engine TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 571 of 2000

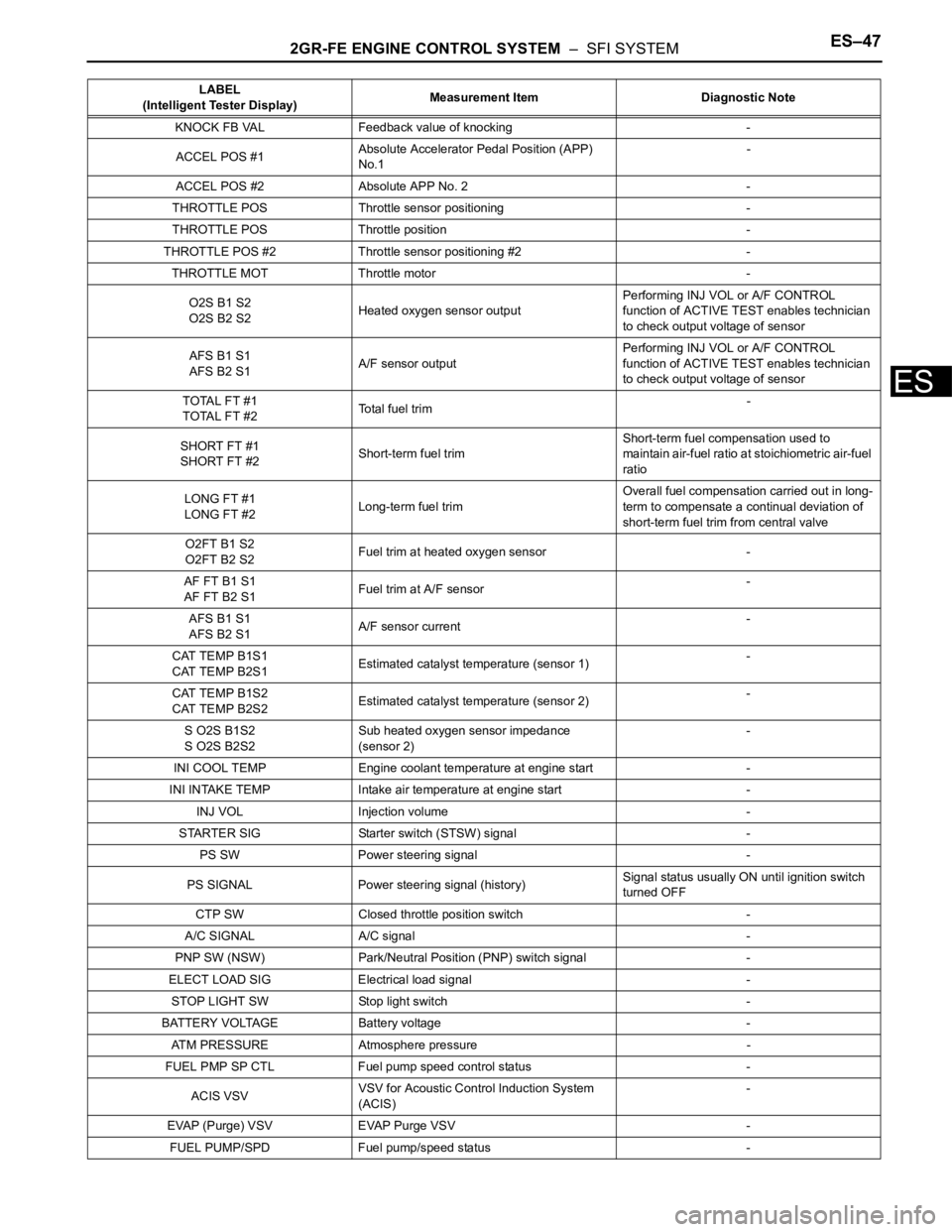

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–47

ES

KNOCK FB VAL Feedback value of knocking -

ACCEL POS #1Absolute Accelerator Pedal Position (APP)

No.1-

ACCEL POS #2 Absolute APP No. 2 -

THROTTLE POS Throttle sensor positioning -

THROTTLE POS Throttle position -

THROTTLE POS #2 Throttle sensor positioning #2 -

THROTTLE MOT Throttle motor -

O2S B1 S2

O2S B2 S2Heated oxygen sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check output voltage of sensor

AFS B1 S1

AFS B2 S1A/F sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check output voltage of sensor

TOTAL FT #1

TOTAL FT #2Total fuel trim -

SHORT FT #1

SHORT FT #2Short-term fuel trimShort-term fuel compensation used to

maintain air-fuel ratio at stoichiometric air-fuel

ratio

LONG FT #1

LONG FT #2Long-term fuel trimOverall fuel compensation carried out in long-

term to compensate a continual deviation of

short-term fuel trim from central valve

O2FT B1 S2

O2FT B2 S2Fuel trim at heated oxygen sensor -

AF FT B1 S1

AF FT B2 S1Fuel trim at A/F sensor-

AFS B1 S1

AFS B2 S1A/F sensor current-

CAT TEMP B1S1

CAT TEMP B2S1Estimated catalyst temperature (sensor 1)-

CAT TEMP B1S2

CAT TEMP B2S2Estimated catalyst temperature (sensor 2)-

S O2S B1S2

S O2S B2S2Sub heated oxygen sensor impedance

(sensor 2)-

INI COOL TEMP Engine coolant temperature at engine start -

INI INTAKE TEMP Intake air temperature at engine start -

INJ VOL Injection volume -

STARTER SIG Starter switch (STSW) signal -

PS SW Power steering signal -

PS SIGNAL Power steering signal (history)Signal status usually ON until ignition switch

turned OFF

CTP SW Closed throttle position switch -

A/C SIGNAL A/C signal -

PNP SW (NSW) Park/Neutral Position (PNP) switch signal -

ELECT LOAD SIG Electrical load signal -

STOP LIGHT SW Stop light switch -

BATTERY VOLTAGE Battery voltage -

ATM PRESSURE Atmosphere pressure -

FUEL PMP SP CTL Fuel pump speed control status -

ACIS VSVVSV for Acoustic Control Induction System

(ACIS)-

EVAP (Purge) VSV EVAP Purge VSV -

FUEL PUMP/SPD Fuel pump/speed status -LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

Page 572 of 2000

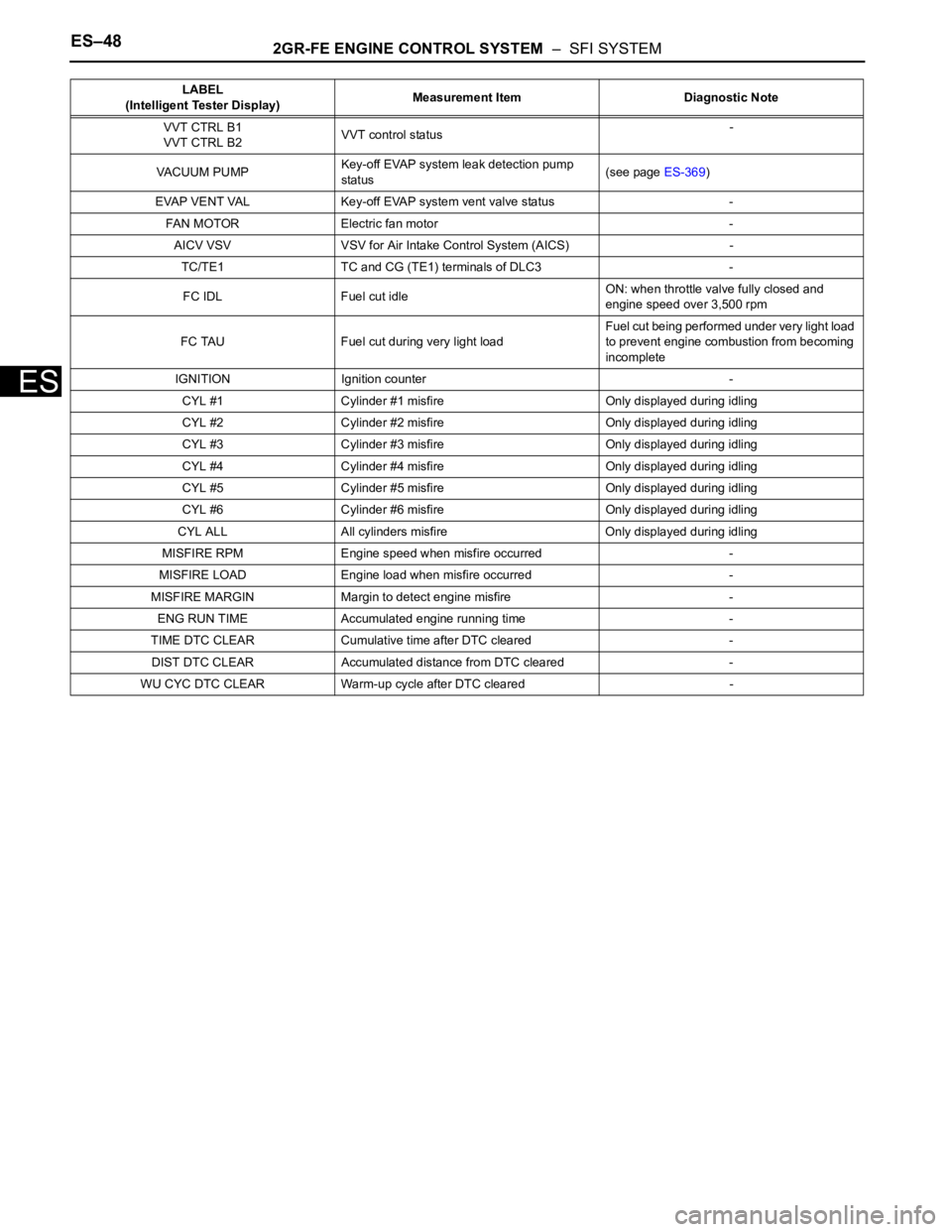

ES–482GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

VVT CTRL B1

VVT CTRL B2VVT control status-

VA C U U M P U M PKey-off EVAP system leak detection pump

status(see page ES-369)

EVAP VENT VAL Key-off EVAP system vent valve status -

FAN MOTOR Electric fan motor -

AICV VSV VSV for Air Intake Control System (AICS) -

TC/TE1 TC and CG (TE1) terminals of DLC3 -

FC IDL Fuel cut idleON: when throttle valve fully closed and

engine speed over 3,500 rpm

FC TAU Fuel cut during very light loadFuel cut being performed under very light load

to prevent engine combustion from becoming

incomplete

IGNITION Ignition counter -

CYL #1 Cylinder #1 misfire Only displayed during idling

CYL #2 Cylinder #2 misfire Only displayed during idling

CYL #3 Cylinder #3 misfire Only displayed during idling

CYL #4 Cylinder #4 misfire Only displayed during idling

CYL #5 Cylinder #5 misfire Only displayed during idling

CYL #6 Cylinder #6 misfire Only displayed during idling

CYL ALL All cylinders misfire Only displayed during idling

MISFIRE RPM Engine speed when misfire occurred -

MISFIRE LOAD Engine load when misfire occurred -

MISFIRE MARGIN Margin to detect engine misfire -

ENG RUN TIME Accumulated engine running time -

TIME DTC CLEAR Cumulative time after DTC cleared -

DIST DTC CLEAR Accumulated distance from DTC cleared -

WU CYC DTC CLEAR Warm-up cycle after DTC cleared -LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

Page 573 of 2000

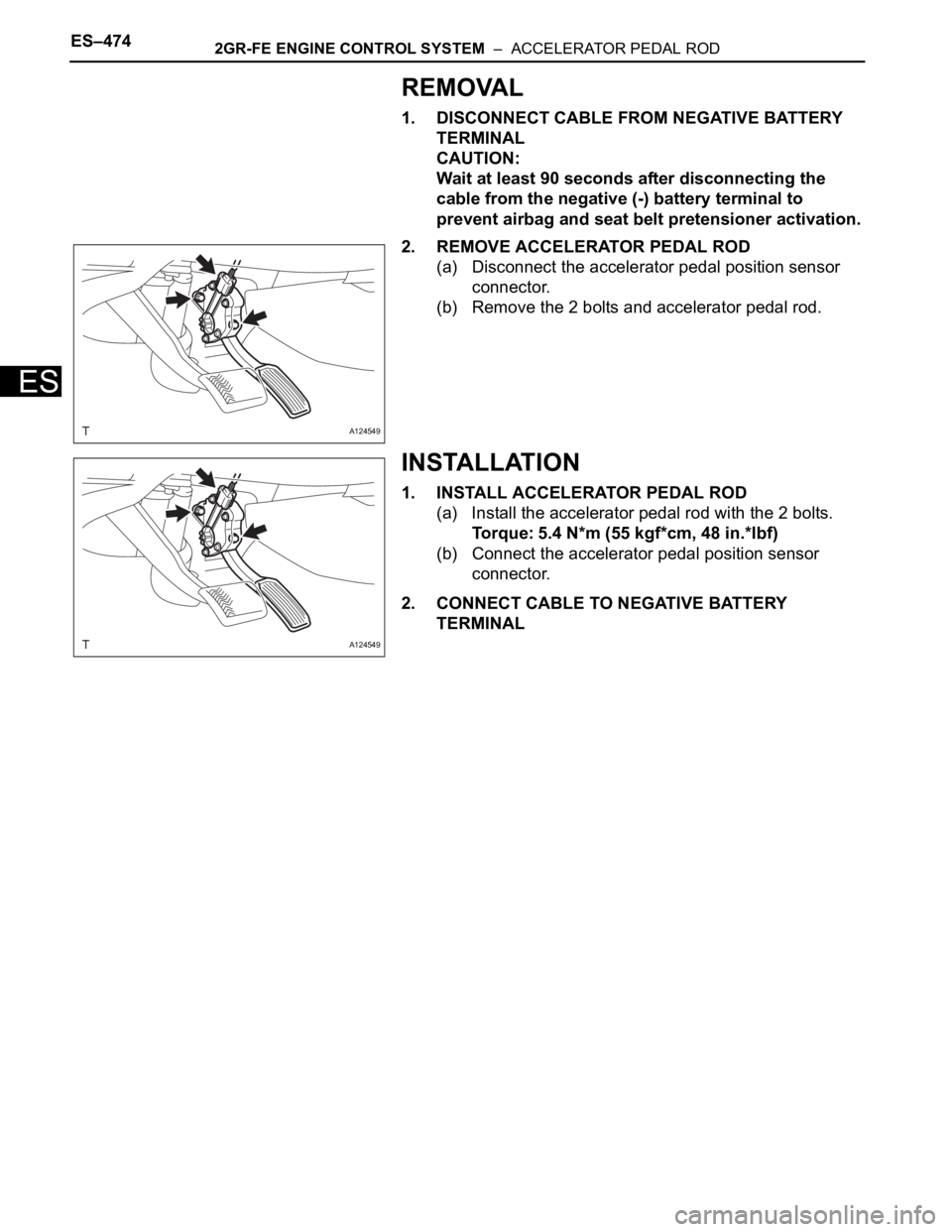

ES–4742GR-FE ENGINE CONTROL SYSTEM – ACCELERATOR PEDAL ROD

ES

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

2. REMOVE ACCELERATOR PEDAL ROD

(a) Disconnect the accelerator pedal position sensor

connector.

(b) Remove the 2 bolts and accelerator pedal rod.

INSTALLATION

1. INSTALL ACCELERATOR PEDAL ROD

(a) Install the accelerator pedal rod with the 2 bolts.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

(b) Connect the accelerator pedal position sensor

connector.

2. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

A124549

A124549

Page 579 of 2000

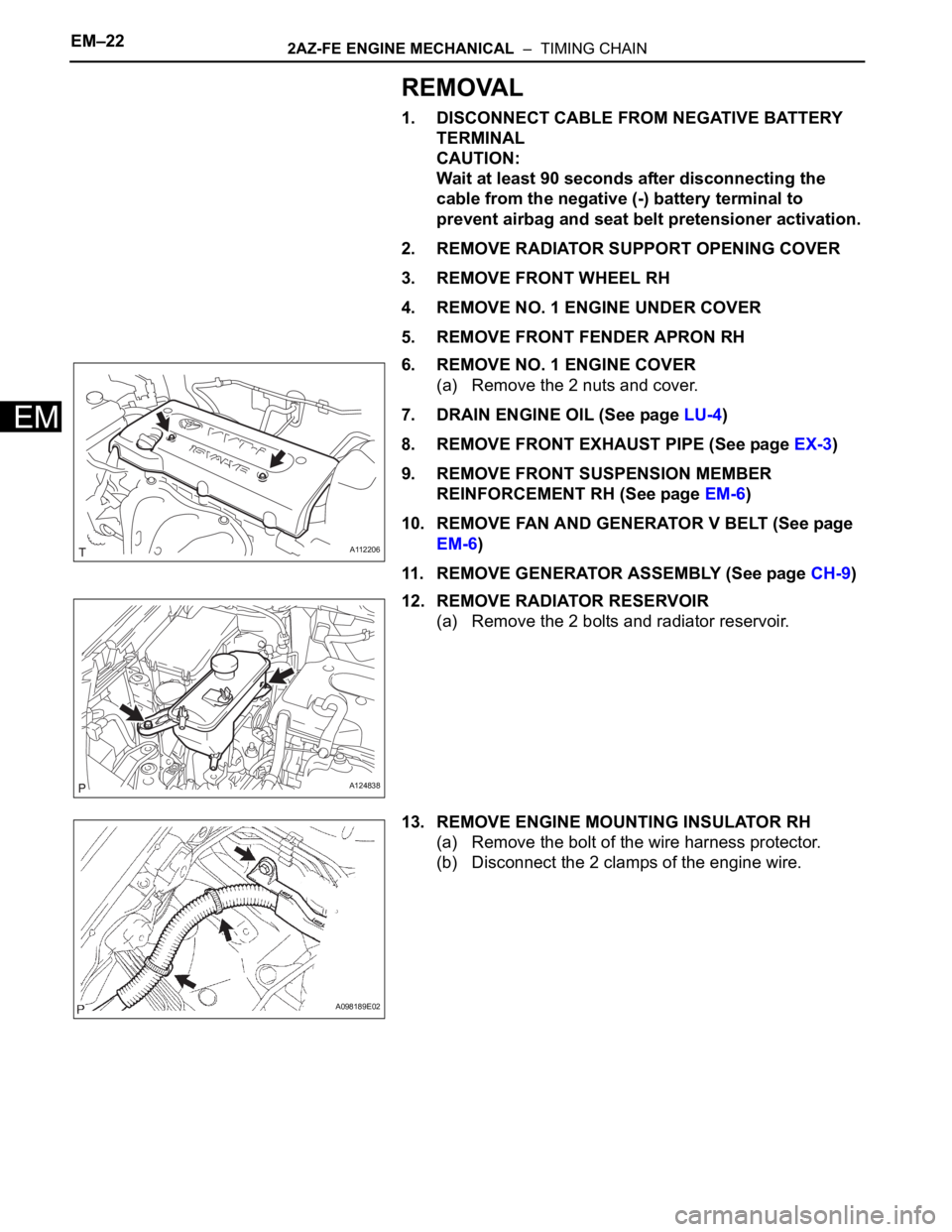

EM–222AZ-FE ENGINE MECHANICAL – TIMING CHAIN

EM

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

2. REMOVE RADIATOR SUPPORT OPENING COVER

3. REMOVE FRONT WHEEL RH

4. REMOVE NO. 1 ENGINE UNDER COVER

5. REMOVE FRONT FENDER APRON RH

6. REMOVE NO. 1 ENGINE COVER

(a) Remove the 2 nuts and cover.

7. DRAIN ENGINE OIL (See page LU-4)

8. REMOVE FRONT EXHAUST PIPE (See page EX-3)

9. REMOVE FRONT SUSPENSION MEMBER

REINFORCEMENT RH (See page EM-6)

10. REMOVE FAN AND GENERATOR V BELT (See page

EM-6)

11. REMOVE GENERATOR ASSEMBLY (See page CH-9)

12. REMOVE RADIATOR RESERVOIR

(a) Remove the 2 bolts and radiator reservoir.

13. REMOVE ENGINE MOUNTING INSULATOR RH

(a) Remove the bolt of the wire harness protector.

(b) Disconnect the 2 clamps of the engine wire.

A112206

A124838

A098189E02

Page 580 of 2000

2AZ-FE ENGINE MECHANICAL – TIMING CHAINEM–23

EM

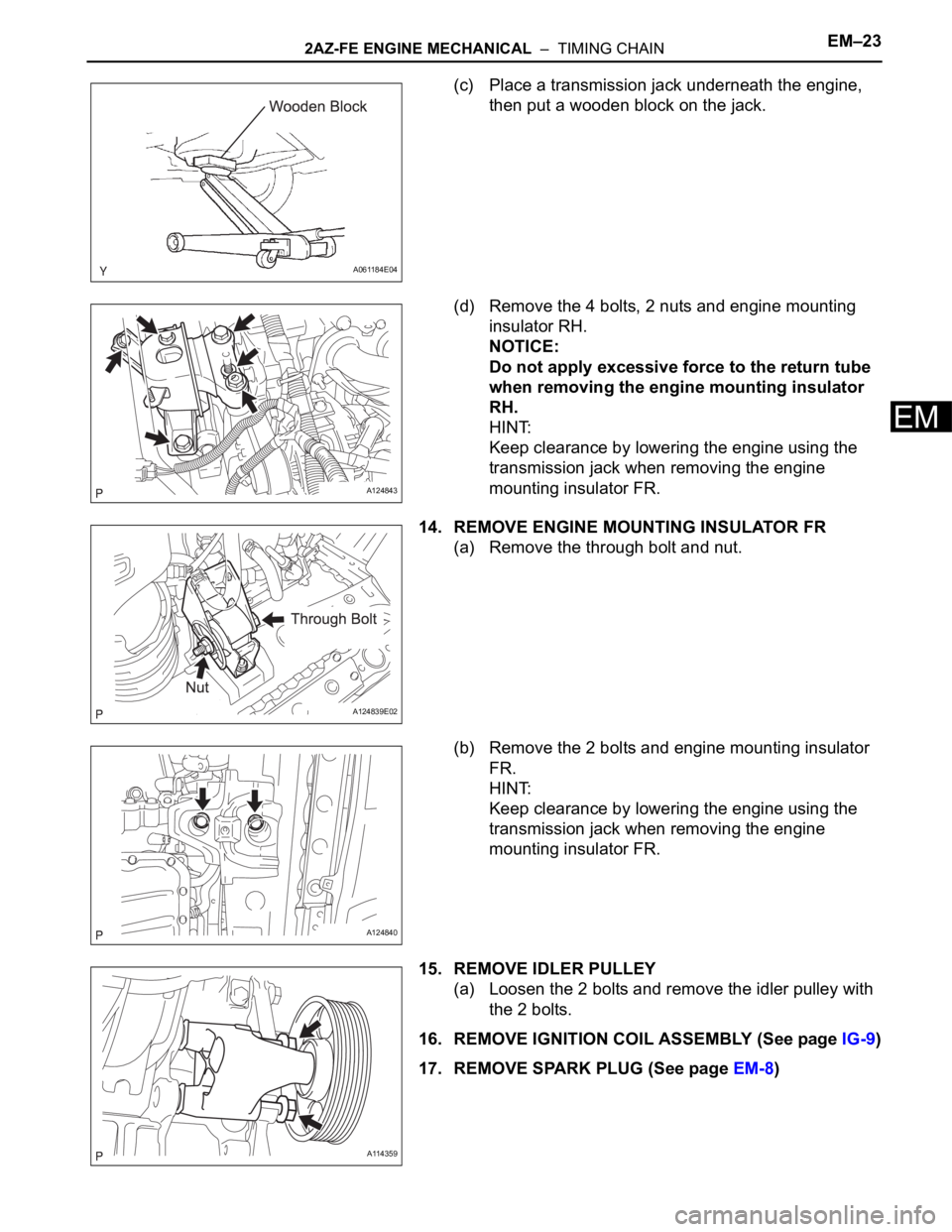

(c) Place a transmission jack underneath the engine,

then put a wooden block on the jack.

(d) Remove the 4 bolts, 2 nuts and engine mounting

insulator RH.

NOTICE:

Do not apply excessive force to the return tube

when removing the engine mounting insulator

RH.

HINT:

Keep clearance by lowering the engine using the

transmission jack when removing the engine

mounting insulator FR.

14. REMOVE ENGINE MOUNTING INSULATOR FR

(a) Remove the through bolt and nut.

(b) Remove the 2 bolts and engine mounting insulator

FR.

HINT:

Keep clearance by lowering the engine using the

transmission jack when removing the engine

mounting insulator FR.

15. REMOVE IDLER PULLEY

(a) Loosen the 2 bolts and remove the idler pulley with

the 2 bolts.

16. REMOVE IGNITION COIL ASSEMBLY (See page IG-9)

17. REMOVE SPARK PLUG (See page EM-8)

A061184E04

A124843

A124839E02

A124840

A114359

Page 581 of 2000

EM–242AZ-FE ENGINE MECHANICAL – TIMING CHAIN

EM

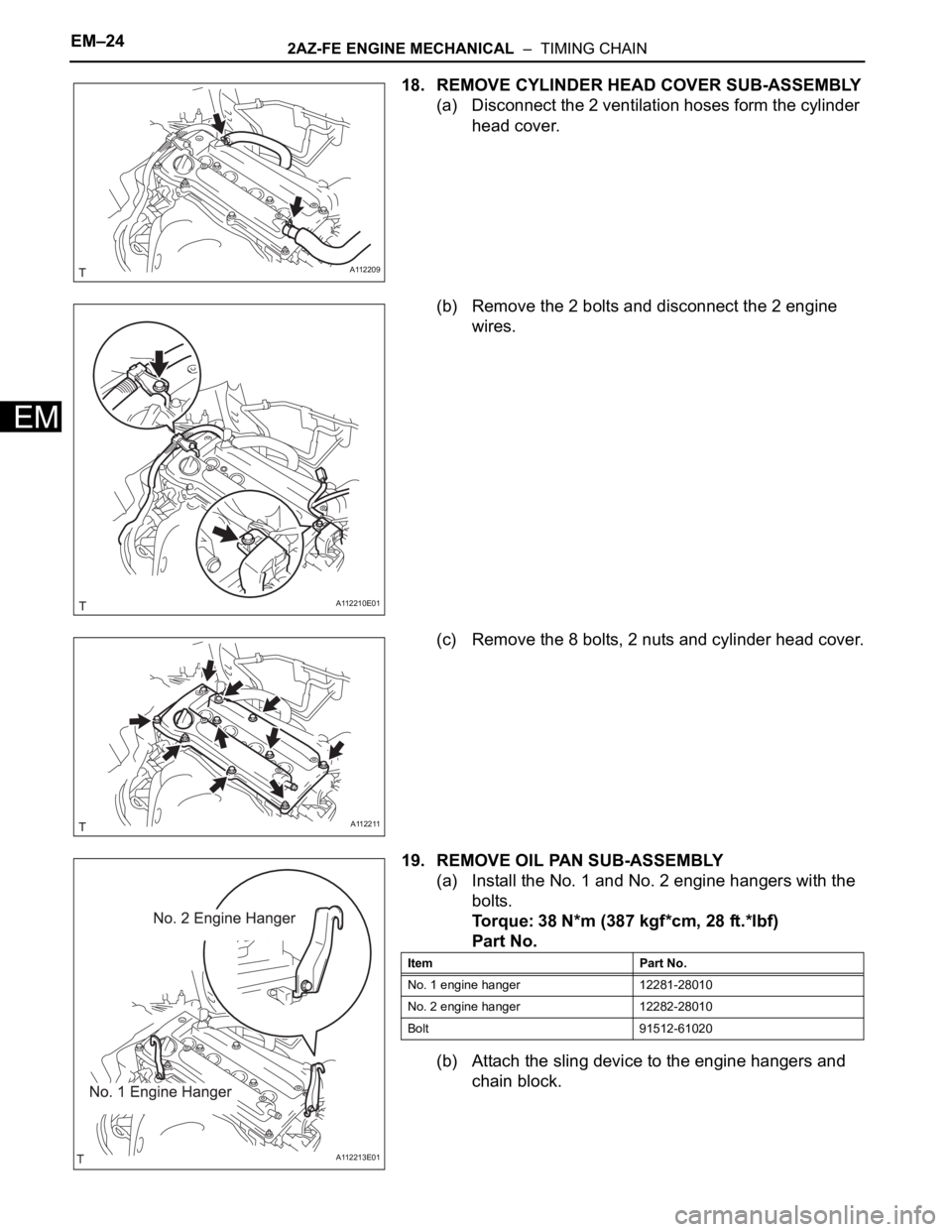

18. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

(a) Disconnect the 2 ventilation hoses form the cylinder

head cover.

(b) Remove the 2 bolts and disconnect the 2 engine

wires.

(c) Remove the 8 bolts, 2 nuts and cylinder head cover.

19. REMOVE OIL PAN SUB-ASSEMBLY

(a) Install the No. 1 and No. 2 engine hangers with the

bolts.

Torque: 38 N*m (387 kgf*cm, 28 ft.*lbf)

Part No.

(b) Attach the sling device to the engine hangers and

chain block.

A112209

A112210E01

A112211

A112213E01

Item Part No.

No. 1 engine hanger 12281-28010

No. 2 engine hanger 12282-28010

Bolt 91512-61020

Page 582 of 2000

2AZ-FE ENGINE MECHANICAL – TIMING CHAINEM–25

EM

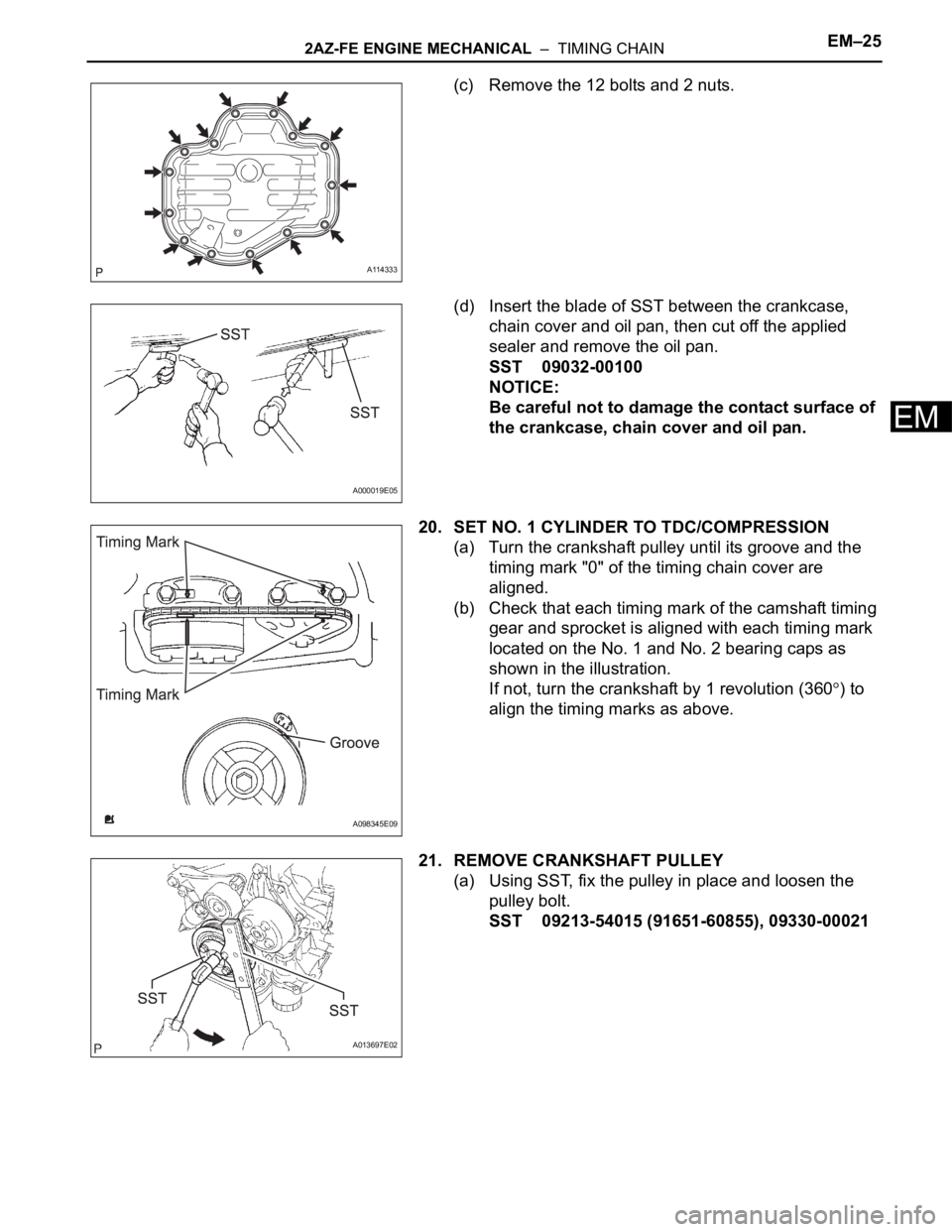

(c) Remove the 12 bolts and 2 nuts.

(d) Insert the blade of SST between the crankcase,

chain cover and oil pan, then cut off the applied

sealer and remove the oil pan.

SST 09032-00100

NOTICE:

Be careful not to damage the contact surface of

the crankcase, chain cover and oil pan.

20. SET NO. 1 CYLINDER TO TDC/COMPRESSION

(a) Turn the crankshaft pulley until its groove and the

timing mark "0" of the timing chain cover are

aligned.

(b) Check that each timing mark of the camshaft timing

gear and sprocket is aligned with each timing mark

located on the No. 1 and No. 2 bearing caps as

shown in the illustration.

If not, turn the crankshaft by 1 revolution (360

) to

align the timing marks as above.

21. REMOVE CRANKSHAFT PULLEY

(a) Using SST, fix the pulley in place and loosen the

pulley bolt.

SST 09213-54015 (91651-60855), 09330-00021

A114333

A000019E05

A098345E09

A013697E02

Page 583 of 2000

EM–262AZ-FE ENGINE MECHANICAL – TIMING CHAIN

EM

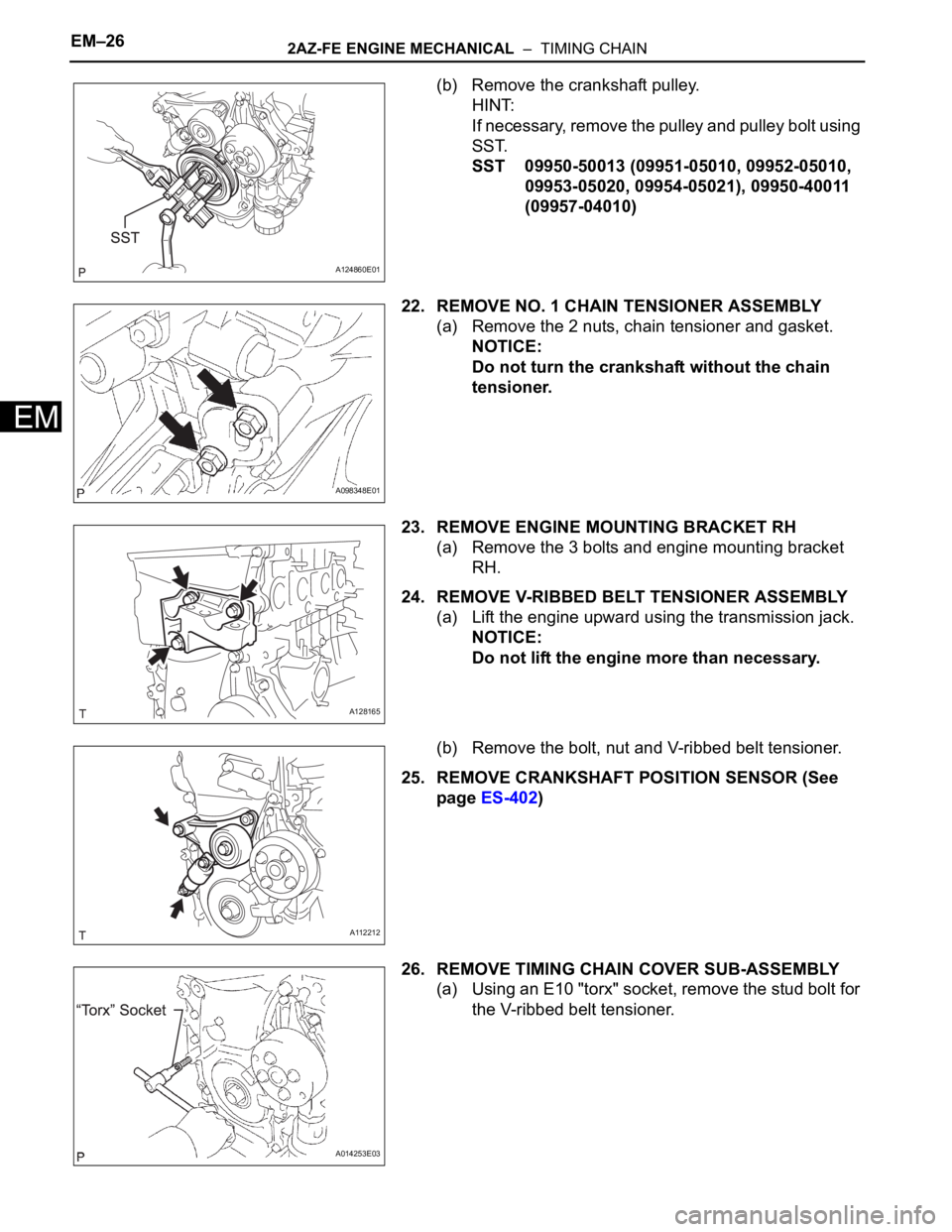

(b) Remove the crankshaft pulley.

HINT:

If necessary, remove the pulley and pulley bolt using

SST.

SST 09950-50013 (09951-05010, 09952-05010,

09953-05020, 09954-05021), 09950-40011

(09957-04010)

22. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

(a) Remove the 2 nuts, chain tensioner and gasket.

NOTICE:

Do not turn the crankshaft without the chain

tensioner.

23. REMOVE ENGINE MOUNTING BRACKET RH

(a) Remove the 3 bolts and engine mounting bracket

RH.

24. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

(a) Lift the engine upward using the transmission jack.

NOTICE:

Do not lift the engine more than necessary.

(b) Remove the bolt, nut and V-ribbed belt tensioner.

25. REMOVE CRANKSHAFT POSITION SENSOR (See

page ES-402)

26. REMOVE TIMING CHAIN COVER SUB-ASSEMBLY

(a) Using an E10 "torx" socket, remove the stud bolt for

the V-ribbed belt tensioner.

A124860E01

A098348E01

A128165

A112212

A014253E03

Page 584 of 2000

2AZ-FE ENGINE MECHANICAL – TIMING CHAINEM–27

EM

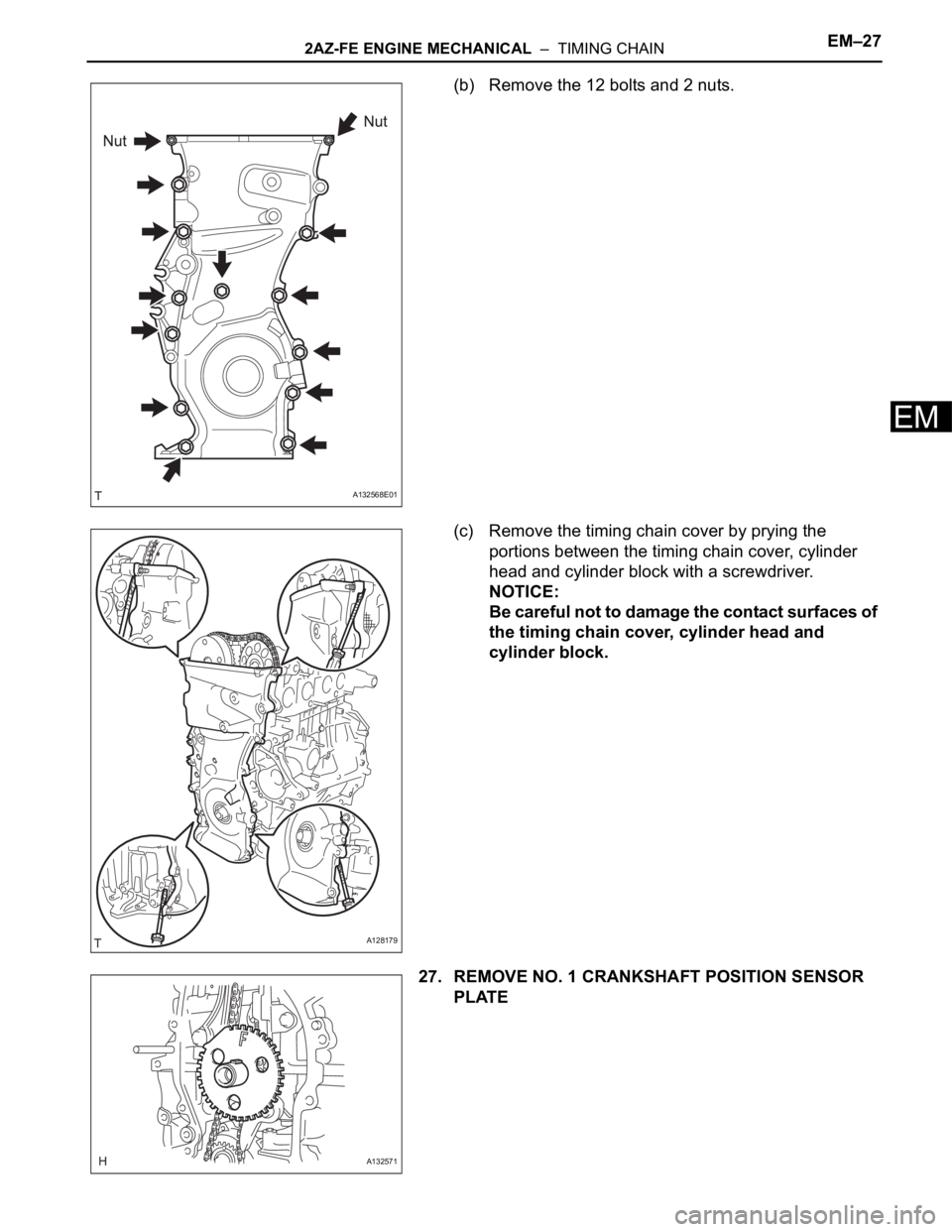

(b) Remove the 12 bolts and 2 nuts.

(c) Remove the timing chain cover by prying the

portions between the timing chain cover, cylinder

head and cylinder block with a screwdriver.

NOTICE:

Be careful not to damage the contact surfaces of

the timing chain cover, cylinder head and

cylinder block.

27. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR

PLATE

A132568E01

A128179

A132571

Page 585 of 2000

EM–282AZ-FE ENGINE MECHANICAL – TIMING CHAIN

EM

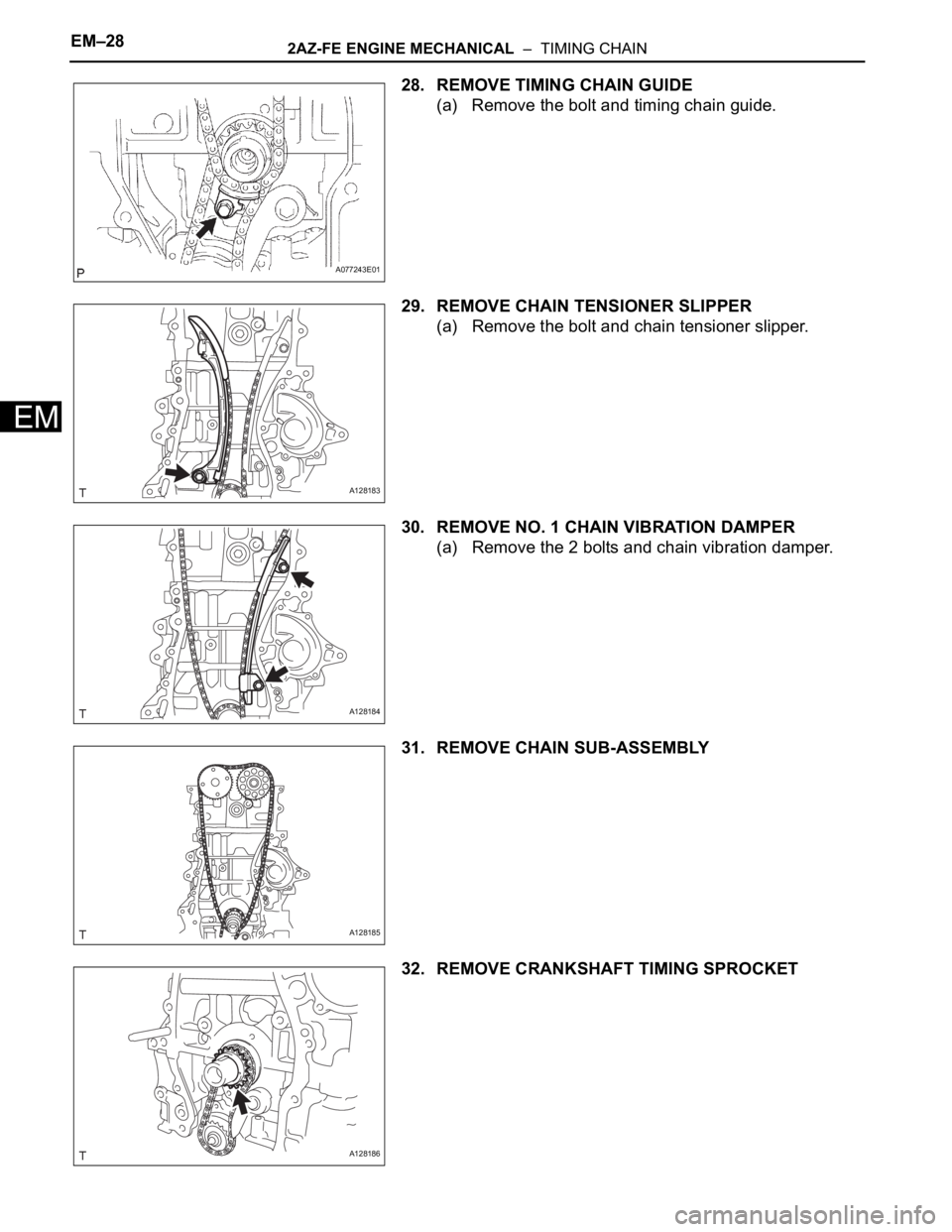

28. REMOVE TIMING CHAIN GUIDE

(a) Remove the bolt and timing chain guide.

29. REMOVE CHAIN TENSIONER SLIPPER

(a) Remove the bolt and chain tensioner slipper.

30. REMOVE NO. 1 CHAIN VIBRATION DAMPER

(a) Remove the 2 bolts and chain vibration damper.

31. REMOVE CHAIN SUB-ASSEMBLY

32. REMOVE CRANKSHAFT TIMING SPROCKET

A077243E01

A128183

A128184

A128185

A128186