transaxle TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 967 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–33

AX

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) When troubleshooting On-Board Diagnostic (OBD

II) vehicles, the vehicle must be connected to the

OBD II scan tool (complying with SAE J1987).

Various data output from the vehicle's ECM can

then be read.

(b) OBD II regulations require that the vehicle's on-

board computer illuminates the Malfunction

Indicator Lamp (MIL) on the instrument panel when

the computer detects a malfunction in:

(1) The emission control system/components

(2) The powertrain control components (which affect

vehicle emissions)

(3) The computer

In addition, the applicable Diagnostic Trouble

Codes (DTCs) prescribed by SAE J2012 are

recorded in the ECM memory.

When the malfunction does not reoccur, the MIL

stays illuminated until the ignition switch is

turned OFF, and the MIL turns OFF when the

engine is started. However, the DTCs remain

recorded in the ECM memory.

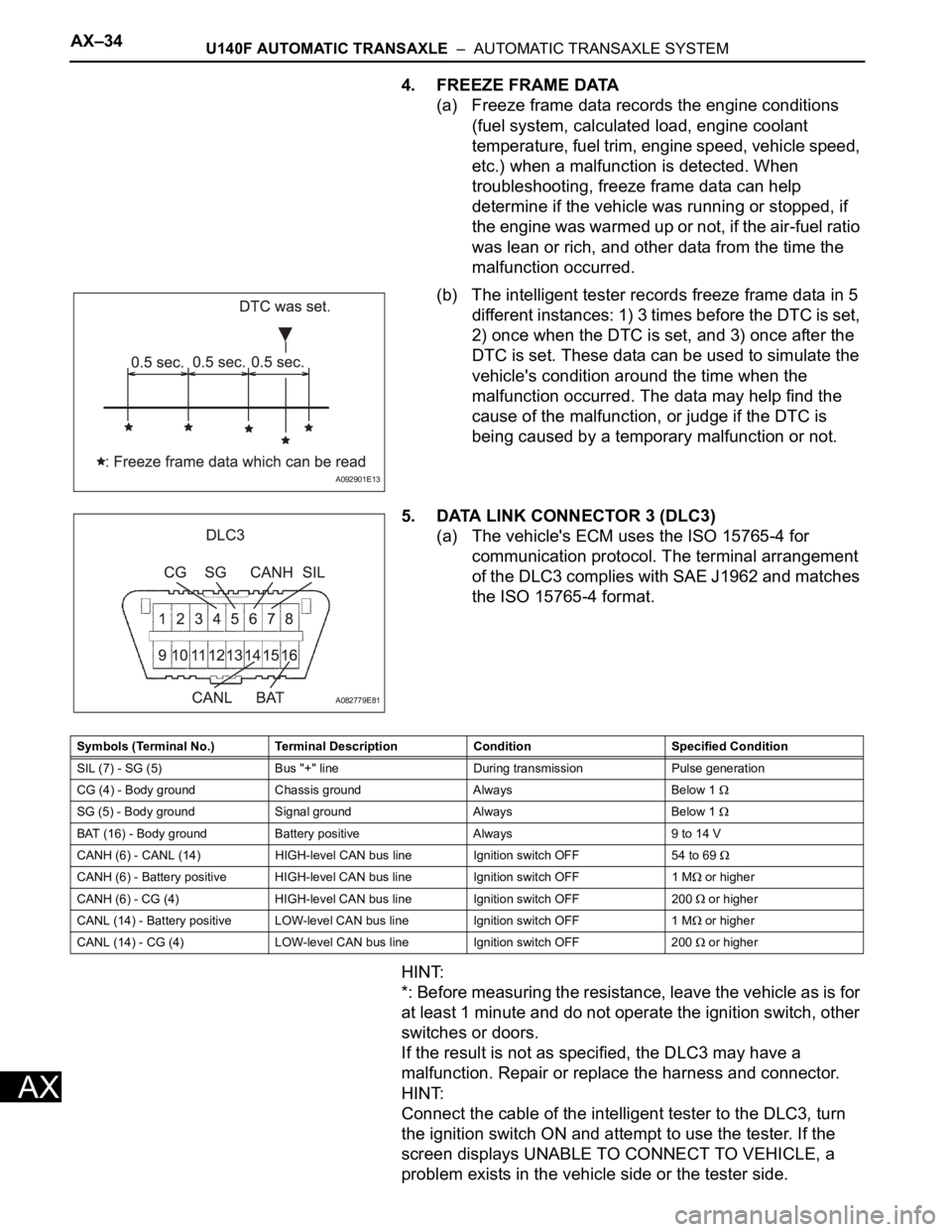

(c) To check DTCs, connect the intelligent tester to the

Data Link Connector 3 (DLC3) of the vehicle. The

tester displays DTCs, the freeze frame data and a

variety of the engine data.

The DTCs and freeze frame data can be erased

with the tester (see page AX-29).

2. NORMAL MODE AND CHECK MODE

(a) The diagnosis system operates in "normal mode"

during normal vehicle use. In normal mode, "2 trip

detection logic" is used to ensure accurate detection

of malfunctions. "Check mode" is also available to

technicians as an option. In check mode, "1 trip

detection logic" is used for simulating malfunction

symptoms and increasing the system's ability to

detect malfunctions, including intermittent

malfunctions.

3. 2 TRIP DETECTION LOGIC

(a) When a malfunction is first detected, the

malfunction is temporarily stored in the ECM

memory (1st trip). If the same malfunction is

detected during the next drive cycle, the MIL is

illuminated (2nd trip).

FI00534E01

B127989E02

Page 968 of 2000

AX–34U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

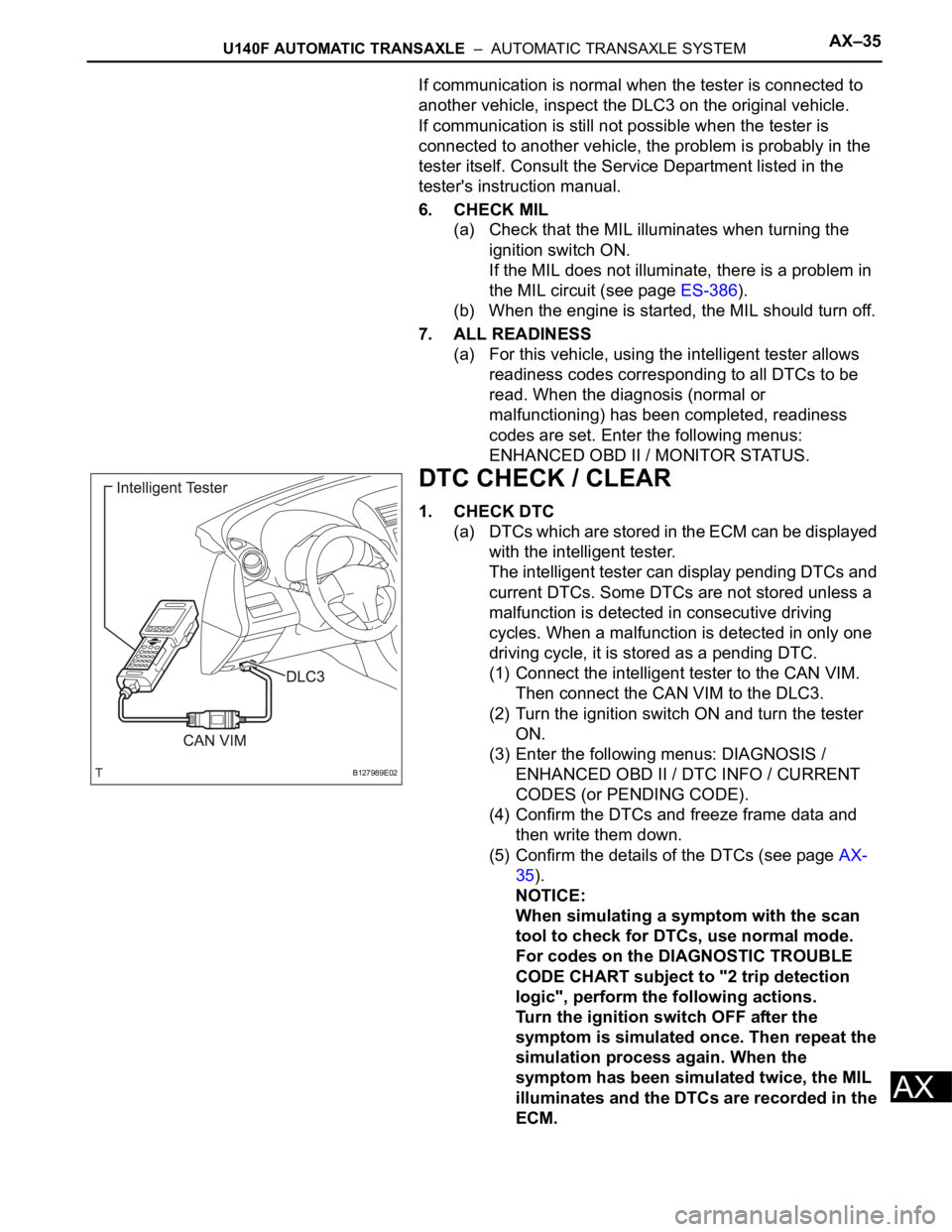

4. FREEZE FRAME DATA

(a) Freeze frame data records the engine conditions

(fuel system, calculated load, engine coolant

temperature, fuel trim, engine speed, vehicle speed,

etc.) when a malfunction is detected. When

troubleshooting, freeze frame data can help

determine if the vehicle was running or stopped, if

the engine was warmed up or not, if the air-fuel ratio

was lean or rich, and other data from the time the

malfunction occurred.

(b) The intelligent tester records freeze frame data in 5

different instances: 1) 3 times before the DTC is set,

2) once when the DTC is set, and 3) once after the

DTC is set. These data can be used to simulate the

vehicle's condition around the time when the

malfunction occurred. The data may help find the

cause of the malfunction, or judge if the DTC is

being caused by a temporary malfunction or not.

5. DATA LINK CONNECTOR 3 (DLC3)

(a) The vehicle's ECM uses the ISO 15765-4 for

communication protocol. The terminal arrangement

of the DLC3 complies with SAE J1962 and matches

the ISO 15765-4 format.

HINT:

*: Before measuring the resistance, leave the vehicle as is for

at least 1 minute and do not operate the ignition switch, other

switches or doors.

If the result is not as specified, the DLC3 may have a

malfunction. Repair or replace the harness and connector.

HINT:

Connect the cable of the intelligent tester to the DLC3, turn

the ignition switch ON and attempt to use the tester. If the

screen displays UNABLE TO CONNECT TO VEHICLE, a

problem exists in the vehicle side or the tester side.

A092901E13

A082779E81

Symbols (Terminal No.) Terminal Description Condition Specified Condition

SIL (7) - SG (5) Bus "+" line During transmission Pulse generation

CG (4) - Body ground Chassis ground Always Below 1

SG (5) - Body ground Signal ground Always Below 1

BAT (16) - Body ground Battery positive Always 9 to 14 V

CANH (6) - CANL (14) HIGH-level CAN bus line Ignition switch OFF 54 to 69

CANH (6) - Battery positive HIGH-level CAN bus line Ignition switch OFF 1 M or higher

CANH (6) - CG (4) HIGH-level CAN bus line Ignition switch OFF 200

or higher

CANL (14) - Battery positive LOW-level CAN bus line Ignition switch OFF 1 M

or higher

CANL (14) - CG (4) LOW-level CAN bus line Ignition switch OFF 200

or higher

Page 969 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–35

AX

If communication is normal when the tester is connected to

another vehicle, inspect the DLC3 on the original vehicle.

If communication is still not possible when the tester is

connected to another vehicle, the problem is probably in the

tester itself. Consult the Service Department listed in the

tester's instruction manual.

6. CHECK MIL

(a) Check that the MIL illuminates when turning the

ignition switch ON.

If the MIL does not illuminate, there is a problem in

the MIL circuit (see page ES-386).

(b) When the engine is started, the MIL should turn off.

7. ALL READINESS

(a) For this vehicle, using the intelligent tester allows

readiness codes corresponding to all DTCs to be

read. When the diagnosis (normal or

malfunctioning) has been completed, readiness

codes are set. Enter the following menus:

ENHANCED OBD II / MONITOR STATUS.

DTC CHECK / CLEAR

1. CHECK DTC

(a) DTCs which are stored in the ECM can be displayed

with the intelligent tester.

The intelligent tester can display pending DTCs and

current DTCs. Some DTCs are not stored unless a

malfunction is detected in consecutive driving

cycles. When a malfunction is detected in only one

driving cycle, it is stored as a pending DTC.

(1) Connect the intelligent tester to the CAN VIM.

Then connect the CAN VIM to the DLC3.

(2) Turn the ignition switch ON and turn the tester

ON.

(3) Enter the following menus: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT

CODES (or PENDING CODE).

(4) Confirm the DTCs and freeze frame data and

then write them down.

(5) Confirm the details of the DTCs (see page AX-

35).

NOTICE:

When simulating a symptom with the scan

tool to check for DTCs, use normal mode.

For codes on the DIAGNOSTIC TROUBLE

CODE CHART subject to "2 trip detection

logic", perform the following actions.

Turn the ignition switch OFF after the

symptom is simulated once. Then repeat the

simulation process again. When the

symptom has been simulated twice, the MIL

illuminates and the DTCs are recorded in the

ECM.

B127989E02

Page 970 of 2000

AX–36U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

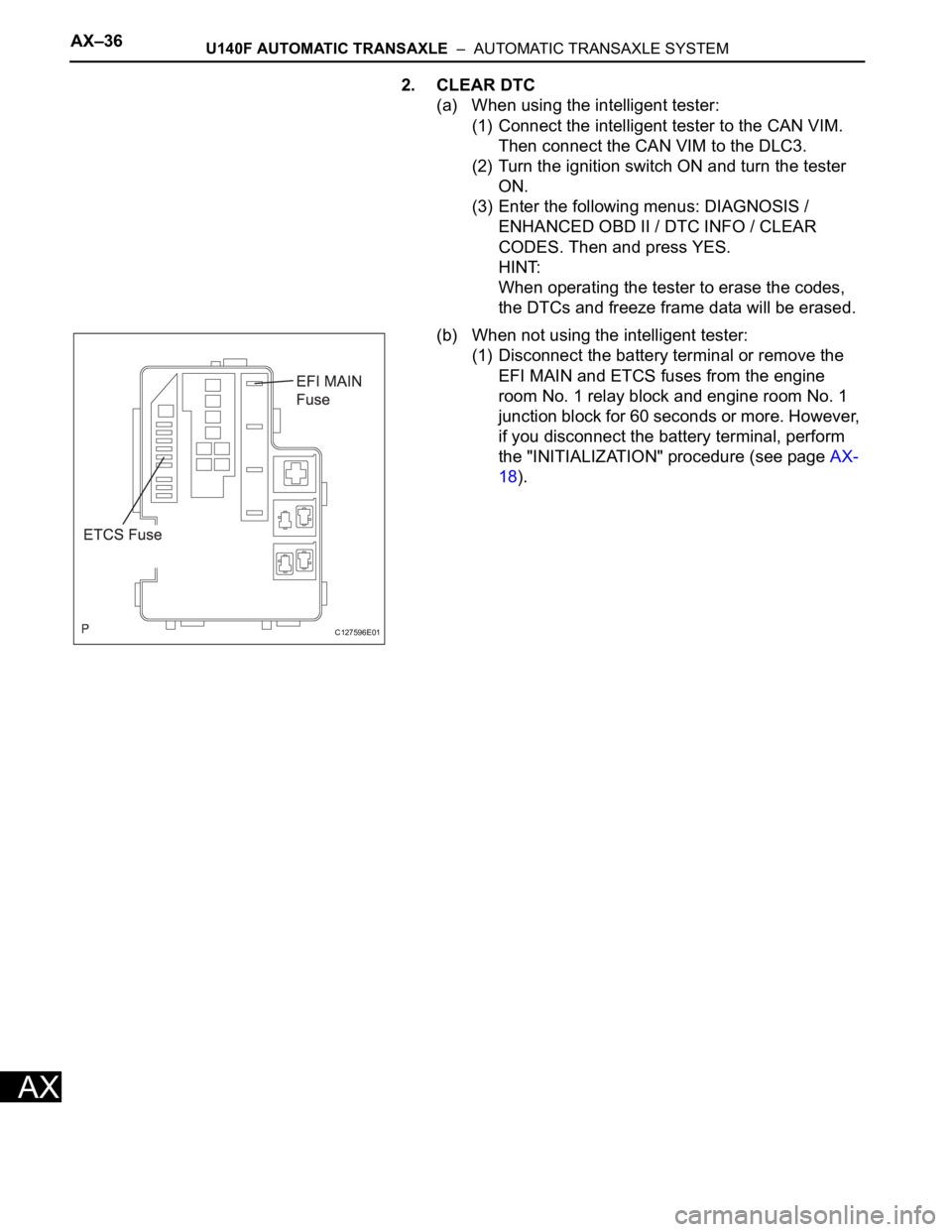

2. CLEAR DTC

(a) When using the intelligent tester:

(1) Connect the intelligent tester to the CAN VIM.

Then connect the CAN VIM to the DLC3.

(2) Turn the ignition switch ON and turn the tester

ON.

(3) Enter the following menus: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CLEAR

CODES. Then and press YES.

HINT:

When operating the tester to erase the codes,

the DTCs and freeze frame data will be erased.

(b) When not using the intelligent tester:

(1) Disconnect the battery terminal or remove the

EFI MAIN and ETCS fuses from the engine

room No. 1 relay block and engine room No. 1

junction block for 60 seconds or more. However,

if you disconnect the battery terminal, perform

the "INITIALIZATION" procedure (see page AX-

18).

C127596E01

Page 971 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–37

AX

CHECK MODE PROCEDURE

1. DESCRIPTION

(a) Check mode has a higher sensitivity to malfunctions

and can detect malfunctions that normal mode

cannot detect. Check mode can also detect all the

malfunctions that normal mode can detect. In check

mode, DTCs are detected with 1 trip detection logic.

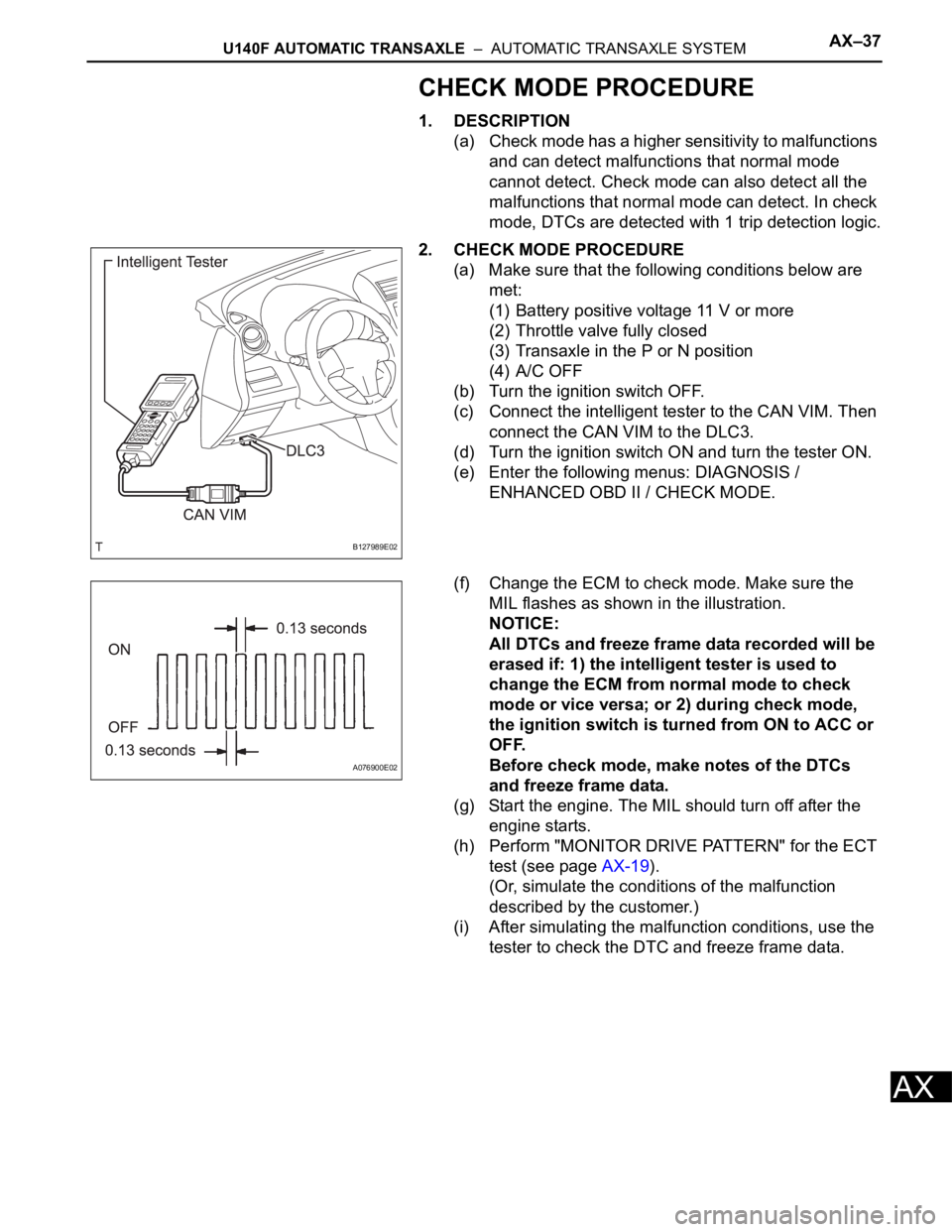

2. CHECK MODE PROCEDURE

(a) Make sure that the following conditions below are

met:

(1) Battery positive voltage 11 V or more

(2) Throttle valve fully closed

(3) Transaxle in the P or N position

(4) A/C OFF

(b) Turn the ignition switch OFF.

(c) Connect the intelligent tester to the CAN VIM. Then

connect the CAN VIM to the DLC3.

(d) Turn the ignition switch ON and turn the tester ON.

(e) Enter the following menus: DIAGNOSIS /

ENHANCED OBD II / CHECK MODE.

(f) Change the ECM to check mode. Make sure the

MIL flashes as shown in the illustration.

NOTICE:

All DTCs and freeze frame data recorded will be

erased if: 1) the intelligent tester is used to

change the ECM from normal mode to check

mode or vice versa; or 2) during check mode,

the ignition switch is turned from ON to ACC or

OFF.

Before check mode, make notes of the DTCs

and freeze frame data.

(g) Start the engine. The MIL should turn off after the

engine starts.

(h) Perform "MONITOR DRIVE PATTERN" for the ECT

test (see page AX-19).

(Or, simulate the conditions of the malfunction

described by the customer.)

(i) After simulating the malfunction conditions, use the

tester to check the DTC and freeze frame data.

B127989E02

A076900E02

Page 972 of 2000

U140F AUTOMATIC TRANSAXLE – FLOOR SHIFT ASSEMBLYAX–139

AX

ADJUSTMENT

1. INSPECT SHIFT LEVER POSITION

(a) When shifting the lever from P to the R position with

the ignition switch ON and the brake pedal

depressed, make sure that the shift lever moves

smoothly and moves correctly into position.

(b) Start the engine and make sure that the vehicle

moves forward when shifting the lever from N to the

D position and moves rearward when shifting the

lever to the R position.

If the operation cannot be performed as specified,

inspect the park/neutral position switch assembly

and check the shift lever assembly installation

condition.

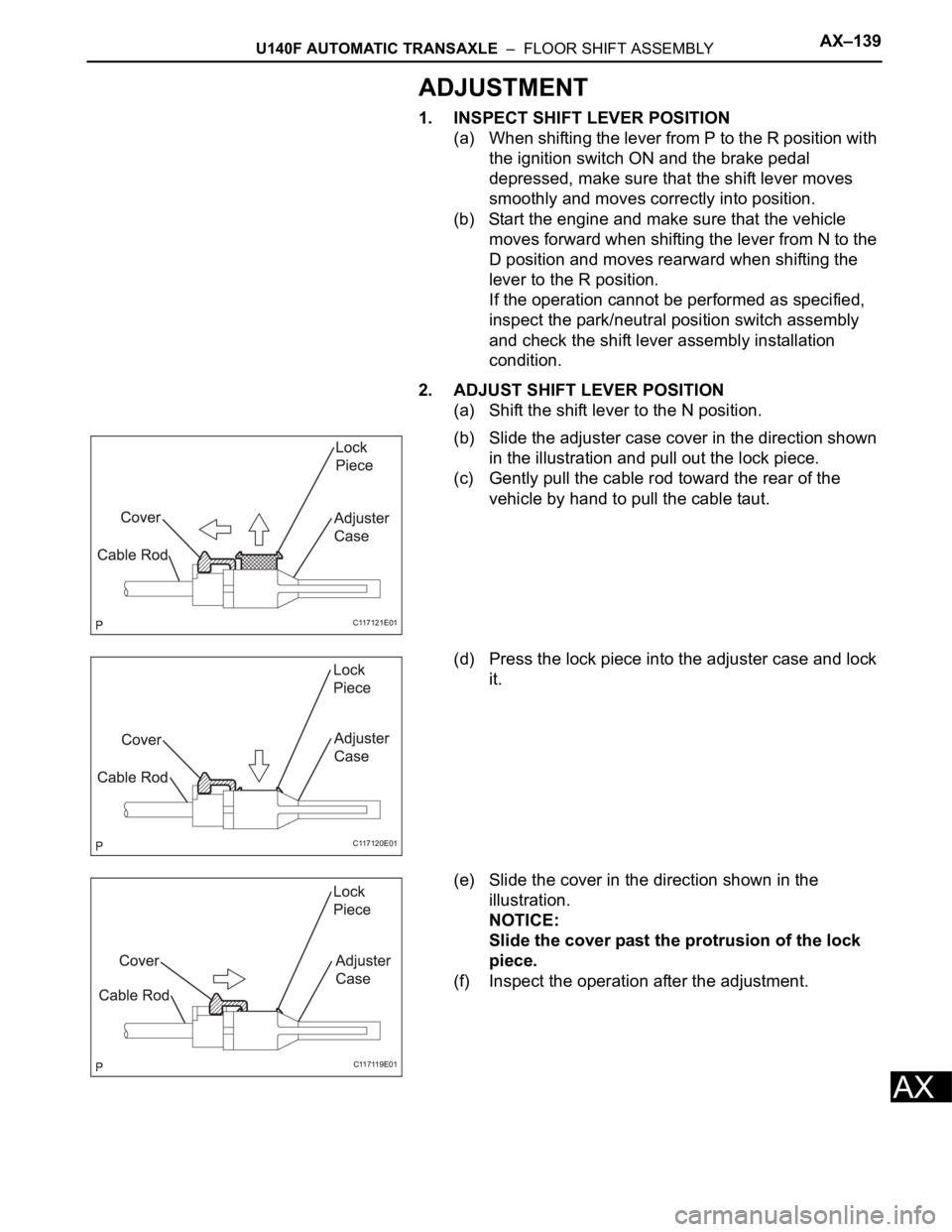

2. ADJUST SHIFT LEVER POSITION

(a) Shift the shift lever to the N position.

(b) Slide the adjuster case cover in the direction shown

in the illustration and pull out the lock piece.

(c) Gently pull the cable rod toward the rear of the

vehicle by hand to pull the cable taut.

(d) Press the lock piece into the adjuster case and lock

it.

(e) Slide the cover in the direction shown in the

illustration.

NOTICE:

Slide the cover past the protrusion of the lock

piece.

(f) Inspect the operation after the adjustment.

C117121E01

C117120E01

C117119E01

Page 973 of 2000

AX–140U140F AUTOMATIC TRANSAXLE – FLOOR SHIFT ASSEMBLY

AX

REASSEMBLY

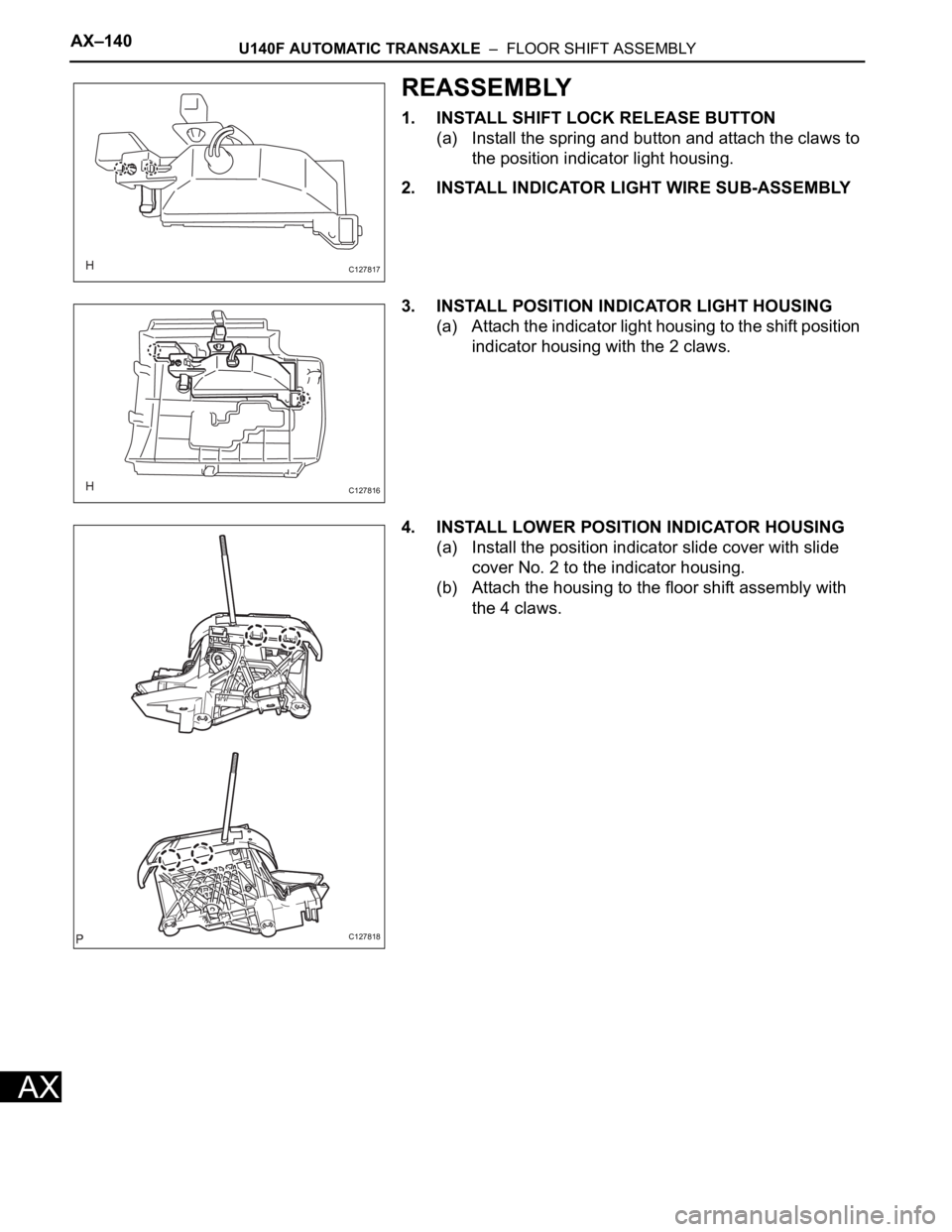

1. INSTALL SHIFT LOCK RELEASE BUTTON

(a) Install the spring and button and attach the claws to

the position indicator light housing.

2. INSTALL INDICATOR LIGHT WIRE SUB-ASSEMBLY

3. INSTALL POSITION INDICATOR LIGHT HOUSING

(a) Attach the indicator light housing to the shift position

indicator housing with the 2 claws.

4. INSTALL LOWER POSITION INDICATOR HOUSING

(a) Install the position indicator slide cover with slide

cover No. 2 to the indicator housing.

(b) Attach the housing to the floor shift assembly with

the 4 claws.

C127817

C127816

C127818

Page 974 of 2000

U140F AUTOMATIC TRANSAXLE – FLOOR SHIFT ASSEMBLYAX–141

AX

INSTALLATION

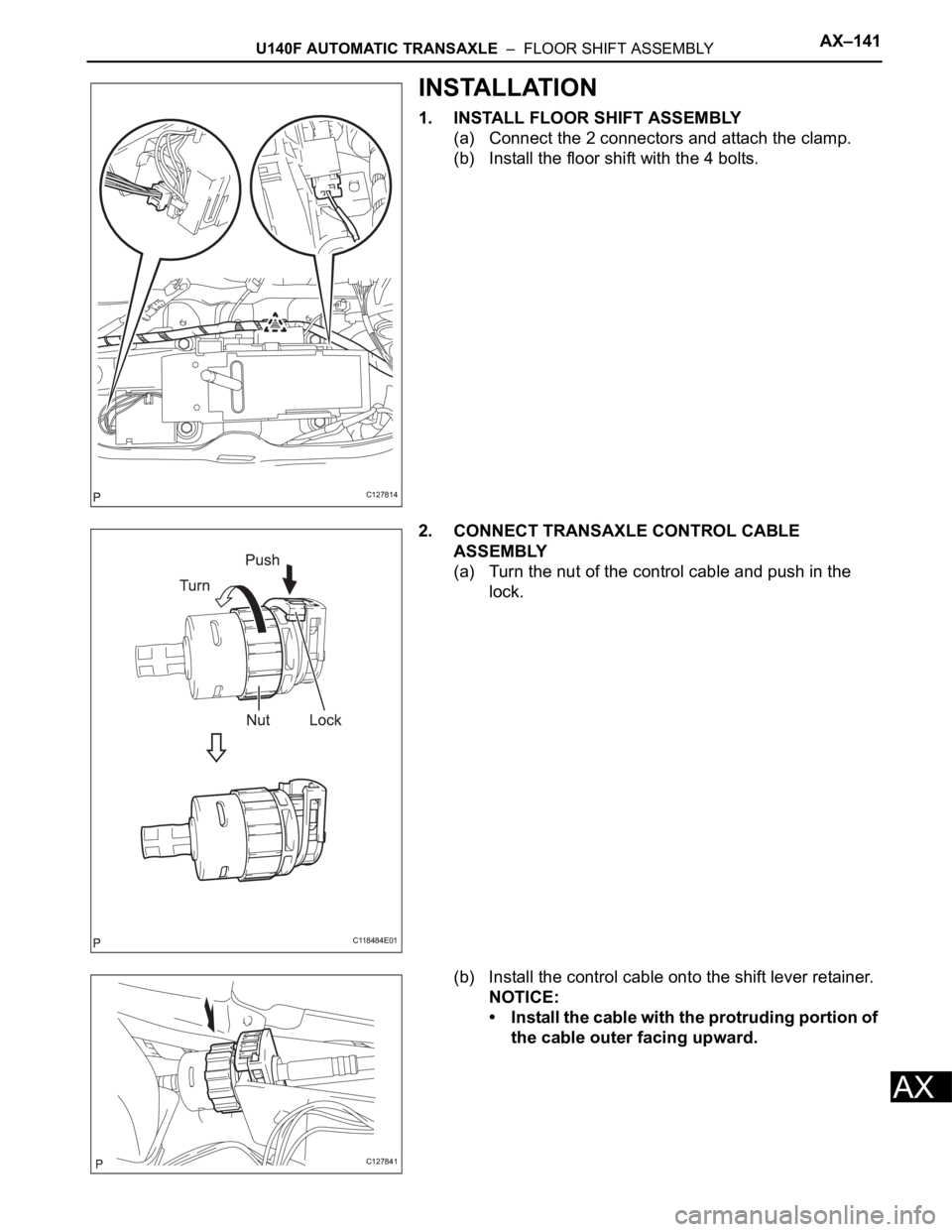

1. INSTALL FLOOR SHIFT ASSEMBLY

(a) Connect the 2 connectors and attach the clamp.

(b) Install the floor shift with the 4 bolts.

2. CONNECT TRANSAXLE CONTROL CABLE

ASSEMBLY

(a) Turn the nut of the control cable and push in the

lock.

(b) Install the control cable onto the shift lever retainer.

NOTICE:

• Install the cable with the protruding portion of

the cable outer facing upward.

C127814

C118484E01

C127841

Page 975 of 2000

AX–142U140F AUTOMATIC TRANSAXLE – FLOOR SHIFT ASSEMBLY

AX

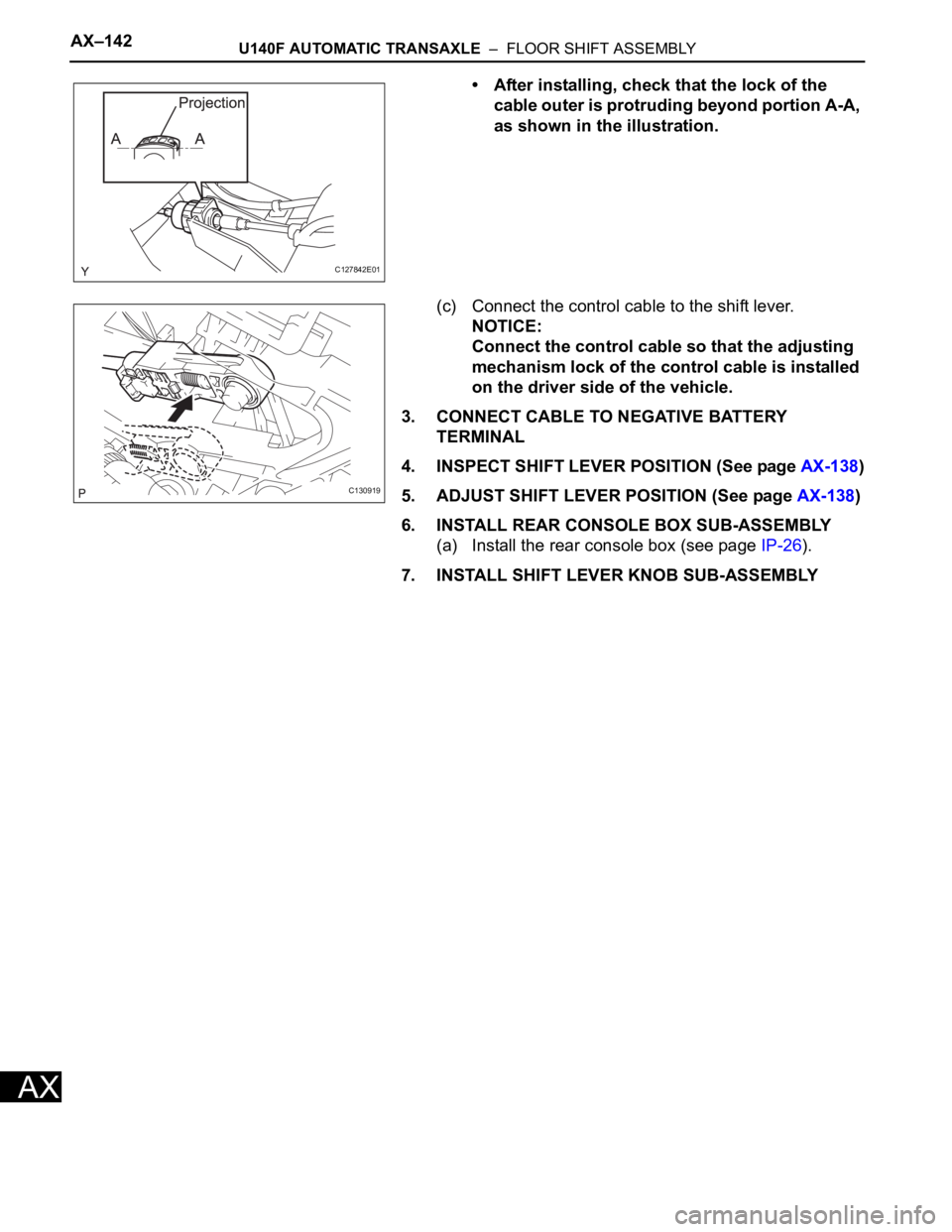

• After installing, check that the lock of the

cable outer is protruding beyond portion A-A,

as shown in the illustration.

(c) Connect the control cable to the shift lever.

NOTICE:

Connect the control cable so that the adjusting

mechanism lock of the control cable is installed

on the driver side of the vehicle.

3. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

4. INSPECT SHIFT LEVER POSITION (See page AX-138)

5. ADJUST SHIFT LEVER POSITION (See page AX-138)

6. INSTALL REAR CONSOLE BOX SUB-ASSEMBLY

(a) Install the rear console box (see page IP-26).

7. INSTALL SHIFT LEVER KNOB SUB-ASSEMBLY

C127842E01

C130919

Page 976 of 2000

AX–144U140F AUTOMATIC TRANSAXLE – DIFFERENTIAL OIL SEAL

AX

REPLACEMENT

1. REPLACE TRANSAXLE HOUSING OIL SEAL LH

(a) Drain the automatic transaxle fluid.

(1) Remove the drain plug and gasket, and drain

AT F.

(2) Install a new gasket and drain plug.

Torque: 47 N*m (479 kgf*cm, 35 ft.*lbf)

(b) Remove the front drive shaft LH (see page DS-41).

(c) Remove the transaxle housing oil seal LH.

(1) Using SST, tap out the oil seal.

SST 09308-00010

(d) Install a new transaxle housing oil seal LH.

(1) Coat the lip of a new oil seal with MP grease.

(2) Using SST and a hammer, tap in the oil seal.

SST 09726-27012 (09726-02041), 09950-

70010 (09951-07200, 09951-07200)

Standard depth:

0 +-0.5 mm (0 +-0.020 in.)

(e) Install the front drive shaft LH (see page DS-65).

(f) Add automatic transaxle fluid.

Fluid type:

Toyota Genuine ATF WS

(g) Inspect the transaxle fluid level (see page AX-102).

2. REPLACE TRANSAXLE HOUSING OIL SEAL RH

(a) Remove the engine with transaxle (see page EM-

98).

(b) Drain the automatic transaxle fluid.

(1) Remove the drain plug and gasket, and drain

AT F.

(2) Install a new gasket and the drain plug.

Torque: 47 N*m (479 kgf*cm, 35 ft.*lbf)

(c) Remove the 3 bolts and drive shaft bearing bracket.

(d) Remove the 3 bolts and engine mount bracket RR.

(e) Remove the transfer assembly (see page TF-59).

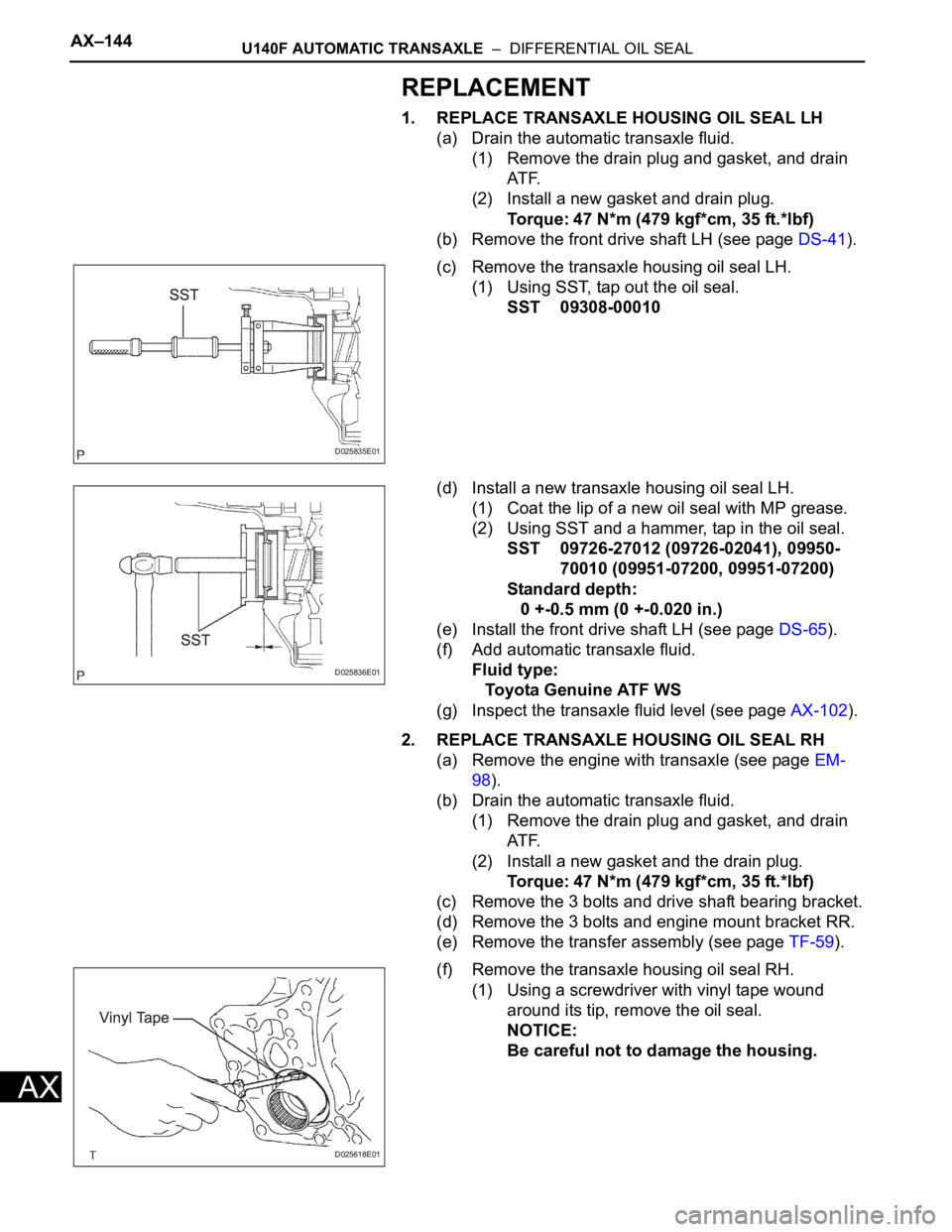

(f) Remove the transaxle housing oil seal RH.

(1) Using a screwdriver with vinyl tape wound

around its tip, remove the oil seal.

NOTICE:

Be careful not to damage the housing.

D025835E01

D025836E01

D025618E01