torque TOYOTA RAV4 2006 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 136 of 2000

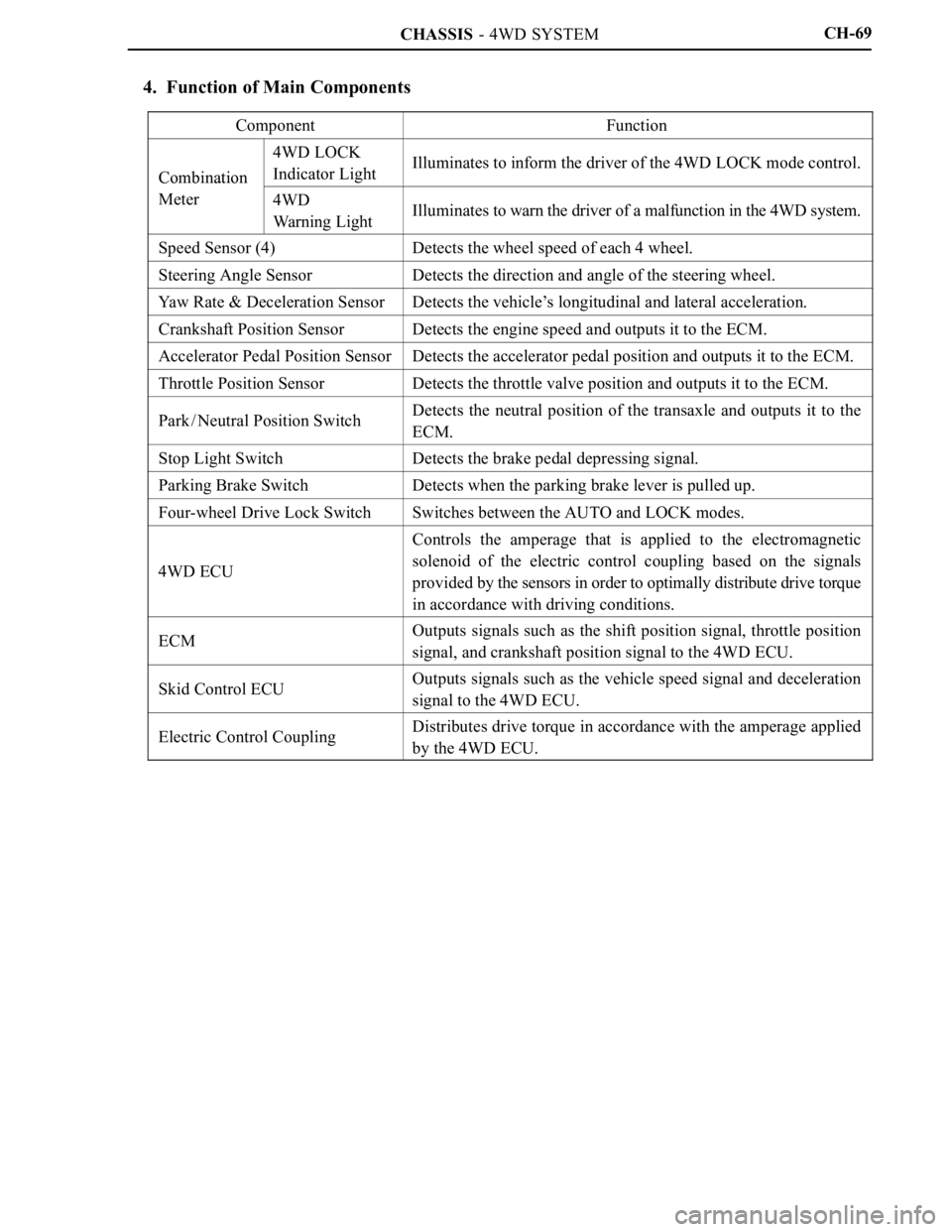

CHASSIS - 4WD SYSTEMCH-69

4. Function of Main Components

ComponentFunction

Combination

4WD LOCK

Indicator LightIlluminates to inform the driver of the 4WD LOCK mode control.Combination

Meter4WD

Warning LightIlluminates to warn the driver of a malfunction in the 4WD system.

Speed Sensor (4)Detects the wheel speed of each 4 wheel.

Steering Angle SensorDetects the direction and angle of the steering wheel.

Yaw Rate & Deceleration SensorDetects the vehicle’s longitudinal and lateral acceleration.

Crankshaft Position SensorDetects the engine speed and outputs it to the ECM.

Accelerator Pedal Position SensorDetects the accelerator pedal position and outputs it to the ECM.

Throttle Position SensorDetects the throttle valve position and outputs it to the ECM.

Park / Neutral Position SwitchDetects the neutral position of the transaxle and outputs it to the

ECM.

Stop Light SwitchDetects the brake pedal depressing signal.

Parking Brake SwitchDetects when the parking brake lever is pulled up.

Four-wheel Drive Lock SwitchSwitches between the AUTO and LOCK modes.

4WD ECU

Controls the amperage that is applied to the electromagnetic

solenoid of the electric control coupling based on the signals

provided by the sensors in order to optimally distribute drive torque

in accordance with driving conditions.

ECMOutputs signals such as the shift position signal, throttle position

signal, and crankshaft position signal to the 4WD ECU.

Skid Control ECUOutputs signals such as the vehicle speed signal and deceleration

signal to the 4WD ECU.

Electric Control CouplingDistributes drive torque in accordance with the amperage applied

by the 4WD ECU.

Page 137 of 2000

CHASSIS - 4WD SYSTEM

01NCH38Y

Torque Distribution

to Rear WheelsTorque Distribution

to Rear Wheels

Straightline Driving Low-Speed Cornering

01NCH39Y

Torque Distribution

to Rear WheelsTorque Distribution

to Rear Wheels

Steady Driving Straightline Acceleration

NOTICE

In the LOCK mode after the four-wheel drive lock switch is pressed, the system starts control upon

judging that the vehicle is operating in a stable manner. During this judgment, the 4WD LOCK

indicator light blinks.

CH-70

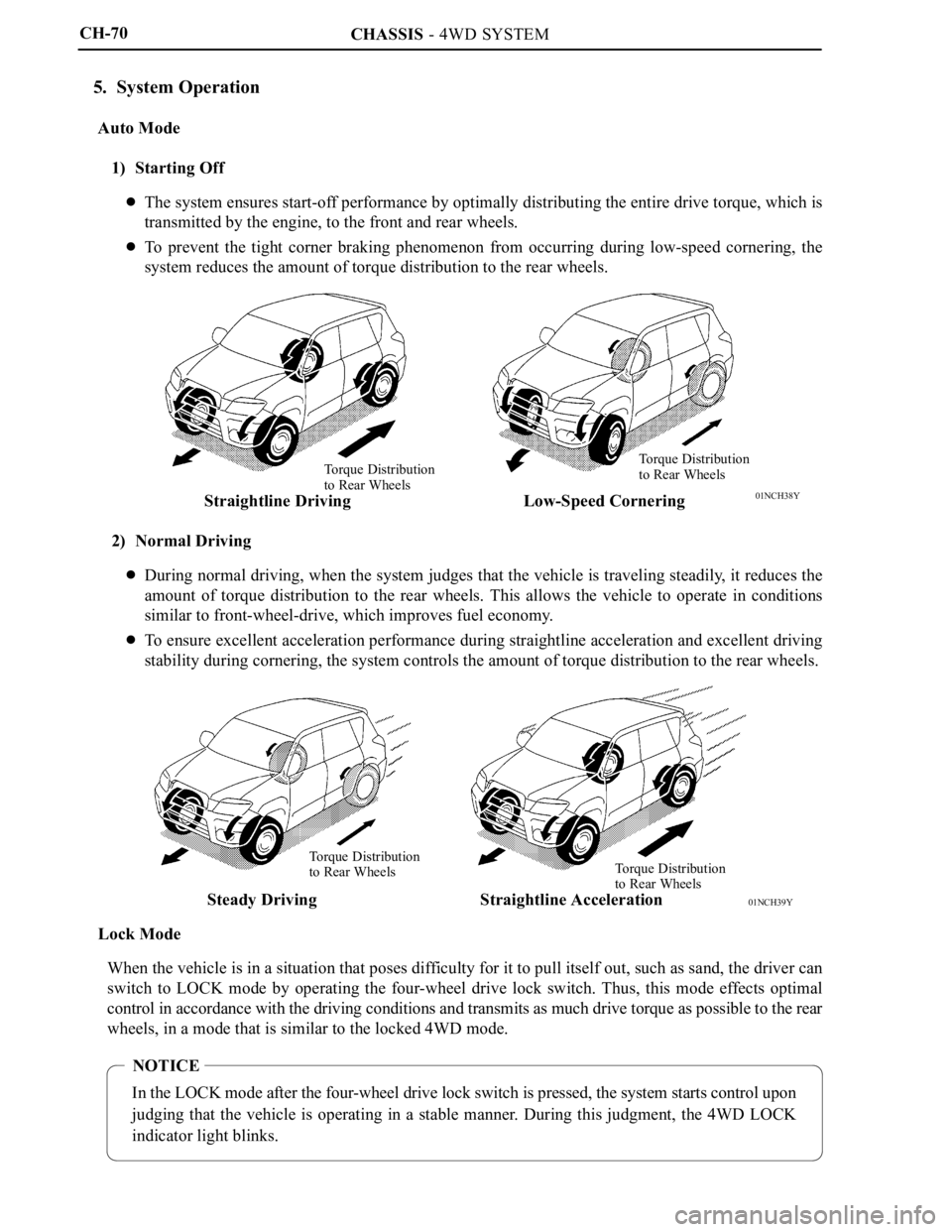

5. System Operation

Auto Mode

1) Starting Off

The system ensures start-off performance by optimally distributing the entire drive torque, which is

transmitted by the engine, to the front and rear wheels.

To prevent the tight corner braking phenomenon from occurring during low-speed cornering, the

system reduces the amount of torque distribution to the rear wheels.

2) Normal Driving

During normal driving, when the system judges that the vehicle is traveling steadily, it reduces the

amount of torque distribution to the rear wheels. This allows the vehicle to operate in conditions

similar to front-wheel-drive, which improves fuel economy.

To ensure excellent acceleration performance during straightline acceleration and excellent driving

stability during cornering, the system controls the amount of torque distribution to the rear wheels.

Lock Mode

When the vehicle is in a situation that poses difficulty for it to pull itself out, such as sand, the driver can

switch to LOCK mode by operating the four-wheel drive lock switch. Thus, this mode effects optimal

control in accordance with the driving conditions and transmits as much drive torque as possible to the rear

wheels, in a mode that is similar to the locked 4WD mode.

Page 171 of 2000

PREPARATION – 2AZ-FE ENGINE CONTROL SYSTEMPP–3

PP

EQUIPMENT

Ohmmeter -

Service wire -

Torque wrench -

Page 179 of 2000

SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSMISSIONSS–47

SS

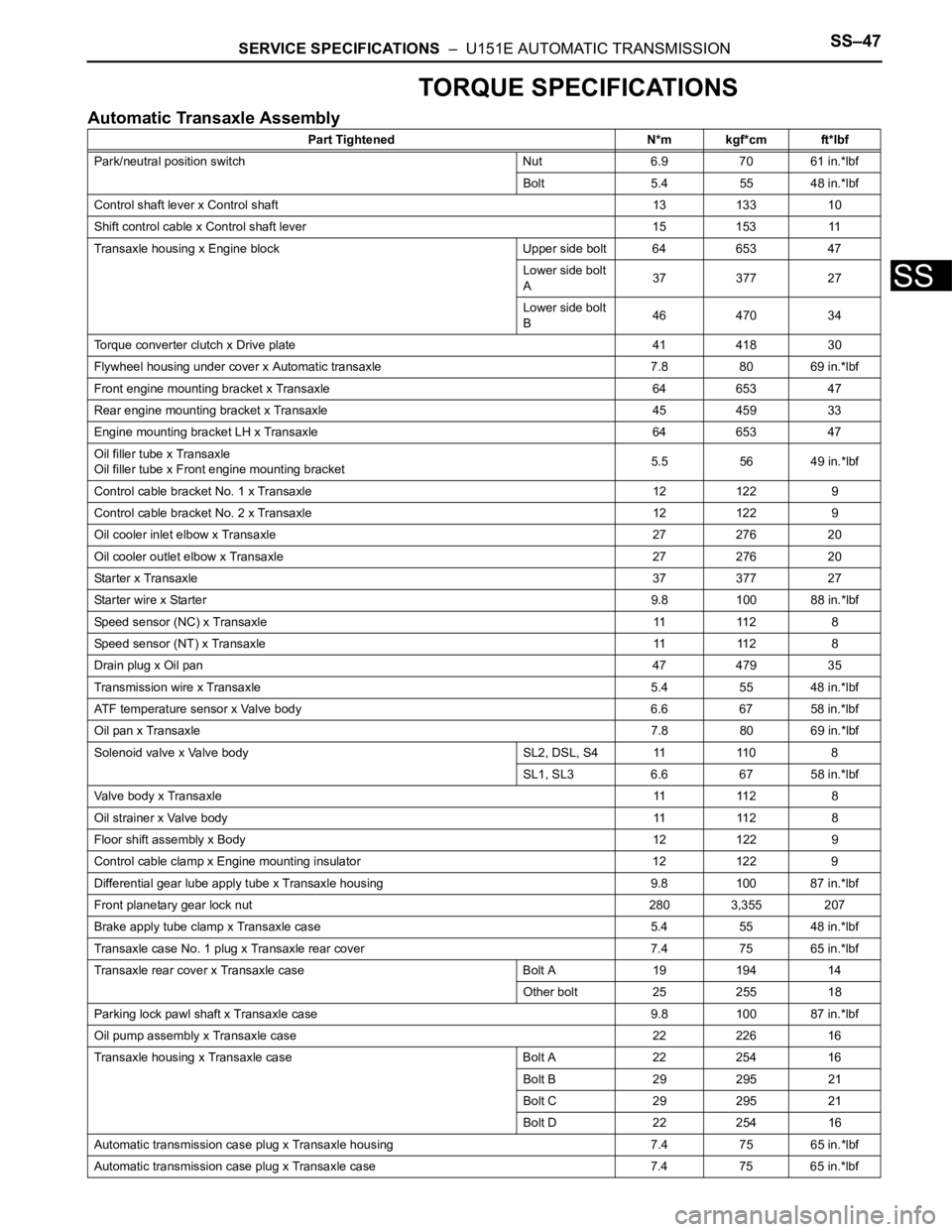

TORQUE SPECIFICATIONS

Automatic Transaxle Assembly

Part Tightened N*m kgf*cm ft*lbf

Park/neutral position switch Nut 6.9 70 61 in.*lbf

Bolt 5.4 55 48 in.*lbf

Control shaft lever x Control shaft 13 133 10

Shift control cable x Control shaft lever 15 153 11

Transaxle housing x Engine block Upper side bolt 64 653 47

Lower side bolt

A37 377 27

Lower side bolt

B46 470 34

Torque converter clutch x Drive plate 41 418 30

Flywheel housing under cover x Automatic transaxle 7.8 80 69 in.*lbf

Front engine mounting bracket x Transaxle 64 653 47

Rear engine mounting bracket x Transaxle 45 459 33

Engine mounting bracket LH x Transaxle 64 653 47

Oil filler tube x Transaxle

Oil filler tube x Front engine mounting bracket5.5 56 49 in.*lbf

Control cable bracket No. 1 x Transaxle 12 122 9

Control cable bracket No. 2 x Transaxle 12 122 9

Oil cooler inlet elbow x Transaxle 27 276 20

Oil cooler outlet elbow x Transaxle 27 276 20

Starter x Transaxle37 377 27

Starter wire x Starter9.8 100 88 in.*lbf

Speed sensor (NC) x Transaxle 11 112 8

Speed sensor (NT) x Transaxle 11 112 8

Drain plug x Oil pan47 479 35

Transmission wire x Transaxle 5.4 55 48 in.*lbf

ATF temperature sensor x Valve body 6.6 67 58 in.*lbf

Oil pan x Transaxle7.8 80 69 in.*lbf

Solenoid valve x Valve body SL2, DSL, S4 11 110 8

SL1, SL3 6.6 67 58 in.*lbf

Valve body x Transaxle11 11 2 8

Oil strainer x Valve body11 11 2 8

Floor shift assembly x Body12 122 9

Control cable clamp x Engine mounting insulator 12 122 9

Differential gear lube apply tube x Transaxle housing 9.8 100 87 in.*lbf

Front planetary gear lock nut 280 3,355 207

Brake apply tube clamp x Transaxle case 5.4 55 48 in.*lbf

Transaxle case No. 1 plug x Transaxle rear cover 7.4 75 65 in.*lbf

Transaxle rear cover x Transaxle case Bolt A 19 194 14

Other bolt 25 255 18

Parking lock pawl shaft x Transaxle case 9.8 100 87 in.*lbf

Oil pump assembly x Transaxle case 22 226 16

Transaxle housing x Transaxle case Bolt A 22 254 16

Bolt B 29 295 21

Bolt C 29 295 21

Bolt D 22 254 16

Automatic transmission case plug x Transaxle housing 7.4 75 65 in.*lbf

Automatic transmission case plug x Transaxle case 7.4 75 65 in.*lbf

Page 181 of 2000

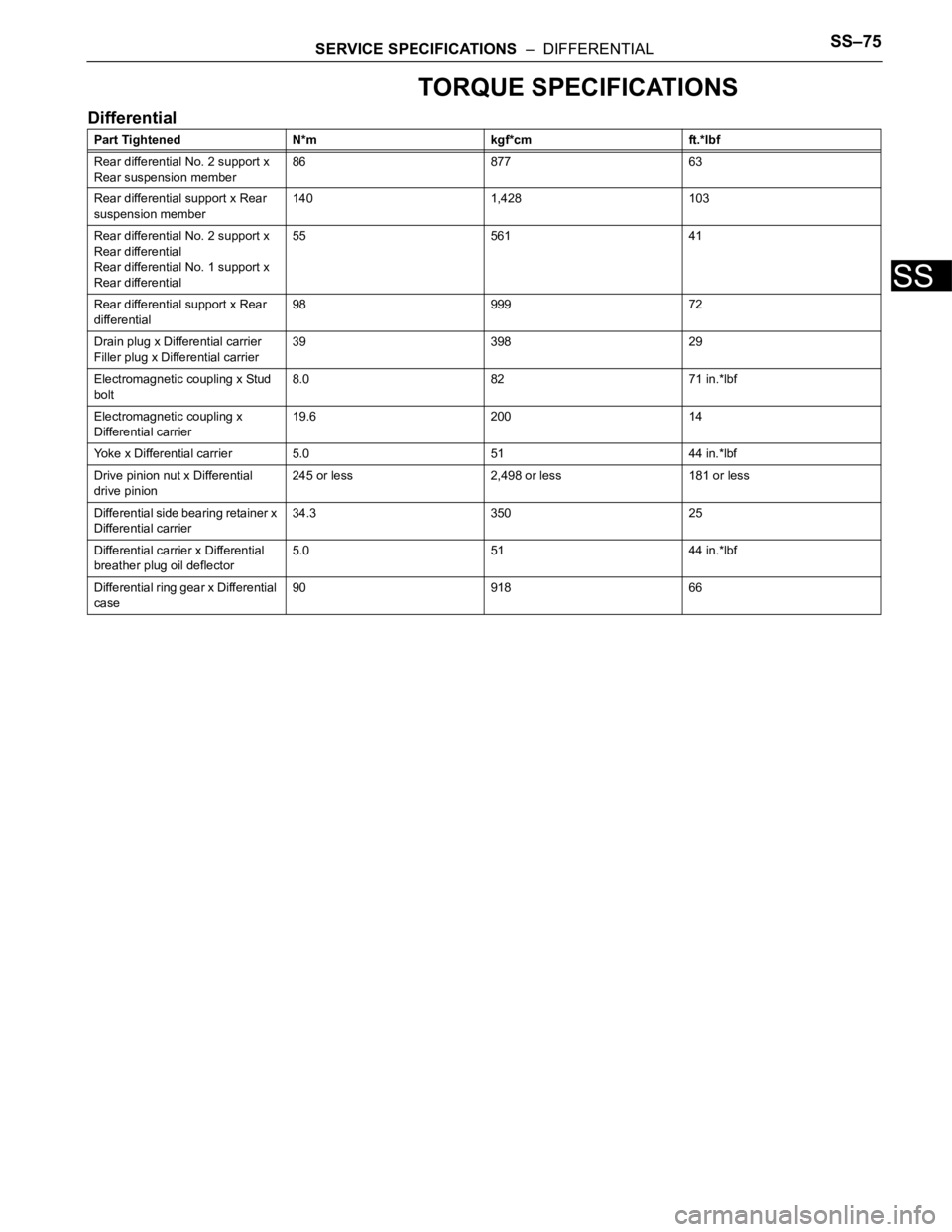

SERVICE SPECIFICATIONS – DIFFERENTIALSS–75

SS

TORQUE SPECIFICATIONS

Differential

Part Tightened N*m kgf*cm ft.*lbf

Rear differential No. 2 support x

Rear suspension member86 877 63

Rear differential support x Rear

suspension member140 1,428 103

Rear differential No. 2 support x

Rear differential

Rear differential No. 1 support x

Rear differential55 561 41

Rear differential support x Rear

differential98 999 72

Drain plug x Differential carrier

Filler plug x Differential carrier39 398 29

Electromagnetic coupling x Stud

bolt8.0 82 71 in.*lbf

Electromagnetic coupling x

Differential carrier19.6 200 14

Yoke x Differential carrier 5.0 51 44 in.*lbf

Drive pinion nut x Differential

drive pinion245 or less 2,498 or less 181 or less

Differential side bearing retainer x

Differential carrier34.3 350 25

Differential carrier x Differential

breather plug oil deflector5.0 51 44 in.*lbf

Differential ring gear x Differential

case90 918 66

Page 187 of 2000

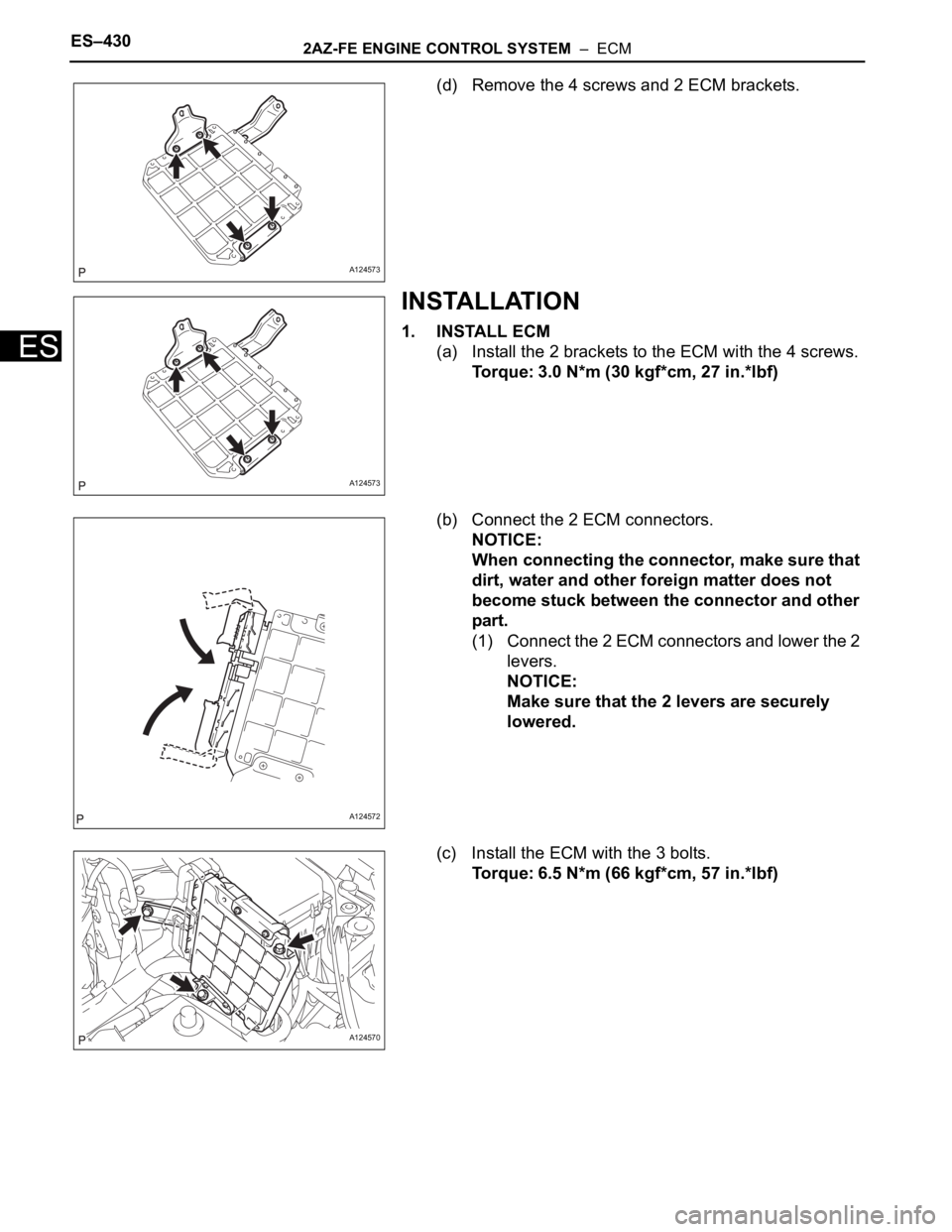

ES–4302AZ-FE ENGINE CONTROL SYSTEM – ECM

ES

(d) Remove the 4 screws and 2 ECM brackets.

INSTALLATION

1. INSTALL ECM

(a) Install the 2 brackets to the ECM with the 4 screws.

Torque: 3.0 N*m (30 kgf*cm, 27 in.*lbf)

(b) Connect the 2 ECM connectors.

NOTICE:

When connecting the connector, make sure that

dirt, water and other foreign matter does not

become stuck between the connector and other

part.

(1) Connect the 2 ECM connectors and lower the 2

levers.

NOTICE:

Make sure that the 2 levers are securely

lowered.

(c) Install the ECM with the 3 bolts.

Torque: 6.5 N*m (66 kgf*cm, 57 in.*lbf)

A124573

A124573

A124572

A124570

Page 188 of 2000

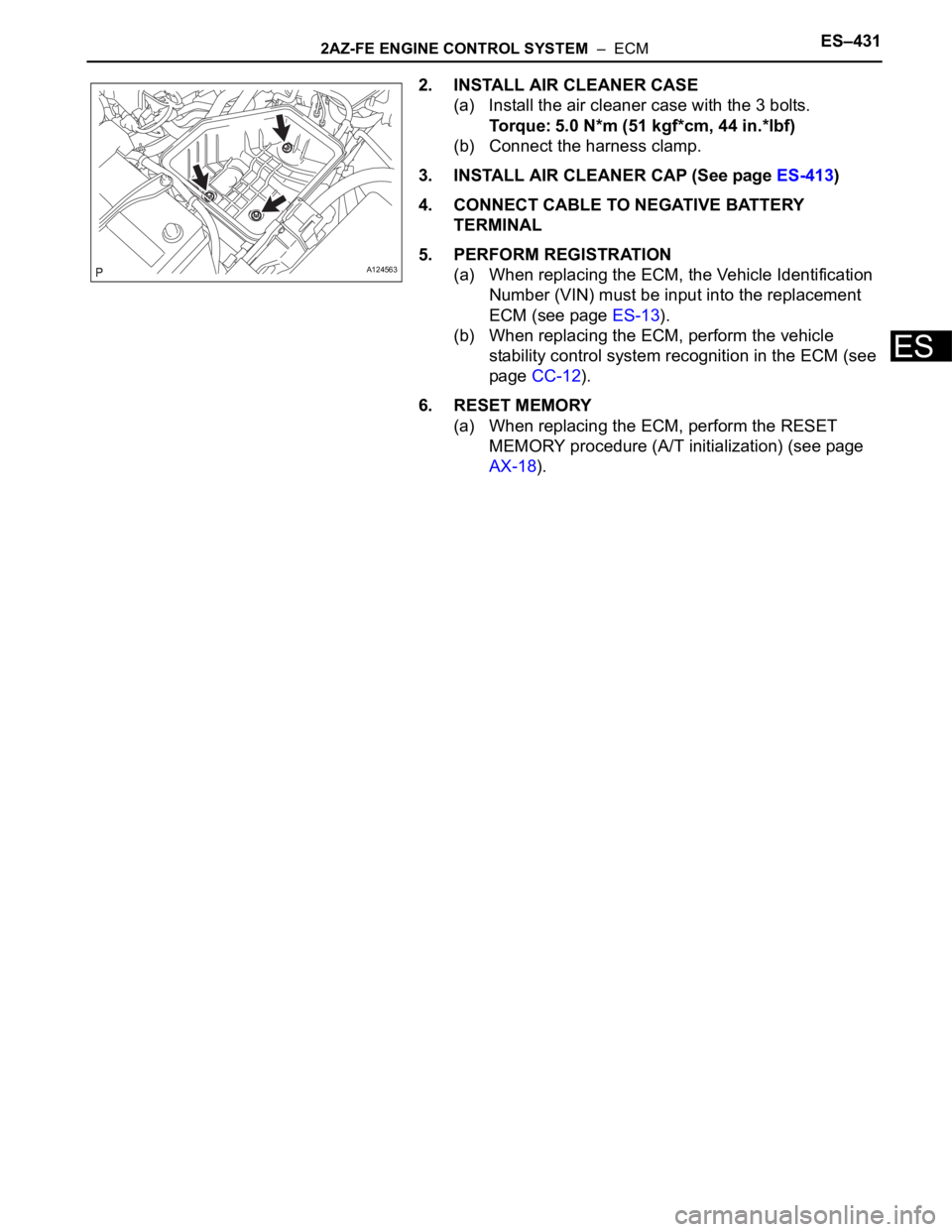

2AZ-FE ENGINE CONTROL SYSTEM – ECMES–431

ES

2. INSTALL AIR CLEANER CASE

(a) Install the air cleaner case with the 3 bolts.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

(b) Connect the harness clamp.

3. INSTALL AIR CLEANER CAP (See page ES-413)

4. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

5. PERFORM REGISTRATION

(a) When replacing the ECM, the Vehicle Identification

Number (VIN) must be input into the replacement

ECM (see page ES-13).

(b) When replacing the ECM, perform the vehicle

stability control system recognition in the ECM (see

page CC-12).

6. RESET MEMORY

(a) When replacing the ECM, perform the RESET

MEMORY procedure (A/T initialization) (see page

AX-18).

A124563

Page 194 of 2000

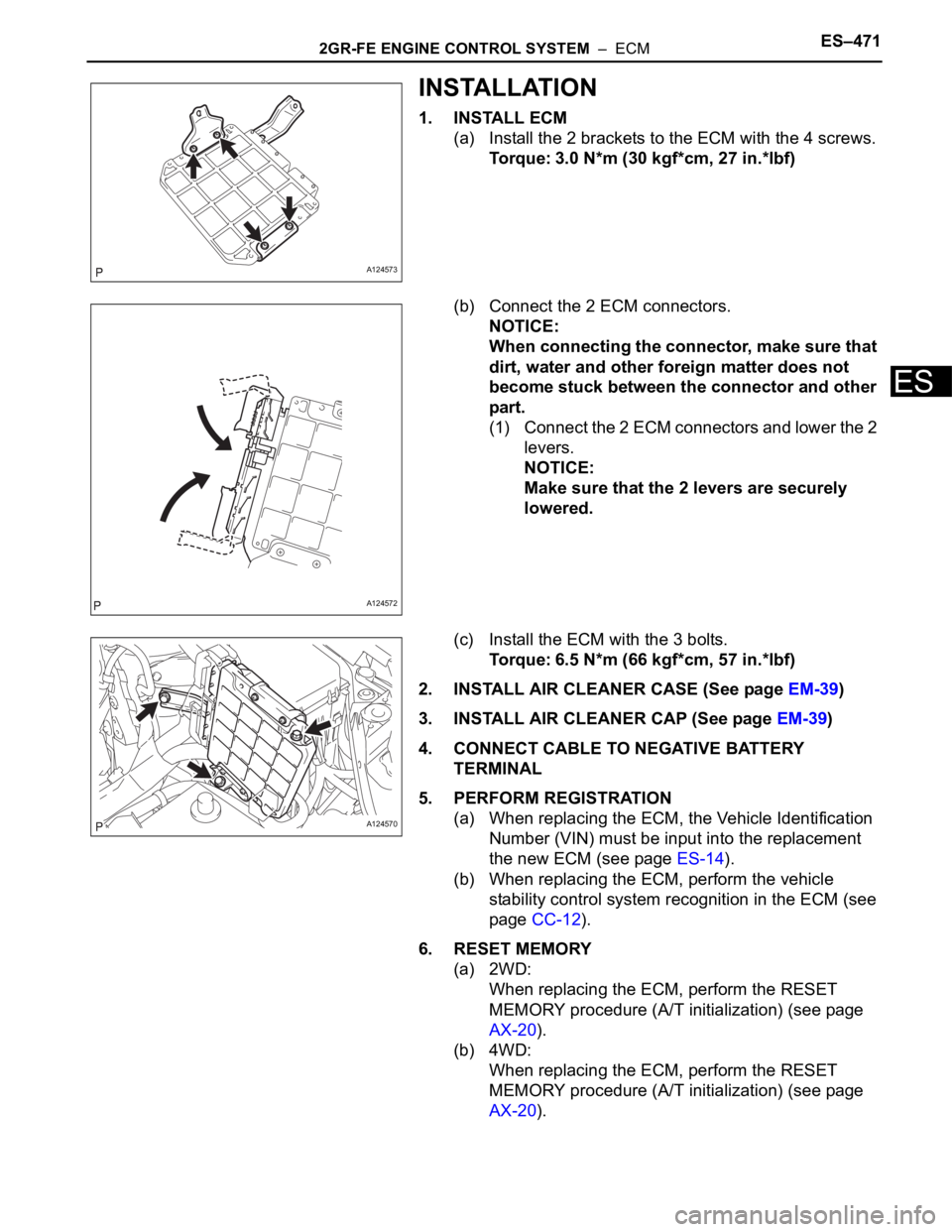

2GR-FE ENGINE CONTROL SYSTEM – ECMES–471

ES

INSTALLATION

1. INSTALL ECM

(a) Install the 2 brackets to the ECM with the 4 screws.

Torque: 3.0 N*m (30 kgf*cm, 27 in.*lbf)

(b) Connect the 2 ECM connectors.

NOTICE:

When connecting the connector, make sure that

dirt, water and other foreign matter does not

become stuck between the connector and other

part.

(1) Connect the 2 ECM connectors and lower the 2

levers.

NOTICE:

Make sure that the 2 levers are securely

lowered.

(c) Install the ECM with the 3 bolts.

Torque: 6.5 N*m (66 kgf*cm, 57 in.*lbf)

2. INSTALL AIR CLEANER CASE (See page EM-39)

3. INSTALL AIR CLEANER CAP (See page EM-39)

4. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

5. PERFORM REGISTRATION

(a) When replacing the ECM, the Vehicle Identification

Number (VIN) must be input into the replacement

the new ECM (see page ES-14).

(b) When replacing the ECM, perform the vehicle

stability control system recognition in the ECM (see

page CC-12).

6. RESET MEMORY

(a) 2WD:

When replacing the ECM, perform the RESET

MEMORY procedure (A/T initialization) (see page

AX-20).

(b) 4WD:

When replacing the ECM, perform the RESET

MEMORY procedure (A/T initialization) (see page

AX-20).

A124573

A124572

A124570

Page 195 of 2000

2AZ-FE ENGINE MECHANICAL – DRIVE BELTEM–7

EM

REMOVAL

1. REMOVE RADIATOR SUPPORT OPENING COVER

2. REMOVE FRONT WHEEL RH

3. REMOVE FRONT FENDER APRON RH

4. REMOVE FRONT SUSPENSION MEMBER

REINFORCEMENT RH

(a) Remove the 4 bolts and reinforcement RH.

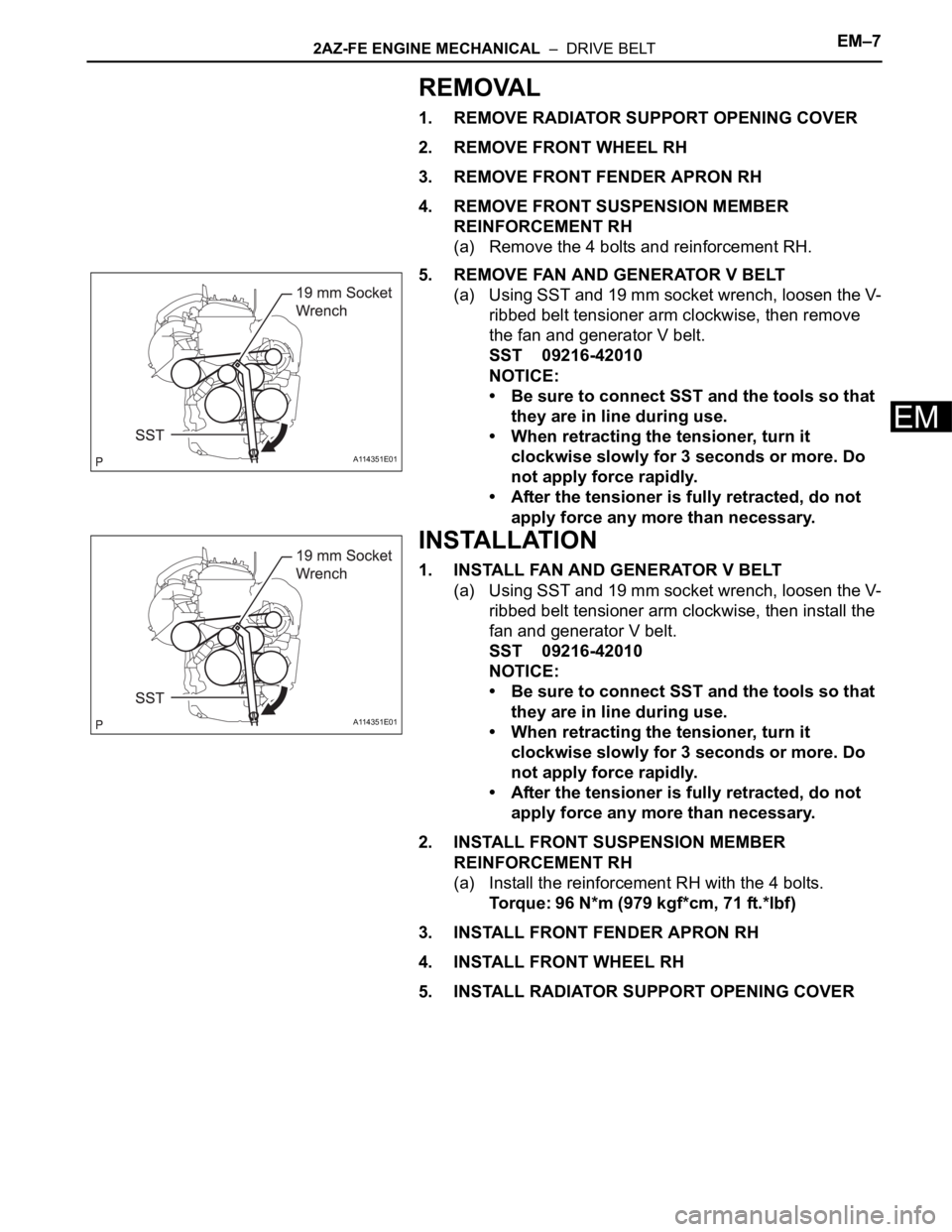

5. REMOVE FAN AND GENERATOR V BELT

(a) Using SST and 19 mm socket wrench, loosen the V-

ribbed belt tensioner arm clockwise, then remove

the fan and generator V belt.

SST 09216-42010

NOTICE:

• Be sure to connect SST and the tools so that

they are in line during use.

• When retracting the tensioner, turn it

clockwise slowly for 3 seconds or more. Do

not apply force rapidly.

• After the tensioner is fully retracted, do not

apply force any more than necessary.

INSTALLATION

1. INSTALL FAN AND GENERATOR V BELT

(a) Using SST and 19 mm socket wrench, loosen the V-

ribbed belt tensioner arm clockwise, then install the

fan and generator V belt.

SST 09216-42010

NOTICE:

• Be sure to connect SST and the tools so that

they are in line during use.

• When retracting the tensioner, turn it

clockwise slowly for 3 seconds or more. Do

not apply force rapidly.

• After the tensioner is fully retracted, do not

apply force any more than necessary.

2. INSTALL FRONT SUSPENSION MEMBER

REINFORCEMENT RH

(a) Install the reinforcement RH with the 4 bolts.

Torque: 96 N*m (979 kgf*cm, 71 ft.*lbf)

3. INSTALL FRONT FENDER APRON RH

4. INSTALL FRONT WHEEL RH

5. INSTALL RADIATOR SUPPORT OPENING COVER

A114351E01

A114351E01

Page 199 of 2000

EM–242GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

(b) 4WD:

Disconnect the control cable (see page AX-154).

31. REMOVE FRONT EXHAUST PIPE ASSEMBLY (See

page EX-3)

32. REMOVE CENTER EXHAUST PIPE ASSEMBLY (See

page EX-2)

33. REMOVE PROPELLER WITH CENTER BEARING

SHAFT ASSEMBLY (See page PR-3)

34. REMOVE FRONT WHEELS

35. REMOVE FRONT AXLE HUB NUT LH

(a) Remove the hub nut (see page AH-8).

36. REMOVE FRONT AXLE HUB NUT RH

(a) Remove the hub nut (see page AH-8).

37. DISCONNECT FRONT STABILIZER LINK ASSEMBLY

LH (See page SP-30)

38. DISCONNECT FRONT STABILIZER LINK ASSEMBLY

RH (See page SP-30)

39. DISCONNECT STEERING INTERMEDIATE SHAFT

(See page PS-44)

40. DISCONNECT TIE ROD END SUB-ASSEMBLY RH

(See page PS-42)

41. DISCONNECT TIE ROD END SUB-ASSEMBLY LH

(See page PS-42)

42. REMOVE FRONT DRIVE SHAFT LH

(a) 2WD:

Remove the drive shaft (see page DS-10).

(b) 4WD:

Remove the drive shaft (see page DS-43).

43. REMOVE FRONT DRIVE SHAFT RH

(a) 2WD:

Remove the drive shaft (see page DS-10).

(b) 4WD:

Remove the drive shaft (see page DS-43).

44. REMOVE ENGINE WITH TRANSAXLE

(a) Install the No. 1 and No. 2 engine hangers with the

4 bolts as shown in the illustration.

Torque: 33 N*m (337 kgf*cm, 24 ft.*lbf)

HINT:

• Insert the claw of the hanger into hole of the

cylinder head.

• Fit the fork part of the hanger onto the rib of the

cylinder head.

A129635E02

Part Name Part No.

No. 1 engine hanger 12281-31120

No. 2 engine hanger 12282-31100

Bolt 91671-10825