boot TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 76 of 1632

REMOVAL & INSTALLATION

AIR BAG SENSOR ASSEMBLY

Removal & Installation

1. Before proceeding, see SERVICE PRECAUTIONS . Air bag sensor assembly is located on the floor

inside center console box. See Fig. 10

. Turn ignition switch to LOCK position. Disconnect negative

battery cable. Wait at least 90 seconds.

2. Remove shift lever and boot. Ash tray and console box hole cover. Remove console box. Remove 4 Torx

screws retaining air bag sensor assembly. Remove air bag sensor assembly.

3. To install, reverse removal procedure. Tighten air bag sensor assembly Torx screws to specification. See

TORQUE SPECIFICATIONS

. Check AIR BAG warning light to ensure system is functioning

properl

y. See SYSTEM OPERATION CHECK. WARNING:Failure to follow service precautions may result in air bag deployment and

personal injury. See SERVICE PRECAUTIONS

. After component

replacement, check system operation. See SYSTEM OPERATION CHECK

.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:22 AMPage 13 © 2005 Mitchell Repair Information Company, LLC.

Page 126 of 1632

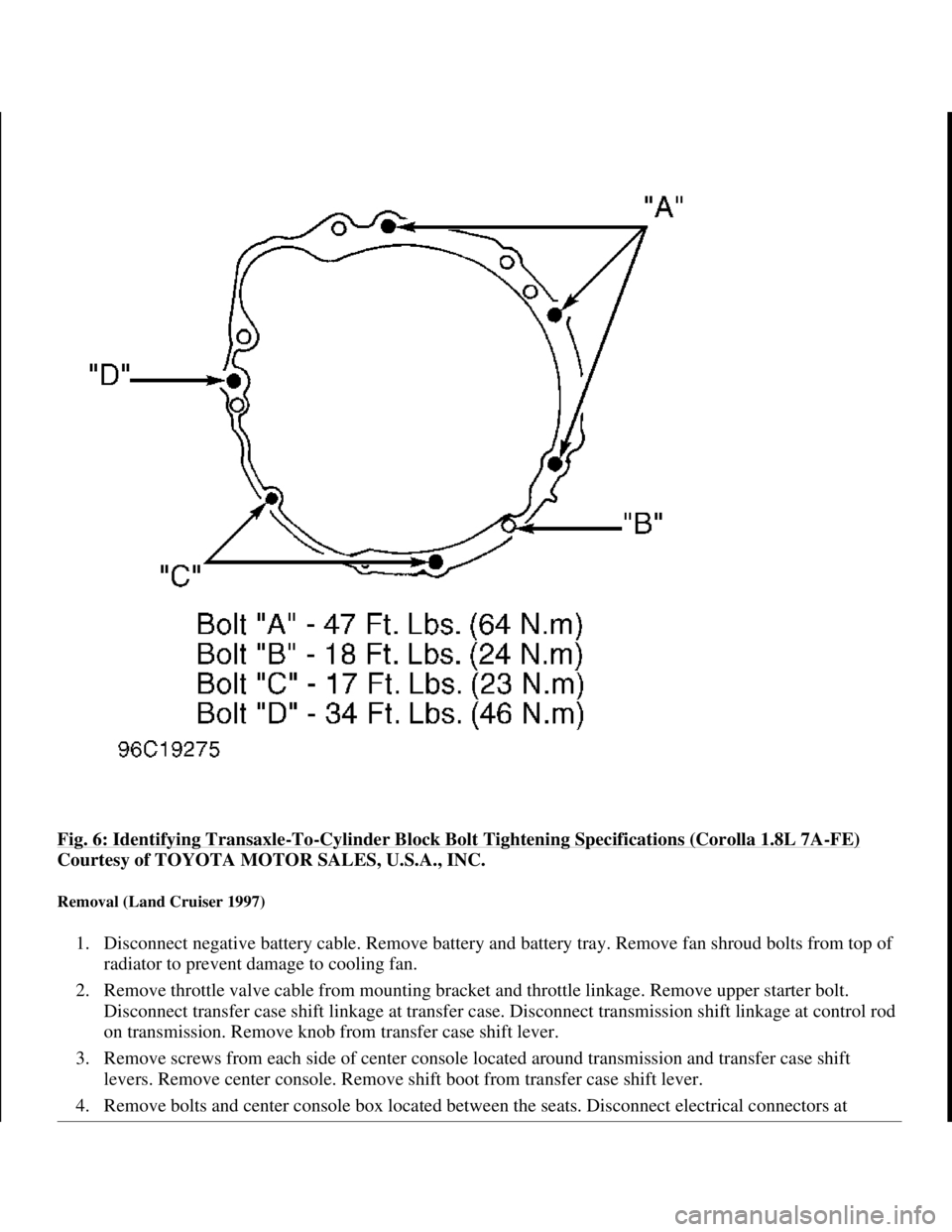

Fig. 6: Identifying Transaxle-To-Cylinder Block Bolt Tightening Specifications (Corolla 1.8L 7A-FE)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Removal (Land Cruiser 1997)

1. Disconnect negative battery cable. Remove battery and battery tray. Remove fan shroud bolts from top of

radiator to prevent damage to cooling fan.

2. Remove throttle valve cable from mounting bracket and throttle linkage. Remove upper starter bolt.

Disconnect transfer case shift linkage at transfer case. Disconnect transmission shift linkage at control rod

on transmission. Remove knob from transfer case shift lever.

3. Remove screws from each side of center console located around transmission and transfer case shift

levers. Remove center console. Remove shift boot from transfer case shift lever.

4. Remove bolts and center console box located between the seats. Disconnect electrical connectors at

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:28 AMPage 14 © 2005 Mitchell Repair Information Company, LLC.

Page 128 of 1632

clutch, fan shroud and radiator. Remove transmission dipstick. Remove dipstick tube upper bolt.

Disconnect 2 bleeder hoses.

2. Remove knob from transfer case shift lever. Remove upper console panel. Remove 4 boots to transfer

shift lever boot and remove shift lever boot. Raise and support vehicle. Remove 2 lower engine covers.

Remove exhaust pipes as necessary. Place reference marks on drive shaft flanges for reassembly

reference. Remove bolts and all drive shafts.

3. Remove dipstick tube lower bolt. Remove dipstick tube and "O" ring. Remove nut and plate washer, and

disconnect transmission shift control rod. Remove clip, plate washer and collar, and disconnect transfer

shift lever rod assembly. Disconnect all necessary electrical connectors for transmission and transfer case

removal. Remove 2 bolts and cover from front of transmission for access to torque converter bolts.

Remove torque converter bolts. Remove oil cooler pipe union nuts and pipe bracket bolt from

transmission.

4. Support transmission with transmission jack. Remove 8 bolts and 2 nuts from crossmember and remove

crossmember. Lower rear of transmission. Remove transmission wire clamp bolt. Remove 10

transmission-to-cylinder block bolts. Lower transmission with transfer case from vehicle.

Installation

1. Before installing transmission, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transmission. To ensure torque converter is fully seated, torque converter

depth should be checked. Using straightedge and caliper, measure torque converter depth from torque

converter bolt lug on torque converter to the surface on transmission. See Fig. 1

.

3. Torque converter depth should be more than .673" (17.10 mm). If torque converter depth is less than

specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installing. Ensure the Green torque converter bolt is installed first before installing the

remaining torque converter bolts.

5. Install NEW "O" ring on dipstick tube. Use NEW gaskets and NEW nuts when installing front exhaust

pipe. Fill cooling system and check for leaks. Adjust shift linkages and fill with ATF. See appropriate

TRANSMISSION SERVICING article.

Removal (Paseo)

1. Disconnect negative battery cable. Remove transaxle oil dipstick. Disconnect throttle valve cable from

throttle body. Remove air cleaner assembly along with air intake duct to air cleaner.

2. Remove upper bolt from starter. Remove the 2 upper transaxle-to-cylinder block bolts located at top of

transaxle. Raise and support vehicle. Remove lower engine covers.

3. Support engine with hoist. Remove front wheels. Drain transaxle fluid. Remove axle shafts from

transaxle. See FWD AXLE SHAFTS article in DRIVE AXLES.

4. Disconnect necessary electrical connectors, ground cables, speedometer cable, control cables and oil

cooler lines for transaxle removal. Remove the 2 vertical bottom bolts from front (radiator side) transaxle

mount.

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:28 AMPage 16 © 2005 Mitchell Repair Information Company, LLC.

Page 141 of 1632

2. With engine and transmission removed, remove starter if not previously removed. Remove torque

converter cover from front of transmission. Remove torque converter bolts. Remove transmission-to-

cylinder block bolts. Separate transmission from engine.

Installation

1. Before installing transaxle, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transmission. To ensure torque converter is fully seated, torque converter

depth should be checked. Using straightedge and caliper, measure torque converter depth from torque

converter bolt lug on torque converter to the surface on transmission. See Fig. 1

.

3. Torque converter depth should be more than 1.250" (31.75 mm) for 2.7L 4-cylinder or .707" (17.95 mm)

for 3.4L V6. If torque converter depth is less than specified, check for improperly seated torque converter.

4. To install, reverse removal procedure. Tighten all bolts/nuts to specification. See TORQUE

SPECIFICATIONS . When installing torque converter bolts, apply Loctite to torque converter bolt

threads before installing.

5. Once engine and transmission are installed, adjust all cables and fill with ATF. See appropriate

TRANSMISSION SERVICING article.

Removal (T100 4WD)

1. Disconnect negative battery cable. Remove knob from transfer case shift lever. Remove screws and boot

from transfer case shift lever. Remove snap ring and transfer case shift lever from transfer case.

2. Disconnect throttle valve cable from throttle body. Raise and support vehicle. Remove lower engine

cover. Remove transmission oil dipstick, dipstick tube and "O" ring.

3. Place reference marks on drive shaft flanges for reassembly reference. Remove drive shafts. Remove

front exhaust pipe located between exhaust manifold and catalytic converter.

4. Disconnect speedometer cable and necessary electrical connectors for transmission and transfer case

removal. Disconnect shift linkage at side of transmission. Remove shift linkage cross shaft located

between frame and shift lever on transmission.

5. Remove starter. Remove transmission oil cooler pipes and brackets as necessary. Remove stiffener plates

located on each side of cylinder block. Stiffener plate fits between side of cylinder block and front of

transmission.

6. Remove stabilizer bar. Support transmission with floor jack. Remove bolts and dynamic damper

transmission crossmember. Dynamic damper is located on driver's side of transmission crossmember,

next to transmission mount bolts and is fastened to bottom of transmission crossmember using 2 bolts.

7. Remove transmission mount-to-transmission crossmember bolts. Remove transmission crossmember

located below transmission and transfer case.

8. Remove torque converter cover from front of transmission. Remove torque converter bolts. Remove

transmission-to-cylinder block bolts. Lower transmission with transfer case from vehicle.

Installation

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 29 © 2005 Mitchell Repair Information Company, LLC.

Page 143 of 1632

installing the remaining torque converter bolts.

5. Use NEW gasket when installing front exhaust pipe. Adjust all cables, shift linkages and fill with ATF.

See appropriate TRANSMISSION SERVICING article.

Removal (4Runner 4WD)

1. Disconnect negative battery cable. Remove rear console upper panel and disconnect electrical connectors.

Rear console upper panel is located on the top of the console, near emergency brake lever.

2. Remove heater control knobs from instrument panel. Using screwdriver, pry heater control plate from

center finish panel on instrument panel. Center finish panel is the panel that fits around the radio and air

outlet ducts, located at center of instrument panel.

3. Remove screws and disconnect electrical connectors from center finish panel from instrument panel.

Remove center finish panel.

4. On models without 2-4 selector button on side of transfer case shift lever, unscrew knob from transfer

case shift lever. On models with2-4 selector button on side of transfer case shift lever, remove screw from

knob on transfer case shift lever. Remove knob from transfer case shift lever and lay aside with wire

attached.

5. On all models, remove upper console panel which contains boot for transfer case shift lever and is located

on center console. On models with 2-4 selector button on side of transfer case shift lever, disconnect

electrical connector for 2-4 selector button and remove knob on transfer case shift lever.

6. On all models, remove screws, clips and front console box, located around transmission shift lever

assembly and transfer case shift lever. Raise and support vehicle. Disconnect shift linkage at transmission

shift lever.

7. Disconnect electrical connectors for removal of transmission shift lever assembly. Remove transmission

shift lever assembly. Remove snap ring and transfer case shift lever.

8. Remove transmission oil dipstick, dipstick tube and "O" ring. Remove lower engine covers. Place

reference marks on drive shaft flanges for reassembly reference. Remove drive shafts.

9. Remove front exhaust pipe, located between exhaust manifold and catalytic converter on rear exhaust

pipe. Disconnect and necessary electrical connectors for transmission and transfer case removal. Separate

wiring harness from transmission and transfer case.

10. Remove starter. Remove transmission oil cooler pipes and brackets as necessary. On 3.4L V6, it may be

necessary to remove stabilizer bar.

11. On all models, support transmission with floor jack. Remove rear transmission mount-to-transmission

crossmember bolts. Remove transmission crossmember, located below transmission and transfer case.

12. Remove torque converter cover from front of transmission. On 3.4L, note location of Green torque

converter bolt for re-installation reference. Remove torque converter bolts. Remove transmission-to-

cylinder block bolts. Lower transmission with transfer case from vehicle.

Installation

1. Before installing transmission, use dial indicator to check drive plate runout. Drive plate runout should be

checked right next to the starter ring gear on the drive plate. Replace drive plate if runout

exceeds .0079" (.200 mm).

2. Install torque converter on transmission. To ensure torque converter is fully seated, torque converter

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 31 © 2005 Mitchell Repair Information Company, LLC.

Page 149 of 1632

PASEO

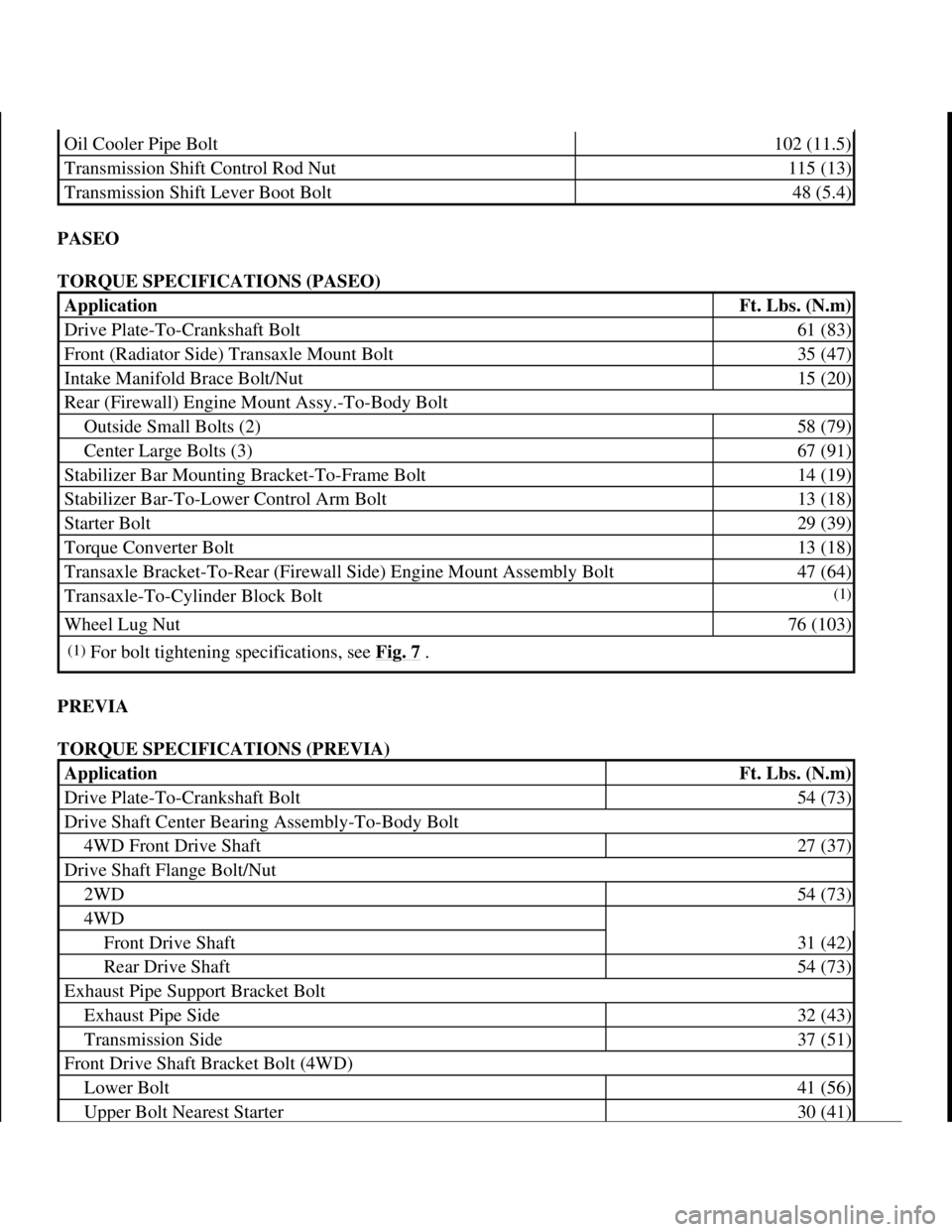

TORQUE SPECIFICATIONS (PASEO)

PREVIA

TORQUE SPECIFICATIONS (PREVIA)

Oil Cooler Pipe Bolt102 (11.5)

Transmission Shift Control Rod Nut115 (13)

Transmission Shift Lever Boot Bolt48 (5.4)

ApplicationFt. Lbs. (N.m)

Drive Plate-To-Crankshaft Bolt61 (83)

Front (Radiator Side) Transaxle Mount Bolt35 (47)

Intake Manifold Brace Bolt/Nut15 (20)

Rear (Firewall) Engine Mount Assy.-To-Body Bolt

Outside Small Bolts (2)58 (79)

Center Large Bolts (3)67 (91)

Stabilizer Bar Mounting Bracket-To-Frame Bolt14 (19)

Stabilizer Bar-To-Lower Control Arm Bolt13 (18)

Starter Bolt29 (39)

Torque Converter Bolt13 (18)

Transaxle Bracket-To-Rear (Firewall Side) Engine Mount Assembly Bolt47 (64)

Transaxle-To-Cylinder Block Bolt(1)

Wheel Lug Nut76 (103)

(1)For bolt tightening specifications, see Fig. 7 .

ApplicationFt. Lbs. (N.m)

Drive Plate-To-Crankshaft Bolt54 (73)

Drive Shaft Center Bearing Assembly-To-Body Bolt

4WD Front Drive Shaft27 (37)

Drive Shaft Flange Bolt/Nut

2WD54 (73)

4WD

Front Drive Shaft31 (42)

Rear Drive Shaft54 (73)

Exhaust Pipe Support Bracket Bolt

Exhaust Pipe Side32 (43)

Transmission Side37 (51)

Front Drive Shaft Bracket Bolt (4WD)

Lower Bolt41 (56)

Upper Bolt Nearest Starter30 (41)

1998 Toyota Avalon XLS

TRANSMISSION SERVICING - A/T 1997-98 TRANSMISSION SERVICING Toyota - Transmission Removal &

Installation

Helpmelearn

November-03-08 10:30:29 AMPage 37 © 2005 Mitchell Repair Information Company, LLC.

Page 269 of 1632

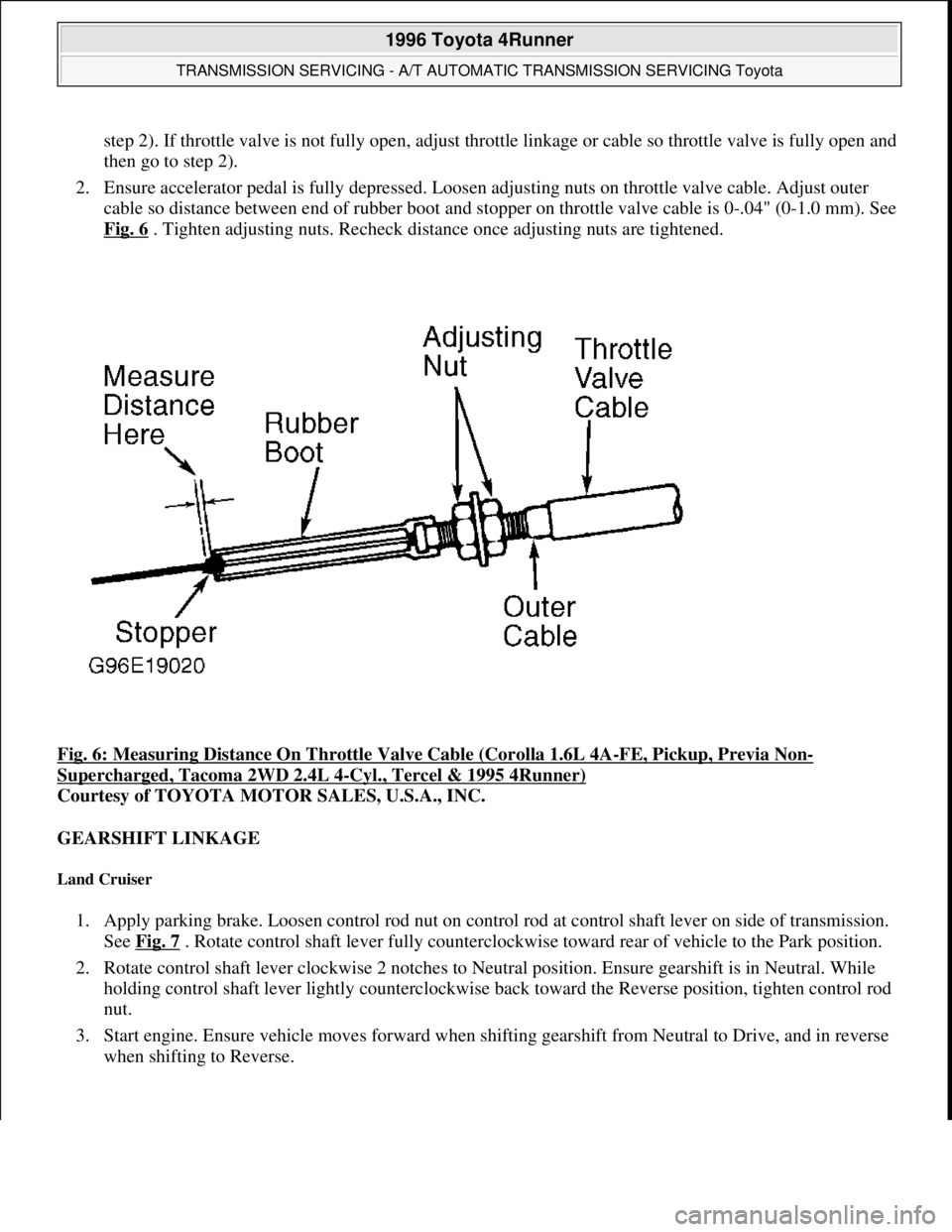

step 2). If throttle valve is not fully open, adjust throttle linkage or cable so throttle valve is fully open and

then go to step 2).

2. Ensure accelerator pedal is fully depressed. Loosen adjusting nuts on throttle valve cable. Adjust outer

cable so distance between end of rubber boot and stopper on throttle valve cable is 0-.04" (0-1.0 mm). See

Fig. 6

. Tighten adjusting nuts. Recheck distance once adjusting nuts are tightened.

Fig. 6: Measuring Distance On Throttle Valve Cable (Corolla 1.6L 4A

-FE, Pickup, Previa Non-

Supercharged, Tacoma 2WD 2.4L 4-Cyl., Tercel & 1995 4Runner)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

GEARSHIFT LINKAGE

Land Cruiser

1. Apply parking brake. Loosen control rod nut on control rod at control shaft lever on side of transmission.

See Fig. 7

. Rotate control shaft lever fully counterclockwise toward rear of vehicle to the Park position.

2. Rotate control shaft lever clockwise 2 notches to Neutral position. Ensure gearshift is in Neutral. While

holding control shaft lever lightly counterclockwise back toward the Reverse position, tighten control rod

nut.

3. Start engine. Ensure vehicle moves forward when shifting gearshift from Neutral to Drive, and in reverse

when shiftin

g to Reverse.

1996 Toyota 4Runner

TRANSMISSION SERVICING - A/T AUTOMATIC TRANSMISSION SERVICING Toyota

Microsoft

Tuesday, August 18, 2009 7:18:46 PMPage 13 © 2005 Mitchell Repair Information Company, LLC.

Page 322 of 1632

1999-2000 DRIVE AXLES

AWD & FWD Axle Shafts - RAV4 & RWD Axle Shafts - MR2

DESCRIPTION & OPERATION

On RAV4 models, axle shafts transfer power from transaxle to front wheels (FWD), or front and rear wheels

(AWD). MR2 are a mid-engine, RWD design. Axle shafts transfer power from transaxle to rear wheels. Axle

shaft consists of axle shaft with flexible Constant Velocity (CV) joint at each end. On RAV4 models, front inner

CV joint is splined to transaxle. Rear inner CV joint is bolted to differential. Outer CV joint is splined to front

or rear hub assembly. On MR2 models, rear inner CV joint is splined to transaxle and Outer CV joint is splined

to rear hub assembly.

Inner and outer CV joints are enclosed by a CV joint boot. Boot maintains lubrication in CV joint and prevents

contamination of CV lubricant. Boots must be replaced if cracked, torn or damaged. Inner CV joint can be

repaired without replacing assembly but outer CV joint must be replaced as an assembly.

TROUBLE SHOOTING

REMOVAL & INSTALLATION

FRONT AXLE SHAFTS

Removal (RAV4)

1. Raise and support vehicle. Remove front wheel. Remove engine undercover. Drain gear oil from

transaxle into proper container. Remove ABS speed sensor (if equipped). Remove cotter pin and lock cap.

See Fig. 1

or Fig. 2 . Apply brakes, and remove axle shaft nut from end of axle shaft. Release brakes.

2. Remove cotter pin and nut from tie rod end. Using Tie Rod End Remover (SST 09610-20012), disconnect

tie rod end from steering knuckle. Disconnect stabilizer bar link from lower suspension arm. Remove bolt

and 2 nuts, and separate lower ball joint from suspension arm.

3. Using a plastic hammer, tap axle shaft from hub. Pull steering knuckle outward, and disconnect axle shaft

from steering knuckle.

4. To remove axle shaft (except left side on AWD), use a brass drift and hammer and tap on inner joint to

separate from transaxle. Slide axle shaft toward steering knuckle until free of transaxle assembly. NOTE: See DRIVE AXLE NOISE DIAGNOSIS article in GENERAL INFORMATION.

NOTE: DO NOT damage oil seal, axle shaft boots or Anti-Lock Brake System (ABS)

speed sensor rotor when removing axle shaft.

NOTE: On FWD vehicles, removal of right-side axle shaft requires disassembly of

center bearing axle support. See Fig. 3

or Fig. 4 .

1999 Toyota RAV4

1999-2000 DRIVE AXLES AWD & FWD Axle Shafts - RAV4 & RWD Axle Shafts - MR2

1999 Toyota RAV4

1999-2000 DRIVE AXLES AWD & FWD Axle Shafts - RAV4 & RWD Axle Shafts - MR2

Microsoft

Sunday, November 22, 2009 10:08:21 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, November 22, 2009 10:08:25 AMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 328 of 1632

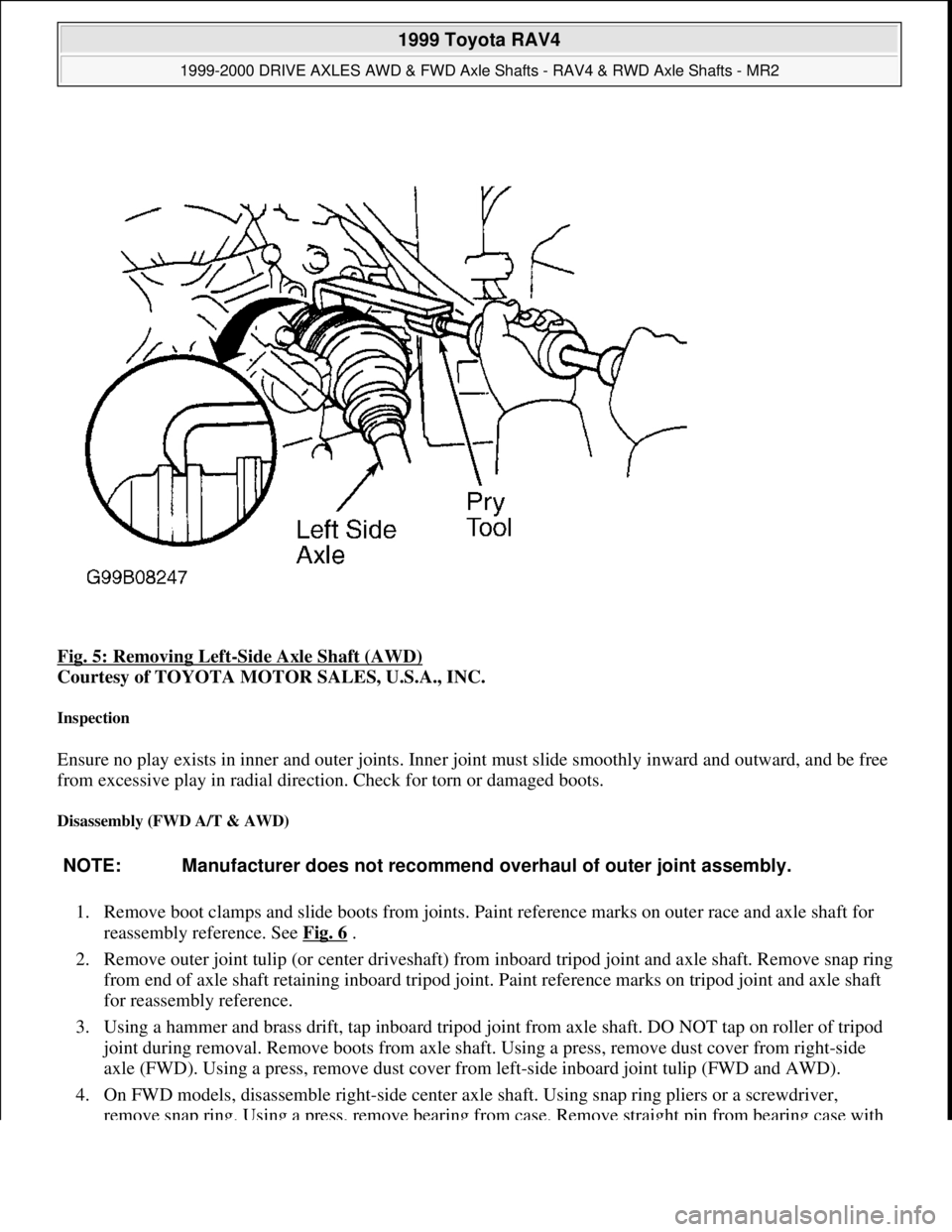

Fig. 5: Removing Left-Side Axle Shaft (AWD)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Inspection

Ensure no play exists in inner and outer joints. Inner joint must slide smoothly inward and outward, and be free

from excessive play in radial direction. Check for torn or damaged boots.

Disassembly (FWD A/T & AWD)

1. Remove boot clamps and slide boots from joints. Paint reference marks on outer race and axle shaft for

reassembly reference. See Fig. 6

.

2. Remove outer joint tulip (or center driveshaft) from inboard tripod joint and axle shaft. Remove snap ring

from end of axle shaft retaining inboard tripod joint. Paint reference marks on tripod joint and axle shaft

for reassembly reference.

3. Using a hammer and brass drift, tap inboard tripod joint from axle shaft. DO NOT tap on roller of tripod

joint during removal. Remove boots from axle shaft. Using a press, remove dust cover from right-side

axle (FWD). Using a press, remove dust cover from left-side inboard joint tulip (FWD and AWD).

4. On FWD models, disassemble right-side center axle shaft. Using snap ring pliers or a screwdriver,

remove snap ring. Using a press, remove bearing from case. Remove straight pin from bearing case with

NOTE: Manufacturer does not recommend overhaul of outer joint assembly.

1999 Toyota RAV4

1999-2000 DRIVE AXLES AWD & FWD Axle Shafts - RAV4 & RWD Axle Shafts - MR2

Microsoft

Sunday, November 22, 2009 10:08:21 AMPage 7 © 2005 Mitchell Repair Information Company, LLC.

Page 330 of 1632

2. Using a press, install bearing assembly on axle shaft. Install NEW snap ring. Press NEW dust cover

against bearing, leaving .039" (1.0 mm) between bearing and dust cover.

3. Using a press, install NEW dust cover onto axle shaft. Right-side (transaxle side) dust cover must be

positioned 3.39-3.43" (86.0-87.0 mm) from end of axle shaft. Wrap splines on axle shaft with tape to

prevent damaging boots during installation. Install NEW boots and NEW boot clamps onto axle shaft.

4. Apply grease supplied with overhaul kit to outboard joint and boot. Install boot and boot clamps onto

outboard joint.

5. Install inboard tripod joint onto axle shaft, with reference mark aligned. Using a hammer and brass drift,

drive on inner race until fully seated on axle shaft. DO NOT allow brass drift to contact cage on inboard

tripod joint during installation.

6. Install NEW snap ring on end of axle shaft. Apply grease supplied with overhaul kit into inboard joint

housing and boot.

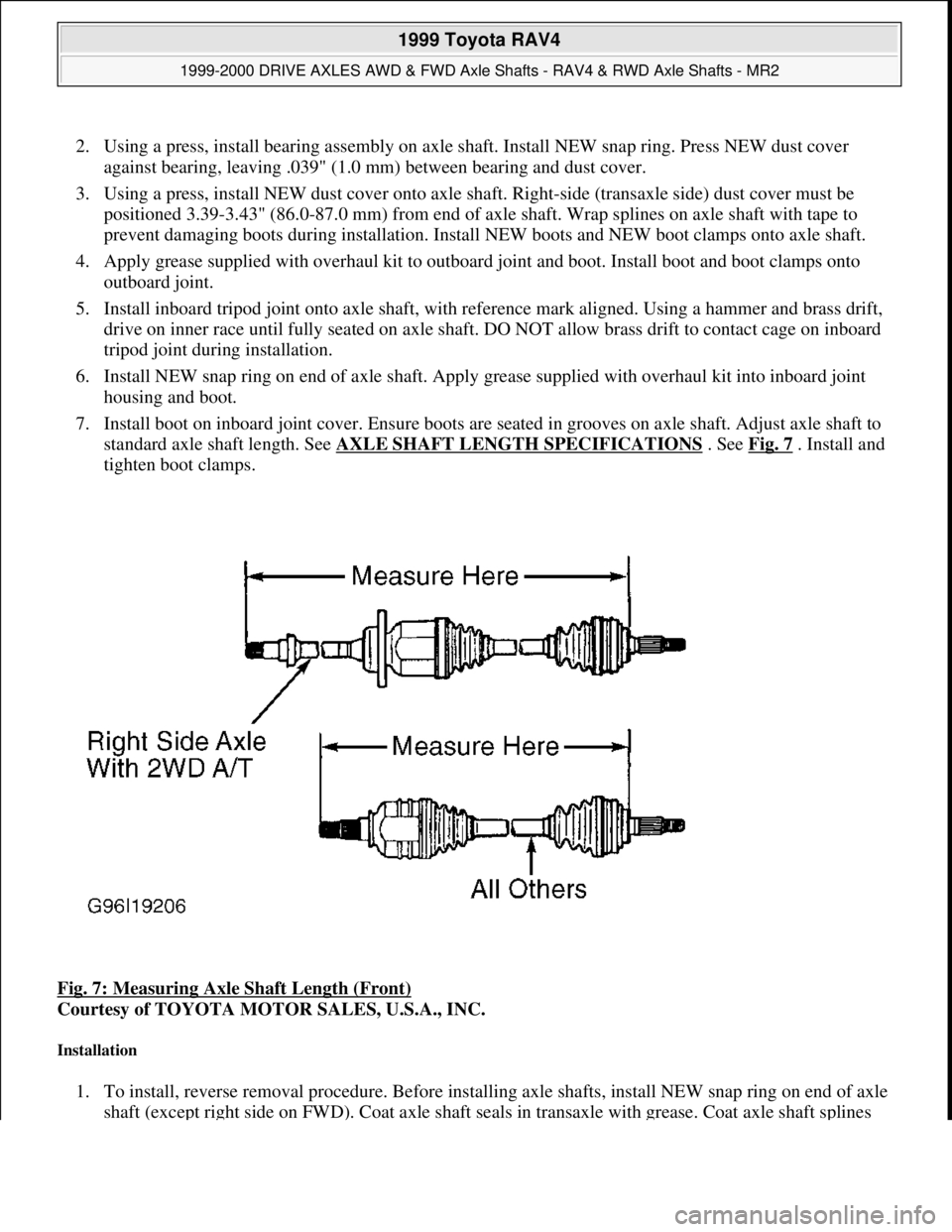

7. Install boot on inboard joint cover. Ensure boots are seated in grooves on axle shaft. Adjust axle shaft to

standard axle shaft length. See AXLE SHAFT LENGTH SPECIFICATIONS

. See Fig. 7 . Install and

tighten boot clamps.

Fig. 7: Measuring Axle Shaft Length (Front)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Installation

1. To install, reverse removal procedure. Before installing axle shafts, install NEW snap ring on end of axle

shaft (except ri

ght side on FWD). Coat axle shaft seals in transaxle with grease. Coat axle shaft splines

1999 Toyota RAV4

1999-2000 DRIVE AXLES AWD & FWD Axle Shafts - RAV4 & RWD Axle Shafts - MR2

Microsoft

Sunday, November 22, 2009 10:08:21 AMPage 9 © 2005 Mitchell Repair Information Company, LLC.