transaxle TOYOTA RAV4 2006 Service Manual PDF

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 419 of 2000

MA–12MAINTENANCE – CHASSIS

MA

GENERAL MAINTENANCE

(2006/01- )

1. INSPECT STEERING LINKAGE AND GEAR HOUSING

(a) Check the steering wheel free play.

(b) Check the steering linkage for looseness or

damage.

(1) Check that the tie rod ends do not have

excessive play.

(2) Check that the dust seals and boots are not

damaged.

(3) Check that the boot clamps are not loose.

(4) Check that the steering gear housing is not

damaged.

(5) Check that the connectors are properly

connected to the steering gear housing.

2. INSPECT BALL JOINTS AND DUST COVERS

(a) Inspect the ball joints for excessive looseness.

(1) Jack up the front of the vehicle and place

wooden blocks with a height of 180 to 200 mm

(7.09 to 7.87 in.) under the front tires.

(2) Lower the vehicle until the front coil spring has

about half its ordinary load. Place stands under

the vehicle for safety.

(3) Check that the front wheels are pointing

straight ahead. Use wheel chocks on all 4

wheels.

(4) Using a lever, pry up the end of the lower arm.

Check the amount of play.

Maximum ball joint vertical play:

0 mm (0 in.)

If there is any play, replace the ball joint.

(b) Check the dust cover for damage.

3. INSPECT DRIVE SHAFT BOOTS

(a) Check the drive shaft boots for loose clamps,

grease leakage, kinks or damage.

4. INSPECT AUTOMATIC TRANSAXLE FLUID LEVEL

(a) Visually check the transmission for fluid leakage. If

oil is leaking, find the cause and repair it.

5. INSPECT TRANSFER OIL (for 4WD)

(a) Visually check the transfer for oil leakage. If oil is

leaking, find the cause and repair it.

6. INSPECT REAR DIFFERENTIAL OIL (for 4WD)

(a) For the rear differential oil inspection, refer to the

following procedures (see page DF-3).

Type See procedures

U151E See page AX-126

U151F See page AX-126

Type See procedures

Front Oil See page TF-45

Rear Oil See page TF-45

Page 633 of 2000

EM–982AZ-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE (See page

FU-9)

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

3. REMOVE HOOD SUB-ASSEMBLY (See page ED-4)

4. REMOVE RADIATOR SUPPORT OPENING COVER

5. REMOVE BATTERY CLAMP SUB-ASSEMBLY

(a) Loosen the bolt and nut, and remove the battery

clamp.

6. REMOVE BATTERY

7. REMOVE BATTERY TRAY

8. REMOVE FRONT WHEEL

9. REMOVE NO. 1 ENGINE UNDER COVER

10. REMOVE NO. 2 ENGINE UNDER COVER

11. REMOVE FRONT FENDER APRON RH

12. REMOVE NO. 1 ENGINE COVER (See page EM-22)

13. DRAIN ENGINE COOLANT (See page CO-6)

14. DRAIN AUTOMATIC TRANSAXLE FLUID

(a) Drain automatic transaxle fluid for U241E (2WD)

(see page AX-146).

(b) Drain automatic transaxle fluid for U140F (4WD)

(see page AX-147).

15. REMOVE RADIATOR ASSEMBLY

(a) Remove the radiator (see page CO-29).

16. REMOVE RADIATOR RESERVOIR

(a) Remove the 2 bolts and reservoir.

17. REMOVE PURGE VSV (See page EC-15)

18. REMOVE AIR CLEANER CAP (See page ES-411)

19. REMOVE AIR CLEANER FILTER ELEMENT SUB-

ASSEMBLY

A124838

Page 635 of 2000

EM–1002AZ-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

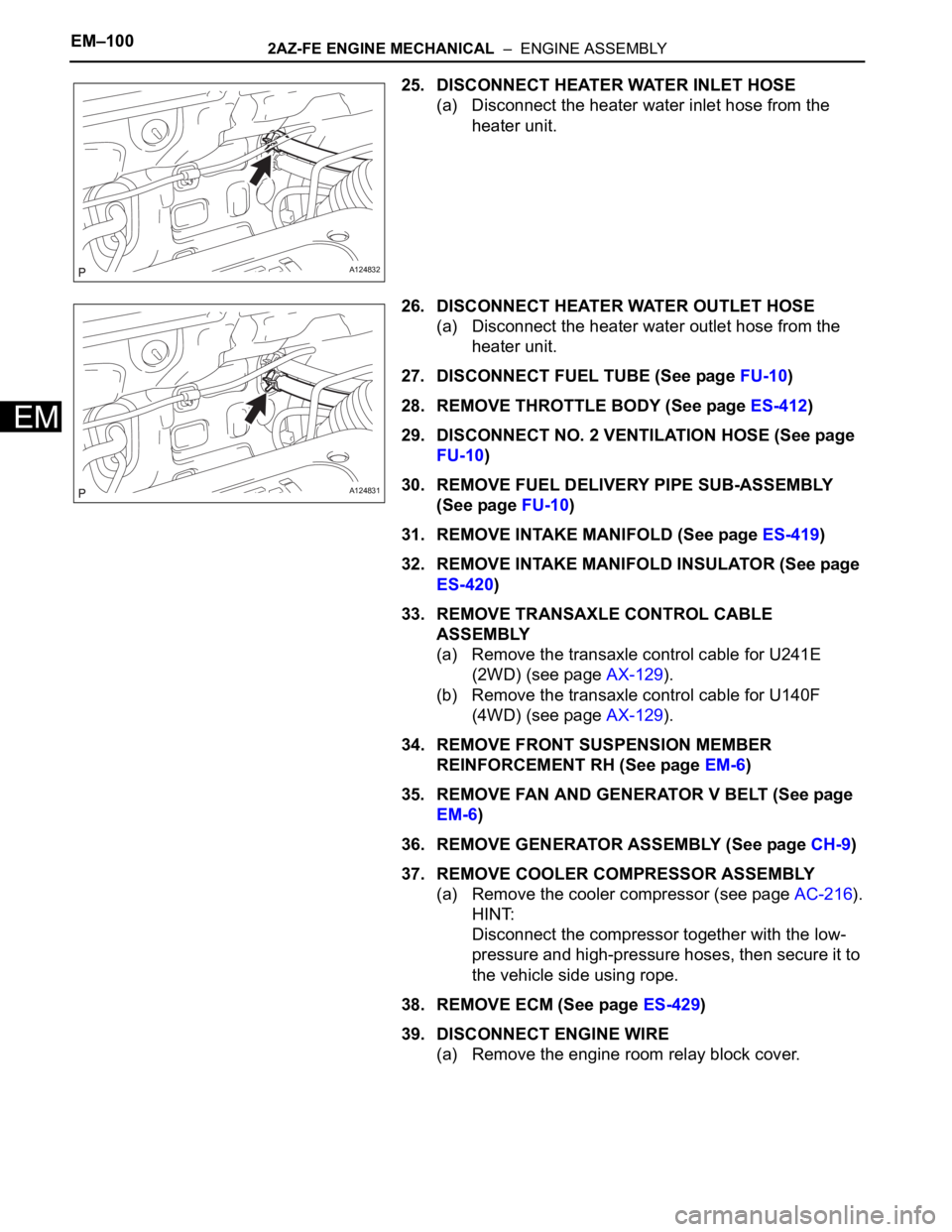

25. DISCONNECT HEATER WATER INLET HOSE

(a) Disconnect the heater water inlet hose from the

heater unit.

26. DISCONNECT HEATER WATER OUTLET HOSE

(a) Disconnect the heater water outlet hose from the

heater unit.

27. DISCONNECT FUEL TUBE (See page FU-10)

28. REMOVE THROTTLE BODY (See page ES-412)

29. DISCONNECT NO. 2 VENTILATION HOSE (See page

FU-10)

30. REMOVE FUEL DELIVERY PIPE SUB-ASSEMBLY

(See page FU-10)

31. REMOVE INTAKE MANIFOLD (See page ES-419)

32. REMOVE INTAKE MANIFOLD INSULATOR (See page

ES-420)

33. REMOVE TRANSAXLE CONTROL CABLE

ASSEMBLY

(a) Remove the transaxle control cable for U241E

(2WD) (see page AX-129).

(b) Remove the transaxle control cable for U140F

(4WD) (see page AX-129).

34. REMOVE FRONT SUSPENSION MEMBER

REINFORCEMENT RH (See page EM-6)

35. REMOVE FAN AND GENERATOR V BELT (See page

EM-6)

36. REMOVE GENERATOR ASSEMBLY (See page CH-9)

37. REMOVE COOLER COMPRESSOR ASSEMBLY

(a) Remove the cooler compressor (see page AC-216).

HINT:

Disconnect the compressor together with the low-

pressure and high-pressure hoses, then secure it to

the vehicle side using rope.

38. REMOVE ECM (See page ES-429)

39. DISCONNECT ENGINE WIRE

(a) Remove the engine room relay block cover.

A124832

A124831

Page 638 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–103

EM

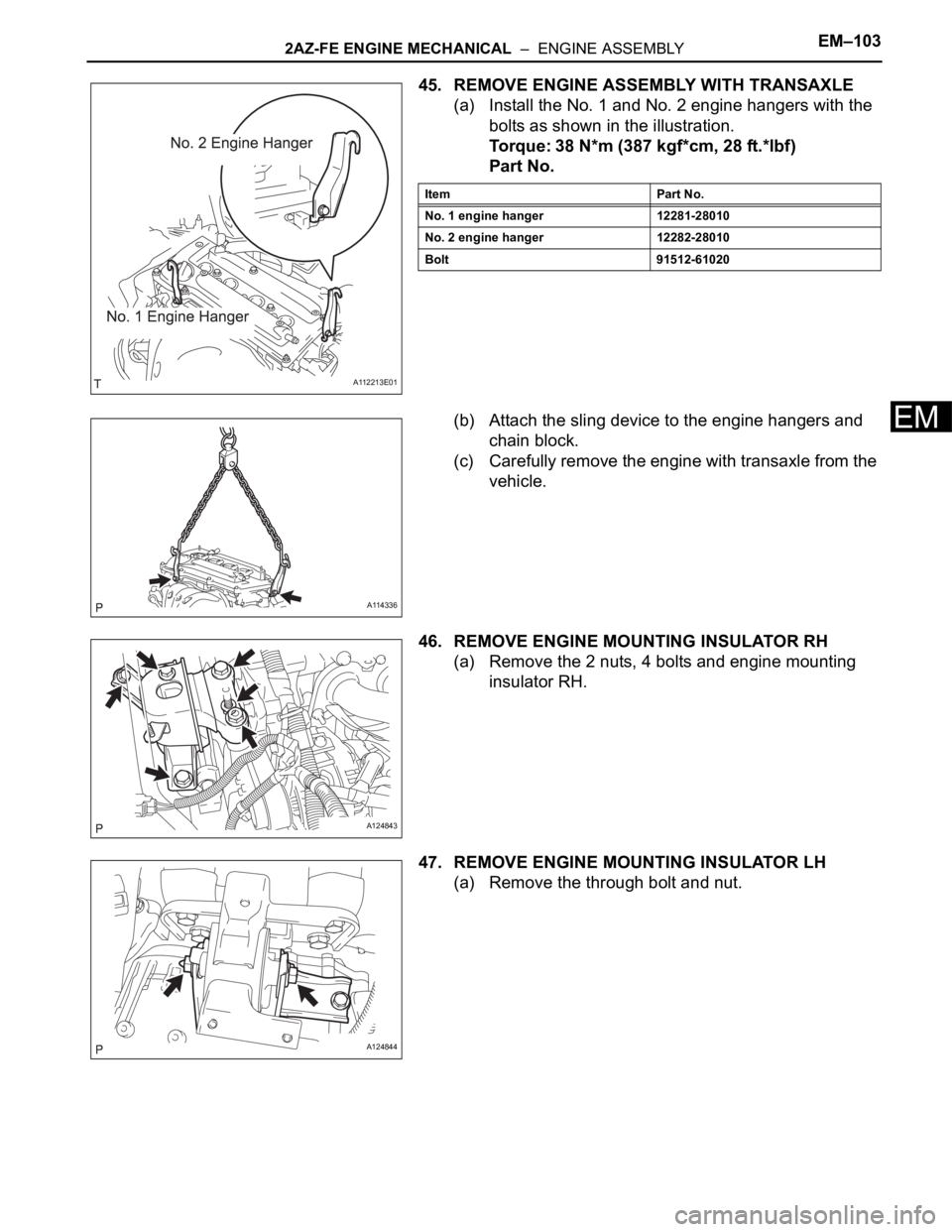

45. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

(a) Install the No. 1 and No. 2 engine hangers with the

bolts as shown in the illustration.

Torque: 38 N*m (387 kgf*cm, 28 ft.*lbf)

Part No.

(b) Attach the sling device to the engine hangers and

chain block.

(c) Carefully remove the engine with transaxle from the

vehicle.

46. REMOVE ENGINE MOUNTING INSULATOR RH

(a) Remove the 2 nuts, 4 bolts and engine mounting

insulator RH.

47. REMOVE ENGINE MOUNTING INSULATOR LH

(a) Remove the through bolt and nut.

A112213E01

Item Part No.

No. 1 engine hanger 12281-28010

No. 2 engine hanger 12282-28010

Bolt 91512-61020

A114336

A124843

A124844

Page 639 of 2000

EM–1042AZ-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

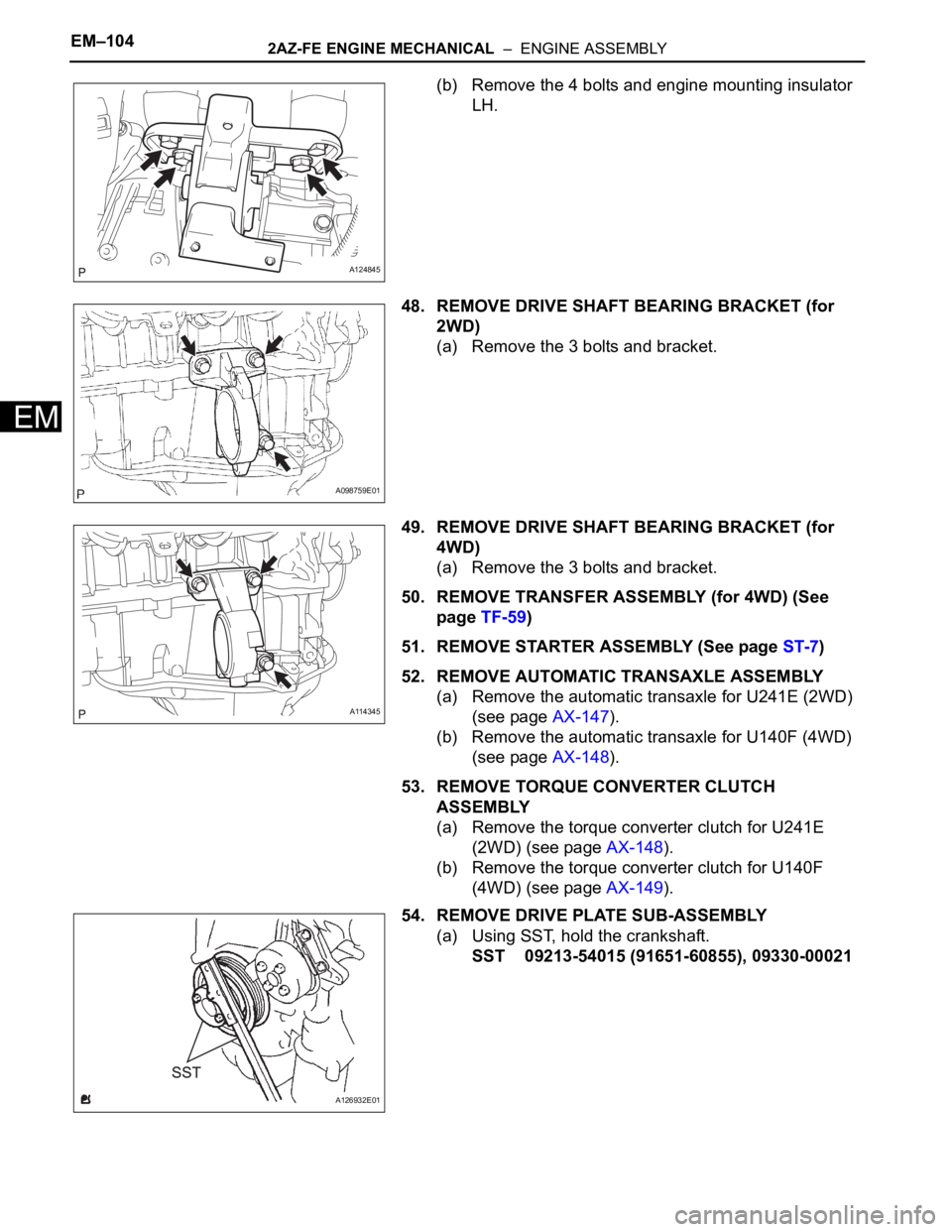

(b) Remove the 4 bolts and engine mounting insulator

LH.

48. REMOVE DRIVE SHAFT BEARING BRACKET (for

2WD)

(a) Remove the 3 bolts and bracket.

49. REMOVE DRIVE SHAFT BEARING BRACKET (for

4WD)

(a) Remove the 3 bolts and bracket.

50. REMOVE TRANSFER ASSEMBLY (for 4WD) (See

page TF-59)

51. REMOVE STARTER ASSEMBLY (See page ST-7)

52. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY

(a) Remove the automatic transaxle for U241E (2WD)

(see page AX-147).

(b) Remove the automatic transaxle for U140F (4WD)

(see page AX-148).

53. REMOVE TORQUE CONVERTER CLUTCH

ASSEMBLY

(a) Remove the torque converter clutch for U241E

(2WD) (see page AX-148).

(b) Remove the torque converter clutch for U140F

(4WD) (see page AX-149).

54. REMOVE DRIVE PLATE SUB-ASSEMBLY

(a) Using SST, hold the crankshaft.

SST 09213-54015 (91651-60855), 09330-00021

A124845

A098759E01

A114345

A126932E01

Page 642 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–107

EM

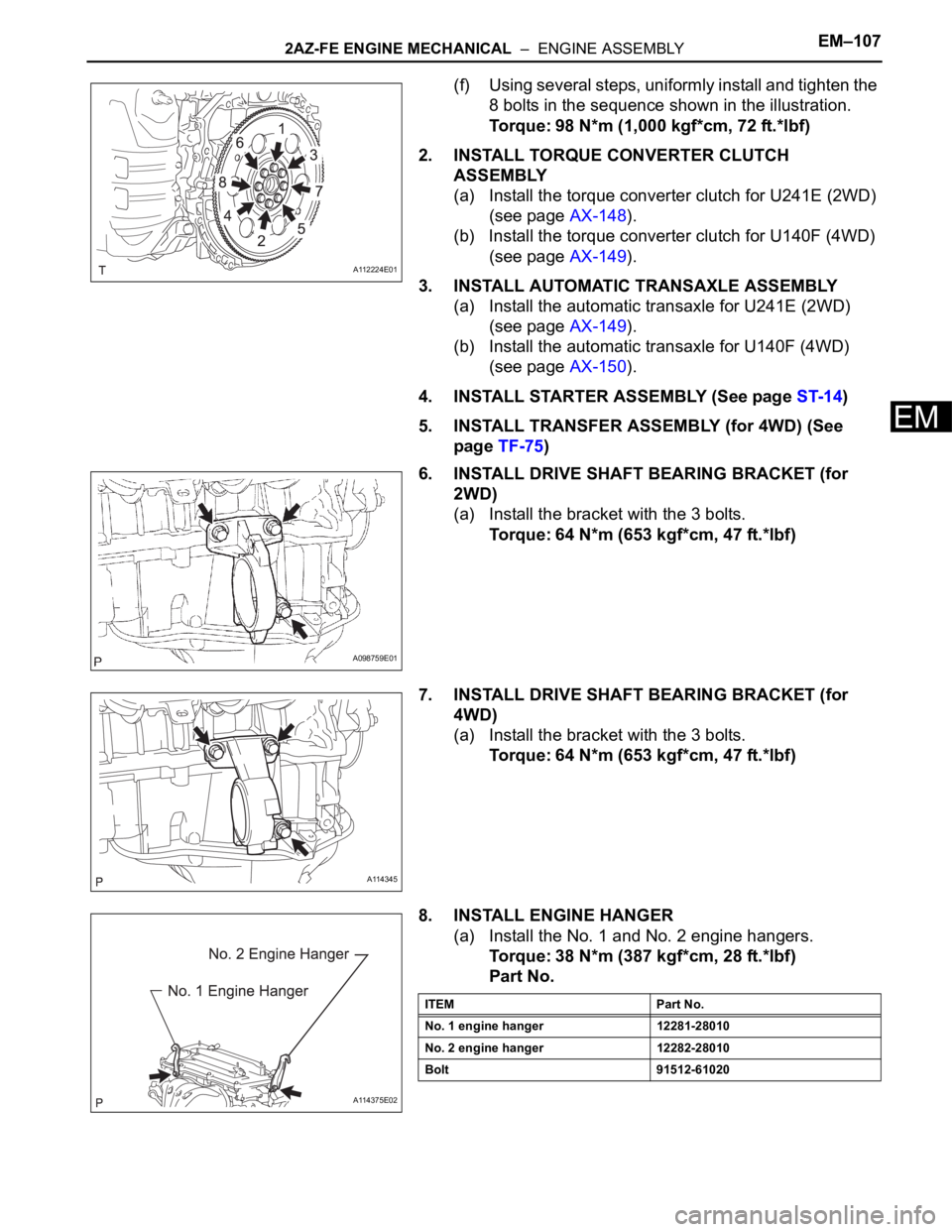

(f) Using several steps, uniformly install and tighten the

8 bolts in the sequence shown in the illustration.

Torque: 98 N*m (1,000 kgf*cm, 72 ft.*lbf)

2. INSTALL TORQUE CONVERTER CLUTCH

ASSEMBLY

(a) Install the torque converter clutch for U241E (2WD)

(see page AX-148).

(b) Install the torque converter clutch for U140F (4WD)

(see page AX-149).

3. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY

(a) Install the automatic transaxle for U241E (2WD)

(see page AX-149).

(b) Install the automatic transaxle for U140F (4WD)

(see page AX-150).

4. INSTALL STARTER ASSEMBLY (See page ST-14)

5. INSTALL TRANSFER ASSEMBLY (for 4WD) (See

page TF-75)

6. INSTALL DRIVE SHAFT BEARING BRACKET (for

2WD)

(a) Install the bracket with the 3 bolts.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf)

7. INSTALL DRIVE SHAFT BEARING BRACKET (for

4WD)

(a) Install the bracket with the 3 bolts.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf)

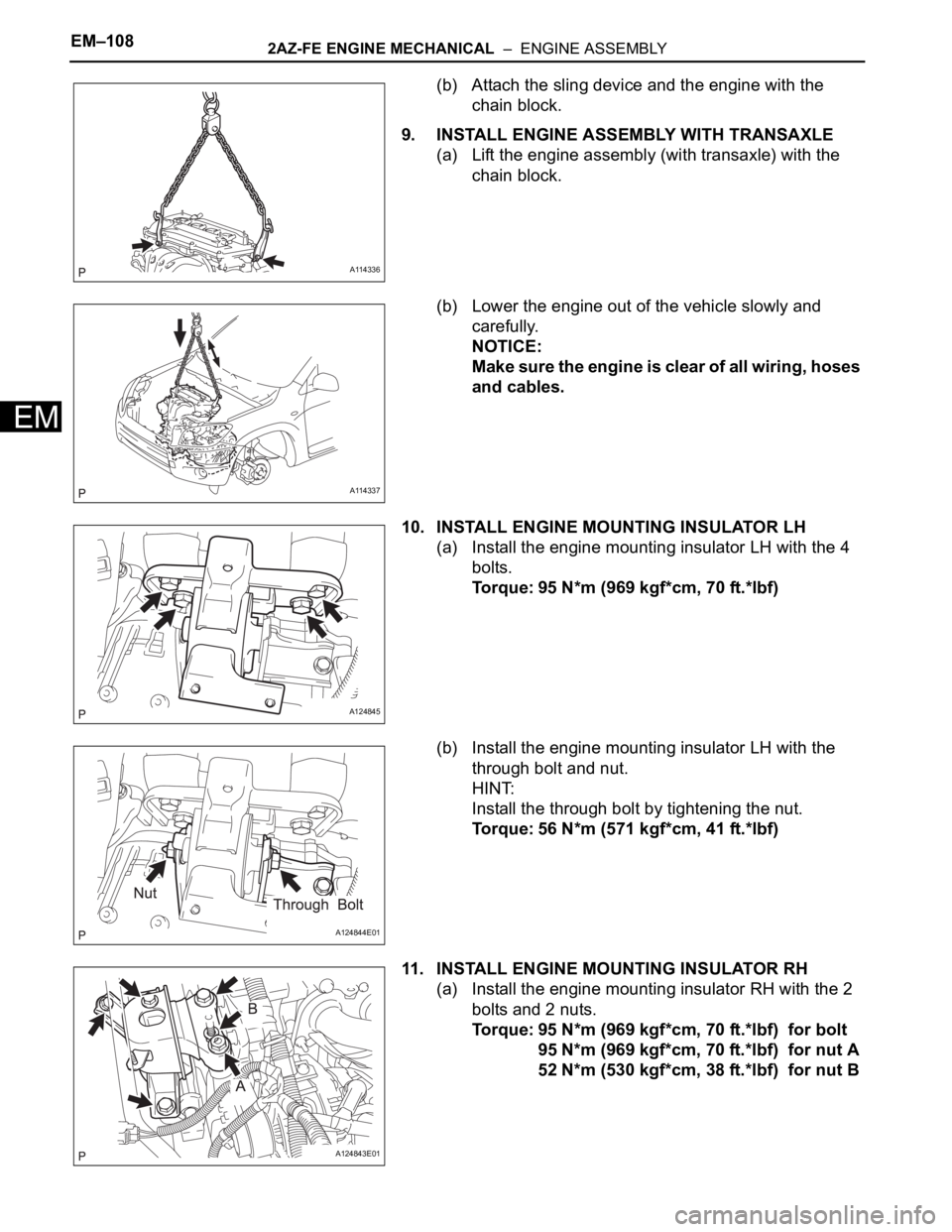

8. INSTALL ENGINE HANGER

(a) Install the No. 1 and No. 2 engine hangers.

Torque: 38 N*m (387 kgf*cm, 28 ft.*lbf)

Part No.

A112224E01

A098759E01

A114345

A114375E02

ITEM Part No.

No. 1 engine hanger 12281-28010

No. 2 engine hanger 12282-28010

Bolt 91512-61020

Page 643 of 2000

EM–1082AZ-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

(b) Attach the sling device and the engine with the

chain block.

9. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

(a) Lift the engine assembly (with transaxle) with the

chain block.

(b) Lower the engine out of the vehicle slowly and

carefully.

NOTICE:

Make sure the engine is clear of all wiring, hoses

and cables.

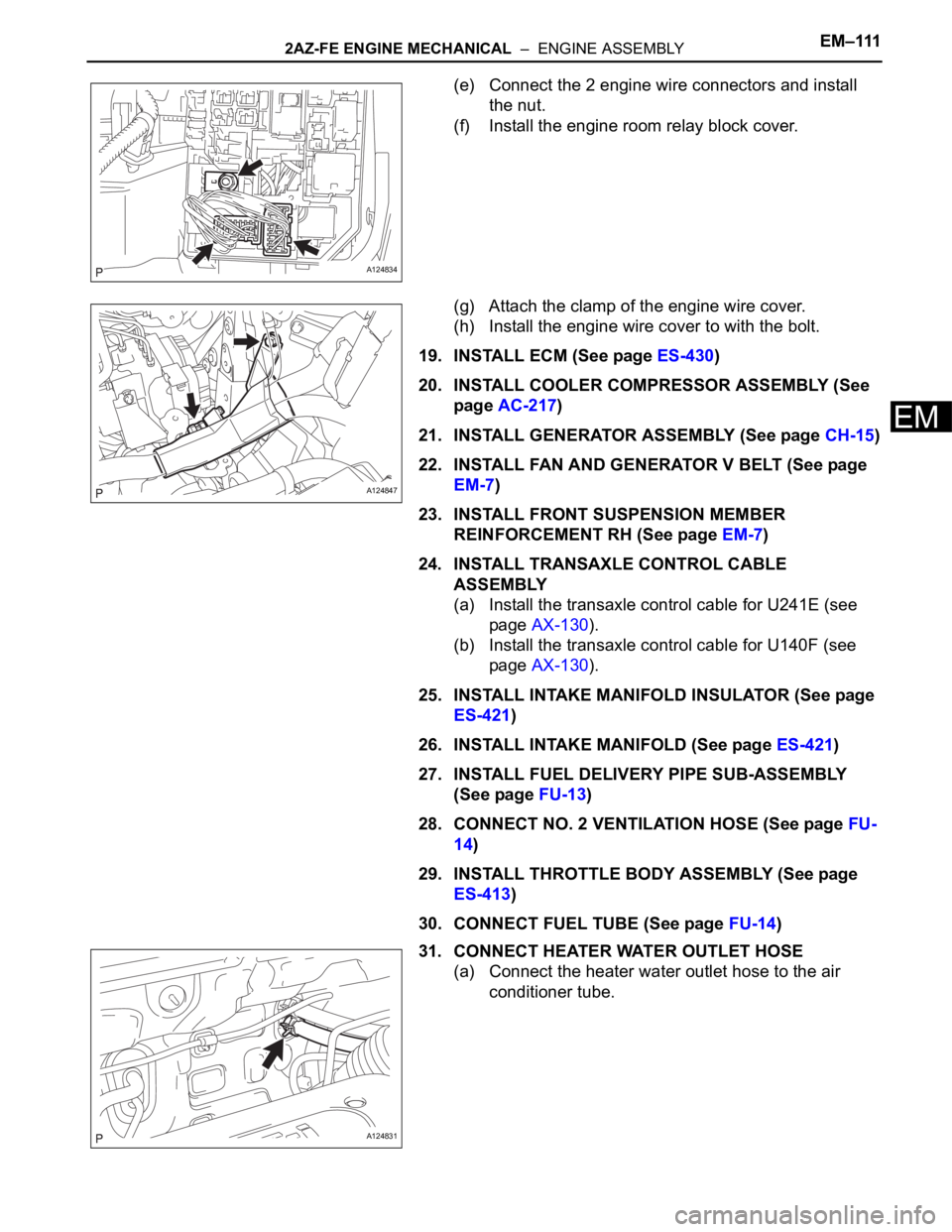

10. INSTALL ENGINE MOUNTING INSULATOR LH

(a) Install the engine mounting insulator LH with the 4

bolts.

Torque: 95 N*m (969 kgf*cm, 70 ft.*lbf)

(b) Install the engine mounting insulator LH with the

through bolt and nut.

HINT:

Install the through bolt by tightening the nut.

Torque: 56 N*m (571 kgf*cm, 41 ft.*lbf)

11. INSTALL ENGINE MOUNTING INSULATOR RH

(a) Install the engine mounting insulator RH with the 2

bolts and 2 nuts.

Torque: 95 N*m (969 kgf*cm, 70 ft.*lbf) for bolt

95 N*m (969 kgf*cm, 70 ft.*lbf) for nut A

52 N*m (530 kgf*cm, 38 ft.*lbf) for nut B

A114336

A114337

A124845

A124844E01

A124843E01

Page 646 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–111

EM

(e) Connect the 2 engine wire connectors and install

the nut.

(f) Install the engine room relay block cover.

(g) Attach the clamp of the engine wire cover.

(h) Install the engine wire cover to with the bolt.

19. INSTALL ECM (See page ES-430)

20. INSTALL COOLER COMPRESSOR ASSEMBLY (See

page AC-217)

21. INSTALL GENERATOR ASSEMBLY (See page CH-15)

22. INSTALL FAN AND GENERATOR V BELT (See page

EM-7)

23. INSTALL FRONT SUSPENSION MEMBER

REINFORCEMENT RH (See page EM-7)

24. INSTALL TRANSAXLE CONTROL CABLE

ASSEMBLY

(a) Install the transaxle control cable for U241E (see

page AX-130).

(b) Install the transaxle control cable for U140F (see

page AX-130).

25. INSTALL INTAKE MANIFOLD INSULATOR (See page

ES-421)

26. INSTALL INTAKE MANIFOLD (See page ES-421)

27. INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY

(See page FU-13)

28. CONNECT NO. 2 VENTILATION HOSE (See page FU-

14)

29. INSTALL THROTTLE BODY ASSEMBLY (See page

ES-413)

30. CONNECT FUEL TUBE (See page FU-14)

31. CONNECT HEATER WATER OUTLET HOSE

(a) Connect the heater water outlet hose to the air

conditioner tube.

A124834

A124847

A124831

Page 648 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–113

EM

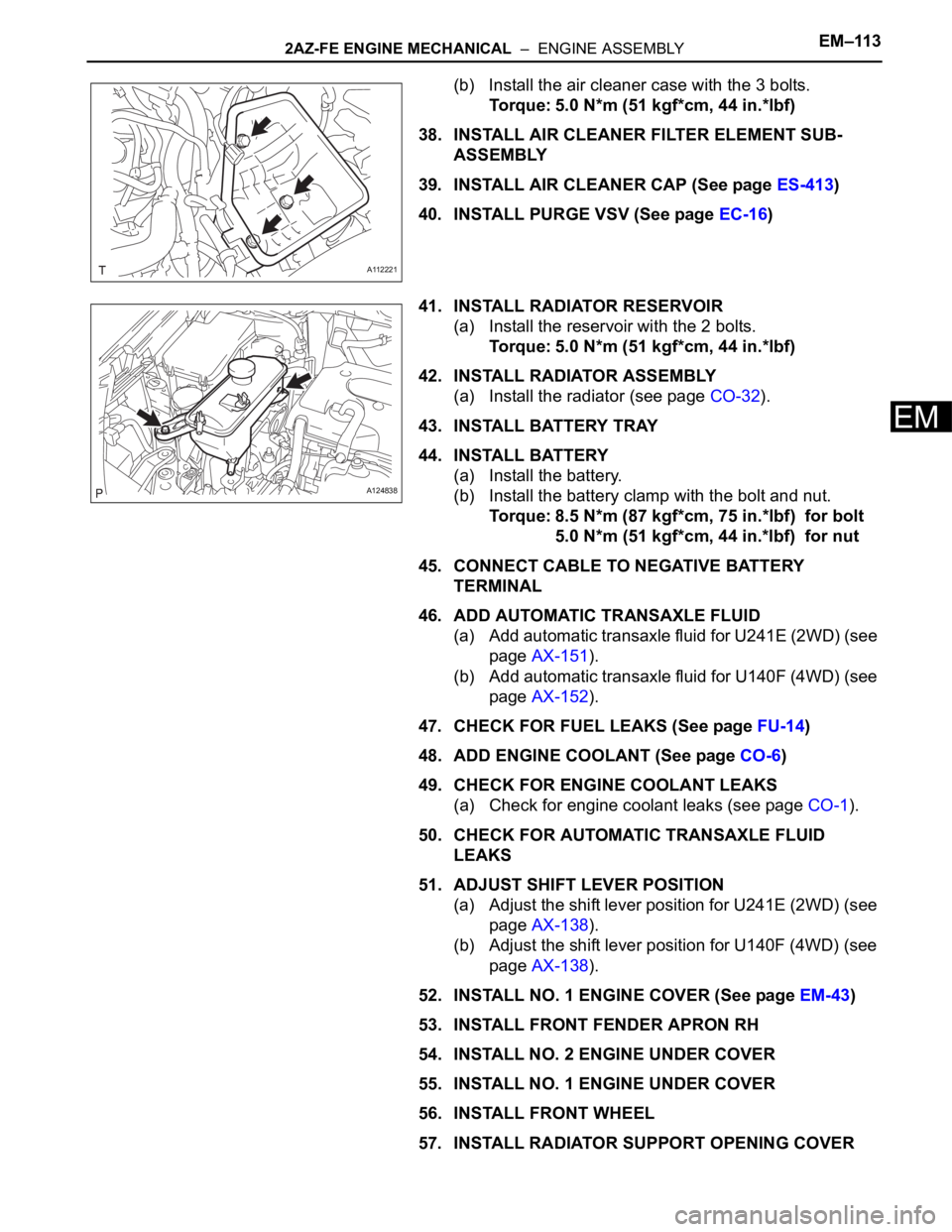

(b) Install the air cleaner case with the 3 bolts.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

38. INSTALL AIR CLEANER FILTER ELEMENT SUB-

ASSEMBLY

39. INSTALL AIR CLEANER CAP (See page ES-413)

40. INSTALL PURGE VSV (See page EC-16)

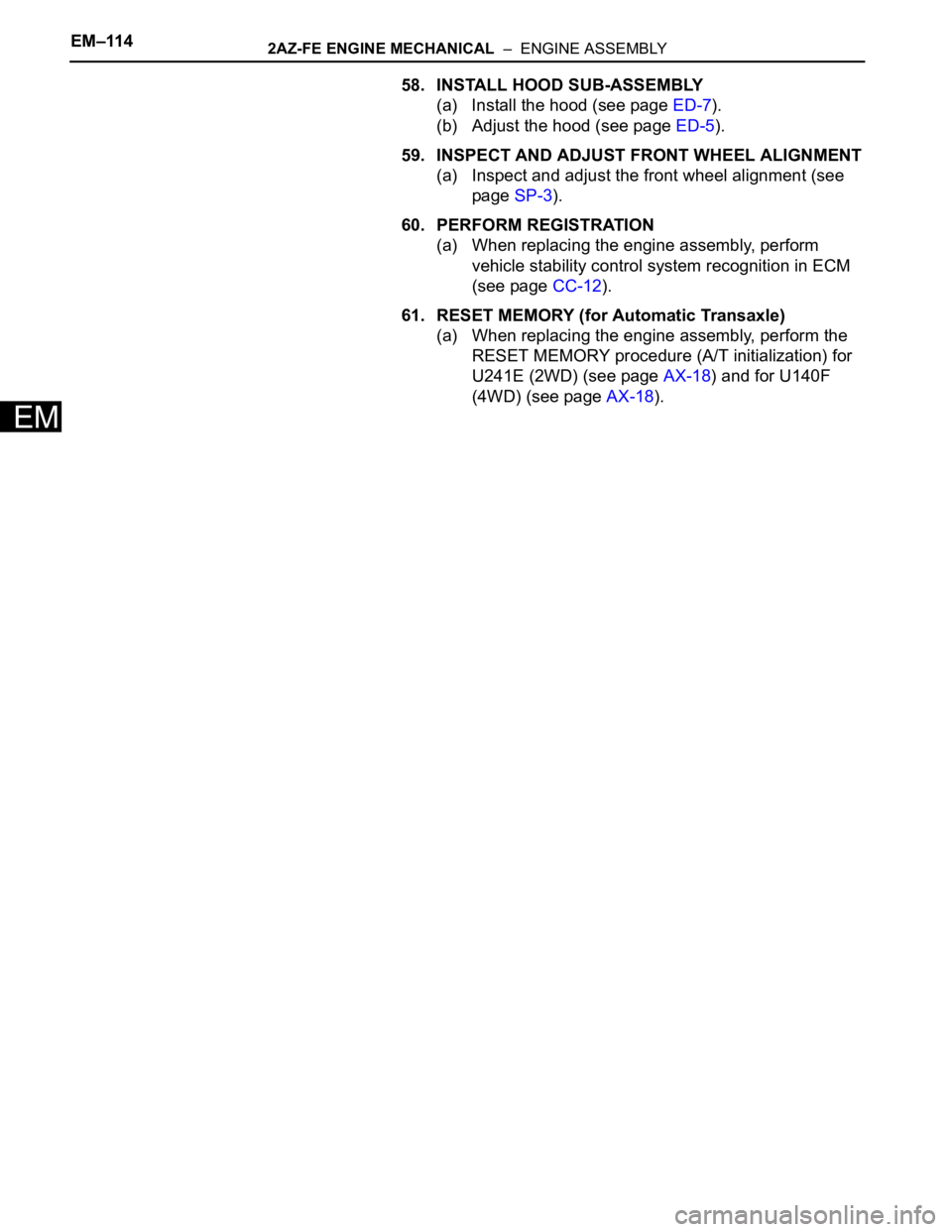

41. INSTALL RADIATOR RESERVOIR

(a) Install the reservoir with the 2 bolts.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

42. INSTALL RADIATOR ASSEMBLY

(a) Install the radiator (see page CO-32).

43. INSTALL BATTERY TRAY

44. INSTALL BATTERY

(a) Install the battery.

(b) Install the battery clamp with the bolt and nut.

Torque: 8.5 N*m (87 kgf*cm, 75 in.*lbf) for bolt

5.0 N*m (51 kgf*cm, 44 in.*lbf) for nut

45. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

46. ADD AUTOMATIC TRANSAXLE FLUID

(a) Add automatic transaxle fluid for U241E (2WD) (see

page AX-151).

(b) Add automatic transaxle fluid for U140F (4WD) (see

page AX-152).

47. CHECK FOR FUEL LEAKS (See page FU-14)

48. ADD ENGINE COOLANT (See page CO-6)

49. CHECK FOR ENGINE COOLANT LEAKS

(a) Check for engine coolant leaks (see page CO-1).

50. CHECK FOR AUTOMATIC TRANSAXLE FLUID

LEAKS

51. ADJUST SHIFT LEVER POSITION

(a) Adjust the shift lever position for U241E (2WD) (see

page AX-138).

(b) Adjust the shift lever position for U140F (4WD) (see

page AX-138).

52. INSTALL NO. 1 ENGINE COVER (See page EM-43)

53. INSTALL FRONT FENDER APRON RH

54. INSTALL NO. 2 ENGINE UNDER COVER

55. INSTALL NO. 1 ENGINE UNDER COVER

56. INSTALL FRONT WHEEL

57. INSTALL RADIATOR SUPPORT OPENING COVER

A112221

A124838

Page 649 of 2000

EM–1142AZ-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

58. INSTALL HOOD SUB-ASSEMBLY

(a) Install the hood (see page ED-7).

(b) Adjust the hood (see page ED-5).

59. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

(a) Inspect and adjust the front wheel alignment (see

page SP-3).

60. PERFORM REGISTRATION

(a) When replacing the engine assembly, perform

vehicle stability control system recognition in ECM

(see page CC-12).

61. RESET MEMORY (for Automatic Transaxle)

(a) When replacing the engine assembly, perform the

RESET MEMORY procedure (A/T initialization) for

U241E (2WD) (see page AX-18) and for U140F

(4WD) (see page AX-18).