TOYOTA RAV4 1996 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 1996,

Model line: RAV4,

Model: TOYOTA RAV4 1996

Pages: 1354, PDF Size: 30.43 MB

TOYOTA RAV4 1996 Service Repair Manual

RAV4 1996

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57462/w960_57462-0.png

TOYOTA RAV4 1996 Service Repair Manual

Trending: 4WD, heating, Electric diagram, stop start, adding oil, clutch, seats

Page 1261 of 1354

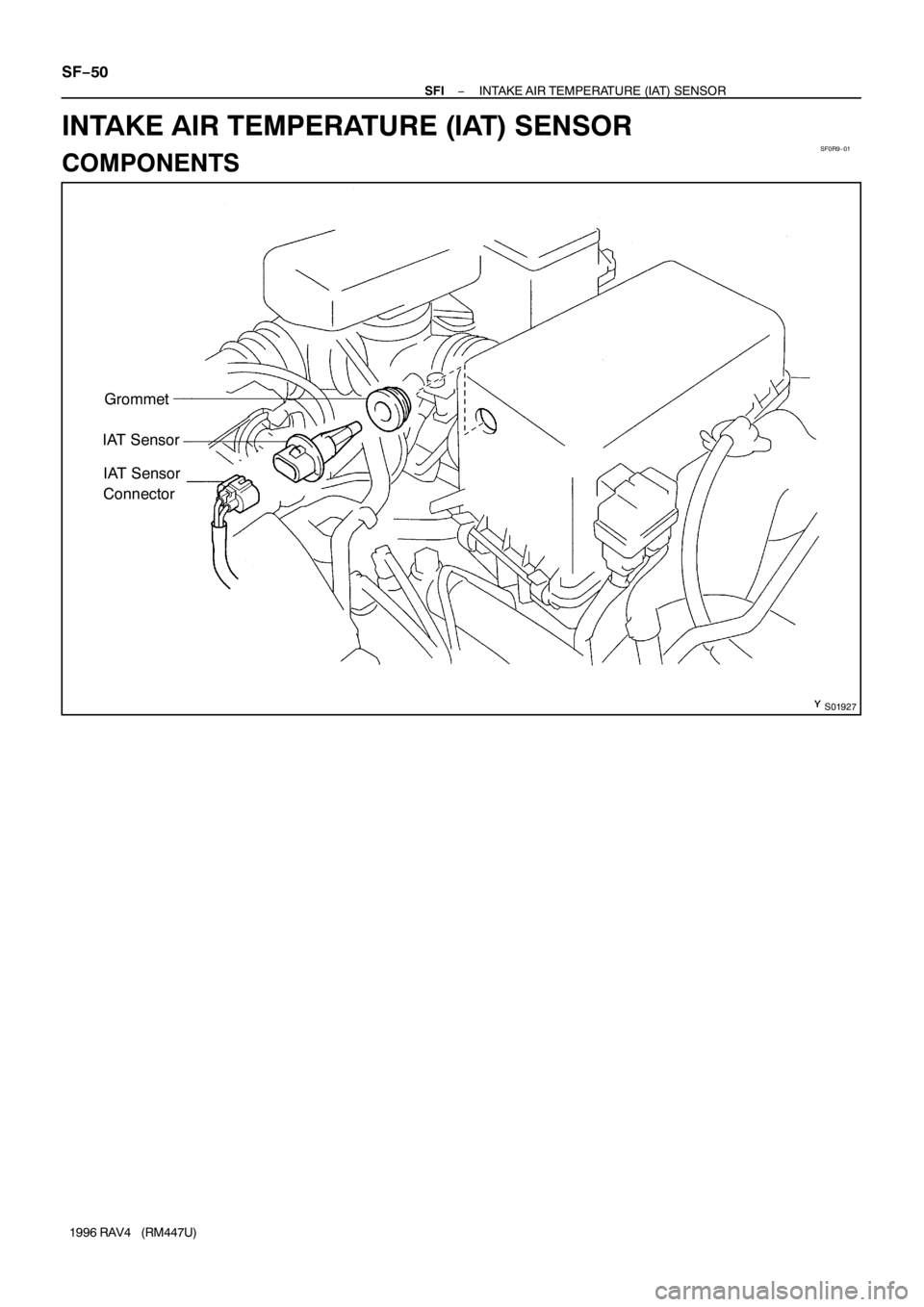

SF0R9−01

S01927

Grommet

IAT Sensor

IAT Sensor

Connector SF−50

− SFIINTAKE AIR TEMPERATURE (IAT) SENSOR

1996 RAV4 (RM447U)

INTAKE AIR TEMPERATURE (IAT) SENSOR

COMPONENTS

Page 1262 of 1354

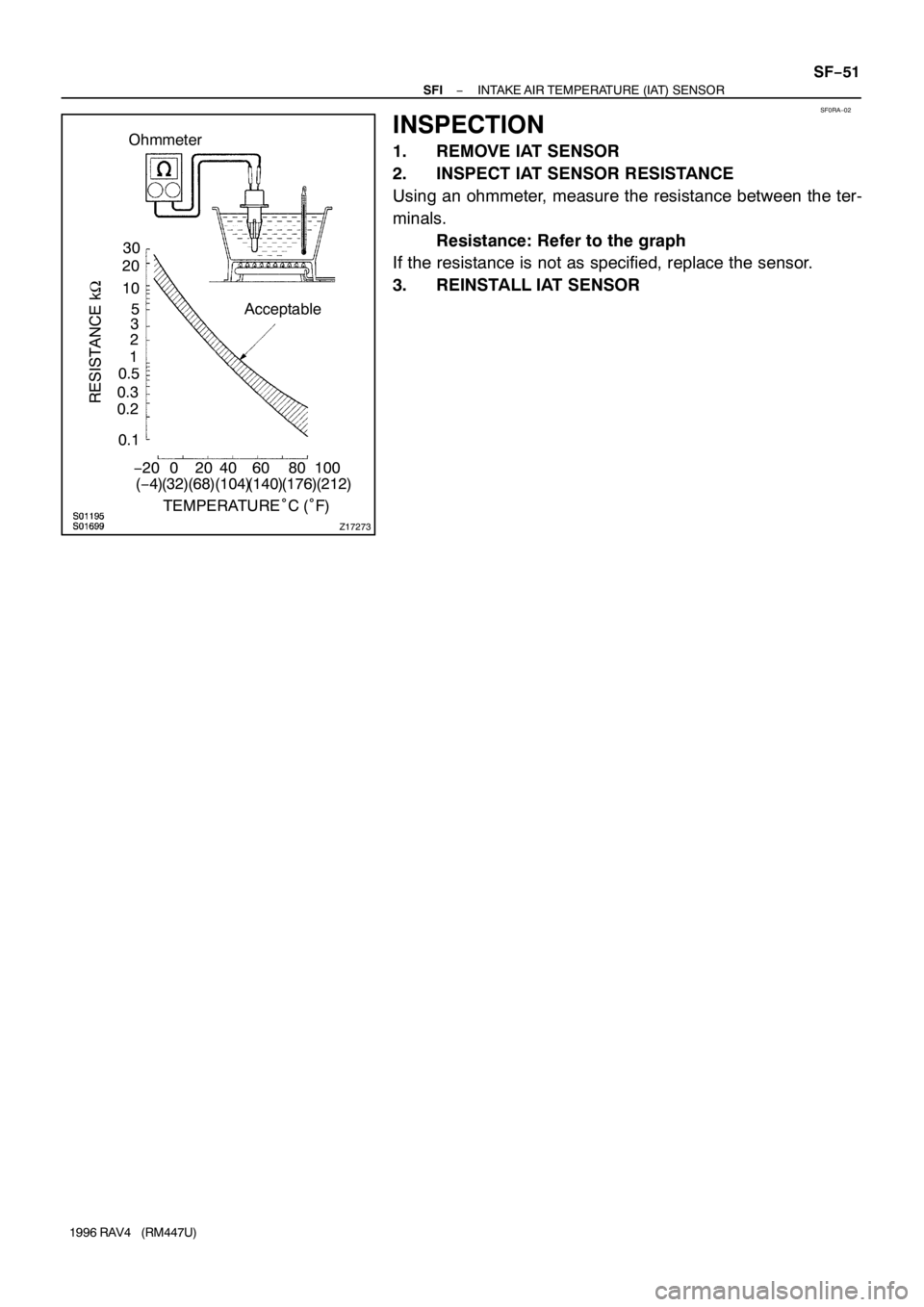

SF0RA−02

Z17273

Ohmmeter

Acceptable

TEMPERATURE°C (°F) −20 0 20 40 60

(32)(68)(104)(140)(176)(212) (−4)100 80 35 10 2030

RESISTANCE kΩ

2

1

0.5

0.3

0.2

0.1

− SFIINTAKE AIR TEMPERATURE (IAT) SENSOR

SF−51

1996 RAV4 (RM447U)

INSPECTION

1. REMOVE IAT SENSOR

2. INSPECT IAT SENSOR RESISTANCE

Using an ohmmeter, measure the resistance between the ter-

minals.

Resistance: Refer to the graph

If the resistance is not as specified, replace the sensor.

3. REINSTALL IAT SENSOR

Page 1263 of 1354

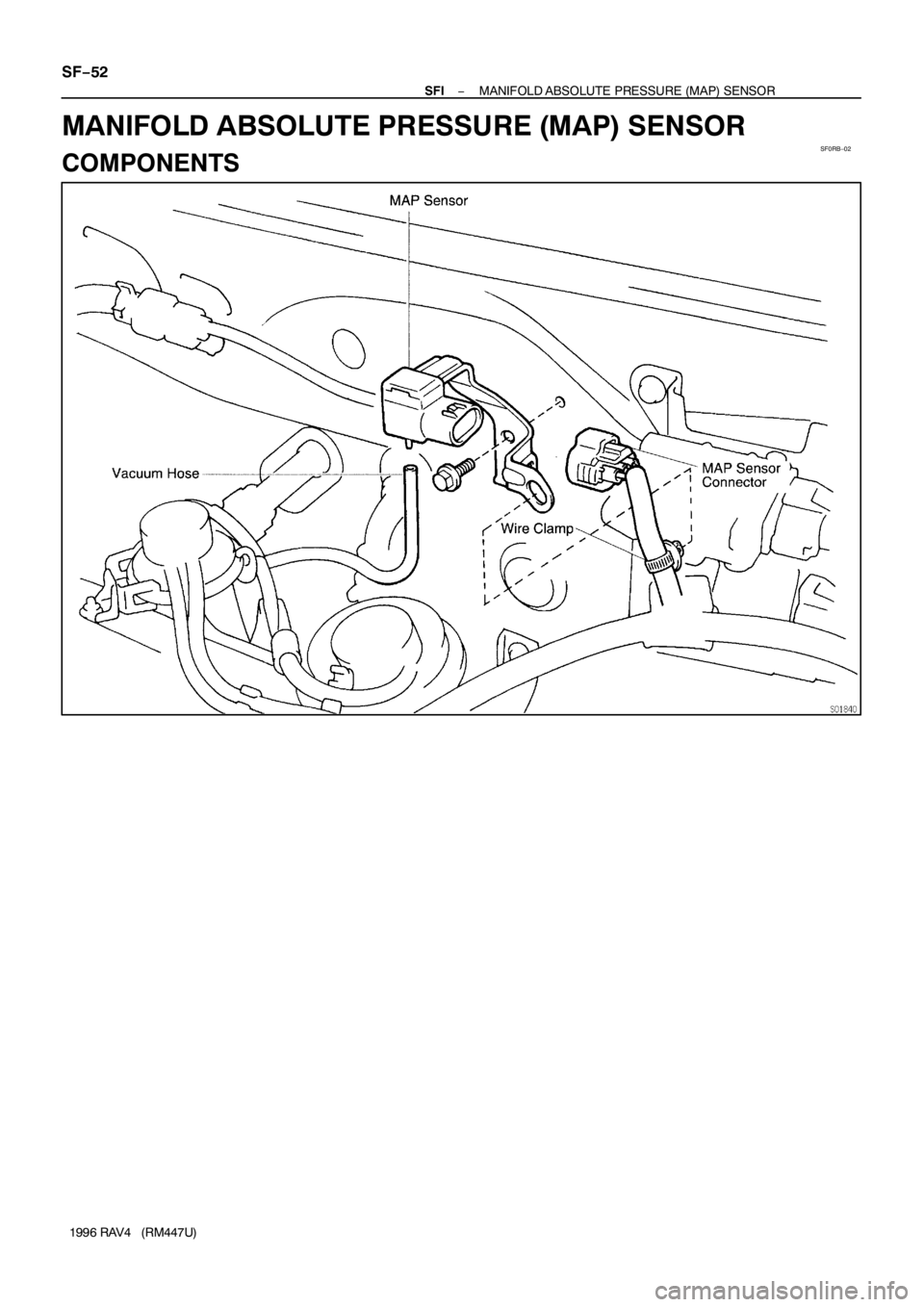

SF0RB−02

SF−52

− SFIMANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

1996 RAV4 (RM447U)

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

COMPONENTS

Page 1264 of 1354

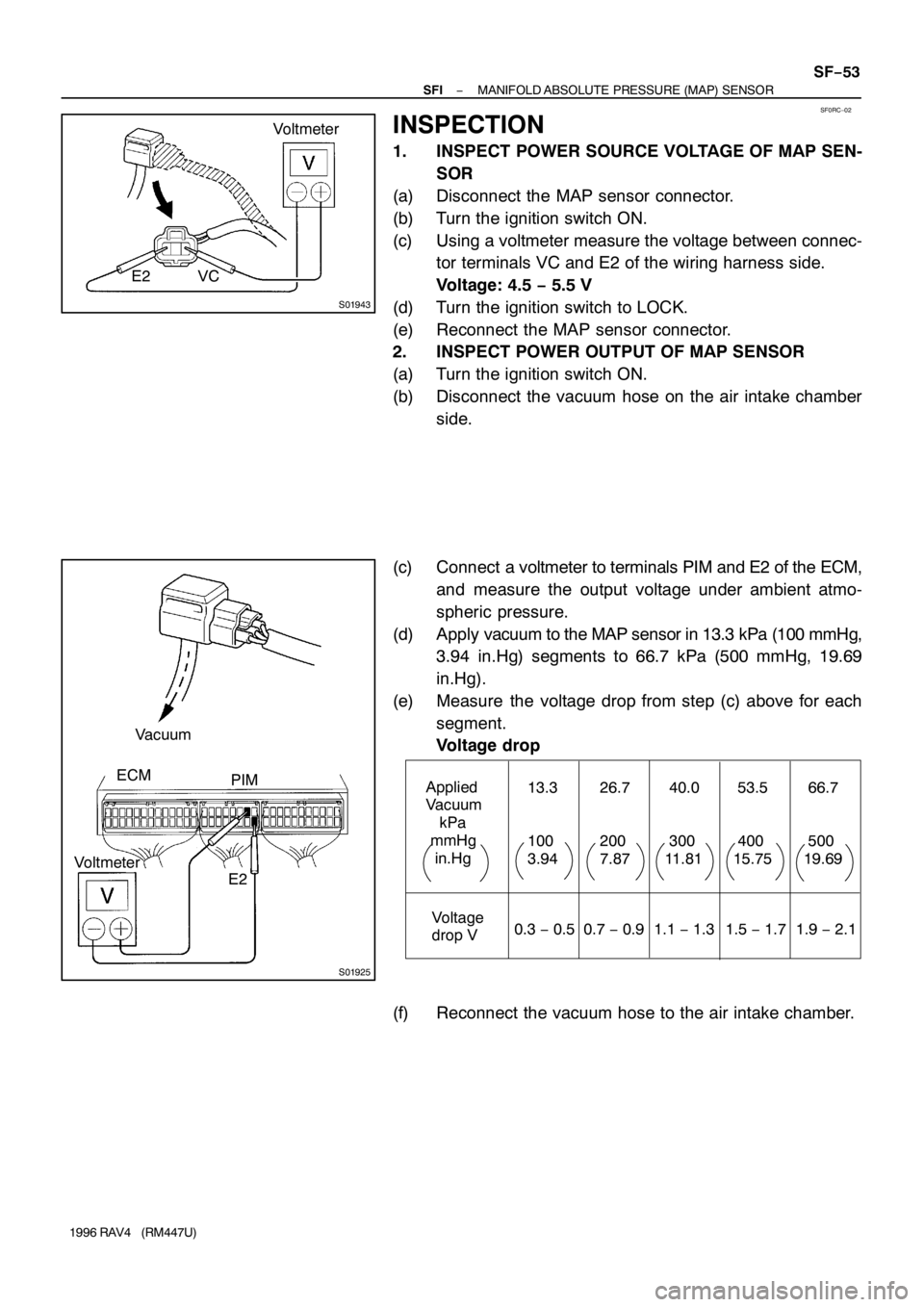

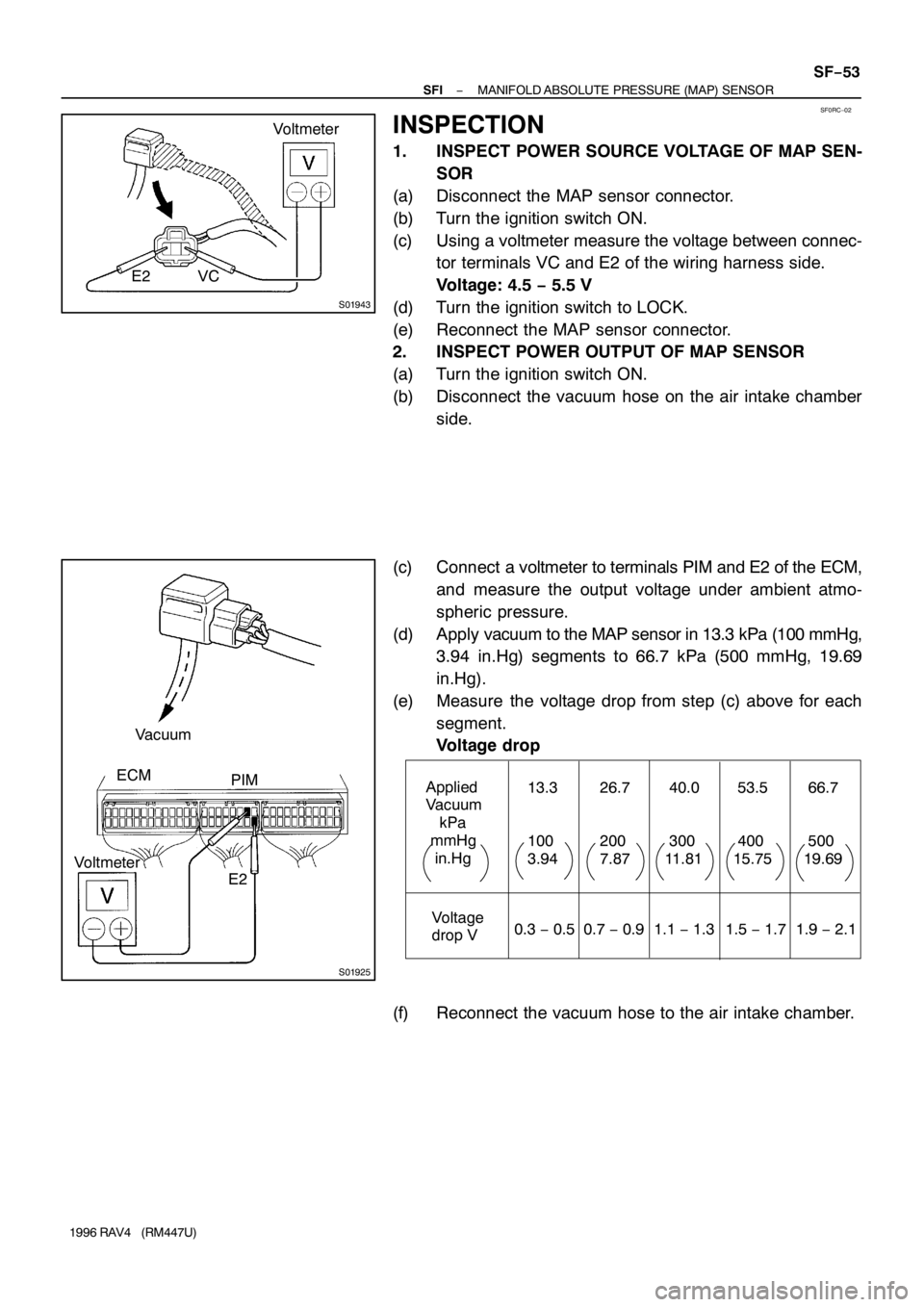

SF0RC−02

S01943

Voltmeter

E2 VC

S01925

Vacuum

ECM

PIM

E2 Voltmeter

66.7

500

19.69Applied

Vacuum

kPa

mmHg

in.Hg

Voltage

drop V0.3 − 0.5 0.7 − 0.9 1.1 − 1.3 1.5 − 1.7 1.9 − 2.1 13.3

100

3.94 26.7

200

7.87 40.0

300

11.81 53.5

400

15.75

− SFIMANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

SF−53

1996 RAV4 (RM447U)

INSPECTION

1. INSPECT POWER SOURCE VOLTAGE OF MAP SEN-

SOR

(a) Disconnect the MAP sensor connector.

(b) Turn the ignition switch ON.

(c) Using a voltmeter measure the voltage between connec-

tor terminals VC and E2 of the wiring harness side.

Voltage: 4.5 − 5.5 V

(d) Turn the ignition switch to LOCK.

(e) Reconnect the MAP sensor connector.

2. INSPECT POWER OUTPUT OF MAP SENSOR

(a) Turn the ignition switch ON.

(b) Disconnect the vacuum hose on the air intake chamber

side.

(c) Connect a voltmeter to terminals PIM and E2 of the ECM,

and measure the output voltage under ambient atmo-

spheric pressure.

(d) Apply vacuum to the MAP sensor in 13.3 kPa (100 mmHg,

3.94 in.Hg) segments to 66.7 kPa (500 mmHg, 19.69

in.Hg).

(e) Measure the voltage drop from step (c) above for each

segment.

Voltage drop

(f) Reconnect the vacuum hose to the air intake chamber.

Page 1265 of 1354

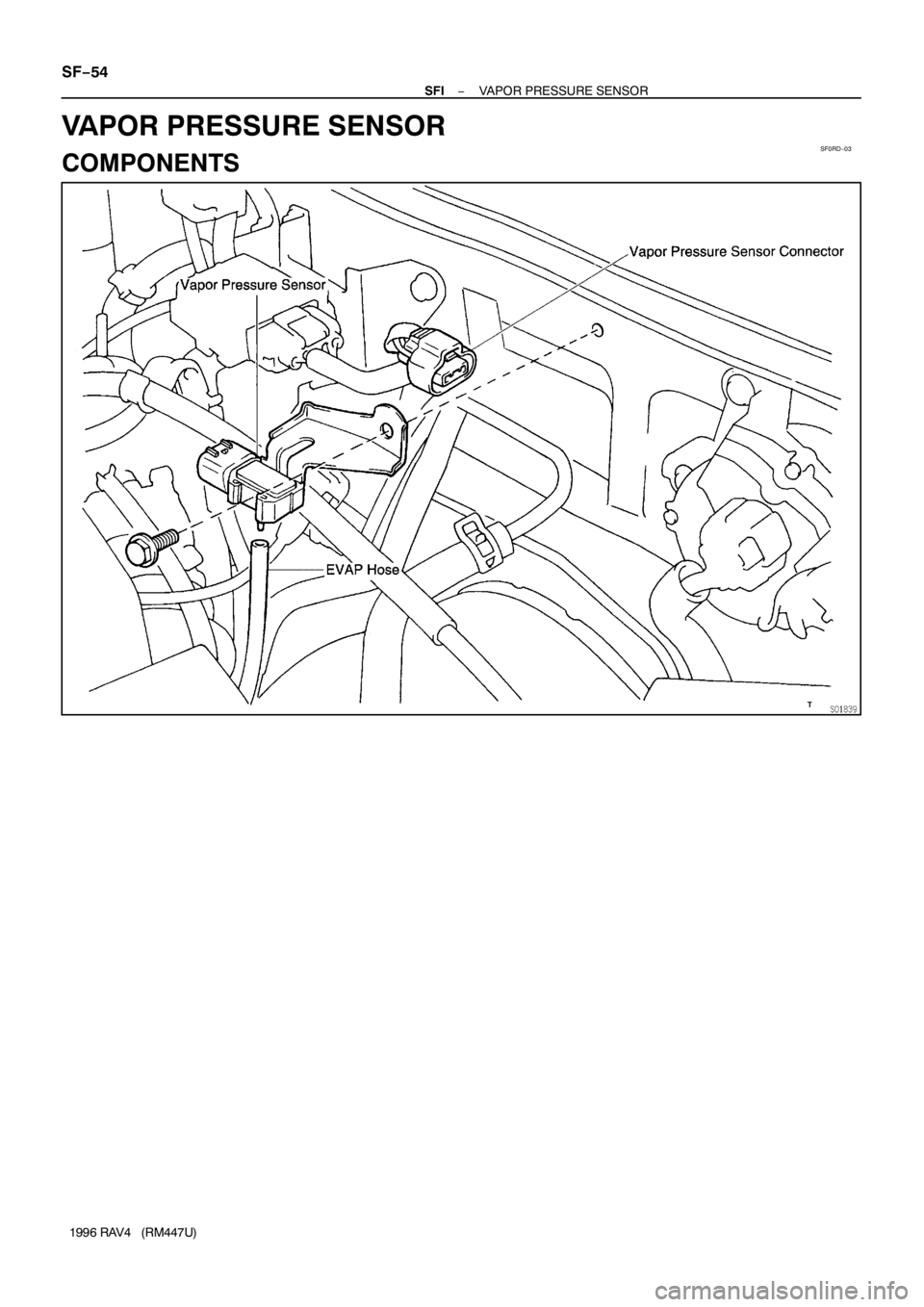

SF0RD−03

SF−54

− SFIVAPOR PRESSURE SENSOR

1996 RAV4 (RM447U)

VAPOR PRESSURE SENSOR

COMPONENTS

Page 1266 of 1354

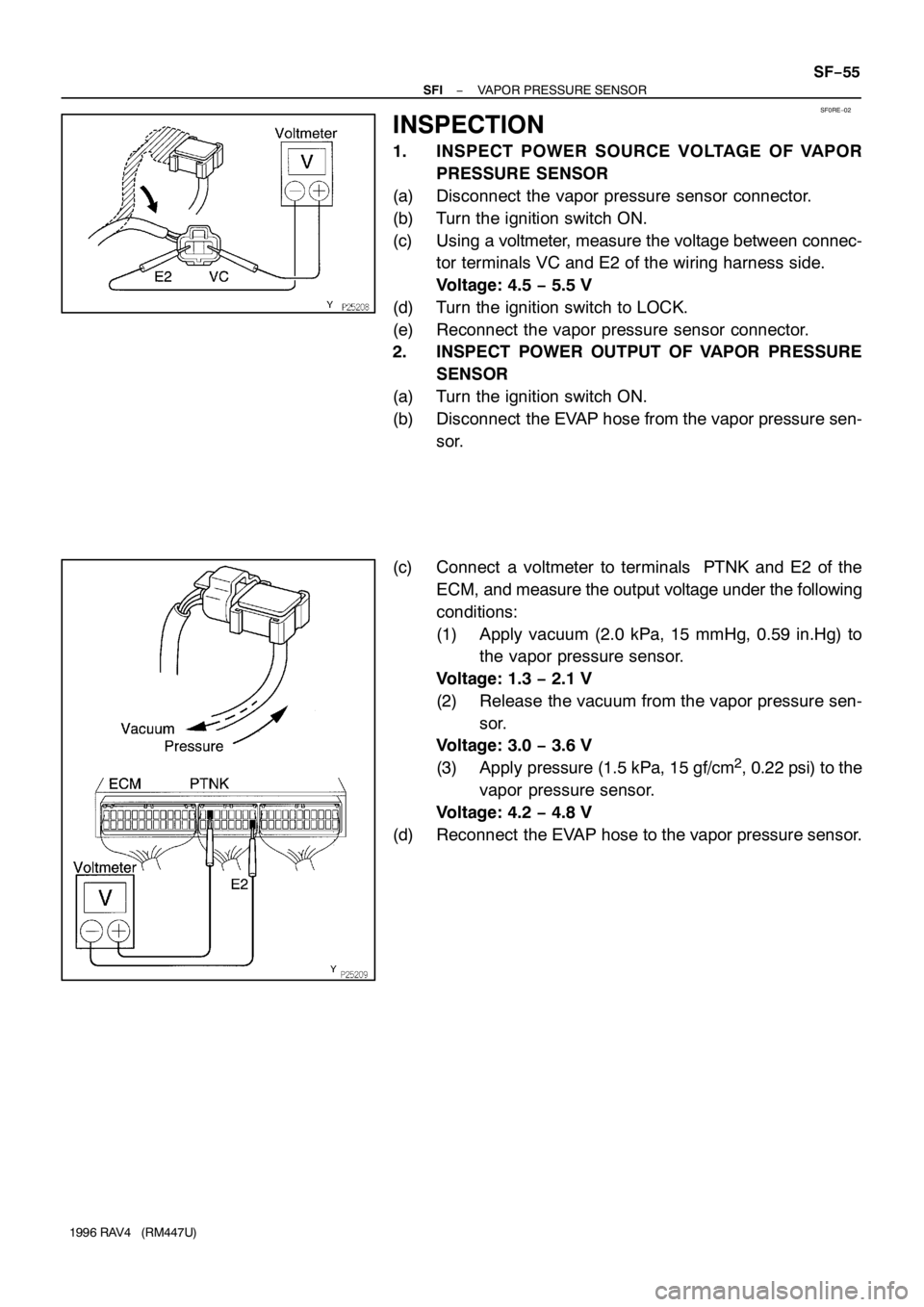

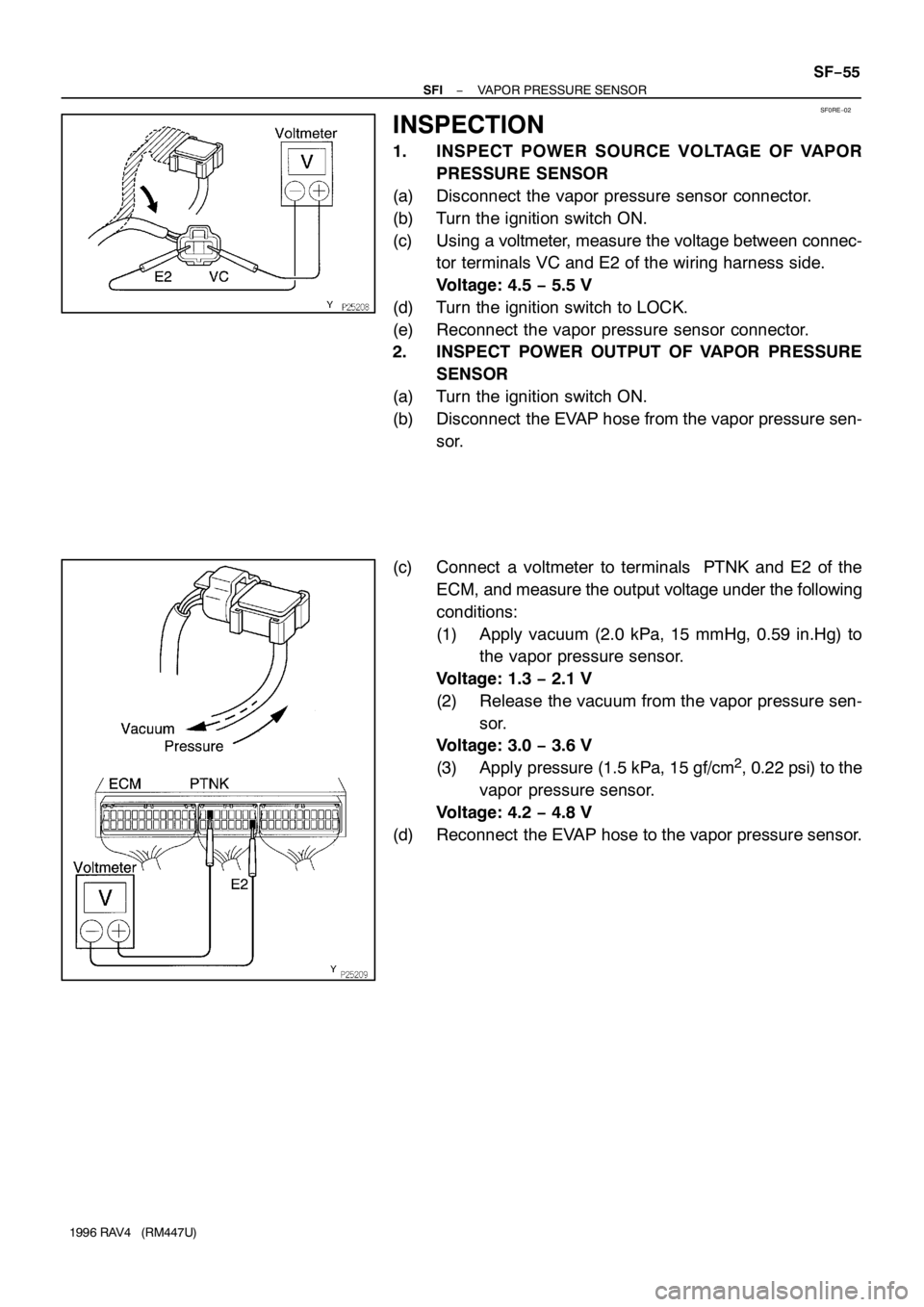

SF0RE−02

− SFIVAPOR PRESSURE SENSOR

SF−55

1996 RAV4 (RM447U)

INSPECTION

1. INSPECT POWER SOURCE VOLTAGE OF VAPOR

PRESSURE SENSOR

(a) Disconnect the vapor pressure sensor connector.

(b) Turn the ignition switch ON.

(c) Using a voltmeter, measure the voltage between connec-

tor terminals VC and E2 of the wiring harness side.

Voltage: 4.5 − 5.5 V

(d) Turn the ignition switch to LOCK.

(e) Reconnect the vapor pressure sensor connector.

2. INSPECT POWER OUTPUT OF VAPOR PRESSURE

SENSOR

(a) Turn the ignition switch ON.

(b) Disconnect the EVAP hose from the vapor pressure sen-

sor.

(c) Connect a voltmeter to terminals PTNK and E2 of the

ECM, and measure the output voltage under the following

conditions:

(1) Apply vacuum (2.0 kPa, 15 mmHg, 0.59 in.Hg) to

the vapor pressure sensor.

Voltage: 1.3 − 2.1 V

(2) Release the vacuum from the vapor pressure sen-

sor.

Voltage: 3.0 − 3.6 V

(3) Apply pressure (1.5 kPa, 15 gf/cm

2, 0.22 psi) to the

vapor pressure sensor.

Voltage: 4.2 − 4.8 V

(d) Reconnect the EVAP hose to the vapor pressure sensor.

Page 1267 of 1354

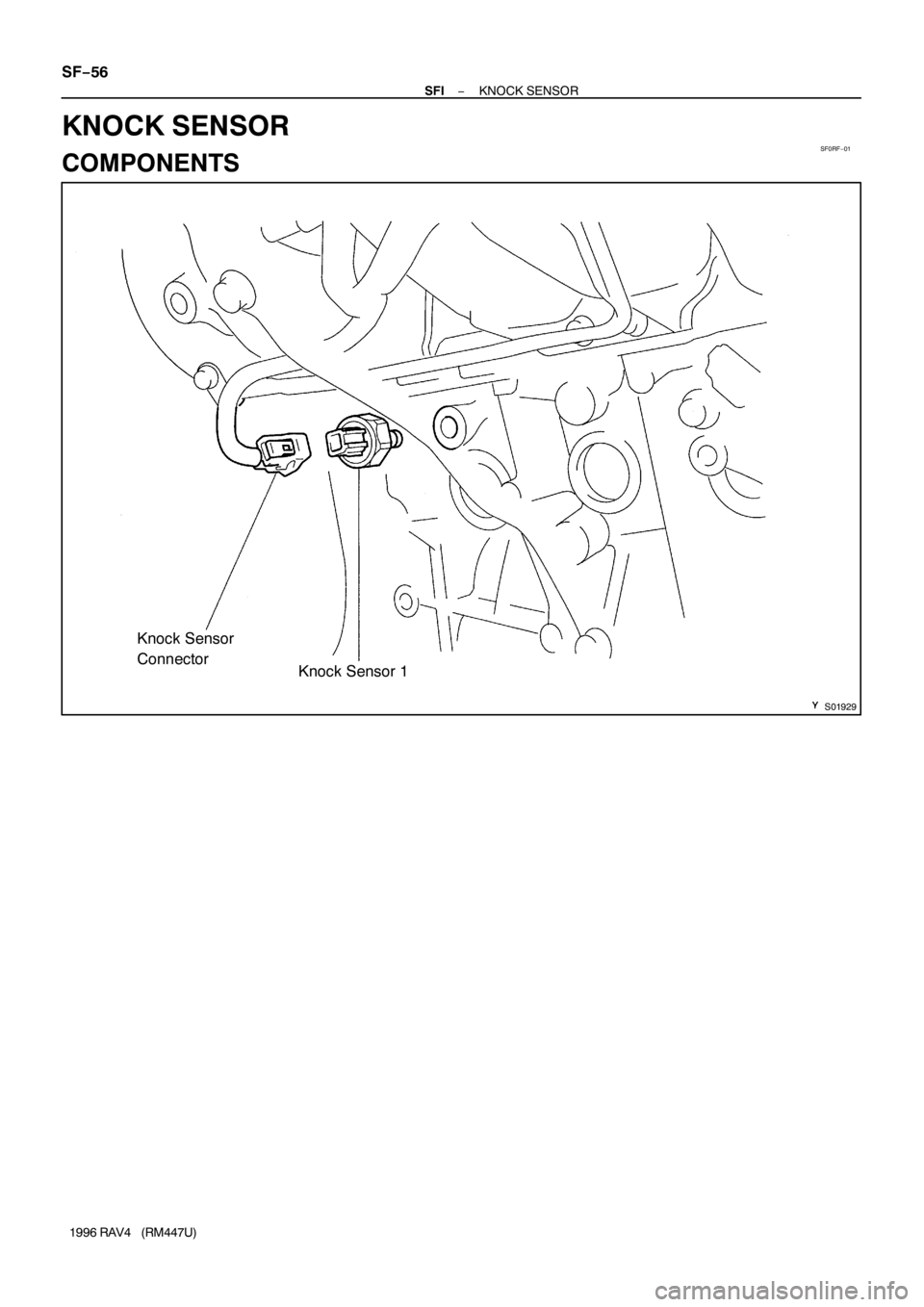

SF0RF−01

S01929

Knock Sensor

Connector

Knock Sensor 1 SF−56

− SFIKNOCK SENSOR

1996 RAV4 (RM447U)

KNOCK SENSOR

COMPONENTS

Page 1268 of 1354

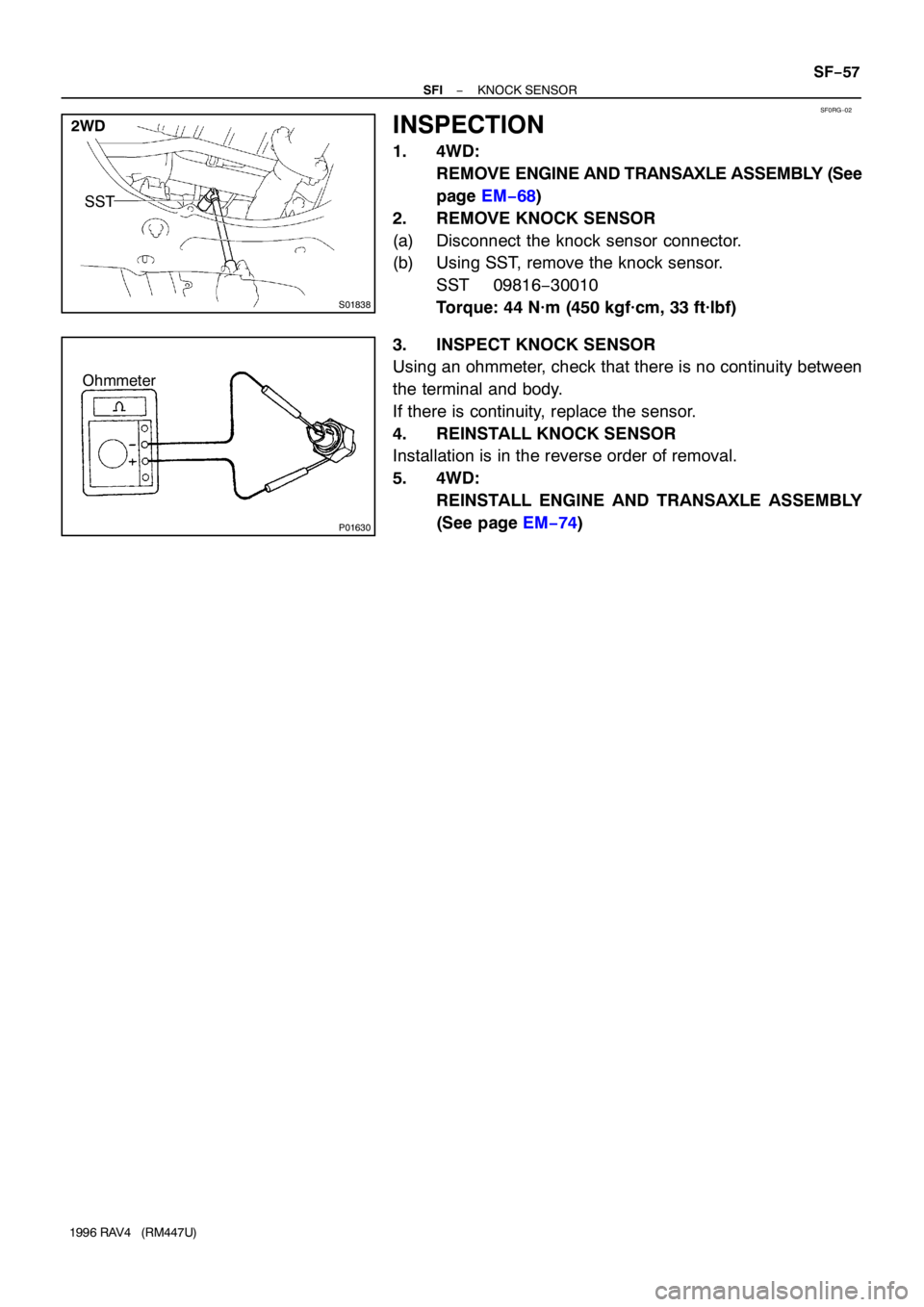

SF0RG−02

S01838

2WD

SST

P01630

Ohmmeter

− SFIKNOCK SENSOR

SF−57

1996 RAV4 (RM447U)

INSPECTION

1. 4WD:

REMOVE ENGINE AND TRANSAXLE ASSEMBLY (See

page EM−68)

2. REMOVE KNOCK SENSOR

(a) Disconnect the knock sensor connector.

(b) Using SST, remove the knock sensor.

SST 09816−30010

Torque: 44 N·m (450 kgf·cm, 33 ft·lbf)

3. INSPECT KNOCK SENSOR

Using an ohmmeter, check that there is no continuity between

the terminal and body.

If there is continuity, replace the sensor.

4. REINSTALL KNOCK SENSOR

Installation is in the reverse order of removal.

5. 4WD:

REINSTALL ENGINE AND TRANSAXLE ASSEMBLY

(See page EM−74)

Page 1269 of 1354

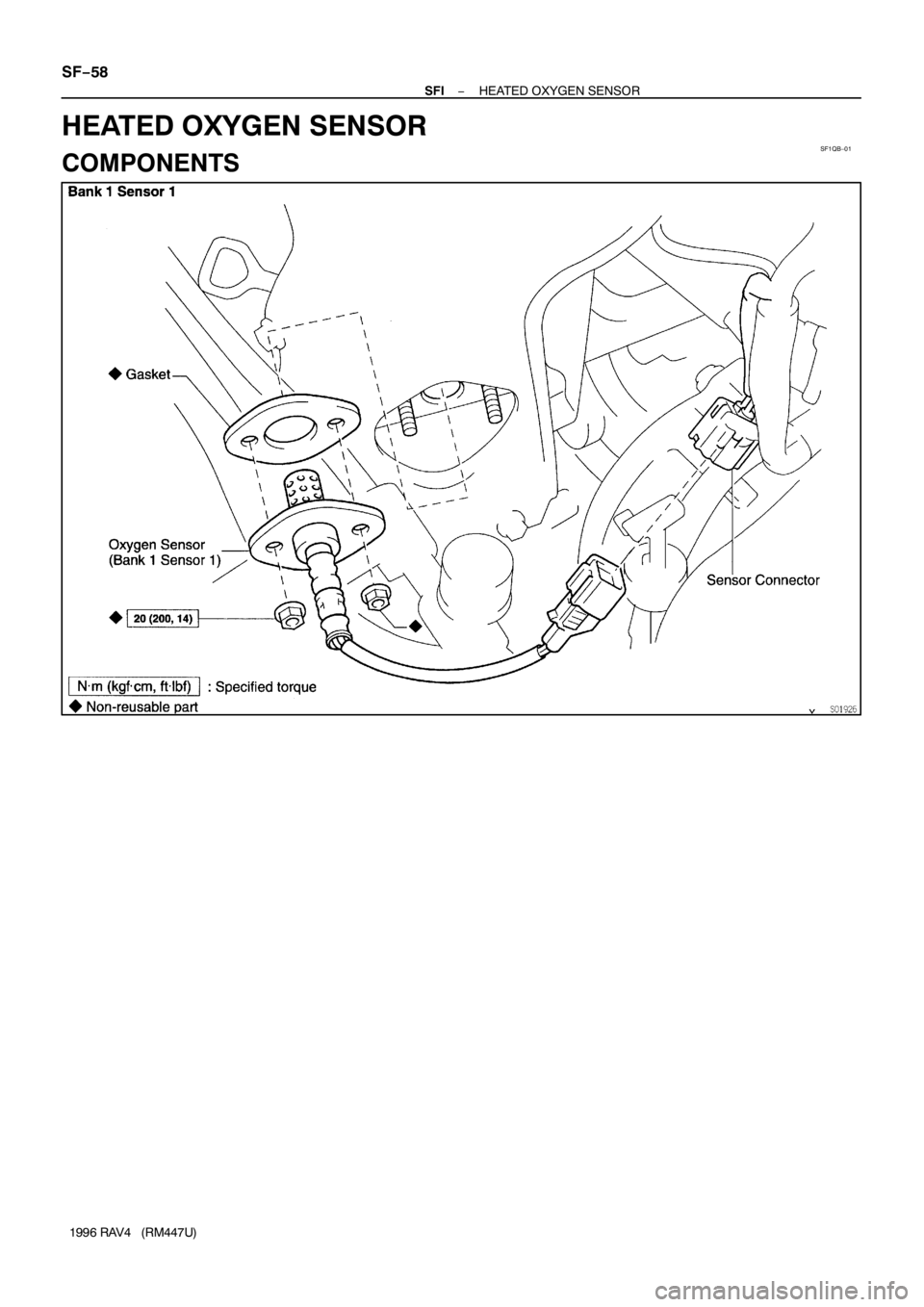

SF1QB−01

SF−58

− SFIHEATED OXYGEN SENSOR

1996 RAV4 (RM447U)

HEATED OXYGEN SENSOR

COMPONENTS

Page 1270 of 1354

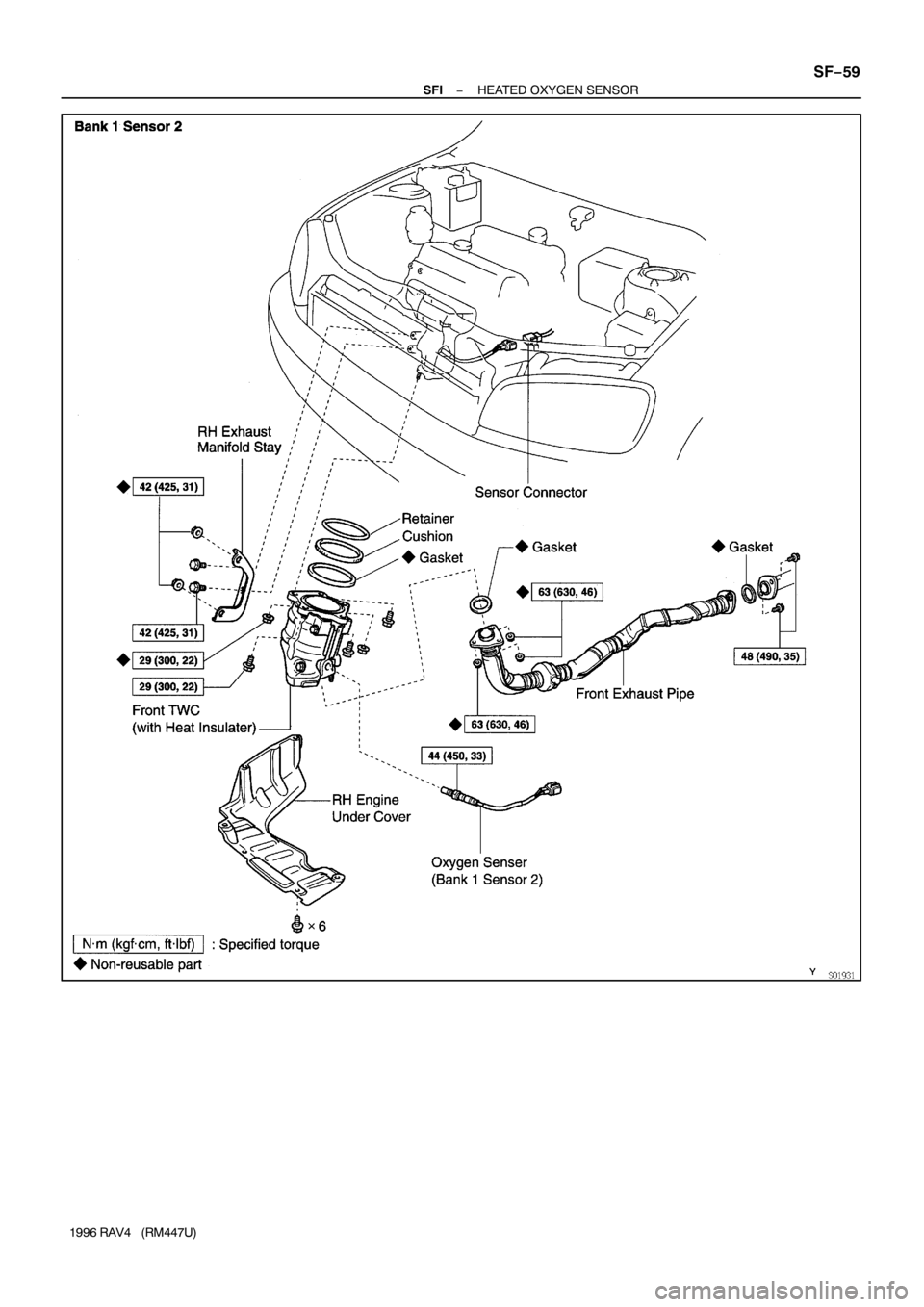

− SFIHEATED OXYGEN SENSOR

SF−59

1996 RAV4 (RM447U)

Trending: high beam, fuel pump, tow bar, brake, headlight, low beam, wipers