Engine TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 1064 of 1632

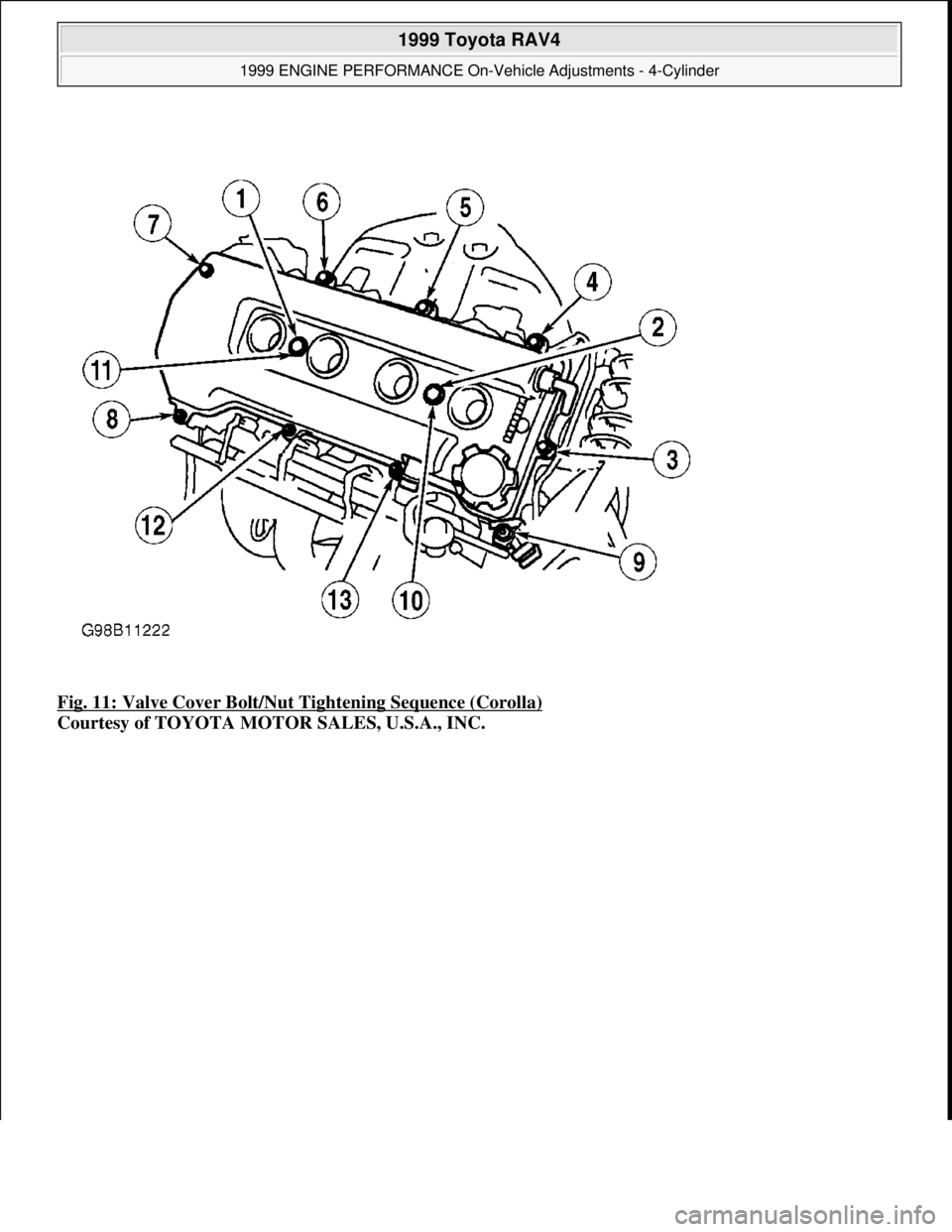

Fig. 11: Valve Cover Bolt/Nut Tightening Sequence (Corolla)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1999 Toyota RAV4

1999 ENGINE PERFORMANCE On-Vehicle Adjustments - 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:25:31 AMPage 13 © 2005 Mitchell Repair Information Company, LLC.

Page 1065 of 1632

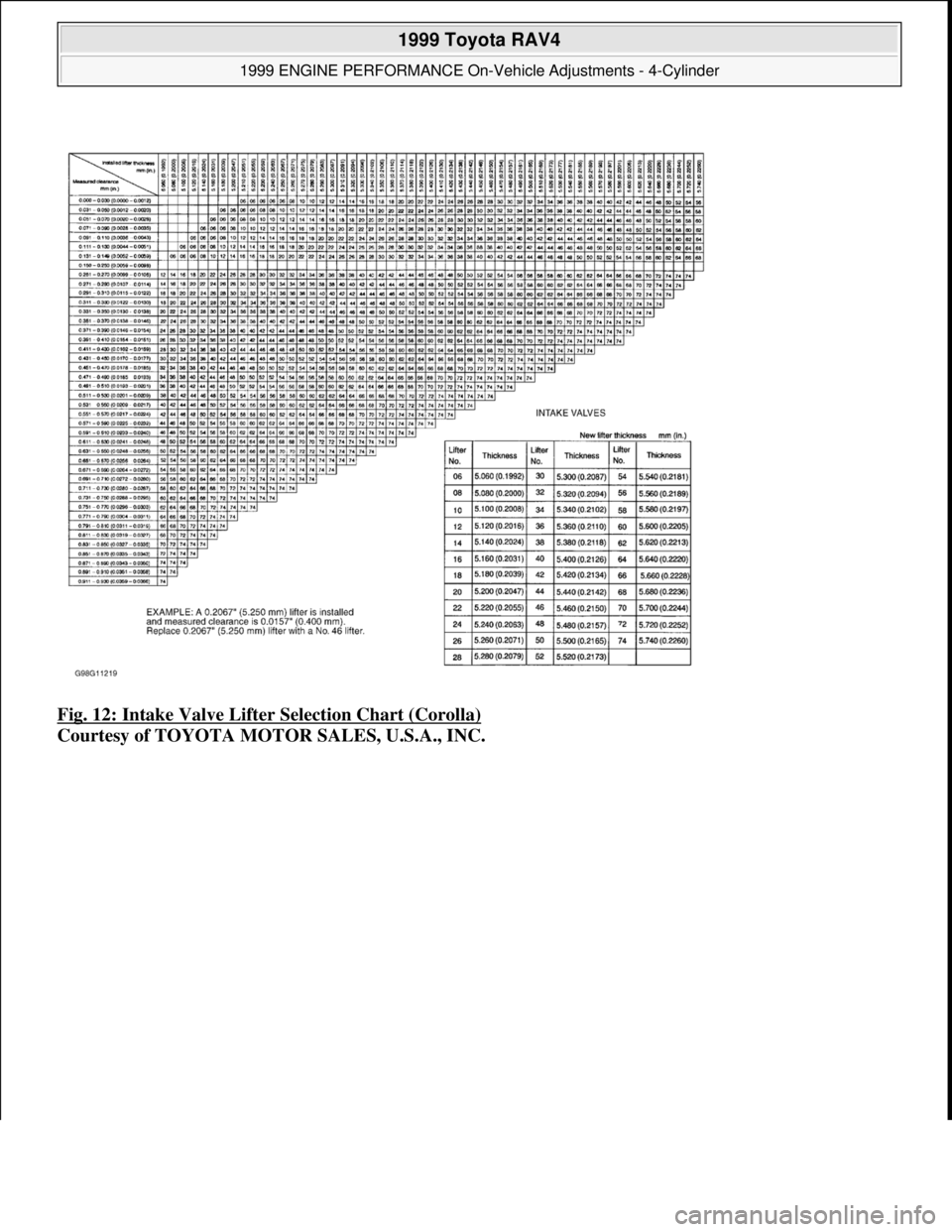

Fig. 12: Intake Valve Lifter Selection Chart (Corolla)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1999 Toyota RAV4

1999 ENGINE PERFORMANCE On-Vehicle Adjustments - 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:25:31 AMPage 14 © 2005 Mitchell Repair Information Company, LLC.

Page 1066 of 1632

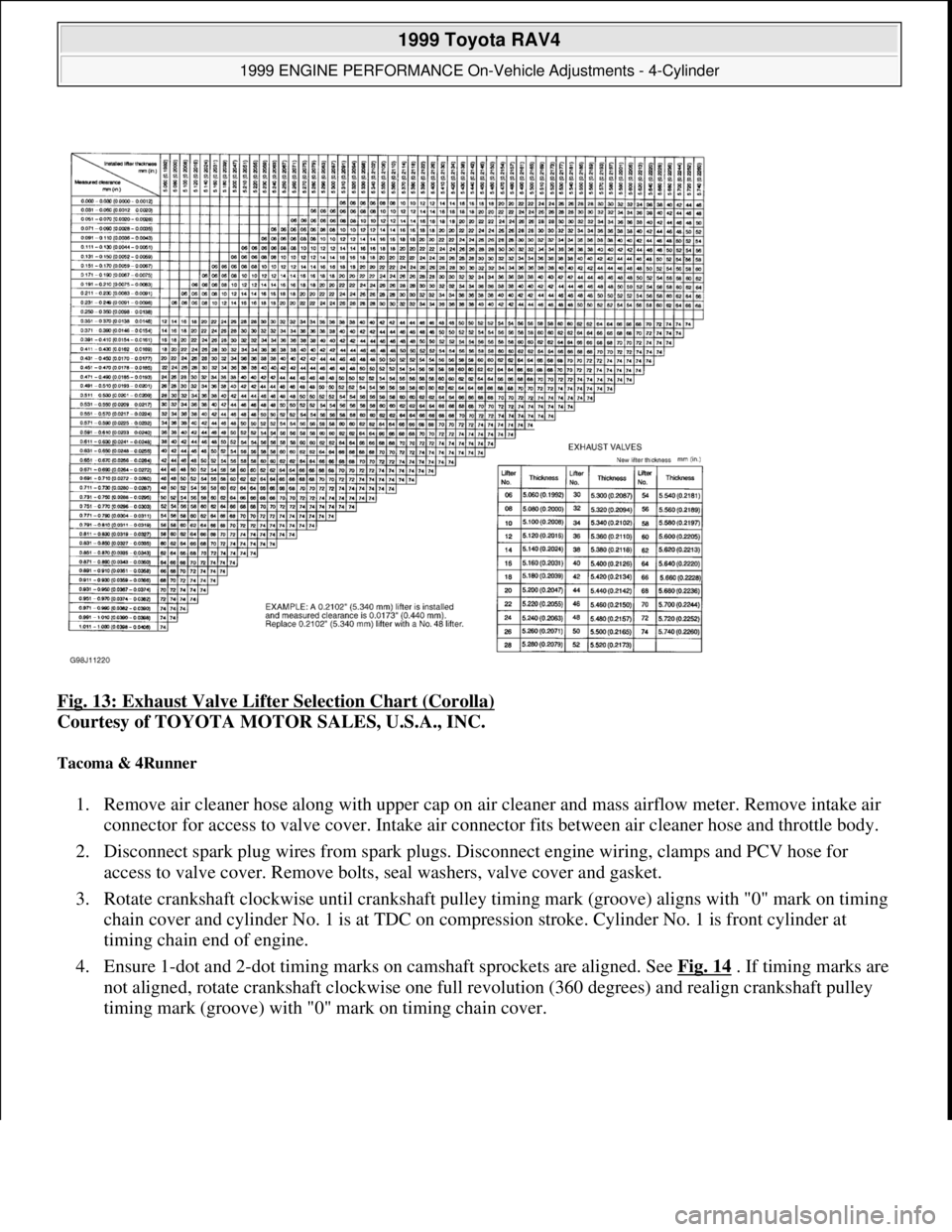

Fig. 13: Exhaust Valve Lifter Selection Chart (Corolla)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Tacoma & 4Runner

1. Remove air cleaner hose along with upper cap on air cleaner and mass airflow meter. Remove intake air

connector for access to valve cover. Intake air connector fits between air cleaner hose and throttle body.

2. Disconnect spark plug wires from spark plugs. Disconnect engine wiring, clamps and PCV hose for

access to valve cover. Remove bolts, seal washers, valve cover and gasket.

3. Rotate crankshaft clockwise until crankshaft pulley timing mark (groove) aligns with "0" mark on timing

chain cover and cylinder No. 1 is at TDC on compression stroke. Cylinder No. 1 is front cylinder at

timing chain end of engine.

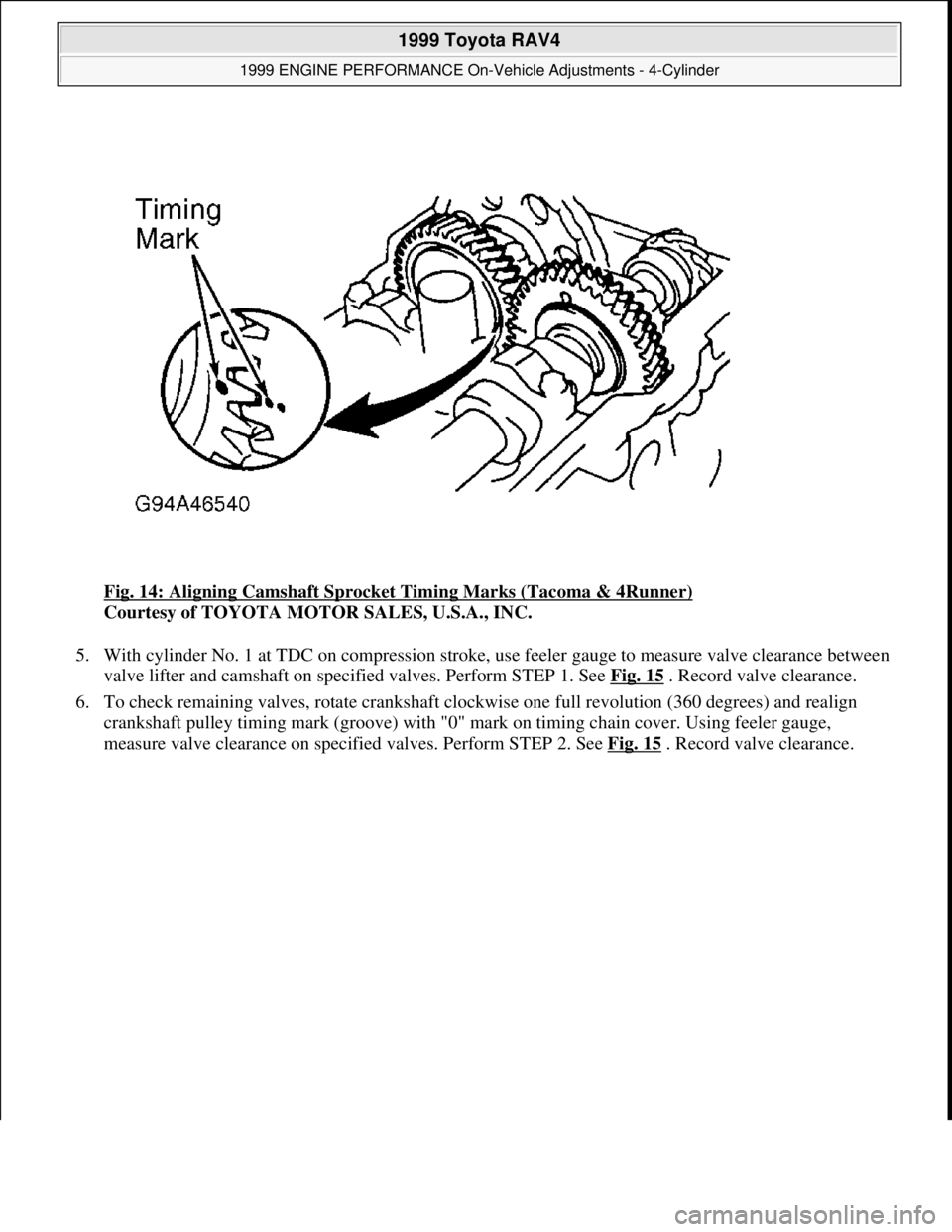

4. Ensure 1-dot and 2-dot timing marks on camshaft sprockets are aligned. See Fig. 14

. If timing marks are

not aligned, rotate crankshaft clockwise one full revolution (360 degrees) and realign crankshaft pulley

timin

g mark (groove) with "0" mark on timing chain cover.

1999 Toyota RAV4

1999 ENGINE PERFORMANCE On-Vehicle Adjustments - 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:25:31 AMPage 15 © 2005 Mitchell Repair Information Company, LLC.

Page 1067 of 1632

Fig. 14: Aligning Camshaft Sprocket Timing Marks (Tacoma & 4Runner)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

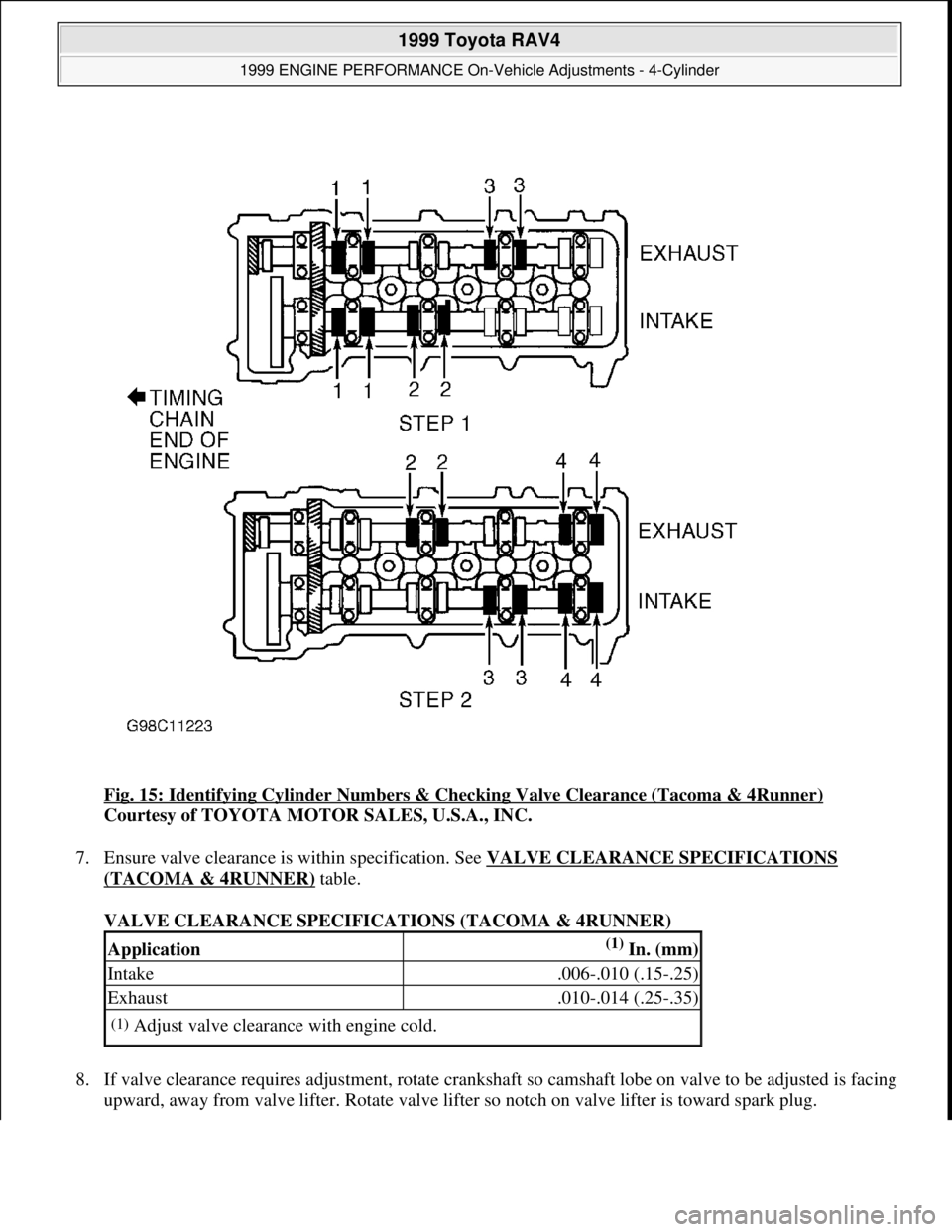

5. With cylinder No. 1 at TDC on compression stroke, use feeler gauge to measure valve clearance between

valve lifter and camshaft on specified valves. Perform STEP 1. See Fig. 15

. Record valve clearance.

6. To check remaining valves, rotate crankshaft clockwise one full revolution (360 degrees) and realign

crankshaft pulley timing mark (groove) with "0" mark on timing chain cover. Using feeler gauge,

measure valve clearance on specified valves. Perform STEP 2. See Fig. 15

. Record valve clearance.

1999 Toyota RAV4

1999 ENGINE PERFORMANCE On-Vehicle Adjustments - 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:25:31 AMPage 16 © 2005 Mitchell Repair Information Company, LLC.

Page 1068 of 1632

Fig. 15: Identifying Cylinder Numbers & Checking Valve Clearance (Tacoma & 4Runner)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

7. Ensure valve clearance is within specification. See VALVE CLEARANCE SPECIFICATIONS

(TACOMA & 4RUNNER) table.

VALVE CLEARANCE SPECIFICATIONS (TACOMA & 4RUNNER)

8. If valve clearance requires adjustment, rotate crankshaft so camshaft lobe on valve to be adjusted is facing

upward, awa

y from valve lifter. Rotate valve lifter so notch on valve lifter is toward spark plug.

Application(1) In. (mm)

Intake.006-.010 (.15-.25)

Exhaust.010-.014 (.25-.35)

(1)Adjust valve clearance with engine cold.

1999 Toyota RAV4

1999 ENGINE PERFORMANCE On-Vehicle Adjustments - 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:25:31 AMPage 17 © 2005 Mitchell Repair Information Company, LLC.

Page 1069 of 1632

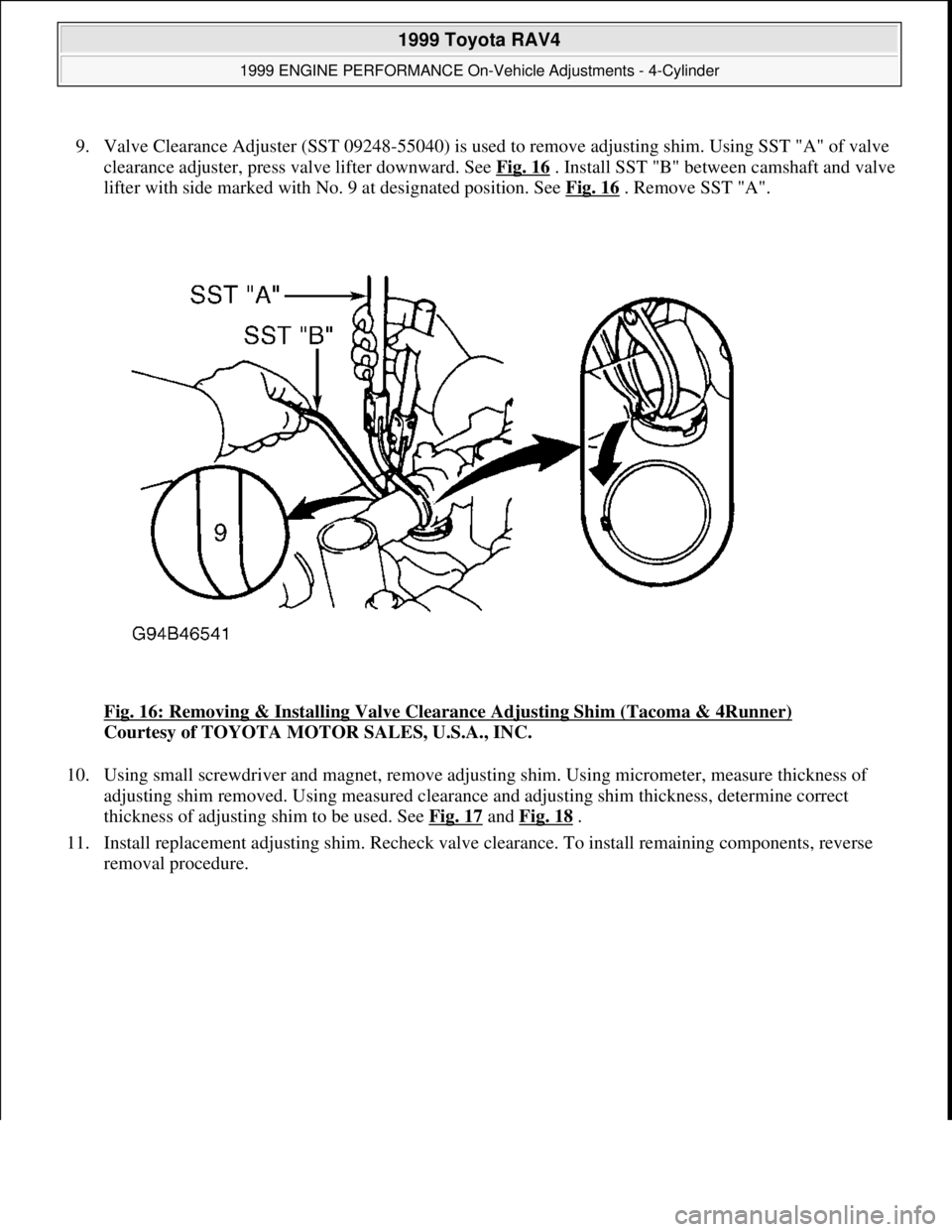

9. Valve Clearance Adjuster (SST 09248-55040) is used to remove adjusting shim. Using SST "A" of valve

clearance adjuster, press valve lifter downward. See Fig. 16

. Install SST "B" between camshaft and valve

lifter with side marked with No. 9 at designated position. See Fig. 16

. Remove SST "A".

Fig. 16: Removing & Installing Valve Clearance Adjusting Shim (Tacoma & 4Runner)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

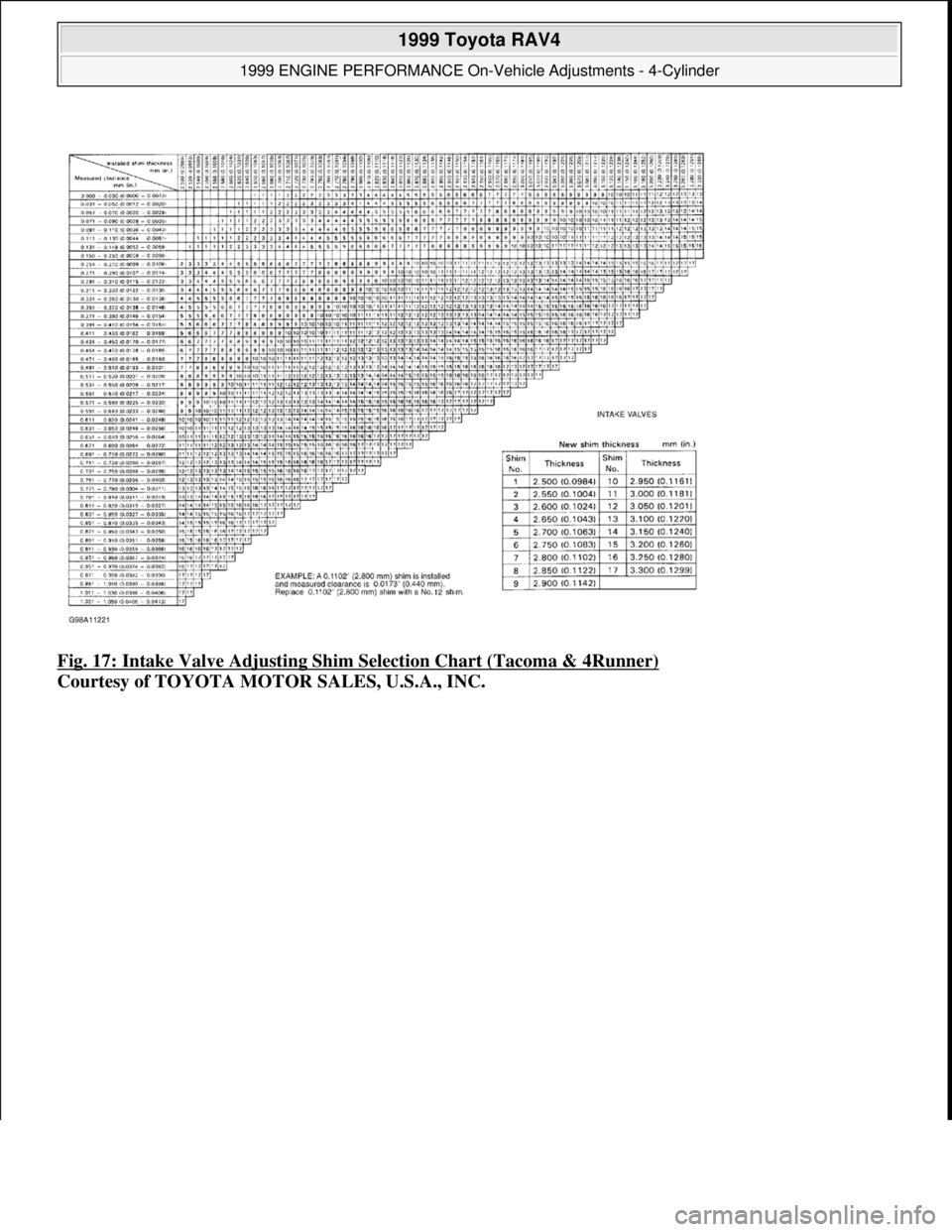

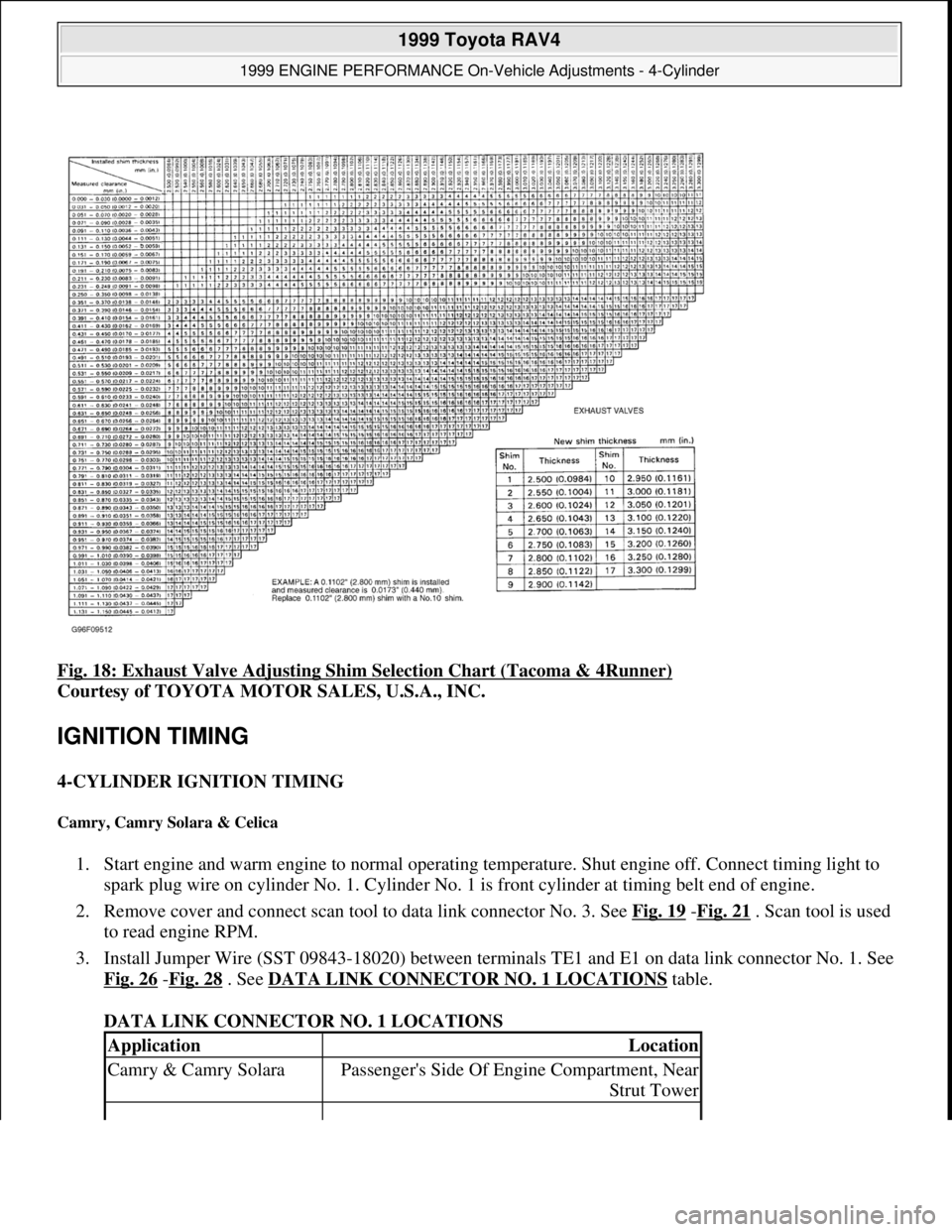

10. Using small screwdriver and magnet, remove adjusting shim. Using micrometer, measure thickness of

adjusting shim removed. Using measured clearance and adjusting shim thickness, determine correct

thickness of adjusting shim to be used. See Fig. 17

and Fig. 18 .

11. Install replacement adjusting shim. Recheck valve clearance. To install remaining components, reverse

removal procedure.

1999 Toyota RAV4

1999 ENGINE PERFORMANCE On-Vehicle Adjustments - 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:25:31 AMPage 18 © 2005 Mitchell Repair Information Company, LLC.

Page 1070 of 1632

Fig. 17: Intake Valve Adjusting Shim Selection Chart (Tacoma & 4Runner)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1999 Toyota RAV4

1999 ENGINE PERFORMANCE On-Vehicle Adjustments - 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:25:31 AMPage 19 © 2005 Mitchell Repair Information Company, LLC.

Page 1071 of 1632

Fig. 18: Exhaust Valve Adjusting Shim Selection Chart (Tacoma & 4Runner)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

IGNITION TIMING

4-CYLINDER IGNITION TIMING

Camry, Camry Solara & Celica

1. Start engine and warm engine to normal operating temperature. Shut engine off. Connect timing light to

spark plug wire on cylinder No. 1. Cylinder No. 1 is front cylinder at timing belt end of engine.

2. Remove cover and connect scan tool to data link connector No. 3. See Fig. 19

-Fig. 21 . Scan tool is used

to read engine RPM.

3. Install Jumper Wire (SST 09843-18020) between terminals TE1 and E1 on data link connector No. 1. See

Fig. 26

-Fig. 28 . See DATA LINK CONNECTOR NO. 1 LOCATIONS table.

DATA LINK CONNECTOR NO. 1 LOCATIONS

ApplicationLocation

Camry & Camry SolaraPassenger's Side Of Engine Compartment, Near

Strut Tower

1999 Toyota RAV4

1999 ENGINE PERFORMANCE On-Vehicle Adjustments - 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:25:31 AMPage 20 © 2005 Mitchell Repair Information Company, LLC.

Page 1072 of 1632

4. Apply parking brake. Place transaxle in Neutral. Start engine and maintain engine at 1000-1300 RPM for

5 seconds and then ensure engine returns to idle.

5. Timing marks are located on timing belt cover, near crankshaft pulley. Ensure base timing is within

specification at idle with transaxle in Neutral, and with A/C and all accessories off. See IGNITION

TIMING SPECIFICATIONS table.

6. Remove jumper wire from data link connector No. 1. Ensure ECM controlled timing is within

specification. See IGNITION TIMING SPECIFICATIONS

table. Shut engine off. Remove timing

light and scan tool.

Corolla

1. Start engine and warm engine to normal operating temperature. Shut engine off. Connect timing light to

spark plug wire on cylinder No. 1. Cylinder No. 1 is front cylinder at timing chain end of engine.

2. Connect scan tool to data link connector No. 3. See Fig. 22

. Scan tool is used to read engine RPM.

3. Install Jumper Wire (SST 09843-18020) between terminals TE1 and E1 on data link connector No. 1. See

Fig. 29

. Data link connector No. 1 is located at driver's side of engine compartment, near strut tower.

4. Apply parking brake. Place transaxle in Neutral. Start engine and maintain engine at 1000-1300 RPM for

5 seconds and then ensure engine returns to idle.

5. Timing marks are located on timing chain cover, near crankshaft pulley. Ensure base timing is within

specification at idle with transaxle in Neutral, and with A/C and all accessories off. See IGNITION

TIMING SPECIFICATIONS table.

6. Remove jumper wire from data link connector No. 1. Ensure ECM controlled timing is within

specification. See IGNITION TIMING SPECIFICATIONS

table. Shut engine off. Remove timing

light and scan tool.

RAV4

1. Start engine and warm engine to normal operating temperature. Shut engine off. Connect timing light to

spark plug wire on cylinder No. 1. Cylinder No. 1 is front cylinder at timing belt end of engine.

2. Remove cover from instrument panel and connect scan tool to data link connector No. 3. See Fig. 23

.

Scan tool is used to read engine RPM.

3. Install Jumper Wire (SST 09843-18020) between terminals TE1 and E1 on data link connector No. 1. See

Fig. 30

. Data link connector No. 1 is located on timing belt end of engine, above generator.

4. Apply parking brake. Place transaxle in Neutral. Start engine and allow engine to idle.

5. Timing marks are located on timing belt cover, near crankshaft pulley. Ensure base timing is within

specification at idle with transaxle in Neutral, and with A/C and all accessories off. See IGNITION

TIMING SPECIFICATIONS table.

6. Remove jumper wire from data link connector No. 1. Ensure ECM controlled timing is within

specification. See IGNITION TIMING SPECIFICATIONS

table. Shut engine off. Remove timing

li

ght and scan tool.

CelicaDriver's Side Rear Corner Of Engine

Compartment, Near Brake Booster

1999 Toyota RAV4

1999 ENGINE PERFORMANCE On-Vehicle Adjustments - 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:25:31 AMPage 21 © 2005 Mitchell Repair Information Company, LLC.

Page 1073 of 1632

Tacoma & 4Runner

1. Start engine and warm engine to normal operating temperature. Shut engine off. Connect timing light to

spark plug wire on cylinder No. 1. Cylinder No. 1 is front cylinder at timing chain end of engine.

2. Connect scan tool to data link connector No. 3. See Fig. 24

and Fig. 25 . Scan tool is used to read engine

RPM.

3. Install Jumper Wire (SST 09843-18020) between terminals TE1 and E1 on data link connector No. 1. See

Fig. 31

. Data link connector No. 1 is located on end of intake manifold at front of engine.

4. Apply parking brake. Place transmission in Neutral. Start engine. Maintain engine at 1000 RPM for 5

seconds and then ensure engine returns to idle.

5. Timing marks are located on timing chain cover, near crankshaft pulley. Ensure base timing is within

specification at idle with transmission in Neutral, and with A/C and all accessories off. See IGNITION

TIMING SPECIFICATIONS table.

6. Remove jumper wire from data link connector No. 1. Ensure ECM controlled timing is within

specification. See IGNITION TIMING SPECIFICATIONS

table. Shut engine off. Remove timing

light and scan tool.

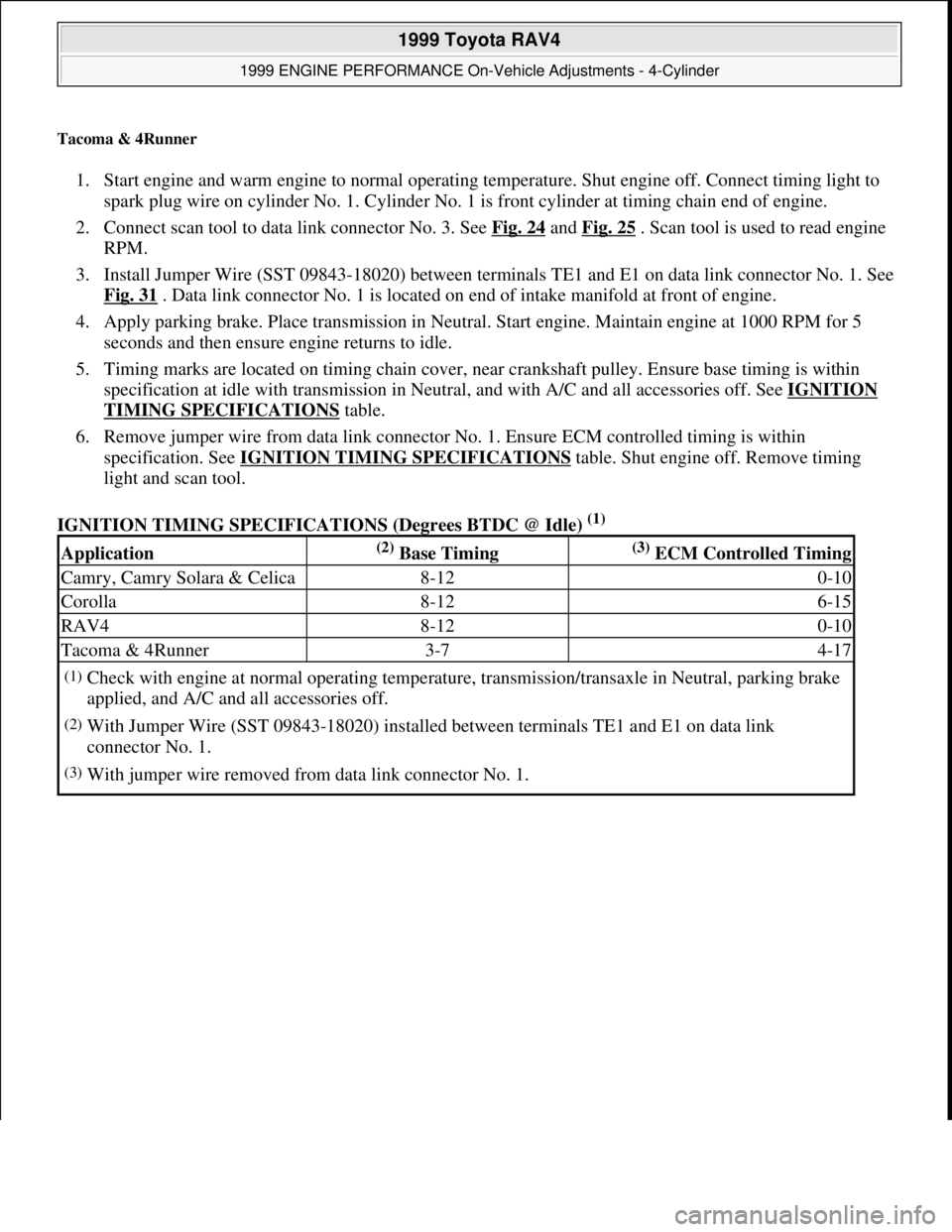

IGNITION TIMING SPECIFICATIONS (Degrees BTDC @ Idle)

(1)

Application(2) Base Timing(3) ECM Controlled Timing

Camry, Camry Solara & Celica8-120-10

Corolla8-126-15

RAV48-120-10

Tacoma & 4Runner3-74-17

(1)Check with engine at normal operating temperature, transmission/transaxle in Neutral, parking brake

applied, and A/C and all accessories off.

(2)With Jumper Wire (SST 09843-18020) installed between terminals TE1 and E1 on data link

connector No. 1.

(3)With jumper wire removed from data link connector No. 1.

1999 Toyota RAV4

1999 ENGINE PERFORMANCE On-Vehicle Adjustments - 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:25:31 AMPage 22 © 2005 Mitchell Repair Information Company, LLC.