engine TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 793 of 1632

Piston & Rod Assembly (1997)

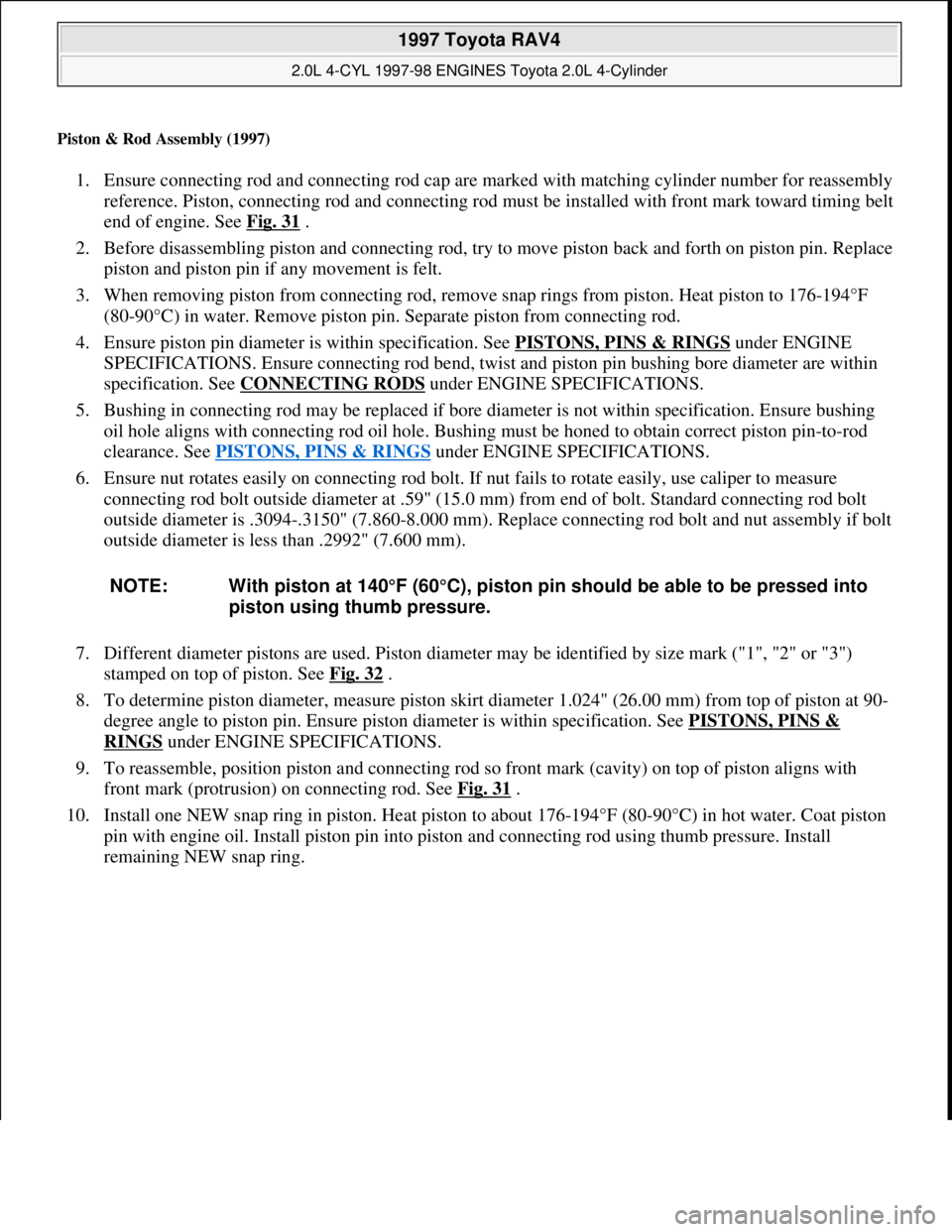

1. Ensure connecting rod and connecting rod cap are marked with matching cylinder number for reassembly

reference. Piston, connecting rod and connecting rod must be installed with front mark toward timing belt

end of engine. See Fig. 31

.

2. Before disassembling piston and connecting rod, try to move piston back and forth on piston pin. Replace

piston and piston pin if any movement is felt.

3. When removing piston from connecting rod, remove snap rings from piston. Heat piston to 176-194°F

(80-90°C) in water. Remove piston pin. Separate piston from connecting rod.

4. Ensure piston pin diameter is within specification. See PISTONS, PINS & RINGS

under ENGINE

SPECIFICATIONS. Ensure connecting rod bend, twist and piston pin bushing bore diameter are within

specification. See CONNECTING RODS

under ENGINE SPECIFICATIONS.

5. Bushing in connecting rod may be replaced if bore diameter is not within specification. Ensure bushing

oil hole aligns with connecting rod oil hole. Bushing must be honed to obtain correct piston pin-to-rod

clearance. See PISTONS, PINS & RINGS

under ENGINE SPECIFICATIONS.

6. Ensure nut rotates easily on connecting rod bolt. If nut fails to rotate easily, use caliper to measure

connecting rod bolt outside diameter at .59" (15.0 mm) from end of bolt. Standard connecting rod bolt

outside diameter is .3094-.3150" (7.860-8.000 mm). Replace connecting rod bolt and nut assembly if bolt

outside diameter is less than .2992" (7.600 mm).

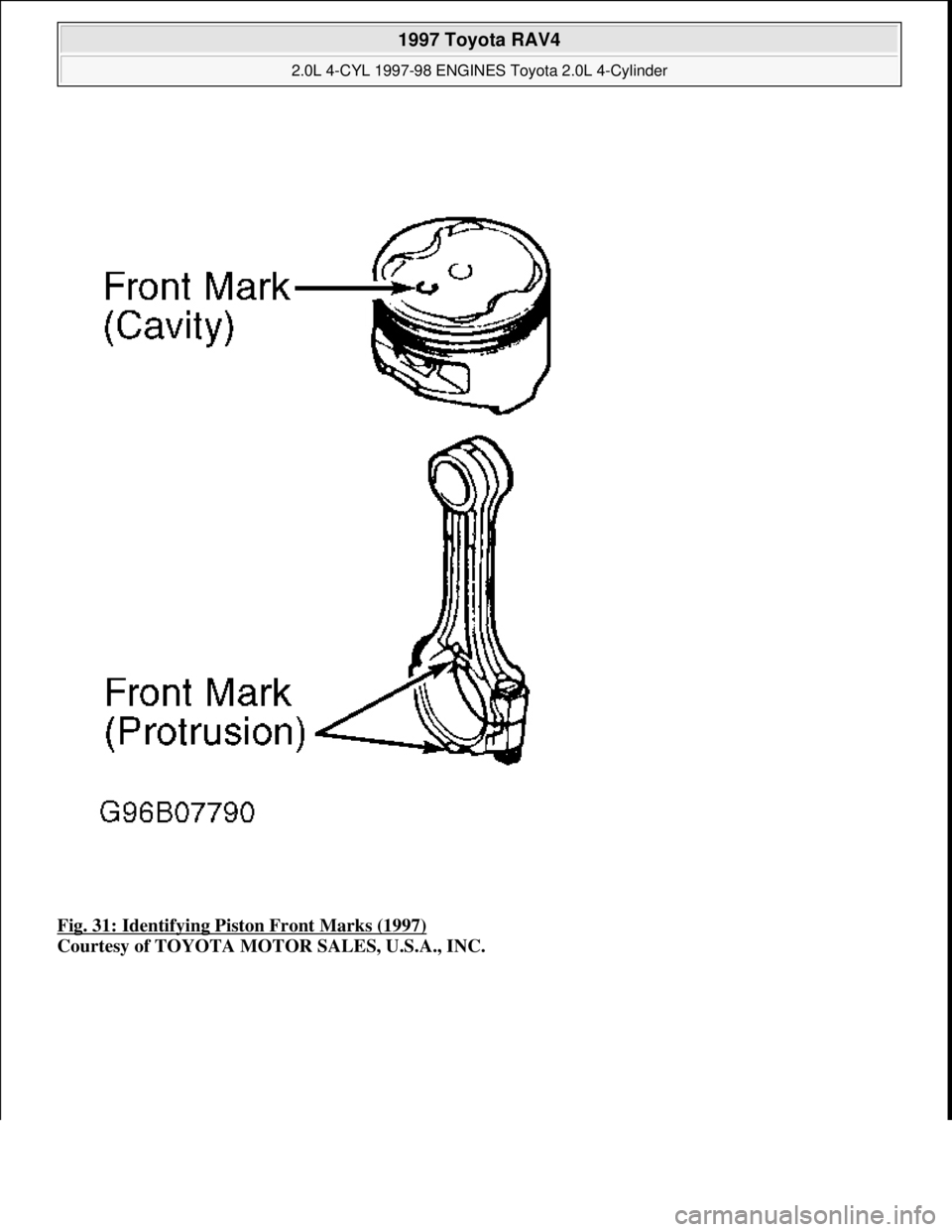

7. Different diameter pistons are used. Piston diameter may be identified by size mark ("1", "2" or "3")

stamped on top of piston. See Fig. 32

.

8. To determine piston diameter, measure piston skirt diameter 1.024" (26.00 mm) from top of piston at 90-

degree angle to piston pin. Ensure piston diameter is within specification. See PISTONS, PINS &

RINGS under ENGINE SPECIFICATIONS.

9. To reassemble, position piston and connecting rod so front mark (cavity) on top of piston aligns with

front mark (protrusion) on connecting rod. See Fig. 31

.

10. Install one NEW snap ring in piston. Heat piston to about 176-194°F (80-90°C) in hot water. Coat piston

pin with engine oil. Install piston pin into piston and connecting rod using thumb pressure. Install

remaining NEW snap ring. NOTE: With piston at 140°F (60°C), piston pin should be able to be pressed into

piston using thumb pressure.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 45 © 2005 Mitchell Repair Information Company, LLC.

Page 794 of 1632

Fig. 31: Identifying Piston Front Marks (1997)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 46 © 2005 Mitchell Repair Information Company, LLC.

Page 795 of 1632

Fig. 32: Identifying Piston Size Marks

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Piston & Rod Assembly (1998)

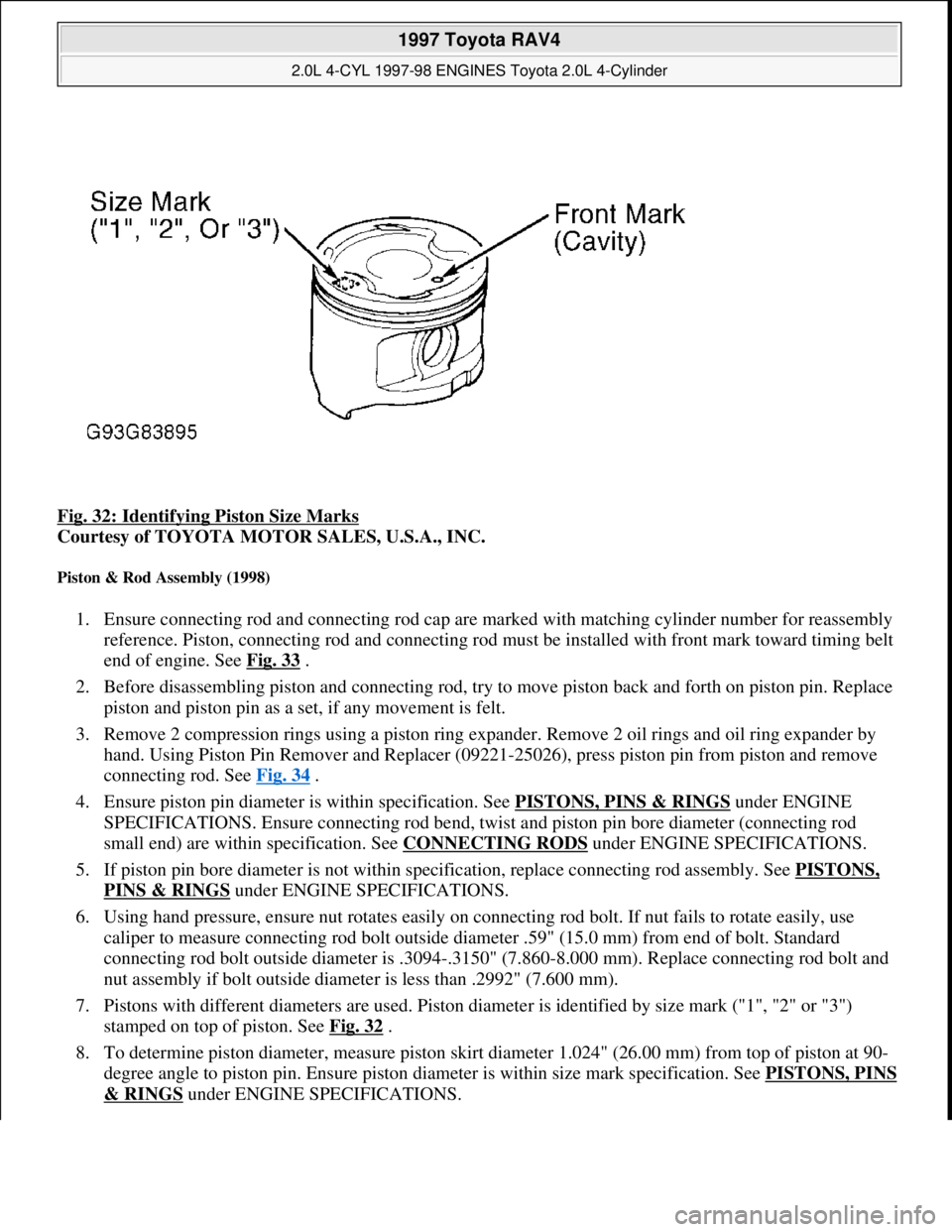

1. Ensure connecting rod and connecting rod cap are marked with matching cylinder number for reassembly

reference. Piston, connecting rod and connecting rod must be installed with front mark toward timing belt

end of engine. See Fig. 33

.

2. Before disassembling piston and connecting rod, try to move piston back and forth on piston pin. Replace

piston and piston pin as a set, if any movement is felt.

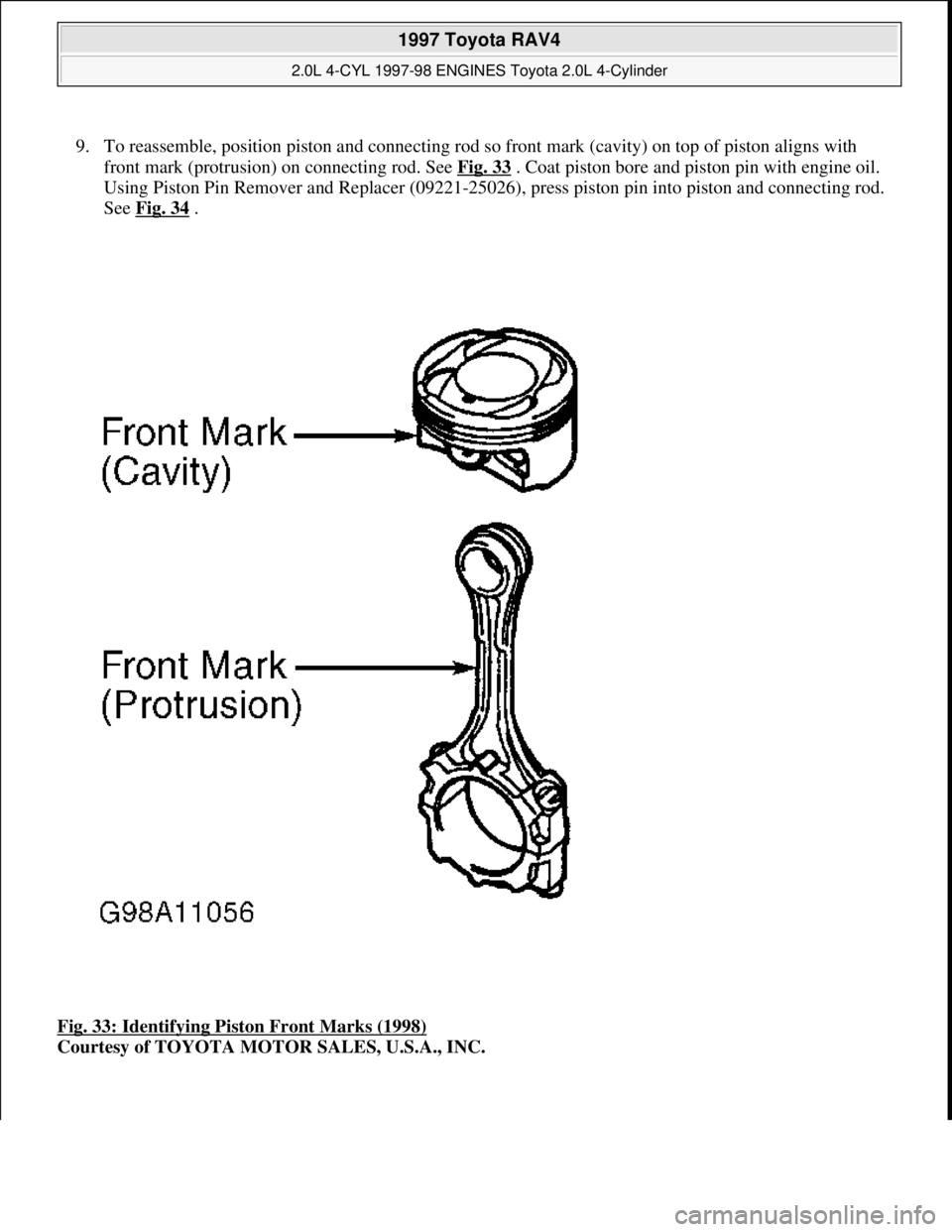

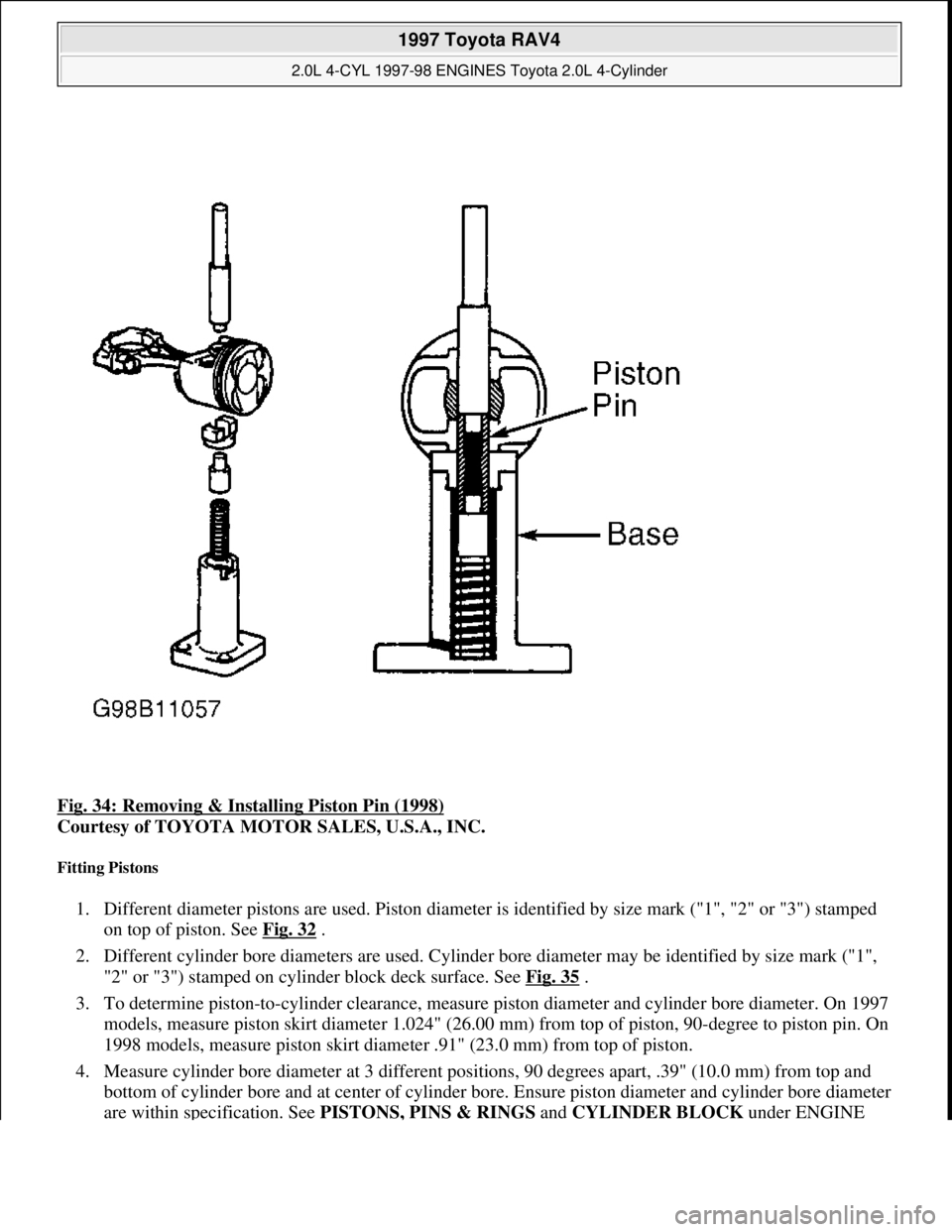

3. Remove 2 compression rings using a piston ring expander. Remove 2 oil rings and oil ring expander by

hand. Using Piston Pin Remover and Replacer (09221-25026), press piston pin from piston and remove

connecting rod. See Fig. 34

.

4. Ensure piston pin diameter is within specification. See PISTONS, PINS & RINGS

under ENGINE

SPECIFICATIONS. Ensure connecting rod bend, twist and piston pin bore diameter (connecting rod

small end) are within specification. See CONNECTING RODS

under ENGINE SPECIFICATIONS.

5. If piston pin bore diameter is not within specification, replace connecting rod assembly. See PISTONS,

PINS & RINGS under ENGINE SPECIFICATIONS.

6. Using hand pressure, ensure nut rotates easily on connecting rod bolt. If nut fails to rotate easily, use

caliper to measure connecting rod bolt outside diameter .59" (15.0 mm) from end of bolt. Standard

connecting rod bolt outside diameter is .3094-.3150" (7.860-8.000 mm). Replace connecting rod bolt and

nut assembly if bolt outside diameter is less than .2992" (7.600 mm).

7. Pistons with different diameters are used. Piston diameter is identified by size mark ("1", "2" or "3")

stamped on top of piston. See Fig. 32

.

8. To determine piston diameter, measure piston skirt diameter 1.024" (26.00 mm) from top of piston at 90-

degree angle to piston pin. Ensure piston diameter is within size mark specification. See PISTONS, PINS

& RINGS under ENGINE SPECIFICATIONS.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 47 © 2005 Mitchell Repair Information Company, LLC.

Page 796 of 1632

9. To reassemble, position piston and connecting rod so front mark (cavity) on top of piston aligns with

front mark (protrusion) on connecting rod. See Fig. 33

. Coat piston bore and piston pin with engine oil.

Using Piston Pin Remover and Replacer (09221-25026), press piston pin into piston and connecting rod.

See Fig. 34

.

Fig. 33: Identifying Piston Front Marks (1998)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 48 © 2005 Mitchell Repair Information Company, LLC.

Page 797 of 1632

Fig. 34: Removing & Installing Piston Pin (1998)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Fitting Pistons

1. Different diameter pistons are used. Piston diameter is identified by size mark ("1", "2" or "3") stamped

on top of piston. See Fig. 32

.

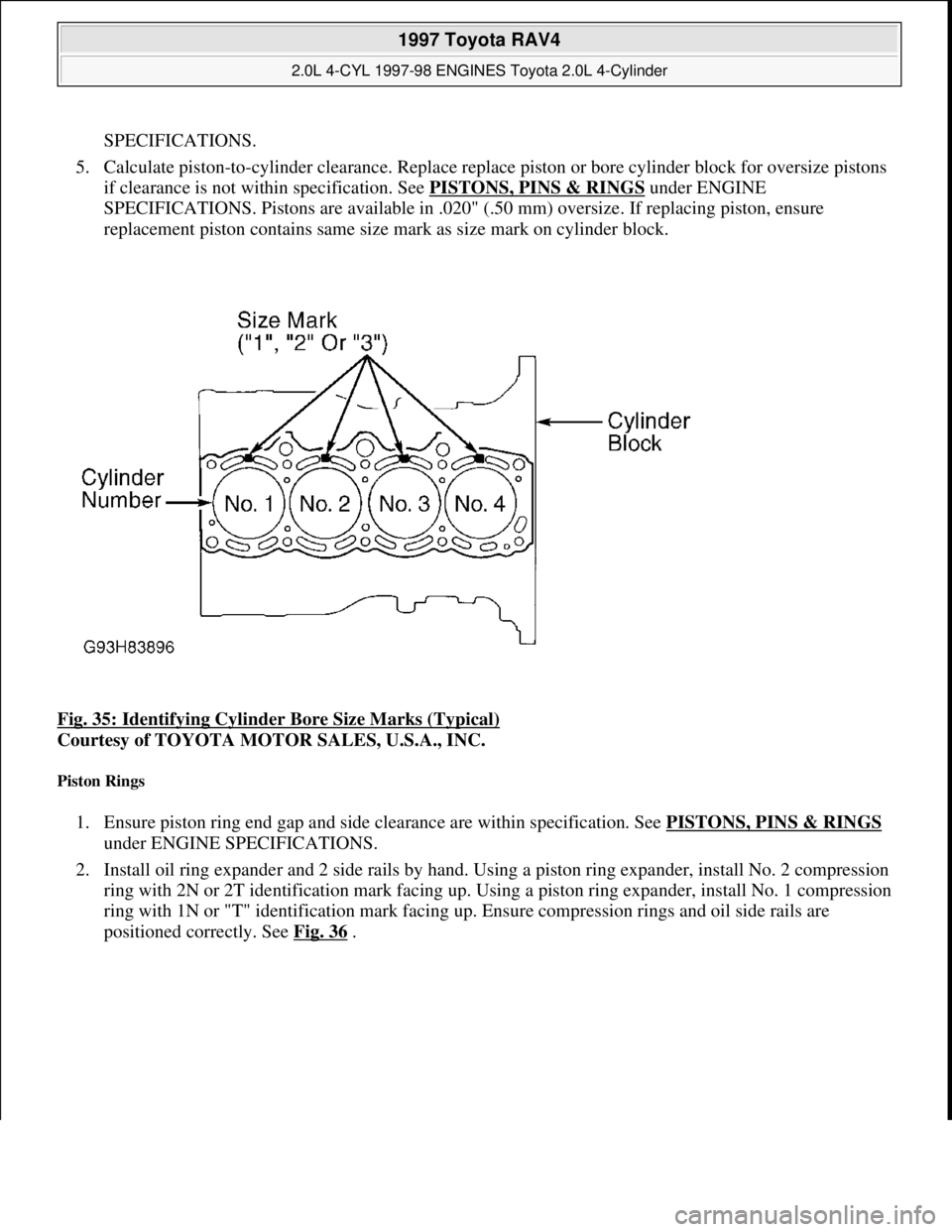

2. Different cylinder bore diameters are used. Cylinder bore diameter may be identified by size mark ("1",

"2" or "3") stamped on cylinder block deck surface. See Fig. 35

.

3. To determine piston-to-cylinder clearance, measure piston diameter and cylinder bore diameter. On 1997

models, measure piston skirt diameter 1.024" (26.00 mm) from top of piston, 90-degree to piston pin. On

1998 models, measure piston skirt diameter .91" (23.0 mm) from top of piston.

4. Measure cylinder bore diameter at 3 different positions, 90 degrees apart, .39" (10.0 mm) from top and

bottom of cylinder bore and at center of cylinder bore. Ensure piston diameter and cylinder bore diameter

are within specification. See PISTONS, PINS & RINGS

and CYLINDER BLOCK under ENGINE

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 49 © 2005 Mitchell Repair Information Company, LLC.

Page 798 of 1632

SPECIFICATIONS.

5. Calculate piston-to-cylinder clearance. Replace replace piston or bore cylinder block for oversize pistons

if clearance is not within specification. See PISTONS, PINS & RINGS

under ENGINE

SPECIFICATIONS. Pistons are available in .020" (.50 mm) oversize. If replacing piston, ensure

replacement piston contains same size mark as size mark on cylinder block.

Fig. 35: Identifying Cylinder Bore Size Marks (Typical)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

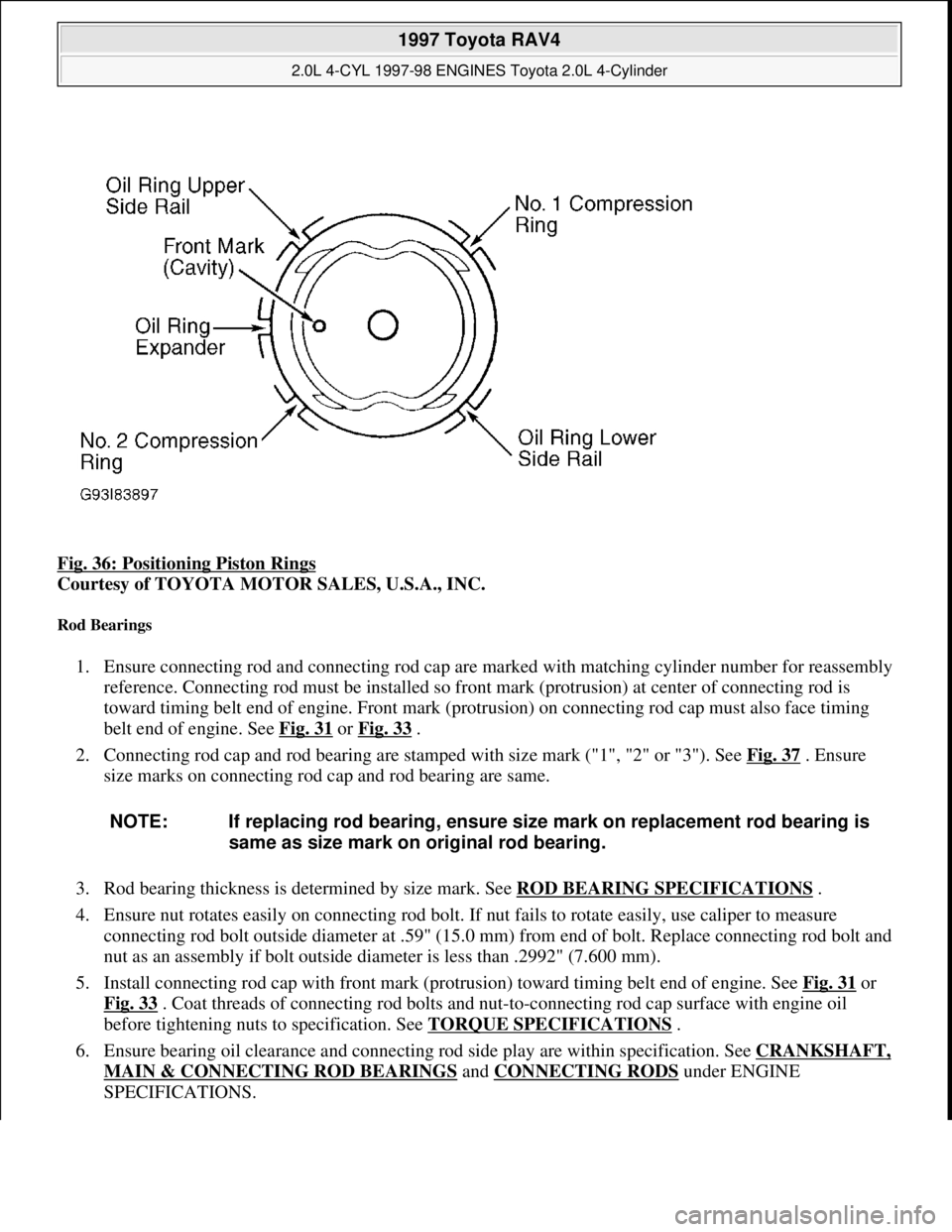

Piston Rings

1. Ensure piston ring end gap and side clearance are within specification. See PISTONS, PINS & RINGS

under ENGINE SPECIFICATIONS.

2. Install oil ring expander and 2 side rails by hand. Using a piston ring expander, install No. 2 compression

ring with 2N or 2T identification mark facing up. Using a piston ring expander, install No. 1 compression

ring with 1N or "T" identification mark facing up. Ensure compression rings and oil side rails are

positioned correctl

y. See Fig. 36 .

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 50 © 2005 Mitchell Repair Information Company, LLC.

Page 799 of 1632

Fig. 36: Positioning Piston Rings

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

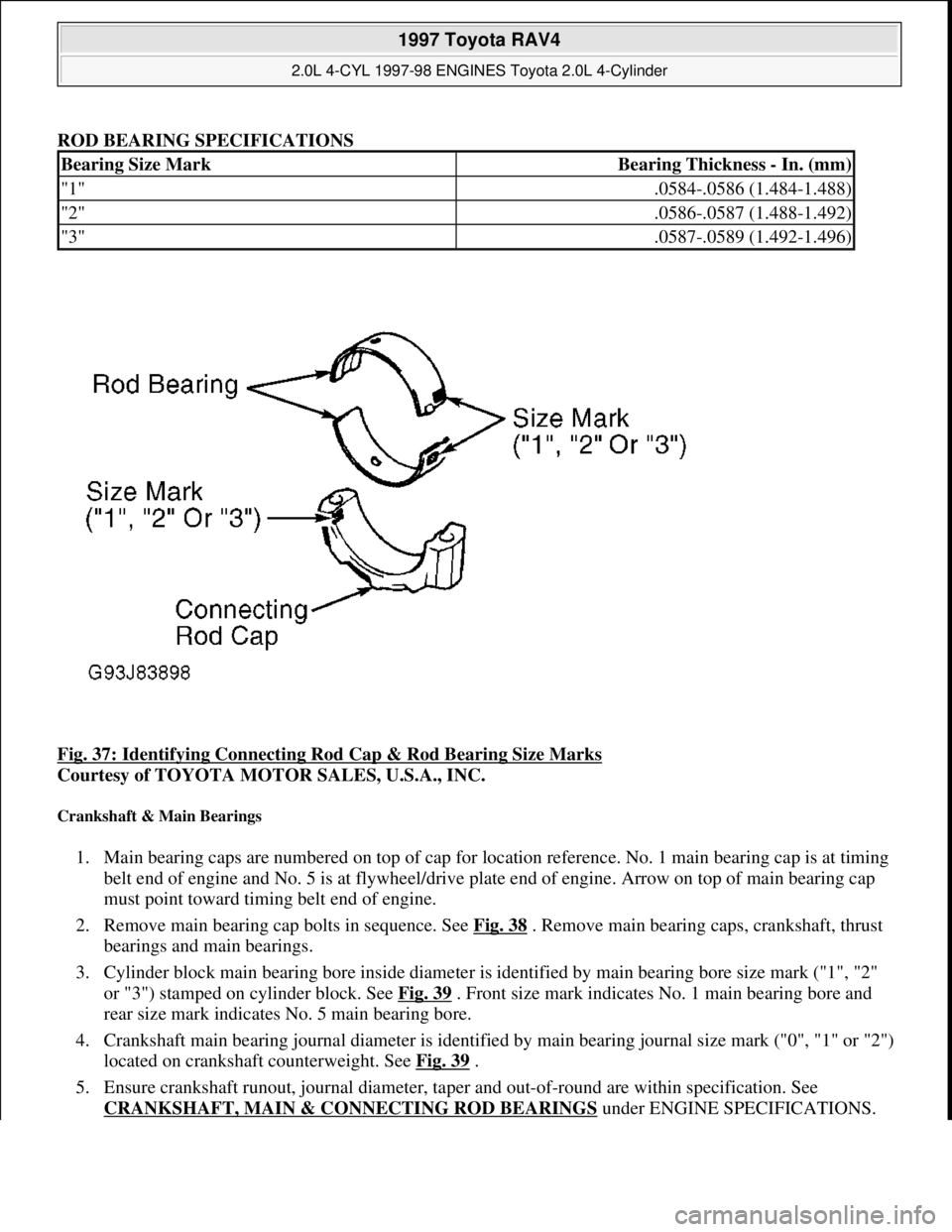

Rod Bearings

1. Ensure connecting rod and connecting rod cap are marked with matching cylinder number for reassembly

reference. Connecting rod must be installed so front mark (protrusion) at center of connecting rod is

toward timing belt end of engine. Front mark (protrusion) on connecting rod cap must also face timing

belt end of engine. See Fig. 31

or Fig. 33 .

2. Connecting rod cap and rod bearing are stamped with size mark ("1", "2" or "3"). See Fig. 37

. Ensure

size marks on connecting rod cap and rod bearing are same.

3. Rod bearing thickness is determined by size mark. See ROD BEARING SPECIFICATIONS

.

4. Ensure nut rotates easily on connecting rod bolt. If nut fails to rotate easily, use caliper to measure

connecting rod bolt outside diameter at .59" (15.0 mm) from end of bolt. Replace connecting rod bolt and

nut as an assembly if bolt outside diameter is less than .2992" (7.600 mm).

5. Install connecting rod cap with front mark (protrusion) toward timing belt end of engine. See Fig. 31

or

Fig. 33

. Coat threads of connecting rod bolts and nut-to-connecting rod cap surface with engine oil

before tightening nuts to specification. See TORQUE SPECIFICATIONS

.

6. Ensure bearing oil clearance and connecting rod side play are within specification. See CRANKSHAFT,

MAIN & CONNECTING ROD BEARINGS and CONNECTING RODS under ENGINE

SPECIFICATIONS.

NOTE: If replacing rod bearing, ensure size mark on replacement rod bearing is

same as size mark on original rod bearing.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 51 © 2005 Mitchell Repair Information Company, LLC.

Page 800 of 1632

ROD BEARING SPECIFICATIONS

Fig. 37: Identifying Connecting Rod Cap & Rod Bearing Size Marks

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Crankshaft & Main Bearings

1. Main bearing caps are numbered on top of cap for location reference. No. 1 main bearing cap is at timing

belt end of engine and No. 5 is at flywheel/drive plate end of engine. Arrow on top of main bearing cap

must point toward timing belt end of engine.

2. Remove main bearing cap bolts in sequence. See Fig. 38

. Remove main bearing caps, crankshaft, thrust

bearings and main bearings.

3. Cylinder block main bearing bore inside diameter is identified by main bearing bore size mark ("1", "2"

or "3") stamped on cylinder block. See Fig. 39

. Front size mark indicates No. 1 main bearing bore and

rear size mark indicates No. 5 main bearing bore.

4. Crankshaft main bearing journal diameter is identified by main bearing journal size mark ("0", "1" or "2")

located on crankshaft counterweight. See Fig. 39

.

5. Ensure crankshaft runout, journal diameter, taper and out-of-round are within specification. See

CRANKSHAFT, MAIN & CONNECTING ROD BEARINGS

under ENGINE SPECIFICATIONS.

Bearing Size MarkBearing Thickness - In. (mm)

"1".0584-.0586 (1.484-1.488)

"2".0586-.0587 (1.488-1.492)

"3".0587-.0589 (1.492-1.496)

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 52 © 2005 Mitchell Repair Information Company, LLC.

Page 801 of 1632

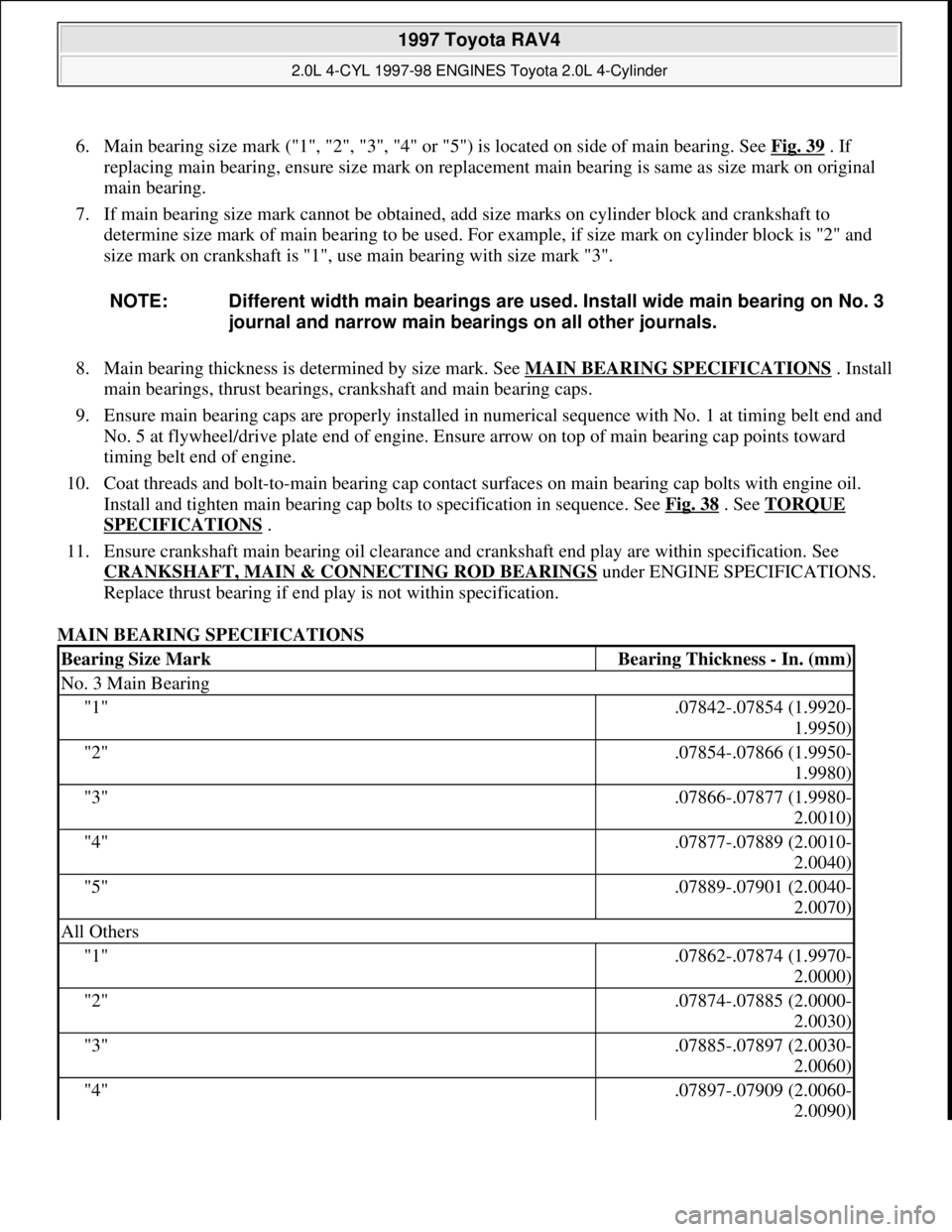

6. Main bearing size mark ("1", "2", "3", "4" or "5") is located on side of main bearing. See Fig. 39 . If

replacing main bearing, ensure size mark on replacement main bearing is same as size mark on original

main bearing.

7. If main bearing size mark cannot be obtained, add size marks on cylinder block and crankshaft to

determine size mark of main bearing to be used. For example, if size mark on cylinder block is "2" and

size mark on crankshaft is "1", use main bearing with size mark "3".

8. Main bearing thickness is determined by size mark. See MAIN BEARING SPECIFICATIONS

. Install

main bearings, thrust bearings, crankshaft and main bearing caps.

9. Ensure main bearing caps are properly installed in numerical sequence with No. 1 at timing belt end and

No. 5 at flywheel/drive plate end of engine. Ensure arrow on top of main bearing cap points toward

timing belt end of engine.

10. Coat threads and bolt-to-main bearing cap contact surfaces on main bearing cap bolts with engine oil.

Install and tighten main bearing cap bolts to specification in sequence. See Fig. 38

. See TORQUE

SPECIFICATIONS .

11. Ensure crankshaft main bearing oil clearance and crankshaft end play are within specification. See

CRANKSHAFT, MAIN & CONNECTING ROD BEARINGS

under ENGINE SPECIFICATIONS.

Replace thrust bearing if end play is not within specification.

MAIN BEARING SPECIFICATIONS NOTE: Different width main bearings are used. Install wide main bearing on No. 3

journal and narrow main bearings on all other journals.

Bearing Size MarkBearing Thickness - In. (mm)

No. 3 Main Bearing

"1".07842-.07854 (1.9920-

1.9950)

"2".07854-.07866 (1.9950-

1.9980)

"3".07866-.07877 (1.9980-

2.0010)

"4".07877-.07889 (2.0010-

2.0040)

"5".07889-.07901 (2.0040-

2.0070)

All Others

"1".07862-.07874 (1.9970-

2.0000)

"2".07874-.07885 (2.0000-

2.0030)

"3".07885-.07897 (2.0030-

2.0060)

"4".07897-.07909 (2.0060-

2.0090)

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 53 © 2005 Mitchell Repair Information Company, LLC.

Page 802 of 1632

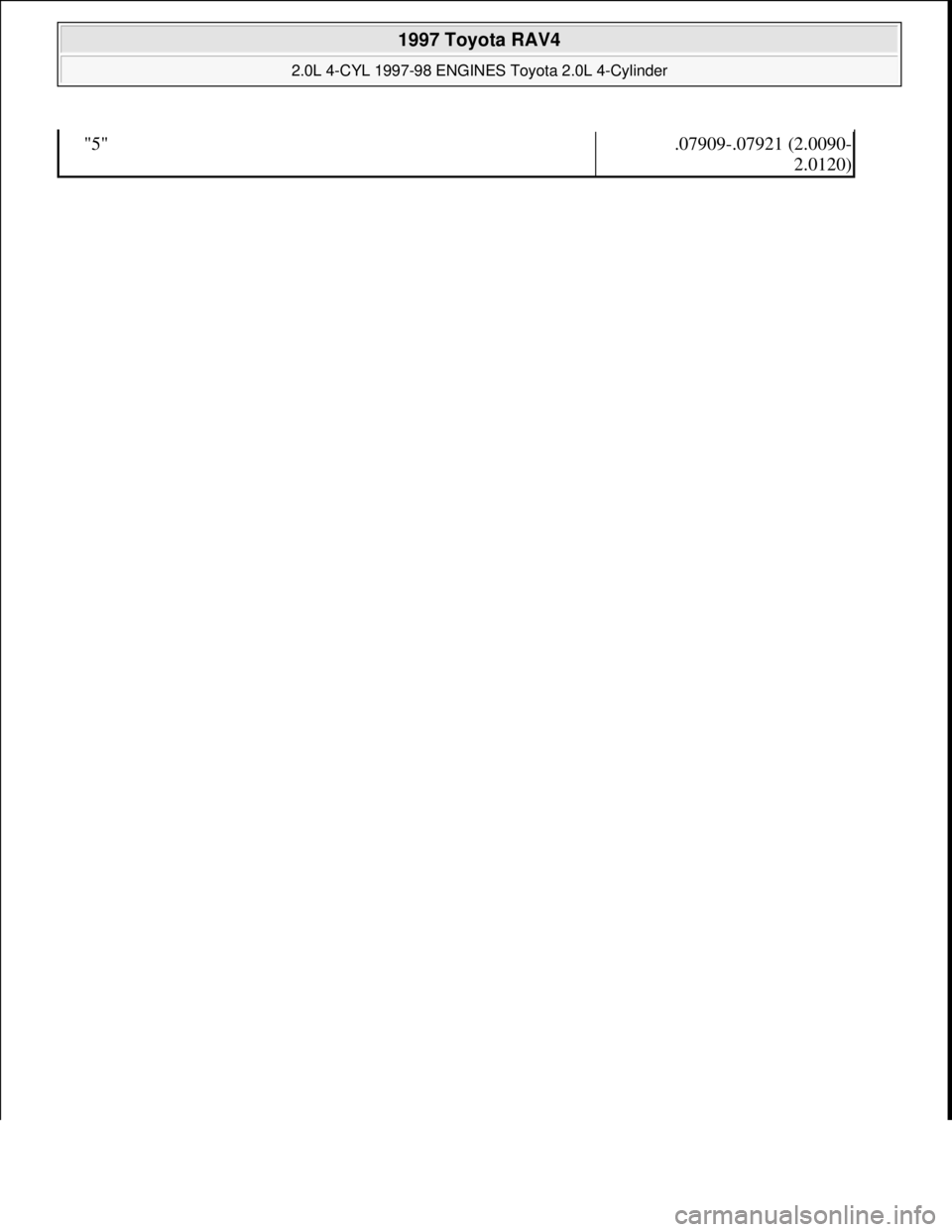

"5".07909-.07921 (2.0090-

2.0120)

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 54 © 2005 Mitchell Repair Information Company, LLC.