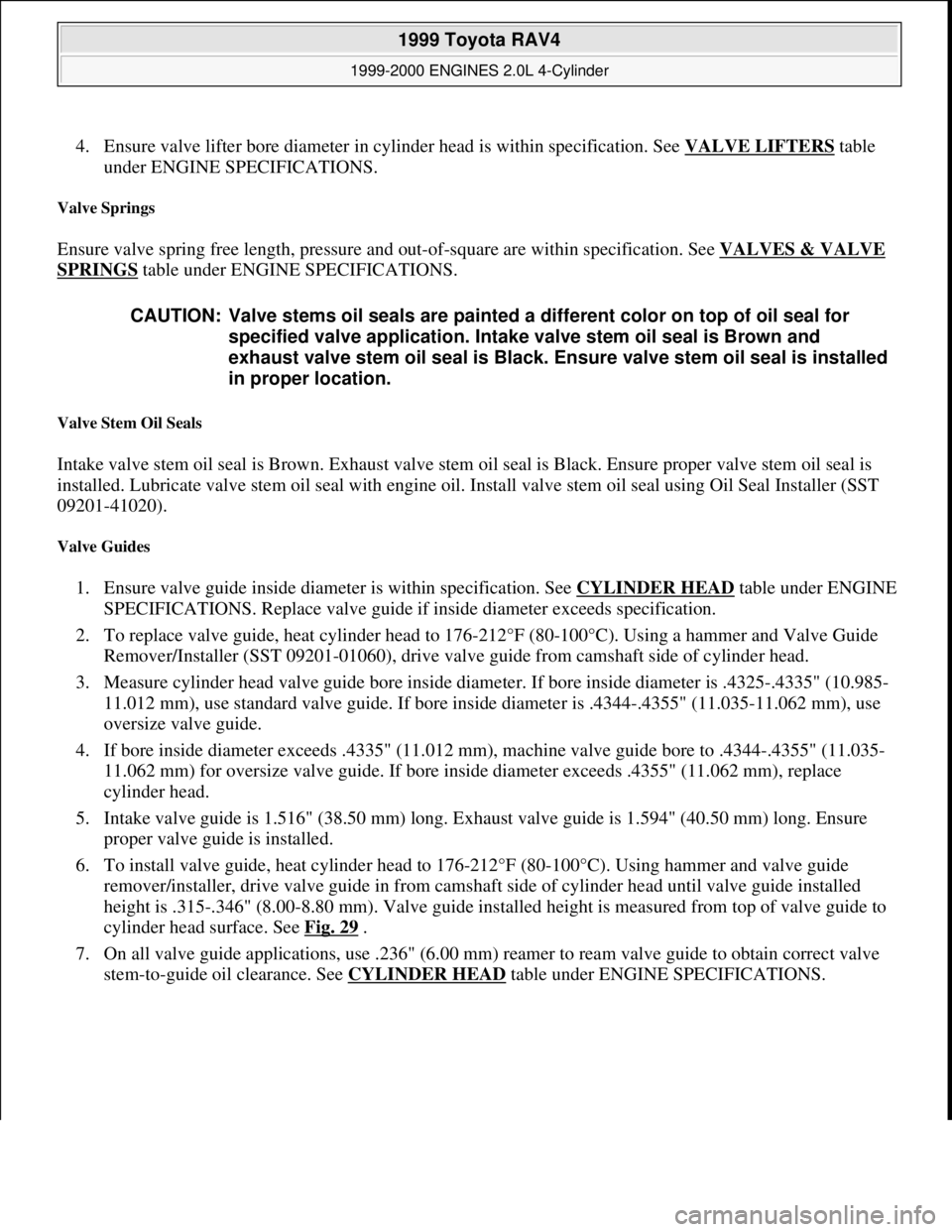

4. Ensure valve lifter bore diameter in cylinder head is within specification. See VALVE LIFTERS table

under ENGINE SPECIFICATIONS.

Valve Springs

Ensure valve spring free length, pressure and out-of-square are within specification. See VALVES & VALVE

SPRINGS table under ENGINE SPECIFICATIONS.

Valve Stem Oil Seals

Intake valve stem oil seal is Brown. Exhaust valve stem oil seal is Black. Ensure proper valve stem oil seal is

installed. Lubricate valve stem oil seal with engine oil. Install valve stem oil seal using Oil Seal Installer (SST

09201-41020).

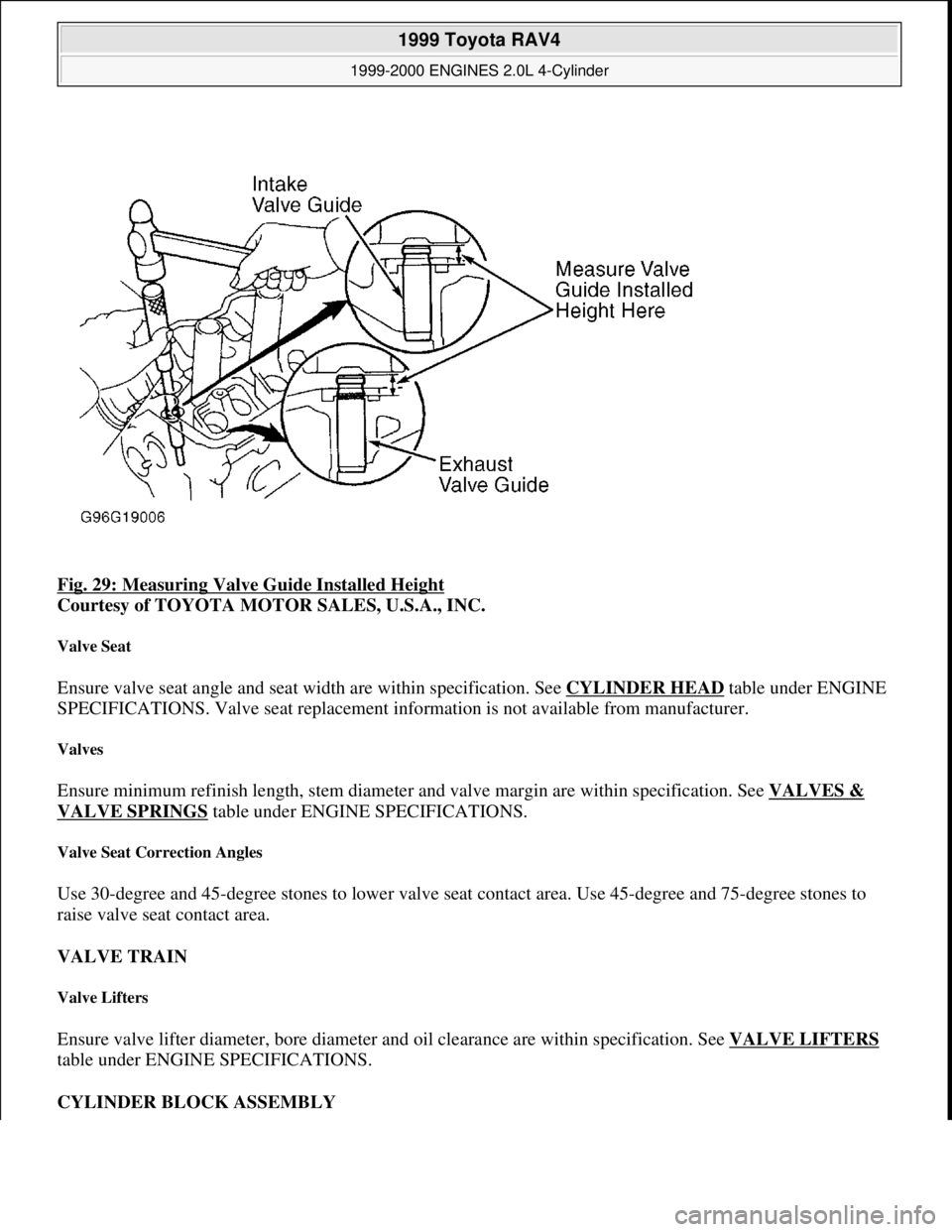

Valve Guides

1. Ensure valve guide inside diameter is within specification. See CYLINDER HEAD table under ENGINE

SPECIFICATIONS. Replace valve guide if inside diameter exceeds specification.

2. To replace valve guide, heat cylinder head to 176-212°F (80-100°C). Using a hammer and Valve Guide

Remover/Installer (SST 09201-01060), drive valve guide from camshaft side of cylinder head.

3. Measure cylinder head valve guide bore inside diameter. If bore inside diameter is .4325-.4335" (10.985-

11.012 mm), use standard valve guide. If bore inside diameter is .4344-.4355" (11.035-11.062 mm), use

oversize valve guide.

4. If bore inside diameter exceeds .4335" (11.012 mm), machine valve guide bore to .4344-.4355" (11.035-

11.062 mm) for oversize valve guide. If bore inside diameter exceeds .4355" (11.062 mm), replace

cylinder head.

5. Intake valve guide is 1.516" (38.50 mm) long. Exhaust valve guide is 1.594" (40.50 mm) long. Ensure

proper valve guide is installed.

6. To install valve guide, heat cylinder head to 176-212°F (80-100°C). Using hammer and valve guide

remover/installer, drive valve guide in from camshaft side of cylinder head until valve guide installed

height is .315-.346" (8.00-8.80 mm). Valve guide installed height is measured from top of valve guide to

cylinder head surface. See Fig. 29

.

7. On all valve guide applications, use .236" (6.00 mm) reamer to ream valve guide to obtain correct valve

stem-to-guide oil clearance. See CYLINDER HEAD

table under ENGINE SPECIFICATIONS. CAUTION: Valve stems oil seals are painted a different color on top of oil seal for

specified valve application. Intake valve stem oil seal is Brown and

exhaust valve stem oil seal is Black. Ensure valve stem oil seal is installed

in proper location.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 43 © 2005 Mitchell Repair Information Company, LLC.

Page 727 of 1632

Fig. 29: Measuring Valve Guide Installed Height

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Valve Seat

Ensure valve seat angle and seat width are within specification. See CYLINDER HEAD table under ENGINE

SPECIFICATIONS. Valve seat replacement information is not available from manufacturer.

Valves

Ensure minimum refinish length, stem diameter and valve margin are within specification. See VALVES &

VALVE SPRINGS table under ENGINE SPECIFICATIONS.

Valve Seat Correction Angles

Use 30-degree and 45-degree stones to lower valve seat contact area. Use 45-degree and 75-degree stones to

raise valve seat contact area.

VALVE TRAIN

Valve Lifters

Ensure valve lifter diameter, bore diameter and oil clearance are within specification. See VALVE LIFTERS

table under ENGINE SPECIFICATIONS.

CYLINDER BLOCK ASSEMBLY

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 44 © 2005 Mitchell Repair Information Company, LLC.

Page 728 of 1632

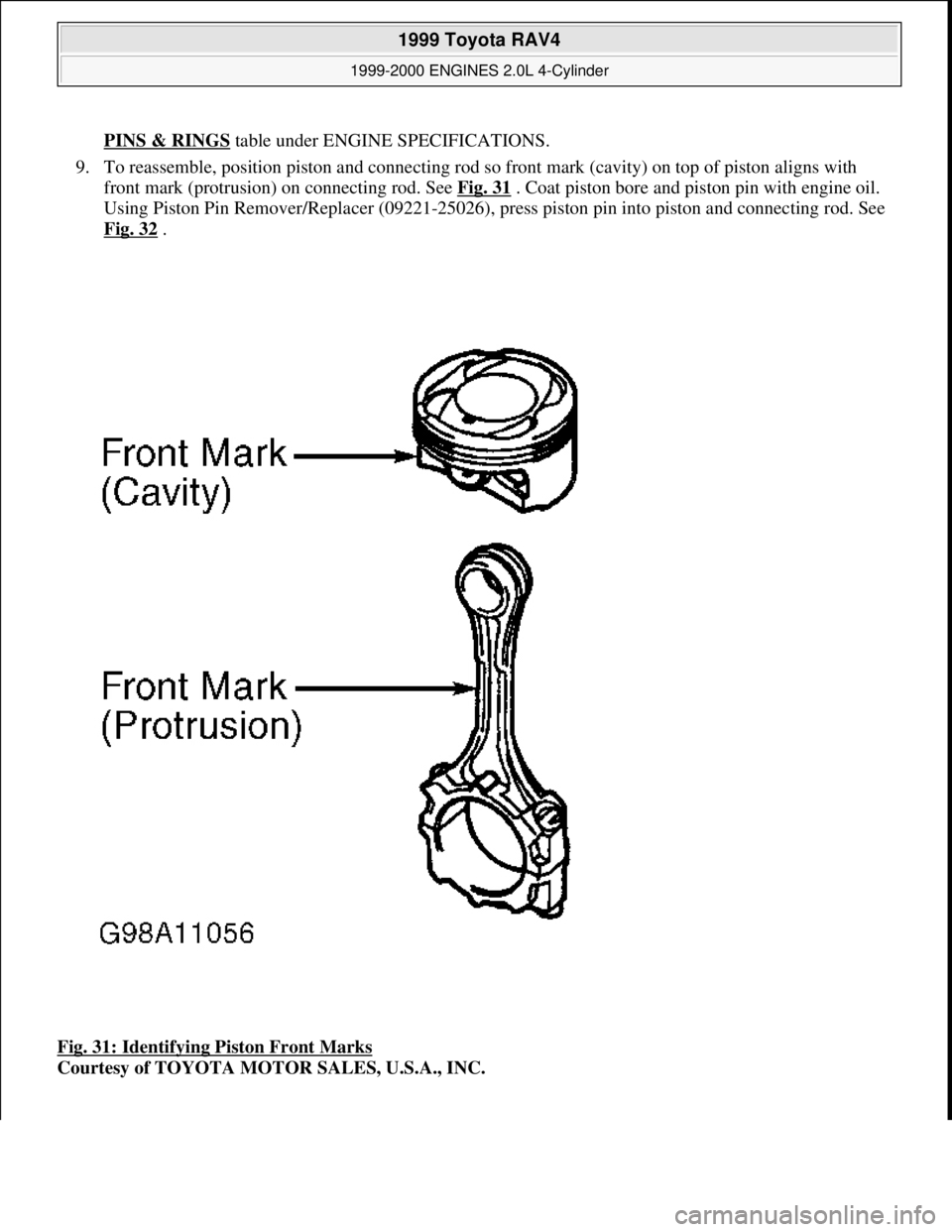

Piston & Rod Assembly

1. Ensure connecting rod and connecting rod cap are marked with matching cylinder number for reassembly

reference. Piston, connecting rod and connecting rod must be installed with front mark toward timing belt

end of engine. See Fig. 31

.

2. Before disassembling piston and connecting rod, try to move piston back and forth on piston pin. Replace

piston and piston pin as a set, if any movement is felt.

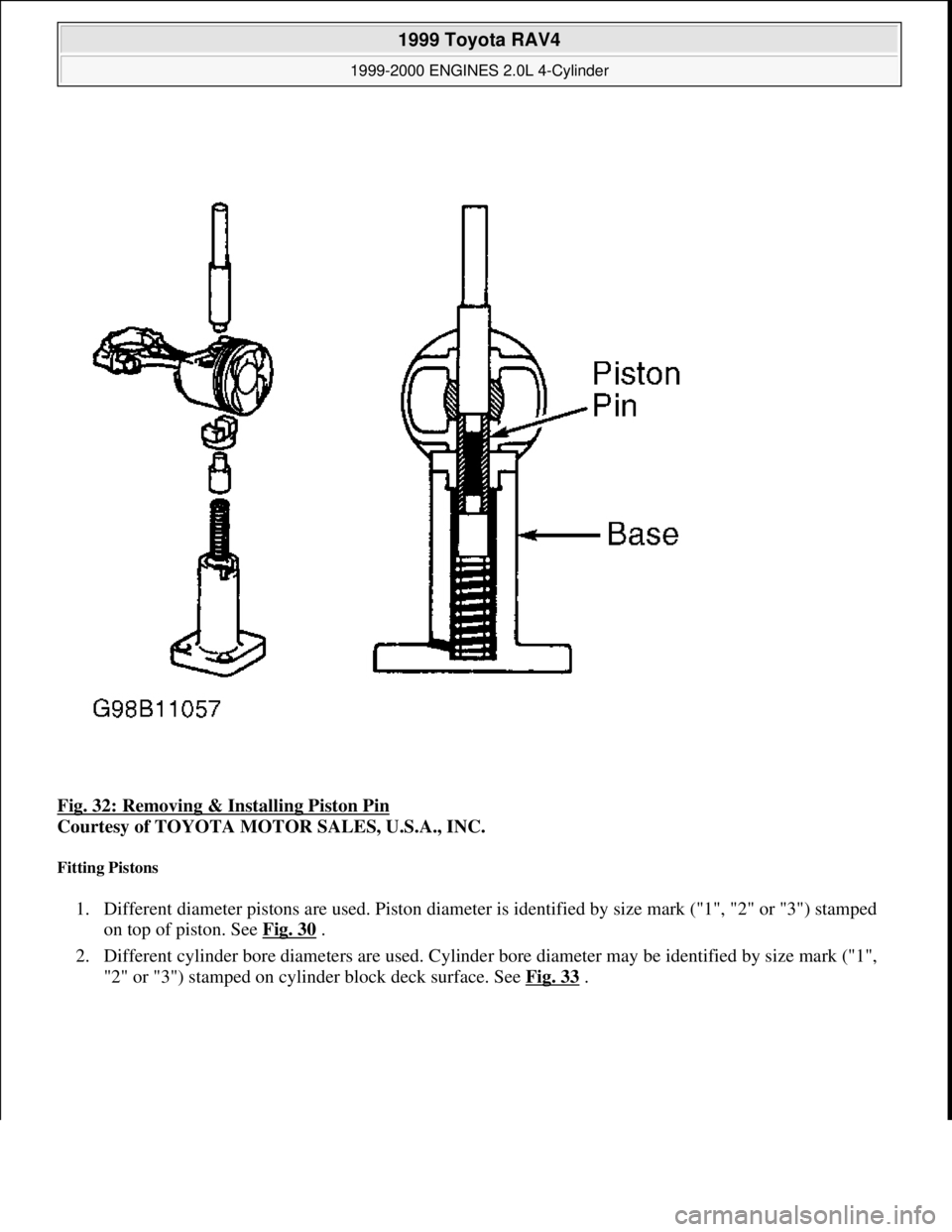

3. Remove 2 compression rings using a piston ring expander. Remove 2 oil rings and oil ring expander by

hand. Using Piston Pin Remover/Replacer (09221-25026), press piston pin from piston, and remove

connecting rod. See Fig. 32

.

4. Ensure piston pin diameter is within specification. See PISTONS, PINS & RINGS

table under ENGINE

SPECIFICATIONS. Ensure connecting rod bend, twist and piston pin bore diameter (connecting rod

small end) are within specification. See CONNECTING RODS

table under ENGINE

SPECIFICATIONS.

5. If piston pin bore diameter is not within specification, replace connecting rod assembly. See

CONNECTING RODS

table under ENGINE SPECIFICATIONS.

6. Using hand pressure, ensure nut rotates easily on connecting rod bolt. If nut fails to rotate easily, use

caliper to measure connecting rod bolt outside diameter .59" (15.0 mm) from end of bolt. Standard

connecting rod bolt outside diameter is .3094-.3150" (7.860-8.000 mm). Replace connecting rod bolt and

nut assembly if bolt outside diameter is less than .2992" (7.600 mm).

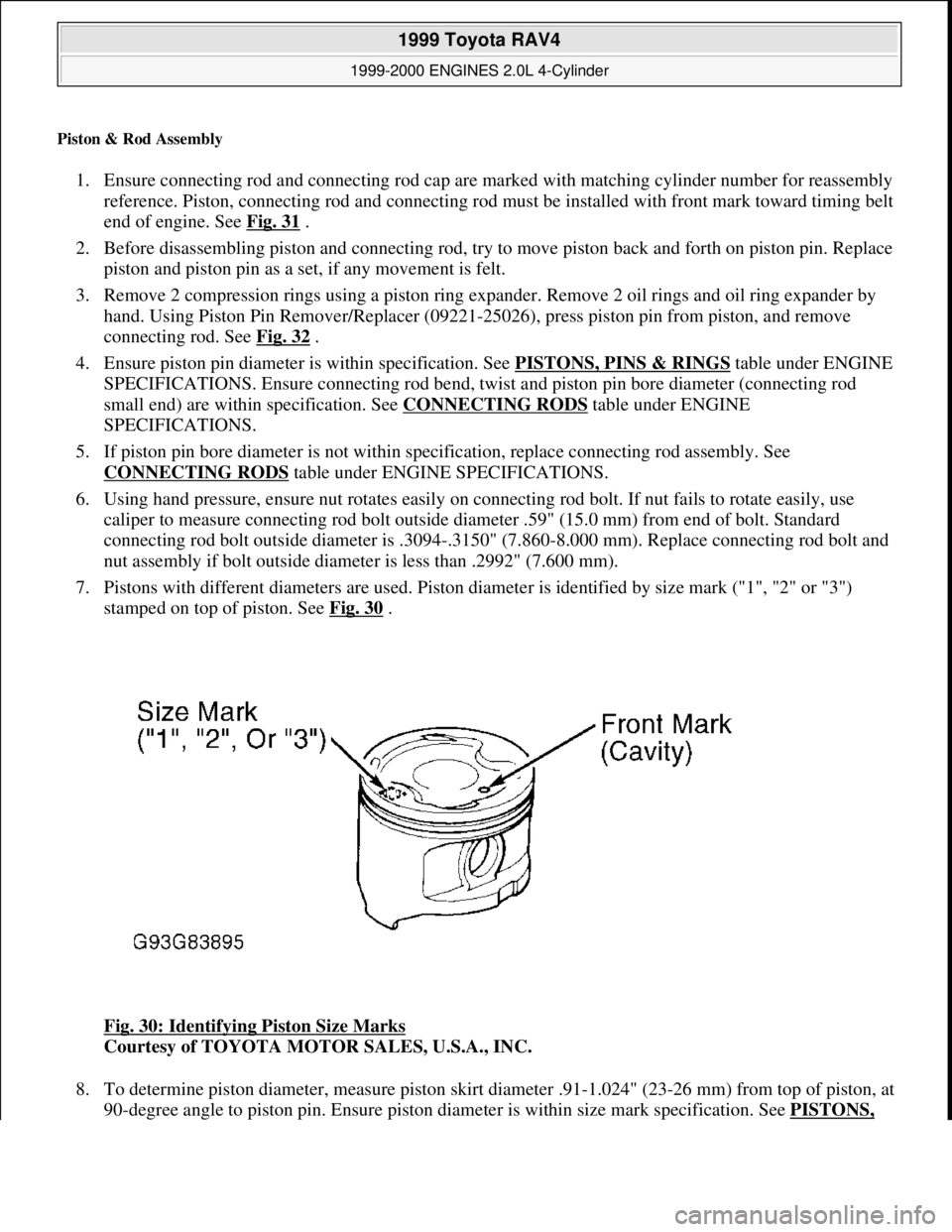

7. Pistons with different diameters are used. Piston diameter is identified by size mark ("1", "2" or "3")

stamped on top of piston. See Fig. 30

.

Fig. 30: Identifying Piston Size Marks

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

8. To determine piston diameter, measure piston skirt diameter .91-1.024" (23-26 mm) from top of piston, at

90-de

gree angle to piston pin. Ensure piston diameter is within size mark specification. See PISTONS,

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 45 © 2005 Mitchell Repair Information Company, LLC.

Page 729 of 1632

PINS & RINGS table under ENGINE SPECIFICATIONS.

9. To reassemble, position piston and connecting rod so front mark (cavity) on top of piston aligns with

front mark (protrusion) on connecting rod. See Fig. 31

. Coat piston bore and piston pin with engine oil.

Using Piston Pin Remover/Replacer (09221-25026), press piston pin into piston and connecting rod. See

Fig. 32

.

Fig. 31: Identifying Piston Front Marks

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 46 © 2005 Mitchell Repair Information Company, LLC.

Page 730 of 1632

Fig. 32: Removing & Installing Piston Pin

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Fitting Pistons

1. Different diameter pistons are used. Piston diameter is identified by size mark ("1", "2" or "3") stamped

on top of piston. See Fig. 30

.

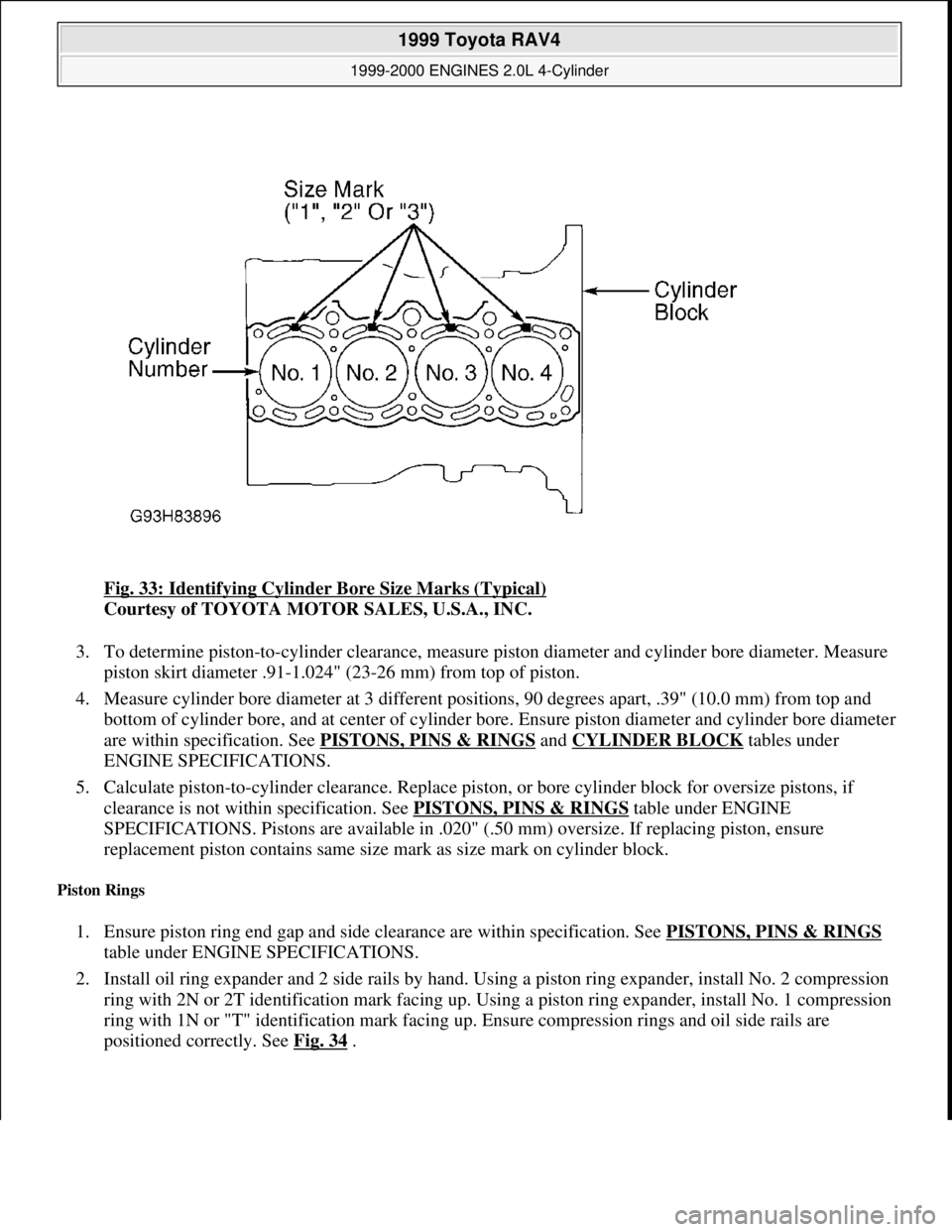

2. Different cylinder bore diameters are used. Cylinder bore diameter may be identified by size mark ("1",

"2" or "3") stamped on c

ylinder block deck surface. See Fig. 33.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 47 © 2005 Mitchell Repair Information Company, LLC.

Page 731 of 1632

Fig. 33: Identifying Cylinder Bore Size Marks (Typical)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3. To determine piston-to-cylinder clearance, measure piston diameter and cylinder bore diameter. Measure

piston skirt diameter .91-1.024" (23-26 mm) from top of piston.

4. Measure cylinder bore diameter at 3 different positions, 90 degrees apart, .39" (10.0 mm) from top and

bottom of cylinder bore, and at center of cylinder bore. Ensure piston diameter and cylinder bore diameter

are within specification. See PISTONS, PINS & RINGS

and CYLINDER BLOCK tables under

ENGINE SPECIFICATIONS.

5. Calculate piston-to-cylinder clearance. Replace piston, or bore cylinder block for oversize pistons, if

clearance is not within specification. See PISTONS, PINS & RINGS

table under ENGINE

SPECIFICATIONS. Pistons are available in .020" (.50 mm) oversize. If replacing piston, ensure

replacement piston contains same size mark as size mark on cylinder block.

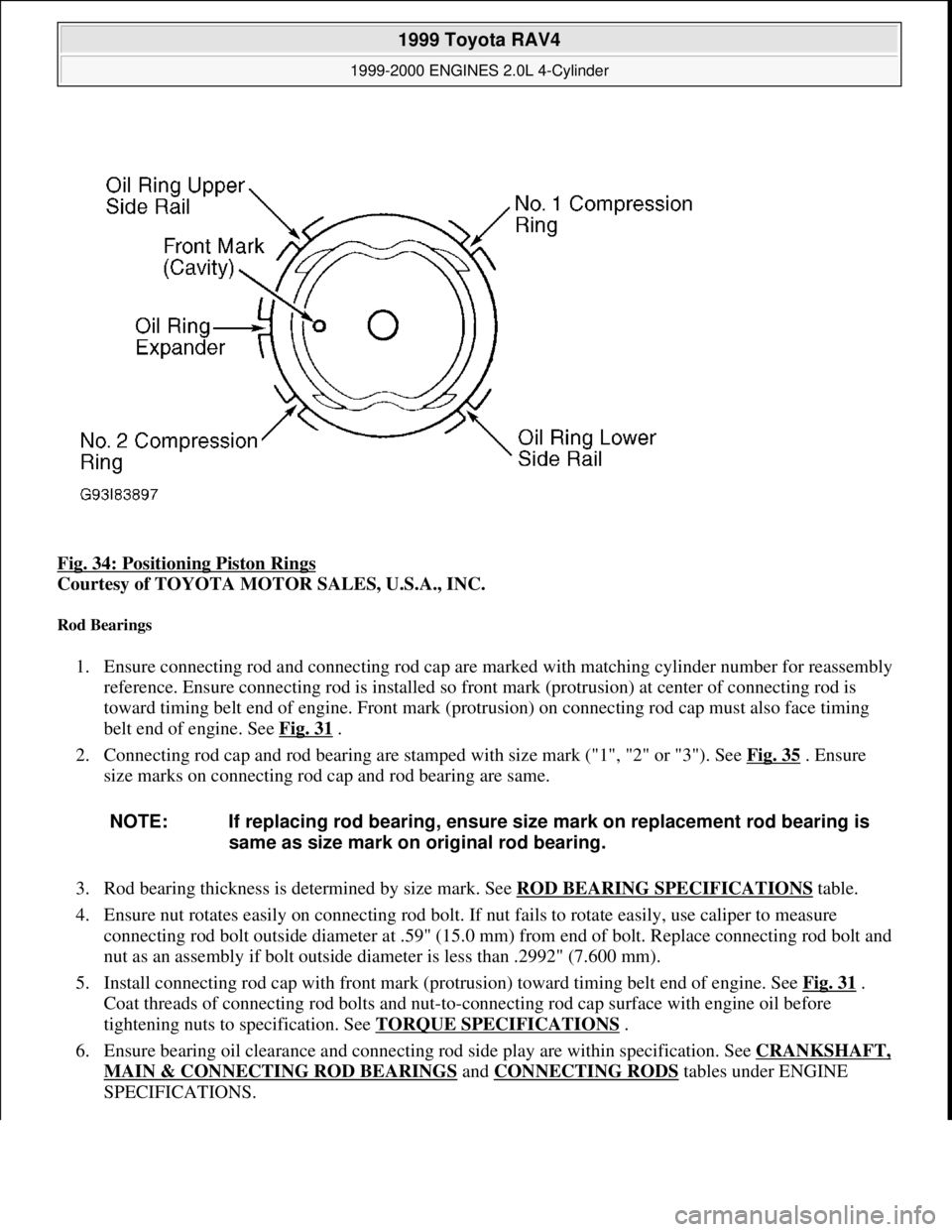

Piston Rings

1. Ensure piston ring end gap and side clearance are within specification. See PISTONS, PINS & RINGS

table under ENGINE SPECIFICATIONS.

2. Install oil ring expander and 2 side rails by hand. Using a piston ring expander, install No. 2 compression

ring with 2N or 2T identification mark facing up. Using a piston ring expander, install No. 1 compression

ring with 1N or "T" identification mark facing up. Ensure compression rings and oil side rails are

positioned correctl

y. See Fig. 34 .

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 48 © 2005 Mitchell Repair Information Company, LLC.

Page 732 of 1632

Fig. 34: Positioning Piston Rings

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Rod Bearings

1. Ensure connecting rod and connecting rod cap are marked with matching cylinder number for reassembly

reference. Ensure connecting rod is installed so front mark (protrusion) at center of connecting rod is

toward timing belt end of engine. Front mark (protrusion) on connecting rod cap must also face timing

belt end of engine. See Fig. 31

.

2. Connecting rod cap and rod bearing are stamped with size mark ("1", "2" or "3"). See Fig. 35

. Ensure

size marks on connecting rod cap and rod bearing are same.

3. Rod bearing thickness is determined by size mark. See ROD BEARING SPECIFICATIONS

table.

4. Ensure nut rotates easily on connecting rod bolt. If nut fails to rotate easily, use caliper to measure

connecting rod bolt outside diameter at .59" (15.0 mm) from end of bolt. Replace connecting rod bolt and

nut as an assembly if bolt outside diameter is less than .2992" (7.600 mm).

5. Install connecting rod cap with front mark (protrusion) toward timing belt end of engine. See Fig. 31

.

Coat threads of connecting rod bolts and nut-to-connecting rod cap surface with engine oil before

tightening nuts to specification. See TORQUE SPECIFICATIONS

.

6. Ensure bearing oil clearance and connecting rod side play are within specification. See CRANKSHAFT,

MAIN & CONNECTING ROD BEARINGS and CONNECTING RODS tables under ENGINE

SPECIFICATIONS.

NOTE: If replacing rod bearing, ensure size mark on replacement rod bearing is

same as size mark on original rod bearing.

1999 Toyota RAV4

1999-2000 ENGINES 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:22:27 AMPage 49 © 2005 Mitchell Repair Information Company, LLC.