engine TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 676 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE UNITEM–149

EM

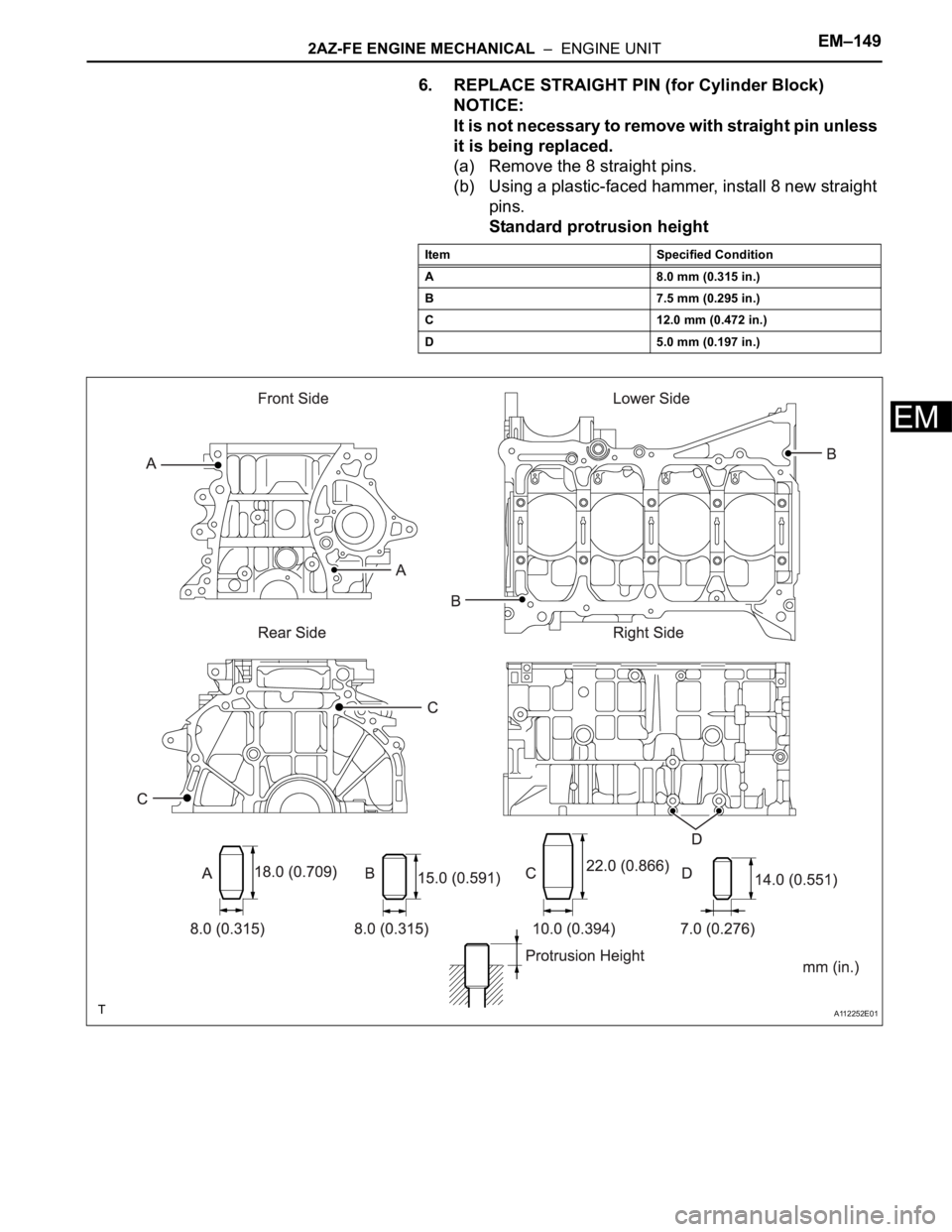

6. REPLACE STRAIGHT PIN (for Cylinder Block)

NOTICE:

It is not necessary to remove with straight pin unless

it is being replaced.

(a) Remove the 8 straight pins.

(b) Using a plastic-faced hammer, install 8 new straight

pins.

Standard protrusion height

Item Specified Condition

A 8.0 mm (0.315 in.)

B 7.5 mm (0.295 in.)

C 12.0 mm (0.472 in.)

D 5.0 mm (0.197 in.)

A112252E01

Page 677 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–31

EM

INSTALLATION

1. INSTALL ENGINE COOLANT TEMPERATURE

SENSOR

(a) Using a 19 mm deep socket wrench, install the

sensor and a new gasket.

Torque: 20 N*m (204 kgf*cm, 14 ft.*lbf)

2. INSTALL KNOCK SENSOR (See page ES-459)

3. INSTALL ENGINE OIL PRESSURE SWITCH

ASSEMBLY

(a) Clean the threads of the oil pressure switch. Apply

adhesive to 2 or 3 threads of the oil pressure switch.

Adhesive:

Toyota Genuine Adhesive 1344, Three Bond

1344 or Equivalent

(b) Using a 24 mm deep socket wrench, install the oil

pressure switch.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

4. INSTALL NO. 1 FRONT ENGINE MOUNTING

BRACKET LH

(a) Install the mounting bracket with the 6 bolts.

Torque: 54 N*m (551 kgf*cm, 40 ft.*lbf)

5. INSTALL WATER PUMP PULLEY (See page CO-14)

6. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY

(a) Install the idler pulley and cover plate with the bolt.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

7. INSTALL NO. 2 TIMING GEAR COVER

(a) Install the gear cover with the 2 bolts.

Torque: 6.0 N*m (61 kgf*cm, 53 in.*lbf)

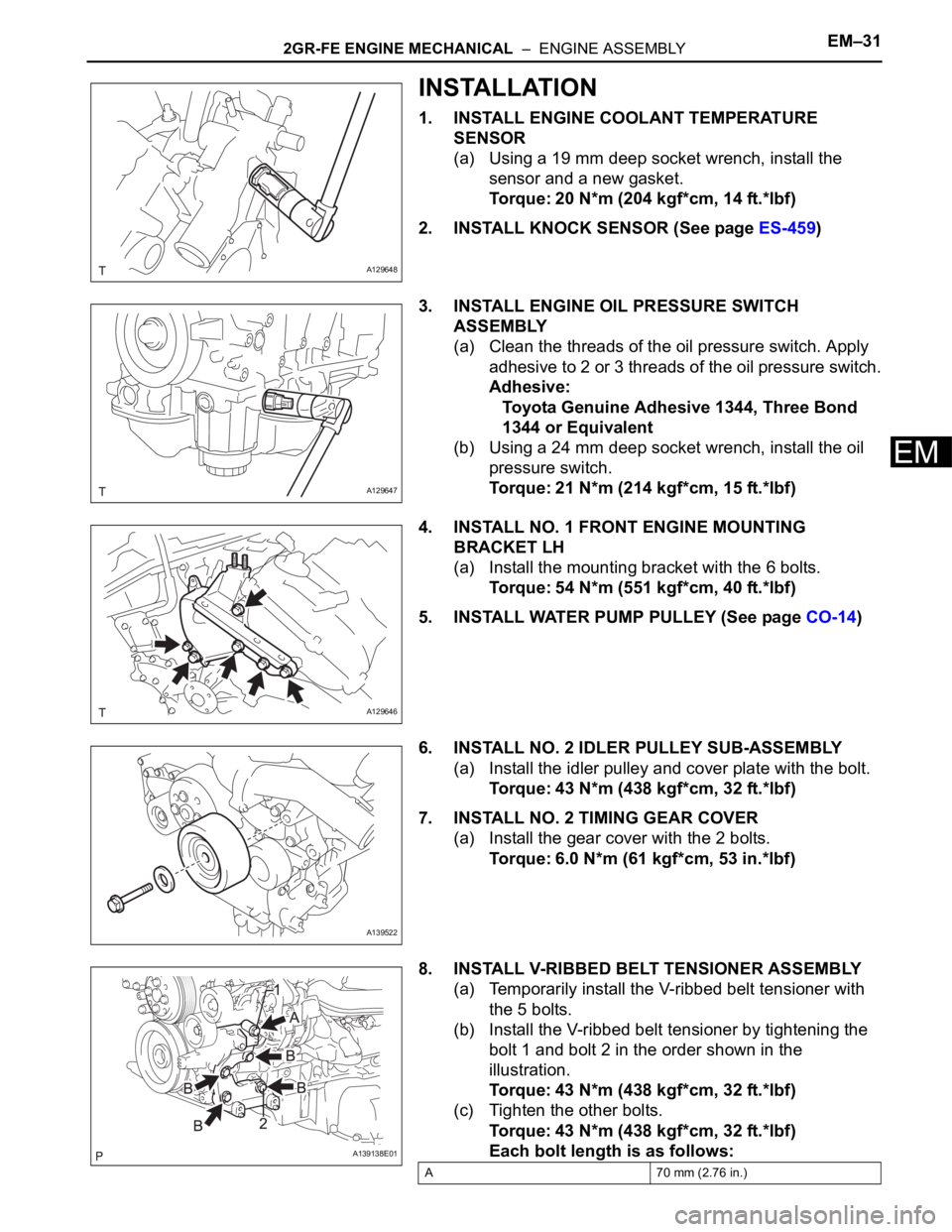

8. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

(a) Temporarily install the V-ribbed belt tensioner with

the 5 bolts.

(b) Install the V-ribbed belt tensioner by tightening the

bolt 1 and bolt 2 in the order shown in the

illustration.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

(c) Tighten the other bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

Each bolt length is as follows:

A129648

A129647

A129646

A139522

A139138E01

A 70 mm (2.76 in.)

Page 678 of 2000

EM–322GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

9. INSTALL DRIVE SHAFT BEARING BRACKET

(a) Install the drive shaft bearing bracket with the 3

bolts.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf)

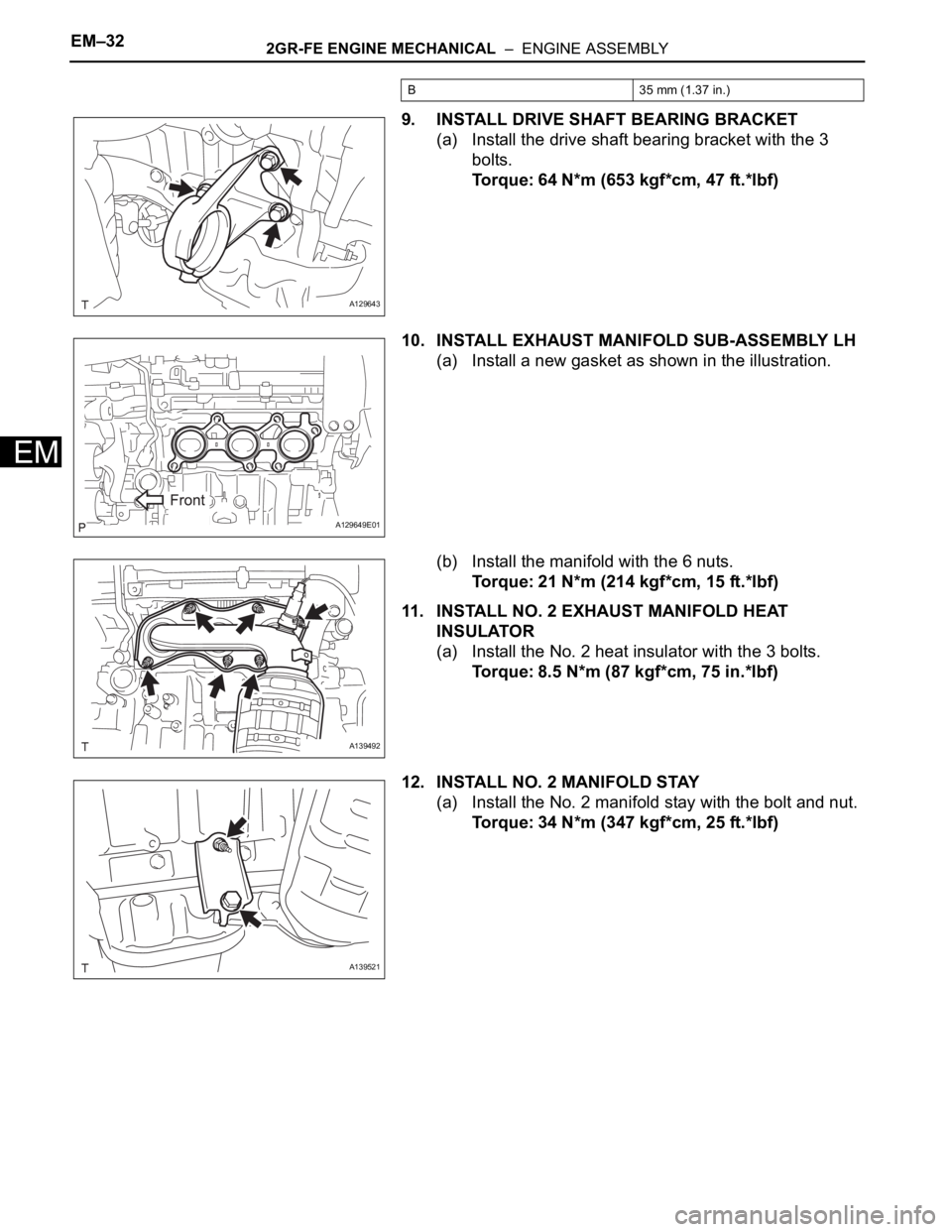

10. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY LH

(a) Install a new gasket as shown in the illustration.

(b) Install the manifold with the 6 nuts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

11. INSTALL NO. 2 EXHAUST MANIFOLD HEAT

INSULATOR

(a) Install the No. 2 heat insulator with the 3 bolts.

Torque: 8.5 N*m (87 kgf*cm, 75 in.*lbf)

12. INSTALL NO. 2 MANIFOLD STAY

(a) Install the No. 2 manifold stay with the bolt and nut.

Torque: 34 N*m (347 kgf*cm, 25 ft.*lbf)

B 35 mm (1.37 in.)

A129643

A129649E01

A139492

A139521

Page 679 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–33

EM

13. INSTALL OIL DIPSTICK GUIDE

(a) Install 2 new O-rings to the guide.

(b) Apply a light coat of engine oil to the O-rings.

(c) Push in the guide end into the guide hole.

(d) Install the No. 1 guide with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(e) Install the No. 2 guide with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(f) Install the dipstick.

14. INSTALL GENERATOR ASSEMBLY (See page CH-19)

15. INSTALL COMPRESSOR WITH PULLEY ASSEMBLY

(See page AC-221)

16. INSTALL FAN AND GENERATOR V BELT (See page

EM-8)

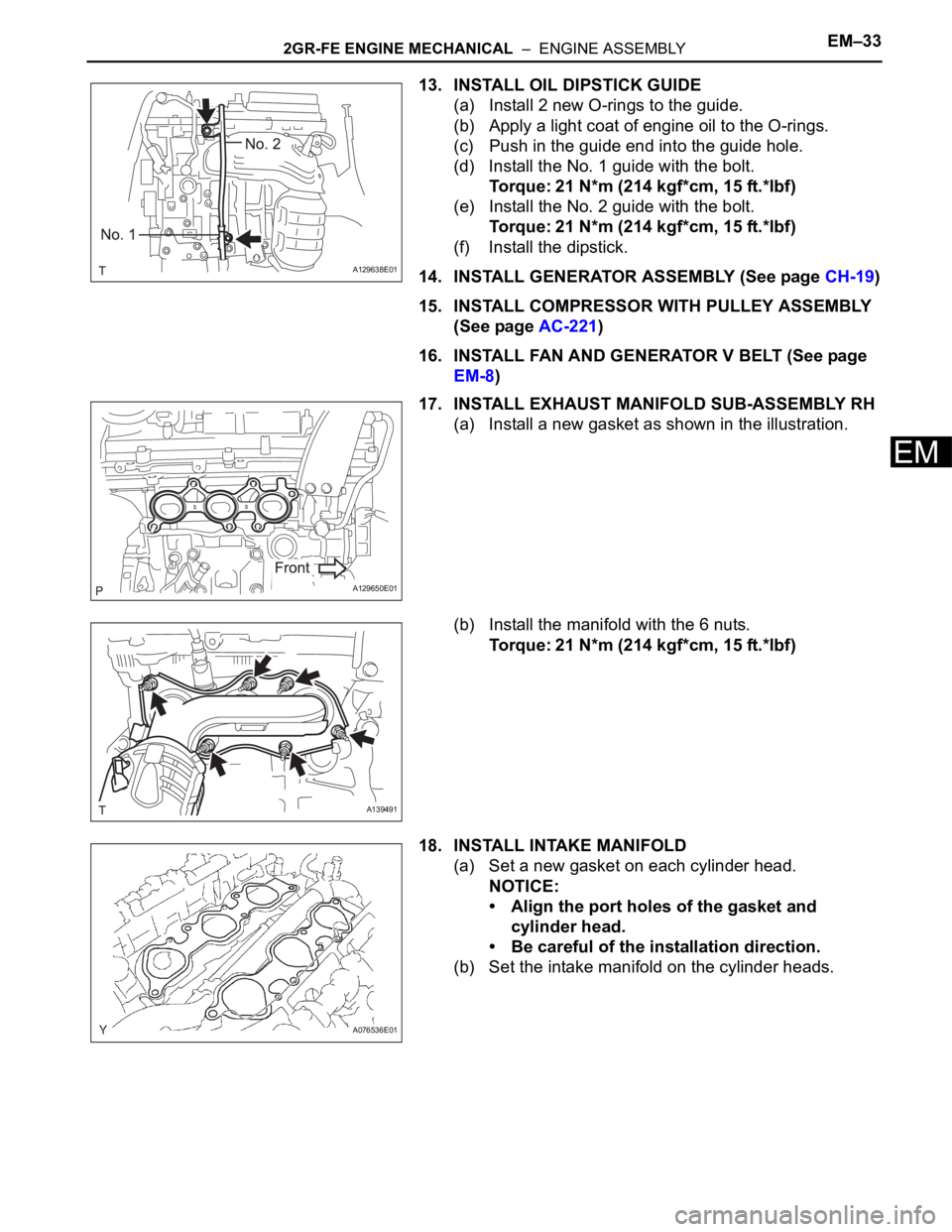

17. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY RH

(a) Install a new gasket as shown in the illustration.

(b) Install the manifold with the 6 nuts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

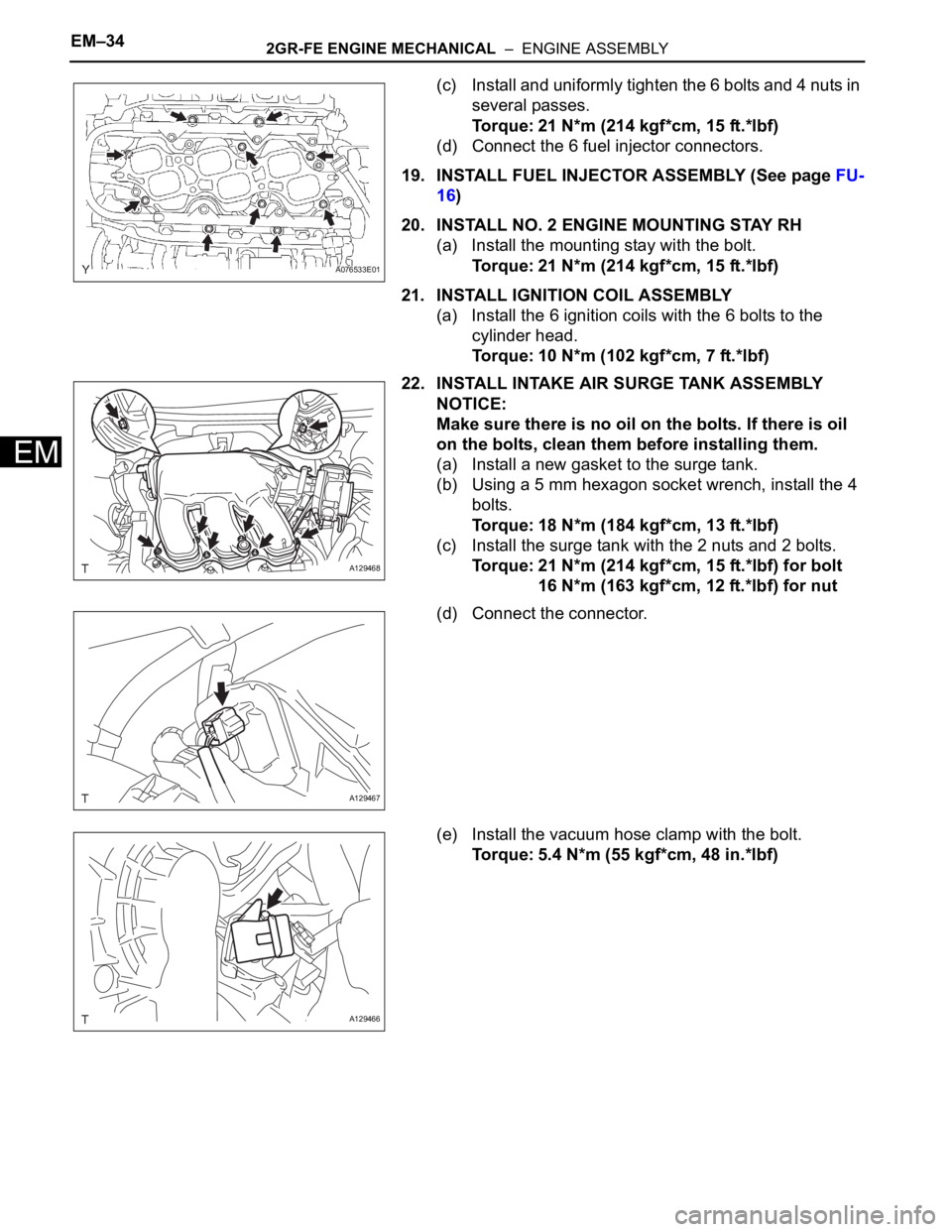

18. INSTALL INTAKE MANIFOLD

(a) Set a new gasket on each cylinder head.

NOTICE:

• Align the port holes of the gasket and

cylinder head.

• Be careful of the installation direction.

(b) Set the intake manifold on the cylinder heads.

A129638E01

A129650E01

A139491

A076536E01

Page 680 of 2000

EM–342GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

(c) Install and uniformly tighten the 6 bolts and 4 nuts in

several passes.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(d) Connect the 6 fuel injector connectors.

19. INSTALL FUEL INJECTOR ASSEMBLY (See page FU-

16)

20. INSTALL NO. 2 ENGINE MOUNTING STAY RH

(a) Install the mounting stay with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

21. INSTALL IGNITION COIL ASSEMBLY

(a) Install the 6 ignition coils with the 6 bolts to the

cylinder head.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

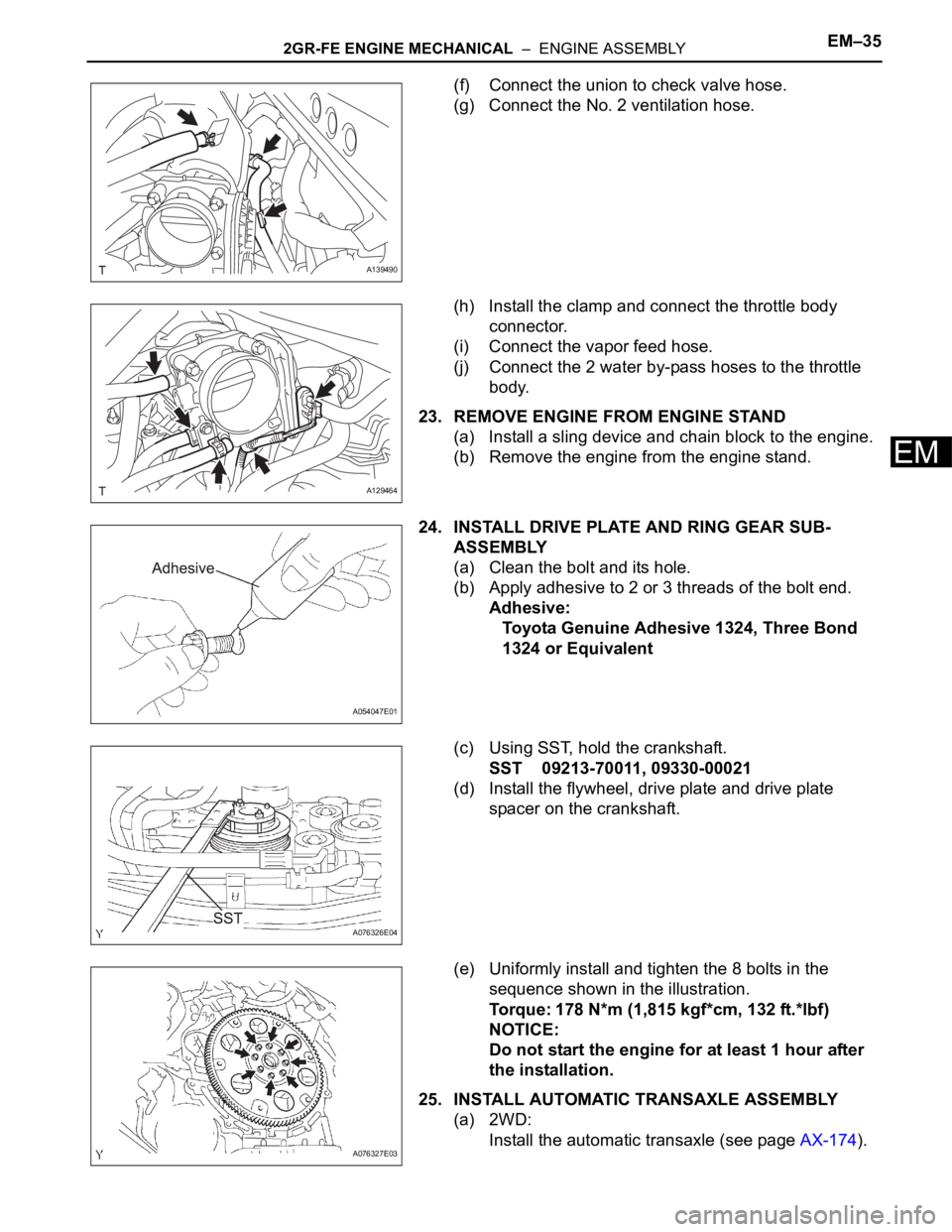

22. INSTALL INTAKE AIR SURGE TANK ASSEMBLY

NOTICE:

Make sure there is no oil on the bolts. If there is oil

on the bolts, clean them before installing them.

(a) Install a new gasket to the surge tank.

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts.

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

(c) Install the surge tank with the 2 nuts and 2 bolts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf) for bolt

16 N*m (163 kgf*cm, 12 ft.*lbf) for nut

(d) Connect the connector.

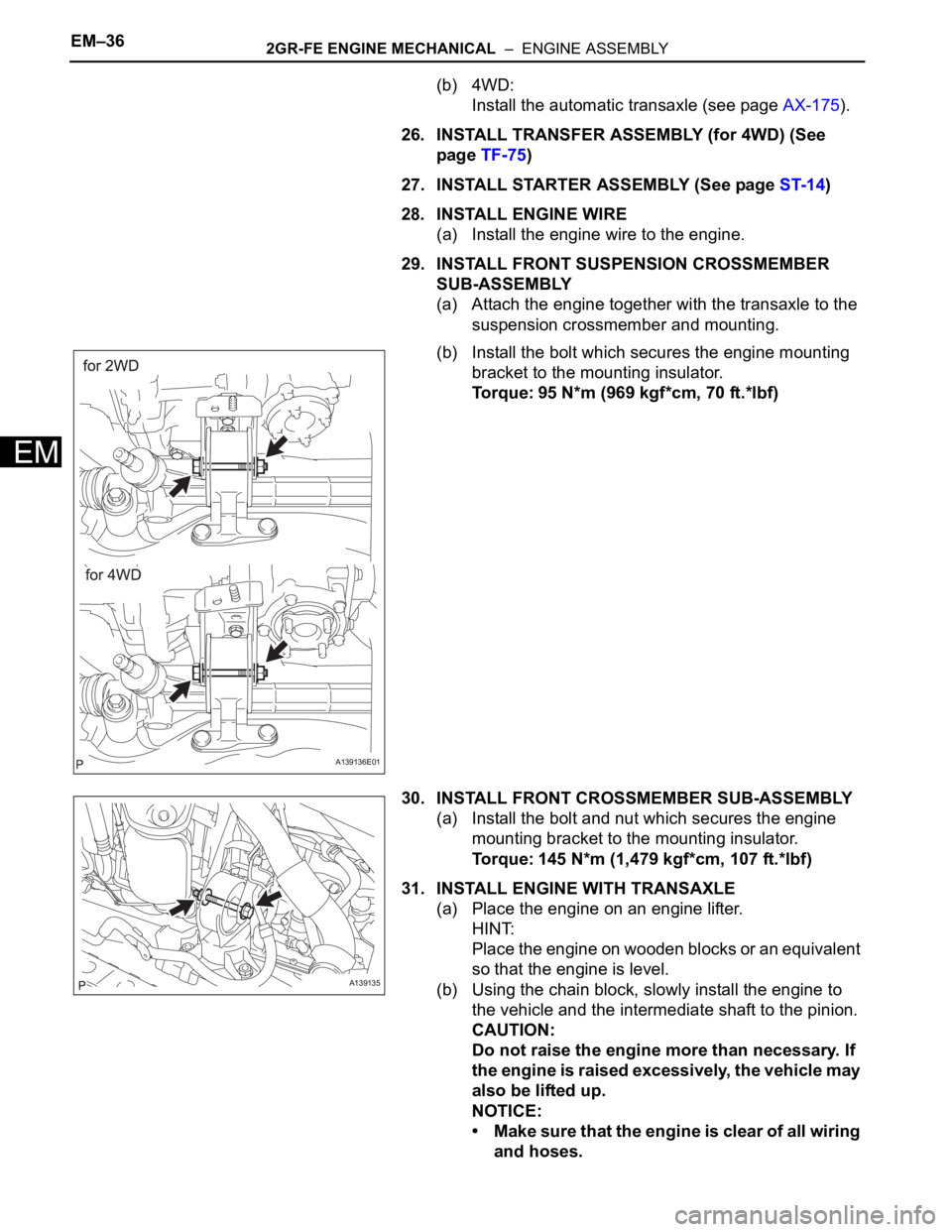

(e) Install the vacuum hose clamp with the bolt.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

A076533E01

A129468

A129467

A129466

Page 681 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–35

EM

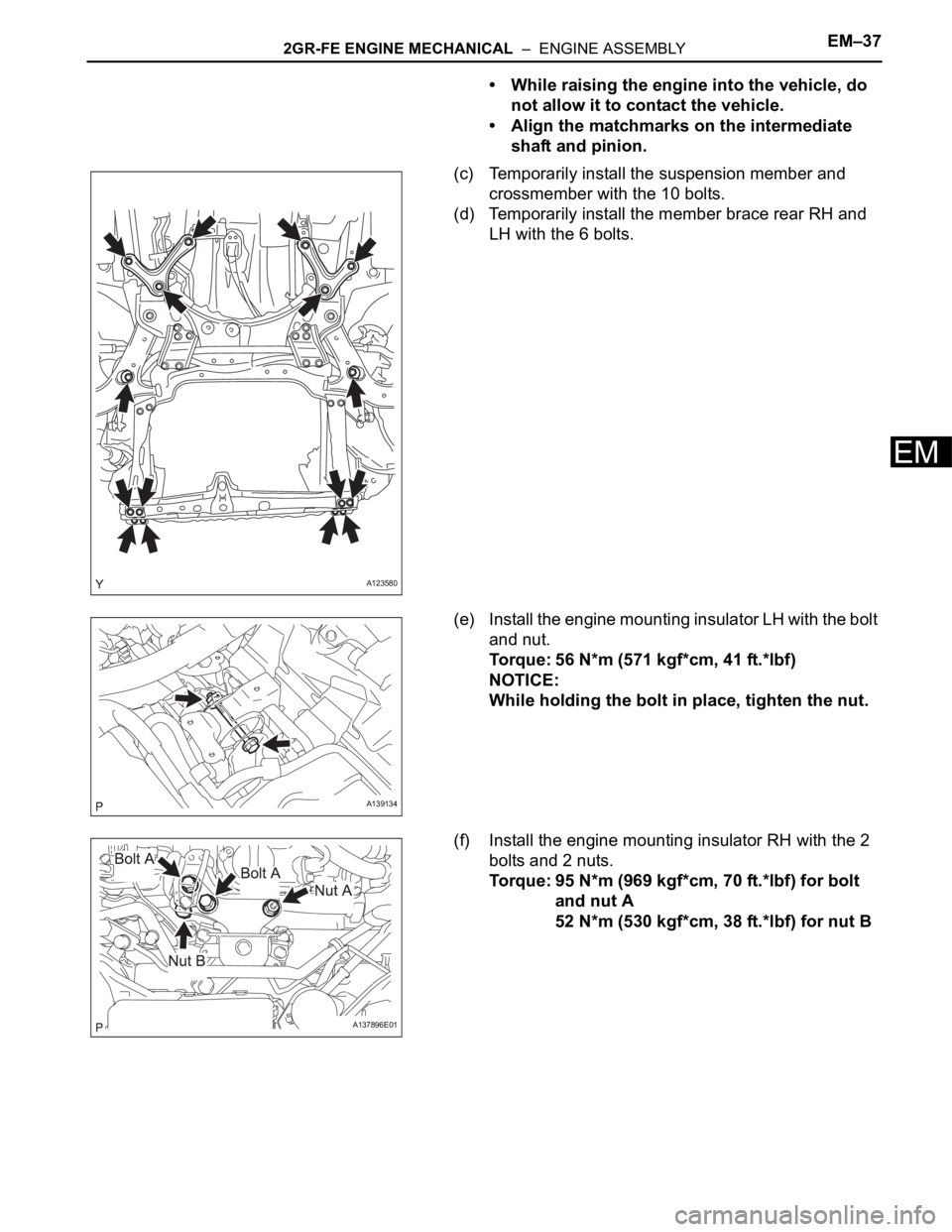

(f) Connect the union to check valve hose.

(g) Connect the No. 2 ventilation hose.

(h) Install the clamp and connect the throttle body

connector.

(i) Connect the vapor feed hose.

(j) Connect the 2 water by-pass hoses to the throttle

body.

23. REMOVE ENGINE FROM ENGINE STAND

(a) Install a sling device and chain block to the engine.

(b) Remove the engine from the engine stand.

24. INSTALL DRIVE PLATE AND RING GEAR SUB-

ASSEMBLY

(a) Clean the bolt and its hole.

(b) Apply adhesive to 2 or 3 threads of the bolt end.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond

1324 or Equivalent

(c) Using SST, hold the crankshaft.

SST 09213-70011, 09330-00021

(d) Install the flywheel, drive plate and drive plate

spacer on the crankshaft.

(e) Uniformly install and tighten the 8 bolts in the

sequence shown in the illustration.

Torque: 178 N*m (1,815 kgf*cm, 132 ft.*lbf)

NOTICE:

Do not start the engine for at least 1 hour after

the installation.

25. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY

(a) 2WD:

Install the automatic transaxle (see page AX-174).

A139490

A129464

A054047E01

A076326E04

A076327E03

Page 682 of 2000

EM–362GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

(b) 4WD:

Install the automatic transaxle (see page AX-175).

26. INSTALL TRANSFER ASSEMBLY (for 4WD) (See

page TF-75)

27. INSTALL STARTER ASSEMBLY (See page ST-14)

28. INSTALL ENGINE WIRE

(a) Install the engine wire to the engine.

29. INSTALL FRONT SUSPENSION CROSSMEMBER

SUB-ASSEMBLY

(a) Attach the engine together with the transaxle to the

suspension crossmember and mounting.

(b) Install the bolt which secures the engine mounting

bracket to the mounting insulator.

Torque: 95 N*m (969 kgf*cm, 70 ft.*lbf)

30. INSTALL FRONT CROSSMEMBER SUB-ASSEMBLY

(a) Install the bolt and nut which secures the engine

mounting bracket to the mounting insulator.

Torque: 145 N*m (1,479 kgf*cm, 107 ft.*lbf)

31. INSTALL ENGINE WITH TRANSAXLE

(a) Place the engine on an engine lifter.

HINT:

Place the engine on wooden blocks or an equivalent

so that the engine is level.

(b) Using the chain block, slowly install the engine to

the vehicle and the intermediate shaft to the pinion.

CAUTION:

Do not raise the engine more than necessary. If

the engine is raised excessively, the vehicle may

also be lifted up.

NOTICE:

• Make sure that the engine is clear of all wiring

and hoses.

A139136E01

A139135

Page 683 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–37

EM

• While raising the engine into the vehicle, do

not allow it to contact the vehicle.

• Align the matchmarks on the intermediate

shaft and pinion.

(c) Temporarily install the suspension member and

crossmember with the 10 bolts.

(d) Temporarily install the member brace rear RH and

LH with the 6 bolts.

(e) Install the engine mounting insulator LH with the bolt

and nut.

Torque: 56 N*m (571 kgf*cm, 41 ft.*lbf)

NOTICE:

While holding the bolt in place, tighten the nut.

(f) Install the engine mounting insulator RH with the 2

bolts and 2 nuts.

Torque: 95 N*m (969 kgf*cm, 70 ft.*lbf) for bolt

and nut A

52 N*m (530 kgf*cm, 38 ft.*lbf) for nut B

A123580

A139134

A137896E01

Page 684 of 2000

EM–382GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

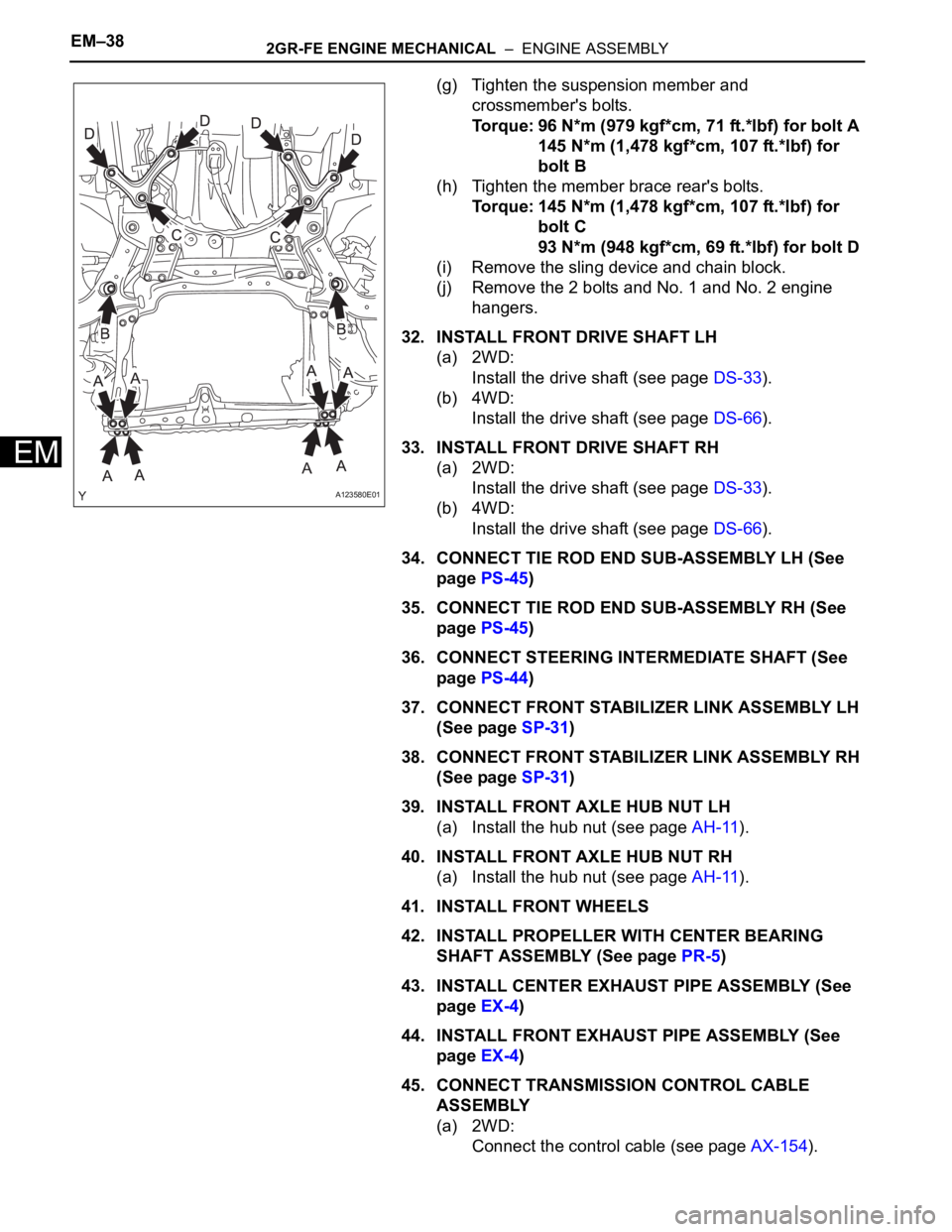

(g) Tighten the suspension member and

crossmember's bolts.

Torque: 96 N*m (979 kgf*cm, 71 ft.*lbf) for bolt A

145 N*m (1,478 kgf*cm, 107 ft.*lbf) for

bolt B

(h) Tighten the member brace rear's bolts.

Torque: 145 N*m (1,478 kgf*cm, 107 ft.*lbf) for

bolt C

93 N*m (948 kgf*cm, 69 ft.*lbf) for bolt D

(i) Remove the sling device and chain block.

(j) Remove the 2 bolts and No. 1 and No. 2 engine

hangers.

32. INSTALL FRONT DRIVE SHAFT LH

(a) 2WD:

Install the drive shaft (see page DS-33).

(b) 4WD:

Install the drive shaft (see page DS-66).

33. INSTALL FRONT DRIVE SHAFT RH

(a) 2WD:

Install the drive shaft (see page DS-33).

(b) 4WD:

Install the drive shaft (see page DS-66).

34. CONNECT TIE ROD END SUB-ASSEMBLY LH (See

page PS-45)

35. CONNECT TIE ROD END SUB-ASSEMBLY RH (See

page PS-45)

36. CONNECT STEERING INTERMEDIATE SHAFT (See

page PS-44)

37. CONNECT FRONT STABILIZER LINK ASSEMBLY LH

(See page SP-31)

38. CONNECT FRONT STABILIZER LINK ASSEMBLY RH

(See page SP-31)

39. INSTALL FRONT AXLE HUB NUT LH

(a) Install the hub nut (see page AH-11).

40. INSTALL FRONT AXLE HUB NUT RH

(a) Install the hub nut (see page AH-11).

41. INSTALL FRONT WHEELS

42. INSTALL PROPELLER WITH CENTER BEARING

SHAFT ASSEMBLY (See page PR-5)

43. INSTALL CENTER EXHAUST PIPE ASSEMBLY (See

page EX-4)

44. INSTALL FRONT EXHAUST PIPE ASSEMBLY (See

page EX-4)

45. CONNECT TRANSMISSION CONTROL CABLE

ASSEMBLY

(a) 2WD:

Connect the control cable (see page AX-154).

A123580E01

Page 685 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–39

EM

(b) 4WD:

Connect the control cable (see page AX-154).

46. CONNECT RADIATOR HOSE INLET

47. CONNECT RADIATOR HOSE OUTLET

48. CONNECT OIL COOLER HOSE

49. CONNECT SUCTION HOSE SUB-ASSEMBLY (See

page AC-221)

50. INSTALL DISCHARGE HOSE SUB-ASSEMBLY (See

page AC-221)

51. INSTALL RADIATOR RESERVOIR TANK ASSEMBLY

(a) Install the reservoir tank with the 2 bolts.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

(b) Connect the 2 hoses

52. INSTALL ECM (See page ES-471)

53. CONNECT HOSES AND CONNECTORS

(a) Connect the 2 ECM connectors.

(b) Connect the 2 heater hoses.

(c) Connect the fuel hoses.

(d) Connect the starter wire with the nut.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

(e) Connect the 3 connectors and wire with the nut.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

(f) Install the engine room junction block cover (upper).

54. INSTALL AIR CLEANER CASE

(a) Install the air cleaner case with the 3 bolts.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

(b) Connect the harness clamp.

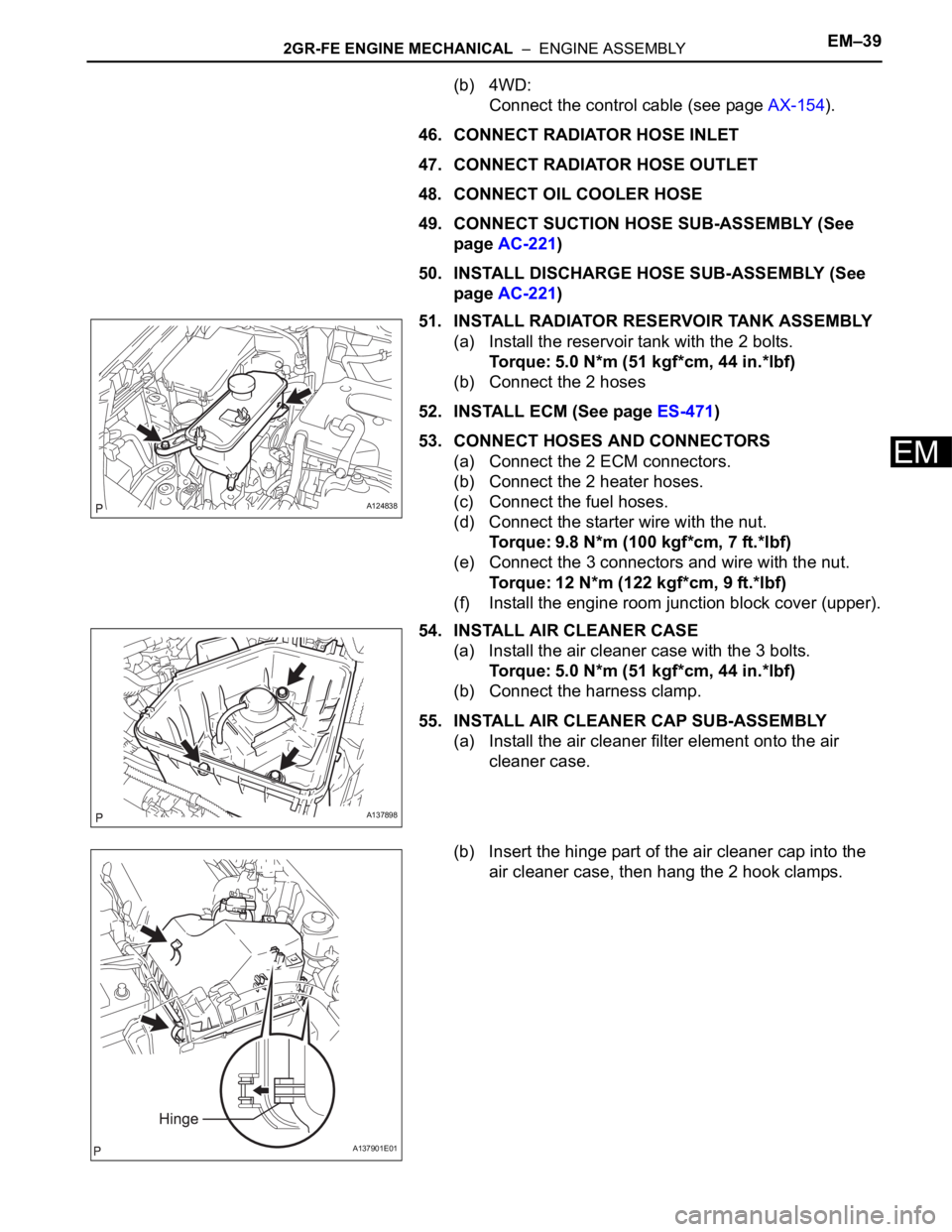

55. INSTALL AIR CLEANER CAP SUB-ASSEMBLY

(a) Install the air cleaner filter element onto the air

cleaner case.

(b) Insert the hinge part of the air cleaner cap into the

air cleaner case, then hang the 2 hook clamps.

A124838

A137898

A137901E01