transaxle TOYOTA RAV4 2006 Service Manual PDF

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 681 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–35

EM

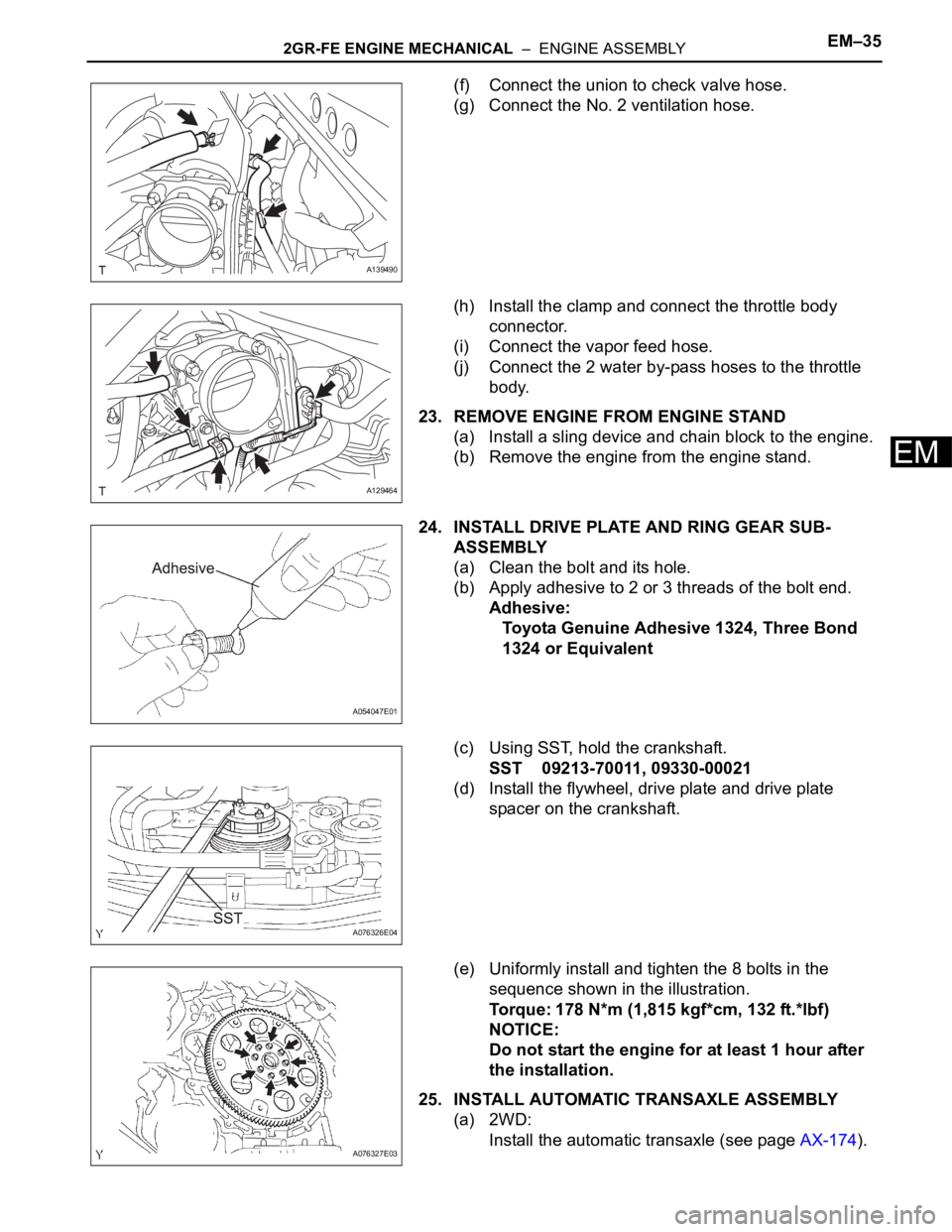

(f) Connect the union to check valve hose.

(g) Connect the No. 2 ventilation hose.

(h) Install the clamp and connect the throttle body

connector.

(i) Connect the vapor feed hose.

(j) Connect the 2 water by-pass hoses to the throttle

body.

23. REMOVE ENGINE FROM ENGINE STAND

(a) Install a sling device and chain block to the engine.

(b) Remove the engine from the engine stand.

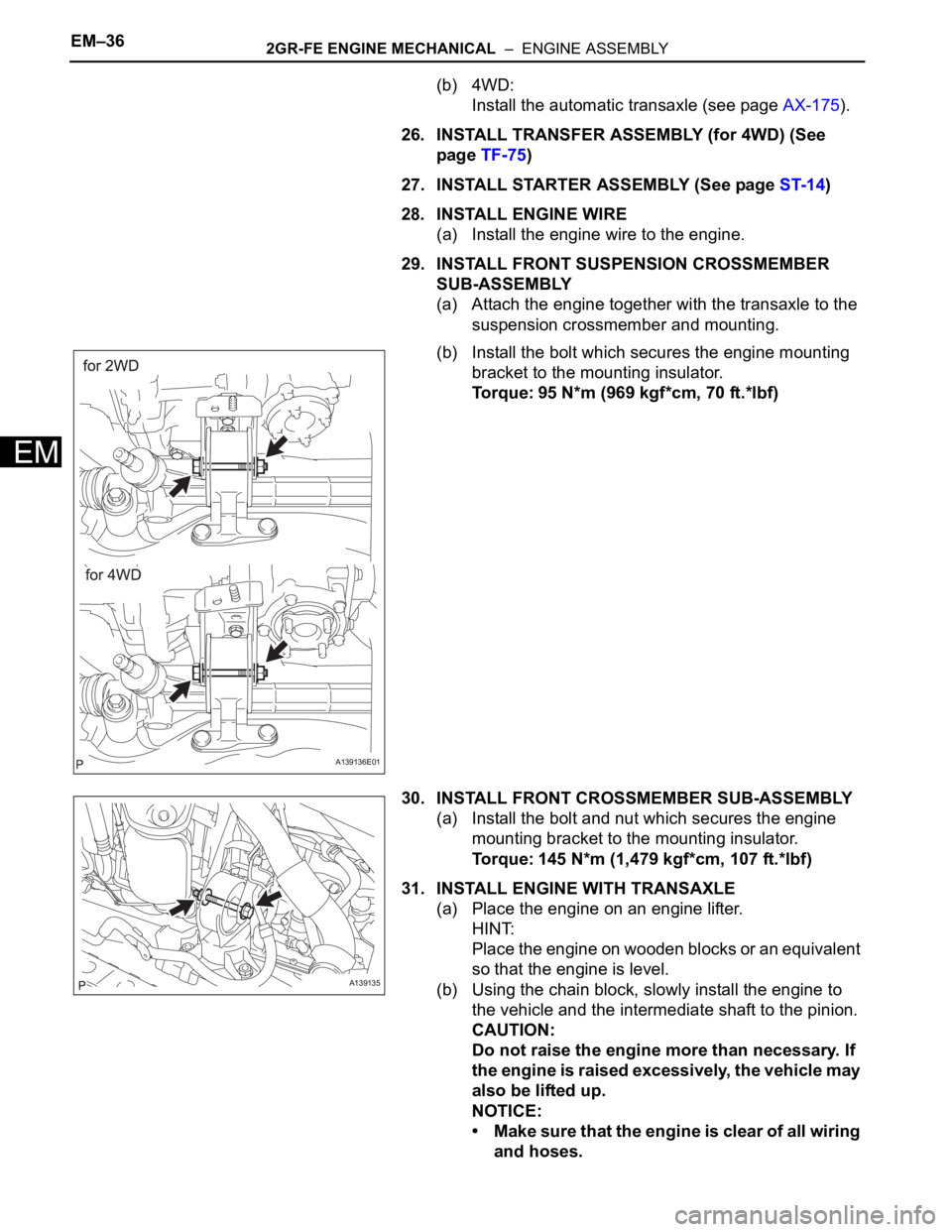

24. INSTALL DRIVE PLATE AND RING GEAR SUB-

ASSEMBLY

(a) Clean the bolt and its hole.

(b) Apply adhesive to 2 or 3 threads of the bolt end.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond

1324 or Equivalent

(c) Using SST, hold the crankshaft.

SST 09213-70011, 09330-00021

(d) Install the flywheel, drive plate and drive plate

spacer on the crankshaft.

(e) Uniformly install and tighten the 8 bolts in the

sequence shown in the illustration.

Torque: 178 N*m (1,815 kgf*cm, 132 ft.*lbf)

NOTICE:

Do not start the engine for at least 1 hour after

the installation.

25. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY

(a) 2WD:

Install the automatic transaxle (see page AX-174).

A139490

A129464

A054047E01

A076326E04

A076327E03

Page 682 of 2000

EM–362GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

(b) 4WD:

Install the automatic transaxle (see page AX-175).

26. INSTALL TRANSFER ASSEMBLY (for 4WD) (See

page TF-75)

27. INSTALL STARTER ASSEMBLY (See page ST-14)

28. INSTALL ENGINE WIRE

(a) Install the engine wire to the engine.

29. INSTALL FRONT SUSPENSION CROSSMEMBER

SUB-ASSEMBLY

(a) Attach the engine together with the transaxle to the

suspension crossmember and mounting.

(b) Install the bolt which secures the engine mounting

bracket to the mounting insulator.

Torque: 95 N*m (969 kgf*cm, 70 ft.*lbf)

30. INSTALL FRONT CROSSMEMBER SUB-ASSEMBLY

(a) Install the bolt and nut which secures the engine

mounting bracket to the mounting insulator.

Torque: 145 N*m (1,479 kgf*cm, 107 ft.*lbf)

31. INSTALL ENGINE WITH TRANSAXLE

(a) Place the engine on an engine lifter.

HINT:

Place the engine on wooden blocks or an equivalent

so that the engine is level.

(b) Using the chain block, slowly install the engine to

the vehicle and the intermediate shaft to the pinion.

CAUTION:

Do not raise the engine more than necessary. If

the engine is raised excessively, the vehicle may

also be lifted up.

NOTICE:

• Make sure that the engine is clear of all wiring

and hoses.

A139136E01

A139135

Page 687 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–41

EM

62. ADD AUTOMATIC TRANSAXLE FLUID

(a) 2WD:

Add automatic transmission fluid (see page AX-

177).

(b) 4WD:

Add automatic transmission fluid (see page AX-

178).

63. ADD TRANSFER OIL (for 4WD) (See page TF-45)

64. ADD ENGINE OIL (See page LU-6)

65. ADD ENGINE COOLANT (See page CO-8)

66. CHARGE REFRIGERANT (See page AC-172)

67. CHECK FOR LEAKAGE OF REFRIGERANT (See

page AC-173)

68. CHECK FOR ENGINE OIL LEAKS (See page LU-6)

69. CHECK FOR ENGINE COOLANT LEAKS (See page

CO-1)

70. CHECK FOR FUEL LEAKS

71. INSPECT EXHAUST GAS LEAKS

72. INSPECT SHIFT LEVER POSITION

(a) 2WD:

Inspect the shift lever position (see page AX-159).

(b) 4WD:

Inspect the shift lever position (see page AX-158).

73. ADJUST TRANSMISSION CONTROL CABLE

(a) 2WD:

Adjust the shift lever position (see page AX-159).

(b) 4WD:

Adjust the shift lever position (see page AX-159).

74. INSTALL FRONT FLOOR COVER (See page FU-39)

75. INSTALL NO. 2 ENGINE UNDER COVER

(a) Install the under cover with the 2 clips.

76. INSTALL REAR ENGINE UNDER COVER LH

(a) Install the under cover with the 2 clips.

77. INSTALL REAR ENGINE UNDER COVER RH

(a) Install the under cover with the 2 clips.

78. INSTALL NO. 1 ENGINE UNDER COVER

(a) Install the under cover with the 4 bolts and 12 clips.

Page 940 of 2000

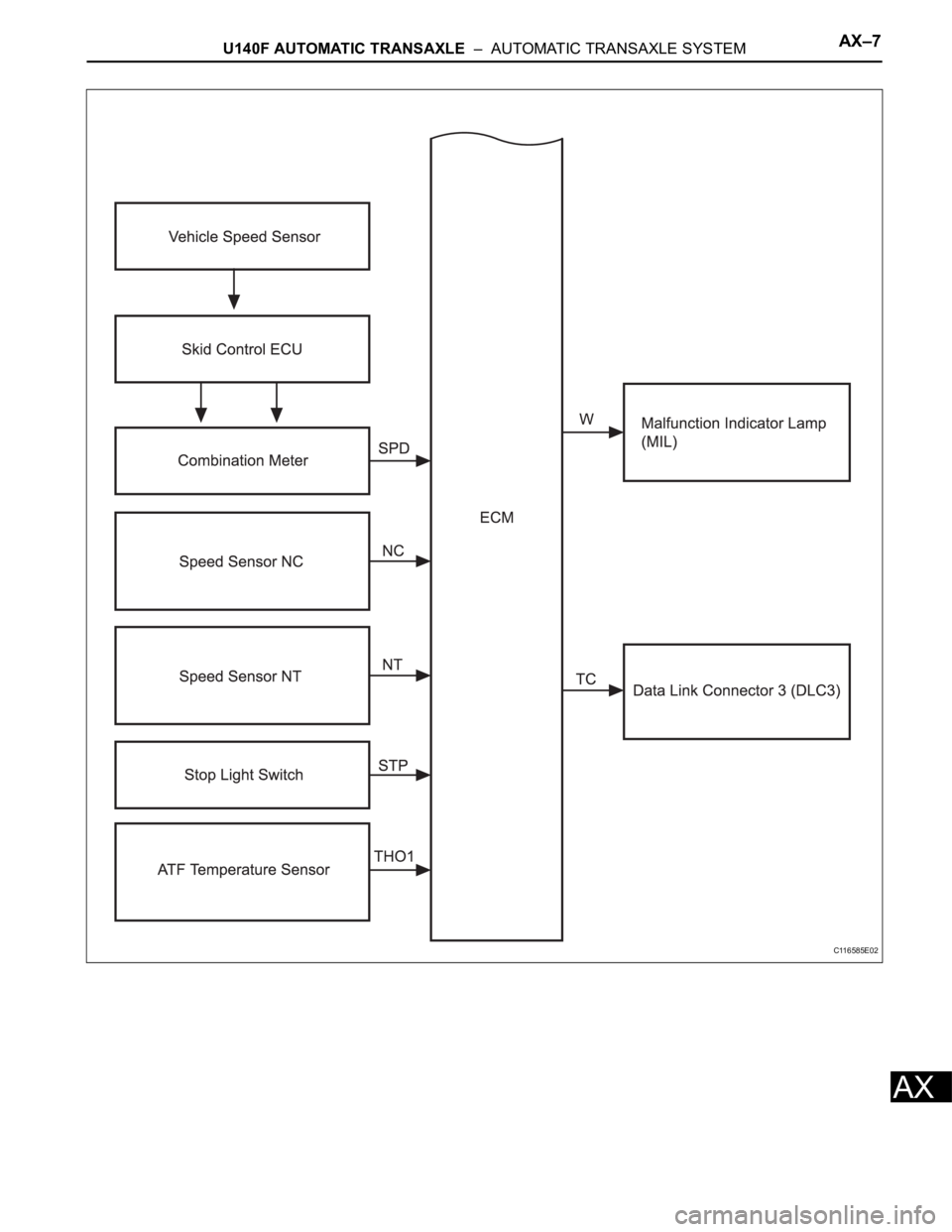

AX–6U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

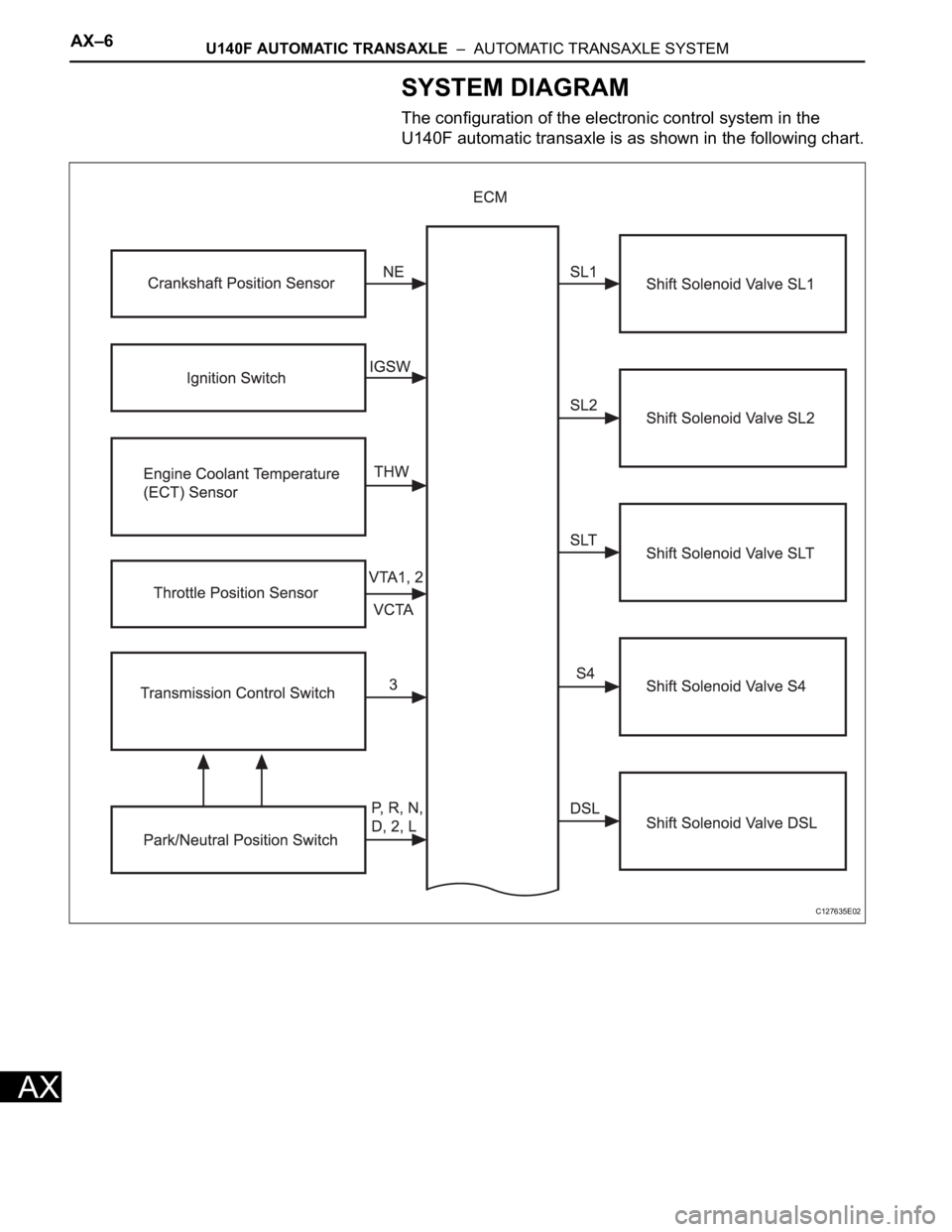

SYSTEM DIAGRAM

The configuration of the electronic control system in the

U140F automatic transaxle is as shown in the following chart.

C127635E02

Page 941 of 2000

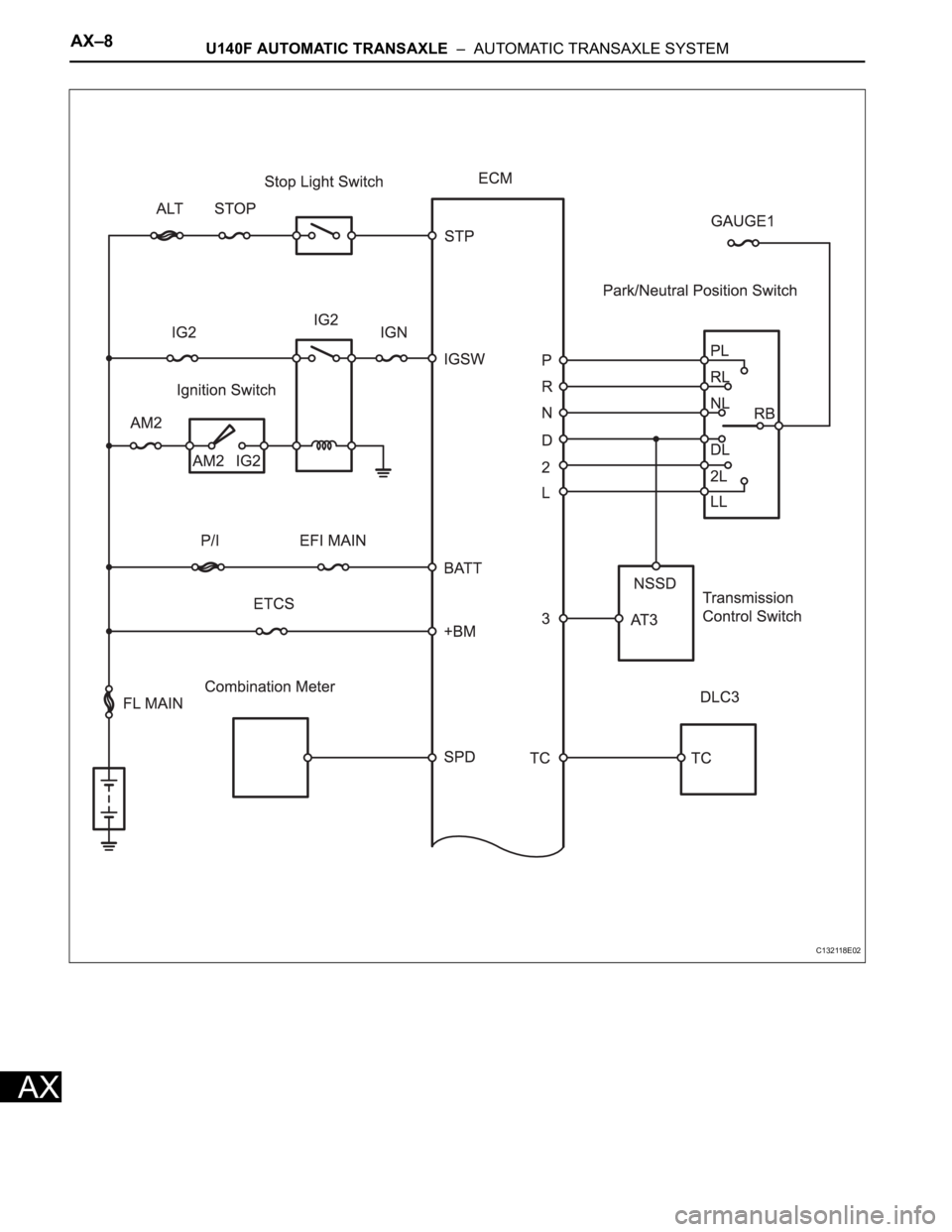

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–7

AX

C116585E02

Page 942 of 2000

AX–8U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

C132118E02

Page 943 of 2000

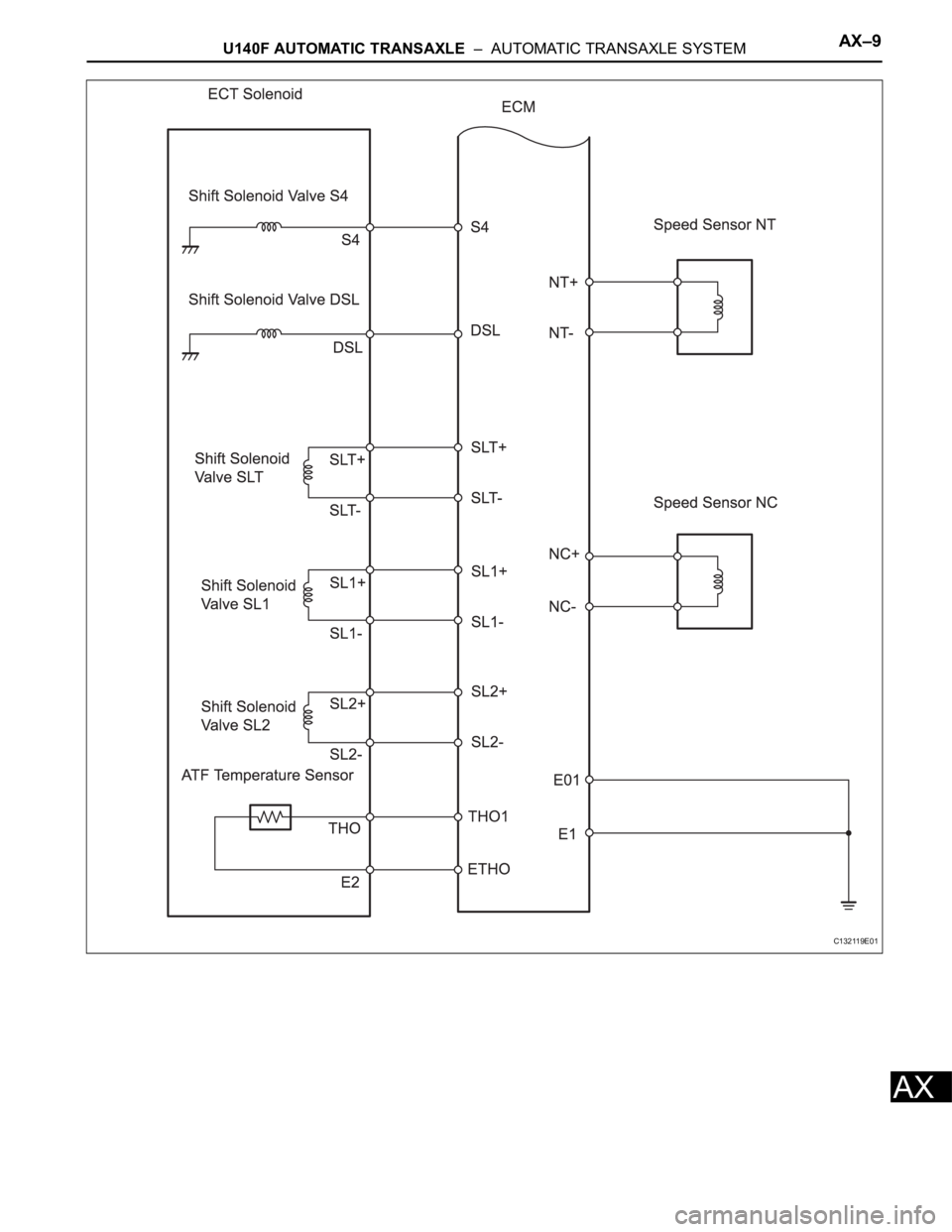

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–9

AX

C132119E01

Page 944 of 2000

AX–10U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

SYSTEM DESCRIPTION

1. SYSTEM DESCRIPTION

(a) The Electronic Controlled Automatic Transaxle

(ECT) is an automatic transaxle that electronically

controls shift timing using the Engine Control

Module (ECM). The ECM detects electrical signals

that indicate engine and driving conditions, and

controls the shift point based on driver habits and

road conditions. As a result, fuel efficiency and

power transaxle performance are improved.

Shift shock is reduced by controlling the engine and

transaxle simultaneously.

In addition, the ECT has the following features:

• Diagnostic function.

• Fail-safe function when a malfunction occurs.

Page 945 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–11

AX

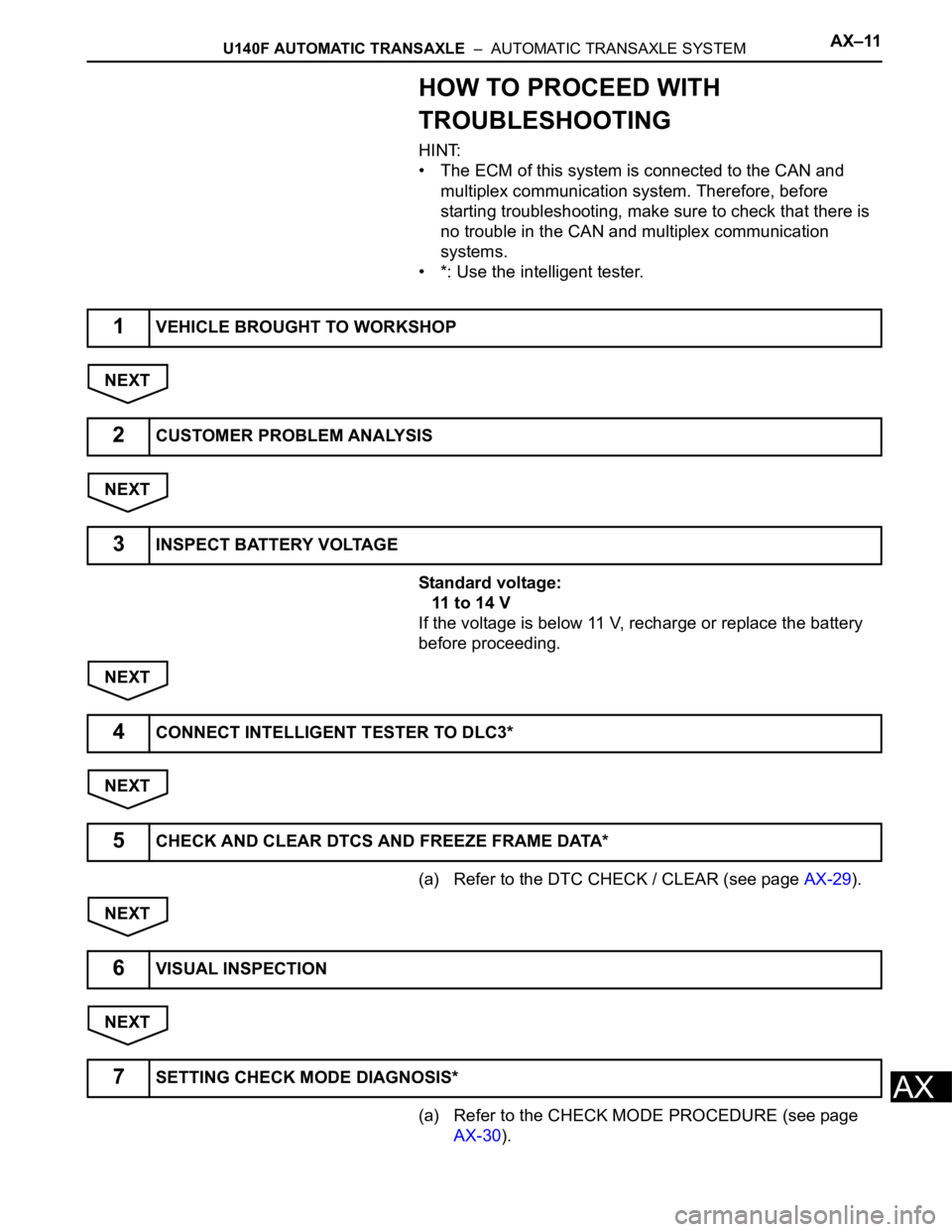

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

• The ECM of this system is connected to the CAN and

multiplex communication system. Therefore, before

starting troubleshooting, make sure to check that there is

no trouble in the CAN and multiplex communication

systems.

• *: Use the intelligent tester.

NEXT

NEXT

Standard voltage:

11 to 14 V

If the voltage is below 11 V, recharge or replace the battery

before proceeding.

NEXT

NEXT

(a) Refer to the DTC CHECK / CLEAR (see page AX-29).

NEXT

NEXT

(a) Refer to the CHECK MODE PROCEDURE (see page

AX-30).

1VEHICLE BROUGHT TO WORKSHOP

2CUSTOMER PROBLEM ANALYSIS

3INSPECT BATTERY VOLTAGE

4CONNECT INTELLIGENT TESTER TO DLC3*

5CHECK AND CLEAR DTCS AND FREEZE FRAME DATA*

6VISUAL INSPECTION

7SETTING CHECK MODE DIAGNOSIS*

Page 946 of 2000

AX–12U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

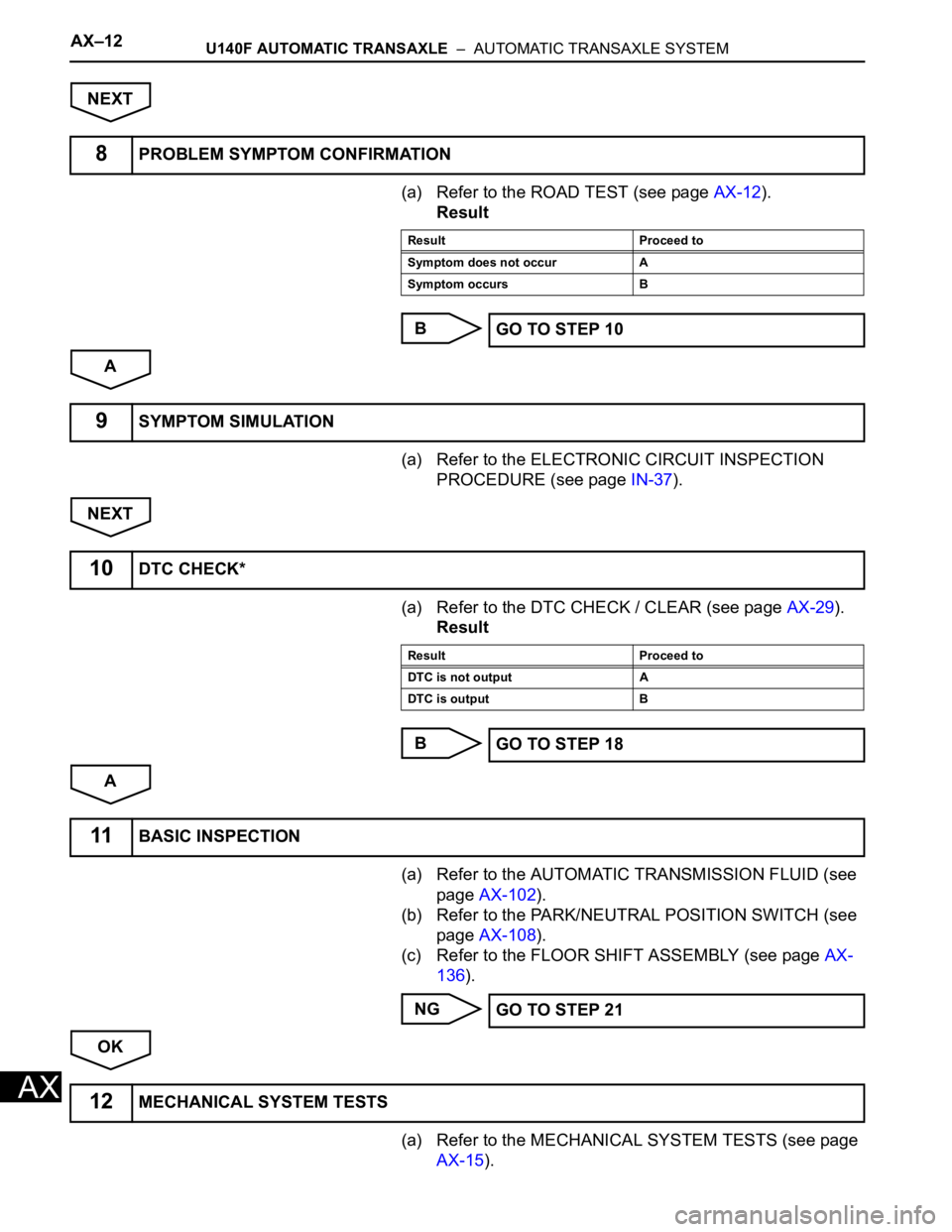

NEXT

(a) Refer to the ROAD TEST (see page AX-12).

Result

B

A

(a) Refer to the ELECTRONIC CIRCUIT INSPECTION

PROCEDURE (see page IN-37).

NEXT

(a) Refer to the DTC CHECK / CLEAR (see page AX-29).

Result

B

A

(a) Refer to the AUTOMATIC TRANSMISSION FLUID (see

page AX-102).

(b) Refer to the PARK/NEUTRAL POSITION SWITCH (see

page AX-108).

(c) Refer to the FLOOR SHIFT ASSEMBLY (see page AX-

136).

NG

OK

(a) Refer to the MECHANICAL SYSTEM TESTS (see page

AX-15).

8PROBLEM SYMPTOM CONFIRMATION

Result Proceed to

Symptom does not occur A

Symptom occurs B

GO TO STEP 10

9SYMPTOM SIMULATION

10DTC CHECK*

Result Proceed to

DTC is not output A

DTC is output B

GO TO STEP 18

11BASIC INSPECTION

GO TO STEP 21

12MECHANICAL SYSTEM TESTS