engine TOYOTA RAV4 1996 Service Workshop Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 259 of 1632

Avalon, Camry, Celica 2.2L 5S-FE, Corolla 1.6L 4A-FE & Tercel With 3-Speed

Check transmission fluid level and transmission/differential fluid level every 15,000 miles or 24 months.

Transmission/differential fluid reservoir is independent from the transmission. Normal operating conditions

service interval is not available.

Celica 1.8L 7A-FE, Corolla 1.8L 7A-FE, MR2, Paseo, RAV4 & Tercel With 4-Speed, Land Cruiser, Pickup, Previa,

Supra, Tacoma, T100 & 4Runner

Check transmission fluid level every 15,000 miles or 24 months. Differential fluid reservoir is incorporated with

the transmission. Normal operating conditions service interval is not available.

CHECKING FLUID LEVEL

Transmission

1. Drive vehicle until engine and transmission reach normal operating temperature. Park vehicle on level

surface and apply parking brake. With engine idling and brakes applied, move gearshift from Park

through Low and back to Park.

2. Check fluid level on transmission dipstick. Fluid level should be in HOT range marked on dipstick. Add

proper type of fluid if necessary. See RECOMMENDED FLUID

under LUBRICATION. DO NOT

overfill transmission.

Transmission/Differential (Avalon, Camry, Celica 2.2L 5S-FE, Corolla 1.6L 4A-FE & Tercel 3-Speed)

Remove filler plug. See Fig. 1 -3. Fluid should be level with bottom edge of filler plug hole. If fluid is low, fill

with proper type fluid until fluid is level with filler plug opening. See RECOMMENDED FLUID

under

LUBRICATION. Reinstall filler plu

g. NOTE: When checking fluid level for the transmission, if vehicle has been operating in

heavy traffic, towing a trailer or at high speeds in hot weather, wait 30 minutes

before checking the fluid level.

NOTE: Some models have a transmission/differential unit. On these models the

differential lubrication is separate from the transmission fluid. It must be

checked and filled separately.

1996 Toyota 4Runner

TRANSMISSION SERVICING - A/T AUTOMATIC TRANSMISSION SERVICING Toyota

Microsoft

Tuesday, August 18, 2009 7:18:46 PMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 266 of 1632

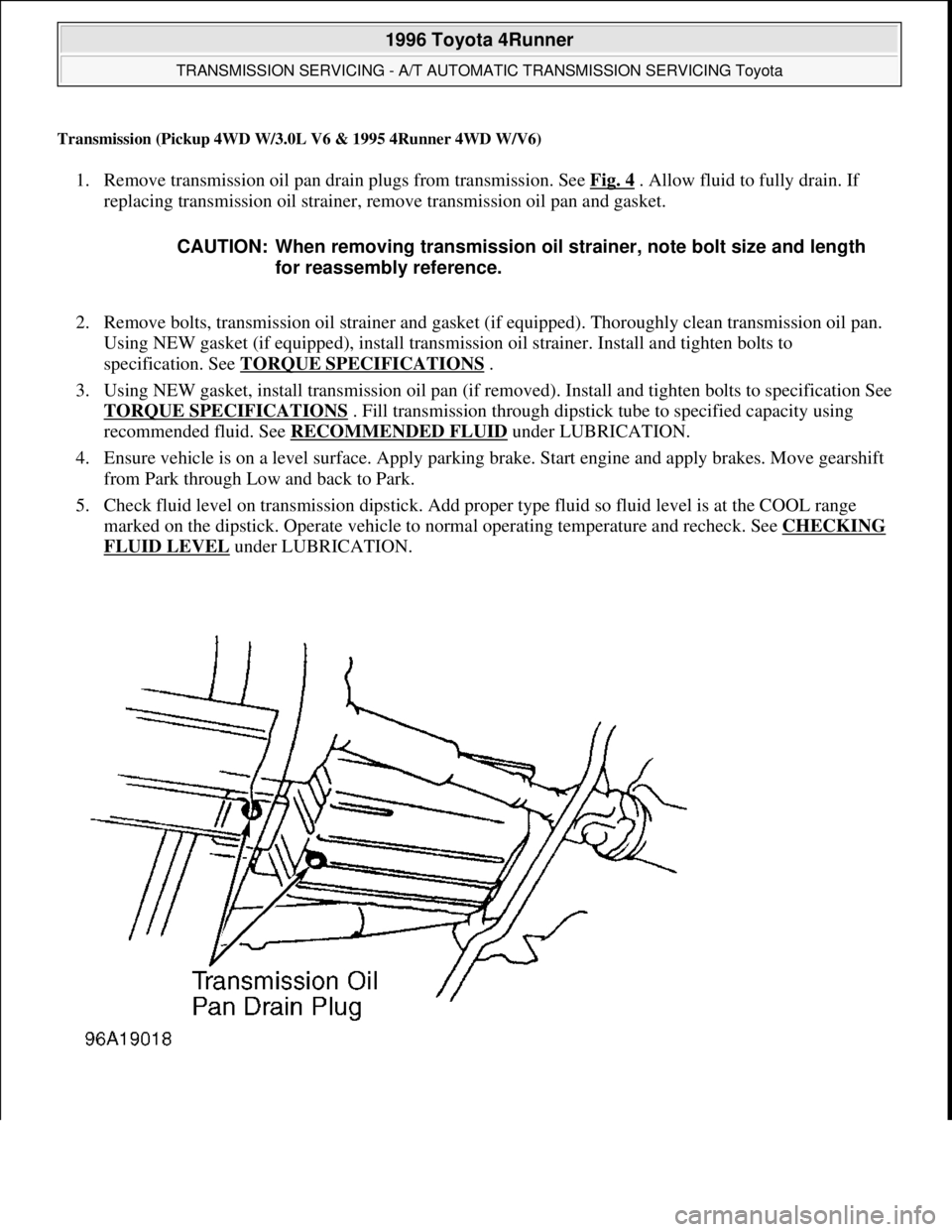

Transmission (Pickup 4WD W/3.0L V6 & 1995 4Runner 4WD W/V6)

1. Remove transmission oil pan drain plugs from transmission. See Fig. 4 . Allow fluid to fully drain. If

replacing transmission oil strainer, remove transmission oil pan and gasket.

2. Remove bolts, transmission oil strainer and gasket (if equipped). Thoroughly clean transmission oil pan.

Using NEW gasket (if equipped), install transmission oil strainer. Install and tighten bolts to

specification. See TORQUE SPECIFICATIONS

.

3. Using NEW gasket, install transmission oil pan (if removed). Install and tighten bolts to specification See

TORQUE SPECIFICATIONS

. Fill transmission through dipstick tube to specified capacity using

recommended fluid. See RECOMMENDED FLUID

under LUBRICATION.

4. Ensure vehicle is on a level surface. Apply parking brake. Start engine and apply brakes. Move gearshift

from Park through Low and back to Park.

5. Check fluid level on transmission dipstick. Add proper type fluid so fluid level is at the COOL range

marked on the dipstick. Operate vehicle to normal operating temperature and recheck. See CHECKING

FLUID LEVEL under LUBRICATION. CAUTION: When removing transmission oil strainer, note bolt size and length

for reassembly reference.

1996 Toyota 4Runner

TRANSMISSION SERVICING - A/T AUTOMATIC TRANSMISSION SERVICING Toyota

Microsoft

Tuesday, August 18, 2009 7:18:46 PMPage 10 © 2005 Mitchell Repair Information Company, LLC.

Page 267 of 1632

Fig. 4: Identifying Transmission Oil Pan Drain Plugs (Pickup 4WD With 3.0L V6 & 1995 4Runner 4WD

With V6)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Transmission (All Others)

1. Remove transmission oil pan drain plug from transmission oil pan. Allow fluid to fully drain. If replacing

transmission oil strainer, remove transmission oil pan and gasket.

2. Remove bolts, transmission oil strainer and gasket (if equipped). Thoroughly clean transmission oil pan.

Using NEW gasket (if equipped), install transmission oil strainer. Install and tighten bolts to

specification. See TORQUE SPECIFICATIONS

.

3. Using NEW gasket, install transmission oil pan (if removed). Install and tighten bolts to specification See

TORQUE SPECIFICATIONS

. Fill transmission through dipstick tube to specified capacity using

recommended fluid. See RECOMMENDED FLUID

under LUBRICATION.

4. Ensure vehicle is on a level surface. Apply parking brake. Start engine and apply brakes. Move gearshift

from Park through Low and back to Park.

5. Check fluid level on transmission dipstick. Add proper type fluid so fluid level is at the COOL range

marked on the dipstick. Operate vehicle to normal operating temperature and recheck. See CHECKING

FLUID LEVEL under LUBRICATION.

Transmission Differential (Avalon, Camry, Celica 2.2L 5S-FE, Corolla 1.6L 4A-FE & Tercel 3-Speed)

1. Remove oil filler and drain plugs from differential. See Fig. 1 . Allow fluid to drain. Reinstall drain plug.

2. Fill differential through oil filler plug hole to specified capacity using recommended fluid. See

RECOMMENDED FLUID

under LUBRICATION. Ensure fluid is level with bottom edge of filler plug

hole. Reinstall filler plug.

Transfer Case (Land Cruiser, Pickup, Previa, Tacoma, T100 & 4Runner)

1. Remove filler plug located on rear of transfer case. Remove drain plug from bottom of transfer case.

Allow fluid to drain. Reinstall drain plug.

2. Fill transfer case through oil filler plug hole to specified capacity using recommended fluid. See

RECOMMENDED FLUID

under LUBRICATION. Ensure fluid is level with bottom edge of filler plug

hole. Reinstall filler plug.

Transfer Case (RAV4)

1. Remove drain plug from bottom of transfer case. Allow fluid to drain. Reinstall drain plug. Fill transfer

case through transfer case oil dipstick tube to specified capacity using recommended fluid. See

RECOMMENDED FLUID

under LUBRICATION.

2. Check fluid level on transfer case dipstick. Fluid level should be in the LOW to HIGH range. Add fluid if CAUTION: When removing transmission oil strainer, note bolt size and length

for reassembly reference.

1996 Toyota 4Runner

TRANSMISSION SERVICING - A/T AUTOMATIC TRANSMISSION SERVICING Toyota

Microsoft

Tuesday, August 18, 2009 7:18:46 PMPage 11 © 2005 Mitchell Repair Information Company, LLC.

Page 269 of 1632

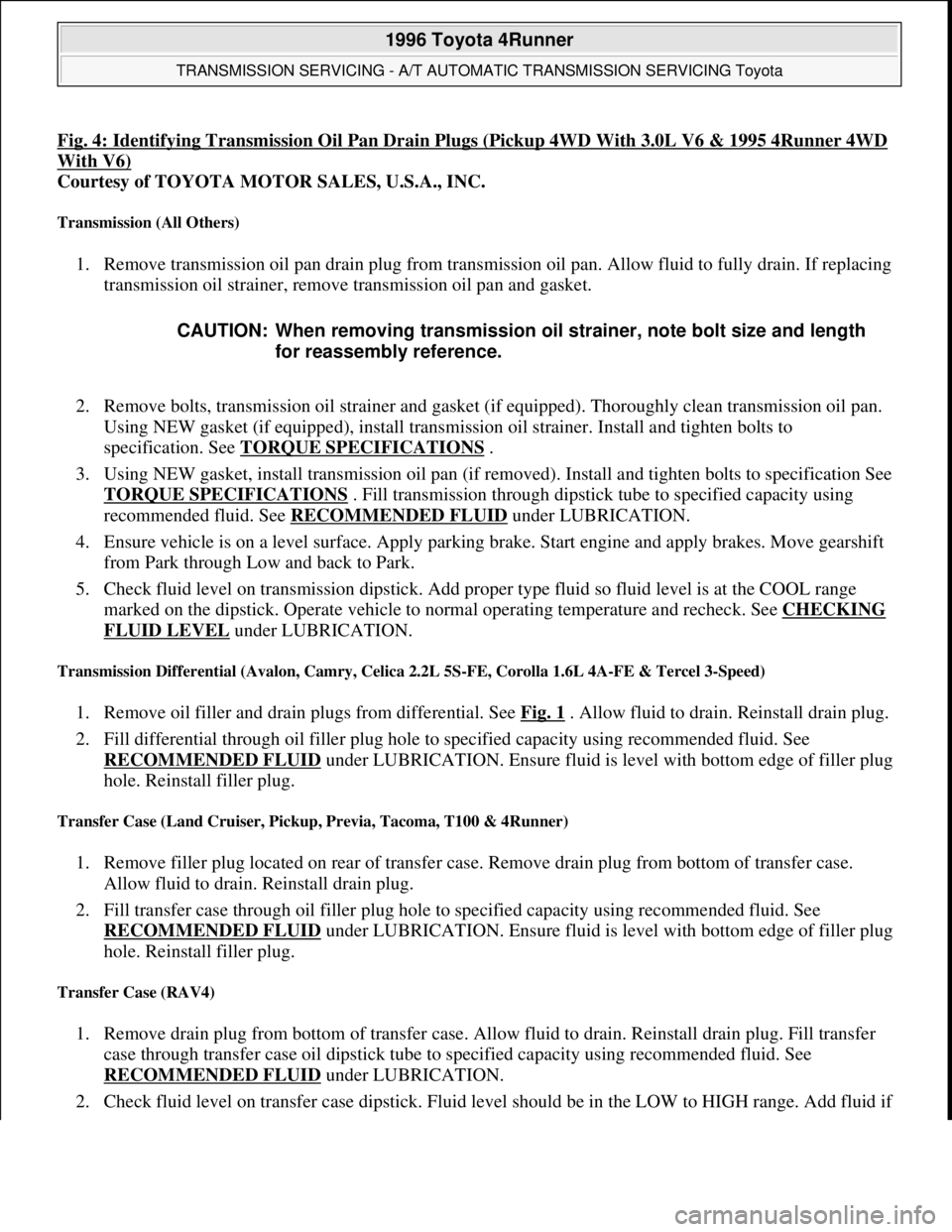

step 2). If throttle valve is not fully open, adjust throttle linkage or cable so throttle valve is fully open and

then go to step 2).

2. Ensure accelerator pedal is fully depressed. Loosen adjusting nuts on throttle valve cable. Adjust outer

cable so distance between end of rubber boot and stopper on throttle valve cable is 0-.04" (0-1.0 mm). See

Fig. 6

. Tighten adjusting nuts. Recheck distance once adjusting nuts are tightened.

Fig. 6: Measuring Distance On Throttle Valve Cable (Corolla 1.6L 4A

-FE, Pickup, Previa Non-

Supercharged, Tacoma 2WD 2.4L 4-Cyl., Tercel & 1995 4Runner)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

GEARSHIFT LINKAGE

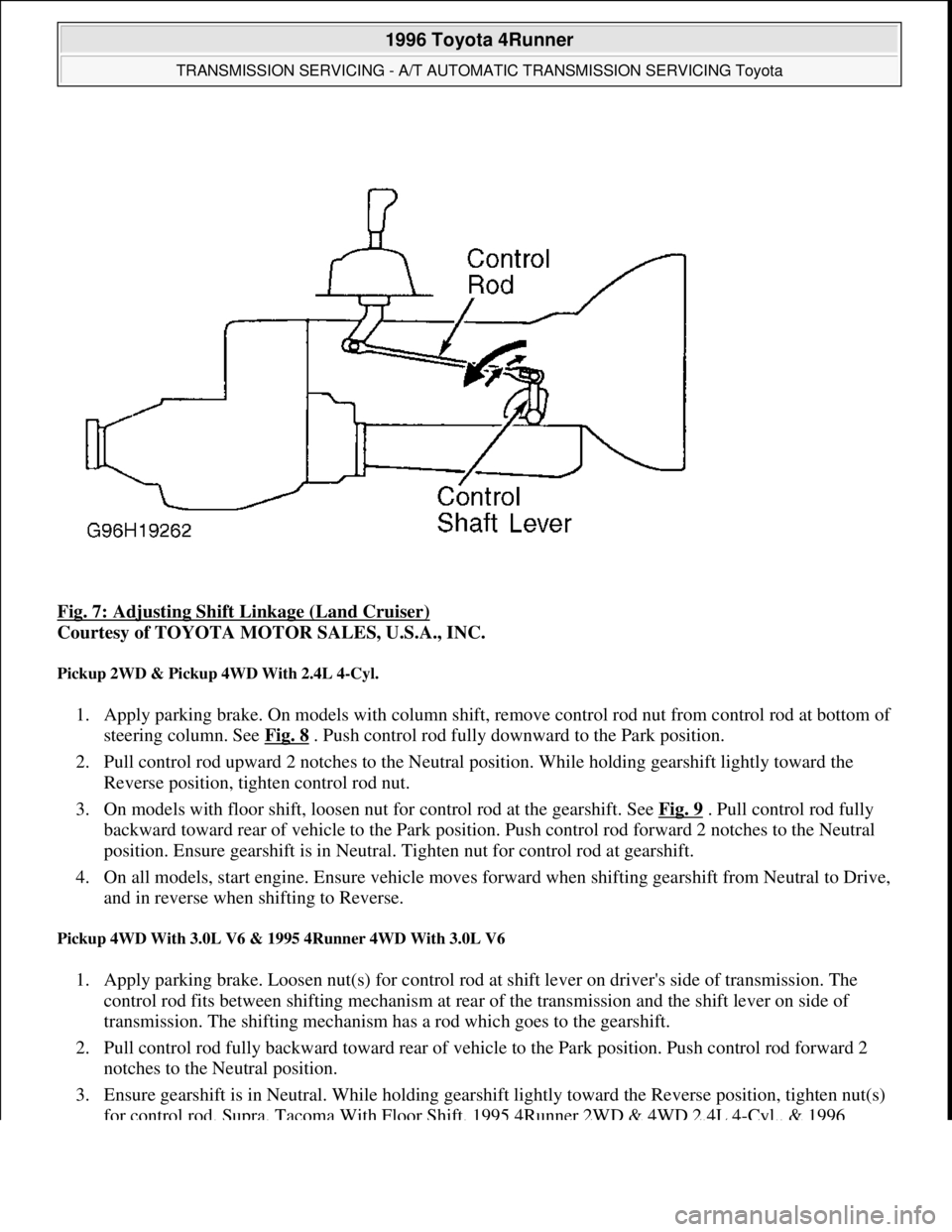

Land Cruiser

1. Apply parking brake. Loosen control rod nut on control rod at control shaft lever on side of transmission.

See Fig. 7

. Rotate control shaft lever fully counterclockwise toward rear of vehicle to the Park position.

2. Rotate control shaft lever clockwise 2 notches to Neutral position. Ensure gearshift is in Neutral. While

holding control shaft lever lightly counterclockwise back toward the Reverse position, tighten control rod

nut.

3. Start engine. Ensure vehicle moves forward when shifting gearshift from Neutral to Drive, and in reverse

when shiftin

g to Reverse.

1996 Toyota 4Runner

TRANSMISSION SERVICING - A/T AUTOMATIC TRANSMISSION SERVICING Toyota

Microsoft

Tuesday, August 18, 2009 7:18:46 PMPage 13 © 2005 Mitchell Repair Information Company, LLC.

Page 270 of 1632

Fig. 7: Adjusting Shift Linkage (Land Cruiser)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

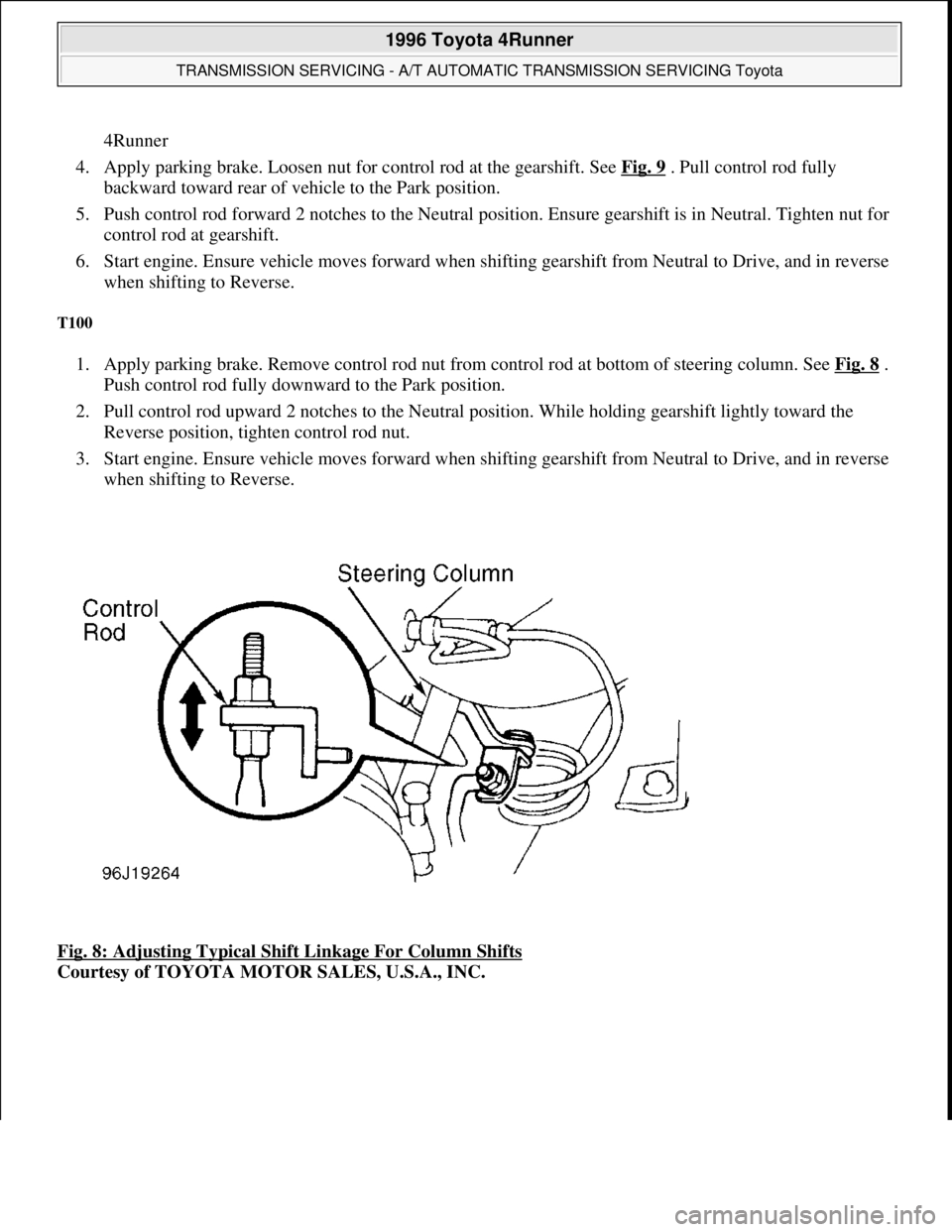

Pickup 2WD & Pickup 4WD With 2.4L 4-Cyl.

1. Apply parking brake. On models with column shift, remove control rod nut from control rod at bottom of

steering column. See Fig. 8

. Push control rod fully downward to the Park position.

2. Pull control rod upward 2 notches to the Neutral position. While holding gearshift lightly toward the

Reverse position, tighten control rod nut.

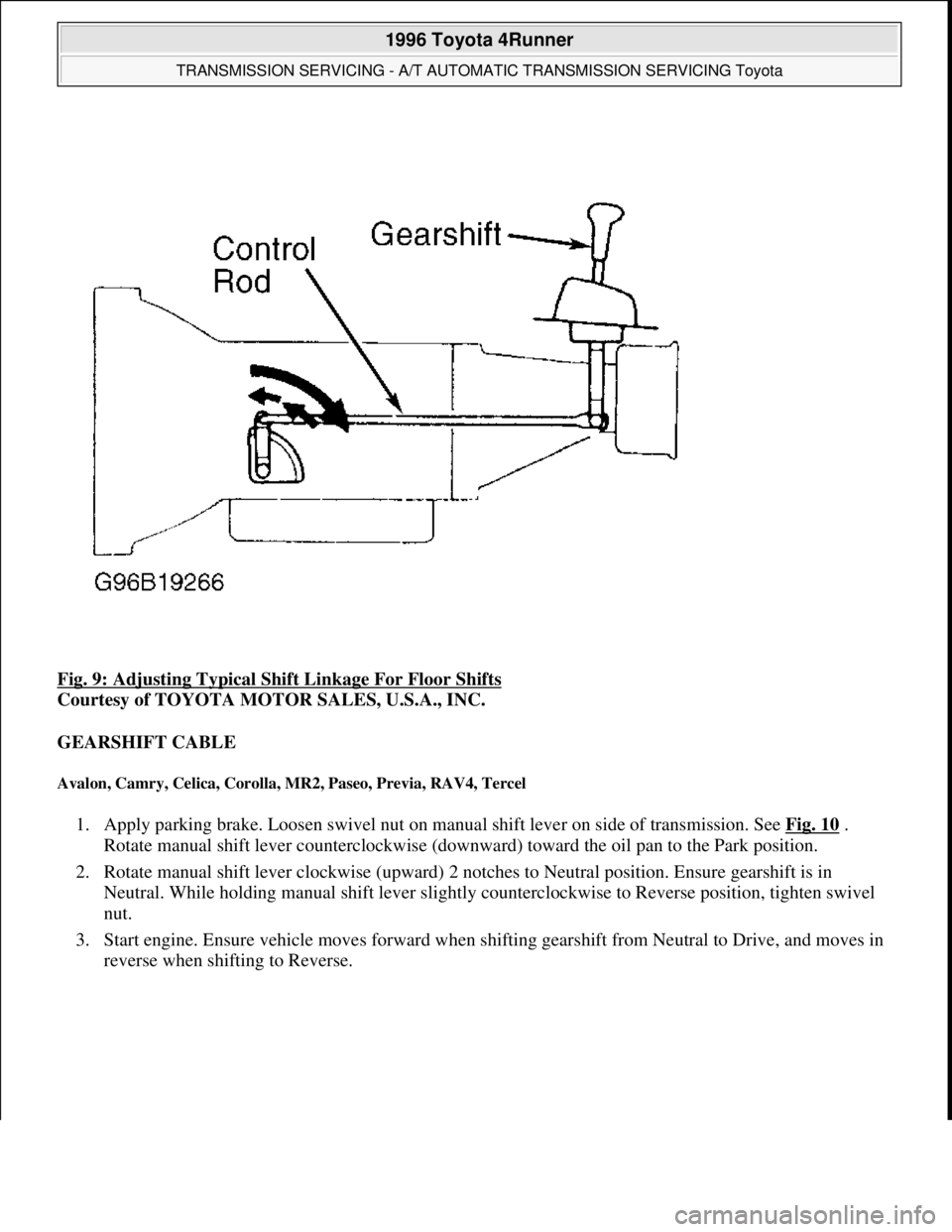

3. On models with floor shift, loosen nut for control rod at the gearshift. See Fig. 9

. Pull control rod fully

backward toward rear of vehicle to the Park position. Push control rod forward 2 notches to the Neutral

position. Ensure gearshift is in Neutral. Tighten nut for control rod at gearshift.

4. On all models, start engine. Ensure vehicle moves forward when shifting gearshift from Neutral to Drive,

and in reverse when shifting to Reverse.

Pickup 4WD With 3.0L V6 & 1995 4Runner 4WD With 3.0L V6

1. Apply parking brake. Loosen nut(s) for control rod at shift lever on driver's side of transmission. The

control rod fits between shifting mechanism at rear of the transmission and the shift lever on side of

transmission. The shifting mechanism has a rod which goes to the gearshift.

2. Pull control rod fully backward toward rear of vehicle to the Park position. Push control rod forward 2

notches to the Neutral position.

3. Ensure gearshift is in Neutral. While holding gearshift lightly toward the Reverse position, tighten nut(s)

for control rod. Supra, Tacoma With Floor Shift, 1995 4Runner 2WD & 4WD 2.4L 4-C

yl., & 1996

1996 Toyota 4Runner

TRANSMISSION SERVICING - A/T AUTOMATIC TRANSMISSION SERVICING Toyota

Microsoft

Tuesday, August 18, 2009 7:18:46 PMPage 14 © 2005 Mitchell Repair Information Company, LLC.

Page 271 of 1632

4Runner

4. Apply parking brake. Loosen nut for control rod at the gearshift. See Fig. 9

. Pull control rod fully

backward toward rear of vehicle to the Park position.

5. Push control rod forward 2 notches to the Neutral position. Ensure gearshift is in Neutral. Tighten nut for

control rod at gearshift.

6. Start engine. Ensure vehicle moves forward when shifting gearshift from Neutral to Drive, and in reverse

when shifting to Reverse.

T100

1. Apply parking brake. Remove control rod nut from control rod at bottom of steering column. See Fig. 8 .

Push control rod fully downward to the Park position.

2. Pull control rod upward 2 notches to the Neutral position. While holding gearshift lightly toward the

Reverse position, tighten control rod nut.

3. Start engine. Ensure vehicle moves forward when shifting gearshift from Neutral to Drive, and in reverse

when shifting to Reverse.

Fig. 8: Adjusting Typical Shift Linkage For Column Shifts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1996 Toyota 4Runner

TRANSMISSION SERVICING - A/T AUTOMATIC TRANSMISSION SERVICING Toyota

Microsoft

Tuesday, August 18, 2009 7:18:46 PMPage 15 © 2005 Mitchell Repair Information Company, LLC.

Page 272 of 1632

Fig. 9: Adjusting Typical Shift Linkage For Floor Shifts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

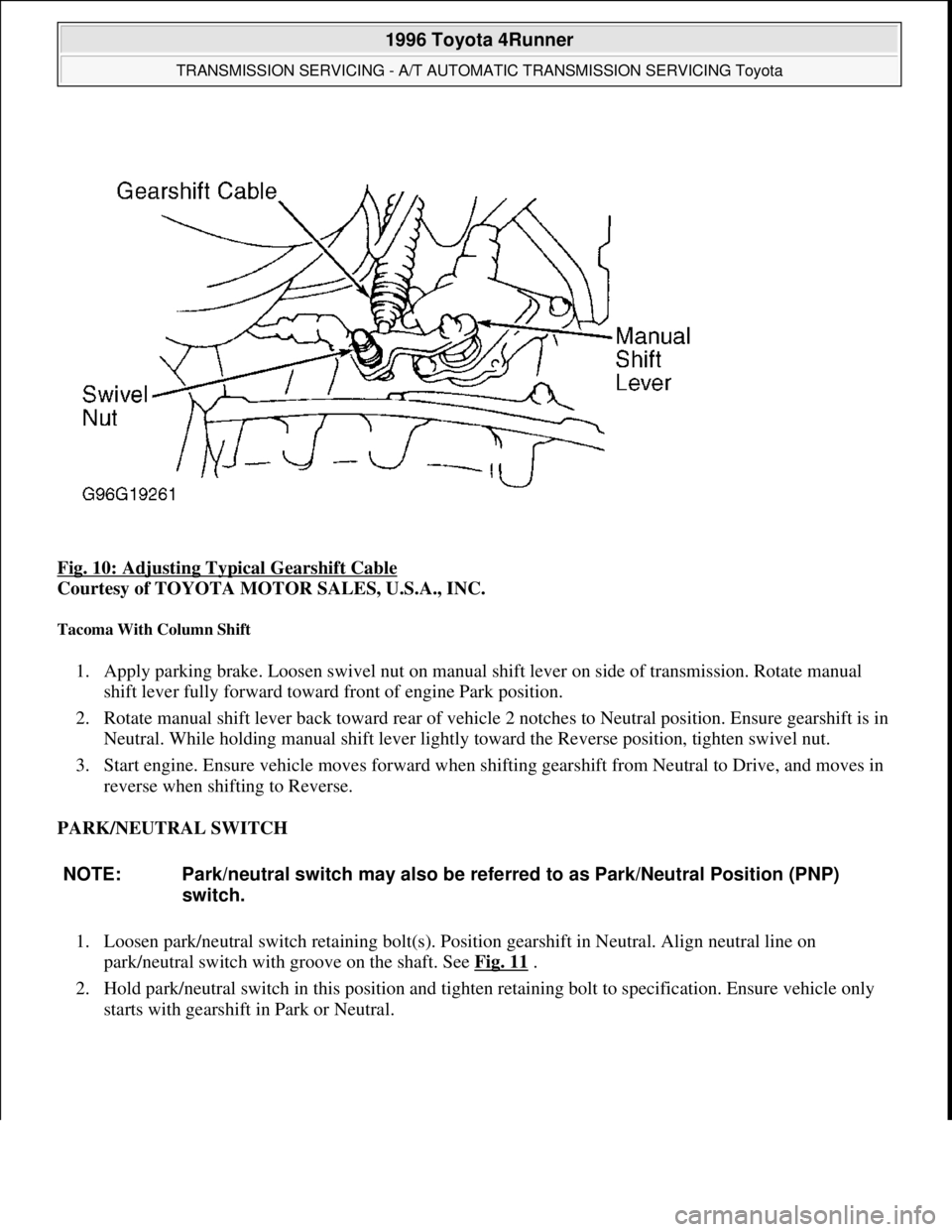

GEARSHIFT CABLE

Avalon, Camry, Celica, Corolla, MR2, Paseo, Previa, RAV4, Tercel

1. Apply parking brake. Loosen swivel nut on manual shift lever on side of transmission. See Fig. 10 .

Rotate manual shift lever counterclockwise (downward) toward the oil pan to the Park position.

2. Rotate manual shift lever clockwise (upward) 2 notches to Neutral position. Ensure gearshift is in

Neutral. While holding manual shift lever slightly counterclockwise to Reverse position, tighten swivel

nut.

3. Start engine. Ensure vehicle moves forward when shifting gearshift from Neutral to Drive, and moves in

reverse when shiftin

g to Reverse.

1996 Toyota 4Runner

TRANSMISSION SERVICING - A/T AUTOMATIC TRANSMISSION SERVICING Toyota

Microsoft

Tuesday, August 18, 2009 7:18:46 PMPage 16 © 2005 Mitchell Repair Information Company, LLC.

Page 273 of 1632

Fig. 10: Adjusting Typical Gearshift Cable

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Tacoma With Column Shift

1. Apply parking brake. Loosen swivel nut on manual shift lever on side of transmission. Rotate manual

shift lever fully forward toward front of engine Park position.

2. Rotate manual shift lever back toward rear of vehicle 2 notches to Neutral position. Ensure gearshift is in

Neutral. While holding manual shift lever lightly toward the Reverse position, tighten swivel nut.

3. Start engine. Ensure vehicle moves forward when shifting gearshift from Neutral to Drive, and moves in

reverse when shifting to Reverse.

PARK/NEUTRAL SWITCH

1. Loosen park/neutral switch retaining bolt(s). Position gearshift in Neutral. Align neutral line on

park/neutral switch with groove on the shaft. See Fig. 11

.

2. Hold park/neutral switch in this position and tighten retaining bolt to specification. Ensure vehicle only

starts with

gearshift in Park or Neutral.

NOTE: Park/neutral switch may also be referred to as Park/Neutral Position (PNP)

switch.

1996 Toyota 4Runner

TRANSMISSION SERVICING - A/T AUTOMATIC TRANSMISSION SERVICING Toyota

Microsoft

Tuesday, August 18, 2009 7:18:46 PMPage 17 © 2005 Mitchell Repair Information Company, LLC.

Page 322 of 1632

1999-2000 DRIVE AXLES

AWD & FWD Axle Shafts - RAV4 & RWD Axle Shafts - MR2

DESCRIPTION & OPERATION

On RAV4 models, axle shafts transfer power from transaxle to front wheels (FWD), or front and rear wheels

(AWD). MR2 are a mid-engine, RWD design. Axle shafts transfer power from transaxle to rear wheels. Axle

shaft consists of axle shaft with flexible Constant Velocity (CV) joint at each end. On RAV4 models, front inner

CV joint is splined to transaxle. Rear inner CV joint is bolted to differential. Outer CV joint is splined to front

or rear hub assembly. On MR2 models, rear inner CV joint is splined to transaxle and Outer CV joint is splined

to rear hub assembly.

Inner and outer CV joints are enclosed by a CV joint boot. Boot maintains lubrication in CV joint and prevents

contamination of CV lubricant. Boots must be replaced if cracked, torn or damaged. Inner CV joint can be

repaired without replacing assembly but outer CV joint must be replaced as an assembly.

TROUBLE SHOOTING

REMOVAL & INSTALLATION

FRONT AXLE SHAFTS

Removal (RAV4)

1. Raise and support vehicle. Remove front wheel. Remove engine undercover. Drain gear oil from

transaxle into proper container. Remove ABS speed sensor (if equipped). Remove cotter pin and lock cap.

See Fig. 1

or Fig. 2 . Apply brakes, and remove axle shaft nut from end of axle shaft. Release brakes.

2. Remove cotter pin and nut from tie rod end. Using Tie Rod End Remover (SST 09610-20012), disconnect

tie rod end from steering knuckle. Disconnect stabilizer bar link from lower suspension arm. Remove bolt

and 2 nuts, and separate lower ball joint from suspension arm.

3. Using a plastic hammer, tap axle shaft from hub. Pull steering knuckle outward, and disconnect axle shaft

from steering knuckle.

4. To remove axle shaft (except left side on AWD), use a brass drift and hammer and tap on inner joint to

separate from transaxle. Slide axle shaft toward steering knuckle until free of transaxle assembly. NOTE: See DRIVE AXLE NOISE DIAGNOSIS article in GENERAL INFORMATION.

NOTE: DO NOT damage oil seal, axle shaft boots or Anti-Lock Brake System (ABS)

speed sensor rotor when removing axle shaft.

NOTE: On FWD vehicles, removal of right-side axle shaft requires disassembly of

center bearing axle support. See Fig. 3

or Fig. 4 .

1999 Toyota RAV4

1999-2000 DRIVE AXLES AWD & FWD Axle Shafts - RAV4 & RWD Axle Shafts - MR2

1999 Toyota RAV4

1999-2000 DRIVE AXLES AWD & FWD Axle Shafts - RAV4 & RWD Axle Shafts - MR2

Microsoft

Sunday, November 22, 2009 10:08:21 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:08:25 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 332 of 1632

1. To install, reverse removal procedure. Before installing axle shafts, install NEW snap ring on end of axle

shaft (except right side). Coat axle shaft seals in transaxle with grease. Coat axle shaft splines and sliding

surfaces with Dexron-II. Position snap ring on end of axle shaft, with opening facing downward.

2. Install axle shaft by lightly tapping axle shaft into transaxle. Ensure axle shaft will move inward and

outward approximately .079-.120" (2.00-3.00 mm), and cannot be pulled from transaxle.

3. To install remaining components, reverse removal procedure. Tighten fasteners to specification. See

TORQUE SPECIFICATIONS

. Fill transaxle with 75W-90 gear oil with API GL-3, GL-4 or GL-5

rating.

REAR AXLE SHAFTS

Removal (MR2)

1. Raise and support vehicle. Remove rear wheels. Remove engine undercovers. Drain differential oil into

proper container. Unstake drive shaft lock nut. Apply brakes and remove nut. Remove bolt and brake flex

hose bracket from shock absorber. Loosen 2 lower shock absorber bolts and nuts.

2. Remove mounting bolts/nuts and disconnect strut rod from axle carrier. Remove mounting bolts/nuts

from No. 1 lower suspension arm. Remove nut and No. 2 lower suspension arm. Remove 2 lower shock

absorber bolts and nuts. See Fig. 8

. Using plastic hammer, remove drive shaft from axle hub. DO NOT

damage oil seal, boots or dust seal. NOTE: DO NOT damage oil seal, axle shaft boots or Anti-Lock Brake System (ABS)

speed sensor rotor when removing axle shaft.

1999 Toyota RAV4

1999-2000 DRIVE AXLES AWD & FWD Axle Shafts - RAV4 & RWD Axle Shafts - MR2

Microsoft

Sunday, November 22, 2009 10:08:21 AMPage 11 © 2005 Mitchell Repair Information Company, LLC.