engine TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 706 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–69

EM

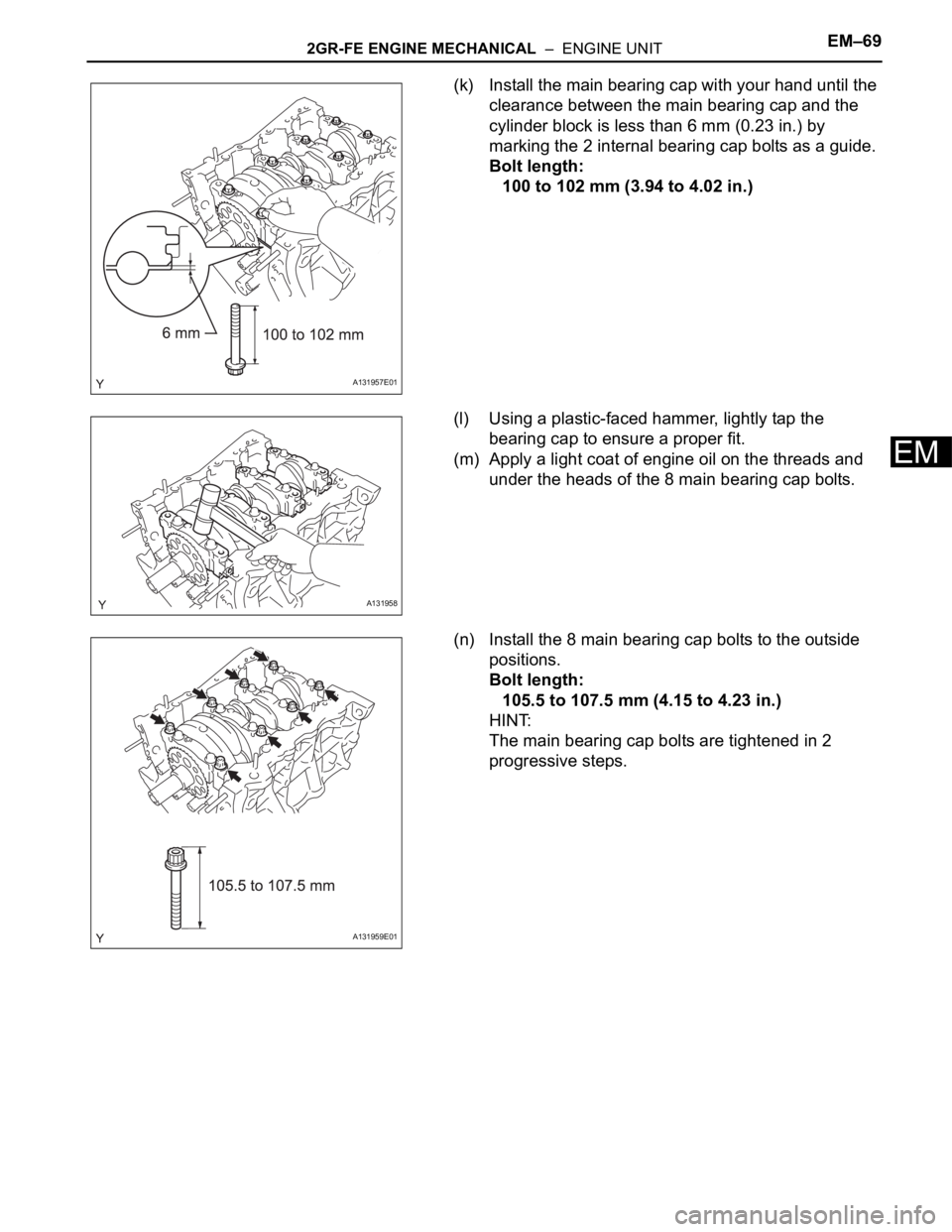

(k) Install the main bearing cap with your hand until the

clearance between the main bearing cap and the

cylinder block is less than 6 mm (0.23 in.) by

marking the 2 internal bearing cap bolts as a guide.

Bolt length:

100 to 102 mm (3.94 to 4.02 in.)

(l) Using a plastic-faced hammer, lightly tap the

bearing cap to ensure a proper fit.

(m) Apply a light coat of engine oil on the threads and

under the heads of the 8 main bearing cap bolts.

(n) Install the 8 main bearing cap bolts to the outside

positions.

Bolt length:

105.5 to 107.5 mm (4.15 to 4.23 in.)

HINT:

The main bearing cap bolts are tightened in 2

progressive steps.

A131957E01

A131958

A131959E01

Page 707 of 2000

EM–702GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

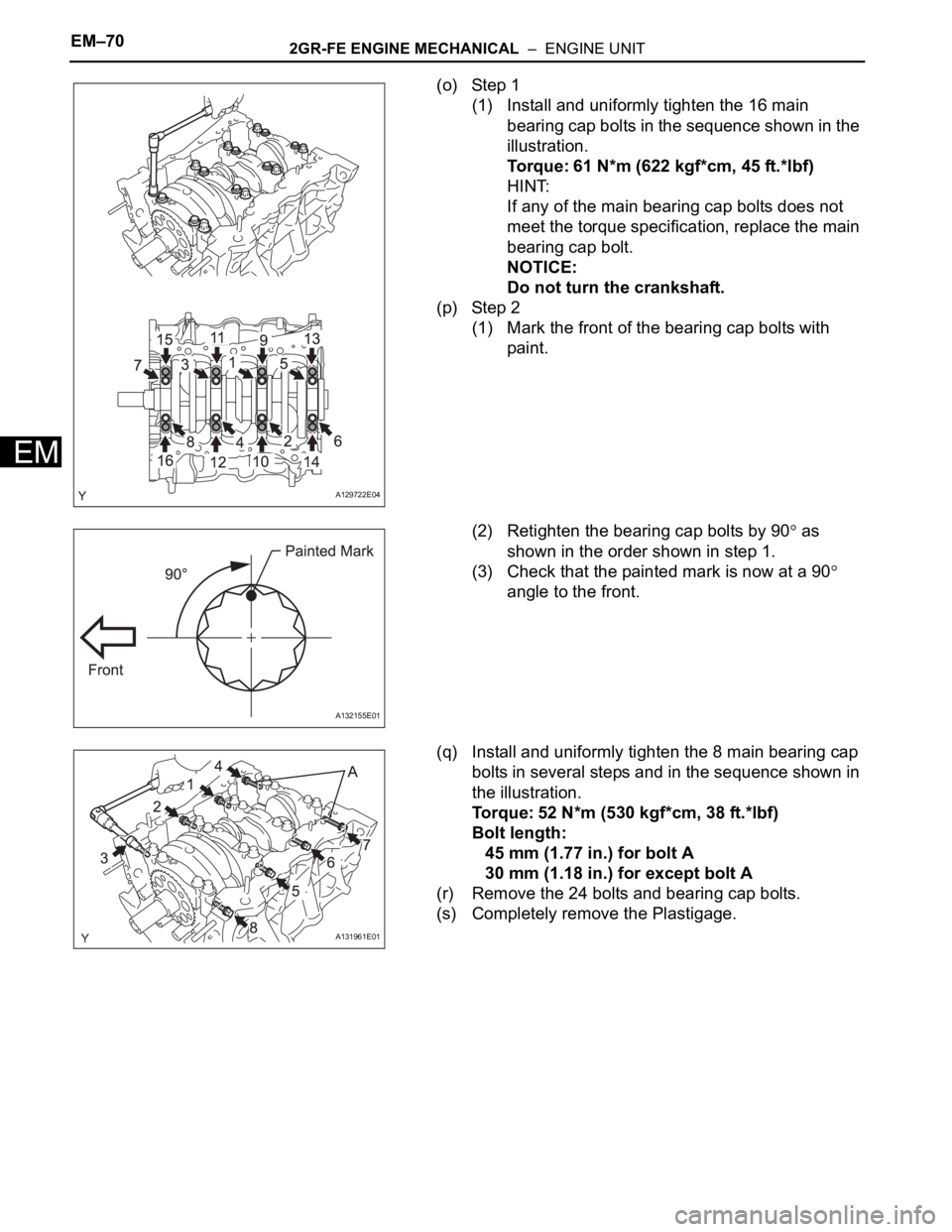

(o) Step 1

(1) Install and uniformly tighten the 16 main

bearing cap bolts in the sequence shown in the

illustration.

Torque: 61 N*m (622 kgf*cm, 45 ft.*lbf)

HINT:

If any of the main bearing cap bolts does not

meet the torque specification, replace the main

bearing cap bolt.

NOTICE:

Do not turn the crankshaft.

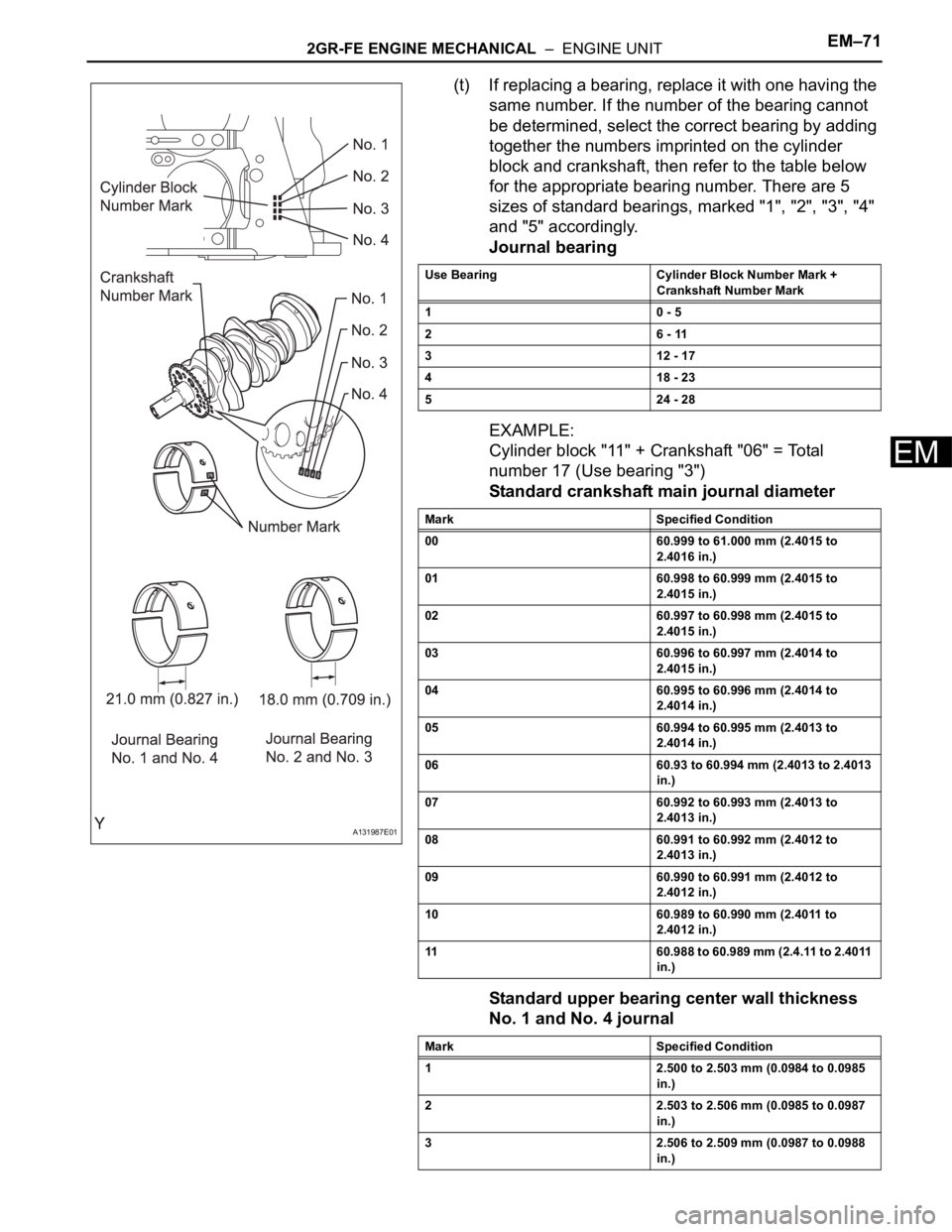

(p) Step 2

(1) Mark the front of the bearing cap bolts with

paint.

(2) Retighten the bearing cap bolts by 90

as

shown in the order shown in step 1.

(3) Check that the painted mark is now at a 90

angle to the front.

(q) Install and uniformly tighten the 8 main bearing cap

bolts in several steps and in the sequence shown in

the illustration.

Torque: 52 N*m (530 kgf*cm, 38 ft.*lbf)

Bolt length:

45 mm (1.77 in.) for bolt A

30 mm (1.18 in.) for except bolt A

(r) Remove the 24 bolts and bearing cap bolts.

(s) Completely remove the Plastigage.

A129722E04

A132155E01

A131961E01

Page 708 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–71

EM

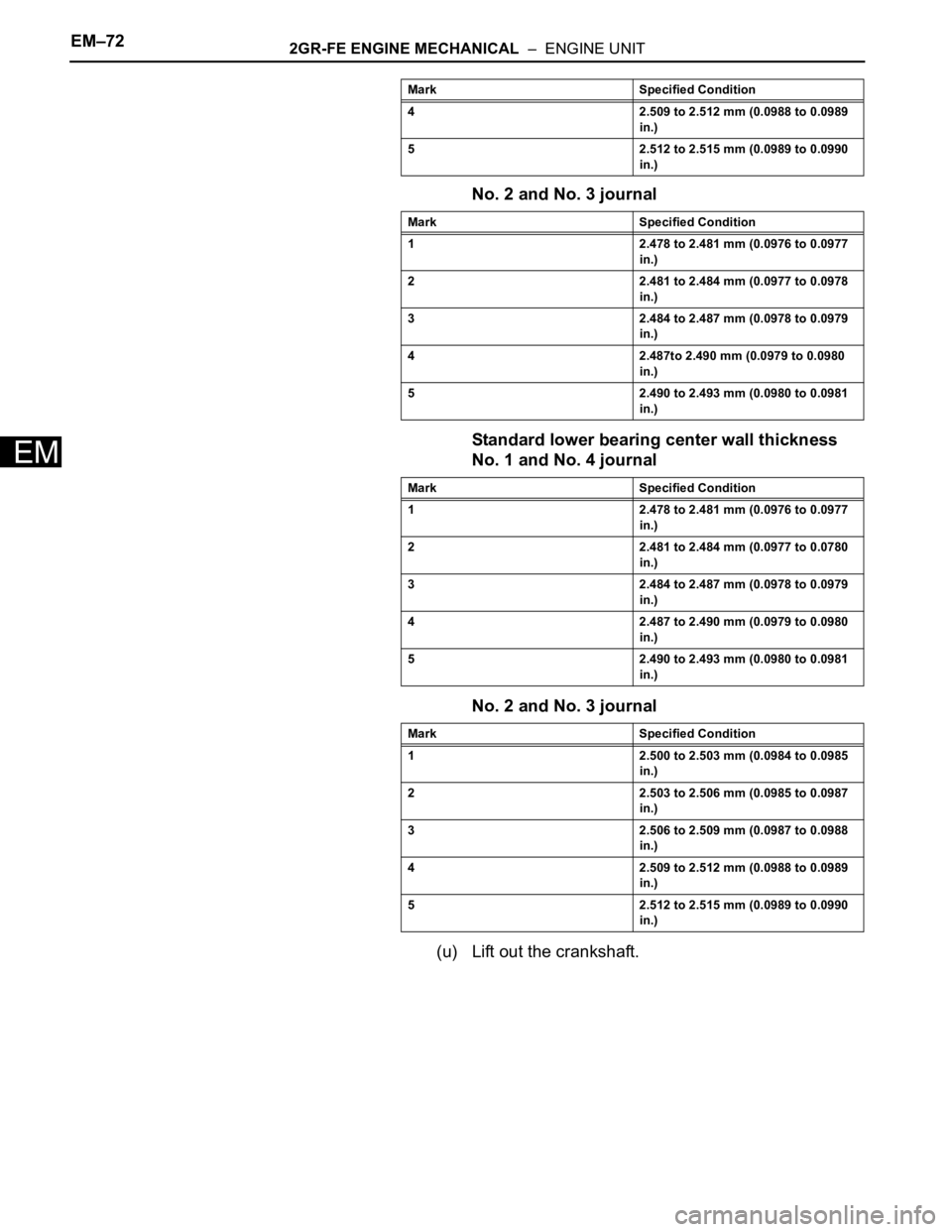

(t) If replacing a bearing, replace it with one having the

same number. If the number of the bearing cannot

be determined, select the correct bearing by adding

together the numbers imprinted on the cylinder

block and crankshaft, then refer to the table below

for the appropriate bearing number. There are 5

sizes of standard bearings, marked "1", "2", "3", "4"

and "5" accordingly.

Journal bearing

EXAMPLE:

Cylinder block "11" + Crankshaft "06" = Total

number 17 (Use bearing "3")

Standard crankshaft main journal diameter

Standard upper bearing center wall thickness

No. 1 and No. 4 journal

A131987E01

Use Bearing Cylinder Block Number Mark +

Crankshaft Number Mark

1 0 - 5

2 6 - 11

312 - 17

418 - 23

524 - 28

Mark Specified Condition

00 60.999 to 61.000 mm (2.4015 to

2.4016 in.)

01 60.998 to 60.999 mm (2.4015 to

2.4015 in.)

02 60.997 to 60.998 mm (2.4015 to

2.4015 in.)

03 60.996 to 60.997 mm (2.4014 to

2.4015 in.)

04 60.995 to 60.996 mm (2.4014 to

2.4014 in.)

05 60.994 to 60.995 mm (2.4013 to

2.4014 in.)

06 60.93 to 60.994 mm (2.4013 to 2.4013

in.)

07 60.992 to 60.993 mm (2.4013 to

2.4013 in.)

08 60.991 to 60.992 mm (2.4012 to

2.4013 in.)

09 60.990 to 60.991 mm (2.4012 to

2.4012 in.)

10 60.989 to 60.990 mm (2.4011 to

2.4012 in.)

11 60.988 to 60.989 mm (2.4.11 to 2.4011

in.)

Mark Specified Condition

1 2.500 to 2.503 mm (0.0984 to 0.0985

in.)

2 2.503 to 2.506 mm (0.0985 to 0.0987

in.)

3 2.506 to 2.509 mm (0.0987 to 0.0988

in.)

Page 709 of 2000

EM–722GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

No. 2 and No. 3 journal

Standard lower bearing center wall thickness

No. 1 and No. 4 journal

No. 2 and No. 3 journal

(u) Lift out the crankshaft.

4 2.509 to 2.512 mm (0.0988 to 0.0989

in.)

5 2.512 to 2.515 mm (0.0989 to 0.0990

in.)

Mark Specified Condition

1 2.478 to 2.481 mm (0.0976 to 0.0977

in.)

2 2.481 to 2.484 mm (0.0977 to 0.0978

in.)

3 2.484 to 2.487 mm (0.0978 to 0.0979

in.)

4 2.487to 2.490 mm (0.0979 to 0.0980

in.)

5 2.490 to 2.493 mm (0.0980 to 0.0981

in.)

Mark Specified Condition

1 2.478 to 2.481 mm (0.0976 to 0.0977

in.)

2 2.481 to 2.484 mm (0.0977 to 0.0780

in.)

3 2.484 to 2.487 mm (0.0978 to 0.0979

in.)

4 2.487 to 2.490 mm (0.0979 to 0.0980

in.)

5 2.490 to 2.493 mm (0.0980 to 0.0981

in.)

Mark Specified Condition

1 2.500 to 2.503 mm (0.0984 to 0.0985

in.)

2 2.503 to 2.506 mm (0.0985 to 0.0987

in.)

3 2.506 to 2.509 mm (0.0987 to 0.0988

in.)

4 2.509 to 2.512 mm (0.0988 to 0.0989

in.)

5 2.512 to 2.515 mm (0.0989 to 0.0990

in.) Mark Specified Condition

Page 710 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–73

EM

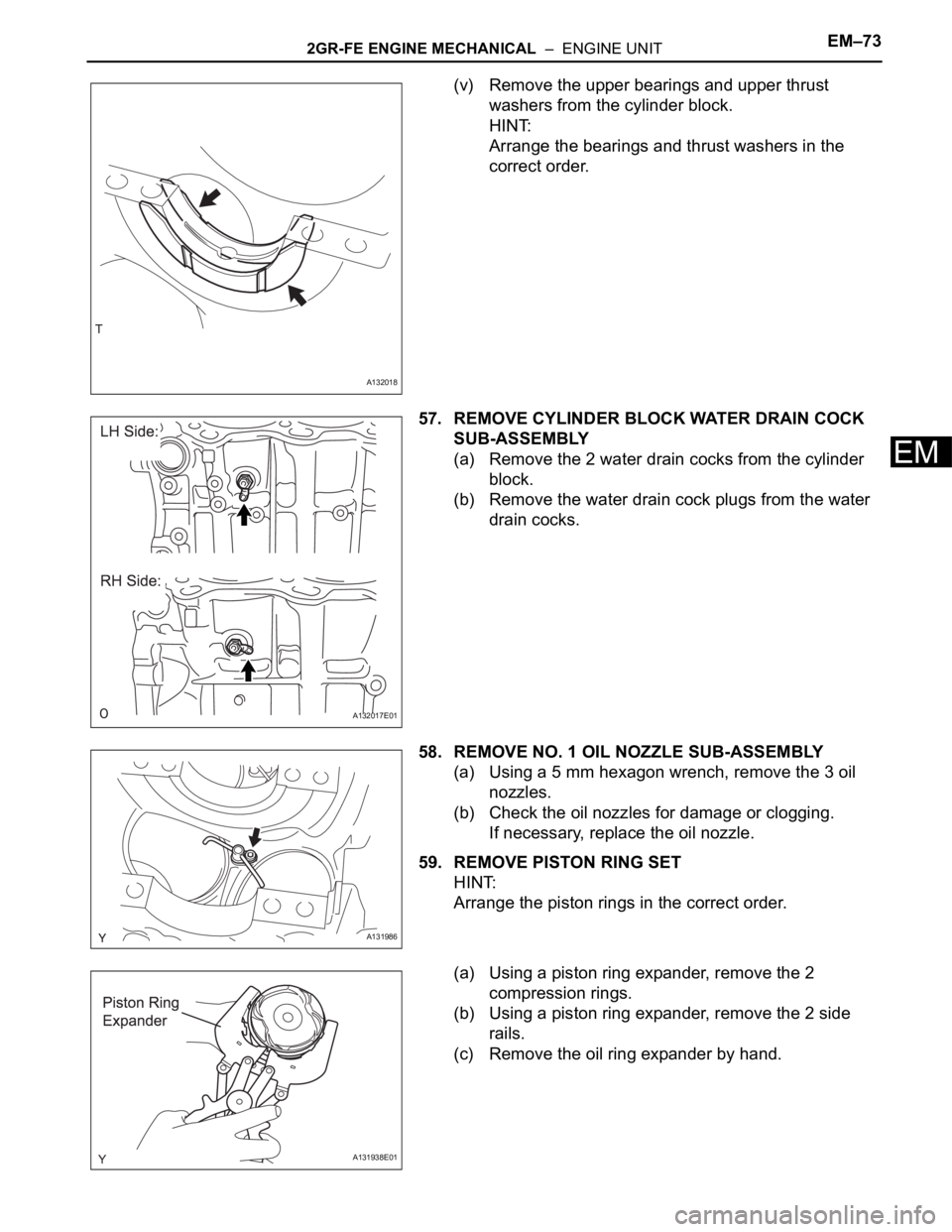

(v) Remove the upper bearings and upper thrust

washers from the cylinder block.

HINT:

Arrange the bearings and thrust washers in the

correct order.

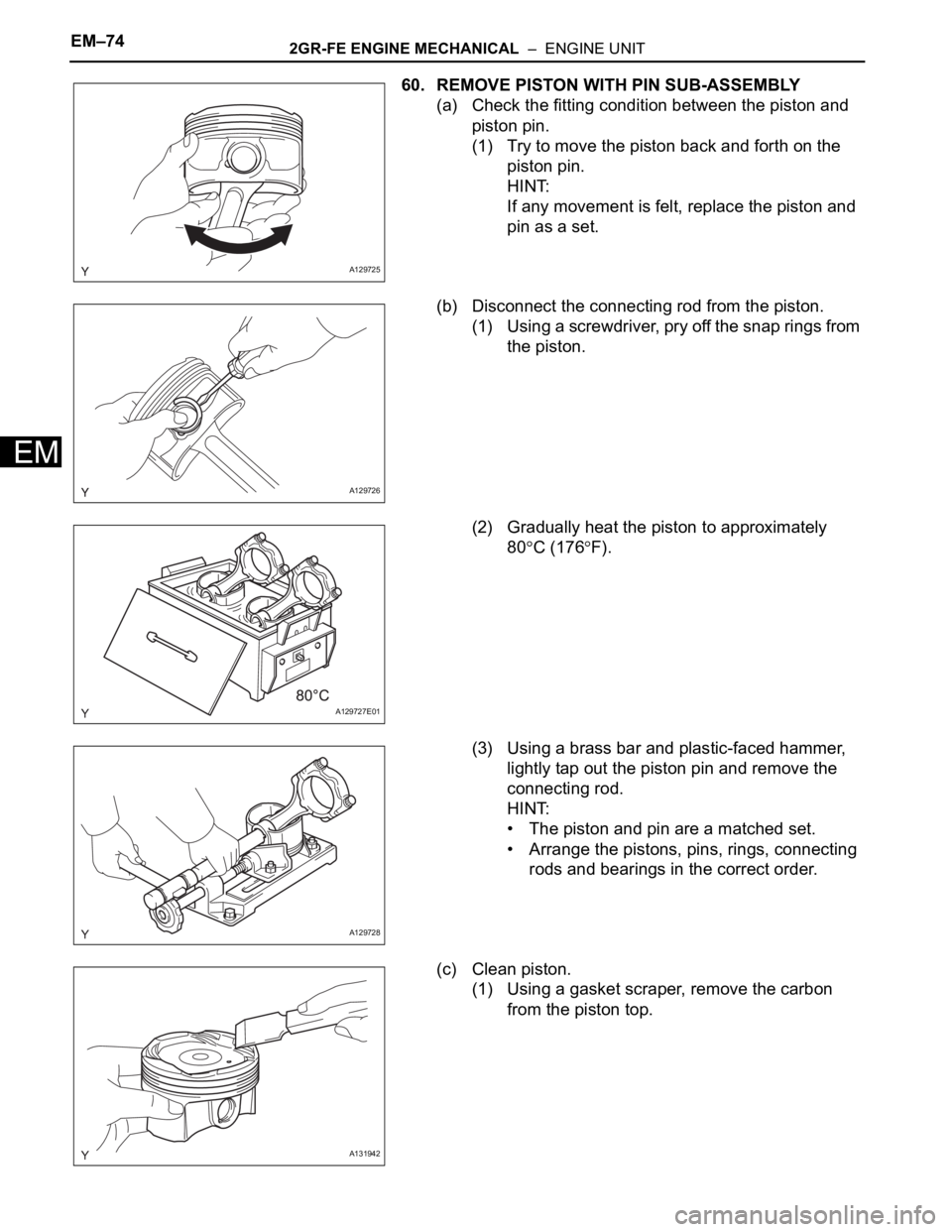

57. REMOVE CYLINDER BLOCK WATER DRAIN COCK

SUB-ASSEMBLY

(a) Remove the 2 water drain cocks from the cylinder

block.

(b) Remove the water drain cock plugs from the water

drain cocks.

58. REMOVE NO. 1 OIL NOZZLE SUB-ASSEMBLY

(a) Using a 5 mm hexagon wrench, remove the 3 oil

nozzles.

(b) Check the oil nozzles for damage or clogging.

If necessary, replace the oil nozzle.

59. REMOVE PISTON RING SET

HINT:

Arrange the piston rings in the correct order.

(a) Using a piston ring expander, remove the 2

compression rings.

(b) Using a piston ring expander, remove the 2 side

rails.

(c) Remove the oil ring expander by hand.

A132018

A132017E01

A131986

A131938E01

Page 711 of 2000

EM–742GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

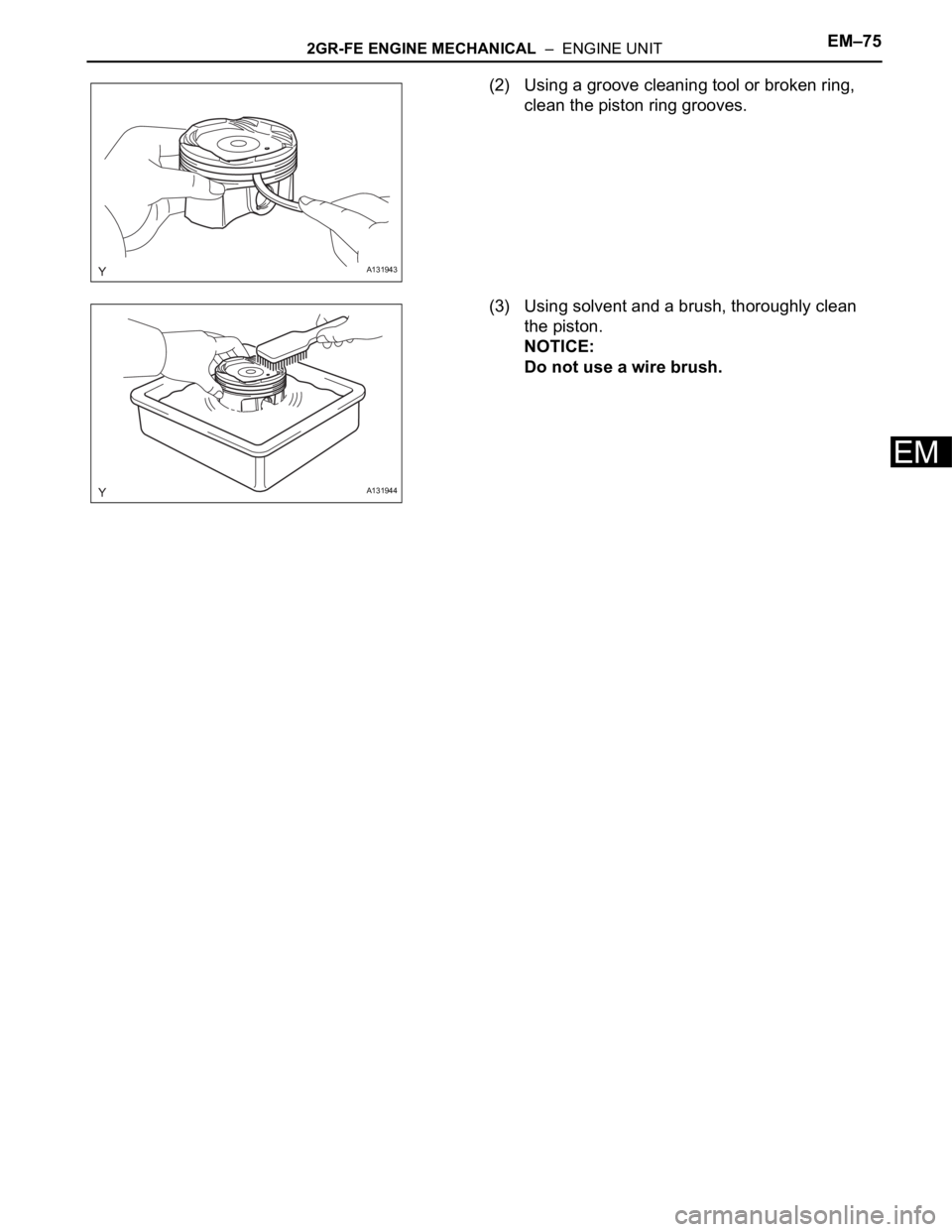

60. REMOVE PISTON WITH PIN SUB-ASSEMBLY

(a) Check the fitting condition between the piston and

piston pin.

(1) Try to move the piston back and forth on the

piston pin.

HINT:

If any movement is felt, replace the piston and

pin as a set.

(b) Disconnect the connecting rod from the piston.

(1) Using a screwdriver, pry off the snap rings from

the piston.

(2) Gradually heat the piston to approximately

80

C (176F).

(3) Using a brass bar and plastic-faced hammer,

lightly tap out the piston pin and remove the

connecting rod.

HINT:

• The piston and pin are a matched set.

• Arrange the pistons, pins, rings, connecting

rods and bearings in the correct order.

(c) Clean piston.

(1) Using a gasket scraper, remove the carbon

from the piston top.

A129725

A129726

A129727E01

A129728

A131942

Page 712 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–75

EM

(2) Using a groove cleaning tool or broken ring,

clean the piston ring grooves.

(3) Using solvent and a brush, thoroughly clean

the piston.

NOTICE:

Do not use a wire brush.

A131943

A131944

Page 713 of 2000

EM–762GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

INSPECTION

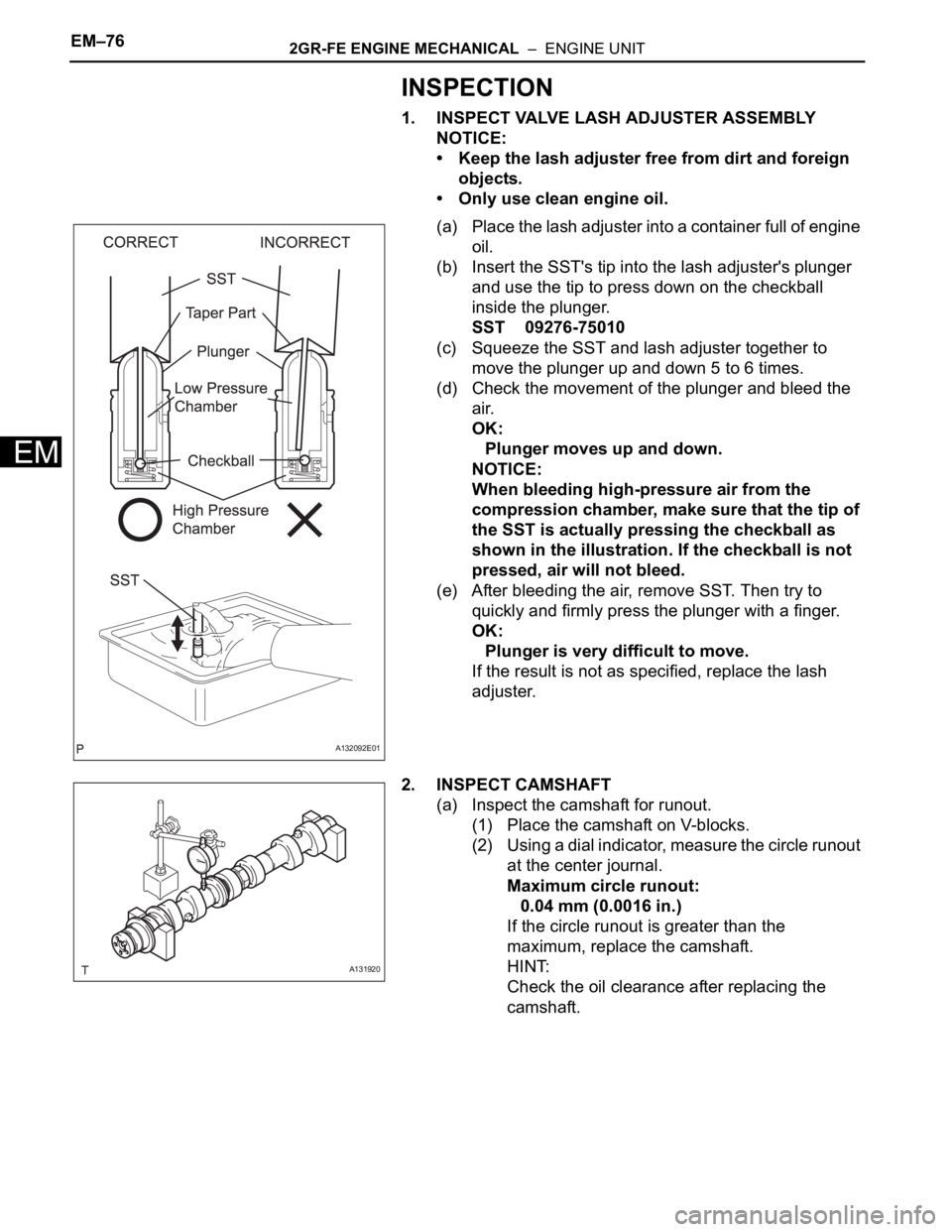

1. INSPECT VALVE LASH ADJUSTER ASSEMBLY

NOTICE:

• Keep the lash adjuster free from dirt and foreign

objects.

• Only use clean engine oil.

(a) Place the lash adjuster into a container full of engine

oil.

(b) Insert the SST's tip into the lash adjuster's plunger

and use the tip to press down on the checkball

inside the plunger.

SST 09276-75010

(c) Squeeze the SST and lash adjuster together to

move the plunger up and down 5 to 6 times.

(d) Check the movement of the plunger and bleed the

air.

OK:

Plunger moves up and down.

NOTICE:

When bleeding high-pressure air from the

compression chamber, make sure that the tip of

the SST is actually pressing the checkball as

shown in the illustration. If the checkball is not

pressed, air will not bleed.

(e) After bleeding the air, remove SST. Then try to

quickly and firmly press the plunger with a finger.

OK:

Plunger is very difficult to move.

If the result is not as specified, replace the lash

adjuster.

2. INSPECT CAMSHAFT

(a) Inspect the camshaft for runout.

(1) Place the camshaft on V-blocks.

(2) Using a dial indicator, measure the circle runout

at the center journal.

Maximum circle runout:

0.04 mm (0.0016 in.)

If the circle runout is greater than the

maximum, replace the camshaft.

HINT:

Check the oil clearance after replacing the

camshaft.

A132092E01

A131920

Page 714 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–77

EM

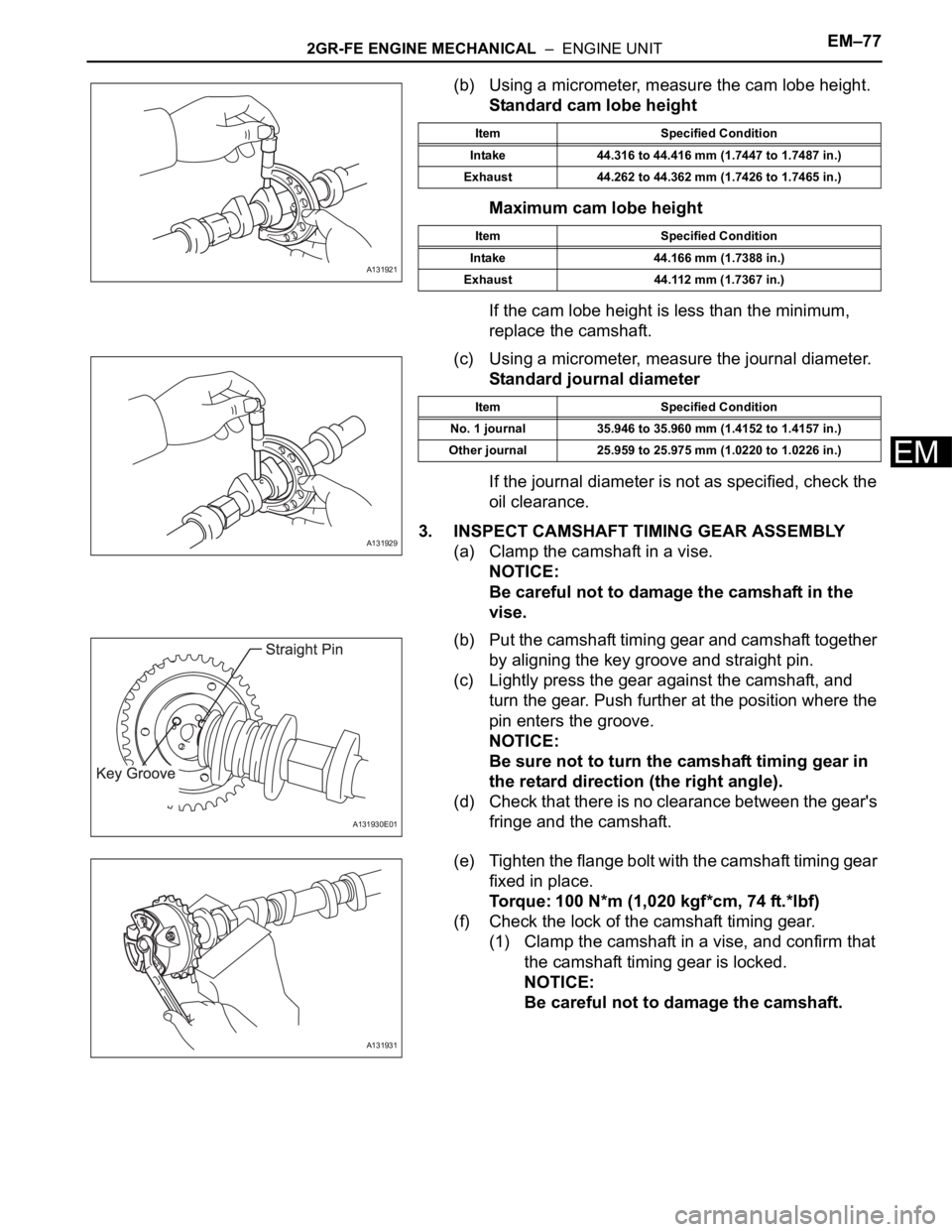

(b) Using a micrometer, measure the cam lobe height.

Standard cam lobe height

Maximum cam lobe height

If the cam lobe height is less than the minimum,

replace the camshaft.

(c) Using a micrometer, measure the journal diameter.

Standard journal diameter

If the journal diameter is not as specified, check the

oil clearance.

3. INSPECT CAMSHAFT TIMING GEAR ASSEMBLY

(a) Clamp the camshaft in a vise.

NOTICE:

Be careful not to damage the camshaft in the

vise.

(b) Put the camshaft timing gear and camshaft together

by aligning the key groove and straight pin.

(c) Lightly press the gear against the camshaft, and

turn the gear. Push further at the position where the

pin enters the groove.

NOTICE:

Be sure not to turn the camshaft timing gear in

the retard direction (the right angle).

(d) Check that there is no clearance between the gear's

fringe and the camshaft.

(e) Tighten the flange bolt with the camshaft timing gear

fixed in place.

Torque: 100 N*m (1,020 kgf*cm, 74 ft.*lbf)

(f) Check the lock of the camshaft timing gear.

(1) Clamp the camshaft in a vise, and confirm that

the camshaft timing gear is locked.

NOTICE:

Be careful not to damage the camshaft.

A131921

Item Specified Condition

Intake 44.316 to 44.416 mm (1.7447 to 1.7487 in.)

Exhaust 44.262 to 44.362 mm (1.7426 to 1.7465 in.)

Item Specified Condition

Intake 44.166 mm (1.7388 in.)

Exhaust 44.112 mm (1.7367 in.)

A131929

Item Specified Condition

No. 1 journal 35.946 to 35.960 mm (1.4152 to 1.4157 in.)

Other journal 25.959 to 25.975 mm (1.0220 to 1.0226 in.)

A131930E01

A131931

Page 715 of 2000

EM–782GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

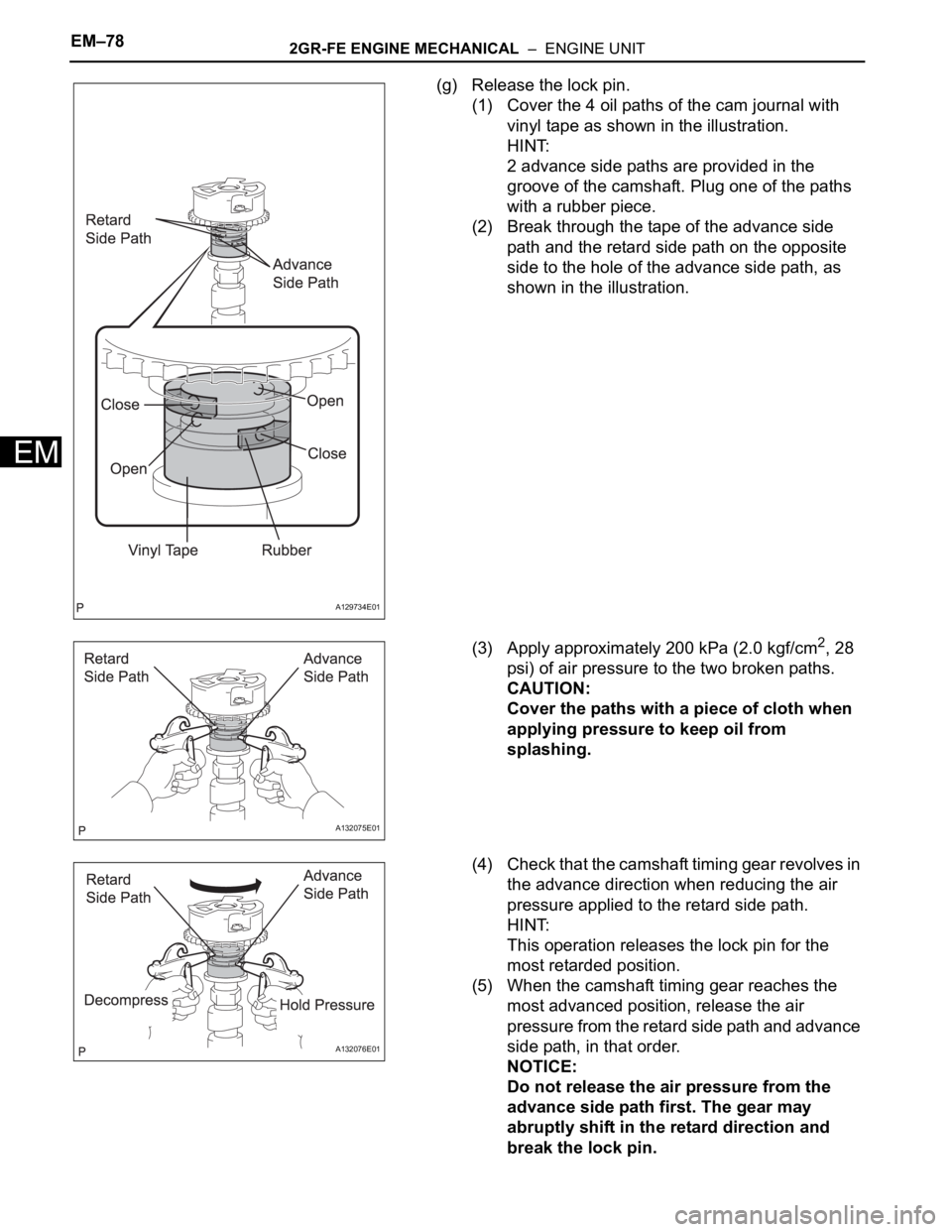

(g) Release the lock pin.

(1) Cover the 4 oil paths of the cam journal with

vinyl tape as shown in the illustration.

HINT:

2 advance side paths are provided in the

groove of the camshaft. Plug one of the paths

with a rubber piece.

(2) Break through the tape of the advance side

path and the retard side path on the opposite

side to the hole of the advance side path, as

shown in the illustration.

(3) Apply approximately 200 kPa (2.0 kgf/cm

2, 28

psi) of air pressure to the two broken paths.

CAUTION:

Cover the paths with a piece of cloth when

applying pressure to keep oil from

splashing.

(4) Check that the camshaft timing gear revolves in

the advance direction when reducing the air

pressure applied to the retard side path.

HINT:

This operation releases the lock pin for the

most retarded position.

(5) When the camshaft timing gear reaches the

most advanced position, release the air

pressure from the retard side path and advance

side path, in that order.

NOTICE:

Do not release the air pressure from the

advance side path first. The gear may

abruptly shift in the retard direction and

break the lock pin.

A129734E01

A132075E01

A132076E01