lights TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 9 of 1632

SYMPTOM TESTS

ABS LIGHT ON: ABS ECU MALFUNCTION

Circuit Description

This circuit is the power source for ABS ECU and actuator.

DTC Detecting Condition

If voltage at ABS ECU terminal IG1 remains more than 17 volts, this DTC will set. If a malfunction occurs in

power source circuit, ABS ECU cuts off current to ABS control relay and prohibits ABS control.

Diagnostic Procedure

1. Retrieve DTCs. See RETRIEVING DTCS under DIAGNOSIS & TESTING. If DTC is output using

ABS warning light, perform appropriate test under DIAGNOSTIC TESTS

. If ABS warning light does

not operate normally, go to next step. If ABS warning light operates normally (lights blink 2 times per

second and no DTCs are present), check ABS control (solenoid) relay. See SOLENOID RELAY

SECTION under ABS CONTROL RELAY under COMPONENT TESTS. Check for short circuit in

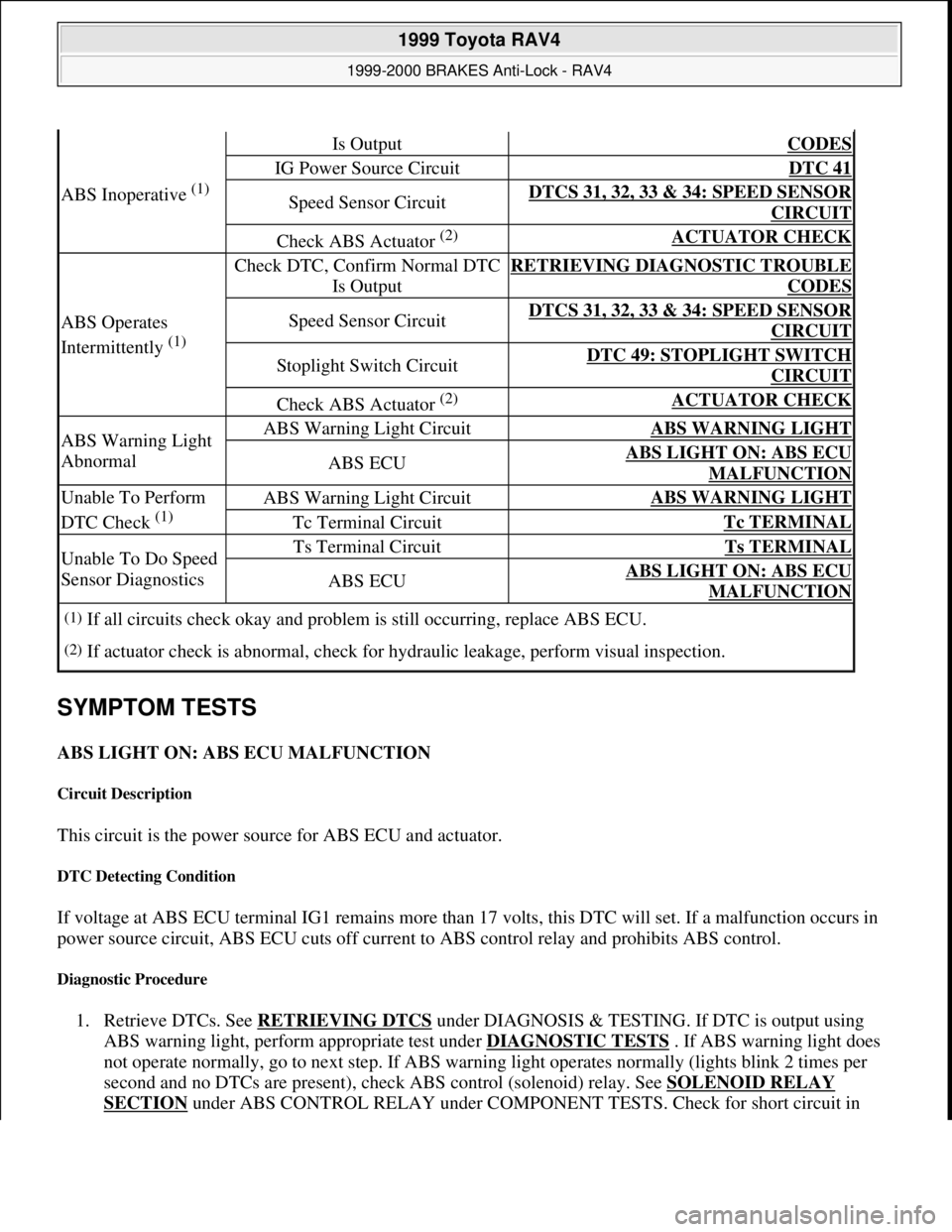

ABS Inoperative (1)

Is OutputCODES

IG Power Source CircuitDTC 41

Speed Sensor CircuitDTCS 31, 32, 33 & 34: SPEED SENSOR

CIRCUIT

Check ABS Actuator (2) ACTUATOR CHECK

ABS Operates

Intermittently

(1)

Check DTC, Confirm Normal DTC

Is OutputRETRIEVING DIAGNOSTIC TROUBLE

CODES

Speed Sensor CircuitDTCS 31, 32, 33 & 34: SPEED SENSOR

CIRCUIT

Stoplight Switch CircuitDTC 49: STOPLIGHT SWITCH

CIRCUIT

Check ABS Actuator (2) ACTUATOR CHECK

ABS Warning Light

AbnormalABS Warning Light CircuitABS WARNING LIGHT

ABS ECUABS LIGHT ON: ABS ECU

MALFUNCTION

Unable To Perform

DTC Check

(1)

ABS Warning Light CircuitABS WARNING LIGHT

Tc Terminal CircuitTc TERMINAL

Unable To Do Speed

Sensor DiagnosticsTs Terminal CircuitTs TERMINAL

ABS ECUABS LIGHT ON: ABS ECU

MALFUNCTION

(1)If all circuits check okay and problem is still occurring, replace ABS ECU.

(2)If actuator check is abnormal, check for hydraulic leakage, perform visual inspection.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 9 © 2005 Mitchell Repair Information Company, LLC.

Page 19 of 1632

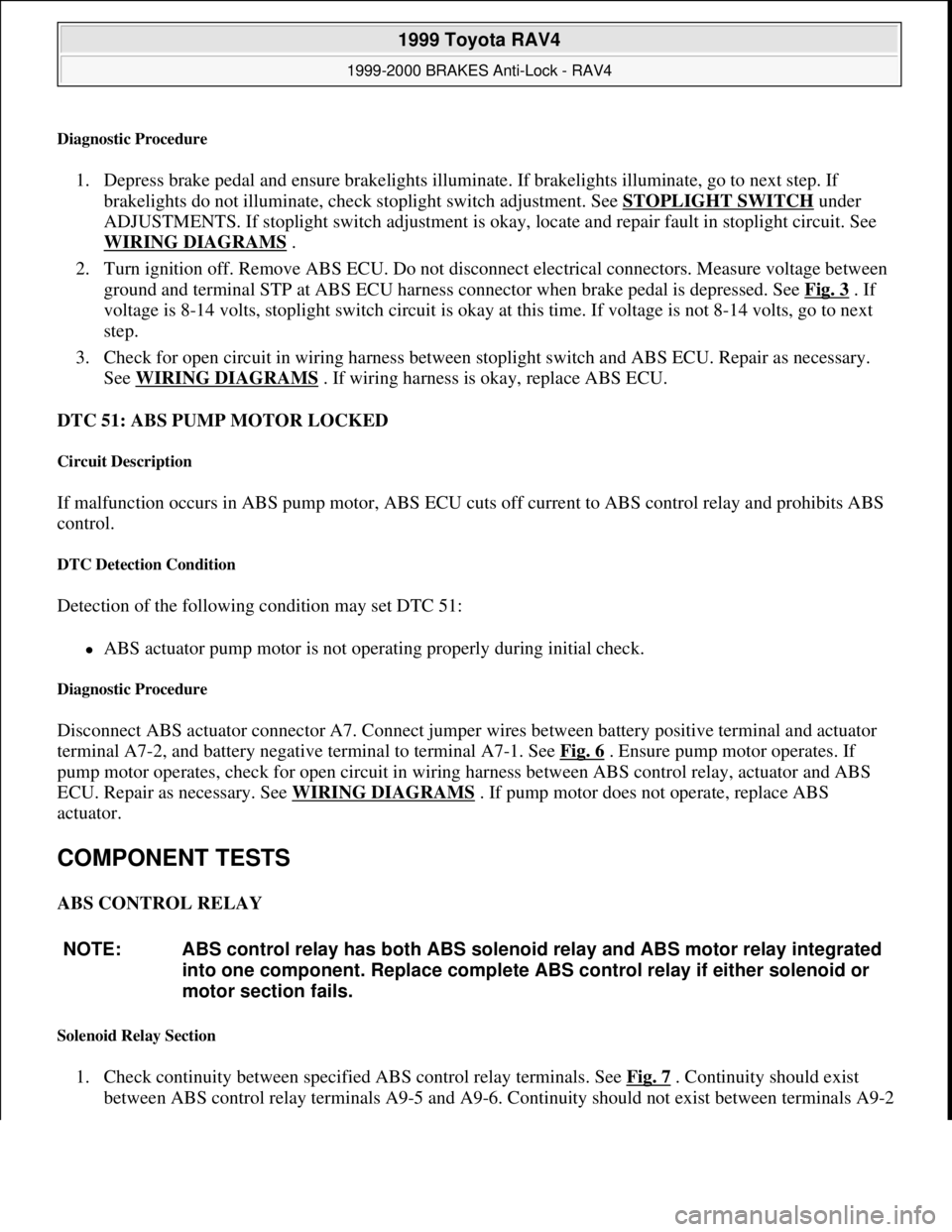

Diagnostic Procedure

1. Depress brake pedal and ensure brakelights illuminate. If brakelights illuminate, go to next step. If

brakelights do not illuminate, check stoplight switch adjustment. See STOPLIGHT SWITCH

under

ADJUSTMENTS. If stoplight switch adjustment is okay, locate and repair fault in stoplight circuit. See

WIRING DIAGRAMS

.

2. Turn ignition off. Remove ABS ECU. Do not disconnect electrical connectors. Measure voltage between

ground and terminal STP at ABS ECU harness connector when brake pedal is depressed. See Fig. 3

. If

voltage is 8-14 volts, stoplight switch circuit is okay at this time. If voltage is not 8-14 volts, go to next

step.

3. Check for open circuit in wiring harness between stoplight switch and ABS ECU. Repair as necessary.

See WIRING DIAGRAMS

. If wiring harness is okay, replace ABS ECU.

DTC 51: ABS PUMP MOTOR LOCKED

Circuit Description

If malfunction occurs in ABS pump motor, ABS ECU cuts off current to ABS control relay and prohibits ABS

control.

DTC Detection Condition

Detection of the following condition may set DTC 51:

ABS actuator pump motor is not operating properly during initial check.

Diagnostic Procedure

Disconnect ABS actuator connector A7. Connect jumper wires between battery positive terminal and actuator

terminal A7-2, and battery negative terminal to terminal A7-1. See Fig. 6

. Ensure pump motor operates. If

pump motor operates, check for open circuit in wiring harness between ABS control relay, actuator and ABS

ECU. Repair as necessary. See WIRING DIAGRAMS

. If pump motor does not operate, replace ABS

actuator.

COMPONENT TESTS

ABS CONTROL RELAY

Solenoid Relay Section

1. Check continuity between specified ABS control relay terminals. See Fig. 7 . Continuity should exist

between ABS control relay terminals A9-5 and A9-6. Continuity should not exist between terminals A9-2 NOTE: ABS control relay has both ABS solenoid relay and ABS motor relay integrated

into one component. Replace complete ABS control relay if either solenoid or

motor section fails.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 19 © 2005 Mitchell Repair Information Company, LLC.

Page 56 of 1632

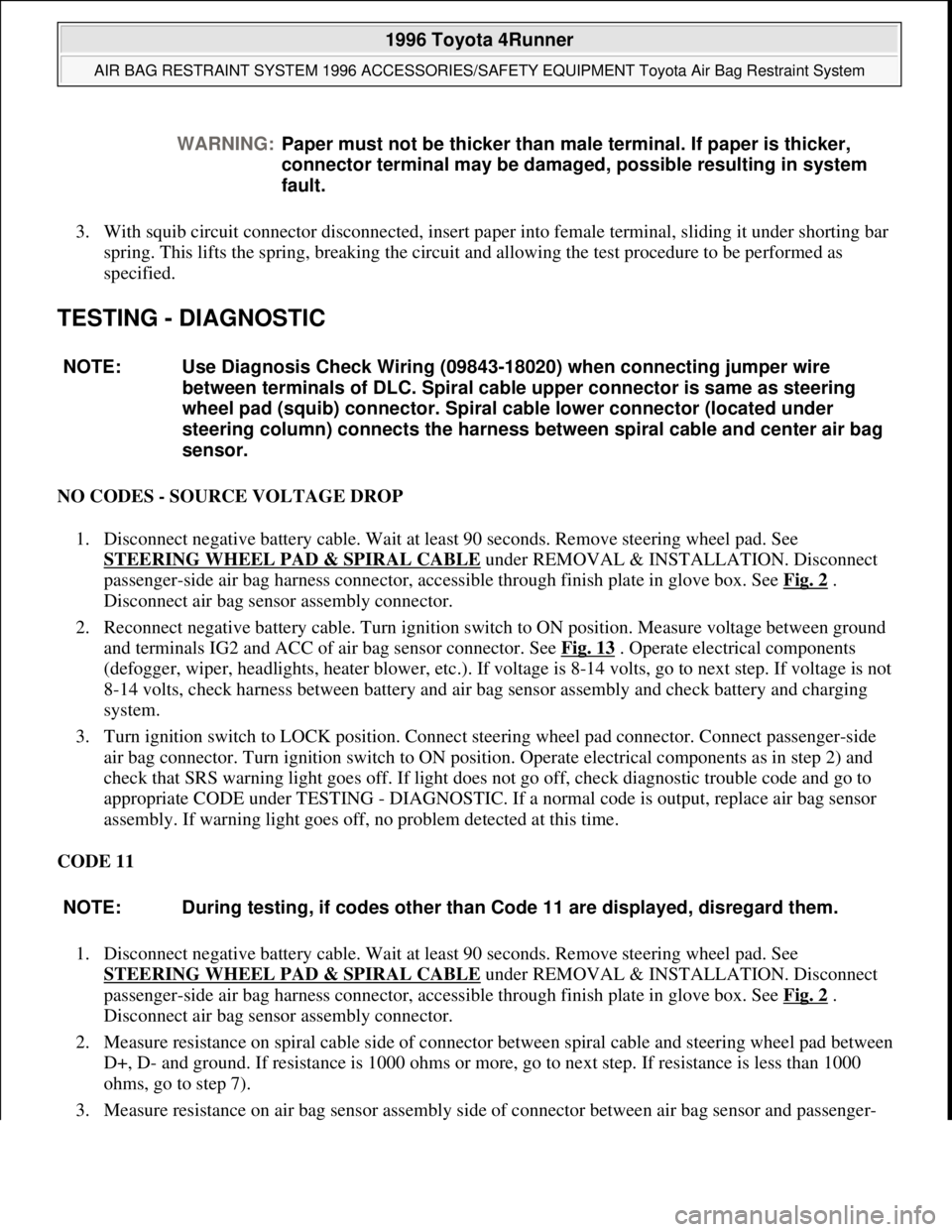

3. With squib circuit connector disconnected, insert paper into female terminal, sliding it under shorting bar

spring. This lifts the spring, breaking the circuit and allowing the test procedure to be performed as

specified.

TESTING - DIAGNOSTIC

NO CODES - SOURCE VOLTAGE DROP

1. Disconnect negative battery cable. Wait at least 90 seconds. Remove steering wheel pad. See

STEERING WHEEL PAD & SPIRAL CABLE

under REMOVAL & INSTALLATION. Disconnect

passenger-side air bag harness connector, accessible through finish plate in glove box. See Fig. 2

.

Disconnect air bag sensor assembly connector.

2. Reconnect negative battery cable. Turn ignition switch to ON position. Measure voltage between ground

and terminals IG2 and ACC of air bag sensor connector. See Fig. 13

. Operate electrical components

(defogger, wiper, headlights, heater blower, etc.). If voltage is 8-14 volts, go to next step. If voltage is not

8-14 volts, check harness between battery and air bag sensor assembly and check battery and charging

system.

3. Turn ignition switch to LOCK position. Connect steering wheel pad connector. Connect passenger-side

air bag connector. Turn ignition switch to ON position. Operate electrical components as in step 2) and

check that SRS warning light goes off. If light does not go off, check diagnostic trouble code and go to

appropriate CODE under TESTING - DIAGNOSTIC. If a normal code is output, replace air bag sensor

assembly. If warning light goes off, no problem detected at this time.

CODE 11

1. Disconnect negative battery cable. Wait at least 90 seconds. Remove steering wheel pad. See

STEERING WHEEL PAD & SPIRAL CABLE

under REMOVAL & INSTALLATION. Disconnect

passenger-side air bag harness connector, accessible through finish plate in glove box. See Fig. 2

.

Disconnect air bag sensor assembly connector.

2. Measure resistance on spiral cable side of connector between spiral cable and steering wheel pad between

D+, D- and ground. If resistance is 1000 ohms or more, go to next step. If resistance is less than 1000

ohms, go to step 7).

3. Measure resistance on air ba

g sensor assembly side of connector between air bag sensor and passenger- WARNING:Paper must not be thicker than male terminal. If paper is thicker,

connector terminal may be damaged, possible resulting in system

fault.

NOTE: Use Diagnosis Check Wiring (09843-18020) when connecting jumper wire

between terminals of DLC. Spiral cable upper connector is same as steering

wheel pad (squib) connector. Spiral cable lower connector (located under

steering column) connects the harness between spiral cable and center air bag

sensor.

NOTE: During testing, if codes other than Code 11 are displayed, disregard them.

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 22 © 2005 Mitchell Repair Information Company, LLC.

Page 91 of 1632

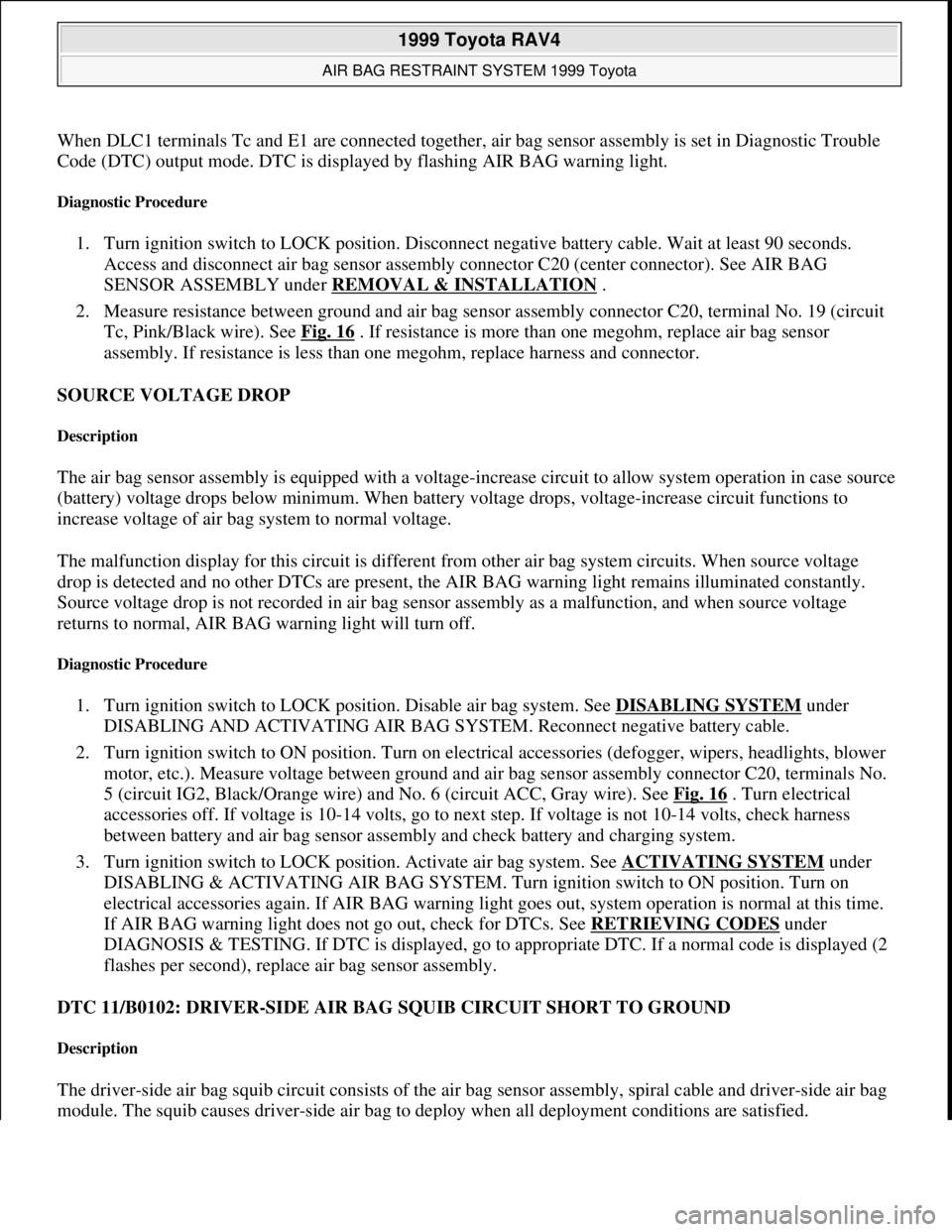

When DLC1 terminals Tc and E1 are connected together, air bag sensor assembly is set in Diagnostic Trouble

Code (DTC) output mode. DTC is displayed by flashing AIR BAG warning light.

Diagnostic Procedure

1. Turn ignition switch to LOCK position. Disconnect negative battery cable. Wait at least 90 seconds.

Access and disconnect air bag sensor assembly connector C20 (center connector). See AIR BAG

SENSOR ASSEMBLY under REMOVAL & INSTALLATION

.

2. Measure resistance between ground and air bag sensor assembly connector C20, terminal No. 19 (circuit

Tc, Pink/Black wire). See Fig. 16

. If resistance is more than one megohm, replace air bag sensor

assembly. If resistance is less than one megohm, replace harness and connector.

SOURCE VOLTAGE DROP

Description

The air bag sensor assembly is equipped with a voltage-increase circuit to allow system operation in case source

(battery) voltage drops below minimum. When battery voltage drops, voltage-increase circuit functions to

increase voltage of air bag system to normal voltage.

The malfunction display for this circuit is different from other air bag system circuits. When source voltage

drop is detected and no other DTCs are present, the AIR BAG warning light remains illuminated constantly.

Source voltage drop is not recorded in air bag sensor assembly as a malfunction, and when source voltage

returns to normal, AIR BAG warning light will turn off.

Diagnostic Procedure

1. Turn ignition switch to LOCK position. Disable air bag system. See DISABLING SYSTEM under

DISABLING AND ACTIVATING AIR BAG SYSTEM. Reconnect negative battery cable.

2. Turn ignition switch to ON position. Turn on electrical accessories (defogger, wipers, headlights, blower

motor, etc.). Measure voltage between ground and air bag sensor assembly connector C20, terminals No.

5 (circuit IG2, Black/Orange wire) and No. 6 (circuit ACC, Gray wire). See Fig. 16

. Turn electrical

accessories off. If voltage is 10-14 volts, go to next step. If voltage is not 10-14 volts, check harness

between battery and air bag sensor assembly and check battery and charging system.

3. Turn ignition switch to LOCK position. Activate air bag system. See ACTIVATING SYSTEM

under

DISABLING & ACTIVATING AIR BAG SYSTEM. Turn ignition switch to ON position. Turn on

electrical accessories again. If AIR BAG warning light goes out, system operation is normal at this time.

If AIR BAG warning light does not go out, check for DTCs. See RETRIEVING CODES

under

DIAGNOSIS & TESTING. If DTC is displayed, go to appropriate DTC. If a normal code is displayed (2

flashes per second), replace air bag sensor assembly.

DTC 11/B0102: DRIVER-SIDE AIR BAG SQUIB CIRCUIT SHORT TO GROUND

Description

The driver-side air bag squib circuit consists of the air bag sensor assembly, spiral cable and driver-side air bag

module. The squib causes drive

r-side air bag to deploy when all deployment conditions are satisfied.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:23 AMPage 28 © 2005 Mitchell Repair Information Company, LLC.

Page 389 of 1632

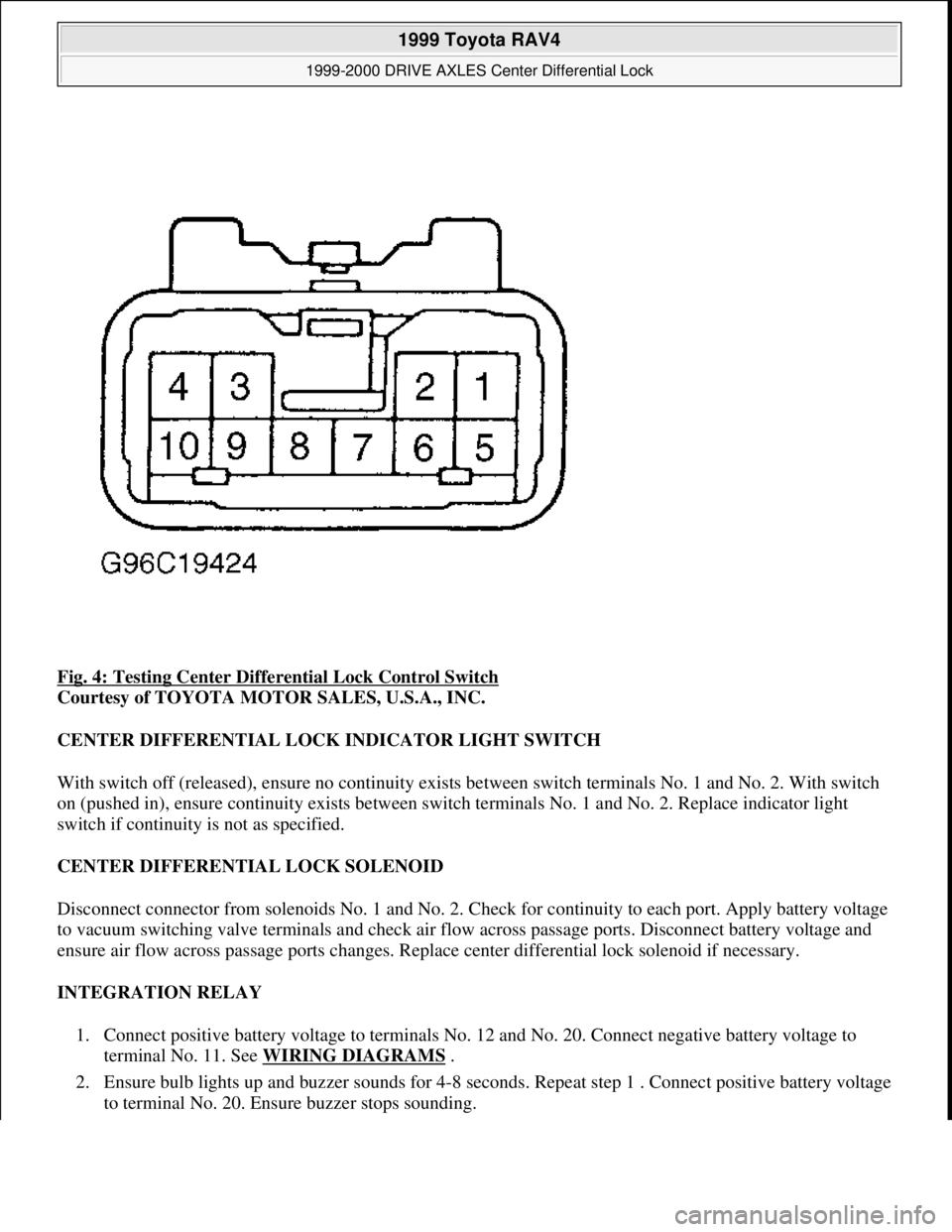

Fig. 4: Testing Center Differential Lock Control Switch

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

CENTER DIFFERENTIAL LOCK INDICATOR LIGHT SWITCH

With switch off (released), ensure no continuity exists between switch terminals No. 1 and No. 2. With switch

on (pushed in), ensure continuity exists between switch terminals No. 1 and No. 2. Replace indicator light

switch if continuity is not as specified.

CENTER DIFFERENTIAL LOCK SOLENOID

Disconnect connector from solenoids No. 1 and No. 2. Check for continuity to each port. Apply battery voltage

to vacuum switching valve terminals and check air flow across passage ports. Disconnect battery voltage and

ensure air flow across passage ports changes. Replace center differential lock solenoid if necessary.

INTEGRATION RELAY

1. Connect positive battery voltage to terminals No. 12 and No. 20. Connect negative battery voltage to

terminal No. 11. See WIRING DIAGRAMS

.

2. Ensure bulb lights up and buzzer sounds for 4-8 seconds. Repeat step 1 . Connect positive battery voltage

to terminal No. 20. Ensure buzzer stops sounding.

1999 Toyota RAV4

1999-2000 DRIVE AXLES Center Differential Lock

Microsoft

Sunday, November 22, 2009 10:08:59 AMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 407 of 1632

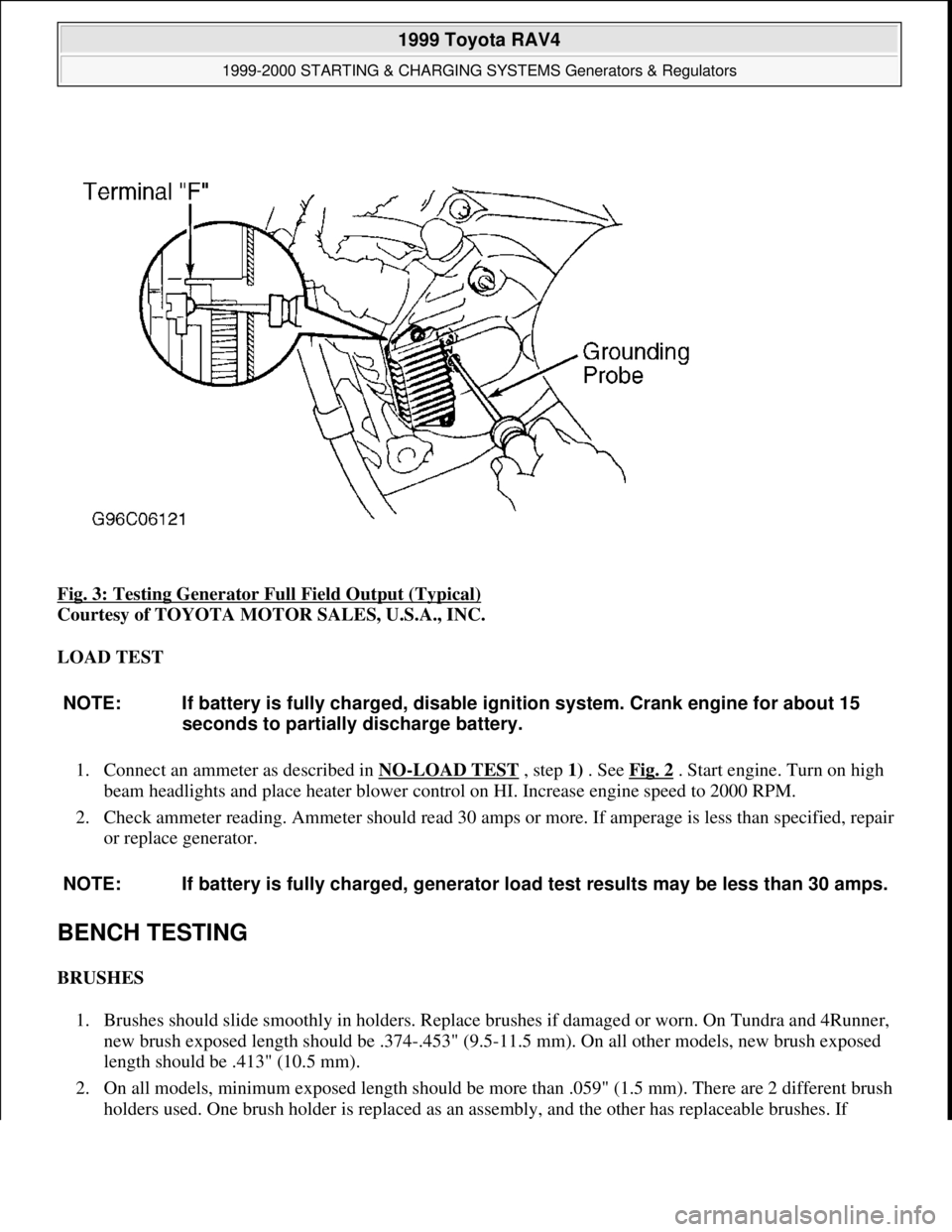

Fig. 3: Testing Generator Full Field Output (Typical)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

LOAD TEST

1. Connect an ammeter as described in NO

-LOAD TEST , step 1) . See Fig. 2 . Start engine. Turn on high

beam headlights and place heater blower control on HI. Increase engine speed to 2000 RPM.

2. Check ammeter reading. Ammeter should read 30 amps or more. If amperage is less than specified, repair

or replace generator.

BENCH TESTING

BRUSHES

1. Brushes should slide smoothly in holders. Replace brushes if damaged or worn. On Tundra and 4Runner,

new brush exposed length should be .374-.453" (9.5-11.5 mm). On all other models, new brush exposed

length should be .413" (10.5 mm).

2. On all models, minimum exposed length should be more than .059" (1.5 mm). There are 2 different brush

holders used. One brush holder is replaced as an assembl

y, and the other has replaceable brushes. If

NOTE: If battery is fully charged, disable ignition system. Crank engine for about 15

seconds to partially discharge battery.

NOTE: If battery is fully charged, generator load test results may be less than 30 amps.

1999 Toyota RAV4

1999-2000 STARTING & CHARGING SYSTEMS Generators & Regulators

Microsoft

Sunday, November 22, 2009 10:13:07 AMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 535 of 1632

1. Check stoplight operation. If stoplight operation is okay, go to next step. If stoplights DO NOT operate

correctly, check and repair stoplight system as necessary. See WIRING DIAGRAMS

.

2. Perform CANCEL SWITCHES test under CRUISE CONTROL FUNCTION TEST

under TROUBLE

SHOOTING. If stoplight input signal is not as specified, go to next step. If stoplight input signal is as

specified, no problem is indicated at this time. Fault may be intermittent. If sent here from SYMPTOM

DIAGNOSIS, perform next test listed.

3. Remove cruise control ECU with connector attached. See Fig. 1

. Turn ignition switch to ON position.

Backprobing cruise control ECU connector, measure voltage between ground and cruise control ECU

connector terminal No. 2 (Green/White wire). With brake pedal depressed, battery voltage should exist.

With brake pedal released, voltage should be less than one volt. If voltage is not as specified, go to next

step. If voltage is as specified, no problem is indicated at this time. Fault may be intermittent. If sent here

from SYMPTOM DIAGNOSIS, perform next test listed.

4. Check for open circuit in wiring harness and connectors between cruise control ECU and stoplight switch.

Repair as necessary and retest system. If wiring harness and connectors are okay, replace cruise control

ECU and retest system.

IDLE SIGNAL CIRCUIT

1. Remove cruise control ECU with connector attached. Disconnect Engine Control Module (ECM) 16-pin

connector. ECM is located behind bottom center of instrument panel, in front of console. Turn ignition

switch to ON position. Backprobing connector, measure voltage between ground and cruise control ECU

connector terminal No. 13 (Blue wire).

2. With throttle valve fully open, battery voltage should exist. With throttle valve fully closed, voltage

should be less than 2 volts. If voltage is not as specified, go to next step. If voltage is as specified, no

problem is indicated at this time. Fault may be intermittent. If sent here from SYMPTOM DIAGNOSIS,

perform next test listed.

3. Check wiring harness and connectors between ECM and TP sensor. Repair as necessary and retest

system. If wiring harness and connectors are okay, go to next step.

4. Disconnect TP sensor 3-pin Black connector. Measure resistance between TP sensor connector terminals

No. 2 (Brown wire) and No. 3 (Blue/Red wire). Resistance should be 2000-10,200 ohms with throttle

valve fully opened, and 200-6300 ohms with throttle valve fully closed. If resistance is as specified, go to

next step. If resistance is not as specified, replace TP sensor and retest system.

5. Check wiring harness and connectors between cruise control ECU and TP sensor, and between TP sensor

and ground. Repair as necessary and retest system. If wiring harness and connectors are okay, replace

cruise control ECU and retest system.

ELECTRONICALLY CONTROLLED TRANSMISSION (ECT) CIRCUIT

1. Start engine and bring to operating temperature. Drive vehicle and ensure overdrive operation is turned on

and off when overdrive ON-OFF switch is operated. If overdrive switch is okay, go to next step. If

overdrive switch is not okay, see appropriate ELECTRONIC CONTROLS article in AUTOMATIC NOTE: Ensure Throttle Position (TP) sensor circuit is operating as designed, and no

fault codes are present for TP sensor circuit. See appropriate ON-VEHICLE

ADJUSTMENTS article in ENGINE PERFORMANCE.

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Cruise Control Systems - RAV4

Microsoft

Sunday, November 22, 2009 10:52:01 AMPage 11 © 2005 Mitchell Repair Information Company, LLC.

Page 891 of 1632

1999-2000 ACCESSORIES & EQUIPMENT

Instrument Panels - Trucks

DESCRIPTION & OPERATION

GAUGES

Standard instrument clusters contain fuel and temperature gauges with telltale warning lights. Some optional

instrument panels are equipped with a tachometer, oil pressure gauge and voltmeter. Gauge internal operating

components use either a 2-terminal bimetallic strip type or a 3-terminal coil type. The 2-terminal type gauges

are generally used on clusters without tachometers.

SWITCHES

All models contain hazard warning switch on instrument panel. All models use a combination switch for

headlight, turn signal, wiper/washer, and cruise control switches. Combination switch is mounted on steering

column. For testing and/or removal and installation procedures for combination switch components, see

appropriate STEERING COLUMN SWITCHES article.

COMPONENT TESTS

A/T OIL TEMPERATURE SWITCH

RAV4

1. Turn ignition switch to OFF position. Disconnect A/T oil temperature switch 1-pin connector. Switch is

located on side of transaxle, near park/neutral position switch. Remove A/T oil temperature switch. Place

probe end of switch and thermometer in a container of water.

2. Connect an ohmmeter between switch terminal and switch body. Heat water and check for continuity.

With temperature at 284-302°F (140-150°C), continuity should exist. If continuity does not exist, replace

switch.

A/T OIL TEMPERATURE WARNING LIGHT

RAV4

Disconnect A/T oil temperature switch connector. Switch is located on side of transaxle, near park/neutral

position switch. Using a jumper wire, connect switch connector terminal to ground. Turn ignition switch to ON

position. A/T oil temperature warning light should be on. If warning light is off, check bulb and wiring harness.

Repair as necessary. WARNING:Deactivate air bag system before performing any service operation. See

AIR BAG RESTRAINT SYSTEMS article. DO NOT apply electrical power to

any component on steering column without first deactivating air bag

system. Air bag may deploy.

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:09 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:54:14 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 950 of 1632

On models equipped with anti-lock brake systems, ALWAYS observe the following cautions:

DO NOT attempt to bleed hydraulic system without first referring to the appropriate ANTI-LOCK

BRAKE SYSTEM article in the BRAKES Section.

DO NOT mix tire sizes. As long as tires remain close to the original diameter, increasing the width is

acceptable. Rolling diameter must be identical for all 4 tires. Some manufacturers recommend tires of the

same brand, style and type. Failure to follow this precaution may cause inaccurate wheel speed readings.

Use ONLY recommended brake fluids. DO NOT use silicone brake fluids in an ABS-equipped vehicle.

BATTERY WARNING

REPLACING BLOWN FUSES

BRAKE PAD WEAR INDICATOR

Indicator will cause a squealing or scraping noise, warning that brake pads need replacement.

CATALYTIC CONVERTER CAUTION: The anti-lock brake system contains electronic equipment that can be

susceptible to interference caused by improperly installed or high output

radio transmitting equipment. Since this interference could cause the

possible loss of the anti-lock braking capability, such equipment should

be installed by qualified professionals.

WARNING:When battery is disconnected, vehicles equipped with computers may

lose memory data. When battery power is restored, driveability problems

may exist on some vehicles. These vehicles may require a relearn

procedure. See COMPUTER RELEARN PROCEDURES article in GENERAL

INFORMATION section.

CAUTION: Before replacing a blown fuse, remove ignition key, turn off all lights and

accessories to avoid damaging the electrical system. Be sure to use fuse

with the correct indicated amperage rating. The use of an incorrect

amperage rating fuse may result in a dangerous electrical system

overload.

CAUTION: Continued operation of vehicle with a severe malfunction could cause

converter to overheat, resulting in possible damage to converter and

vehicle.

CAUTION: Any modification to the exhaust system on turbo models, which reduces

exhaust backpressure, will lead to lean fuel mixtures and excessive spark

advance. This could cause serious engine damage.

1999 Toyota RAV4

MAINTENANCE INFORMATION 1997-99 MAINTENANCE Toyota Maintenance Information

Microsoft

Sunday, November 22, 2009 10:32:42 AMPage 8 © 2005 Mitchell Repair Information Company, LLC.

Page 968 of 1632

System

2 - DOME 15 Amp Personal Lights, Open Door Warning Light, Clock

3 - EFI 15 Amp Multiport Fuel Injection System/Sequential Multiport Fuel Injection System

4 - HAZ-HORN 15 Amp Emergency Flashers, Horns

5 - ALT-S 5 Amp Charging system

6 - SPARE 15 Amp Spare fuse

7 - SPARE 7.5 Amp Spare fues

8 - H-LP (LH) 15 Amp Left-Hand Headlight

9 - H-LP (RH) 15 Amp Right-Hand Headlight

10 - DRL 7.5 Amp Daytime Running Light System

11 - H-LP LH-L 10 Amp Left Hand Headlight (Low Beam)

12 - H-LP RH-L 10 Amp Right Hand Headlight (Low Beam)

13 - H-LP LH-H 10 Amp Left Hand Headlight (High Beam)

14 - H-LP RH-H 10 Amp Right Hand Headlight (High Beam)

15 - TAIL 10 Amp Tail Lights, Parking Lights, License Plate Lights, Interior Lights

16 - GAUGE 10 Amp Gauges And Meters, Service Reminder Indicators (Except Discharge And Open

Door Warning Lights), Back-up Lights, Air Conditioning System, Power Windows, Rear Window

Defogger, Center Differential Lock System, Electronically Controlled Automatic Transaxle System

17 - TURN 7.5 Amp Turn Signal Lights

18 - CIG & RAD 15 Amp Cigarette Lighter, Clock, Car Audio System, Power Rear View Mirrors

19 - DEF-I/UP 7.5 Amp Multiport Fuel Injection System/Sequential Multiport Fuel Injection System

20 - IGN 7.5 Amp Multiport Fuel Injection System/Sequential Multiport Fuel Injection System,

Discharge Warning Light

21 - ECU-IG 7.5 Amp Anti-Lock Brake Syste, Electronically Controlled Automatic Transmission

System

22 - WIPER 20 Amp Windshield Wipers And Washer, Rear Window Wiper And Washer

23 - SRS 7.5 Amp SRS Airbag System

24 - OBD 7.5 Amp On-Board Diagnostic System

25 - STOP 10 Amp Stop Lights

26 - A/C 7.5 Amp Air Conditioning System

27 - MAIN No. 1 30 Amp Starting System, Headlights

28 - RDI FAN 30 Amp Electric Cooling Fan

29 - CDS FAN 30 Amp Electric Cooling Fan

30 - POWER 30 Amp Power Windows, Power Door Lock System

31 - DEF 30 Amp Rear Window Defogger

32 - AM 1 40 Amp CIG & RAD, WIPER, GAUGE, ECU-IG, TURN, TAIL, and PANEL fuses

33 - MAIN 80 Amp AM 2, HAZ-HORN, EFI, DOME, RADIO and ALT-S fuses

34 - ALT 100 Amp Tail lights, ABS, RADIO, HTR, AM 1, POWER, STOP and DEF fuses

1999 Toyota RAV4

MAINTENANCE INFORMATION 1997-99 MAINTENANCE Toyota Maintenance Information

Microsoft

Sunday, November 22, 2009 10:32:42 AMPage 26 © 2005 Mitchell Repair Information Company, LLC.