engine TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 606 of 2000

EM–622AZ-FE ENGINE MECHANICAL – CYLINDER HEAD

EM

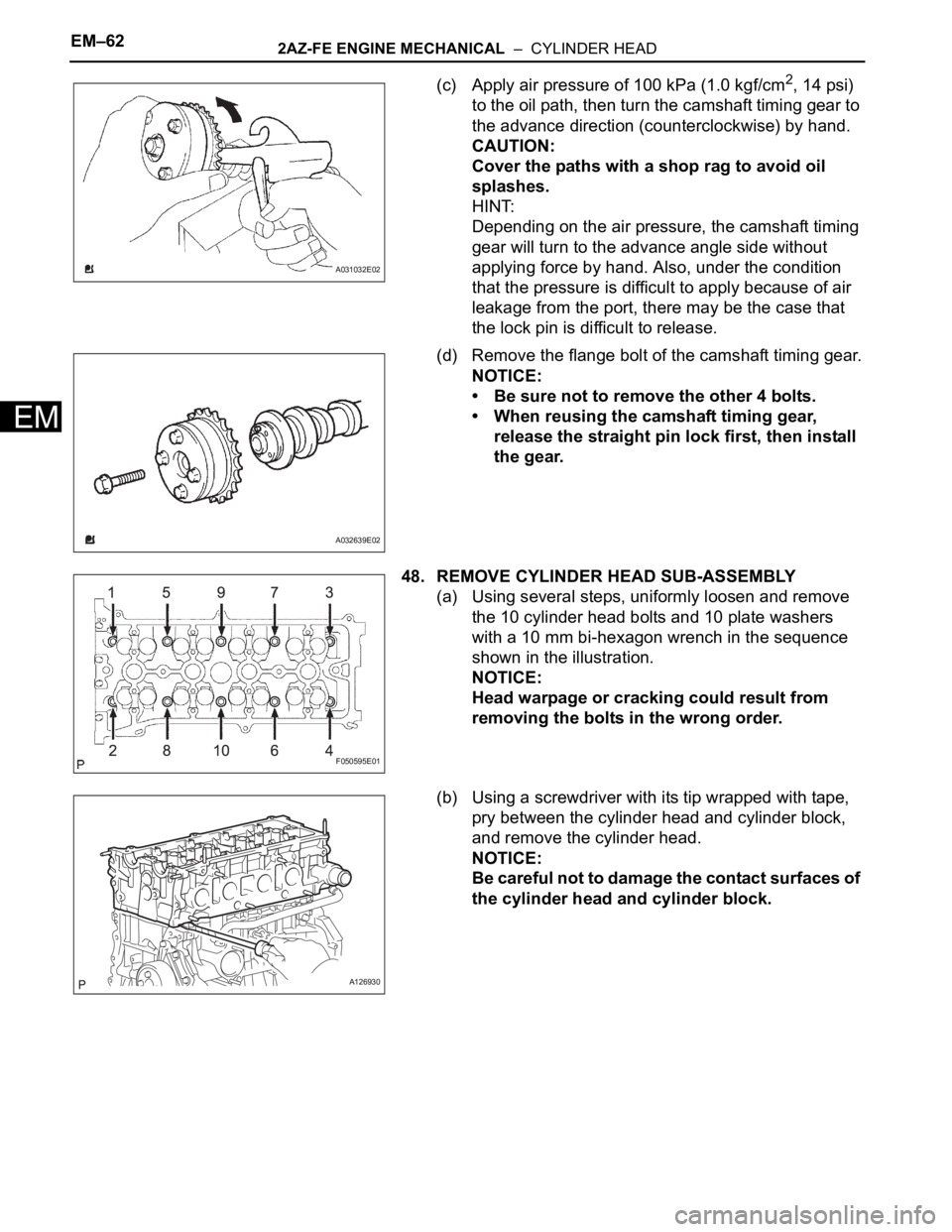

(c) Apply air pressure of 100 kPa (1.0 kgf/cm2, 14 psi)

to the oil path, then turn the camshaft timing gear to

the advance direction (counterclockwise) by hand.

CAUTION:

Cover the paths with a shop rag to avoid oil

splashes.

HINT:

Depending on the air pressure, the camshaft timing

gear will turn to the advance angle side without

applying force by hand. Also, under the condition

that the pressure is difficult to apply because of air

leakage from the port, there may be the case that

the lock pin is difficult to release.

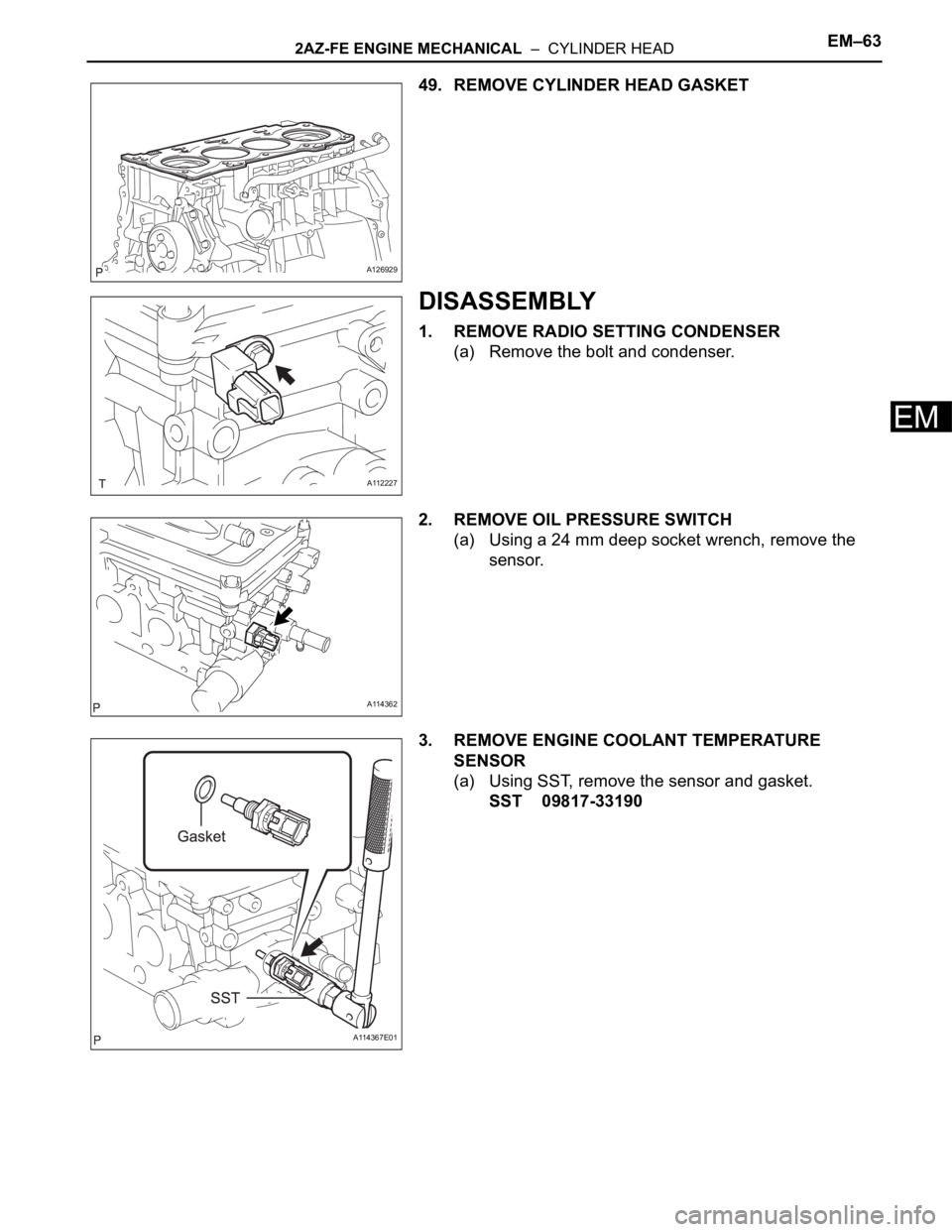

(d) Remove the flange bolt of the camshaft timing gear.

NOTICE:

• Be sure not to remove the other 4 bolts.

• When reusing the camshaft timing gear,

release the straight pin lock first, then install

the gear.

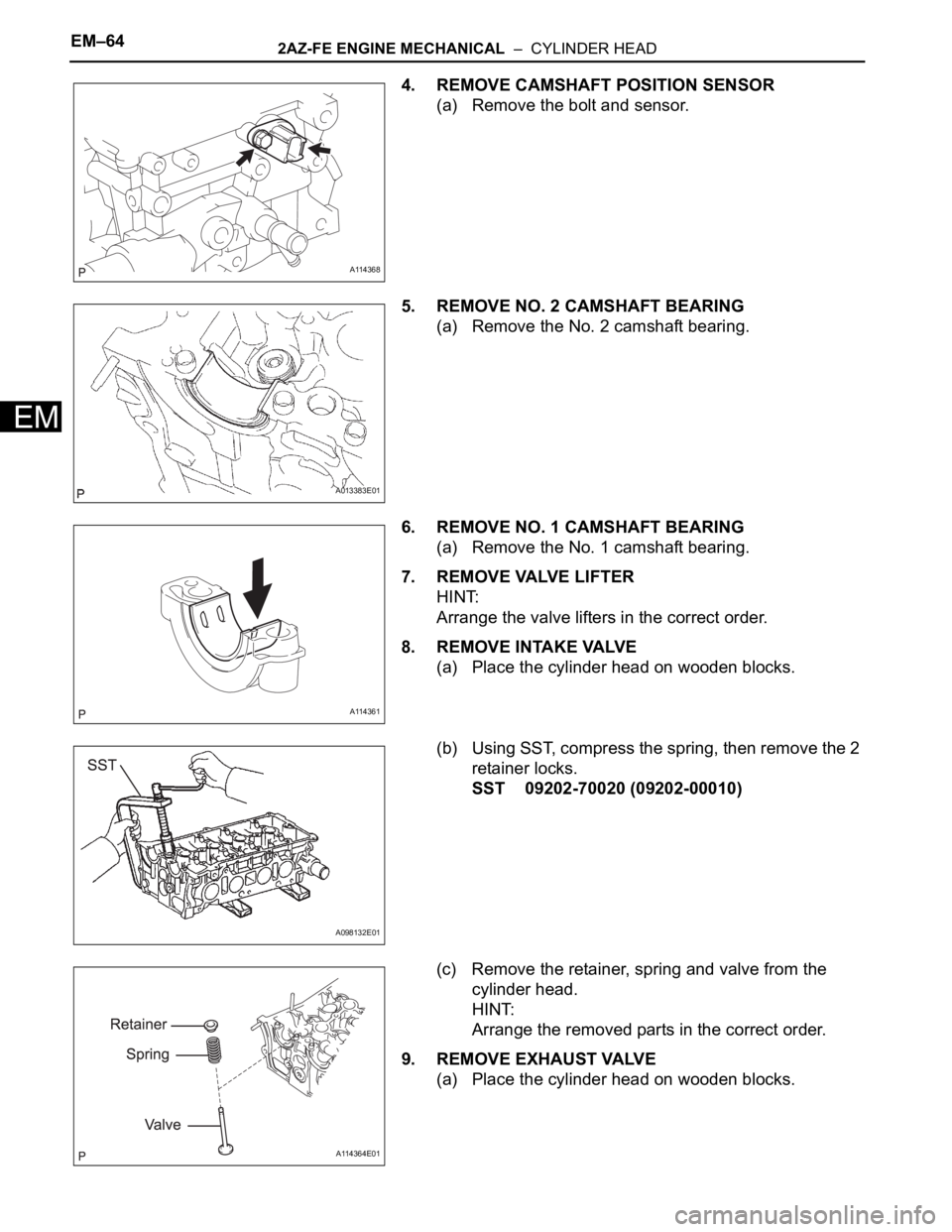

48. REMOVE CYLINDER HEAD SUB-ASSEMBLY

(a) Using several steps, uniformly loosen and remove

the 10 cylinder head bolts and 10 plate washers

with a 10 mm bi-hexagon wrench in the sequence

shown in the illustration.

NOTICE:

Head warpage or cracking could result from

removing the bolts in the wrong order.

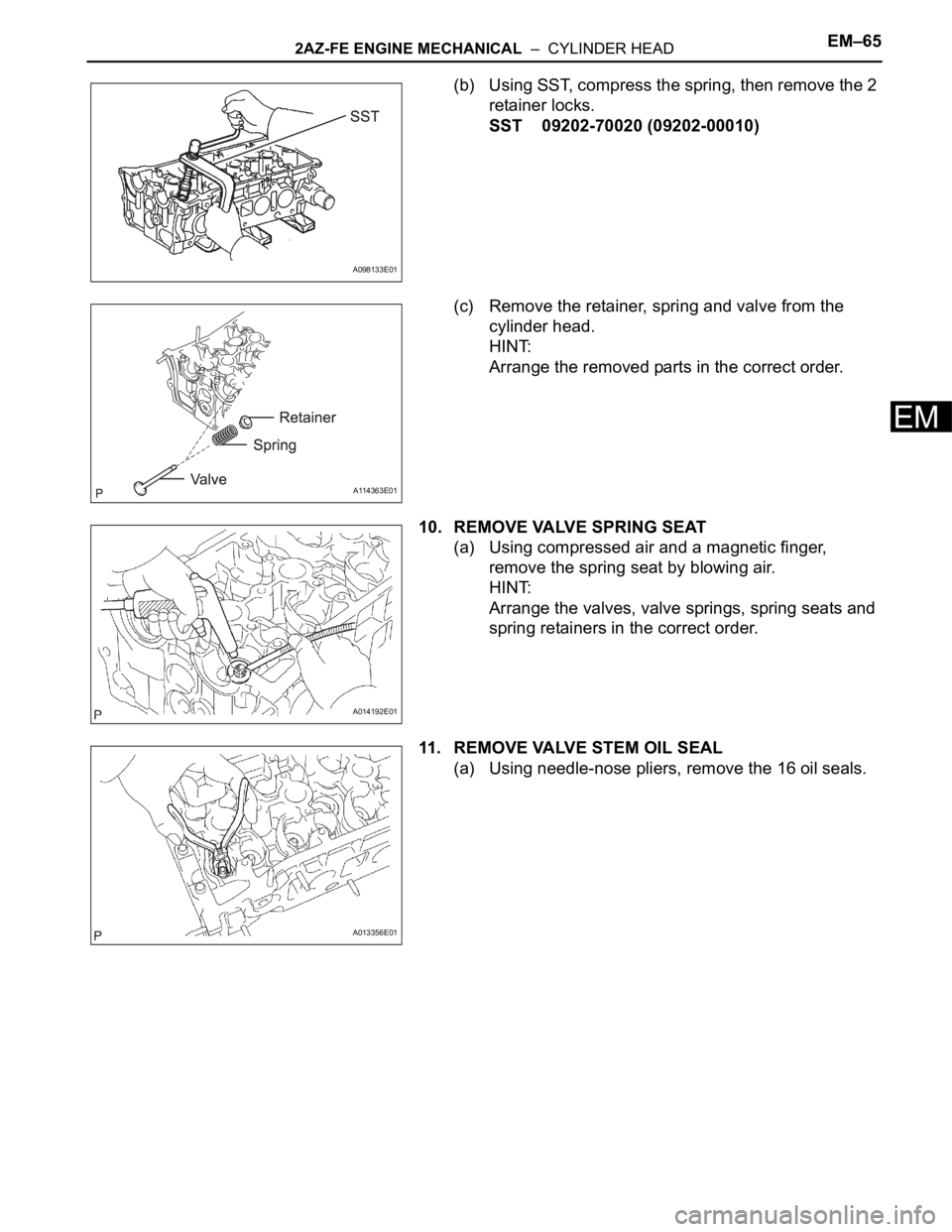

(b) Using a screwdriver with its tip wrapped with tape,

pry between the cylinder head and cylinder block,

and remove the cylinder head.

NOTICE:

Be careful not to damage the contact surfaces of

the cylinder head and cylinder block.

A031032E02

A032639E02

F050595E01

A126930

Page 607 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–63

EM

49. REMOVE CYLINDER HEAD GASKET

DISASSEMBLY

1. REMOVE RADIO SETTING CONDENSER

(a) Remove the bolt and condenser.

2. REMOVE OIL PRESSURE SWITCH

(a) Using a 24 mm deep socket wrench, remove the

sensor.

3. REMOVE ENGINE COOLANT TEMPERATURE

SENSOR

(a) Using SST, remove the sensor and gasket.

SST 09817-33190

A126929

A112227

A114362

A114367E01

Page 608 of 2000

EM–642AZ-FE ENGINE MECHANICAL – CYLINDER HEAD

EM

4. REMOVE CAMSHAFT POSITION SENSOR

(a) Remove the bolt and sensor.

5. REMOVE NO. 2 CAMSHAFT BEARING

(a) Remove the No. 2 camshaft bearing.

6. REMOVE NO. 1 CAMSHAFT BEARING

(a) Remove the No. 1 camshaft bearing.

7. REMOVE VALVE LIFTER

HINT:

Arrange the valve lifters in the correct order.

8. REMOVE INTAKE VALVE

(a) Place the cylinder head on wooden blocks.

(b) Using SST, compress the spring, then remove the 2

retainer locks.

SST 09202-70020 (09202-00010)

(c) Remove the retainer, spring and valve from the

cylinder head.

HINT:

Arrange the removed parts in the correct order.

9. REMOVE EXHAUST VALVE

(a) Place the cylinder head on wooden blocks.

A114368

A013383E01

A114361

A098132E01

A114364E01

Page 609 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–65

EM

(b) Using SST, compress the spring, then remove the 2

retainer locks.

SST 09202-70020 (09202-00010)

(c) Remove the retainer, spring and valve from the

cylinder head.

HINT:

Arrange the removed parts in the correct order.

10. REMOVE VALVE SPRING SEAT

(a) Using compressed air and a magnetic finger,

remove the spring seat by blowing air.

HINT:

Arrange the valves, valve springs, spring seats and

spring retainers in the correct order.

11. REMOVE VALVE STEM OIL SEAL

(a) Using needle-nose pliers, remove the 16 oil seals.

A098133E01

A114363E01

A014192E01

A013356E01

Page 610 of 2000

EM–662AZ-FE ENGINE MECHANICAL – CYLINDER HEAD

EM

INSPECTION

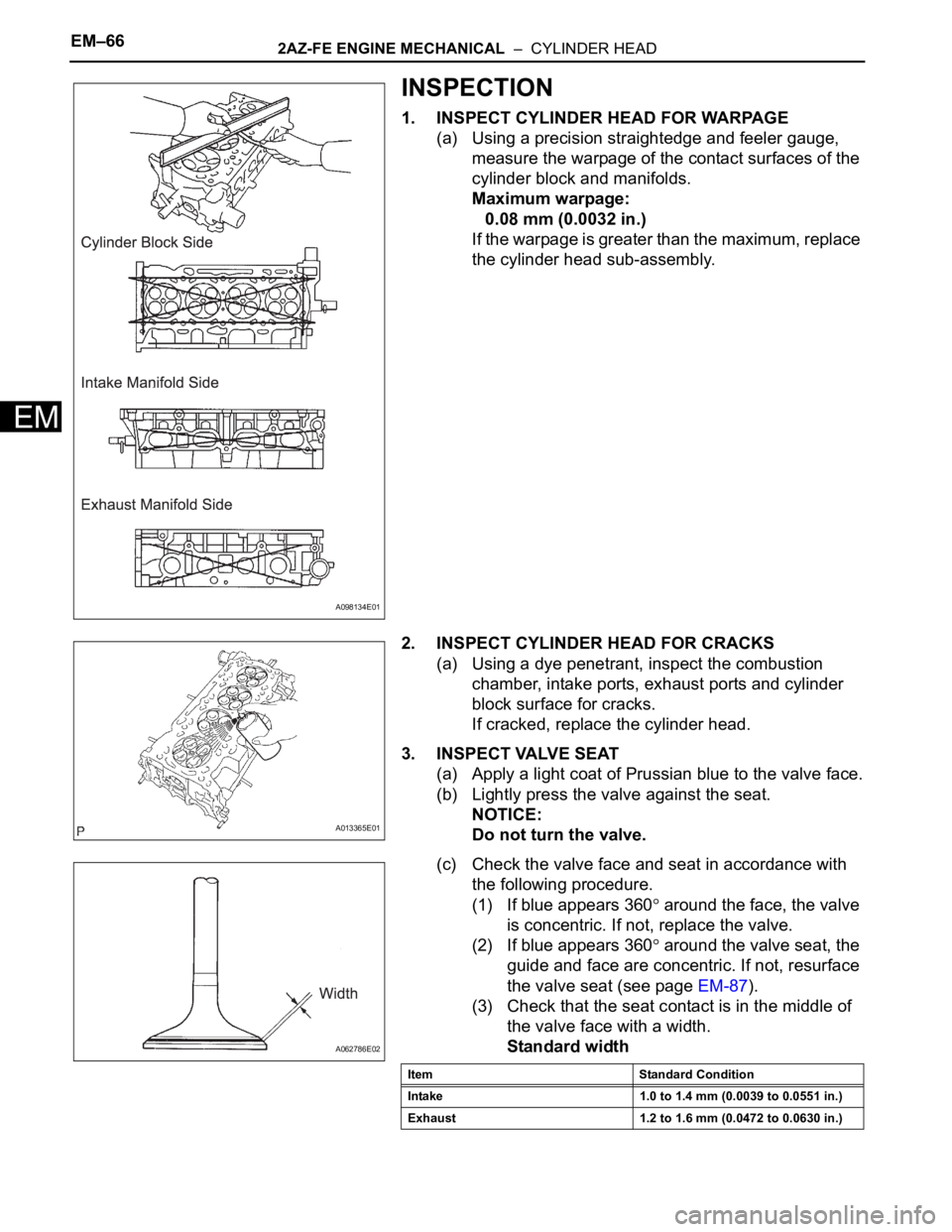

1. INSPECT CYLINDER HEAD FOR WARPAGE

(a) Using a precision straightedge and feeler gauge,

measure the warpage of the contact surfaces of the

cylinder block and manifolds.

Maximum warpage:

0.08 mm (0.0032 in.)

If the warpage is greater than the maximum, replace

the cylinder head sub-assembly.

2. INSPECT CYLINDER HEAD FOR CRACKS

(a) Using a dye penetrant, inspect the combustion

chamber, intake ports, exhaust ports and cylinder

block surface for cracks.

If cracked, replace the cylinder head.

3. INSPECT VALVE SEAT

(a) Apply a light coat of Prussian blue to the valve face.

(b) Lightly press the valve against the seat.

NOTICE:

Do not turn the valve.

(c) Check the valve face and seat in accordance with

the following procedure.

(1) If blue appears 360

around the face, the valve

is concentric. If not, replace the valve.

(2) If blue appears 360

around the valve seat, the

guide and face are concentric. If not, resurface

the valve seat (see page EM-87).

(3) Check that the seat contact is in the middle of

the valve face with a width.

Standard width

A098134E01

A013365E01

A062786E02

Item Standard Condition

Intake 1.0 to 1.4 mm (0.0039 to 0.0551 in.)

Exhaust 1.2 to 1.6 mm (0.0472 to 0.0630 in.)

Page 611 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–67

EM

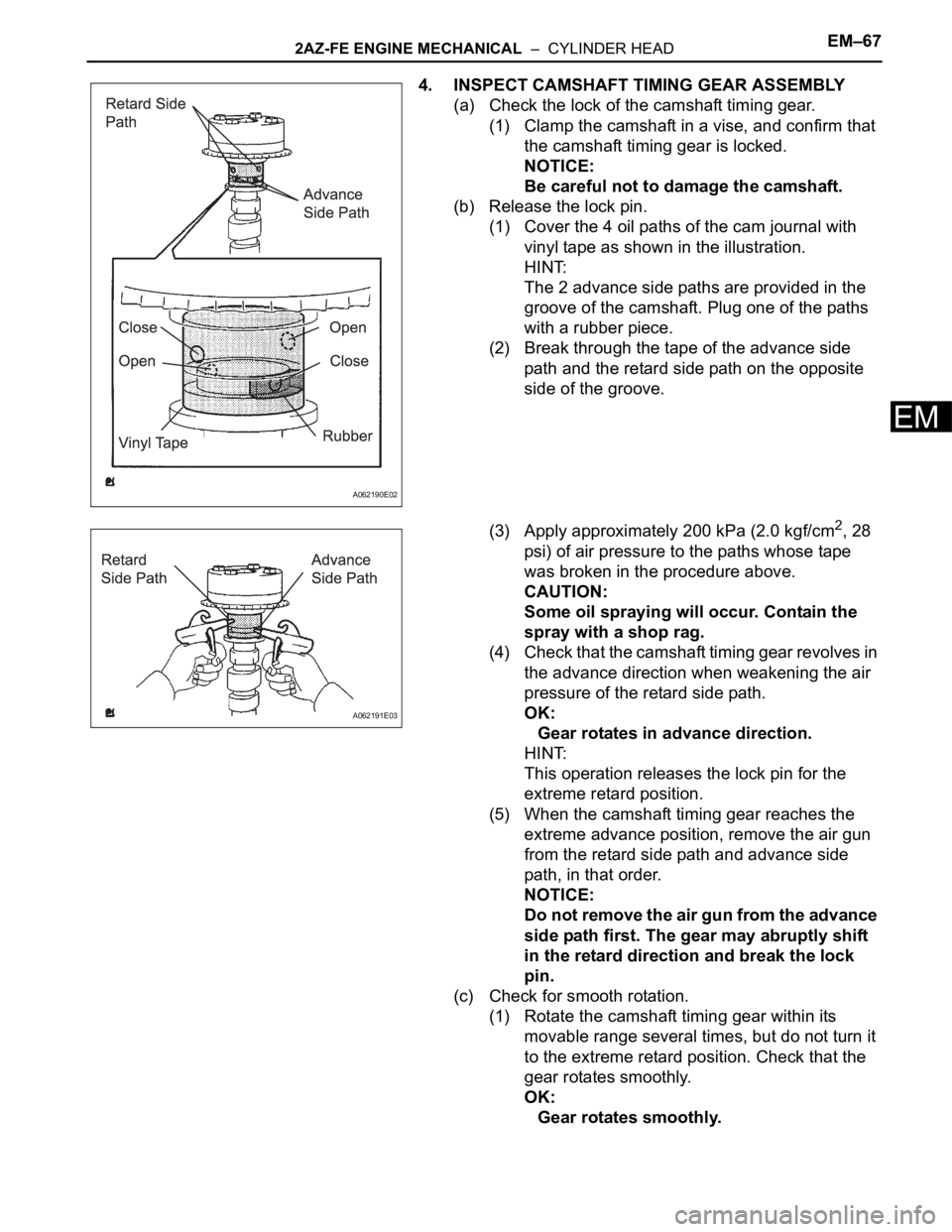

4. INSPECT CAMSHAFT TIMING GEAR ASSEMBLY

(a) Check the lock of the camshaft timing gear.

(1) Clamp the camshaft in a vise, and confirm that

the camshaft timing gear is locked.

NOTICE:

Be careful not to damage the camshaft.

(b) Release the lock pin.

(1) Cover the 4 oil paths of the cam journal with

vinyl tape as shown in the illustration.

HINT:

The 2 advance side paths are provided in the

groove of the camshaft. Plug one of the paths

with a rubber piece.

(2) Break through the tape of the advance side

path and the retard side path on the opposite

side of the groove.

(3) Apply approximately 200 kPa (2.0 kgf/cm

2, 28

psi) of air pressure to the paths whose tape

was broken in the procedure above.

CAUTION:

Some oil spraying will occur. Contain the

spray with a shop rag.

(4) Check that the camshaft timing gear revolves in

the advance direction when weakening the air

pressure of the retard side path.

OK:

Gear rotates in advance direction.

HINT:

This operation releases the lock pin for the

extreme retard position.

(5) When the camshaft timing gear reaches the

extreme advance position, remove the air gun

from the retard side path and advance side

path, in that order.

NOTICE:

Do not remove the air gun from the advance

side path first. The gear may abruptly shift

in the retard direction and break the lock

pin.

(c) Check for smooth rotation.

(1) Rotate the camshaft timing gear within its

movable range several times, but do not turn it

to the extreme retard position. Check that the

gear rotates smoothly.

OK:

Gear rotates smoothly.

A062190E02

A062191E03

Page 612 of 2000

EM–682AZ-FE ENGINE MECHANICAL – CYLINDER HEAD

EM

NOTICE:

Do not use an air gun to perform the

smooth operation check.

(d) Check the lock in the extreme retard position.

(1) Confirm that the camshaft timing gear is locked

at the extreme retard position.

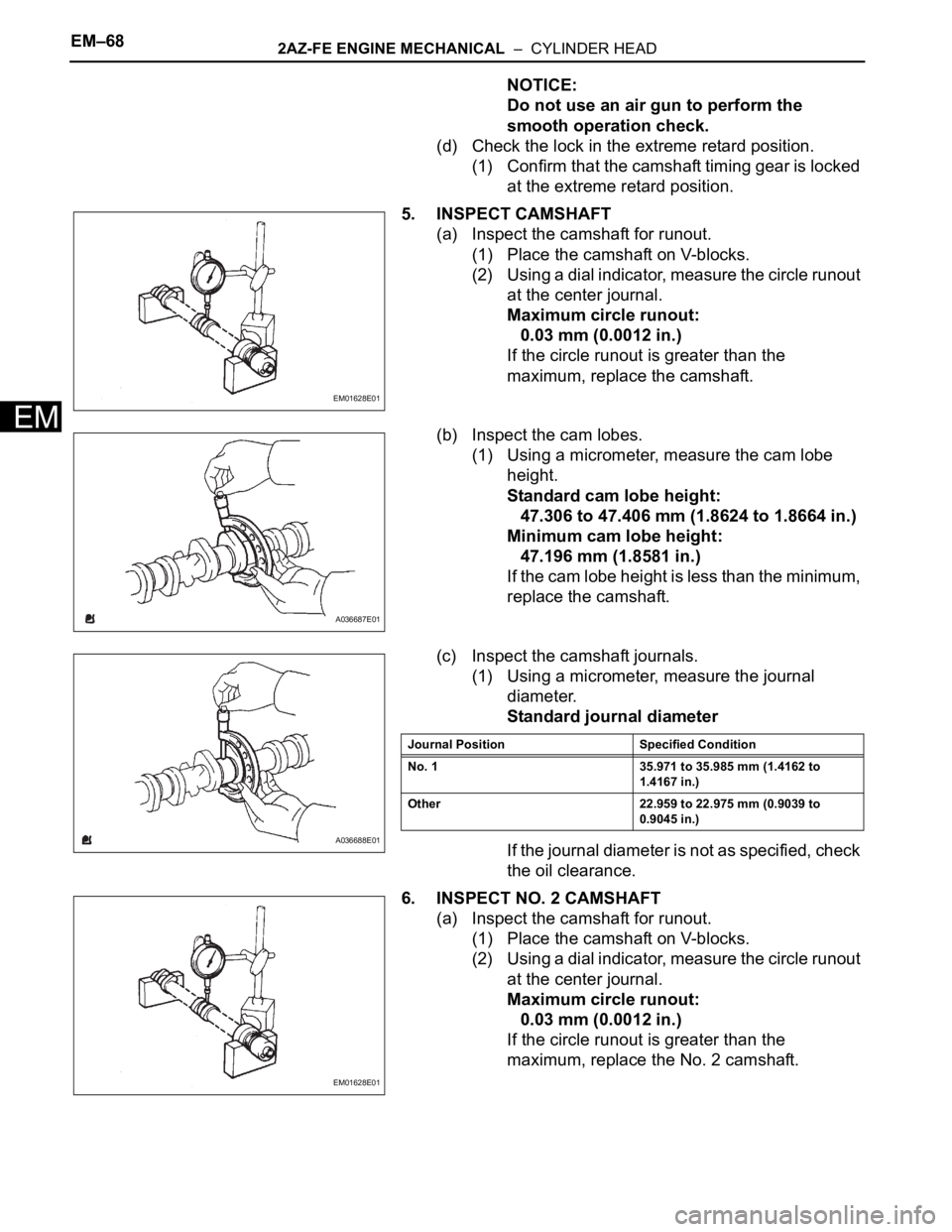

5. INSPECT CAMSHAFT

(a) Inspect the camshaft for runout.

(1) Place the camshaft on V-blocks.

(2) Using a dial indicator, measure the circle runout

at the center journal.

Maximum circle runout:

0.03 mm (0.0012 in.)

If the circle runout is greater than the

maximum, replace the camshaft.

(b) Inspect the cam lobes.

(1) Using a micrometer, measure the cam lobe

height.

Standard cam lobe height:

47.306 to 47.406 mm (1.8624 to 1.8664 in.)

Minimum cam lobe height:

47.196 mm (1.8581 in.)

If the cam lobe height is less than the minimum,

replace the camshaft.

(c) Inspect the camshaft journals.

(1) Using a micrometer, measure the journal

diameter.

Standard journal diameter

If the journal diameter is not as specified, check

the oil clearance.

6. INSPECT NO. 2 CAMSHAFT

(a) Inspect the camshaft for runout.

(1) Place the camshaft on V-blocks.

(2) Using a dial indicator, measure the circle runout

at the center journal.

Maximum circle runout:

0.03 mm (0.0012 in.)

If the circle runout is greater than the

maximum, replace the No. 2 camshaft.

EM01628E01

A036687E01

A036688E01

Journal Position Specified Condition

No. 1 35.971 to 35.985 mm (1.4162 to

1.4167 in.)

Other 22.959 to 22.975 mm (0.9039 to

0.9045 in.)

EM01628E01

Page 613 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–69

EM

(b) Inspect the cam lobes.

(1) Using a micrometer, measure the cam lobe

height.

Standard cam lobe height:

45.983 to 46.083 mm (1.8104 to 1.8143 in.)

Minimum cam lobe height:

45.873 mm (1.8060 in.)

If the cam lobe height is less than the minimum,

replace the No. 2 camshaft.

(c) Inspect the camshaft journals.

(1) Using a micrometer, measure the journal

diameter.

Standard journal diameter

If the journal diameter is not as specified, check

the oil clearance.

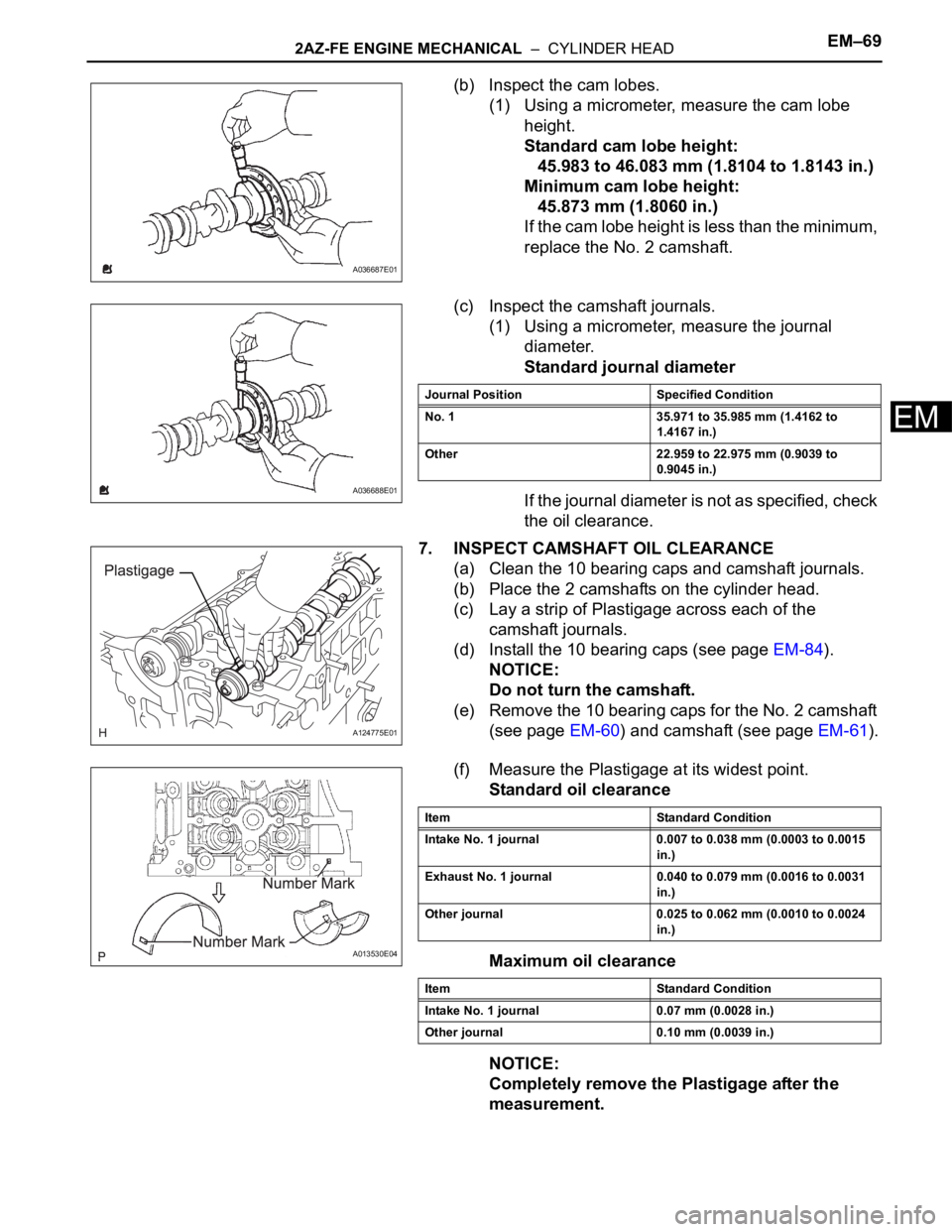

7. INSPECT CAMSHAFT OIL CLEARANCE

(a) Clean the 10 bearing caps and camshaft journals.

(b) Place the 2 camshafts on the cylinder head.

(c) Lay a strip of Plastigage across each of the

camshaft journals.

(d) Install the 10 bearing caps (see page EM-84).

NOTICE:

Do not turn the camshaft.

(e) Remove the 10 bearing caps for the No. 2 camshaft

(see page EM-60) and camshaft (see page EM-61).

(f) Measure the Plastigage at its widest point.

Standard oil clearance

Maximum oil clearance

NOTICE:

Completely remove the Plastigage after the

measurement.

A036687E01

A036688E01

Journal Position Specified Condition

No. 1 35.971 to 35.985 mm (1.4162 to

1.4167 in.)

Other 22.959 to 22.975 mm (0.9039 to

0.9045 in.)

A124775E01

A013530E04

Item Standard Condition

Intake No. 1 journal 0.007 to 0.038 mm (0.0003 to 0.0015

in.)

Exhaust No. 1 journal 0.040 to 0.079 mm (0.0016 to 0.0031

in.)

Other journal 0.025 to 0.062 mm (0.0010 to 0.0024

in.)

Item Standard Condition

Intake No. 1 journal 0.07 mm (0.0028 in.)

Other journal 0.10 mm (0.0039 in.)

Page 614 of 2000

EM–702AZ-FE ENGINE MECHANICAL – CYLINDER HEAD

EM

If the oil clearance on the No. 1 journal is greater

than the maximum, choose a new bearing and

install it.

If the oil clearance on the other journals is greater

than the maximum, replace the cylinder head sub-

assembly or the camshaft.

Standard cylinder head journal bore diameter

Standard bearing center wall thickness

Standard camshaft journal diameter:

35.971 to 35.985 mm (1.4162 to 1.4167 in.)

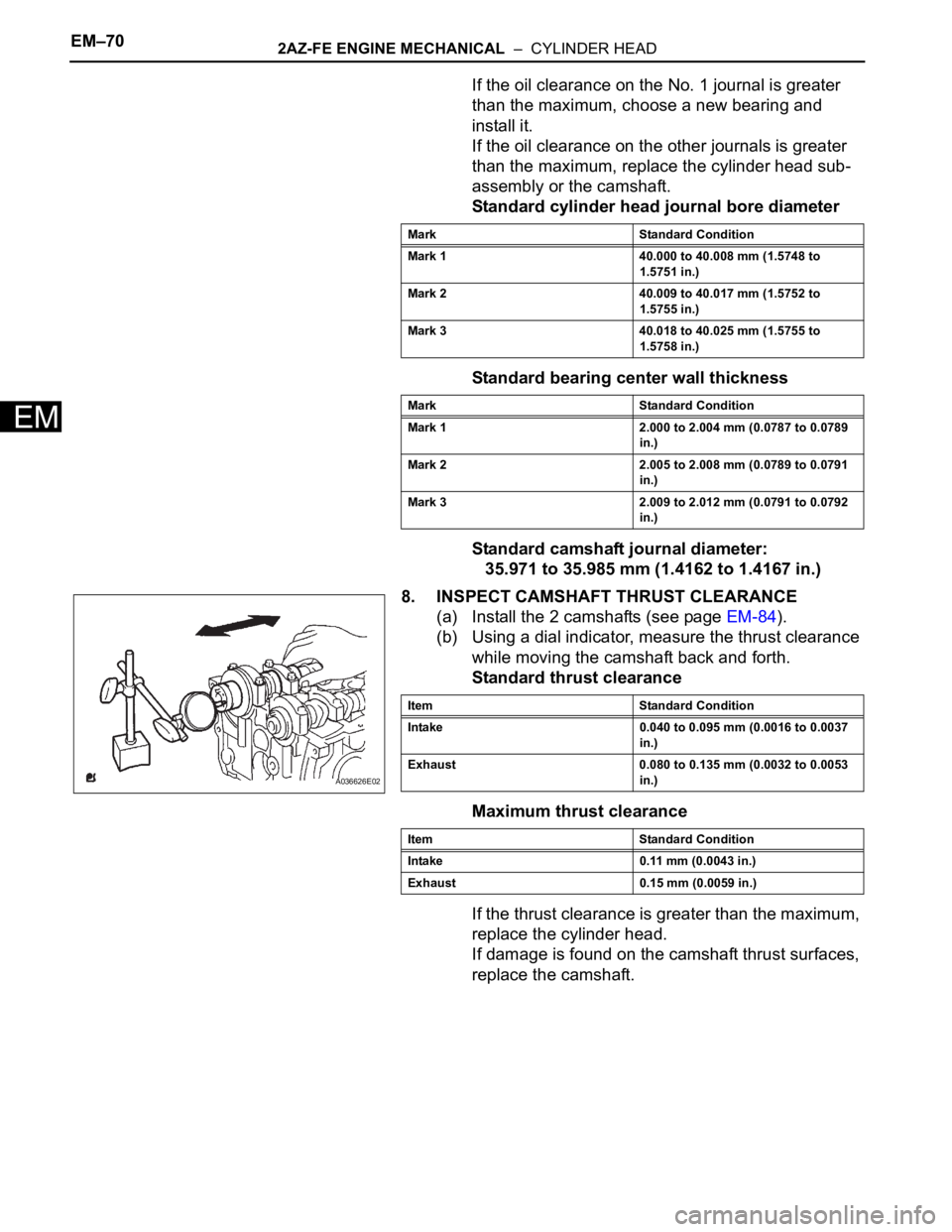

8. INSPECT CAMSHAFT THRUST CLEARANCE

(a) Install the 2 camshafts (see page EM-84).

(b) Using a dial indicator, measure the thrust clearance

while moving the camshaft back and forth.

Standard thrust clearance

Maximum thrust clearance

If the thrust clearance is greater than the maximum,

replace the cylinder head.

If damage is found on the camshaft thrust surfaces,

replace the camshaft.

Mark Standard Condition

Mark 1 40.000 to 40.008 mm (1.5748 to

1.5751 in.)

Mark 2 40.009 to 40.017 mm (1.5752 to

1.5755 in.)

Mark 3 40.018 to 40.025 mm (1.5755 to

1.5758 in.)

Mark Standard Condition

Mark 1 2.000 to 2.004 mm (0.0787 to 0.0789

in.)

Mark 2 2.005 to 2.008 mm (0.0789 to 0.0791

in.)

Mark 3 2.009 to 2.012 mm (0.0791 to 0.0792

in.)

A036626E02

Item Standard Condition

Intake 0.040 to 0.095 mm (0.0016 to 0.0037

in.)

Exhaust 0.080 to 0.135 mm (0.0032 to 0.0053

in.)

Item Standard Condition

Intake 0.11 mm (0.0043 in.)

Exhaust 0.15 mm (0.0059 in.)

Page 615 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–71

EM

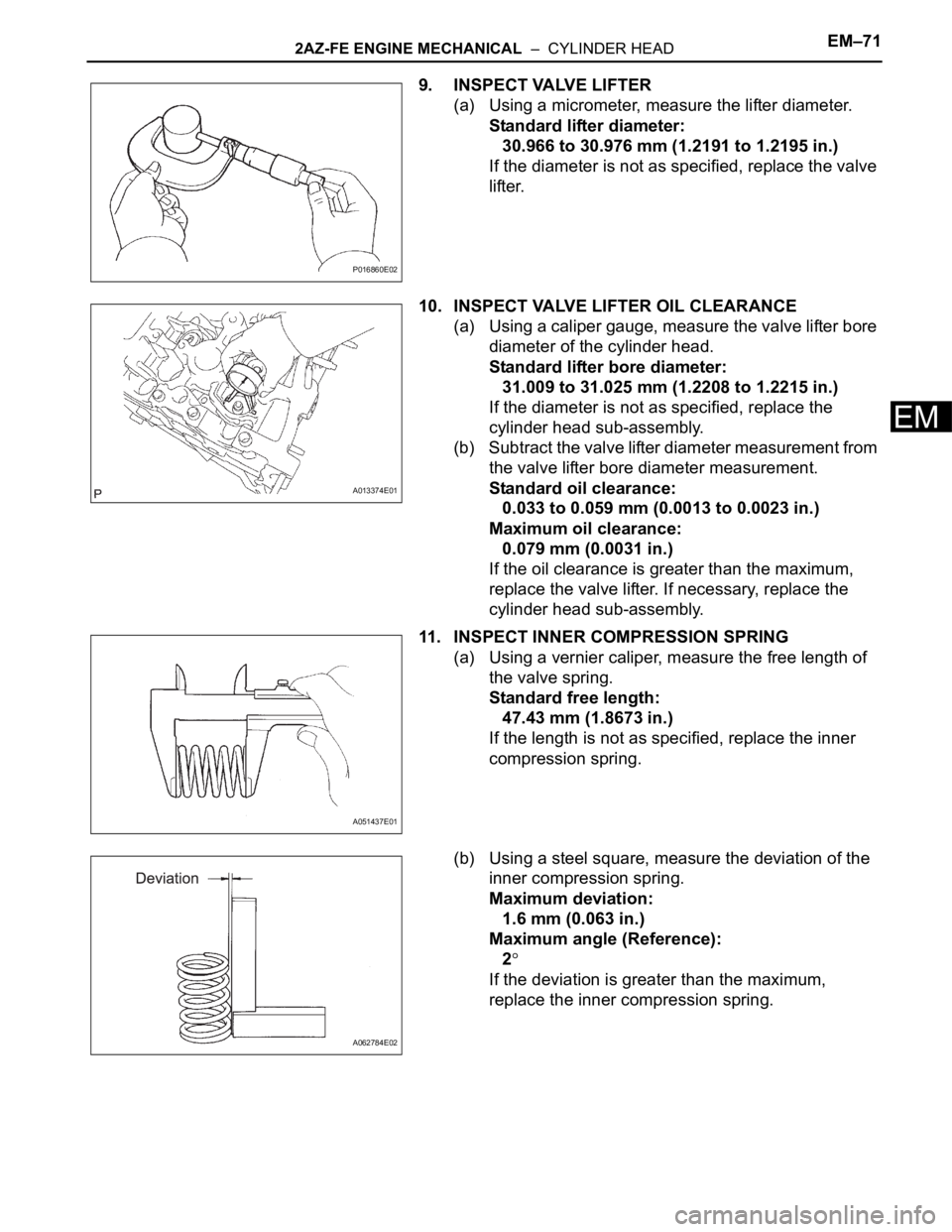

9. INSPECT VALVE LIFTER

(a) Using a micrometer, measure the lifter diameter.

Standard lifter diameter:

30.966 to 30.976 mm (1.2191 to 1.2195 in.)

If the diameter is not as specified, replace the valve

lifter.

10. INSPECT VALVE LIFTER OIL CLEARANCE

(a) Using a caliper gauge, measure the valve lifter bore

diameter of the cylinder head.

Standard lifter bore diameter:

31.009 to 31.025 mm (1.2208 to 1.2215 in.)

If the diameter is not as specified, replace the

cylinder head sub-assembly.

(b) Subtract the valve lifter diameter measurement from

the valve lifter bore diameter measurement.

Standard oil clearance:

0.033 to 0.059 mm (0.0013 to 0.0023 in.)

Maximum oil clearance:

0.079 mm (0.0031 in.)

If the oil clearance is greater than the maximum,

replace the valve lifter. If necessary, replace the

cylinder head sub-assembly.

11. INSPECT INNER COMPRESSION SPRING

(a) Using a vernier caliper, measure the free length of

the valve spring.

Standard free length:

47.43 mm (1.8673 in.)

If the length is not as specified, replace the inner

compression spring.

(b) Using a steel square, measure the deviation of the

inner compression spring.

Maximum deviation:

1.6 mm (0.063 in.)

Maximum angle (Reference):

2

If the deviation is greater than the maximum,

replace the inner compression spring.

P016860E02

A013374E01

A051437E01

A062784E02