Washer TOYOTA RAV4 2006 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 660 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE UNITEM–133

EM

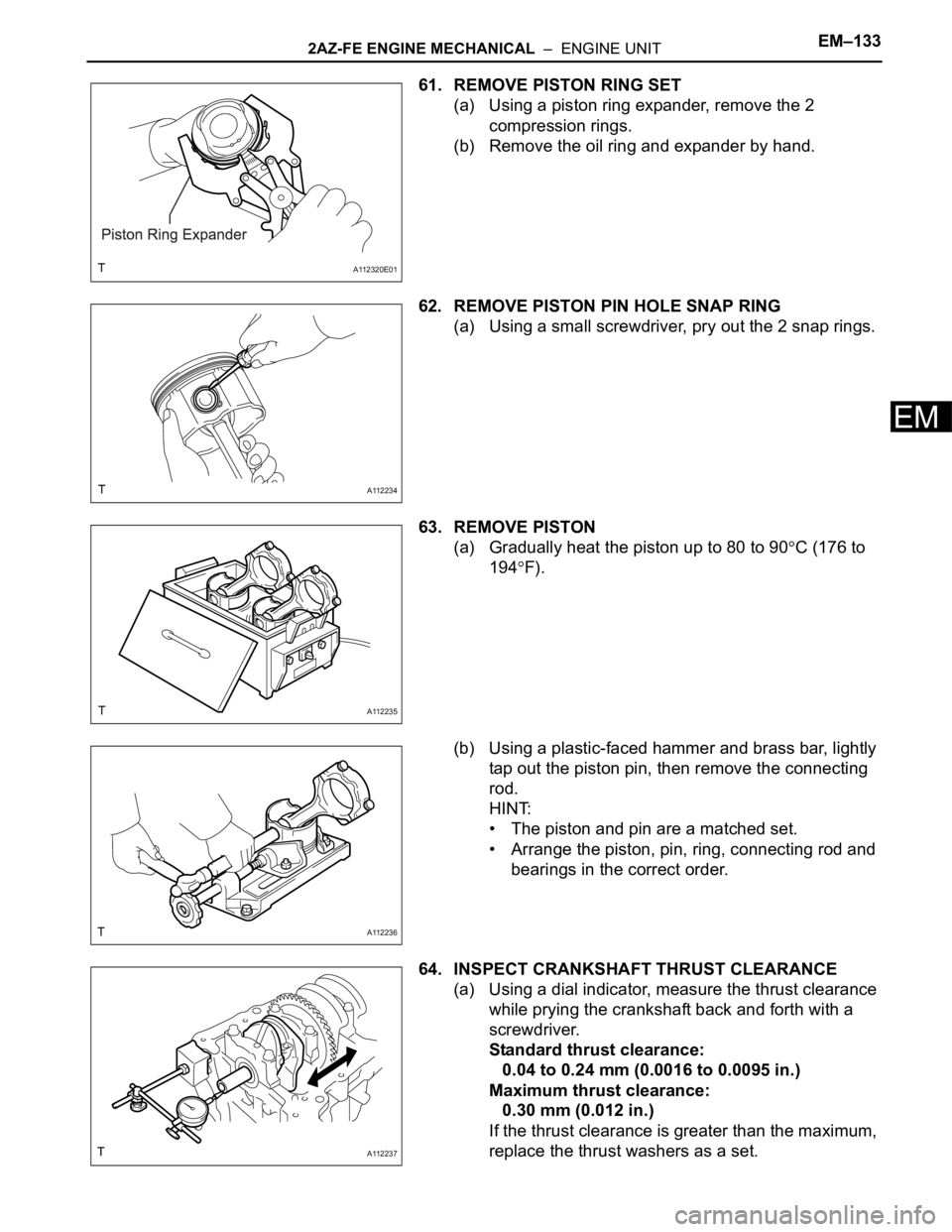

61. REMOVE PISTON RING SET

(a) Using a piston ring expander, remove the 2

compression rings.

(b) Remove the oil ring and expander by hand.

62. REMOVE PISTON PIN HOLE SNAP RING

(a) Using a small screwdriver, pry out the 2 snap rings.

63. REMOVE PISTON

(a) Gradually heat the piston up to 80 to 90

C (176 to

194

F).

(b) Using a plastic-faced hammer and brass bar, lightly

tap out the piston pin, then remove the connecting

rod.

HINT:

• The piston and pin are a matched set.

• Arrange the piston, pin, ring, connecting rod and

bearings in the correct order.

64. INSPECT CRANKSHAFT THRUST CLEARANCE

(a) Using a dial indicator, measure the thrust clearance

while prying the crankshaft back and forth with a

screwdriver.

Standard thrust clearance:

0.04 to 0.24 mm (0.0016 to 0.0095 in.)

Maximum thrust clearance:

0.30 mm (0.012 in.)

If the thrust clearance is greater than the maximum,

replace the thrust washers as a set.

A112320E01

A112234

A112235

A112236

A112237

Page 661 of 2000

EM–1342AZ-FE ENGINE MECHANICAL – ENGINE UNIT

EM

HINT:

The thrust washer thickness is 1.93 to 1.98 mm

(0.0760 to 0.0780 in.).

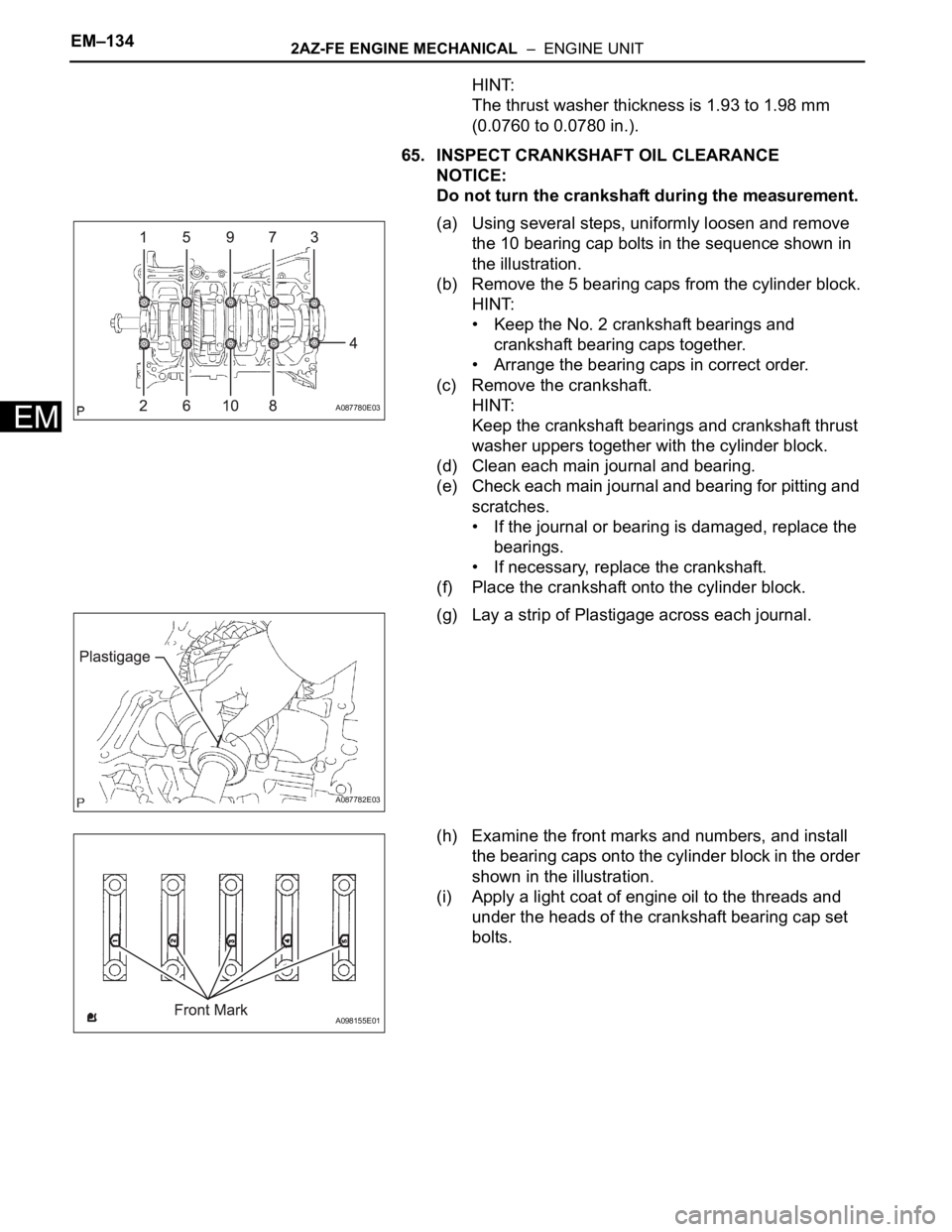

65. INSPECT CRANKSHAFT OIL CLEARANCE

NOTICE:

Do not turn the crankshaft during the measurement.

(a) Using several steps, uniformly loosen and remove

the 10 bearing cap bolts in the sequence shown in

the illustration.

(b) Remove the 5 bearing caps from the cylinder block.

HINT:

• Keep the No. 2 crankshaft bearings and

crankshaft bearing caps together.

• Arrange the bearing caps in correct order.

(c) Remove the crankshaft.

HINT:

Keep the crankshaft bearings and crankshaft thrust

washer uppers together with the cylinder block.

(d) Clean each main journal and bearing.

(e) Check each main journal and bearing for pitting and

scratches.

• If the journal or bearing is damaged, replace the

bearings.

• If necessary, replace the crankshaft.

(f) Place the crankshaft onto the cylinder block.

(g) Lay a strip of Plastigage across each journal.

(h) Examine the front marks and numbers, and install

the bearing caps onto the cylinder block in the order

shown in the illustration.

(i) Apply a light coat of engine oil to the threads and

under the heads of the crankshaft bearing cap set

bolts.

A087780E03

A087782E03

A098155E01

Page 664 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE UNITEM–137

EM

Standard bearing center wall thickness

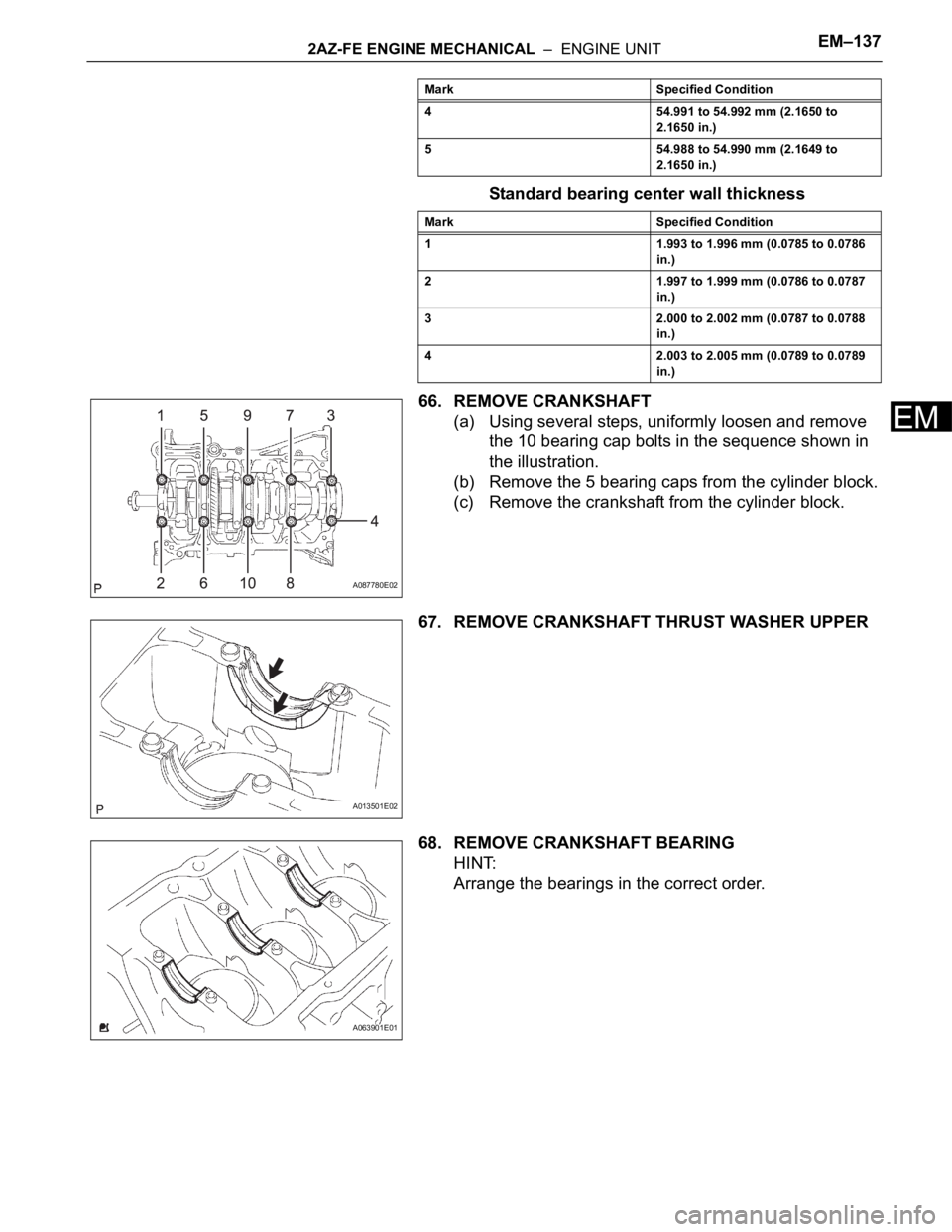

66. REMOVE CRANKSHAFT

(a) Using several steps, uniformly loosen and remove

the 10 bearing cap bolts in the sequence shown in

the illustration.

(b) Remove the 5 bearing caps from the cylinder block.

(c) Remove the crankshaft from the cylinder block.

67. REMOVE CRANKSHAFT THRUST WASHER UPPER

68. REMOVE CRANKSHAFT BEARING

HINT:

Arrange the bearings in the correct order.

4 54.991 to 54.992 mm (2.1650 to

2.1650 in.)

5 54.988 to 54.990 mm (2.1649 to

2.1650 in.)

Mark Specified Condition

1 1.993 to 1.996 mm (0.0785 to 0.0786

in.)

2 1.997 to 1.999 mm (0.0786 to 0.0787

in.)

3 2.000 to 2.002 mm (0.0787 to 0.0788

in.)

4 2.003 to 2.005 mm (0.0789 to 0.0789

in.) Mark Specified Condition

A087780E02

A013501E02

A063901E01

Page 698 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–61

EM

39. REMOVE VALVE LASH ADJUSTER ASSEMBLY

(a) Remove the 24 valve lash adjusters from the

cylinder head.

HINT:

Arrange the removed parts in the correct order.

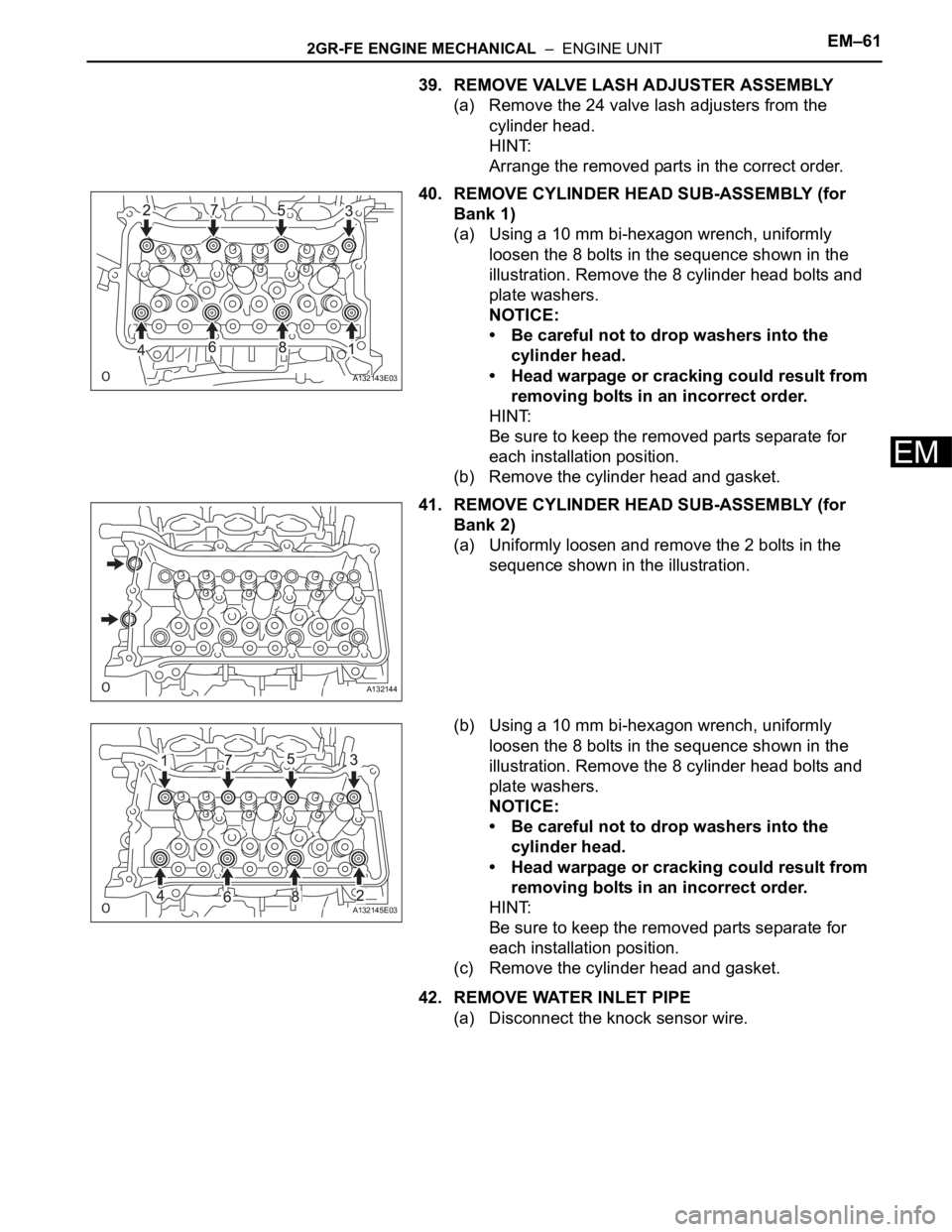

40. REMOVE CYLINDER HEAD SUB-ASSEMBLY (for

Bank 1)

(a) Using a 10 mm bi-hexagon wrench, uniformly

loosen the 8 bolts in the sequence shown in the

illustration. Remove the 8 cylinder head bolts and

plate washers.

NOTICE:

• Be careful not to drop washers into the

cylinder head.

• Head warpage or cracking could result from

removing bolts in an incorrect order.

HINT:

Be sure to keep the removed parts separate for

each installation position.

(b) Remove the cylinder head and gasket.

41. REMOVE CYLINDER HEAD SUB-ASSEMBLY (for

Bank 2)

(a) Uniformly loosen and remove the 2 bolts in the

sequence shown in the illustration.

(b) Using a 10 mm bi-hexagon wrench, uniformly

loosen the 8 bolts in the sequence shown in the

illustration. Remove the 8 cylinder head bolts and

plate washers.

NOTICE:

• Be careful not to drop washers into the

cylinder head.

• Head warpage or cracking could result from

removing bolts in an incorrect order.

HINT:

Be sure to keep the removed parts separate for

each installation position.

(c) Remove the cylinder head and gasket.

42. REMOVE WATER INLET PIPE

(a) Disconnect the knock sensor wire.

A132143E03

A132144

A132145E03

Page 704 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–67

EM

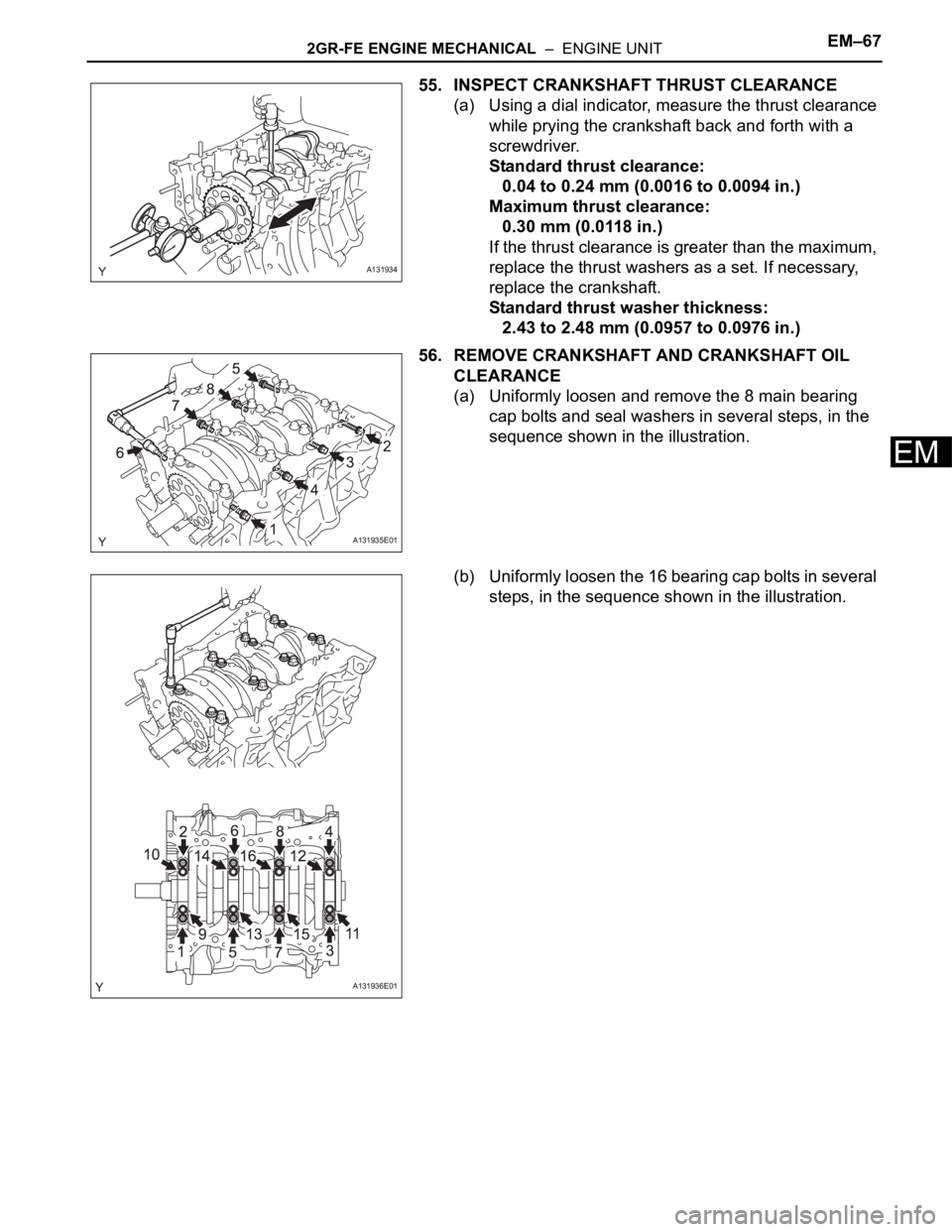

55. INSPECT CRANKSHAFT THRUST CLEARANCE

(a) Using a dial indicator, measure the thrust clearance

while prying the crankshaft back and forth with a

screwdriver.

Standard thrust clearance:

0.04 to 0.24 mm (0.0016 to 0.0094 in.)

Maximum thrust clearance:

0.30 mm (0.0118 in.)

If the thrust clearance is greater than the maximum,

replace the thrust washers as a set. If necessary,

replace the crankshaft.

Standard thrust washer thickness:

2.43 to 2.48 mm (0.0957 to 0.0976 in.)

56. REMOVE CRANKSHAFT AND CRANKSHAFT OIL

CLEARANCE

(a) Uniformly loosen and remove the 8 main bearing

cap bolts and seal washers in several steps, in the

sequence shown in the illustration.

(b) Uniformly loosen the 16 bearing cap bolts in several

steps, in the sequence shown in the illustration.

A131934

A131935E01

A131936E01

Page 710 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–73

EM

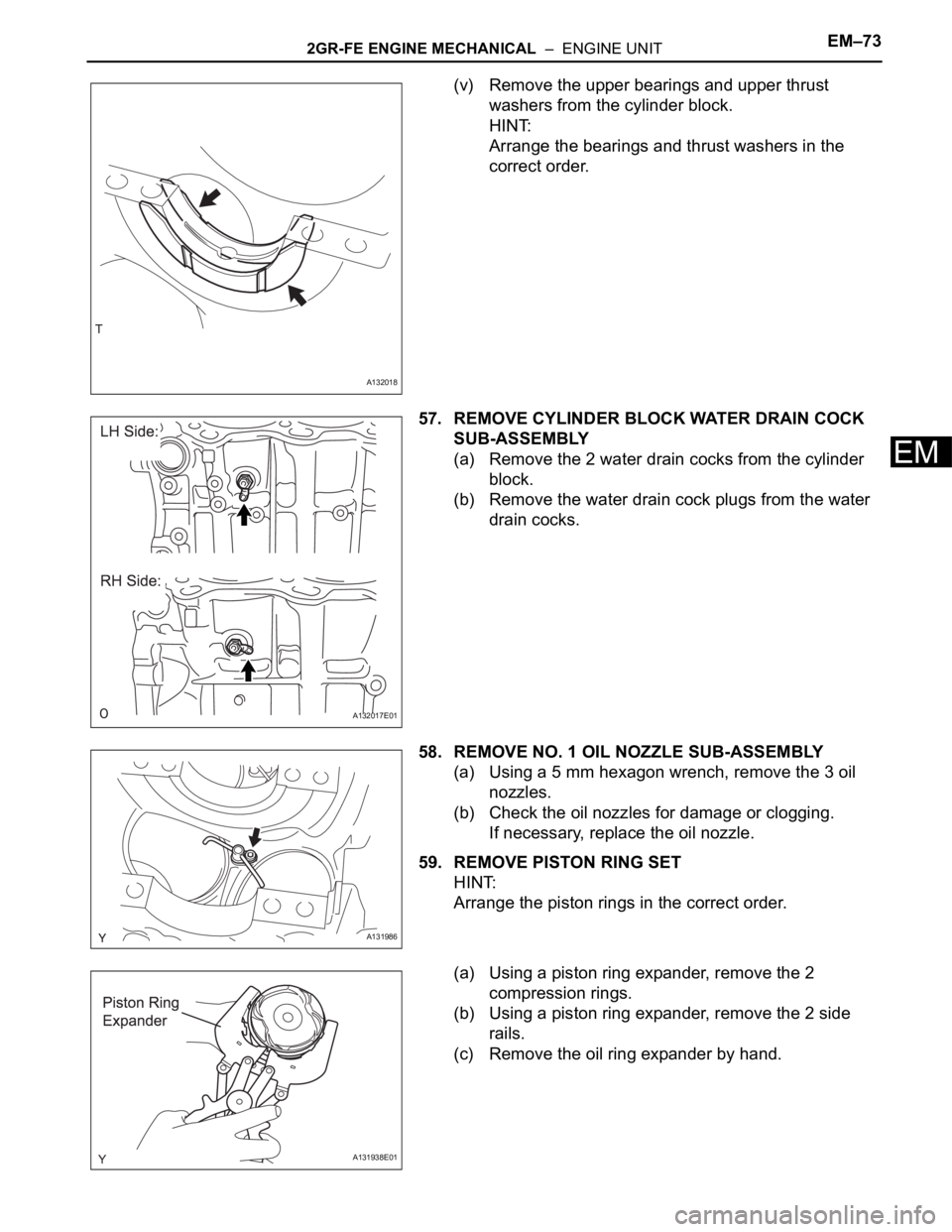

(v) Remove the upper bearings and upper thrust

washers from the cylinder block.

HINT:

Arrange the bearings and thrust washers in the

correct order.

57. REMOVE CYLINDER BLOCK WATER DRAIN COCK

SUB-ASSEMBLY

(a) Remove the 2 water drain cocks from the cylinder

block.

(b) Remove the water drain cock plugs from the water

drain cocks.

58. REMOVE NO. 1 OIL NOZZLE SUB-ASSEMBLY

(a) Using a 5 mm hexagon wrench, remove the 3 oil

nozzles.

(b) Check the oil nozzles for damage or clogging.

If necessary, replace the oil nozzle.

59. REMOVE PISTON RING SET

HINT:

Arrange the piston rings in the correct order.

(a) Using a piston ring expander, remove the 2

compression rings.

(b) Using a piston ring expander, remove the 2 side

rails.

(c) Remove the oil ring expander by hand.

A132018

A132017E01

A131986

A131938E01

Page 746 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–109

EM

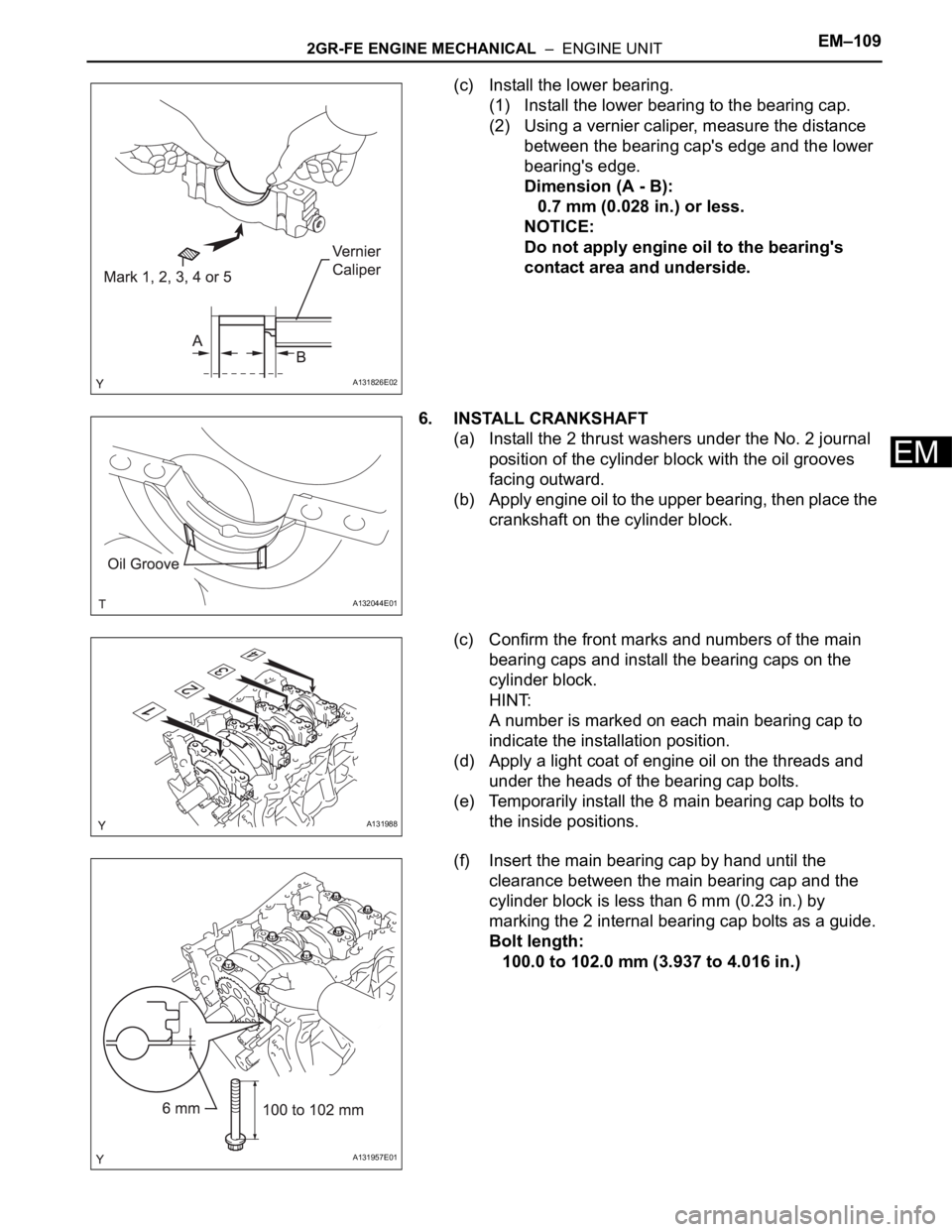

(c) Install the lower bearing.

(1) Install the lower bearing to the bearing cap.

(2) Using a vernier caliper, measure the distance

between the bearing cap's edge and the lower

bearing's edge.

Dimension (A - B):

0.7 mm (0.028 in.) or less.

NOTICE:

Do not apply engine oil to the bearing's

contact area and underside.

6. INSTALL CRANKSHAFT

(a) Install the 2 thrust washers under the No. 2 journal

position of the cylinder block with the oil grooves

facing outward.

(b) Apply engine oil to the upper bearing, then place the

crankshaft on the cylinder block.

(c) Confirm the front marks and numbers of the main

bearing caps and install the bearing caps on the

cylinder block.

HINT:

A number is marked on each main bearing cap to

indicate the installation position.

(d) Apply a light coat of engine oil on the threads and

under the heads of the bearing cap bolts.

(e) Temporarily install the 8 main bearing cap bolts to

the inside positions.

(f) Insert the main bearing cap by hand until the

clearance between the main bearing cap and the

cylinder block is less than 6 mm (0.23 in.) by

marking the 2 internal bearing cap bolts as a guide.

Bolt length:

100.0 to 102.0 mm (3.937 to 4.016 in.)

A131826E02

A132044E01

A131988

A131957E01

Page 753 of 2000

EM–1162GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

17. INSTALL WATER INLET PIPE

(a) Install the water inlet pipe with the 2 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(b) Install the water by-pass hose.

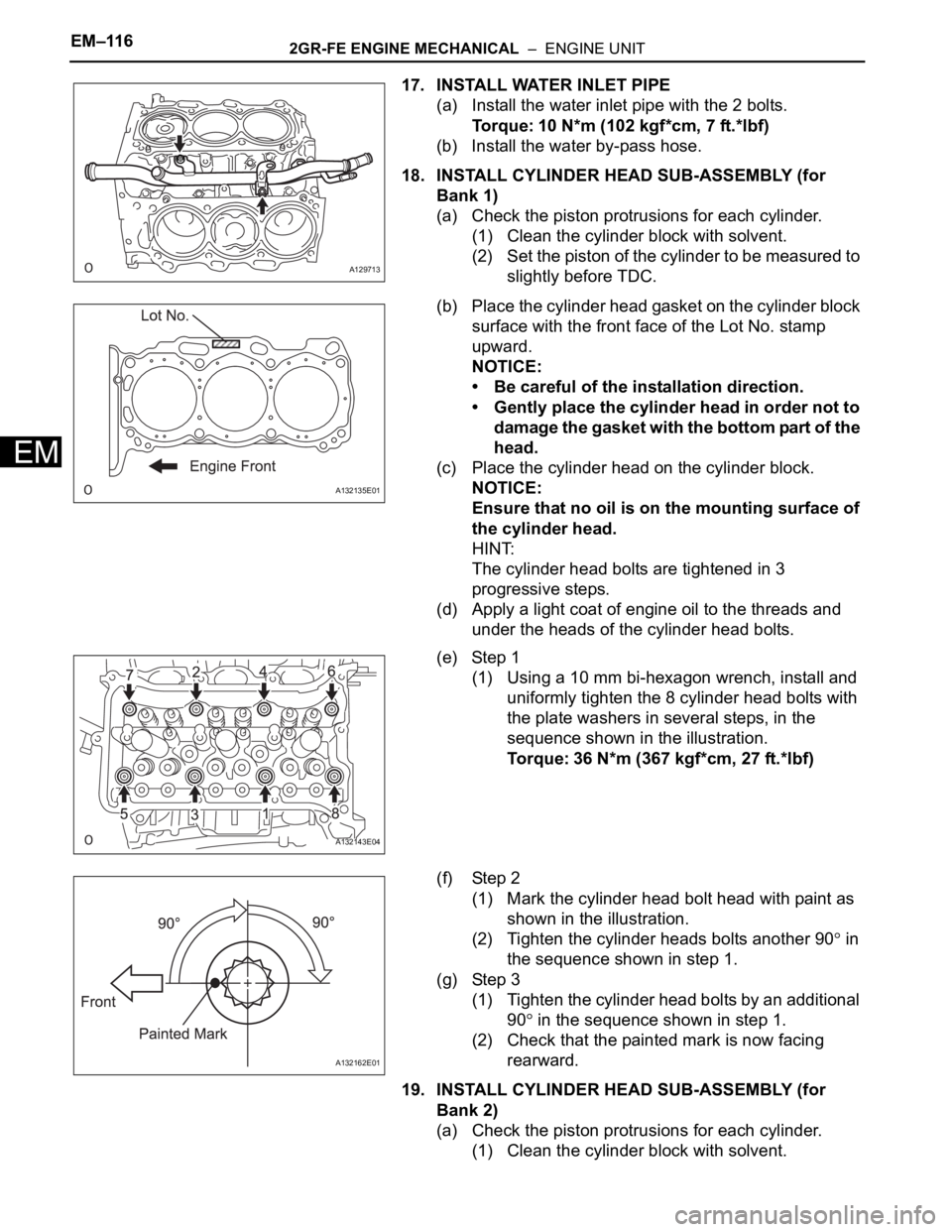

18. INSTALL CYLINDER HEAD SUB-ASSEMBLY (for

Bank 1)

(a) Check the piston protrusions for each cylinder.

(1) Clean the cylinder block with solvent.

(2) Set the piston of the cylinder to be measured to

slightly before TDC.

(b) Place the cylinder head gasket on the cylinder block

surface with the front face of the Lot No. stamp

upward.

NOTICE:

• Be careful of the installation direction.

• Gently place the cylinder head in order not to

damage the gasket with the bottom part of the

head.

(c) Place the cylinder head on the cylinder block.

NOTICE:

Ensure that no oil is on the mounting surface of

the cylinder head.

HINT:

The cylinder head bolts are tightened in 3

progressive steps.

(d) Apply a light coat of engine oil to the threads and

under the heads of the cylinder head bolts.

(e) Step 1

(1) Using a 10 mm bi-hexagon wrench, install and

uniformly tighten the 8 cylinder head bolts with

the plate washers in several steps, in the

sequence shown in the illustration.

Torque: 36 N*m (367 kgf*cm, 27 ft.*lbf)

(f) Step 2

(1) Mark the cylinder head bolt head with paint as

shown in the illustration.

(2) Tighten the cylinder heads bolts another 90

in

the sequence shown in step 1.

(g) Step 3

(1) Tighten the cylinder head bolts by an additional

90

in the sequence shown in step 1.

(2) Check that the painted mark is now facing

rearward.

19. INSTALL CYLINDER HEAD SUB-ASSEMBLY (for

Bank 2)

(a) Check the piston protrusions for each cylinder.

(1) Clean the cylinder block with solvent.

A129713

A132135E01

A132143E04

A132162E01

Page 754 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–117

EM

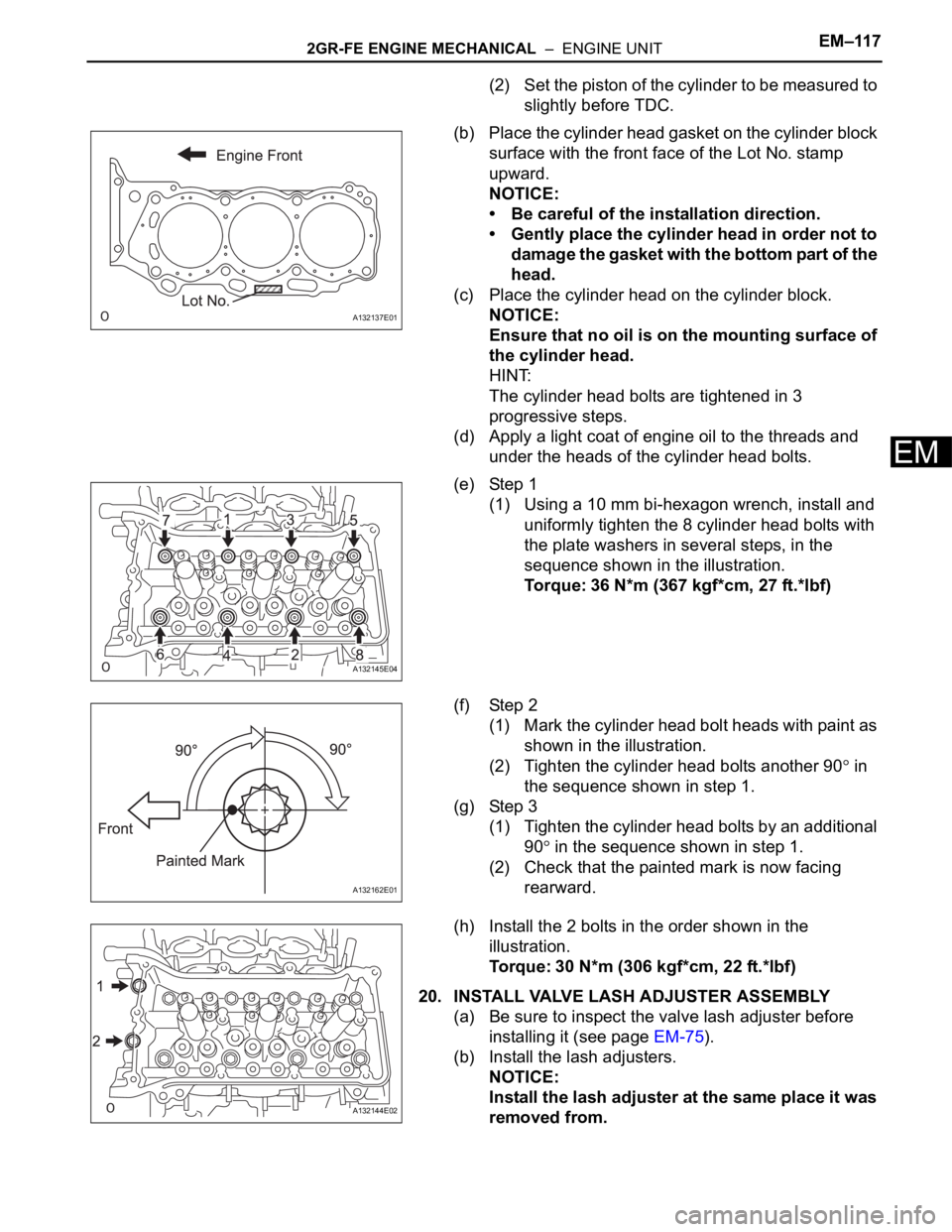

(2) Set the piston of the cylinder to be measured to

slightly before TDC.

(b) Place the cylinder head gasket on the cylinder block

surface with the front face of the Lot No. stamp

upward.

NOTICE:

• Be careful of the installation direction.

• Gently place the cylinder head in order not to

dama ge the gaske t wi th t he b ottom part of t he

head.

(c) Place the cylinder head on the cylinder block.

NOTICE:

Ensure that no oil is on the mounting surface of

the cylinder head.

HINT:

The cylinder head bolts are tightened in 3

progressive steps.

(d) Apply a light coat of engine oil to the threads and

under the heads of the cylinder head bolts.

(e) Step 1

(1) Using a 10 mm bi-hexagon wrench, install and

uniformly tighten the 8 cylinder head bolts with

the plate washers in several steps, in the

sequence shown in the illustration.

Torque: 36 N*m (367 kgf*cm, 27 ft.*lbf)

(f) Step 2

(1) Mark the cylinder head bolt heads with paint as

shown in the illustration.

(2) Tighten the cylinder head bolts another 90

in

the sequence shown in step 1.

(g) Step 3

(1) Tighten the cylinder head bolts by an additional

90

in the sequence shown in step 1.

(2) Check that the painted mark is now facing

rearward.

(h) Install the 2 bolts in the order shown in the

illustration.

Torque: 30 N*m (306 kgf*cm, 22 ft.*lbf)

20. INSTALL VALVE LASH ADJUSTER ASSEMBLY

(a) Be sure to inspect the valve lash adjuster before

installing it (see page EM-75).

(b) Install the lash adjusters.

NOTICE:

Install the lash adjuster at the same place it was

removed from.

A132137E01

A132145E04

A132162E01

A132144E02

Page 900 of 2000

ST–82AZ-FE STARTING – STARTER

ST

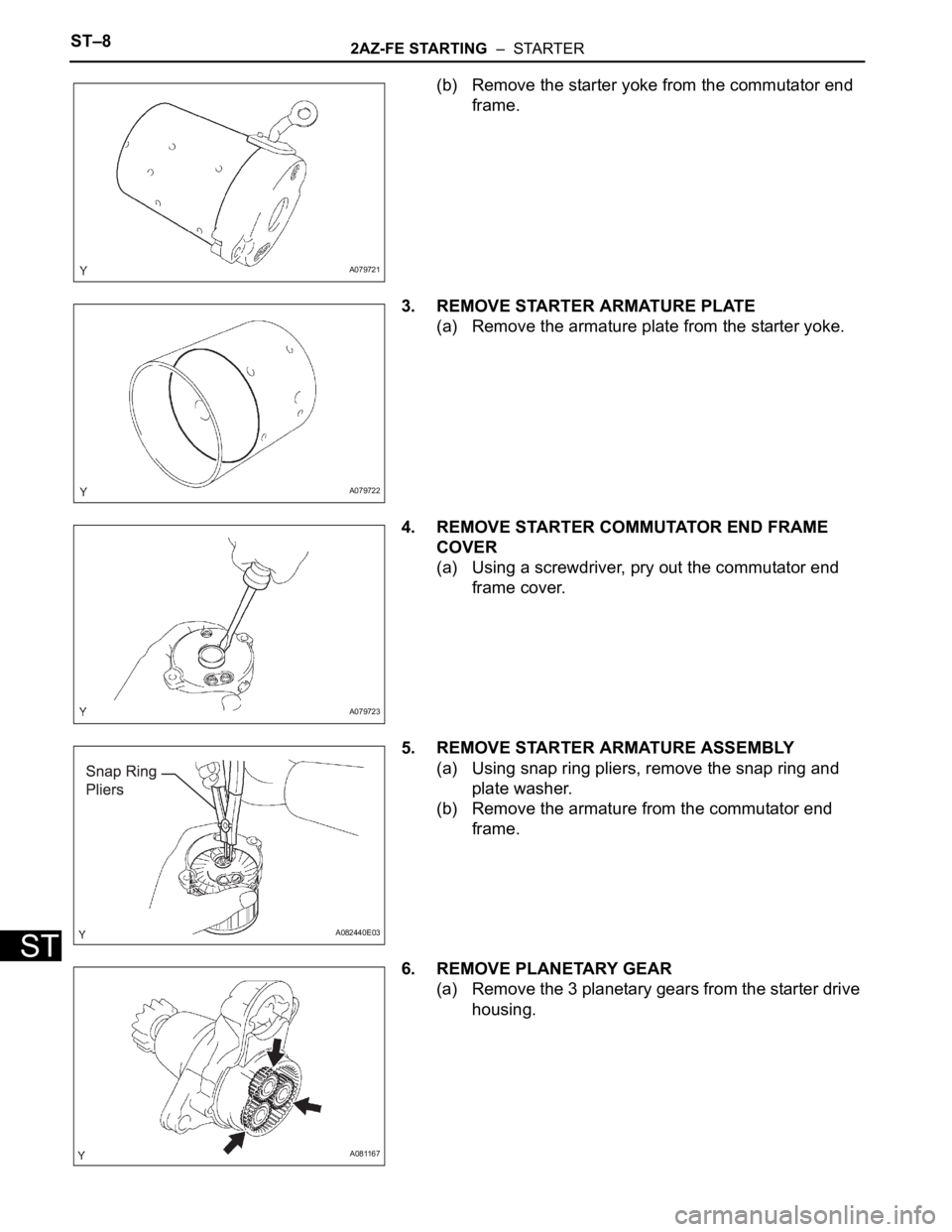

(b) Remove the starter yoke from the commutator end

frame.

3. REMOVE STARTER ARMATURE PLATE

(a) Remove the armature plate from the starter yoke.

4. REMOVE STARTER COMMUTATOR END FRAME

COVER

(a) Using a screwdriver, pry out the commutator end

frame cover.

5. REMOVE STARTER ARMATURE ASSEMBLY

(a) Using snap ring pliers, remove the snap ring and

plate washer.

(b) Remove the armature from the commutator end

frame.

6. REMOVE PLANETARY GEAR

(a) Remove the 3 planetary gears from the starter drive

housing.

A079721

A079722

A079723

A082440E03

A081167