tires TOYOTA RAV4 1996 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 16 of 1632

1. Disconnect front speed sensor connector. Measure resistance between speed sensor connector terminals.

Resistance should be 1.4-1.8 k/ohms. Measure resistance between ground and each speed sensor

connector terminal. Resistance should be one megohm or more. If resistance is as specified, go to step 3 .

If resistance is not as specified, replace speed sensor.

2. Disconnect rear speed sensor connector. Measure resistance between speed sensor connector terminals.

Resistance should be 1.28-1.48 k/ohms. Measure resistance between ground and each speed sensor

connector terminal. Resistance should be one megohm or more. If resistance is as specified, go to next

step. If resistance is not as specified, replace speed sensor.

3. Check for open or short circuit in wiring harness between affected speed sensor and ABS ECU. See

WIRING DIAGRAMS

. Repair as necessary. If wiring harness is okay, go to next step.

4. Check speed sensor installation. Ensure mounting bolt is tightened to specification. See TORQUE

SPECIFICATIONS . Ensure zero clearance exists between sensor and front steering knuckle or rear axle

carrier. Replace speed sensor if necessary. If speed sensor installation is okay, check speed sensor signal.

See SPEED SENSOR DIAGNOSTICS

under DIAGNOSIS & TESTING. If signal is normal, go to next

step.

5. If oscilloscope is available, check speed sensor signal wave form. Remove ABS ECU. Do not disconnect

electrical connectors. Connect oscilloscope between GND terminal and terminals FR+, FL+, RR+ and

RL+ at ABS ECU connector. See Fig. 3

. Drive vehicle at 19 MPH and observe signal wave form. Signal

should be smooth and consistent without any irregular wave forms. If wave form is smooth and

consistent, replace ABS ECU. If wave form is not smooth and consistent, go to next step.

6. Check speed sensor rotor for missing teeth or damage. Check sensor tip for scratches, damage or foreign

objects. Replace components as necessary. If rotor and sensor are okay, replace ABS ECU.

DTC 37: TIRES OF DIFFERENT SIZE (2WD MODELS ONLY)

DTC Detecting Condition

Detection of the following condition may set DTC 37:

Driving vehicle at speed of more than 12 MPH for more than 20 seconds with one or 2 tires of different

sizes, 3 different times continuously will set DTC 37.

Diagnostic Procedure

Ensure vehicle tires are all the same size and correct size for vehicle. Replace tires as necessary. If tire size is

okay, replace ABS ECU.

DTC 41: LOW BATTERY VOLTAGE

Circuit Description

Circuit is power source for ABS ECU, which includes actuator. If malfunction occurs in power source circuit,

ABS ECU cuts off current to ABS control relay and prohibits ABS control. DEFINITIONS

under DIAGNOSIS & TESTING. For front speed sensor diagnosis,

start at step 1 . For rear speed sensor, start at step 2 .

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 16 © 2005 Mitchell Repair Information Company, LLC.

Page 26 of 1632

1. Check charging system voltage. Ensure 10-14 volts is present. If charging system voltage is okay, go to

next step. If charging system voltage is not okay, check and repair charging system.

2. Turn ignition switch to ON position. Ensure ABS warning light comes on, then goes out after 3 seconds.

If ABS warning light does not illuminate, check fuse, bulb, and wiring harness. See ABS WARNING

LIGHT under DIAGNOSIS & TESTING. Turn ignition off.

3. Using a jumper wire, jumper terminals Ts and E

1 of DLC1. DLC1 is located in engine compartment on

left side of engine. See Fig. 2

. Ensure ABS warning light blinks 4 times per second. If ABS light does

not blink, go to ABS WARNING LIGHT

under DIAGNOSIS & TESTING. If ABS warning light

blinks, go to next step.

4. Using a floor jack, slowly jack up rear of vehicle. On vehicles with 215/70R16 tires, raise vehicle to a

height of 25.59-27.95" (650-710 mm). On vehicles with 235/60R16 tires, raise vehicle to a height of

26.38-28.74" (670-730 mm). If ABS warning light illuminates at specified height, check deceleration

sensor installation. If installation is okay, replace deceleration sensor. Lower vehicle.

5. Using a floor jack, slowly jack up front of vehicle. On vehicles with 215/70R16 tires, raise vehicle to a

height of 21.20-23.56" (550-610 mm). On vehicles with 235/60R16 tires, raise vehicle to a height of

22.44-24.80" (570-630 mm). If ABS warning light illuminates at specified height, check deceleration

sensor installation. If installation is okay, replace deceleration sensor. Lower vehicle.

6. Drive vehicle straight ahead at speed of 13 MPH or more. Lightly depress brake pedal. Ensure ABS

warning light pattern is normal (light blinks 4 times per second).

7. While driving vehicle straight ahead at speed of 13 MPH or more, moderately depress brake pedal.

Ensure ABS warning light illuminates in a solid pattern (light does not blink) while braking.

8. While driving vehicle straight ahead at speed of 13 MPH or more, firmly depress brake pedal. Ensure

ABS warning light illumination pattern changes from a solid pattern (light does not blink) to a normal

pattern (light blinks 4 times per second), then back to a solid pattern while braking.

9. If ABS warning light does not illuminate as described in steps 6 -8 , check deceleration sensor

installation. If installation is okay, replace deceleration sensor. Stop vehicle and turn ignition off. Remove

jumper wire from DLC1.

REMOVAL & INSTALLATION

ACTUATOR

Removal & Installation

Turn ignition off. Disconnect brakelines attached to actuator. Remove power steering hose retaining bracket

bolt and power steering reservoir. Disconnect actuator electrical connectors. Remove bolts, nuts and washers.

Remove actuator assembly. Remove actuator from actuator bracket. Remove cushions and holders from NOTE: When measuring vehicle height in following steps, measure at center of

lower body of vehicle.

WARNING:Hydraulic system may be under high pressure. Use caution when opening

hydraulic system.

1999 Toyota RAV4

1999-2000 BRAKES Anti-Lock - RAV4

Microsoft

Sunday, November 22, 2009 10:06:17 AMPage 26 © 2005 Mitchell Repair Information Company, LLC.

Page 42 of 1632

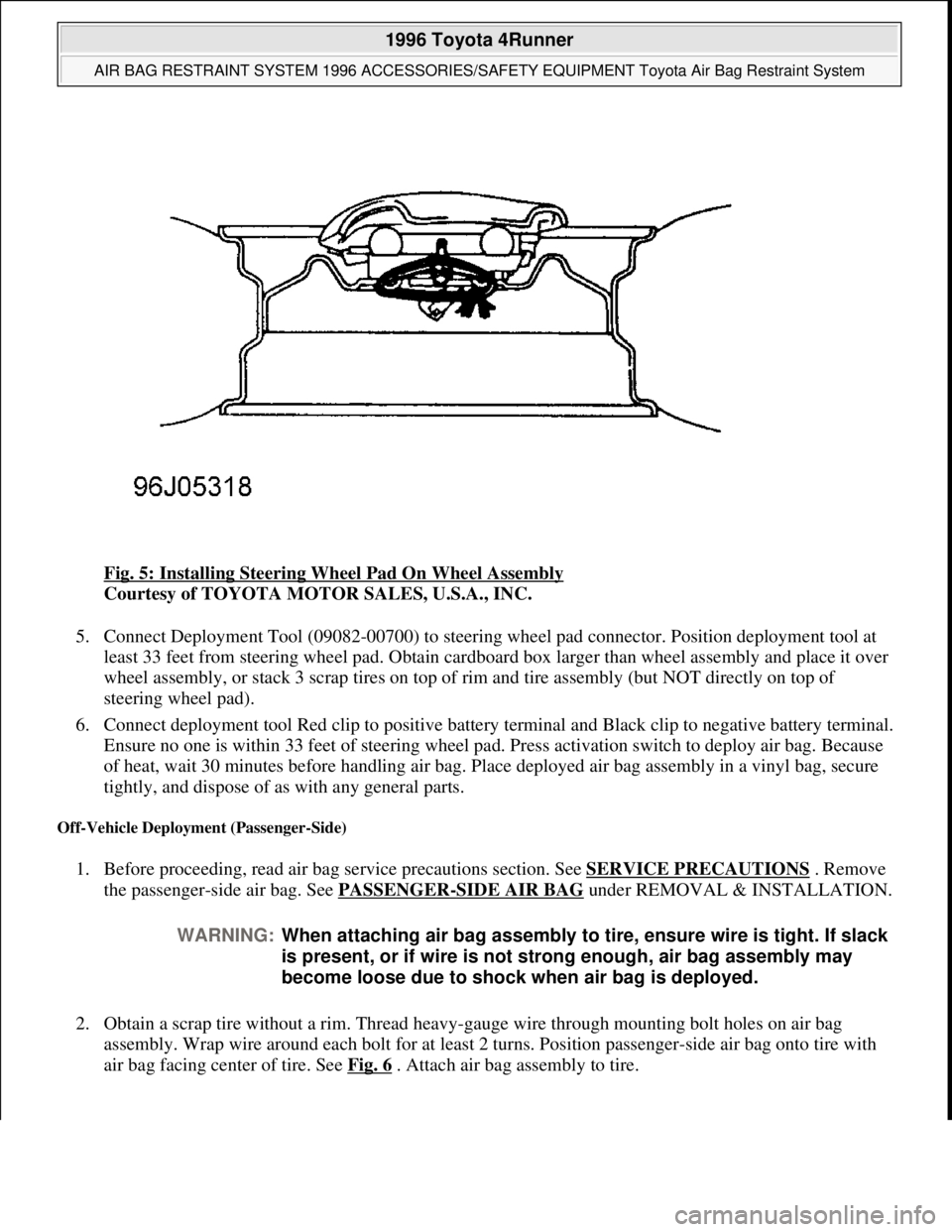

Fig. 5: Installing Steering Wheel Pad On Wheel Assembly

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

5. Connect Deployment Tool (09082-00700) to steering wheel pad connector. Position deployment tool at

least 33 feet from steering wheel pad. Obtain cardboard box larger than wheel assembly and place it over

wheel assembly, or stack 3 scrap tires on top of rim and tire assembly (but NOT directly on top of

steering wheel pad).

6. Connect deployment tool Red clip to positive battery terminal and Black clip to negative battery terminal.

Ensure no one is within 33 feet of steering wheel pad. Press activation switch to deploy air bag. Because

of heat, wait 30 minutes before handling air bag. Place deployed air bag assembly in a vinyl bag, secure

tightly, and dispose of as with any general parts.

Off-Vehicle Deployment (Passenger-Side)

1. Before proceeding, read air bag service precautions section. See SERVICE PRECAUTIONS . Remove

the passenger-side air bag. See PASSENGER

-SIDE AIR BAG under REMOVAL & INSTALLATION.

2. Obtain a scrap tire without a rim. Thread heavy-gauge wire through mounting bolt holes on air bag

assembly. Wrap wire around each bolt for at least 2 turns. Position passenger-side air bag onto tire with

air ba

g facing center of tire. See Fig. 6. Attach air bag assembly to tire.

WARNING:When attaching air bag assembly to tire, ensure wire is tight. If slack

is present, or if wire is not strong enough, air bag assembly may

become loose due to shock when air bag is deployed.

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 8 © 2005 Mitchell Repair Information Company, LLC.

Page 43 of 1632

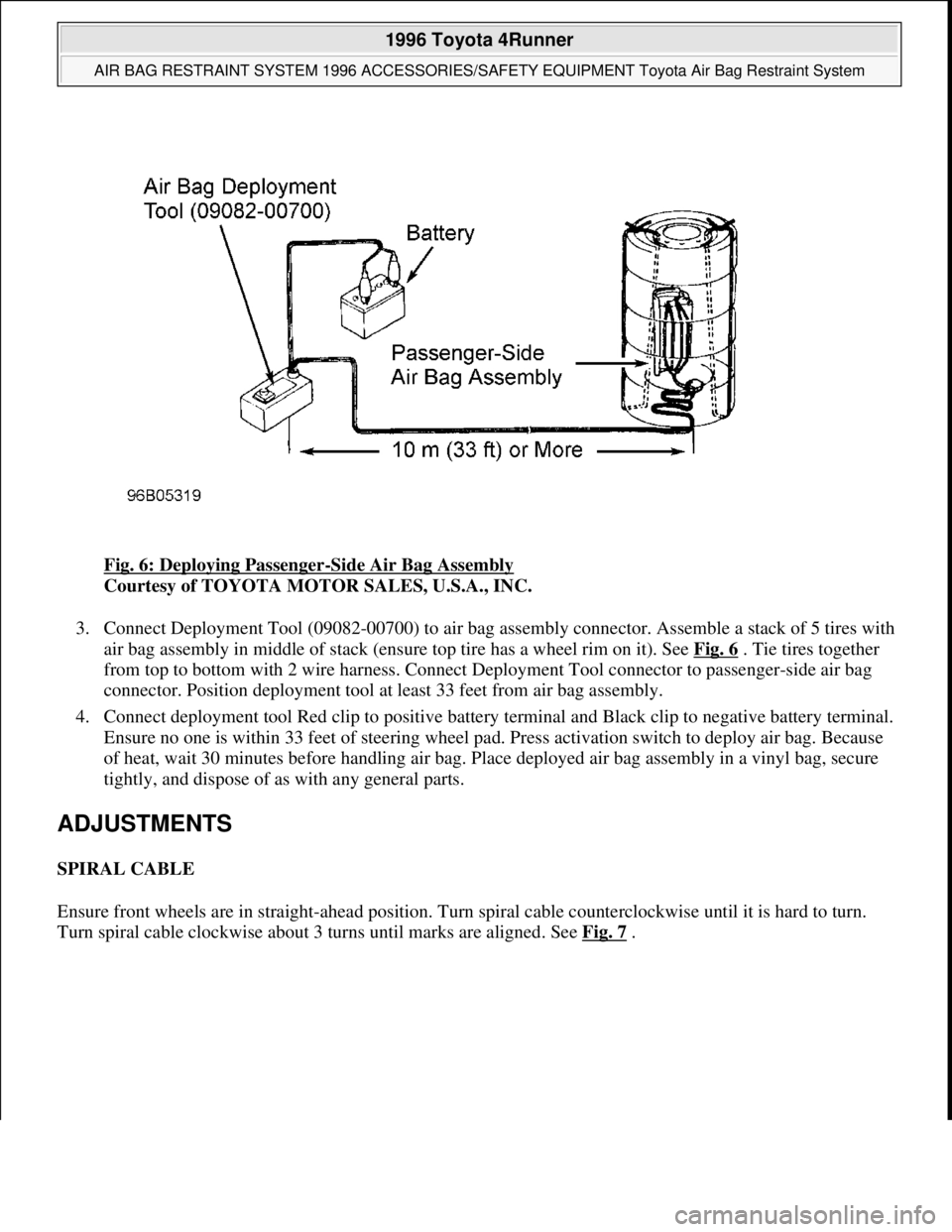

Fig. 6: Deploying Passenger-Side Air Bag Assembly

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3. Connect Deployment Tool (09082-00700) to air bag assembly connector. Assemble a stack of 5 tires with

air bag assembly in middle of stack (ensure top tire has a wheel rim on it). See Fig. 6

. Tie tires together

from top to bottom with 2 wire harness. Connect Deployment Tool connector to passenger-side air bag

connector. Position deployment tool at least 33 feet from air bag assembly.

4. Connect deployment tool Red clip to positive battery terminal and Black clip to negative battery terminal.

Ensure no one is within 33 feet of steering wheel pad. Press activation switch to deploy air bag. Because

of heat, wait 30 minutes before handling air bag. Place deployed air bag assembly in a vinyl bag, secure

tightly, and dispose of as with any general parts.

ADJUSTMENTS

SPIRAL CABLE

Ensure front wheels are in straight-ahead position. Turn spiral cable counterclockwise until it is hard to turn.

Turn spiral cable clockwise about 3 turns until marks are ali

gned. See Fig. 7.

1996 Toyota 4Runner

AIR BAG RESTRAINT SYSTEM 1996 ACCESSORIES/SAFETY EQUIPMENT Toyota Air Bag Restraint System

Microsoft

Tuesday, August 18, 2009 7:33:32 PMPage 9 © 2005 Mitchell Repair Information Company, LLC.

Page 71 of 1632

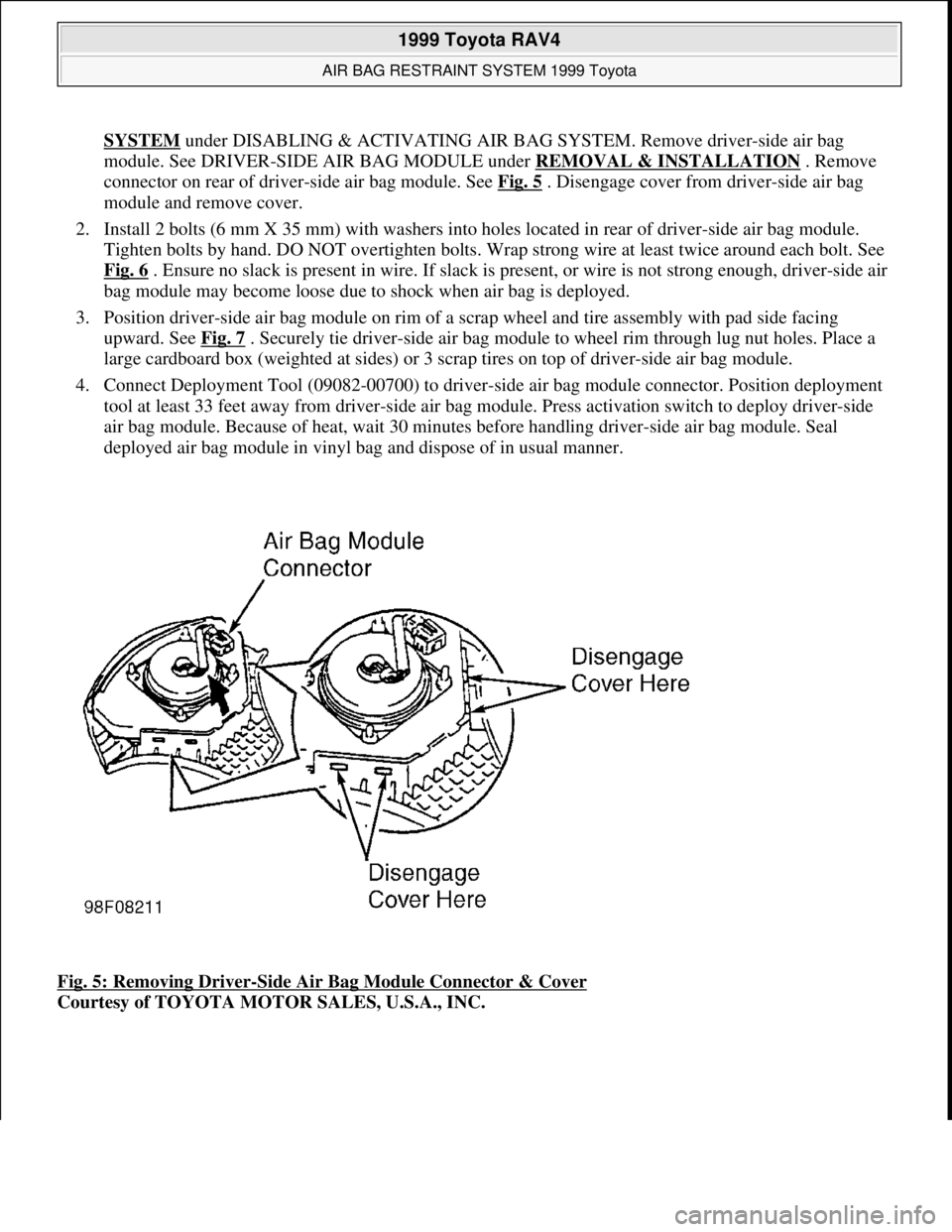

SYSTEM under DISABLING & ACTIVATING AIR BAG SYSTEM. Remove driver-side air bag

module. See DRIVER-SIDE AIR BAG MODULE under REMOVAL & INSTALLATION

. Remove

connector on rear of driver-side air bag module. See Fig. 5

. Disengage cover from driver-side air bag

module and remove cover.

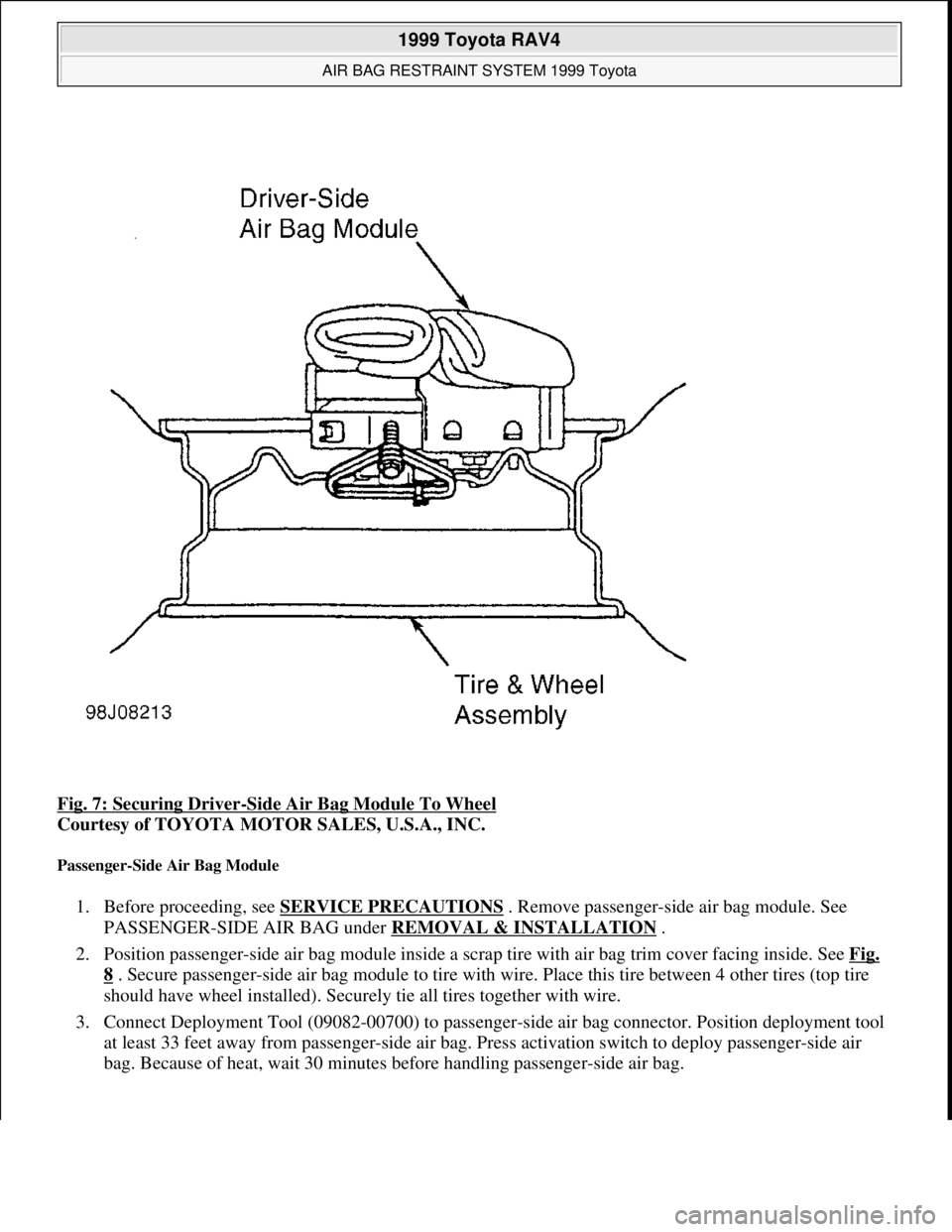

2. Install 2 bolts (6 mm X 35 mm) with washers into holes located in rear of driver-side air bag module.

Tighten bolts by hand. DO NOT overtighten bolts. Wrap strong wire at least twice around each bolt. See

Fig. 6

. Ensure no slack is present in wire. If slack is present, or wire is not strong enough, driver-side air

bag module may become loose due to shock when air bag is deployed.

3. Position driver-side air bag module on rim of a scrap wheel and tire assembly with pad side facing

upward. See Fig. 7

. Securely tie driver-side air bag module to wheel rim through lug nut holes. Place a

large cardboard box (weighted at sides) or 3 scrap tires on top of driver-side air bag module.

4. Connect Deployment Tool (09082-00700) to driver-side air bag module connector. Position deployment

tool at least 33 feet away from driver-side air bag module. Press activation switch to deploy driver-side

air bag module. Because of heat, wait 30 minutes before handling driver-side air bag module. Seal

deployed air bag module in vinyl bag and dispose of in usual manner.

Fig. 5: Removing Driver

-Side Air Bag Module Connector & Cover

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:22 AMPage 8 © 2005 Mitchell Repair Information Company, LLC.

Page 73 of 1632

Fig. 7: Securing Driver-Side Air Bag Module To Wheel

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Passenger-Side Air Bag Module

1. Before proceeding, see SERVICE PRECAUTIONS . Remove passenger-side air bag module. See

PASSENGER-SIDE AIR BAG under REMOVAL & INSTALLATION

.

2. Position passenger-side air bag module inside a scrap tire with air bag trim cover facing inside. See Fig.

8 . Secure passenger-side air bag module to tire with wire. Place this tire between 4 other tires (top tire

should have wheel installed). Securely tie all tires together with wire.

3. Connect Deployment Tool (09082-00700) to passenger-side air bag connector. Position deployment tool

at least 33 feet away from passenger-side air bag. Press activation switch to deploy passenger-side air

bag. Because of heat, wait 30 minutes before handling passenger-side air bag.

1999 Toyota RAV4

AIR BAG RESTRAINT SYSTEM 1999 Toyota

Microsoft

Sunday, November 22, 2009 10:33:22 AMPage 10 © 2005 Mitchell Repair Information Company, LLC.

Page 920 of 1632

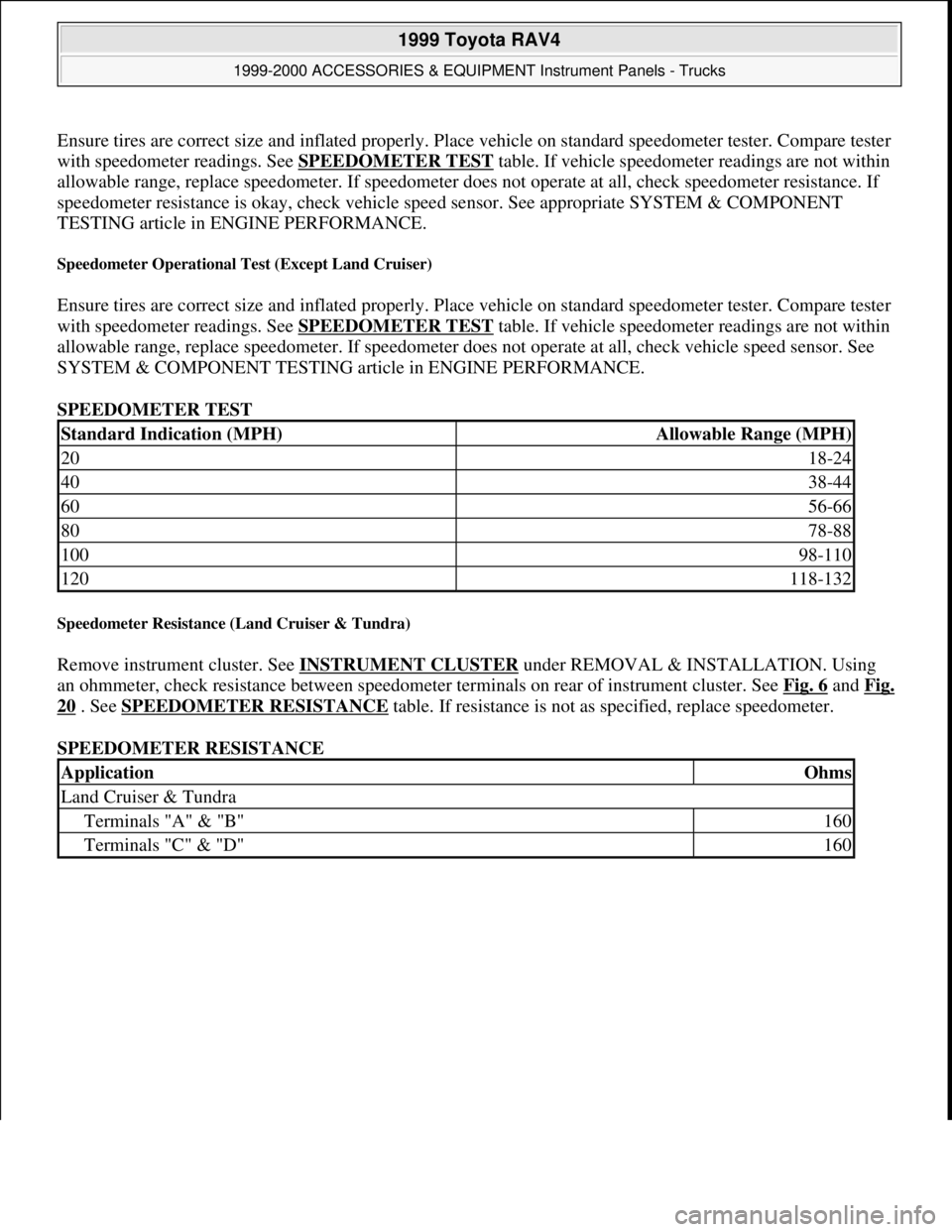

Ensure tires are correct size and inflated properly. Place vehicle on standard speedometer tester. Compare tester

with speedometer readings. See SPEEDOMETER TEST

table. If vehicle speedometer readings are not within

allowable range, replace speedometer. If speedometer does not operate at all, check speedometer resistance. If

speedometer resistance is okay, check vehicle speed sensor. See appropriate SYSTEM & COMPONENT

TESTING article in ENGINE PERFORMANCE.

Speedometer Operational Test (Except Land Cruiser)

Ensure tires are correct size and inflated properly. Place vehicle on standard speedometer tester. Compare tester

with speedometer readings. See SPEEDOMETER TEST

table. If vehicle speedometer readings are not within

allowable range, replace speedometer. If speedometer does not operate at all, check vehicle speed sensor. See

SYSTEM & COMPONENT TESTING article in ENGINE PERFORMANCE.

SPEEDOMETER TEST

Speedometer Resistance (Land Cruiser & Tundra)

Remove instrument cluster. See INSTRUMENT CLUSTER under REMOVAL & INSTALLATION. Using

an ohmmeter, check resistance between speedometer terminals on rear of instrument cluster. See Fig. 6

and Fig.

20 . See SPEEDOMETER RESISTANCE table. If resistance is not as specified, replace speedometer.

SPEEDOMETER RESISTANCE

Standard Indication (MPH)Allowable Range (MPH)

2018-24

4038-44

6056-66

8078-88

10098-110

120118-132

ApplicationOhms

Land Cruiser & Tundra

Terminals "A" & "B"160

Terminals "C" & "D"160

1999 Toyota RAV4

1999-2000 ACCESSORIES & EQUIPMENT Instrument Panels - Trucks

Microsoft

Sunday, November 22, 2009 10:54:10 AMPage 30 © 2005 Mitchell Repair Information Company, LLC.

Page 950 of 1632

On models equipped with anti-lock brake systems, ALWAYS observe the following cautions:

DO NOT attempt to bleed hydraulic system without first referring to the appropriate ANTI-LOCK

BRAKE SYSTEM article in the BRAKES Section.

DO NOT mix tire sizes. As long as tires remain close to the original diameter, increasing the width is

acceptable. Rolling diameter must be identical for all 4 tires. Some manufacturers recommend tires of the

same brand, style and type. Failure to follow this precaution may cause inaccurate wheel speed readings.

Use ONLY recommended brake fluids. DO NOT use silicone brake fluids in an ABS-equipped vehicle.

BATTERY WARNING

REPLACING BLOWN FUSES

BRAKE PAD WEAR INDICATOR

Indicator will cause a squealing or scraping noise, warning that brake pads need replacement.

CATALYTIC CONVERTER CAUTION: The anti-lock brake system contains electronic equipment that can be

susceptible to interference caused by improperly installed or high output

radio transmitting equipment. Since this interference could cause the

possible loss of the anti-lock braking capability, such equipment should

be installed by qualified professionals.

WARNING:When battery is disconnected, vehicles equipped with computers may

lose memory data. When battery power is restored, driveability problems

may exist on some vehicles. These vehicles may require a relearn

procedure. See COMPUTER RELEARN PROCEDURES article in GENERAL

INFORMATION section.

CAUTION: Before replacing a blown fuse, remove ignition key, turn off all lights and

accessories to avoid damaging the electrical system. Be sure to use fuse

with the correct indicated amperage rating. The use of an incorrect

amperage rating fuse may result in a dangerous electrical system

overload.

CAUTION: Continued operation of vehicle with a severe malfunction could cause

converter to overheat, resulting in possible damage to converter and

vehicle.

CAUTION: Any modification to the exhaust system on turbo models, which reduces

exhaust backpressure, will lead to lean fuel mixtures and excessive spark

advance. This could cause serious engine damage.

1999 Toyota RAV4

MAINTENANCE INFORMATION 1997-99 MAINTENANCE Toyota Maintenance Information

Microsoft

Sunday, November 22, 2009 10:32:42 AMPage 8 © 2005 Mitchell Repair Information Company, LLC.

Page 1217 of 1632

3. Align match marks on No. 2 "U" joint assembly and No. 2 intermediate shaft assembly. Align match

marks on control valve shaft and No. 2 intermediate shaft assembly. Install "A" and "B" bolts. See Fig. 3

.

4. Install brake pedal return spring and No. 2 heater to register duct. Install lower finish panel with 4 bolts.

Connect hood lock release lever with 2 screws. Install spiral cable. See SPIRAL CABLE

under

ADJUSTMENTS. Install combination switch with 3 screws. Connect air bag and connectors.

5. Install lower and upper column covers with 3 screws. Ensure tires are in straight-ahead position. Turn

cable counterclockwise until there is resistance. Rotate cable clockwise 2.5 turns to align mark.

6. To install steering wheel, align match marks on wheel and main shaft. Install wheel set nut. Connect

connector. Install steering wheel pad. Connect air bag connector. Install wheel pad when Torx screw is

set in screw case. Using a Torx socket wrench, tighten 2 screws to 78 INCH lbs. (8.8 N.m). Install 2

steering wheel lower No. 2 covers. Check steering wheel center point.

7. Tighten all bolts to specifications. See TORQUE SPECIFICATIONS

. Ensure spiral cable is properly

installed and adjusted. See SPIRAL CABLE

under ADJUSTMENTS.

Removal & Installation (4Runner)

1. Disconnect and shield negative battery cable. Remove steering wheel. See STEERING WHEEL & AIR

BAG .

2. Remove upper and lower steering column covers. Disconnect hood release handle from instrument panel.

Remove fuel lid release lever from instrument panel. Remove 4 bolts and instrument panel lower left

finish panel.

3. Remove starter switch bezel. Remove air duct from instrument panel outlet.

4. Disconnect 3 electrical connectors. Disconnect air bag connector. Remove 3 screws and combination

switch. Remove spiral cable. Remove brake pedal return spring.

5. Place match marks on intermediate shaft and "U" joint, and place match marks on steering gear shaft and

"U" joint. Remove upper and lower clamp bolts from "U" joint. Remove intermediate shaft.

6. Remove floor hole cover. Fully remove upper "U" joint clamp bolt, and remove "U" joint assembly.

7. To install, reverse removal procedure. Tighten all bolts to specifications. See TORQUE

SPECIFICATIONS . Ensure spiral cable is properly installed and adjusted. See SPIRAL CABLEunder

ADJUSTMENTS.

OVERHAUL

STEERING COLUMN

Disassembly (Celica)

1. Place intermediate shaft in vise. Place match marks across intermediate shaft and main shaft. Remove key

cylinder illumination assembly.

2. Center punch and drill into both upper column bracket bolts. Use screw extractor to remove bolts.

3. Remove snap ring from shaft assembly. Using brass bar and hammer, tap out shaft assembly bushing

from column tube. Remove remaining snap ring. See Fig. 5

.

Inspection

1999 Toyota RAV4

1999-2000 STEERING Steering Columns - Standard

Microsoft

Sunday, November 22, 2009 10:34:51 AMPage 10 © 2005 Mitchell Repair Information Company, LLC.

Page 1266 of 1632

1. Insert column hole cover No. 2. Align match marks on column assembly and No. 2 "U" joint assembly.

Install bolt to connect No. 2 "U" joint assembly.

2. Install column assembly with No. 2 "U" joint assembly. Install 4 steering column set nuts. Connect

connectors. On models equipped with A/T, connect transmission control cable assembly to shift lever

assembly.

3. Align match marks on No. 2 "U" joint assembly and No. 2 intermediate shaft assembly. Align match

marks on control valve shaft and No. 2 intermediate shaft assembly. Install "A" and "B" bolts.

4. Install brake pedal return spring and No. 2 heater to register duct. Install lower finish panel with 4 bolts.

Connect hood lock release lever with 2 screws. Install spiral cable. See SPIRAL CABLE

under

ADJUSTMENTS. Install combination switch with 3 screws. Connect air bag and connectors.

5. Install lower and upper column covers with 3 screws. Ensure tires are in straight-ahead position. Turn

cable counterclockwise until there is resistance. Rotate cable clockwise 2.5 turns to align mark.

6. To install steering wheel, align match marks on wheel and main shaft. Install wheel set nut. Connect

connector. Install steering wheel pad. Connect air bag connector. Install wheel pad when Torx screw is

set in screw case. Using a Torx socket wrench, torque 2 screws to 78 INCH lbs. (8.8 N.m). Install 2

steering wheel lower No. 2 covers. Check steering wheel center point.

7. Tighten all bolts to specifications. See TORQUE SPECIFICATIONS

. Ensure spiral cable is properly

installed and adjusted. See SPIRAL CABLE

under ADJUSTMENTS.

Removal & Installation (4Runner)

1. Disconnect negative battery cable. Remove steering wheel. See STEERING WHEEL & AIR BAG .

Remove upper and lower column covers. See Fig. 4

. Remove left-side lower finish panel. Remove starter

switch bezel. Remove No. 2 heater to register duct from under steering column.

2. Remove combination switch with spiral cable. Remove spiral cable. Remove brake pedal return spring.

Mark intermediate shaft No. 2, "U" joints No. 2 and control valve for installation reference. Remove

intermediate shaft No. 2 and bolts. Remove column hole cover and column hole cover No. 2 set bolt.

3. Remove steering column assembly with "U" joint No. 2. Disconnect "U" joint No. 2. To install, reverse

removal procedure. Tighten bolts and nuts to specification. See TORQUE SPECIFICATIONS

.

OVERHAUL

STEERING COLUMN

Disassembly (Land Cruiser)

1. Remove No. 2 lower cover. Mark shaft assembly and main shaft assembly for reassembly reference.

Remove intermediate shaft assembly. See Fig. 6

. Remove transponder key coil with key cylinder lamp

assembly. Remove key cylinder lamp assembly.

1999 Toyota RAV4

1999-2000 STEERING Steering Columns - Tilt Wheel - Trucks & Vans

Microsoft

Sunday, November 22, 2009 10:34:02 AMPage 12 © 2005 Mitchell Repair Information Company, LLC.