ESP TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 37 of 1632

The air bag sensor, which deploys air bags, contains a back-up power supply, safing sensor and diagnostic code

memory. Spiral cable (clockspring) maintains a complete circuit to the steering wheel pad.

SYSTEM OPERATION CHECK

Turn ignition switch to ACC or ON position. Air bag warning light in instrument cluster should come on for

about 6 seconds and then go out. If light does not respond as specified, SRS is malfunctioning and needs repair.

See DIAGNOSIS

.

SERVICE PRECAUTIONS

Observe the following precautions when working on SRS:

Before servicing any SRS or steering column component, disable SRS. See DISABLING &

ACTIVATING AIR BAG SYSTEM . Failure to disable system could result in accidental air bag

deployment and personal injury.

When diagnosing SRS, always check for diagnostic codes before disconnecting battery.

After ignition switch is turned to LOCK position and negative battery cable is disconnected, wait at least

90 seconds before working on SRS. SRS is equipped with a back-up power source that may allow air bag

to deploy within 90 seconds of disconnecting negative battery cable.

In a minor collision in which air bags do not deploy, steering wheel pad must be inspected.

NEVER use air bag parts from another vehicle. Replace air bag parts with new parts.

Air bag sensor assembly contains mercury. After replacement, DO NOT destroy the old part. When

scrapping vehicle or replacing air bag sensor assembly, remove air bag sensor assembly and dispose of as

toxic waste.

Never disassemble or repair system components. Replace cracked, dented or otherwise damaged system

components.

Remove air bag sensor if shocks are likely to be applied to the sensor during repairs.

When diagnosing electrical circuits, use a Digital Volt/Ohmmeter (DVOM) with high impedance (10,000

ohms minimum).

Information labels are attached to air bag components. Follow all notices on labels.

After servicing SRS, check air bag warning light to ensure system is functioning properly. See SYSTEM

OPERATION CHECK .

Always wear safety glasses when servicing or handling an air bag.

When placing a live air bag on a bench or other surface, always face air bag and trim cover up, away from

surface. This will reduce motion of module if accidentally deployed.

After deployment, air bag surface may contain deposits of sodium hydroxide which irritates skin. During

clean-up, always wear safety glasses, rubber gloves and long-sleeved shirt. After clean-up, wash hands

using mild soap and water.

When carrying a live air bag module, trim cover must be pointed away from your body to minimize

injury in case of accidental deployment.

If SRS is not fully functional for any reason, vehicle should not be driven until system is repaired and

a

gain becomes operational. DO NOTremove bulbs, modules, sensors or other components or in any way

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 49 of 1632

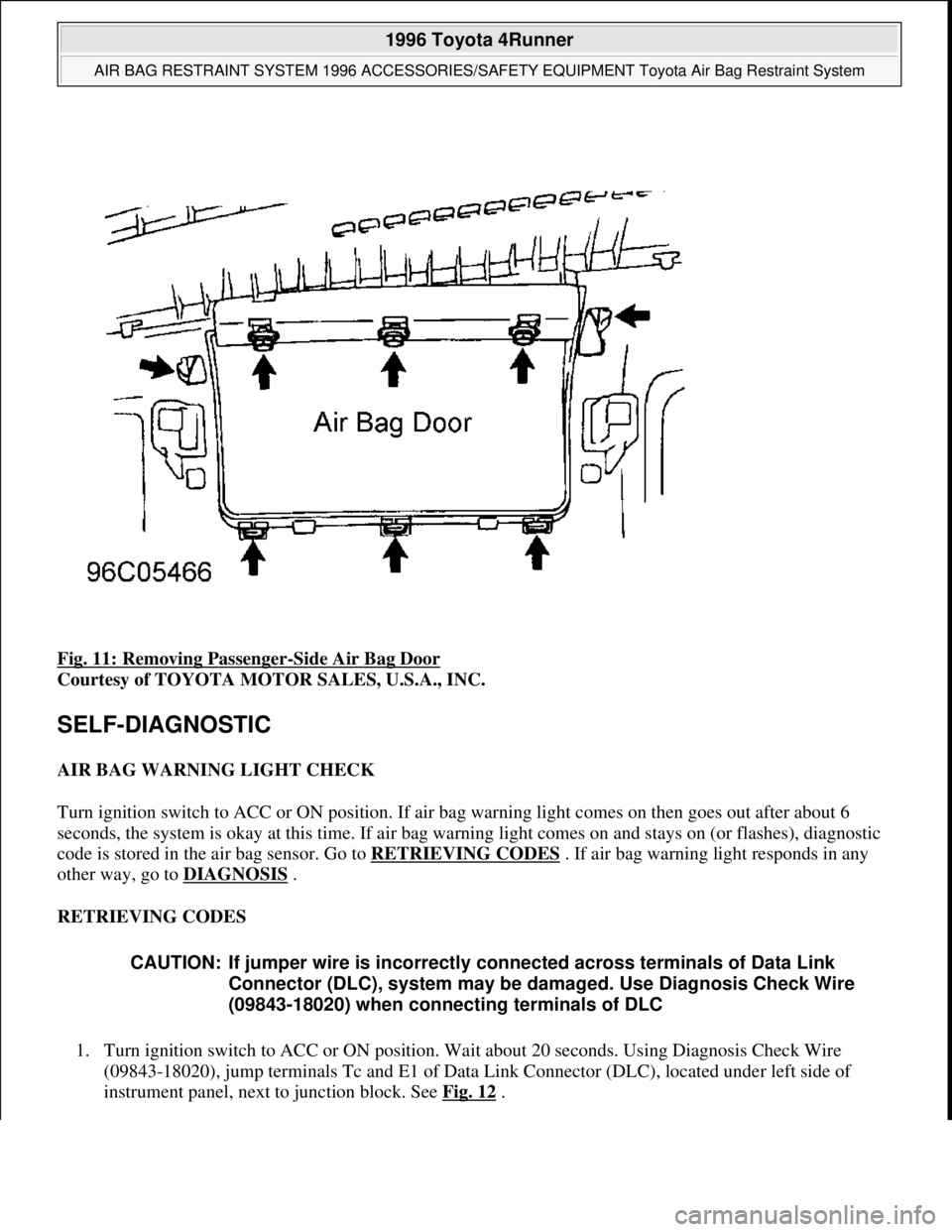

Fig. 11: Removing Passenger-Side Air Bag Door

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

SELF-DIAGNOSTIC

AIR BAG WARNING LIGHT CHECK

Turn ignition switch to ACC or ON position. If air bag warning light comes on then goes out after about 6

seconds, the system is okay at this time. If air bag warning light comes on and stays on (or flashes), diagnostic

code is stored in the air bag sensor. Go to RETRIEVING CODES

. If air bag warning light responds in any

other way, go to DIAGNOSIS

.

RETRIEVING CODES

1. Turn ignition switch to ACC or ON position. Wait about 20 seconds. Using Diagnosis Check Wire

(09843-18020), jump terminals Tc and E1 of Data Link Connector (DLC), located under left side of

instrument panel, next to junction block. See Fig. 12

.

CAUTION: If jumper wire is incorrectly connected across terminals of Data Link

Connector (DLC), system may be damaged. Use Diagnosis Check Wire

(09843-18020) when connecting terminals of DLC

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 15 © 2005 Mitchell Repair Information Company, LLC.

Page 83 of 1632

1. Before proceeding, see SERVICE PRECAUTIONS . Ensure front wheels are in straight-ahead position.

Turn ignition switch to LOCK position. Disconnect negative battery cable. Wait at least 90 seconds.

Remove steering wheel. See STEERING WHEEL

.

2. Remove lower finish panel and instrument panel lower insert. Remove upper and lower steering column

covers. Disconnect and remove combination switch with spiral cable attached. Remove heater-to-register

duct. Match mark steering shaft and steering gear shaft for reassembly performance. Remove steering

column.

3. To install, reverse removal procedure. Tighten fasteners to specification. See TORQUE

SPECIFICATIONS . Check AIR BAG warning light to ensure system is functioning properly. See

SYSTEM OPERATION CHECK

.

STEERING WHEEL

Removal & Installation

1. Before proceeding, see SERVICE PRECAUTIONS . Ensure front wheels are in straight-ahead position.

Turn ignition switch to LOCK position. Disconnect negative battery cable. Wait at least 90 seconds.

Remove driver-side air bag module. See DRIVER

-SIDE AIR BAG MODULE .

2. Remove steering wheel nut. Match mark steering wheel and steering column for reassembly reference.

Using appropriate puller, remove steering wheel.

3. To install, reverse removal procedure. Ensure front wheels are in straight-ahead position and spiral cable

is properly aligned. See SPIRAL CABLE under ADJUSTMENTS

. Tighten steering wheel nut and

driver-side air bag module screws to specification. See TORQUE SPECIFICATIONS

. Check AIR

BAG warning light to ensure system is functioning properly. See SYSTEM OPERATION CHECK

.

SYSTEM OPERATION CHECK

Turn ignition switch to ACC or ON position. AIR BAG warning light should come on for about 6 seconds and

then go out. If AIR BAG warning light does not operate as specified, see DIAGNOSIS & TESTING

.

DIAGNOSIS & TESTING

AIR BAG WARNING LIGHT CHECK

Turn ignition switch to ACC or ON position. If air bag warning light comes on for about 6 seconds and then

goes off, system is functioning properly. If AIR BAG warning light comes on and stays on (or flashes),

Diagnostic Trouble Code (DTC) is stored in air bag sensor assembly. Go to RETRIEVING CODES

. If AIR

BAG warning light responds in any other way, go to DIAGNOSTIC TESTS

.

RETRIEVING CODES

CAUTION: System may be damaged if jumper wire is incorrectly connected across

terminals of Data Link Connector (DLC1). Use Diagnosis Check Wire

(09843-18020) when connecting terminals of DLC1.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:22 AMPage 20 © 2005 Mitchell Repair Information Company, LLC.

Page 203 of 1632

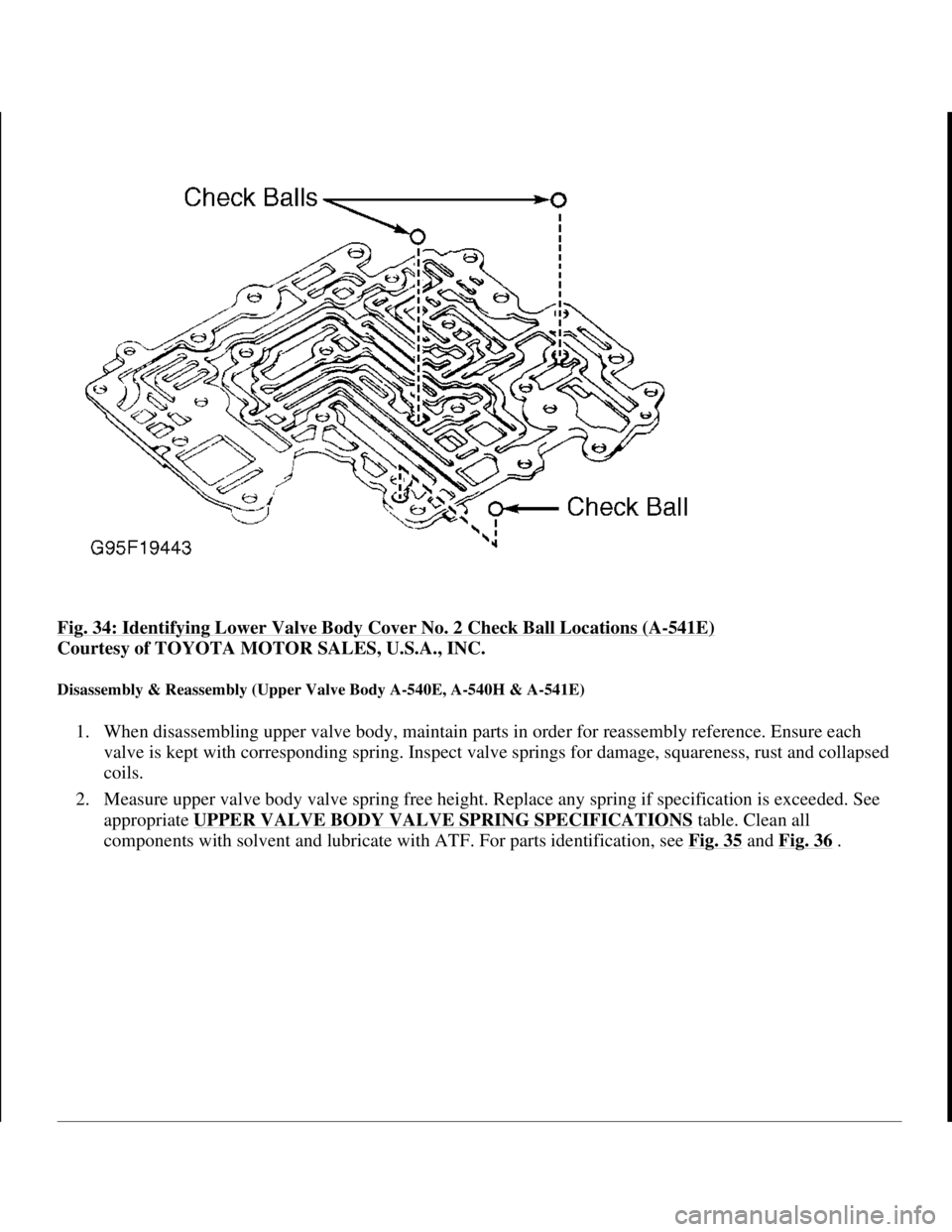

Fig. 34: Identifying Lower Valve Body Cover No. 2 Check Ball Locations (A-541E)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Disassembly & Reassembly (Upper Valve Body A-540E, A-540H & A-541E)

1. When disassembling upper valve body, maintain parts in order for reassembly reference. Ensure each

valve is kept with corresponding spring. Inspect valve springs for damage, squareness, rust and collapsed

coils.

2. Measure upper valve body valve spring free height. Replace any spring if specification is exceeded. See

appropriate UPPER VALVE BODY VALVE SPRING SPECIFICATIONS

table. Clean all

components with solvent and lubricate with ATF. For parts identification, see Fig. 35

and Fig. 36.

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:18 AMPage 49 © 2005 Mitchell Repair Information Company, LLC.

Page 206 of 1632

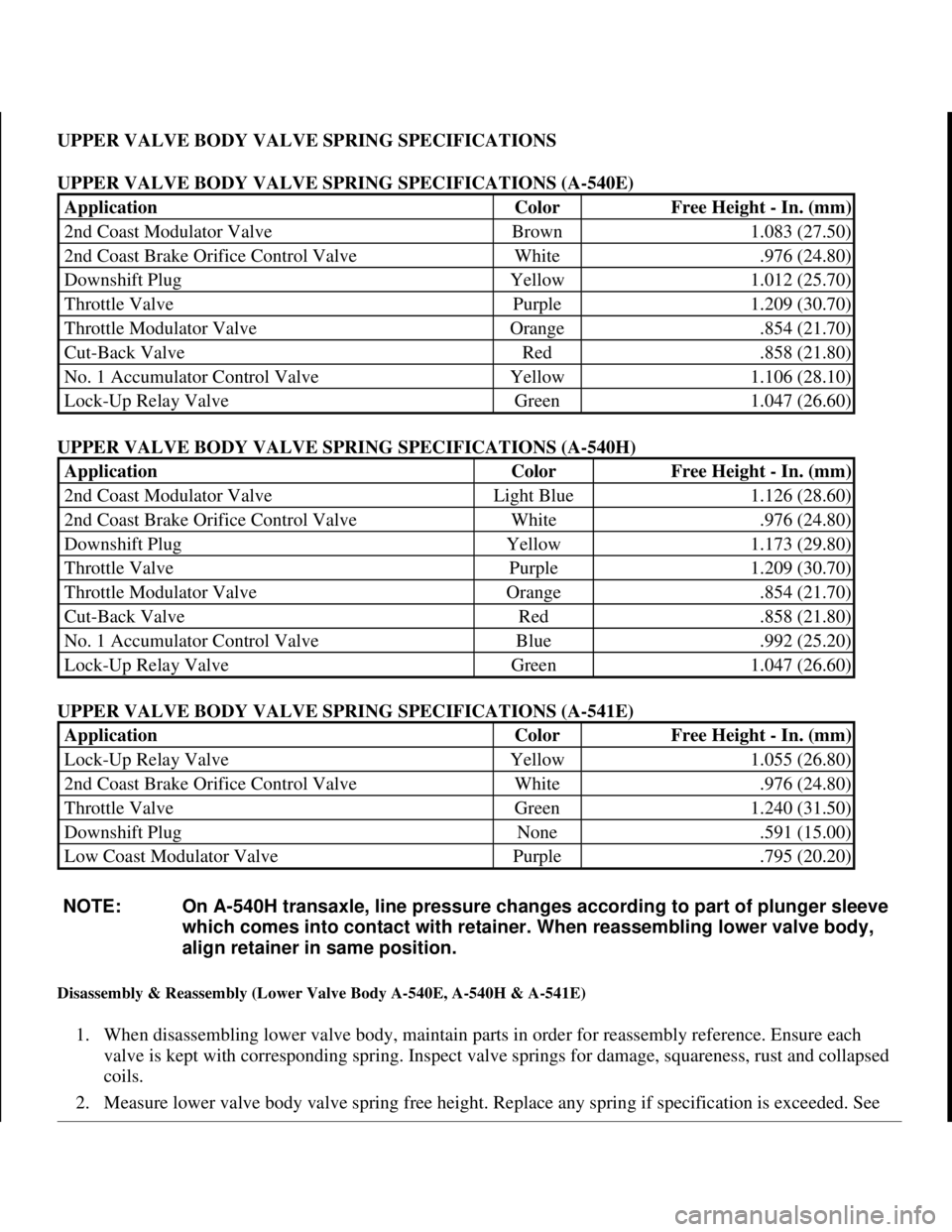

UPPER VALVE BODY VALVE SPRING SPECIFICATIONS

UPPER VALVE BODY VALVE SPRING SPECIFICATIONS (A-540E)

UPPER VALVE BODY VALVE SPRING SPECIFICATIONS (A-540H)

UPPER VALVE BODY VALVE SPRING SPECIFICATIONS (A-541E)

Disassembly & Reassembly (Lower Valve Body A-540E, A-540H & A-541E)

1. When disassembling lower valve body, maintain parts in order for reassembly reference. Ensure each

valve is kept with corresponding spring. Inspect valve springs for damage, squareness, rust and collapsed

coils.

2. Measure lower valve bod

y valve spring free height. Replace any spring if specification is exceeded. See

ApplicationColorFree Height - In. (mm)

2nd Coast Modulator ValveBrown1.083 (27.50)

2nd Coast Brake Orifice Control ValveWhite.976 (24.80)

Downshift PlugYellow1.012 (25.70)

Throttle ValvePurple1.209 (30.70)

Throttle Modulator ValveOrange.854 (21.70)

Cut-Back ValveRed.858 (21.80)

No. 1 Accumulator Control ValveYellow1.106 (28.10)

Lock-Up Relay ValveGreen1.047 (26.60)

ApplicationColorFree Height - In. (mm)

2nd Coast Modulator ValveLight Blue1.126 (28.60)

2nd Coast Brake Orifice Control ValveWhite.976 (24.80)

Downshift PlugYellow1.173 (29.80)

Throttle ValvePurple1.209 (30.70)

Throttle Modulator ValveOrange.854 (21.70)

Cut-Back ValveRed.858 (21.80)

No. 1 Accumulator Control ValveBlue.992 (25.20)

Lock-Up Relay ValveGreen1.047 (26.60)

ApplicationColorFree Height - In. (mm)

Lock-Up Relay ValveYellow1.055 (26.80)

2nd Coast Brake Orifice Control ValveWhite.976 (24.80)

Throttle ValveGreen1.240 (31.50)

Downshift PlugNone.591 (15.00)

Low Coast Modulator ValvePurple.795 (20.20)

NOTE: On A-540H transaxle, line pressure changes according to part of plunger sleeve

which comes into contact with retainer. When reassembling lower valve body,

align retainer in same position.

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:18 AMPage 52 © 2005 Mitchell Repair Information Company, LLC.

Page 235 of 1632

Disassembly

1. Using appropriate puller, remove differential case side bearings. Remove speedometer drive gear. Place

reference marks on differential case and ring gear. Remove ring gear bolts. Using soft-face hammer,

remove ring gear.

2. Mount differential in vise. Using dial indicator, measure pinion gear backlash. See Fig. 61

. Backlash

should be .002-.008" (.05-.20 mm). From ring gear side of case, drive out pinion shaft roll pin. Remove

pinion shaft. Remove pinion gears, side gears and all thrust washers. See Fig. 62

. Examine all

components for wear and replace as needed.

Reassembly

1. Match side gears and pinion gears with corresponding thrust washers. Install gears in differential case.

Install pinion shaft. Check pinion gear backlash.

2. If backlash is not within specification, replace side gear thrust washers with matched set. Washers are

available in 3 thicknesses: .063" (1.60 mm), .067" (1.70 mm) and .071" (1.80 mm). Recheck backlash

after washers have been replaced.

3. Drive in pinion shaft roll pin. Ensure ring gear mounting surface is clean and free of burrs or scratches.

Heat ring gear in oil bath to 212°F (100°C). DO NOT exceed temperature. Install ring gear, aligning

reference marks made during disassembly. Tighten bolts to specification. See TORQUE

SPECIFICATIONS . Install speedometer drive gear. Press side bearing onto differential case. Lubricate

all moving parts with ATF.

1998 Toyota Avalon XLS

1997-99 AUTOMATIC TRANSMISSIONS Toyota A-540E, A-540H & A-541E Overhaul

Helpmelearn

November-03-08 10:28:19 AMPage 81 © 2005 Mitchell Repair Information Company, LLC.

Page 528 of 1632

If cruise control operation is canceled by any canceling switch, vehicle set speed can be resumed and controlled

at the previously set speed by moving cruise control switch to RES/ACC (resume/accelerate) position. Set

speed, however, cannot be resumed if vehicle speed drops to less than 25 MPH, which clears cruise control

ECU set speed stored.

When cruise control switch is moved to RES/ACC (resume/accelerate) position while in cruise control mode,

actuator motor is energized to open engine throttle valve. Vehicle accelerates until switch is released. From then

on, cruise control ECU stores new vehicle speed and maintains that speed.

Cancel Position

When cruise control switch is moved to CANCEL position, a cancellation signal is sent to cruise control ECU

disabling cruise control operation. Previous vehicle set speed is stored in cruise control ECU memory.

CRUISE CONTROL ELECTRONIC CONTROL UNIT (ECU)

Cruise control Electronic Control Unit (ECU) constantly monitors and compares set speed with actual vehicle

speed from input sensors. When vehicle speed is greater than set speed, cruise control ECU activates actuator

motor to close engine throttle valve, reducing vehicle speed. When vehicle speed drops to less than set speed,

cruise control ECU activates actuator motor to open engine throttle valve, increasing vehicle speed.

Cruise control ECU includes a self-diagnostic function. If cruise control system is canceled by any condition

other than driver operation, cruise control ECU assumes a malfunction has occurred and may set a

corresponding trouble code.

VEHICLE SPEED SENSOR

Vehicle speed sensor is mounted on transaxle. Vehicle speed sensor rotor shaft is driven by a gear on transaxle

output shaft. For each shaft rotation, vehicle speed sensor sends a 4-pulse signal to instrument cluster and cruise

control ECU. Cruise control ECU calculates vehicle speed from this pulse signal.

SELF-DIAGNOSTIC SYSTEM

When vehicle is in cruise control mode, system will cancel due to a malfunction in actuator, vehicle speed

sensor or other cruise circuit. When cruise control functions are canceled due to a malfunction, CRUISE

indicator light will blink, indicating a trouble code is stored in cruise control ECU memory. See DIAGNOSTIC

TROUBLE CODE DEFINITIONS table under SELF-DIAGNOSTIC SYSTEM.

If a fault or symptom is present, but no trouble codes were set, a system function test can be performed. See

CRUISE CONTROL FUNCTION TEST

under TROUBLE SHOOTING.

Before proceeding with cruise control system self-diagnostic system, ensure basic inspection of system

connectors and wiring harnesses has been performed. If no faults were found during basic inspection, proceed

with self-diagnostic system.

NOTE: Intermittent failures may cause CRUISE indicator light to flicker or come on.

Light will go out after fault goes away. Fault may or may not be present at time

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Cruise Control Systems - RAV4

Microsoft

Sunday, November 22, 2009 10:52:01 AMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 529 of 1632

ADJUSTMENTS

ACTUATOR CONTROL CABLE

Ensure actuator, control cable and throttle linkage are installed properly. Ensure actuator and bell crank operate

smoothly. Ensure cable is not too loose or tight. Cable free play should be less than .39" (10 mm). If control

cable is too loose, vehicle will lose speed while driving uphill. If control cable is too tight, idle RPM will

increase.

TROUBLE SHOOTING

CRUISE CONTROL FUNCTION TEST

Cruise control function test is used to help determine if cruise control circuits are functioning properly when no

trouble codes are present. To activate function test, turn ignition on. Push cruise control switch to SET/COAST

position and hold. Set cruise ON-OFF (main) switch to ON position. Ensure CRUISE indicator light comes on

and flashes after 3 seconds. Release cruise control switch from SET/COAST position. Activate each switch

circuit in order given. Normal function code will be displayed by CRUISE indicator light, as each circuit is

activated as follows:

SET/COAST Switch

Set cruise control switch to SET/COAST position and hold. If CRUISE control indicator light flashes 2 times

(repeating), indicating a normal Function Code 2, set/coast circuit is okay. Go to next step. If CRUISE control

indicator light does not flash 2 times (repeating), see SYMPTOM DIAGNOSIS

and perform appropriate test

(s).

RES/ACC Switch

Set cruise control switch to RES/ACC position and hold. If CRUISE control indicator light flashes 3 times

(repeating), indicating a normal Function Code 3, RES/ACCEL circuit is okay. Go to next step. If CRUISE

control indicator light does not flash 3 times (repeating), see SYMPTOM DIAGNOSIS

and perform

appropriate test(s).

CANCEL Switches

Observe CRUISE control indicator light and activate each cancel switch. Press CANCEL switch to ON and

OFF positions. Depress and release brake pedal. On A/T models, move shift lever from "D" to "N" position. On of testing. However, a corresponding trouble code may be stored in cruise

control ECU memory. See DIAGNOSTIC PROCEDURE

under SELF-DIAGNOSTIC

SYSTEM.

NOTE: Before performing CRUISE CONTROL FUNCTION TEST, perform DIAGNOSTIC

PROCEDURE under SELF-DIAGNOSTIC SYSTEM. Cruise control function test

should only be performed if no self-diagnostic trouble codes are present.

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Cruise Control Systems - RAV4

Microsoft

Sunday, November 22, 2009 10:52:01 AMPage 5 © 2005 Mitchell Repair Information Company, LLC.

Page 532 of 1632

Cruise Control Does Not Cancel Even With Clutch Pedal Depressed (M/T Only)

Check the following components and/or circuits:

Check actuator control cable adjustment. See ADJUSTMENTS .

Perform CLUTCH SWITCH CIRCUIT test under SYSTEM TESTS.

Perform DTC 11 OR DTC 15: ACTUATOR MOTOR CIRCUIT test under DIAGNOSTIC TESTS.

Replace cruise control ECU with a known-good ECU and retest. If symptom is no longer present, replace

ECU.

Cruise Control Switch Does Not Operate (SET/COAST, RES/ACC Or CANCEL Not Possible)

Check the following components and/or circuits:

Check actuator control cable adjustment. See ADJUSTMENTS .

Perform CRUISE CONTROL SWITCH CIRCUIT test under SYSTEM TESTS.

Perform DTC 11 OR DTC 15: ACTUATOR MOTOR CIRCUIT test under DIAGNOSTIC TESTS.

Replace cruise control ECU with a known-good ECU and retest. If symptom is no longer present, replace

ECU.

SET Possible at 25 MPH Or Less, Or CANCEL Does Not Operate At 25 MPH Or Less

Check the following components and/or circuits:

Check actuator control cable adjustment. See ADJUSTMENTS .

Perform DTC 23: VEHICLE SPEED SENSOR SIGNAL FAULT test under DIAGNOSTIC TESTS.

Perform DTC 11 OR DTC 15: ACTUATOR MOTOR CIRCUIT test under DIAGNOSTIC TESTS.

Replace cruise control ECU with a known-good ECU and retest. If symptom is no longer present, replace

ECU.

Poor Response In ACCEL & RESUME Modes

Check the following components and/or circuits:

Check actuator control cable adjustment. See ADJUSTMENTS .

Perform ELECTRONICALLY CONTROLLED TRANSMISSION (ECT) CIRCUIT test under

SYSTEM TESTS.

Perform DTC 11 OR DTC 15: ACTUATOR MOTOR CIRCUIT test under DIAGNOSTIC TESTS.

Replace cruise control ECU with a known-good ECU and retest. If symptom is no longer present, replace

ECU.

Overdrive Does Not Resume, Even Though Road Is Not Uphill

Check the following components and/or circuits:

1999 Toyota RAV4

1999 ACCESSORIES & EQUIPMENT Cruise Control Systems - RAV4

Microsoft

Sunday, November 22, 2009 10:52:01 AMPage 8 © 2005 Mitchell Repair Information Company, LLC.

Page 852 of 1632

Set control lever to correct position. See AIRFLOW MODE DAMPER CABLE ADJUSTMENTtable.

Remove cable retaining clip. Ensure airflow mode damper and cable are in their respective positions. Install

cable retaining clip.

AIRFLOW MODE DAMPER CABLE ADJUSTMENT

AIR MIX DAMPER CABLE

Set air door lever to cool position. Remove cable retaining clip. Ensure cable and damper are in full cool

position. Install cable retaining clip. Check air mix damper operation.

REAR HEAT DAMPER CABLE

4Runner

Set control lever to warm position. Remove cable retaining clip. Ensure cable and damper are in full warm

position. Install cable retaining clip.

WATER VALVE CONTROL CABLE

Set control lever to cool position. Remove cable retaining clip. Ensure water valve control cable is in full cool

position. Install cable retaining clip.

TROUBLE SHOOTING

BLOWER DOES NOT WORK

Inspect for blown heater fuse or faulty heater relay. Inspect heater blower switch, heater blower resistor, heater

blower motor, or wiring fault. See WIRING DIAGRAMS

.

INCORRECT TEMPERATURE OUTPUT

Inspect for broken or out of adjustment control cables, heater hoses leaking or clogged, or faulty water pump.

Inspect for broken air dampers, clogged air ducts, leaking or clogged heater core, or faulty heater control unit.

TESTING

ApplicationLever Position

Tacoma & 4RunnerFace

RAV4(1)

(1)Information is not available from manufacturer.

WARNING:To avoid injury from accidental air bag deployment, read and carefully

follow all SERVICE PRECAUTIONS and DISABLING & ACTIVATING AIR

BAG SYSTEM procedures in AIR BAG SYSTEM SAFETY article in

GENERAL SERVICING.

1999 Toyota RAV4

1999 HEATER SYSTEMS RAV4, Tacoma & 4Runner

Microsoft

Sunday, November 22, 2009 10:30:50 AMPage 2 © 2005 Mitchell Repair Information Company, LLC.