Engine TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 1177 of 1632

Removal & Installation (RAV4)

Disconnect negative battery cable. Remove engine coolant reservoir. Disconnect relay connectors, PCV hose,

intake air temperature sensor connector, air cleaner intake hose, remaining hoses and lines for air cleaner

removal. Remove air cleaner assembly. Disconnect starter connector. Remove starter wires and remove starter.

To install, reverse removal procedure. Tighten starter bolts to specification. See TORQUE

SPECIFICATIONS .

Removal & Installation (Tacoma, Tundra V6 & 4Runner)

Removal and installation is basically an unbolt and bolt-on procedure. Tighten starter bolts to specification. See

TORQUE SPECIFICATIONS

.

OVERHAUL

NOTE: See Fig. 17 for overhaul procedure.

1999 Toyota RAV4

1999-2000 STARTING & CHARGING SYSTEMS Starters

Microsoft

Sunday, November 22, 2009 10:19:18 AMPage 22 © 2005 Mitchell Repair Information Company, LLC.

Page 1230 of 1632

Fig. 1: Identifying Combination Switch Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

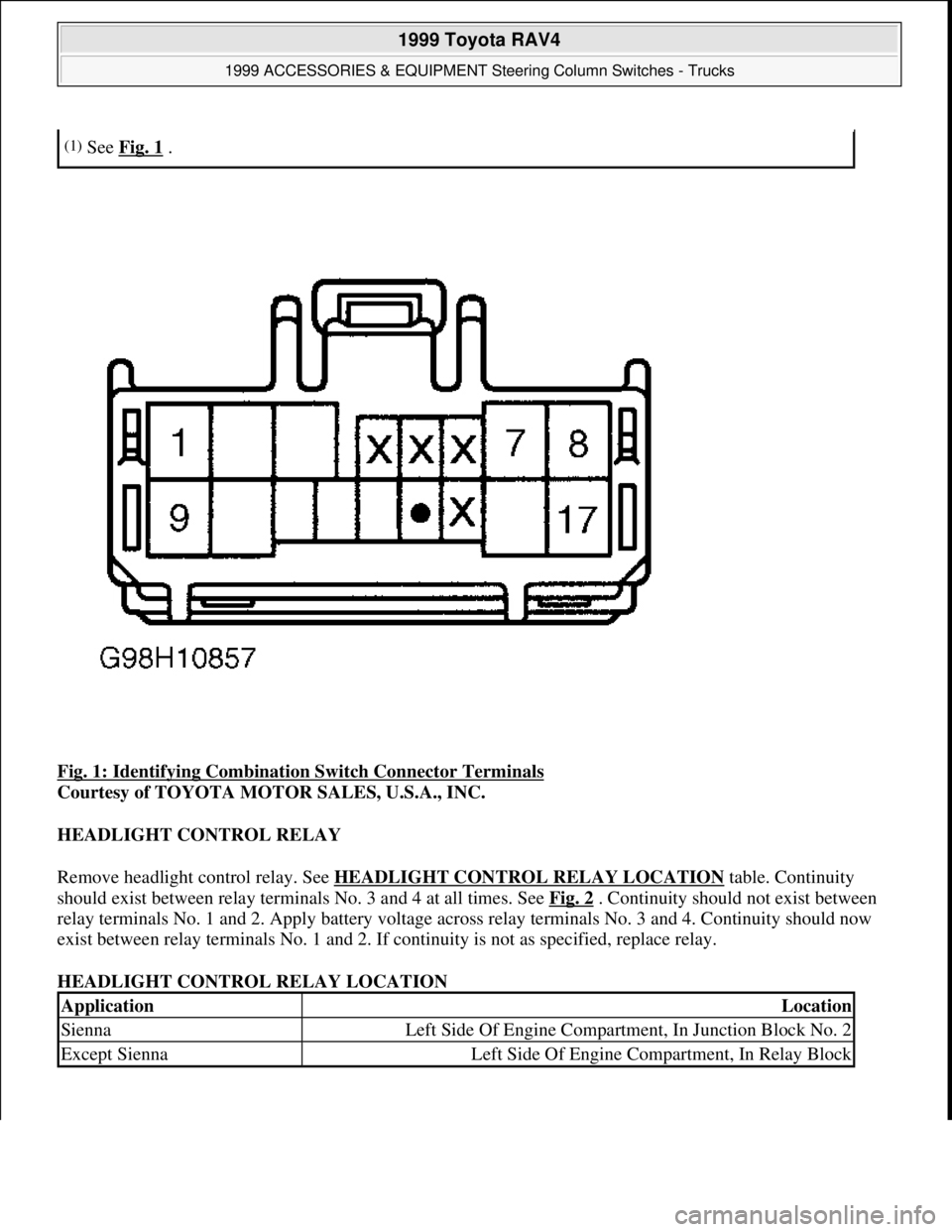

HEADLIGHT CONTROL RELAY

Remove headlight control relay. See HEADLIGHT CONTROL RELAY LOCATION

table. Continuity

should exist between relay terminals No. 3 and 4 at all times. See Fig. 2

. Continuity should not exist between

relay terminals No. 1 and 2. Apply battery voltage across relay terminals No. 3 and 4. Continuity should now

exist between relay terminals No. 1 and 2. If continuity is not as specified, replace relay.

HEADLIGHT CONTROL RELAY LOCATION

(1)See Fig. 1 .

ApplicationLocation

SiennaLeft Side Of Engine Compartment, In Junction Block No. 2

Except SiennaLeft Side Of Engine Compartment, In Relay Block

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Steering Column Switches - Trucks

Microsoft

Sunday, November 22, 2009 10:56:55 AMPage 2 © 2005 Mitchell Repair Information Company, LLC.

Page 1231 of 1632

Fig. 2: Identifying Headlight Control Relay Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

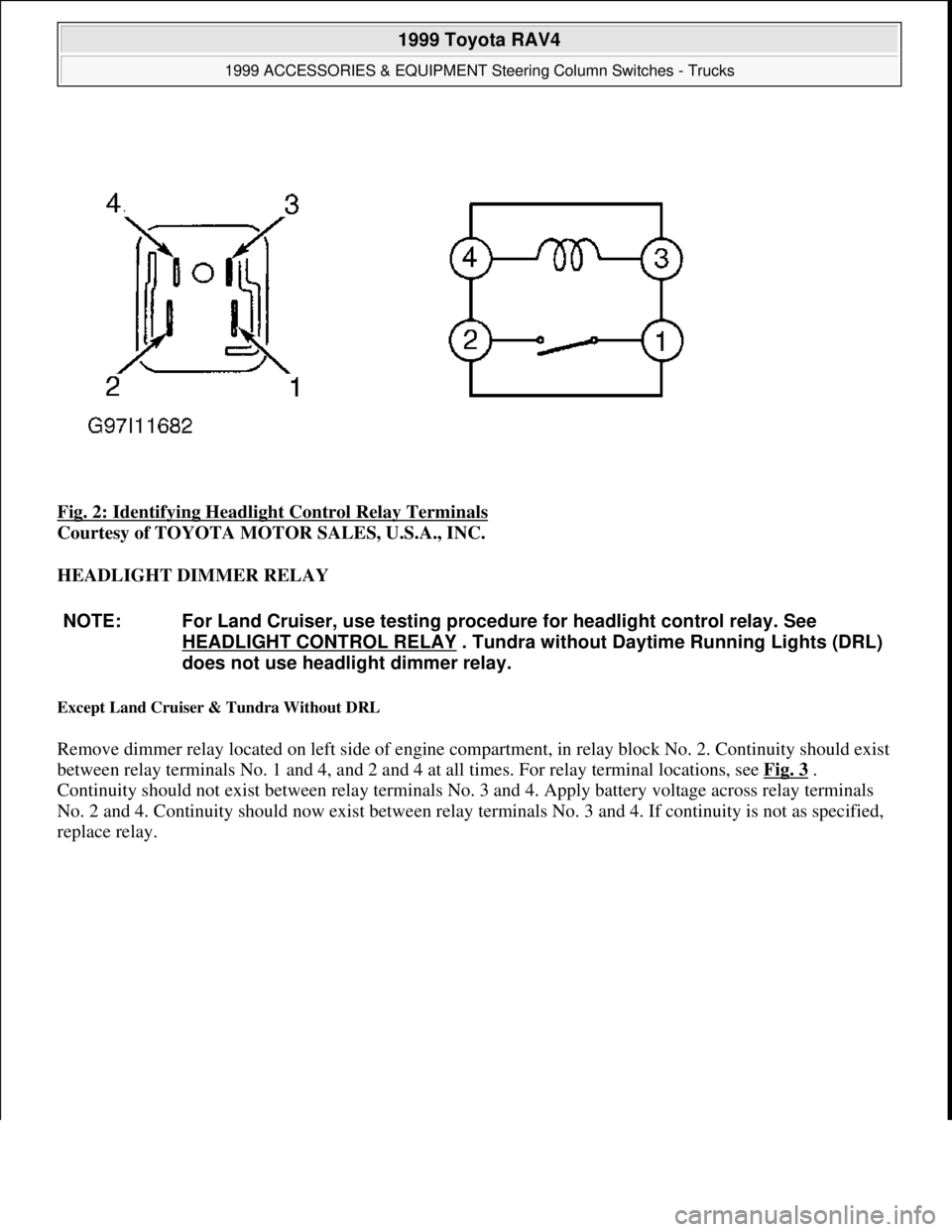

HEADLIGHT DIMMER RELAY

Except Land Cruiser & Tundra Without DRL

Remove dimmer relay located on left side of engine compartment, in relay block No. 2. Continuity should exist

between relay terminals No. 1 and 4, and 2 and 4 at all times. For relay terminal locations, see Fig. 3

.

Continuity should not exist between relay terminals No. 3 and 4. Apply battery voltage across relay terminals

No. 2 and 4. Continuity should now exist between relay terminals No. 3 and 4. If continuity is not as specified,

replace rela

y.

NOTE: For Land Cruiser, use testing procedure for headlight control relay. See

HEADLIGHT CONTROL RELAY

. Tundra without Daytime Running Lights (DRL)

does not use headlight dimmer relay.

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Steering Column Switches - Trucks

Microsoft

Sunday, November 22, 2009 10:56:55 AMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 1232 of 1632

Fig. 3: Headlight Dimmer Relay Terminals (Except Land Cruiser & Tundra Without DRL)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

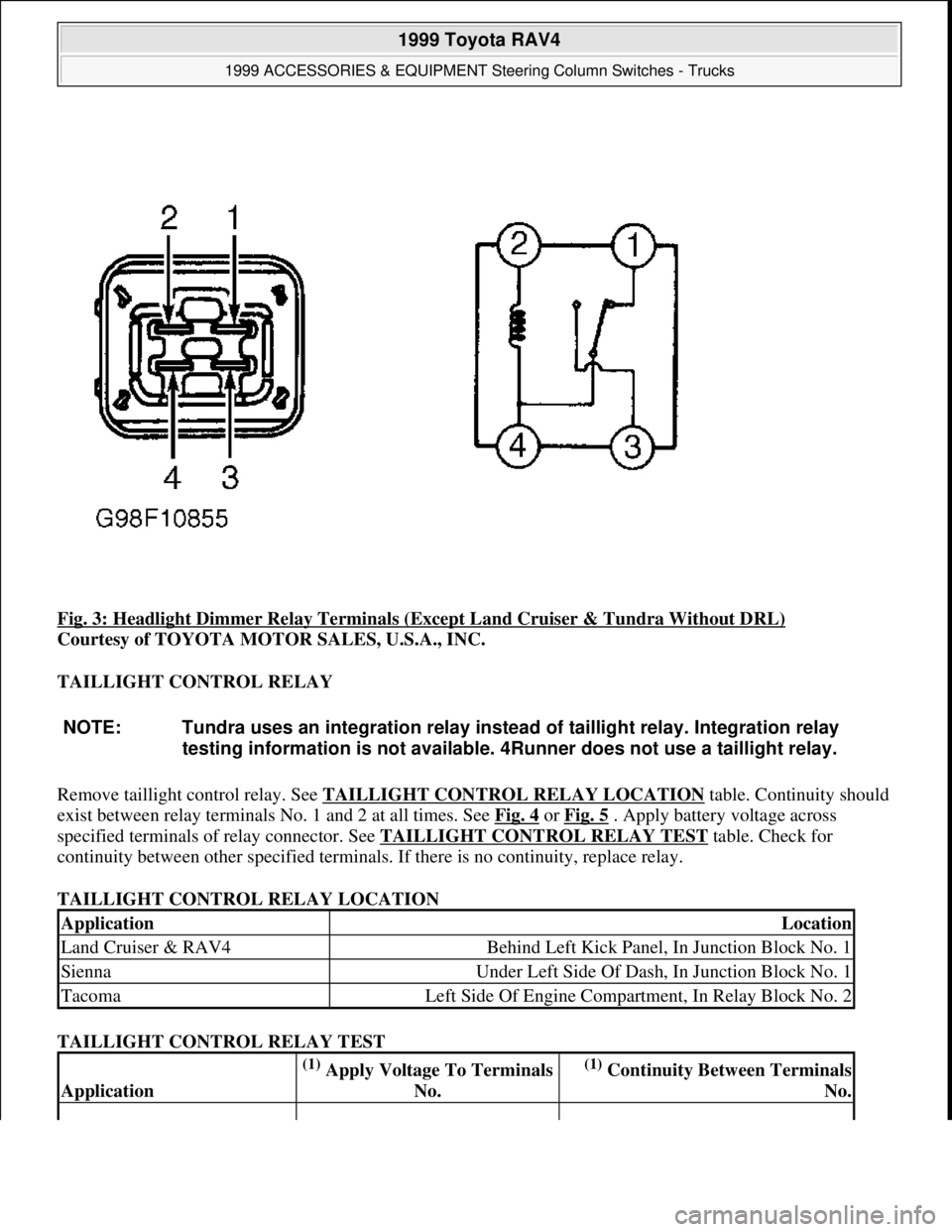

TAILLIGHT CONTROL RELAY

Remove taillight control relay. See TAILLIGHT CONTROL RELAY LOCATION

table. Continuity should

exist between relay terminals No. 1 and 2 at all times. See Fig. 4

or Fig. 5 . Apply battery voltage across

specified terminals of relay connector. See TAILLIGHT CONTROL RELAY TEST

table. Check for

continuity between other specified terminals. If there is no continuity, replace relay.

TAILLIGHT CONTROL RELAY LOCATION

TAILLIGHT CONTROL RELAY TEST

NOTE: Tundra uses an integration relay instead of taillight relay. Integration relay

testing information is not available. 4Runner does not use a taillight relay.

ApplicationLocation

Land Cruiser & RAV4Behind Left Kick Panel, In Junction Block No. 1

SiennaUnder Left Side Of Dash, In Junction Block No. 1

TacomaLeft Side Of Engine Compartment, In Relay Block No. 2

Application

(1) Apply Voltage To Terminals

No.(1)Continuity Between Terminals

No.

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Steering Column Switches - Trucks

Microsoft

Sunday, November 22, 2009 10:56:55 AMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 1234 of 1632

1. Disconnect combination switch connector. With horn pad pressed and held down (horn ON), check

continuity between appropriate wire terminal of combination switch connector. See Fig. 1

. See

appropriate wiring diagram in WIRING DIAGRAMS

.

2. If there is no continuity, repair wiring or replace components as necessary. Components include horn pad

and contact pin, slip ring and spiral cable. If there is continuity, check for open in horn circuit, faulty horn

or faulty horn relay. See HORN RELAY LOCATION

table.

HORN RELAY LOCATION (EXCEPT RAV4, TUNDRA & 4RUNNER)

IGNITION SWITCH

Disconnect ignition switch connector. With ignition switch in specified position, check continuity between

specified terminals of ignition switch connector. For switch terminal locations, see Fig. 6

. Also see IGNITION

SWITCH CONTINUITY TEST table. If continuity is not as specified, replace ignition switch.

IGNITION SWITCH CONTINUITY TEST 4Runner uses body ECU to control horn operation. See ANTI-THEFT SYSTEMS -

4RUNNER article.

ApplicationLocation

Land CruiserLeft Side Of Engine Compartment, In Junction Block

SiennaLeft Side Of Engine Compartment, In Junction Block No. 2

TacomaBehind Left Kick Panel, In Junction Block No. 1

Switch Position(1) Terminals No.Continuity

LOCKNoneNo

ACC2 & 3Yes

ON2, 3 & 4; 6 & 7Yes

START1, 2 & 4; 6, 7 & 8Yes

(1)For switch terminal locations, see Fig. 6 .

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Steering Column Switches - Trucks

Microsoft

Sunday, November 22, 2009 10:56:55 AMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 1295 of 1632

Loosen Torx screws securing sun roof glass. Move sun roof to front or rear as necessary. Tighten Torx screws.

Corolla, Celica (2000) & RAV4 (2-Door)

If front-to-rear position of sun roof is incorrect, loosen Torx screws securing sun roof glass. Move sun roof to

front or rear as necessary. Tighten Torx screws.

Celica (1999), RAV4 (4-Door) & 4Runner

If front-to-rear position of sun roof is incorrect, pry out trim panels from left and right sides of sun roof opening.

Loosen sun roof slider mount nuts. Move sun roof to front or rear as necessary. If front-to-rear position still

does not adjust, remove sun roof glass and adjust guide rail. Using screwdriver, slide link front or rear to align

marks. See Fig. 45

, Fig. 60 or Fig. 65 . Tighten sun roof slider mount nuts.

Land Cruiser

If front-to-rear position of sun roof is incorrect, pry out trim panels from left and right sides of sun roof opening.

Loosen screws securing sun roof glass. Move sun roof to front or rear as necessary. Tighten screws.

SUN ROOF SIDE-TO-SIDE ALIGNMENT

Camry, Camry Solara, Celica (2000), Corolla, Land Cruiser & Sienna

If sun roof closing clearances are unequal between right and left sides, ensure sun roof is completely closed.

Remove sun roof motor assembly and sun roof glass. Adjust drive rail by sliding cables forward or backward.

Align 2 marks shown. See Fig. 45

, Fig. 60 or Fig. 65 . Reinstall sun roof motor assembly.

Avalon & RAV4 (2-Door)

If sun roof is mounted to right or left of center line in roof opening, close sun roof. Remove sun roof motor and

glass. See SUN ROOF ASSEMBLY

under REMOVAL & INSTALLATION. Adjust drive rail by sliding

cables forward or backward. Align 2 marks shown. See Fig. 30

, Fig. 33 or Fig. 52 . Tighten sun roof slider

mount nuts.

Celica (1999), RAV4 (4-Door) & 4Runner

If sun roof is mounted to right or left of center line in roof opening, pry out trim panels from left and right sides

of sun roof opening. Loosen sun roof rear slider mount nuts. Move sun roof right or left as necessary. Tighten

sun roof slider mount nuts.

TROUBLE SHOOTING

PRELIMINARY INSPECTION

With engine running, check time necessary for sun roof to open or close. Open and close time should be about

5-6 seconds. Check for abnormal noise or binding during sun roof operation. Check for water leakage. Adjust as

necessary. See ADJUSTMENTS

.

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Power Sun Roofs

Microsoft

Sunday, November 22, 2009 10:58:29 AMPage 15 © 2005 Mitchell Repair Information Company, LLC.

Page 1393 of 1632

TOYOTA

2.0L 4-Cylinder - RAV4

MANUFACTURER'S SUGGESTED SCHEDULED MAINTENANCE

For 1996-97 model years, the manufacturer recommends the belt be replaced every 60,000 miles for severe

service operating conditions. For 1998 model year, the manufacturer recommends the belt be replaced every

90,000 miles for severe service operating conditions. For 1999-00 model years, the manufacturer recommends

the belt be replaced every 90,000 miles or 72 months.

REMOVAL & INSTALLATION

TIMING BELT

Removal

1. Disconnect negative battery cable. Disconnect power steering reservoir, and remove reservoir bracket.

Disconnect wire harness bracket for Data Link Connector No. 1. Remove generator and generator

bracket.

2. Remove ABS actuator. Raise and support vehicle. Remove right front wheel. Remove right engine

undercover. Remove power steering drive belt. Slightly jack up engine and remove right engine mounting

insulator.

3. Remove spark plugs. Remove crankshaft pulley. See Fig. 1

. Remove right engine mounting bracket.

Remove No. 2 timing belt cover. See Fig. 2

. Temporarily install crankshaft pulley with pulley bolt. Set

No. 1 cylinder to TDC on compression stroke. See Fig. 3

.

4. Loosen mounting bolt of No. 1 idler pulley and shift pulley toward left as far as it will go to relieve belt

tension. See Fig. 4

. Temporarily tighten idler pulley. Remove crankshaft pulley and No. 1 timing belt

cover.

5. If reusing timing belt, mark direction of rotation on belt. Also place match marks on belt and camshaft

pulle

y. See Fig. 5 . Remove timing belt from engine. NOTE: Always turn crankshaft clockwise.

1999 Toyota RAV4

TOYOTA 2.0L 4-Cylinder - RAV4

1999 Toyota RAV4

TOYOTA 2.0L 4-Cylinder - RAV4

Microsoft

Sunday, November 22, 2009 10:24:26 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:24:33 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 1399 of 1632

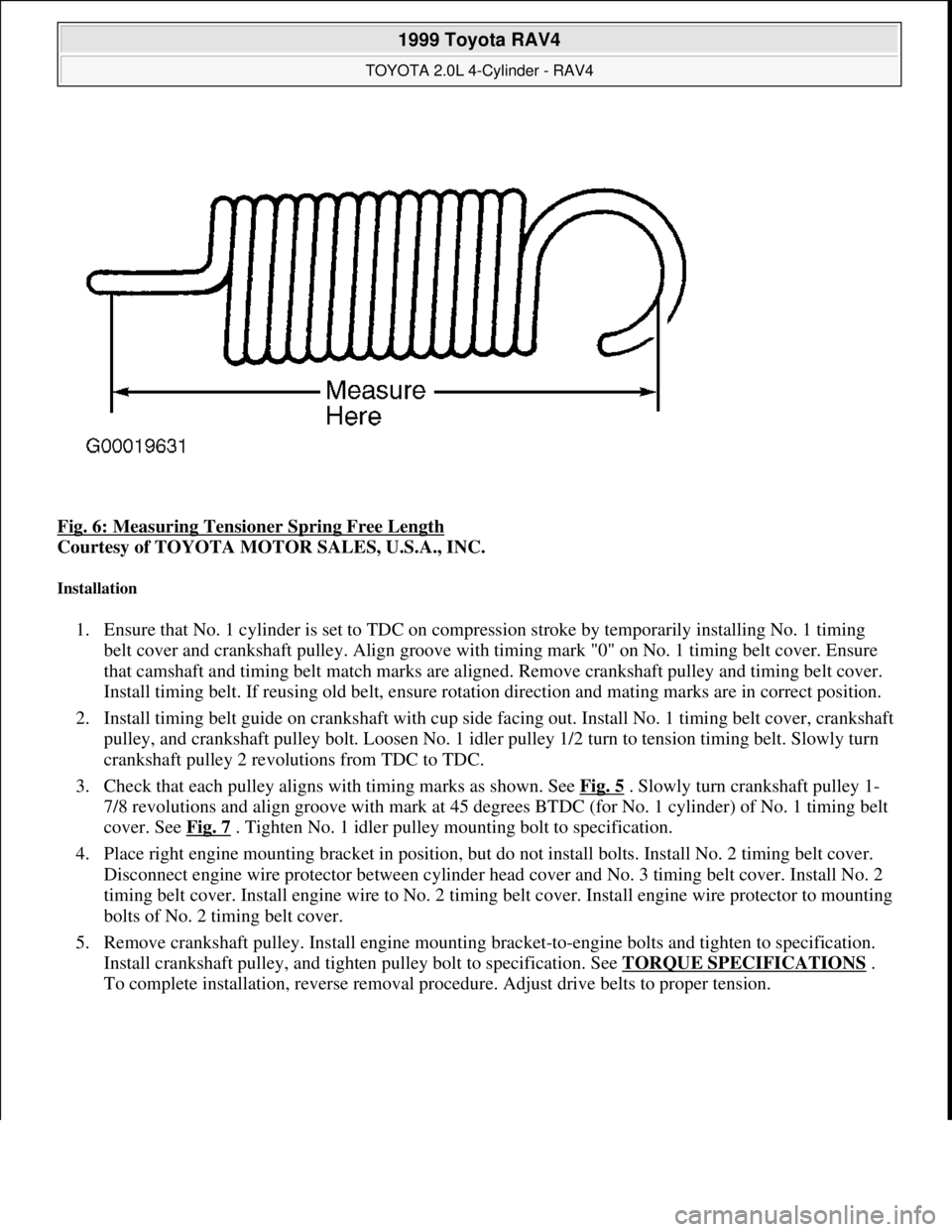

Fig. 6: Measuring Tensioner Spring Free Length

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Installation

1. Ensure that No. 1 cylinder is set to TDC on compression stroke by temporarily installing No. 1 timing

belt cover and crankshaft pulley. Align groove with timing mark "0" on No. 1 timing belt cover. Ensure

that camshaft and timing belt match marks are aligned. Remove crankshaft pulley and timing belt cover.

Install timing belt. If reusing old belt, ensure rotation direction and mating marks are in correct position.

2. Install timing belt guide on crankshaft with cup side facing out. Install No. 1 timing belt cover, crankshaft

pulley, and crankshaft pulley bolt. Loosen No. 1 idler pulley 1/2 turn to tension timing belt. Slowly turn

crankshaft pulley 2 revolutions from TDC to TDC.

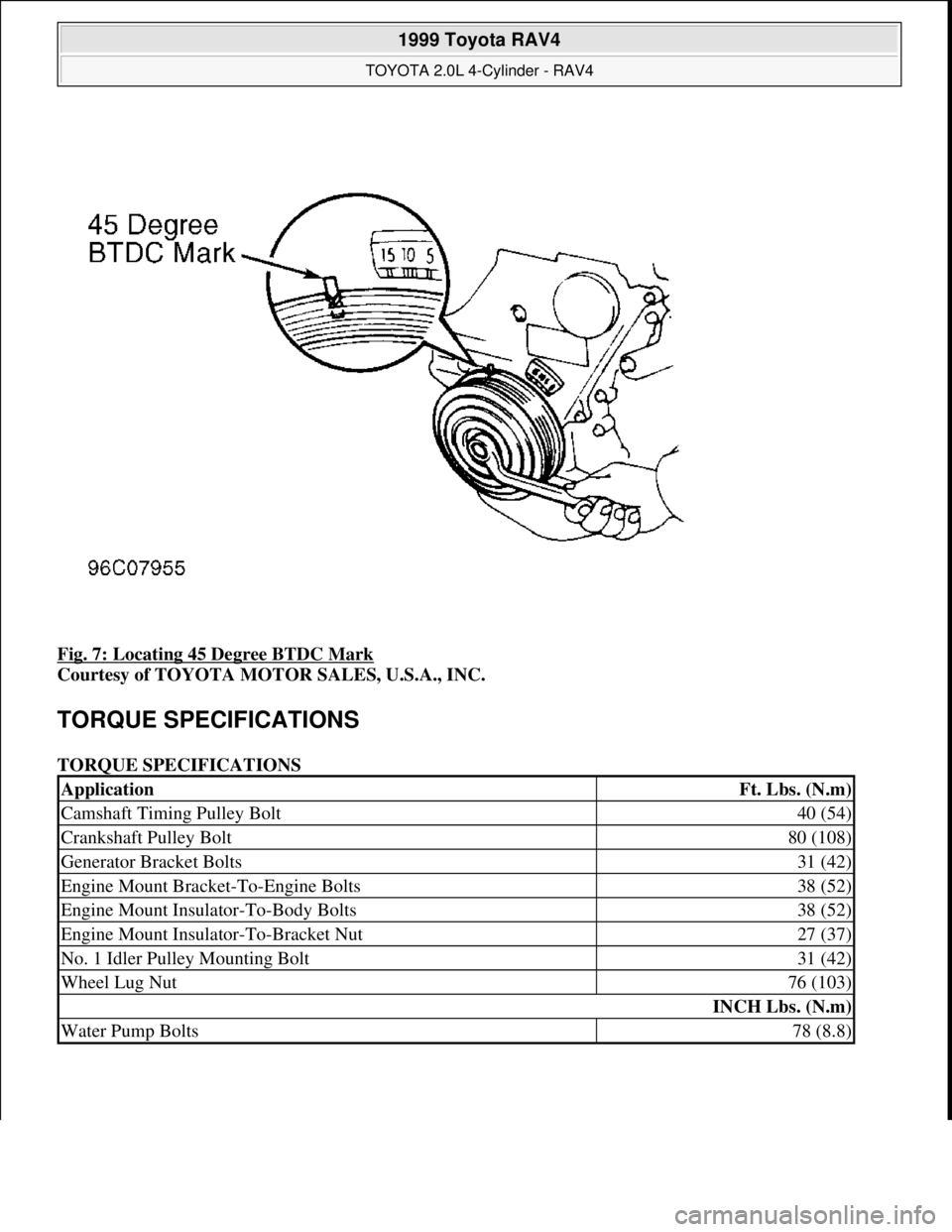

3. Check that each pulley aligns with timing marks as shown. See Fig. 5

. Slowly turn crankshaft pulley 1-

7/8 revolutions and align groove with mark at 45 degrees BTDC (for No. 1 cylinder) of No. 1 timing belt

cover. See Fig. 7

. Tighten No. 1 idler pulley mounting bolt to specification.

4. Place right engine mounting bracket in position, but do not install bolts. Install No. 2 timing belt cover.

Disconnect engine wire protector between cylinder head cover and No. 3 timing belt cover. Install No. 2

timing belt cover. Install engine wire to No. 2 timing belt cover. Install engine wire protector to mounting

bolts of No. 2 timing belt cover.

5. Remove crankshaft pulley. Install engine mounting bracket-to-engine bolts and tighten to specification.

Install crankshaft pulley, and tighten pulley bolt to specification. See TORQUE SPECIFICATIONS

.

To complete installation, reverse removal procedure. Ad

just drive belts to proper tension.

1999 Toyota RAV4

TOYOTA 2.0L 4-Cylinder - RAV4

Microsoft

Sunday, November 22, 2009 10:24:26 AMPage 7 © 2005 Mitchell Repair Information Company, LLC.

Page 1400 of 1632

Fig. 7: Locating 45 Degree BTDC Mark

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

ApplicationFt. Lbs. (N.m)

Camshaft Timing Pulley Bolt40 (54)

Crankshaft Pulley Bolt80 (108)

Generator Bracket Bolts31 (42)

Engine Mount Bracket-To-Engine Bolts38 (52)

Engine Mount Insulator-To-Body Bolts38 (52)

Engine Mount Insulator-To-Bracket Nut27 (37)

No. 1 Idler Pulley Mounting Bolt31 (42)

Wheel Lug Nut76 (103)

INCH Lbs. (N.m)

Water Pump Bolts78 (8.8)

1999 Toyota RAV4

TOYOTA 2.0L 4-Cylinder - RAV4

Microsoft

Sunday, November 22, 2009 10:24:27 AMPage 8 © 2005 Mitchell Repair Information Company, LLC.

Page 1401 of 1632

1999 TRANSFER CASES

Toyota A-540H Overhaul

APPLICATION

TRANSFER CASE APPLICATIONS

DESCRIPTION & OPERATION

The A-540H transfer case is an electronically controlled unit which uses a center differential control solenoid

with an internal valve body. Transfer control solenoid is operated by duty cycle signals from the Electronic

Control Unit (ECU). Duty cycle signals modulate fluid pressure of center differential clutch control valve. For

additional information on electronic control components, see TOYOTA A-540H ELECTRONIC CONTROLS

article in AUTOMATIC TRANSMISSIONS.

ELECTRONIC COMPONENT TESTING

CENTER DIFFERENTIAL CLUTCH CONTROL SOLENOID

1. Ensure transmission fluid is at operating temperature. Block wheels. Remove transfer valve body cover

plug and install pressure gauge. See Fig. 1

.

2. Start vehicle and accelerate 50 percent or more in Park. Ensure center differential clutch control pressure

is more than 42 psi (3.0 kg/cm

2 ). Release accelerator. Ensure center differential clutch control pressure is

1.4 psi (.1 kg/cm

2 ) or less at idle. If pressure is not as specified, go to next step.

3. Install a 24-watt bulb in jumper wire connected between positive battery terminal and control solenoid

terminal No. 1. Connect jumper wire between negative battery terminal and control solenoid terminal No.

3 to activate solenoid. See Fig. 1

. Measure center differential clutch control pressure at idle. See

CONTROL SOLENOID PRESSURE SPECIFICATIONS

table.

4. Measure center differential clutch control pressure at stall speed. Connect tachometer to vehicle and

ensure it is visible to driver. Apply parking and service brakes. Start engine. Position transmission in "D"

ran

ge. Fully depress accelerator pedal. Immediately note highest engine RPM. DO NOT perform test

Vehicle Application(1) Transfer Case Model Number

RAV4 With A-540H A/TA-540H

(1)Identifies transmission code. No additional transfer case model number information is available.

CAUTION: Perform test at normal operating fluid temperature of 122-176°F (50-80°C).

CAUTION: DO NOT maintain stall speed RPM for more than 5 seconds.

1999 Toyota RAV4

1999 TRANSFER CASES Toyota A-540H Overhaul

1999 Toyota RAV4

1999 TRANSFER CASES Toyota A-540H Overhaul

Microsoft

Sunday, November 22, 2009 10:49:16 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:49:19 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.