engine TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 878 of 1632

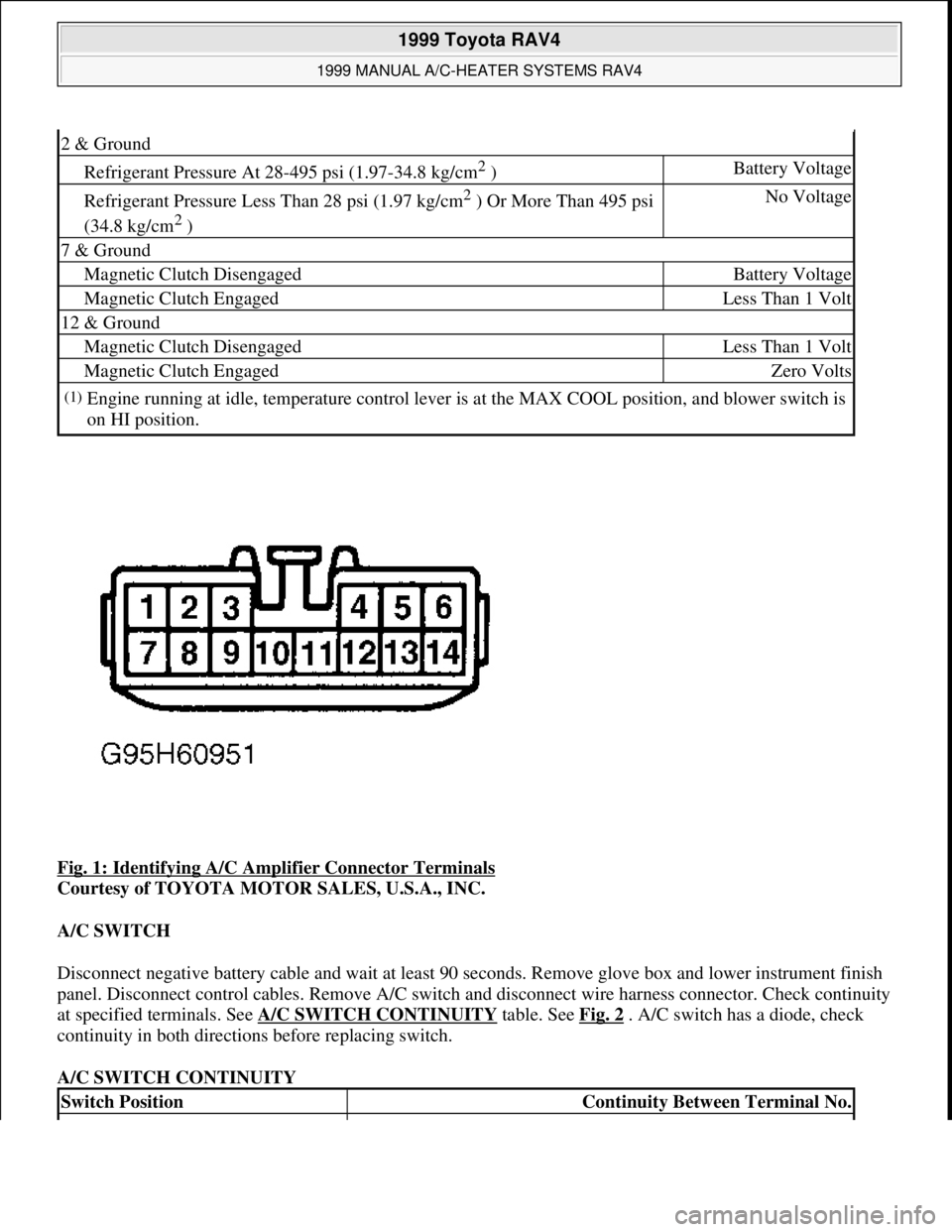

Fig. 1: Identifying A/C Amplifier Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

A/C SWITCH

Disconnect negative battery cable and wait at least 90 seconds. Remove glove box and lower instrument finish

panel. Disconnect control cables. Remove A/C switch and disconnect wire harness connector. Check continuity

at specified terminals. See A/C SWITCH CONTINUITY

table. See Fig. 2 . A/C switch has a diode, check

continuity in both directions before replacing switch.

A/C SWITCH CONTINUITY

2 & Ground

Refrigerant Pressure At 28-495 psi (1.97-34.8 kg/cm2 )Battery Voltage

Refrigerant Pressure Less Than 28 psi (1.97 kg/cm2 ) Or More Than 495 psi

(34.8 kg/cm

2 )

No Voltage

7 & Ground

Magnetic Clutch DisengagedBattery Voltage

Magnetic Clutch EngagedLess Than 1 Volt

12 & Ground

Magnetic Clutch DisengagedLess Than 1 Volt

Magnetic Clutch EngagedZero Volts

(1)Engine running at idle, temperature control lever is at the MAX COOL position, and blower switch is

on HI position.

Switch PositionContinuity Between Terminal No.

1999 Toyota RAV4

1999 MANUAL A/C-HEATER SYSTEMS RAV4

Microsoft

Sunday, November 22, 2009 10:29:28 AMPage 5 © 2005 Mitchell Repair Information Company, LLC.

Page 879 of 1632

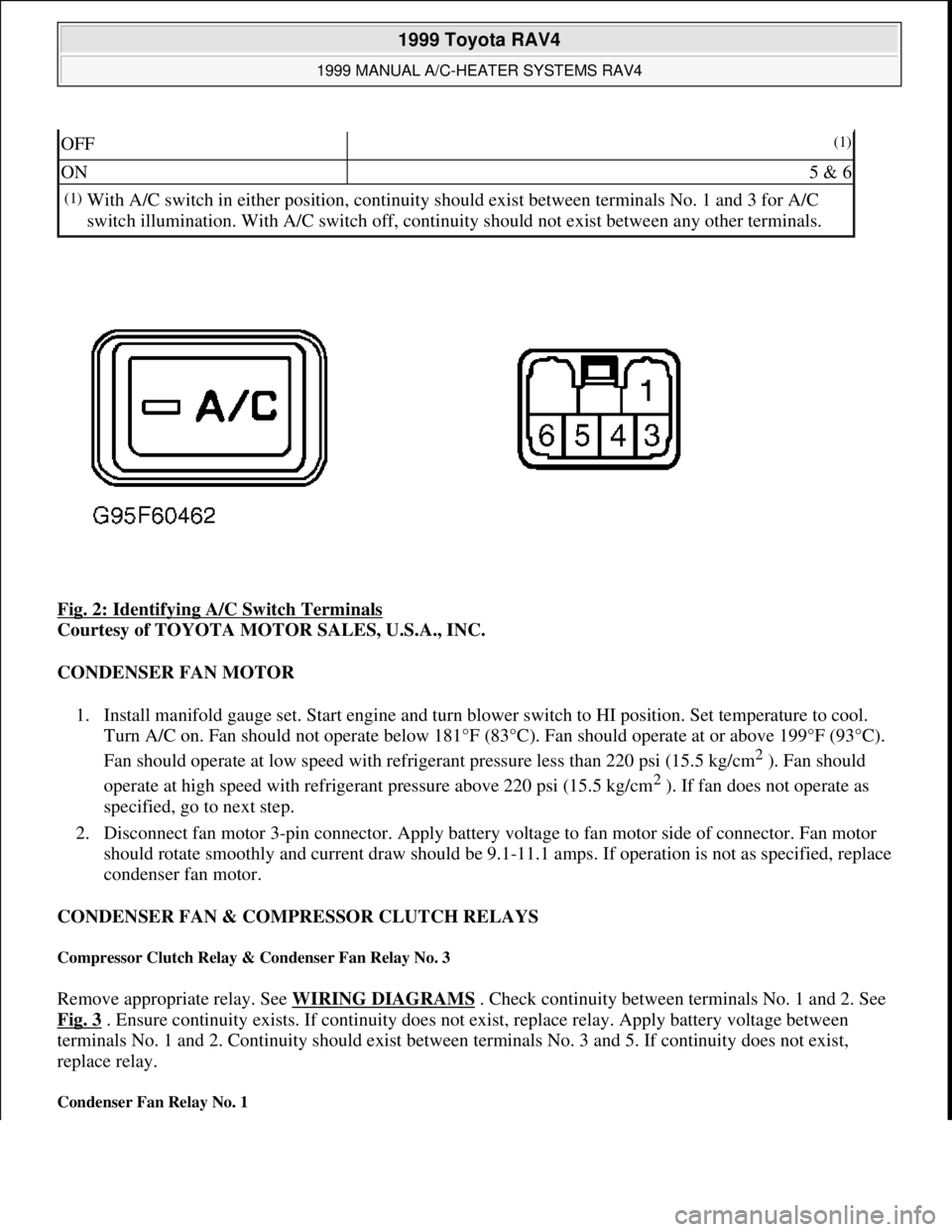

Fig. 2: Identifying A/C Switch Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

CONDENSER FAN MOTOR

1. Install manifold gauge set. Start engine and turn blower switch to HI position. Set temperature to cool.

Turn A/C on. Fan should not operate below 181°F (83°C). Fan should operate at or above 199°F (93°C).

Fan should operate at low speed with refrigerant pressure less than 220 psi (15.5 kg/cm

2 ). Fan should

operate at high speed with refrigerant pressure above 220 psi (15.5 kg/cm

2 ). If fan does not operate as

specified, go to next step.

2. Disconnect fan motor 3-pin connector. Apply battery voltage to fan motor side of connector. Fan motor

should rotate smoothly and current draw should be 9.1-11.1 amps. If operation is not as specified, replace

condenser fan motor.

CONDENSER FAN & COMPRESSOR CLUTCH RELAYS

Compressor Clutch Relay & Condenser Fan Relay No. 3

Remove appropriate relay. See WIRING DIAGRAMS . Check continuity between terminals No. 1 and 2. See

Fig. 3

. Ensure continuity exists. If continuity does not exist, replace relay. Apply battery voltage between

terminals No. 1 and 2. Continuity should exist between terminals No. 3 and 5. If continuity does not exist,

replace relay.

Condenser Fan Relay No. 1

OFF(1)

ON5 & 6

(1)With A/C switch in either position, continuity should exist between terminals No. 1 and 3 for A/C

switch illumination. With A/C switch off, continuity should not exist between any other terminals.

1999 Toyota RAV4

1999 MANUAL A/C-HEATER SYSTEMS RAV4

Microsoft

Sunday, November 22, 2009 10:29:28 AMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 882 of 1632

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

IDLE AIR CONTROL (IAC) VALVE

Start engine and bring to normal operating temperature. Turn A/C switch on, set blower switch to high position

and adjust temperature control lever to maximum cooling. Ensure compressor clutch is engaged. Using

tachometer, ensure when compressor clutch engages, idle RPM increases 100-200 RPM and decreases a similar

amount when clutch is disengaged. If idle does not react as specified, check IAC valve and air intake system.

COMPRESSOR CLUTCH & COMPRESSOR LOCK SENSOR

Inspect pressure plate and rotor for signs of oil contamination. Check clutch bearing for noisy operation and

grease leakage. Check compressor lock sensor resistance. Disconnect compressor clutch/lock sensor 3-pin

connector. Measure resistance between terminals No. 1 (White wire) and No. 2 (Blue wire). Resistance should

be 65-125 ohms at 68°F (20°C). Replace as necessary. Check magnetic clutch operation. Apply battery voltage

to compressor clutch connector terminal No. 3 (Black wire). Connect negative battery lead to ground. Ensure

compressor clutch is energized. If compressor clutch is not energized, replace compressor clutch.

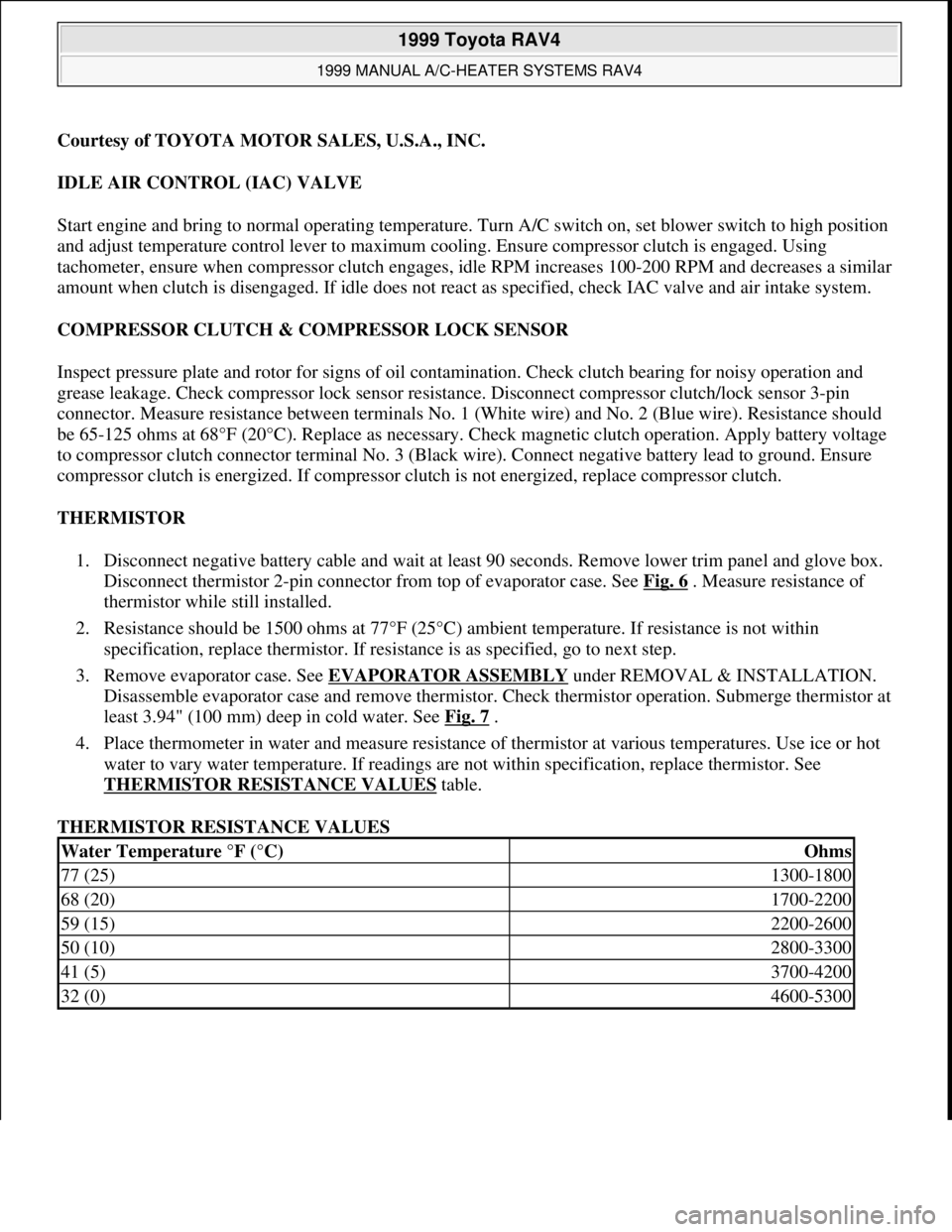

THERMISTOR

1. Disconnect negative battery cable and wait at least 90 seconds. Remove lower trim panel and glove box.

Disconnect thermistor 2-pin connector from top of evaporator case. See Fig. 6

. Measure resistance of

thermistor while still installed.

2. Resistance should be 1500 ohms at 77°F (25°C) ambient temperature. If resistance is not within

specification, replace thermistor. If resistance is as specified, go to next step.

3. Remove evaporator case. See EVAPORATOR ASSEMBLY

under REMOVAL & INSTALLATION.

Disassemble evaporator case and remove thermistor. Check thermistor operation. Submerge thermistor at

least 3.94" (100 mm) deep in cold water. See Fig. 7

.

4. Place thermometer in water and measure resistance of thermistor at various temperatures. Use ice or hot

water to vary water temperature. If readings are not within specification, replace thermistor. See

THERMISTOR RESISTANCE VALUES

table.

THERMISTOR RESISTANCE VALUES

Water Temperature °F (°C)Ohms

77 (25)1300-1800

68 (20)1700-2200

59 (15)2200-2600

50 (10)2800-3300

41 (5)3700-4200

32 (0)4600-5300

1999 Toyota RAV4

1999 MANUAL A/C-HEATER SYSTEMS RAV4

Microsoft

Sunday, November 22, 2009 10:29:28 AMPage 9 © 2005 Mitchell Repair Information Company, LLC.

Page 884 of 1632

Fig. 7: Testing Thermistor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

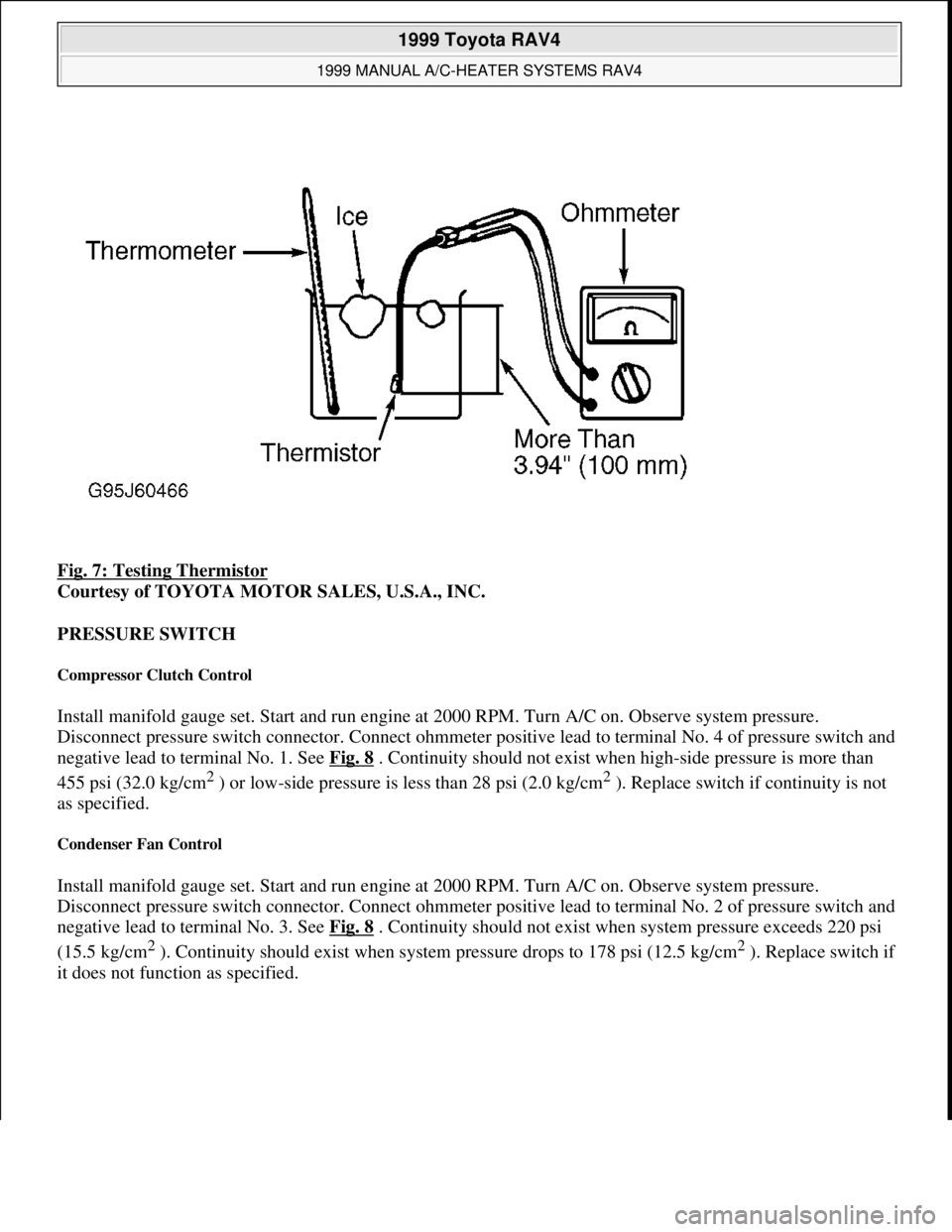

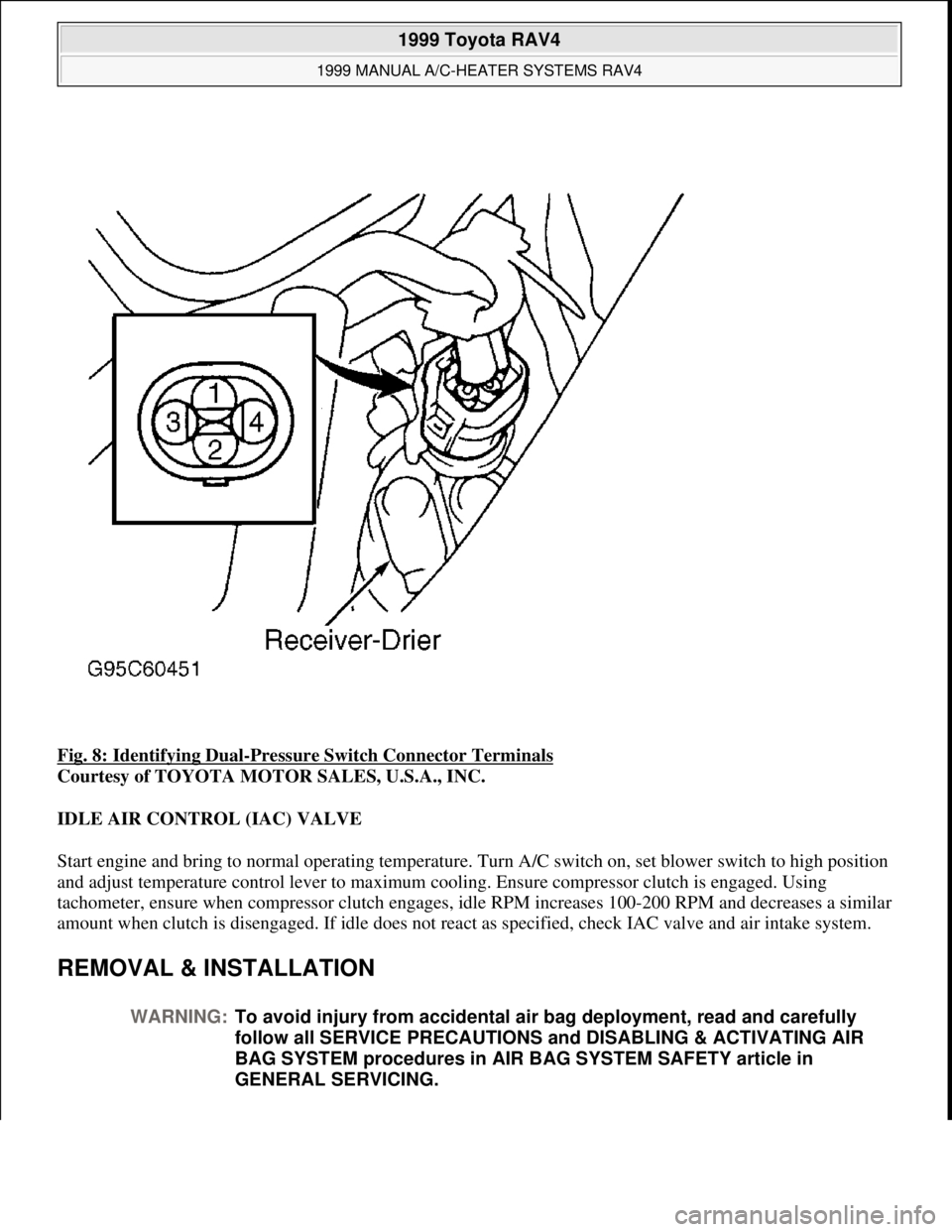

PRESSURE SWITCH

Compressor Clutch Control

Install manifold gauge set. Start and run engine at 2000 RPM. Turn A/C on. Observe system pressure.

Disconnect pressure switch connector. Connect ohmmeter positive lead to terminal No. 4 of pressure switch and

negative lead to terminal No. 1. See Fig. 8

. Continuity should not exist when high-side pressure is more than

455 psi (32.0 kg/cm

2 ) or low-side pressure is less than 28 psi (2.0 kg/cm2 ). Replace switch if continuity is not

as specified.

Condenser Fan Control

Install manifold gauge set. Start and run engine at 2000 RPM. Turn A/C on. Observe system pressure.

Disconnect pressure switch connector. Connect ohmmeter positive lead to terminal No. 2 of pressure switch and

negative lead to terminal No. 3. See Fig. 8

. Continuity should not exist when system pressure exceeds 220 psi

(15.5 kg/cm

2 ). Continuity should exist when system pressure drops to 178 psi (12.5 kg/cm2 ). Replace switch if

it does not function as specified.

1999 Toyota RAV4

1999 MANUAL A/C-HEATER SYSTEMS RAV4

Microsoft

Sunday, November 22, 2009 10:29:28 AMPage 11 © 2005 Mitchell Repair Information Company, LLC.

Page 885 of 1632

Fig. 8: Identifying Dual-Pressure Switch Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

IDLE AIR CONTROL (IAC) VALVE

Start engine and bring to normal operating temperature. Turn A/C switch on, set blower switch to high position

and adjust temperature control lever to maximum cooling. Ensure compressor clutch is engaged. Using

tachometer, ensure when compressor clutch engages, idle RPM increases 100-200 RPM and decreases a similar

amount when clutch is disengaged. If idle does not react as specified, check IAC valve and air intake system.

REMOVAL & INSTALLATION

WARNING:To avoid injury from accidental air bag deployment, read and carefully

follow all SERVICE PRECAUTIONS and DISABLING & ACTIVATING AIR

BAG SYSTEM procedures in AIR BAG SYSTEM SAFETY article in

GENERAL SERVICING.

1999 Toyota RAV4

1999 MANUAL A/C-HEATER SYSTEMS RAV4

Microsoft

Sunday, November 22, 2009 10:29:28 AMPage 12 © 2005 Mitchell Repair Information Company, LLC.

Page 886 of 1632

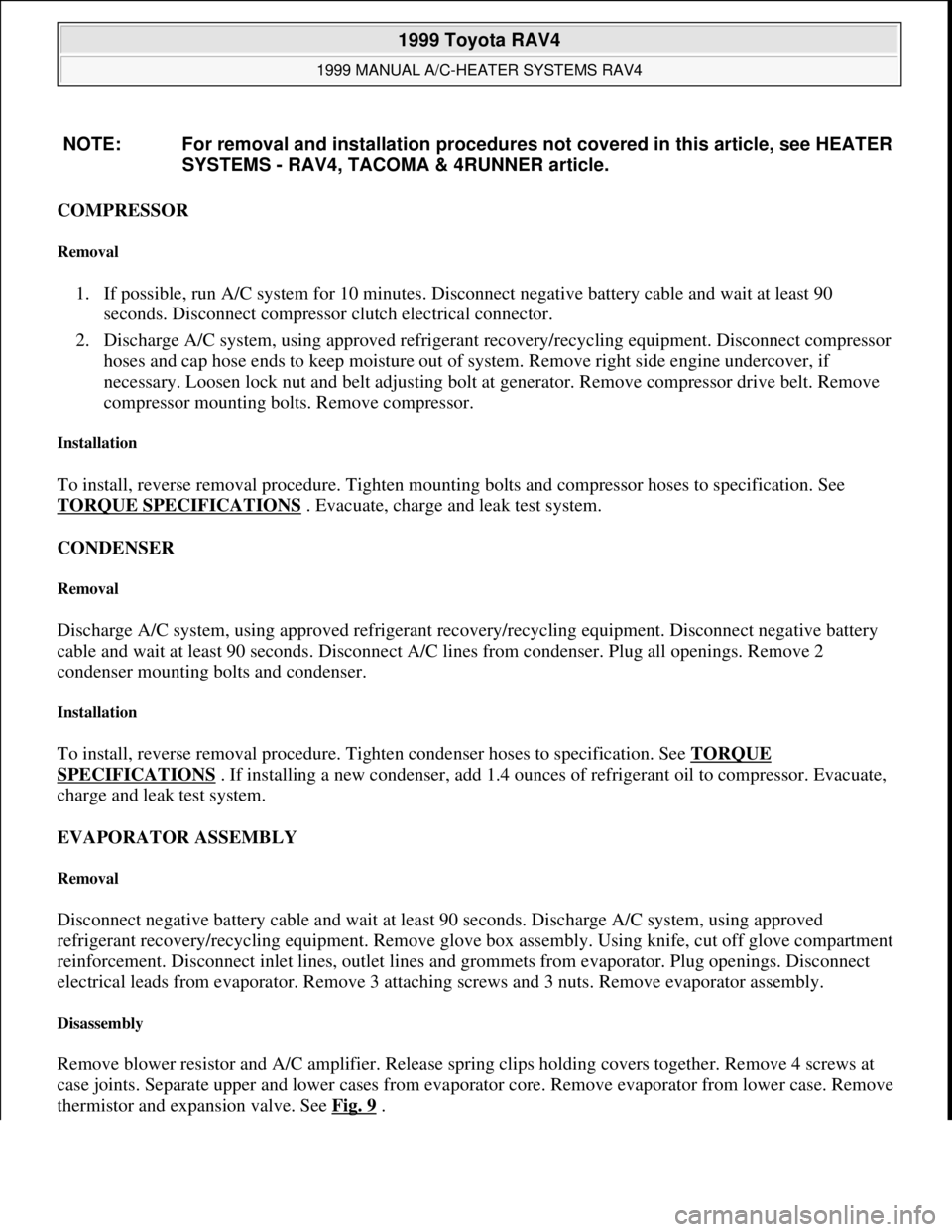

COMPRESSOR

Removal

1. If possible, run A/C system for 10 minutes. Disconnect negative battery cable and wait at least 90

seconds. Disconnect compressor clutch electrical connector.

2. Discharge A/C system, using approved refrigerant recovery/recycling equipment. Disconnect compressor

hoses and cap hose ends to keep moisture out of system. Remove right side engine undercover, if

necessary. Loosen lock nut and belt adjusting bolt at generator. Remove compressor drive belt. Remove

compressor mounting bolts. Remove compressor.

Installation

To install, reverse removal procedure. Tighten mounting bolts and compressor hoses to specification. See

TORQUE SPECIFICATIONS

. Evacuate, charge and leak test system.

CONDENSER

Removal

Discharge A/C system, using approved refrigerant recovery/recycling equipment. Disconnect negative battery

cable and wait at least 90 seconds. Disconnect A/C lines from condenser. Plug all openings. Remove 2

condenser mounting bolts and condenser.

Installation

To install, reverse removal procedure. Tighten condenser hoses to specification. See TORQUE

SPECIFICATIONS . If installing a new condenser, add 1.4 ounces of refrigerant oil to compressor. Evacuate,

charge and leak test system.

EVAPORATOR ASSEMBLY

Removal

Disconnect negative battery cable and wait at least 90 seconds. Discharge A/C system, using approved

refrigerant recovery/recycling equipment. Remove glove box assembly. Using knife, cut off glove compartment

reinforcement. Disconnect inlet lines, outlet lines and grommets from evaporator. Plug openings. Disconnect

electrical leads from evaporator. Remove 3 attaching screws and 3 nuts. Remove evaporator assembly.

Disassembly

Remove blower resistor and A/C amplifier. Release spring clips holding covers together. Remove 4 screws at

case joints. Separate upper and lower cases from evaporator core. Remove evaporator from lower case. Remove

thermistor and expansion valve. See Fig. 9

. NOTE: For removal and installation procedures not covered in this article, see HEATER

SYSTEMS - RAV4, TACOMA & 4RUNNER article.

1999 Toyota RAV4

1999 MANUAL A/C-HEATER SYSTEMS RAV4

Microsoft

Sunday, November 22, 2009 10:29:28 AMPage 13 © 2005 Mitchell Repair Information Company, LLC.

Page 888 of 1632

Removal

Discharge A/C system, using approved refrigerant recovery/recycling equipment. Disconnect negative battery

cable and wait at least 90 seconds. Remove engine coolant reservoir and air cleaner case and duct. Disconnect

A/C lines from receiver-drier and plug all openings. Remove mounting bolts and receiver-drier.

Installation

To install, reverse removal procedure. If installing a new receiver-drier, add 0.3 ounce of refrigerant oil before

reassembly. Evacuate, charge and leak test system.

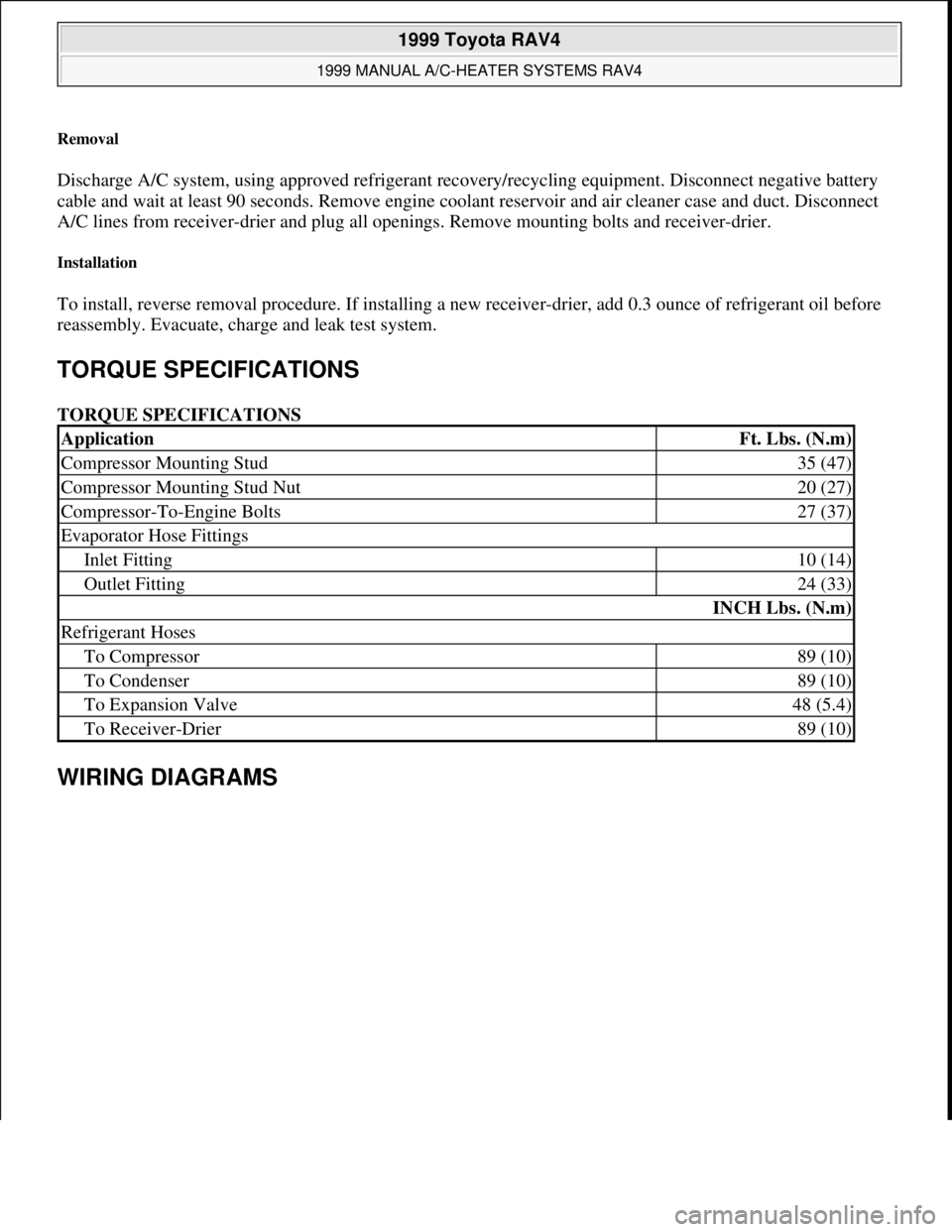

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

WIRING DIAGRAMS

ApplicationFt. Lbs. (N.m)

Compressor Mounting Stud35 (47)

Compressor Mounting Stud Nut20 (27)

Compressor-To-Engine Bolts27 (37)

Evaporator Hose Fittings

Inlet Fitting10 (14)

Outlet Fitting24 (33)

INCH Lbs. (N.m)

Refrigerant Hoses

To Compressor89 (10)

To Condenser89 (10)

To Expansion Valve48 (5.4)

To Receiver-Drier89 (10)

1999 Toyota RAV4

1999 MANUAL A/C-HEATER SYSTEMS RAV4

Microsoft

Sunday, November 22, 2009 10:29:28 AMPage 15 © 2005 Mitchell Repair Information Company, LLC.

Page 893 of 1632

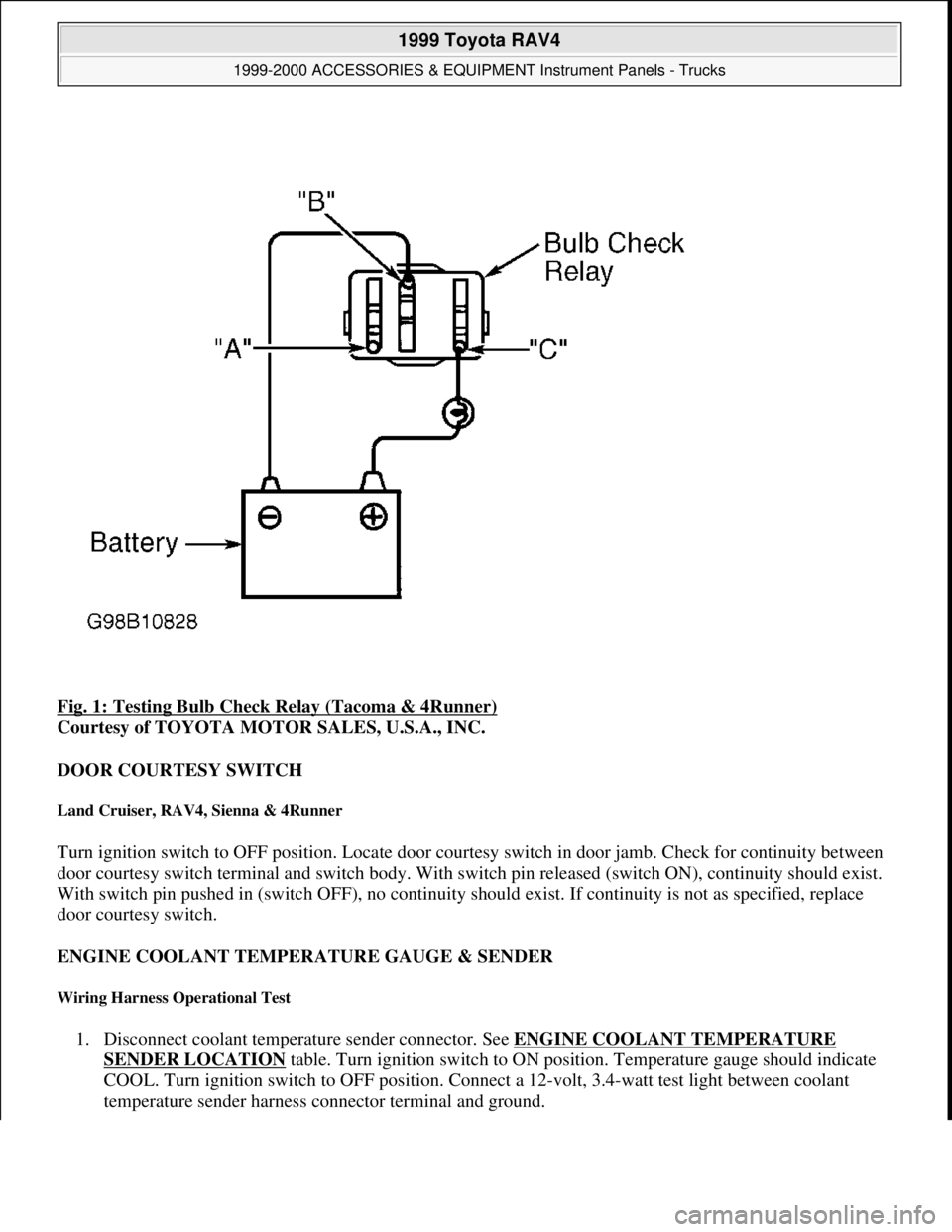

Fig. 1: Testing Bulb Check Relay (Tacoma & 4Runner)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

DOOR COURTESY SWITCH

Land Cruiser, RAV4, Sienna & 4Runner

Turn ignition switch to OFF position. Locate door courtesy switch in door jamb. Check for continuity between

door courtesy switch terminal and switch body. With switch pin released (switch ON), continuity should exist.

With switch pin pushed in (switch OFF), no continuity should exist. If continuity is not as specified, replace

door courtesy switch.

ENGINE COOLANT TEMPERATURE GAUGE & SENDER

Wiring Harness Operational Test

1. Disconnect coolant temperature sender connector. See ENGINE COOLANT TEMPERATURE

SENDER LOCATION table. Turn ignition switch to ON position. Temperature gauge should indicate

COOL. Turn ignition switch to OFF position. Connect a 12-volt, 3.4-watt test light between coolant

temperature sender harness connector terminal and

ground.

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:09 AMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 894 of 1632

2. Turn ignition switch to ON position. Test light should be on and temperature gauge should slowly move

to HOT. If gauge functions as specified, replace sending unit. If gauge does not function as specified,

perform TEMPERATURE GAUGE RESISTANCE TEST

.

Engine Coolant Temperature (ECT) Sender

1. Turn ignition switch to OFF position. Disconnect ECT sender 1-pin connector. See ENGINE

COOLANT TEMPERATURE SENDER LOCATION table. Drain cooling system and remove ECT

sender. Place probe end of ECT sender and thermometer in a container of water. Connect an ohmmeter

between ECT sender terminal and ECT sender body.

2. Heat water and note resistance reading. See ENGINE COOLANT TEMPERATURE SENDER

RESISTANCE table. If resistance is not as specified, replace ECT sender.

ENGINE COOLANT TEMPERATURE SENDER LOCATION

ENGINE COOLANT TEMPERATURE SENDER RESISTANCE

Temperature Gauge Resistance Test

Turn ignition switch to OFF position. Remove instrument cluster. Using ohmmeter, check gauge resistance

between appropriate terminals on back of instrument cluster. See TEMPERATURE GAUGE RESISTANCE

SPECIFICATIONS table. See Fig. 2 -Fig. 8 . If resistance is not as specified, replace temperature gauge. If

resistance is as specified, repair open or short circuit in wiring harness.

TEMPERATURE GAUGE RESISTANCE SPECIFICATIONS

ApplicationLocation

Land CruiserTop Front Of Engine

SiennaTop Of Engine

RAV4Rear Of Cylinder Head, Exhaust Side

Tacoma & 4Runner

4-Cyl.Right Side Of Engine, Under Intake

Manifold

V6Left Cylinder Head

Tundra

V6In Rear Of Intake Manifold

V8In Front Water By-Pass Joint, Next To

ECT Sensor

Application & Water Temp. °F (°C)Ohms

Land Cruiser, Sienna, RAV4 & Tundra

122 (50)160-240

248 (120)17-21

Tacoma & 4Runner

122 (50)234-314

248 (120)24-31

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:09 AMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 913 of 1632

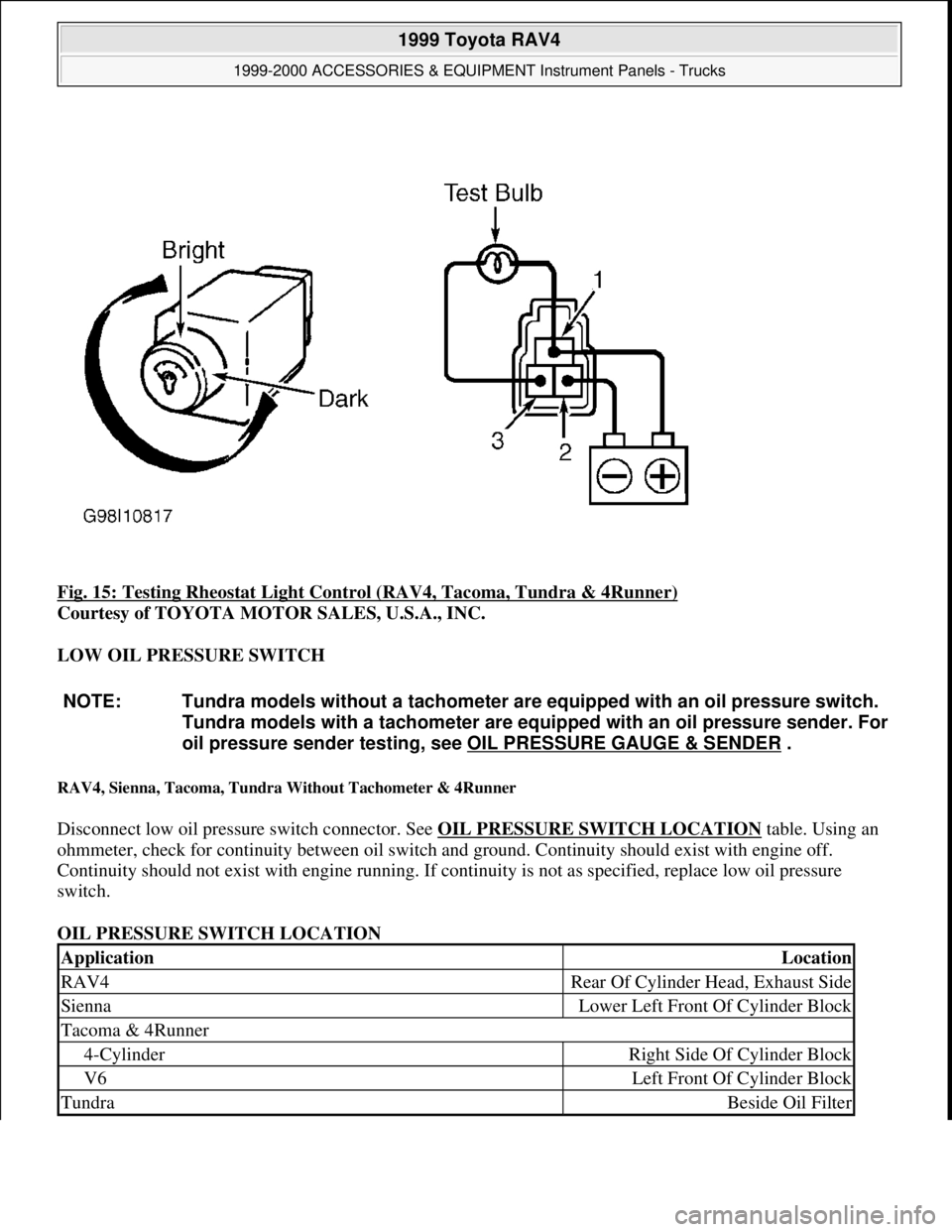

Fig. 15: Testing Rheostat Light Control (RAV4, Tacoma, Tundra & 4Runner)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

LOW OIL PRESSURE SWITCH

RAV4, Sienna, Tacoma, Tundra Without Tachometer & 4Runner

Disconnect low oil pressure switch connector. See OIL PRESSURE SWITCH LOCATION table. Using an

ohmmeter, check for continuity between oil switch and ground. Continuity should exist with engine off.

Continuity should not exist with engine running. If continuity is not as specified, replace low oil pressure

switch.

OIL PRESSURE SWITCH LOCATION

NOTE: Tundra models without a tachometer are equipped with an oil pressure switch.

Tundra models with a tachometer are equipped with an oil pressure sender. For

oil pressure sender testing, see OIL PRESSURE GAUGE & SENDER

.

ApplicationLocation

RAV4Rear Of Cylinder Head, Exhaust Side

SiennaLower Left Front Of Cylinder Block

Tacoma & 4Runner

4-CylinderRight Side Of Cylinder Block

V6Left Front Of Cylinder Block

TundraBeside Oil Filter

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:10 AMPage 23 © 2005 Mitchell Repair Information Company, LLC.