check engine TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1259 of 2000

U241E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–35

AX

If communication is normal when the tester is connected to

another vehicle, inspect the DLC3 on the original vehicle.

If communication is still not possible when the tester is

connected to another vehicle, the problem is probably in the

tester itself. Consult the Service Department listed in the

tester's instruction manual.

6. CHECK MIL

(a) Check that the MIL illuminates when turning the

ignition switch ON.

If the MIL does not illuminate, there is a problem in

the MIL circuit (see page ES-386).

(b) When the engine is started, the MIL should turn off.

7. ALL READINESS

(a) For this vehicle, using the intelligent tester allows

readiness codes corresponding to all DTCs to be

read. When the diagnosis (normal or

malfunctioning) has been completed, readiness

codes are set. Enter the following menus:

ENHANCED OBD II / MONITOR STATUS.

DTC CHECK / CLEAR

1. CHECK DTC

(a) DTCs which are stored in the ECM can be displayed

with the intelligent tester.

The intelligent tester can display pending DTCs and

current DTCs. Some DTCs are not stored unless a

malfunction is detected in consecutive driving

cycles. When a malfunction is detected in only one

driving cycle, it is stored as a pending DTC.

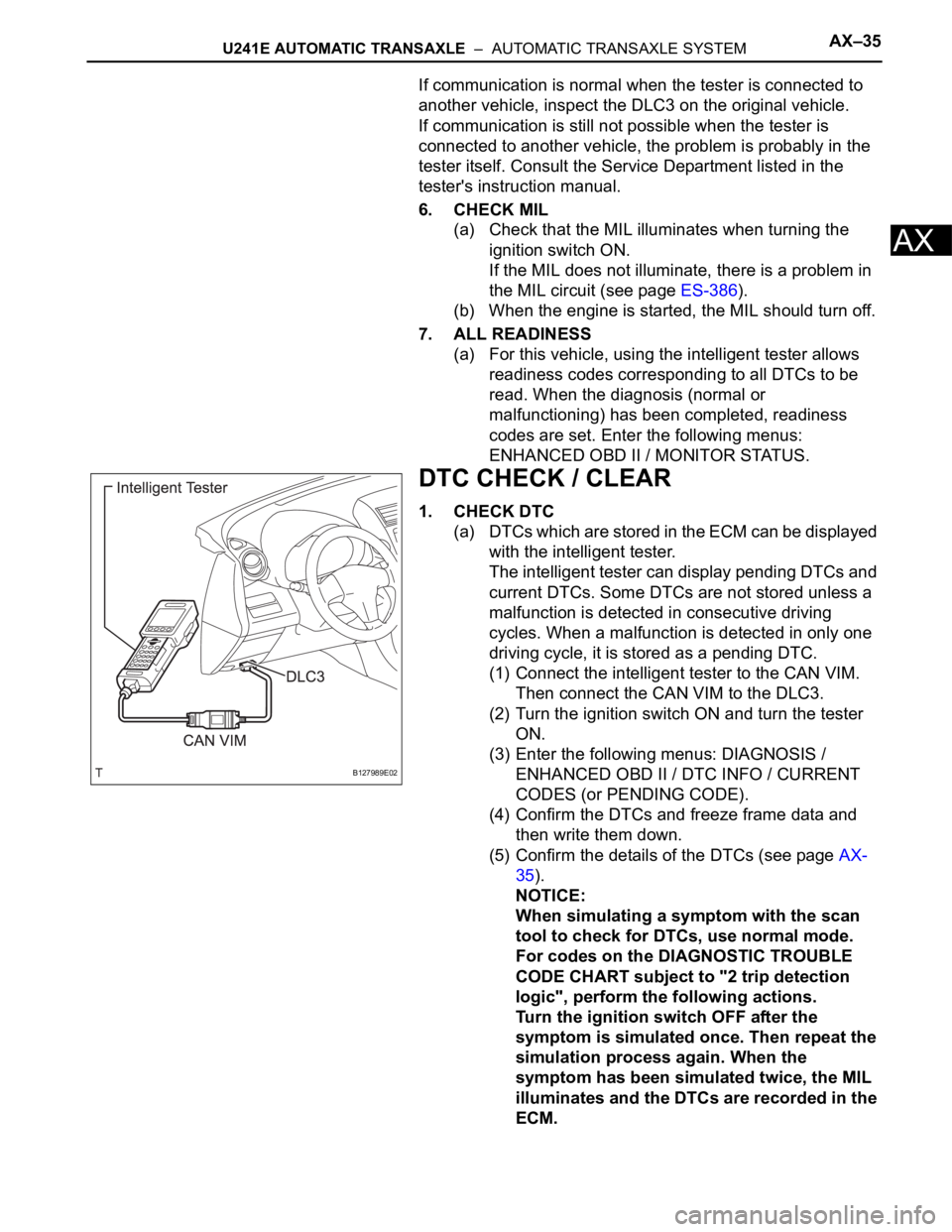

(1) Connect the intelligent tester to the CAN VIM.

Then connect the CAN VIM to the DLC3.

(2) Turn the ignition switch ON and turn the tester

ON.

(3) Enter the following menus: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT

CODES (or PENDING CODE).

(4) Confirm the DTCs and freeze frame data and

then write them down.

(5) Confirm the details of the DTCs (see page AX-

35).

NOTICE:

When simulating a symptom with the scan

tool to check for DTCs, use normal mode.

For codes on the DIAGNOSTIC TROUBLE

CODE CHART subject to "2 trip detection

logic", perform the following actions.

Turn the ignition switch OFF after the

symptom is simulated once. Then repeat the

simulation process again. When the

symptom has been simulated twice, the MIL

illuminates and the DTCs are recorded in the

ECM.

B127989E02

Page 1261 of 2000

U241E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–37

AX

CHECK MODE PROCEDURE

1. DESCRIPTION

(a) Check mode has a higher sensitivity to malfunctions

and can detect malfunctions that normal mode

cannot detect. Check mode can also detect all the

malfunctions that normal mode can detect. In check

mode, DTCs are detected with 1 trip detection logic.

2. CHECK MODE PROCEDURE

(a) Make sure that the following conditions below are

met:

(1) Battery positive voltage 11 V or more

(2) Throttle valve fully closed

(3) Transaxle in the P or N position

(4) A/C OFF

(b) Turn the ignition switch OFF.

(c) Connect the intelligent tester to the CAN VIM. Then

connect the CAN VIM to the DLC3.

(d) Turn the ignition switch ON and turn the tester ON.

(e) Enter the following menus: DIAGNOSIS /

ENHANCED OBD II / CHECK MODE.

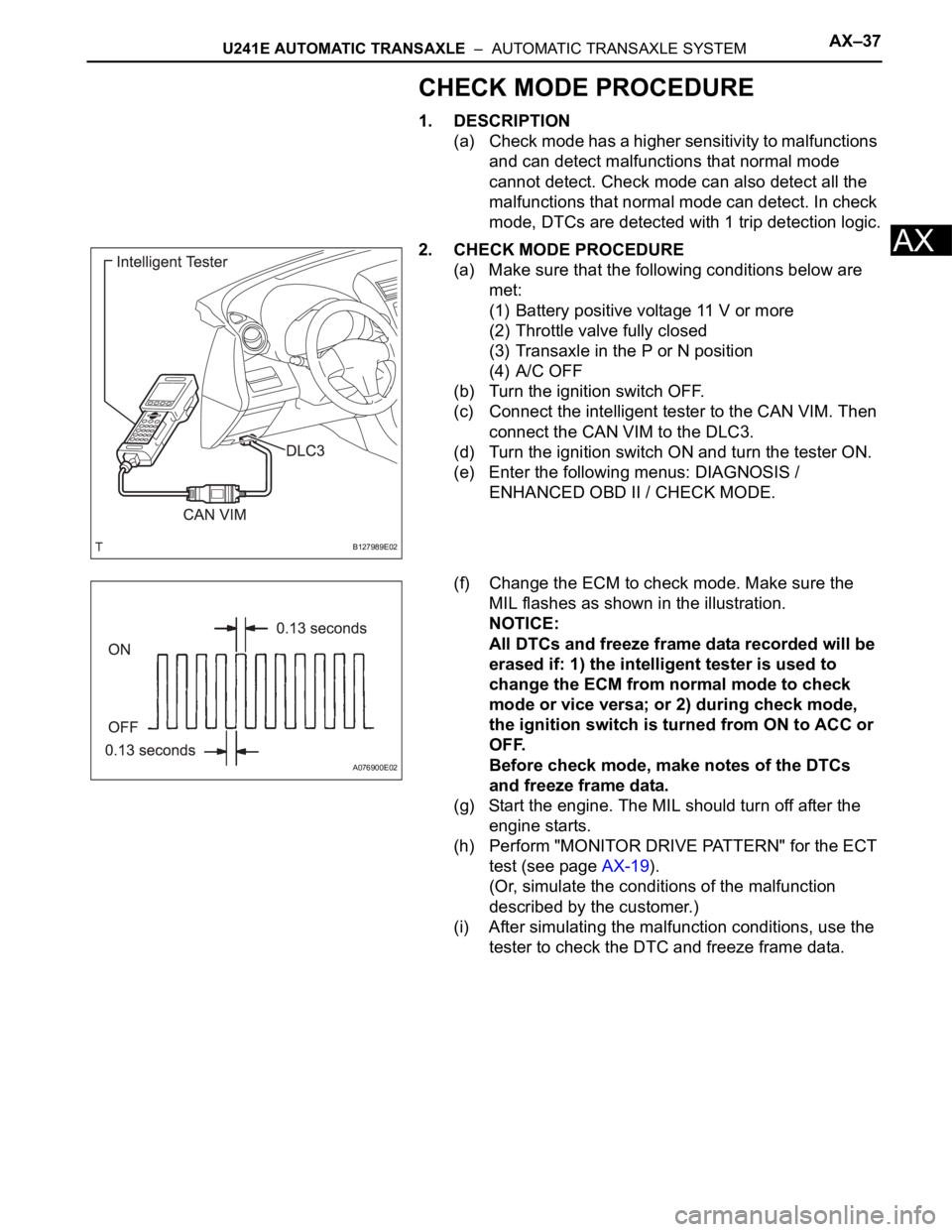

(f) Change the ECM to check mode. Make sure the

MIL flashes as shown in the illustration.

NOTICE:

All DTCs and freeze frame data recorded will be

erased if: 1) the intelligent tester is used to

change the ECM from normal mode to check

mode or vice versa; or 2) during check mode,

the ignition switch is turned from ON to ACC or

OFF.

Before check mode, make notes of the DTCs

and freeze frame data.

(g) Start the engine. The MIL should turn off after the

engine starts.

(h) Perform "MONITOR DRIVE PATTERN" for the ECT

test (see page AX-19).

(Or, simulate the conditions of the malfunction

described by the customer.)

(i) After simulating the malfunction conditions, use the

tester to check the DTC and freeze frame data.

B127989E02

A076900E02

Page 1262 of 2000

U241E AUTOMATIC TRANSAXLE – FLOOR SHIFT ASSEMBLYAX–139

AX

ADJUSTMENT

1. INSPECT SHIFT LEVER POSITION

(a) When shifting the lever from P to the R position with

the ignition switch ON and the brake pedal

depressed, make sure that the shift lever moves

smoothly and moves correctly into position.

(b) Start the engine and make sure that the vehicle

moves forward when shifting the lever from N to the

D position and moves rearward when shifting the

lever to the R position.

If the operation cannot be performed as specified,

inspect the park/neutral position switch assembly

and check the shift lever assembly installation

condition.

2. ADJUST SHIFT LEVER POSITION

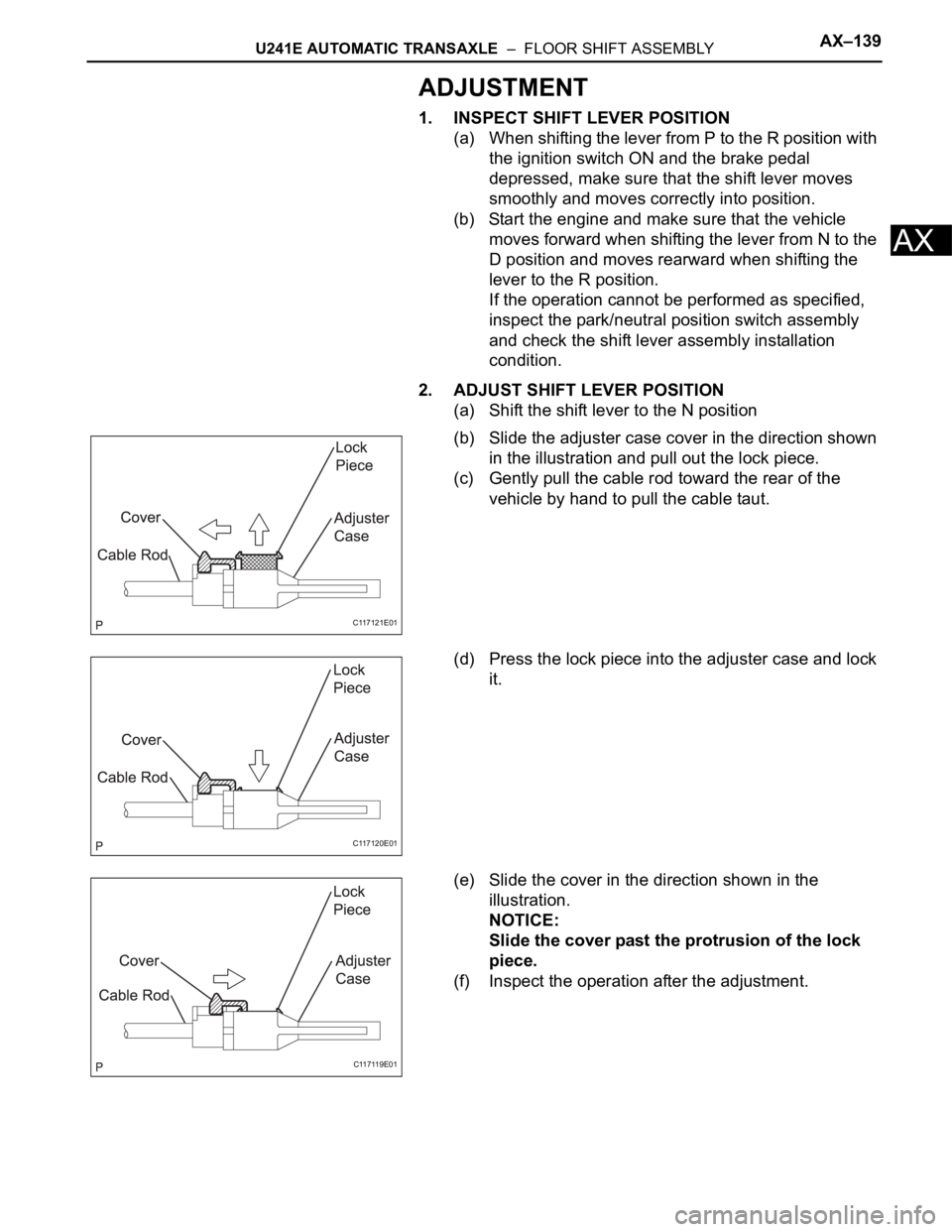

(a) Shift the shift lever to the N position

(b) Slide the adjuster case cover in the direction shown

in the illustration and pull out the lock piece.

(c) Gently pull the cable rod toward the rear of the

vehicle by hand to pull the cable taut.

(d) Press the lock piece into the adjuster case and lock

it.

(e) Slide the cover in the direction shown in the

illustration.

NOTICE:

Slide the cover past the protrusion of the lock

piece.

(f) Inspect the operation after the adjustment.

C117121E01

C117120E01

C117119E01

Page 1342 of 2000

TF–14GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEM

TF

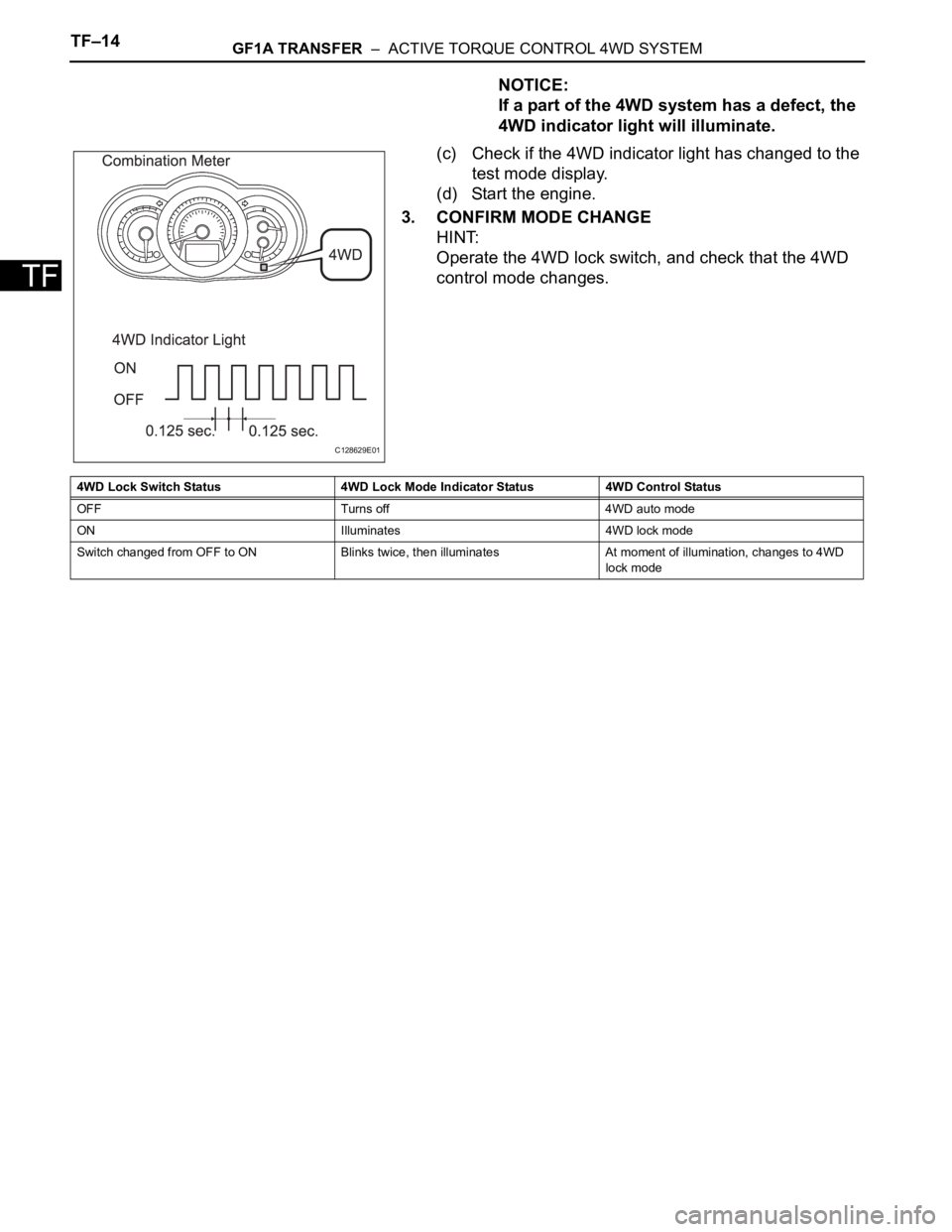

NOTICE:

If a part of the 4WD system has a defect, the

4WD indicator light will illuminate.

(c) Check if the 4WD indicator light has changed to the

test mode display.

(d) Start the engine.

3. CONFIRM MODE CHANGE

HINT:

Operate the 4WD lock switch, and check that the 4WD

control mode changes.

C128629E01

4WD Lock Switch Status 4WD Lock Mode Indicator Status 4WD Control Status

OFF Turns off 4WD auto mode

ON Illuminates 4WD lock mode

Switch changed from OFF to ON Blinks twice, then illuminates At moment of illumination, changes to 4WD

lock mode

Page 1344 of 2000

TF–16GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEM

TF

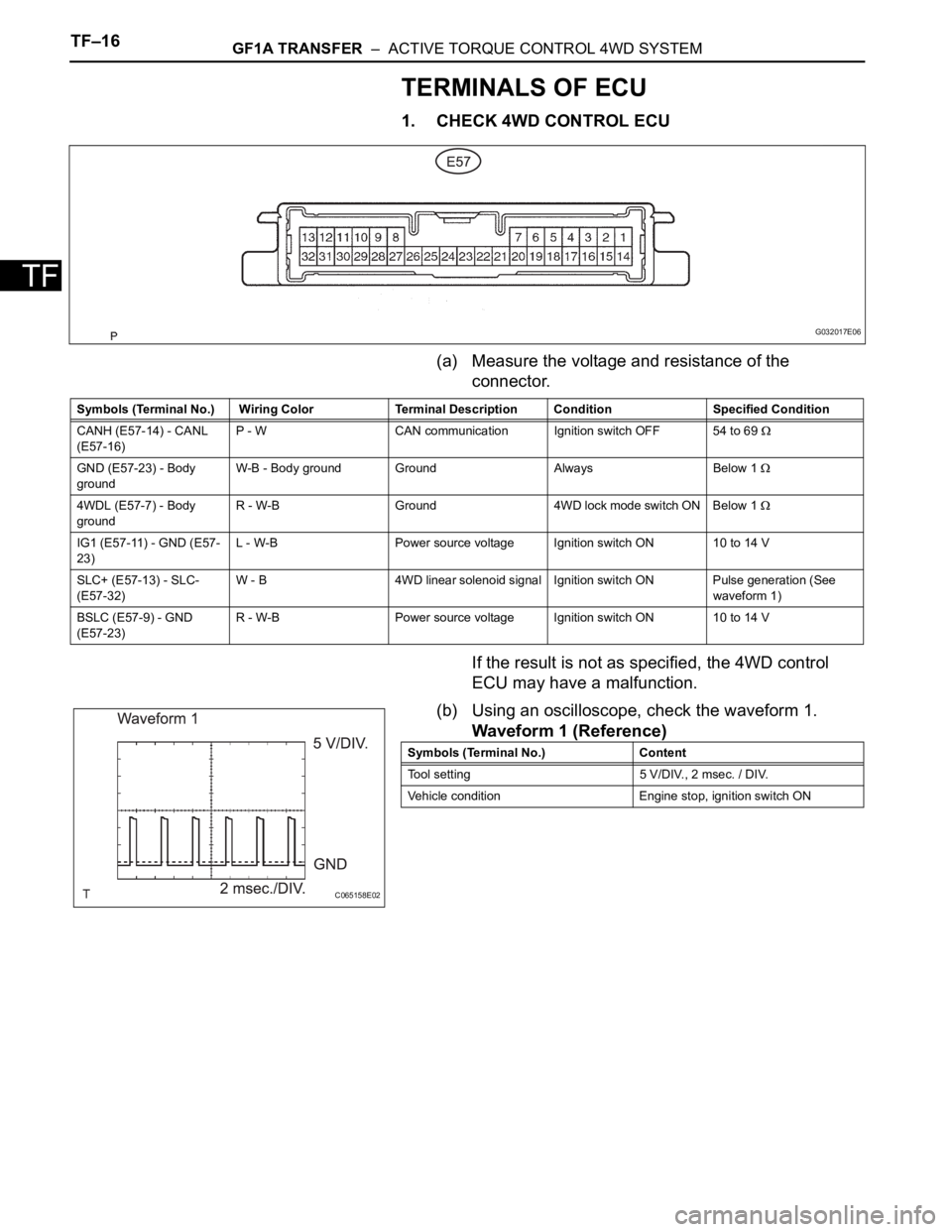

TERMINALS OF ECU

1. CHECK 4WD CONTROL ECU

(a) Measure the voltage and resistance of the

connector.

If the result is not as specified, the 4WD control

ECU may have a malfunction.

(b) Using an oscilloscope, check the waveform 1.

Waveform 1 (Reference)

G032017E06

Symbols (Terminal No.) Wiring Color Terminal Description Condition Specified Condition

CANH (E57-14) - CANL

(E57-16)P - W CAN communication Ignition switch OFF 54 to 69

GND (E57-23) - Body

groundW-B - Body ground Ground Always Below 1

4WDL (E57-7) - Body

groundR - W-B Ground 4WD lock mode switch ON Below 1

IG1 (E57-11) - GND (E57-

23)L - W-B Power source voltage Ignition switch ON 10 to 14 V

SLC+ (E57-13) - SLC-

(E57-32)W - B 4WD linear solenoid signal Ignition switch ON Pulse generation (See

waveform 1)

BSLC (E57-9) - GND

(E57-23)R - W-B Power source voltage Ignition switch ON 10 to 14 V

C065158E02

Symbols (Terminal No.) Content

Tool setting 5 V/DIV., 2 msec. / DIV.

Vehicle condition Engine stop, ignition switch ON

Page 1353 of 2000

GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEMTF–25

TF

(a) Clear the DTC (see page TF-16).

(b) Turn the ignition switch ON and check that no CAN

communication system DTC is output.

(c) Start the engine.

(d) Drive the vehicle, accelerate to a speed of 3 km/h (2

mph) or more, and check that no speed sensor DTC

(brake control system DTC) is output (see page BC-57).

Result

B

C

A

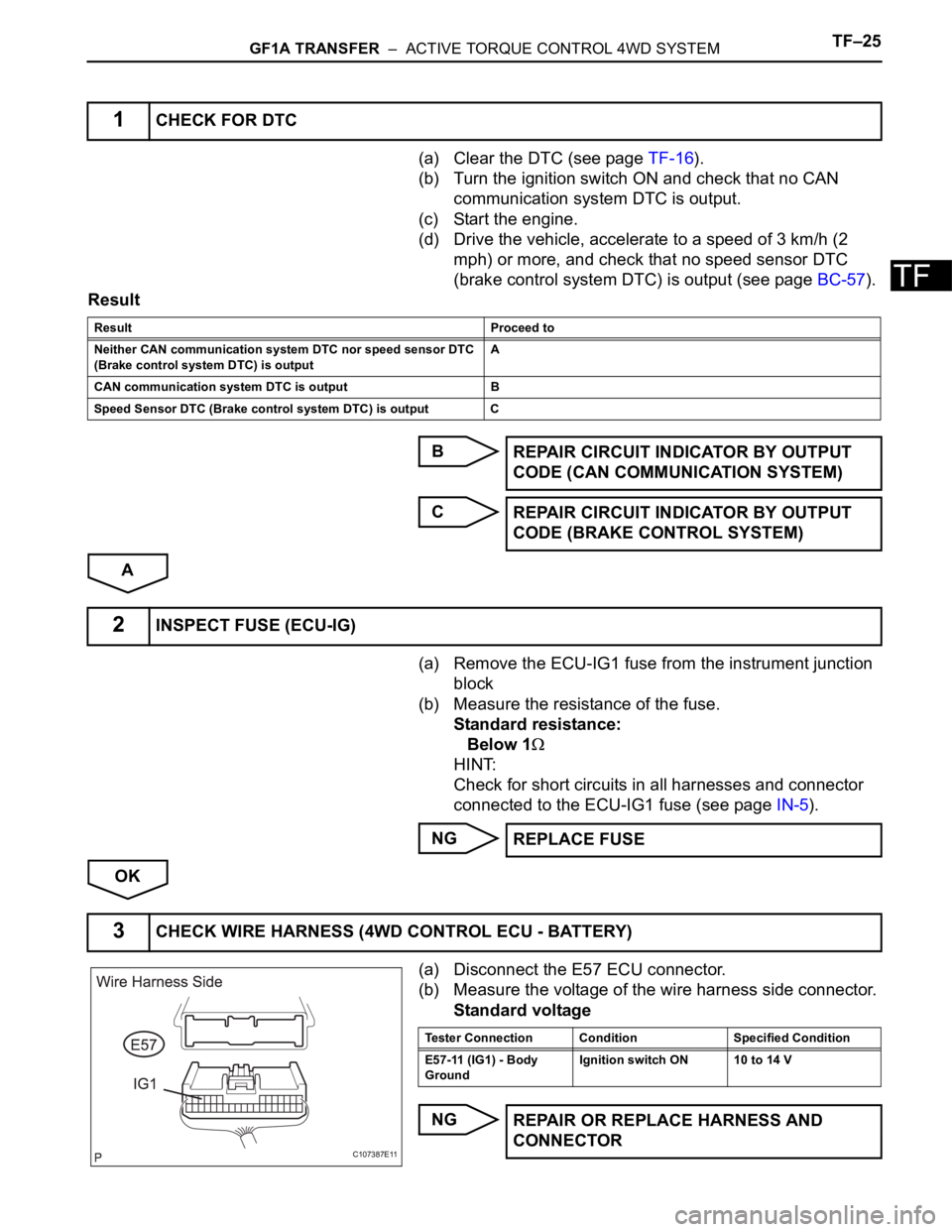

(a) Remove the ECU-IG1 fuse from the instrument junction

block

(b) Measure the resistance of the fuse.

Standard resistance:

Below 1

HINT:

Check for short circuits in all harnesses and connector

connected to the ECU-IG1 fuse (see page IN-5).

NG

OK

(a) Disconnect the E57 ECU connector.

(b) Measure the voltage of the wire harness side connector.

Standard voltage

NG

1CHECK FOR DTC

Result Proceed to

Neither CAN communication system DTC nor speed sensor DTC

(Brake control system DTC) is outputA

CAN communication system DTC is output B

Speed Sensor DTC (Brake control system DTC) is output C

REPAIR CIRCUIT INDICATOR BY OUTPUT

CODE (CAN COMMUNICATION SYSTEM)

REPAIR CIRCUIT INDICATOR BY OUTPUT

CODE (BRAKE CONTROL SYSTEM)

2INSPECT FUSE (ECU-IG)

REPLACE FUSE

3CHECK WIRE HARNESS (4WD CONTROL ECU - BATTERY)

C107387E11

Tester Connection Condition Specified Condition

E57-11 (IG1) - Body

GroundIgnition switch ON 10 to 14 V

REPAIR OR REPLACE HARNESS AND

CONNECTOR

Page 1354 of 2000

TF–26GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEM

TF

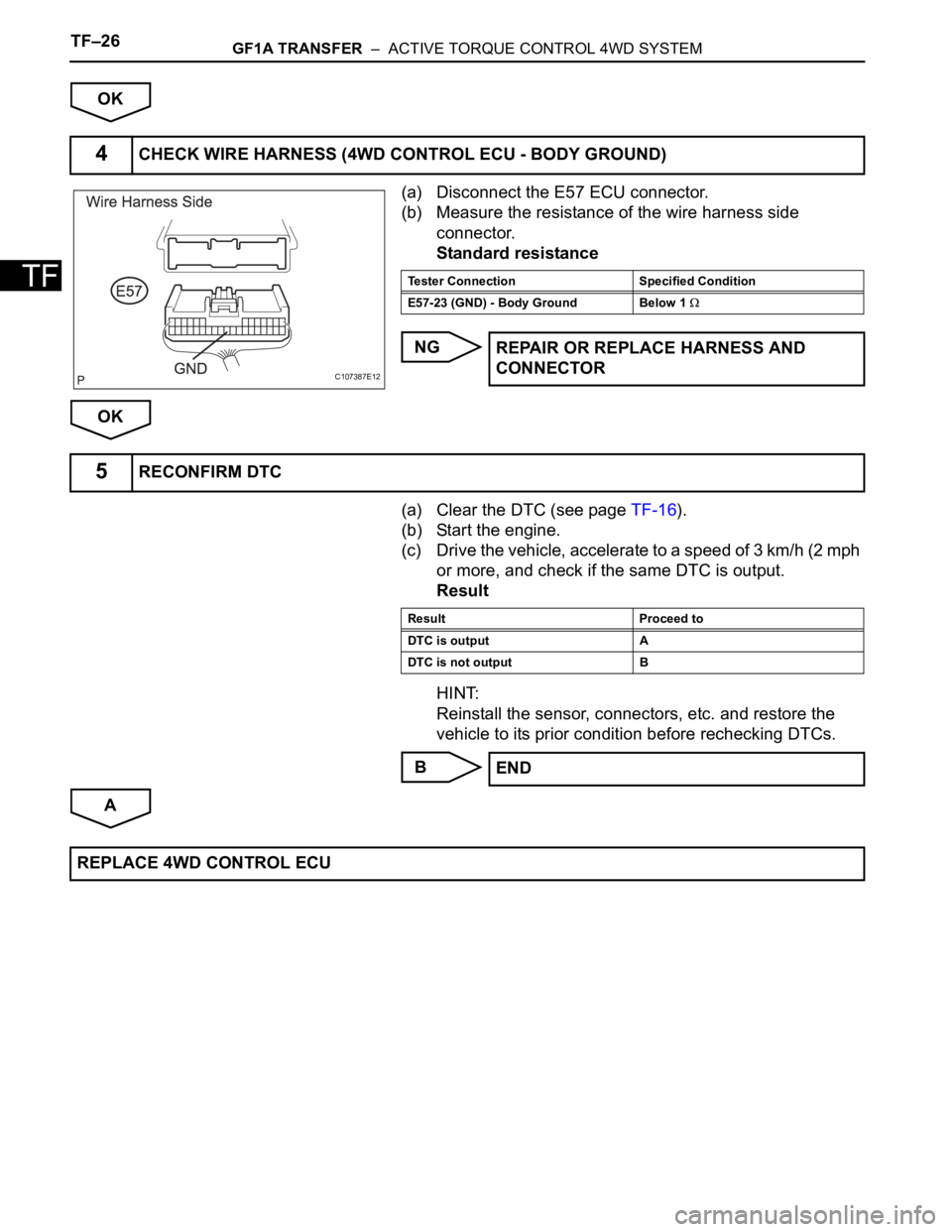

OK

(a) Disconnect the E57 ECU connector.

(b) Measure the resistance of the wire harness side

connector.

Standard resistance

NG

OK

(a) Clear the DTC (see page TF-16).

(b) Start the engine.

(c) Drive the vehicle, accelerate to a speed of 3 km/h (2 mph

or more, and check if the same DTC is output.

Result

HINT:

Reinstall the sensor, connectors, etc. and restore the

vehicle to its prior condition before rechecking DTCs.

B

A

4CHECK WIRE HARNESS (4WD CONTROL ECU - BODY GROUND)

C107387E12

Tester Connection Specified Condition

E57-23 (GND) - Body Ground Below 1

REPAIR OR REPLACE HARNESS AND

CONNECTOR

5RECONFIRM DTC

Result Proceed to

DTC is output A

DTC is not output B

END

REPLACE 4WD CONTROL ECU

Page 1355 of 2000

GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEMTF–27

TF

DESCRIPTION

If a malfunction in the engine control ECU circuit occurs, the 4WD control ECU will output this DTC.

INSPECTION PROCEDURE

HINT:

Check the condition of each related circuit connector before troubleshooting (see page IN-37).

(a) Clear the DTC (see page TF-16).

(b) Turn the ignition switch OFF.

(c) Turn the ignition switch ON and check that can

communication system DTC is not output.

Result

B

A

DTC C1280/82 Engine Circuit Malfunction

DTC No. DTC Detection Condition Trouble Area

C1280/82 When the following continues for 5 seconds

or more:

- Communication with engine control ECU is

operating normally, but throttle position

sensor is malfunctioning.• Throttle position sensor

• Throttle position sensor wire harness and

connector

• CAN communication system

1CHECK FOR DTC

Result Proceed to

CAN communication system DTC is

outputA

Engine control DTC is output B

GO TO ENGINE CONTROL SYSTEM

GO TO CAN COMMUNICATION SYSTEM

Page 1358 of 2000

TF–30GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEM

TF

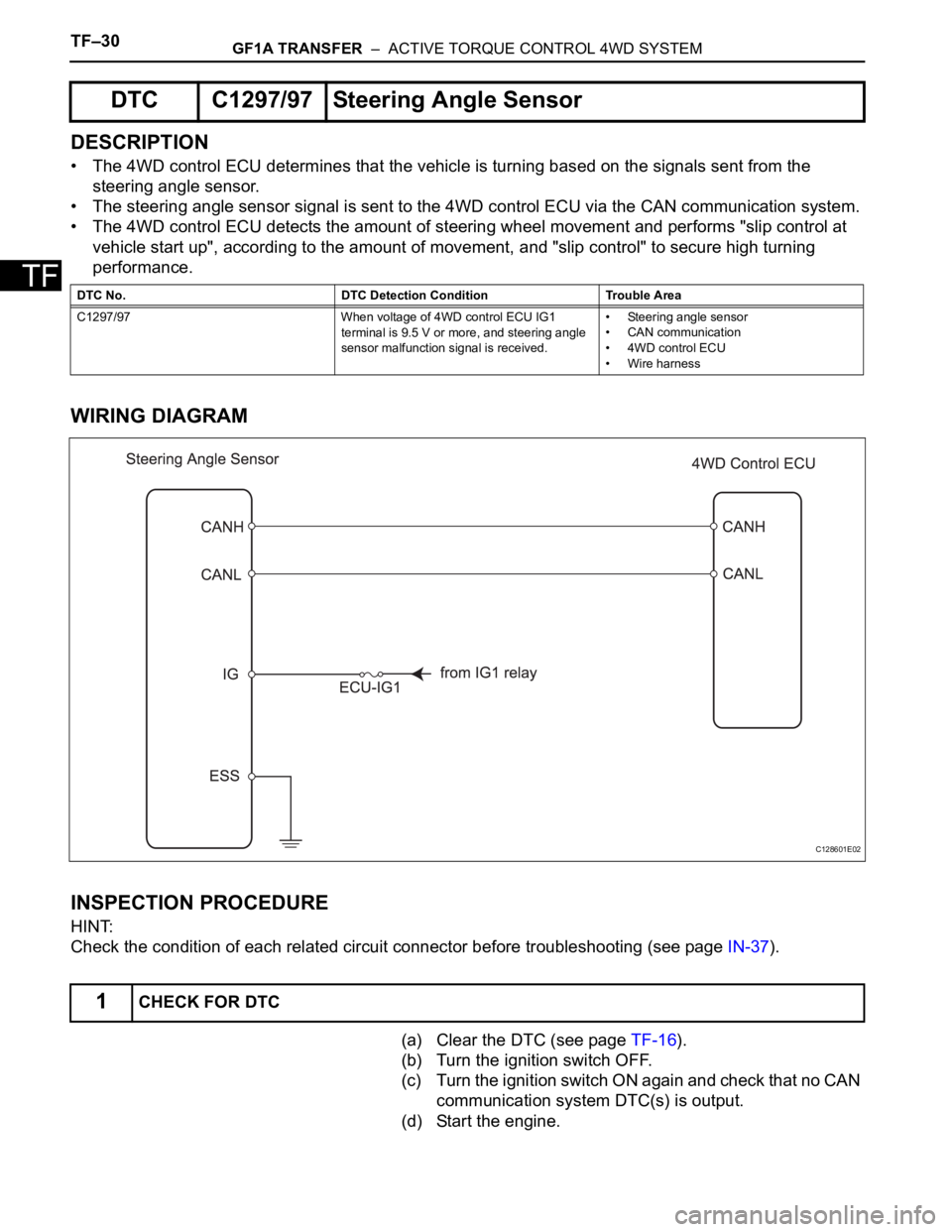

DESCRIPTION

• The 4WD control ECU determines that the vehicle is turning based on the signals sent from the

steering angle sensor.

• The steering angle sensor signal is sent to the 4WD control ECU via the CAN communication system.

• The 4WD control ECU detects the amount of steering wheel movement and performs "slip control at

vehicle start up", according to the amount of movement, and "slip control" to secure high turning

performance.

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

Check the condition of each related circuit connector before troubleshooting (see page IN-37).

(a) Clear the DTC (see page TF-16).

(b) Turn the ignition switch OFF.

(c) Turn the ignition switch ON again and check that no CAN

communication system DTC(s) is output.

(d) Start the engine.

DTC C1297/97 Steering Angle Sensor

DTC No. DTC Detection Condition Trouble Area

C1297/97 When voltage of 4WD control ECU IG1

terminal is 9.5 V or more, and steering angle

sensor malfunction signal is received.• Steering angle sensor

• CAN communication

• 4WD control ECU

• Wire harness

1CHECK FOR DTC

C128601E02

Page 1522 of 2000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–19

BC

4. FAIL SAFE FUNCTION

(a) When a failure occurs in the ABS with BA, TRC and

VSC systems, the ABS and VSC warning lights

illuminate, the slip indicator light comes on*1 or

remains off*2, and the operations of those systems

are prohibited. In addition to this, when a failure

which disables the EBD operation occurs, the brake

warning light comes on and its operation is

prohibited.

HINT:

*1: for 2WD

*2: for 4WD

(b) If control is prohibited due to a malfunction during

operation, control is disabled gradually to avoid

sudden vehicle instability.

5. INITIAL CHECK

(a) When the vehicle speed first reaches approximately

6 km/h (4 mph) or more after the ignition switch is

turned ON, each solenoid valve and the motor of the

ABS and TRACTION actuator are sequentially

activated to perform electrical checks. During the

initial check, the operating sound of the solenoid

valve and motor can be heard from the engine

compartment, but this does not indicate a

malfunction.

6. SERVICE MODE

(a) VSC operation can be disabled by operating the

intelligent tester.

HINT:

Refer to the intelligent tester operator's manual for

further details.

7. FUNCTION OF COMPONENTS

Components Functions

Speed Sensor

(Semiconductor Type)Detects the wheel speed and sends the signal to skid

control ECU

Skid Control ECU

(Housed in ABS and TRACTION Actuator)• Processes the signals from each sensor to control the

ABS, BA, TRC, and VSC

• Sends and receives control signals to and from the

ECM, yaw rate and deceleration sensor, steering

sensor, etc. via CAN communication.

ABS and TRACTION Actuator • Consists of the master cylinder cut solenoid valve,

holding solenoid valve, pressure reduction solenoid

valve, pump motor, and reservoir, and adjusts the brake

fluid pressure applied to each wheel cylinder

• Houses the skid control ECU

Solenoid Relay • Supplies power to each solenoid

• Housed in the skid control ECU

Motor Relay (VSC MTR Relay) • Supplies power to the pump motor

• Installed in engine room No. 1 relay block

Fail-safe Relay (VSC FAIL Relay) • Cuts off power to the motor when the pump motor circuit

malfunctions

• Installed in engine room No. 1 relay block