engine TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 716 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–79

EM

(h) Check for smooth rotation.

(1) Turn the camshaft timing gear within its

movable range (21

) 2 or 3 times, but do not

turn it to the most retarded position. Make sure

that the gear turns smoothly.

NOTICE:

Do not use air pressure to perform the

smooth rotation check.

(i) Check the lock in the most retarded position.

(1) Confirm that the camshaft timing gear is locked

at the most retarded position.

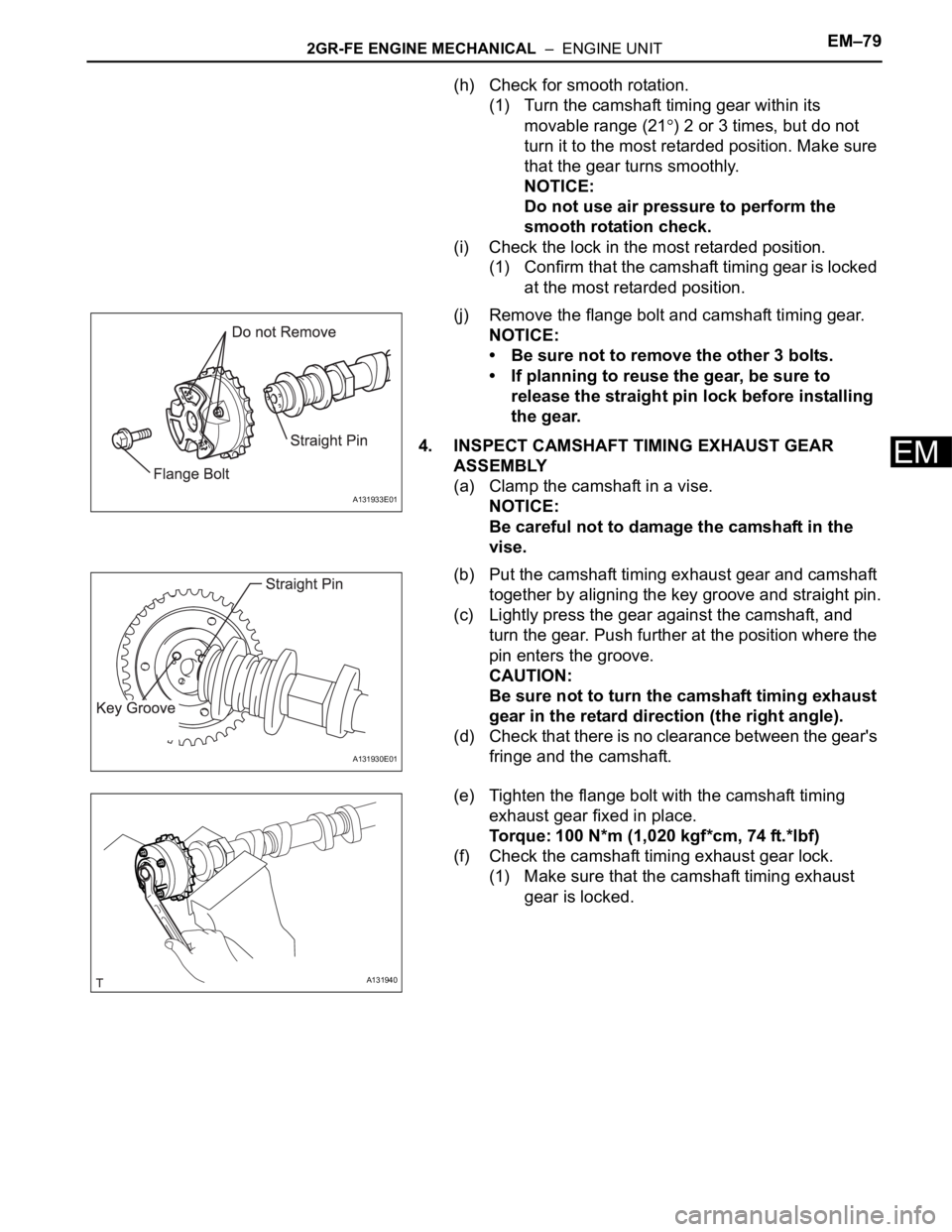

(j) Remove the flange bolt and camshaft timing gear.

NOTICE:

• Be sure not to remove the other 3 bolts.

• If planning to reuse the gear, be sure to

release the straight pin lock before installing

the gear.

4. INSPECT CAMSHAFT TIMING EXHAUST GEAR

ASSEMBLY

(a) Clamp the camshaft in a vise.

NOTICE:

Be careful not to damage the camshaft in the

vise.

(b) Put the camshaft timing exhaust gear and camshaft

together by aligning the key groove and straight pin.

(c) Lightly press the gear against the camshaft, and

turn the gear. Push further at the position where the

pin enters the groove.

CAUTION:

Be sure not to turn the camshaft timing exhaust

gear in the retard direction (the right angle).

(d) Check that there is no clearance between the gear's

fringe and the camshaft.

(e) Tighten the flange bolt with the camshaft timing

exhaust gear fixed in place.

Torque: 100 N*m (1,020 kgf*cm, 74 ft.*lbf)

(f) Check the camshaft timing exhaust gear lock.

(1) Make sure that the camshaft timing exhaust

gear is locked.

A131933E01

A131930E01

A131940

Page 717 of 2000

EM–802GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

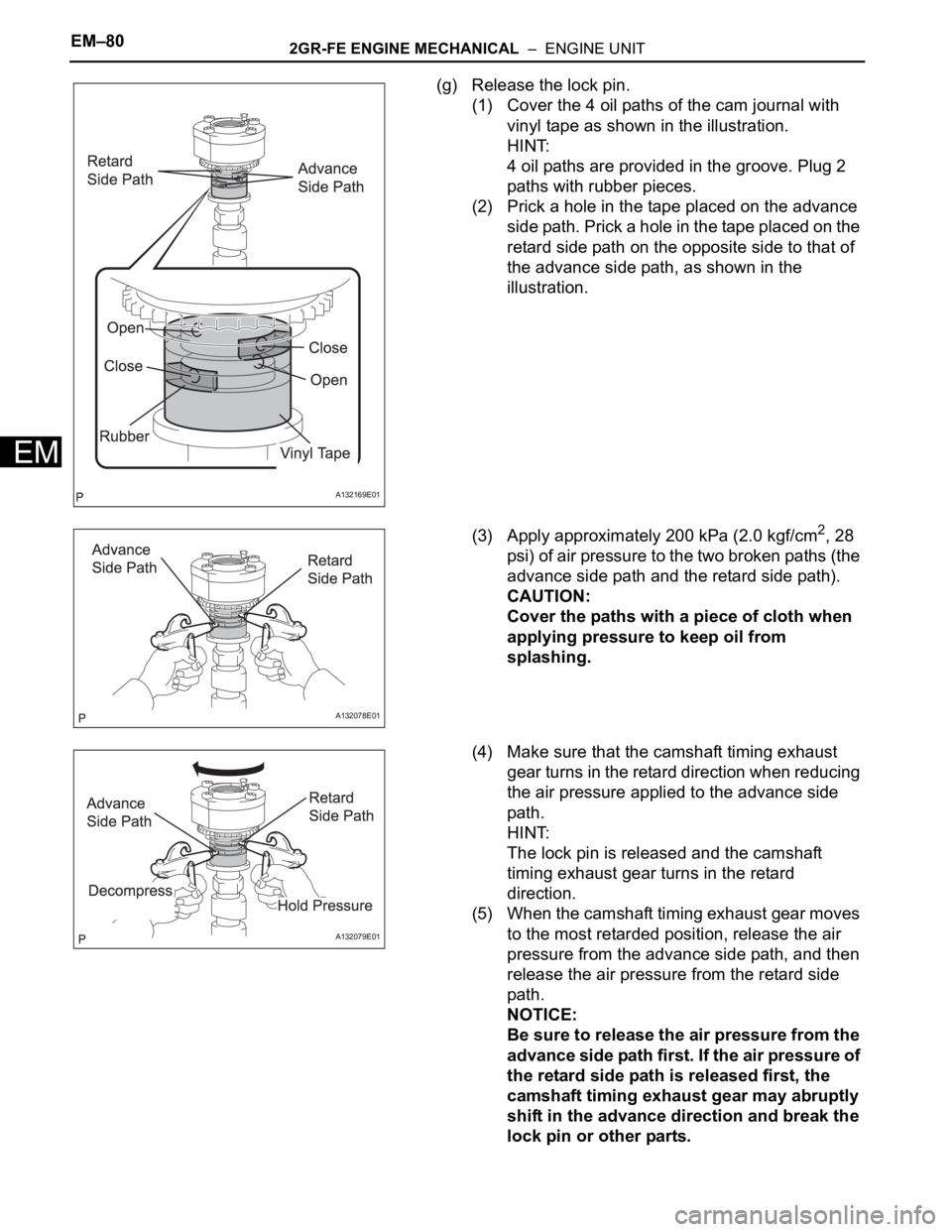

(g) Release the lock pin.

(1) Cover the 4 oil paths of the cam journal with

vinyl tape as shown in the illustration.

HINT:

4 oil paths are provided in the groove. Plug 2

paths with rubber pieces.

(2) Prick a hole in the tape placed on the advance

side path. Prick a hole in the tape placed on the

retard side path on the opposite side to that of

the advance side path, as shown in the

illustration.

(3) Apply approximately 200 kPa (2.0 kgf/cm

2, 28

psi) of air pressure to the two broken paths (the

advance side path and the retard side path).

CAUTION:

Cover the paths with a piece of cloth when

applying pressure to keep oil from

splashing.

(4) Make sure that the camshaft timing exhaust

gear turns in the retard direction when reducing

the air pressure applied to the advance side

path.

HINT:

The lock pin is released and the camshaft

timing exhaust gear turns in the retard

direction.

(5) When the camshaft timing exhaust gear moves

to the most retarded position, release the air

pressure from the advance side path, and then

release the air pressure from the retard side

path.

NOTICE:

Be sure to release the air pressure from the

advance side path first. If the air pressure of

the retard side path is released first, the

camshaft timing exhaust gear may abruptly

shift in the advance direction and break the

lock pin or other parts.

A132169E01

A132078E01

A132079E01

Page 718 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–81

EM

(h) Check for smooth rotation.

(1) Turn the camshaft timing exhaust gear within

its movable range (18.5

) 2 or 3 times, but do

not turn it to the most advanced position. Make

sure that the gear turns smoothly.

NOTICE:

When the air pressure is released from the

advance side path and then from the retard

side path, the gear automatically returns to

the most advanced position due to the

advance assist spring operation and locks.

Gradually release the air pressure from the

retard side path before performing the

smooth rotation check.

(i) Check the lock at the most advanced position.

(1) Make sure that the camshaft timing exhaust

gear is locked at the most advanced position.

(j) Remove the flange bolt and camshaft timing

exhaust gear.

NOTICE:

• Be sure not to remove the other 3 bolts.

• If planning to reuse the gear, be sure to

release the straight pin lock before installing

the gear.

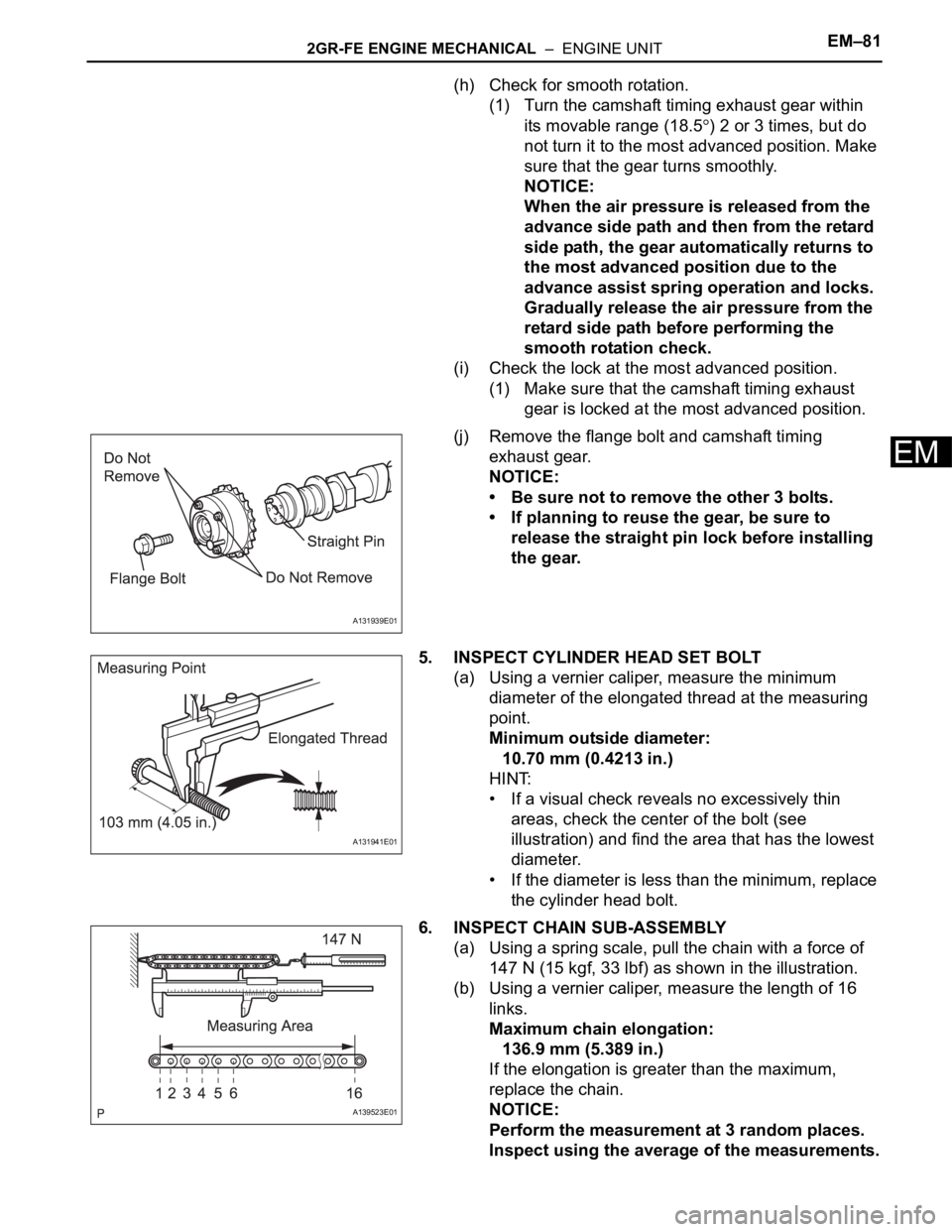

5. INSPECT CYLINDER HEAD SET BOLT

(a) Using a vernier caliper, measure the minimum

diameter of the elongated thread at the measuring

point.

Minimum outside diameter:

10.70 mm (0.4213 in.)

HINT:

• If a visual check reveals no excessively thin

areas, check the center of the bolt (see

illustration) and find the area that has the lowest

diameter.

• If the diameter is less than the minimum, replace

the cylinder head bolt.

6. INSPECT CHAIN SUB-ASSEMBLY

(a) Using a spring scale, pull the chain with a force of

147 N (15 kgf, 33 lbf) as shown in the illustration.

(b) Using a vernier caliper, measure the length of 16

links.

Maximum chain elongation:

136.9 mm (5.389 in.)

If the elongation is greater than the maximum,

replace the chain.

NOTICE:

Perform the measurement at 3 random places.

Inspect using the average of the measurements.

A131939E01

A131941E01

A139523E01

Page 719 of 2000

EM–822GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

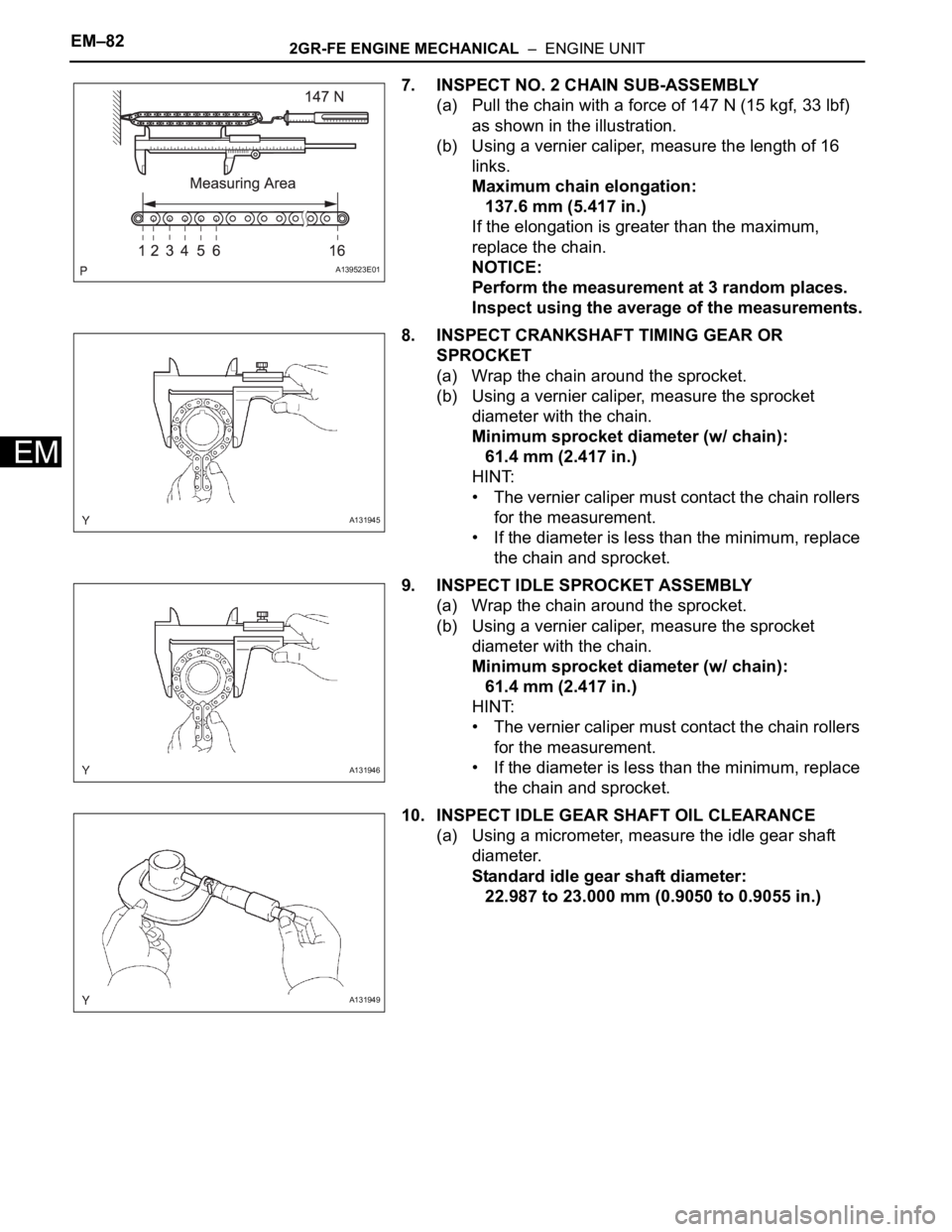

7. INSPECT NO. 2 CHAIN SUB-ASSEMBLY

(a) Pull the chain with a force of 147 N (15 kgf, 33 lbf)

as shown in the illustration.

(b) Using a vernier caliper, measure the length of 16

links.

Maximum chain elongation:

137.6 mm (5.417 in.)

If the elongation is greater than the maximum,

replace the chain.

NOTICE:

Perform the measurement at 3 random places.

Inspect using the average of the measurements.

8. INSPECT CRANKSHAFT TIMING GEAR OR

SPROCKET

(a) Wrap the chain around the sprocket.

(b) Using a vernier caliper, measure the sprocket

diameter with the chain.

Minimum sprocket diameter (w/ chain):

61.4 mm (2.417 in.)

HINT:

• The vernier caliper must contact the chain rollers

for the measurement.

• If the diameter is less than the minimum, replace

the chain and sprocket.

9. INSPECT IDLE SPROCKET ASSEMBLY

(a) Wrap the chain around the sprocket.

(b) Using a vernier caliper, measure the sprocket

diameter with the chain.

Minimum sprocket diameter (w/ chain):

61.4 mm (2.417 in.)

HINT:

• The vernier caliper must contact the chain rollers

for the measurement.

• If the diameter is less than the minimum, replace

the chain and sprocket.

10. INSPECT IDLE GEAR SHAFT OIL CLEARANCE

(a) Using a micrometer, measure the idle gear shaft

diameter.

Standard idle gear shaft diameter:

22.987 to 23.000 mm (0.9050 to 0.9055 in.)

A139523E01

A131945

A131946

A131949

Page 720 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–83

EM

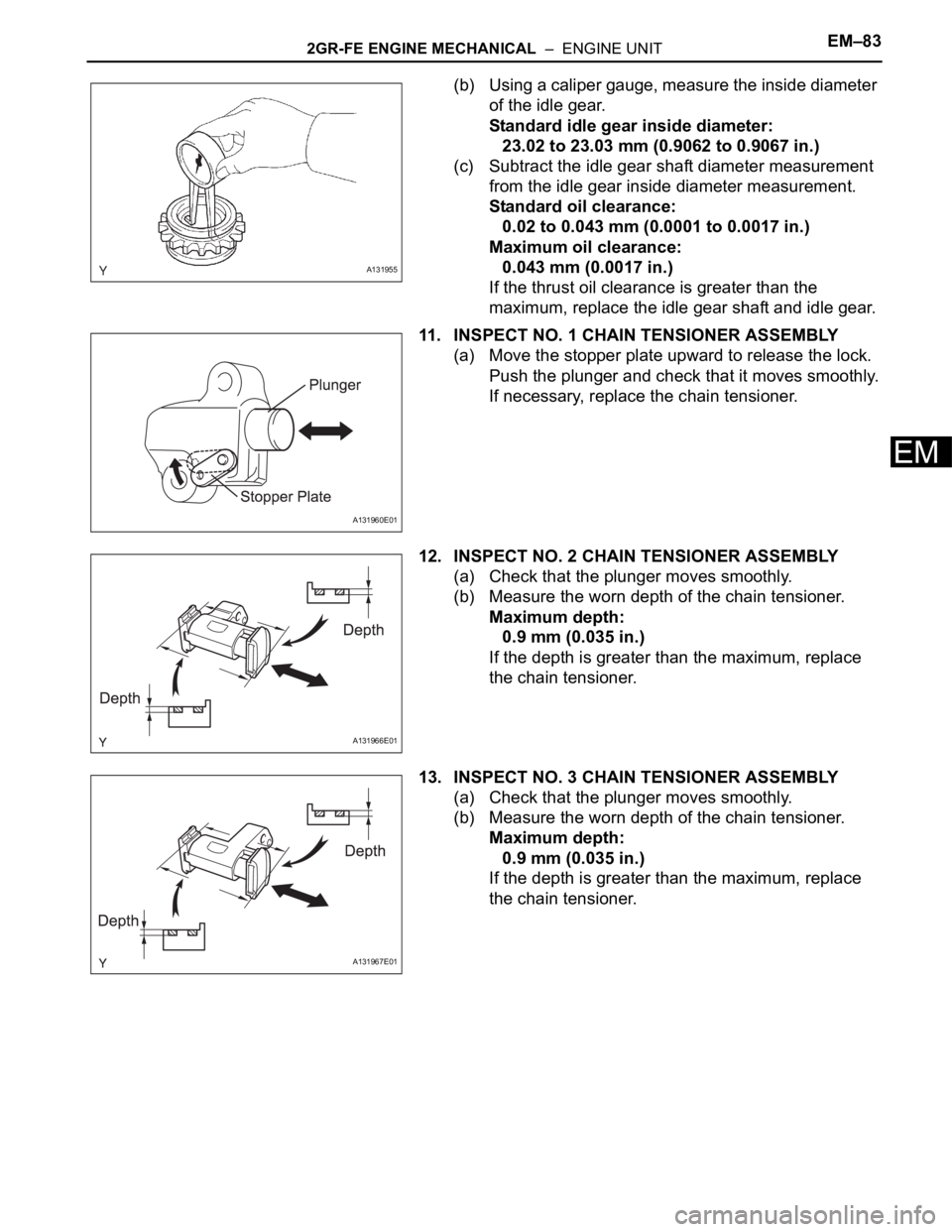

(b) Using a caliper gauge, measure the inside diameter

of the idle gear.

Standard idle gear inside diameter:

23.02 to 23.03 mm (0.9062 to 0.9067 in.)

(c) Subtract the idle gear shaft diameter measurement

from the idle gear inside diameter measurement.

Standard oil clearance:

0.02 to 0.043 mm (0.0001 to 0.0017 in.)

Maximum oil clearance:

0.043 mm (0.0017 in.)

If the thrust oil clearance is greater than the

maximum, replace the idle gear shaft and idle gear.

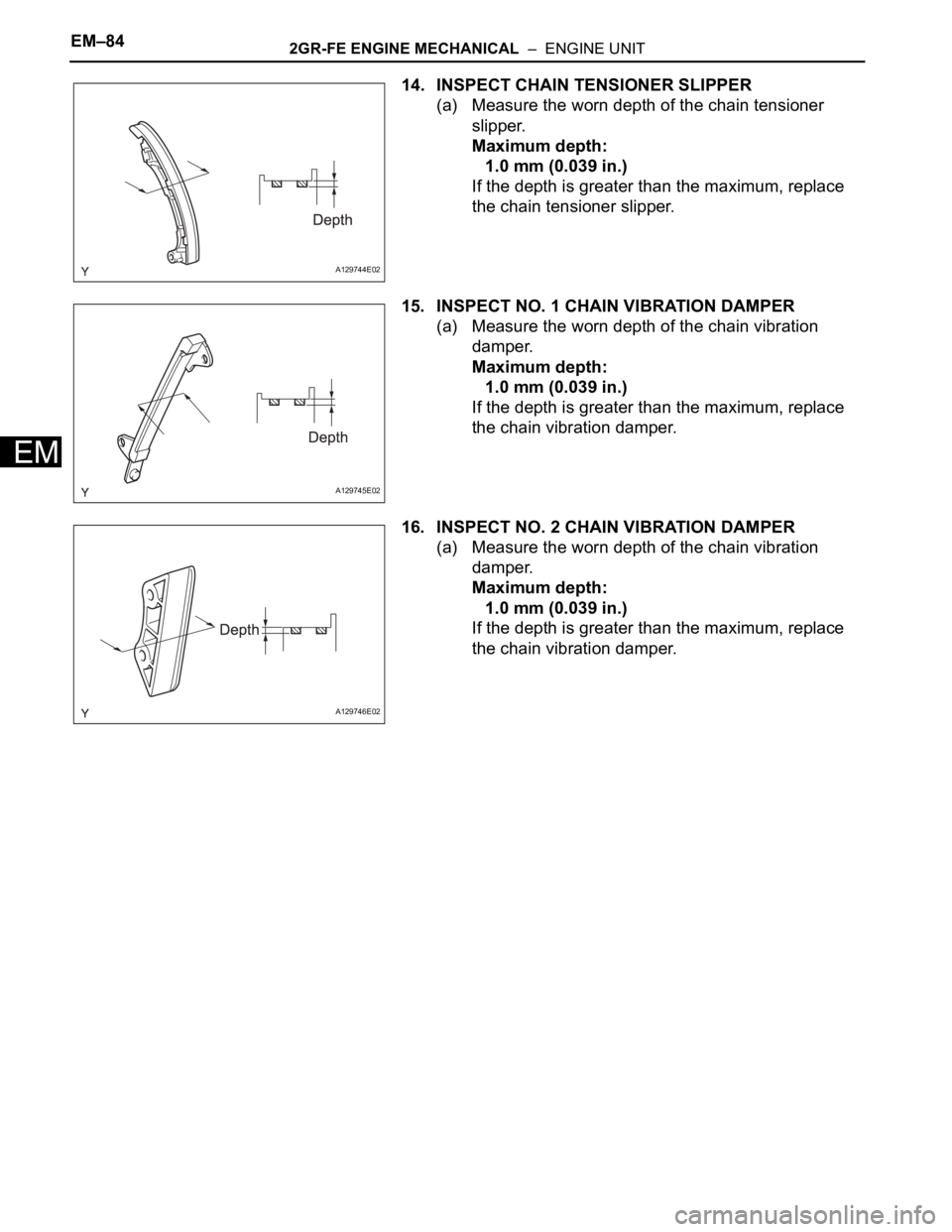

11. INSPECT NO. 1 CHAIN TENSIONER ASSEMBLY

(a) Move the stopper plate upward to release the lock.

Push the plunger and check that it moves smoothly.

If necessary, replace the chain tensioner.

12. INSPECT NO. 2 CHAIN TENSIONER ASSEMBLY

(a) Check that the plunger moves smoothly.

(b) Measure the worn depth of the chain tensioner.

Maximum depth:

0.9 mm (0.035 in.)

If the depth is greater than the maximum, replace

the chain tensioner.

13. INSPECT NO. 3 CHAIN TENSIONER ASSEMBLY

(a) Check that the plunger moves smoothly.

(b) Measure the worn depth of the chain tensioner.

Maximum depth:

0.9 mm (0.035 in.)

If the depth is greater than the maximum, replace

the chain tensioner.

A131955

A131960E01

A131966E01

A131967E01

Page 721 of 2000

EM–842GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

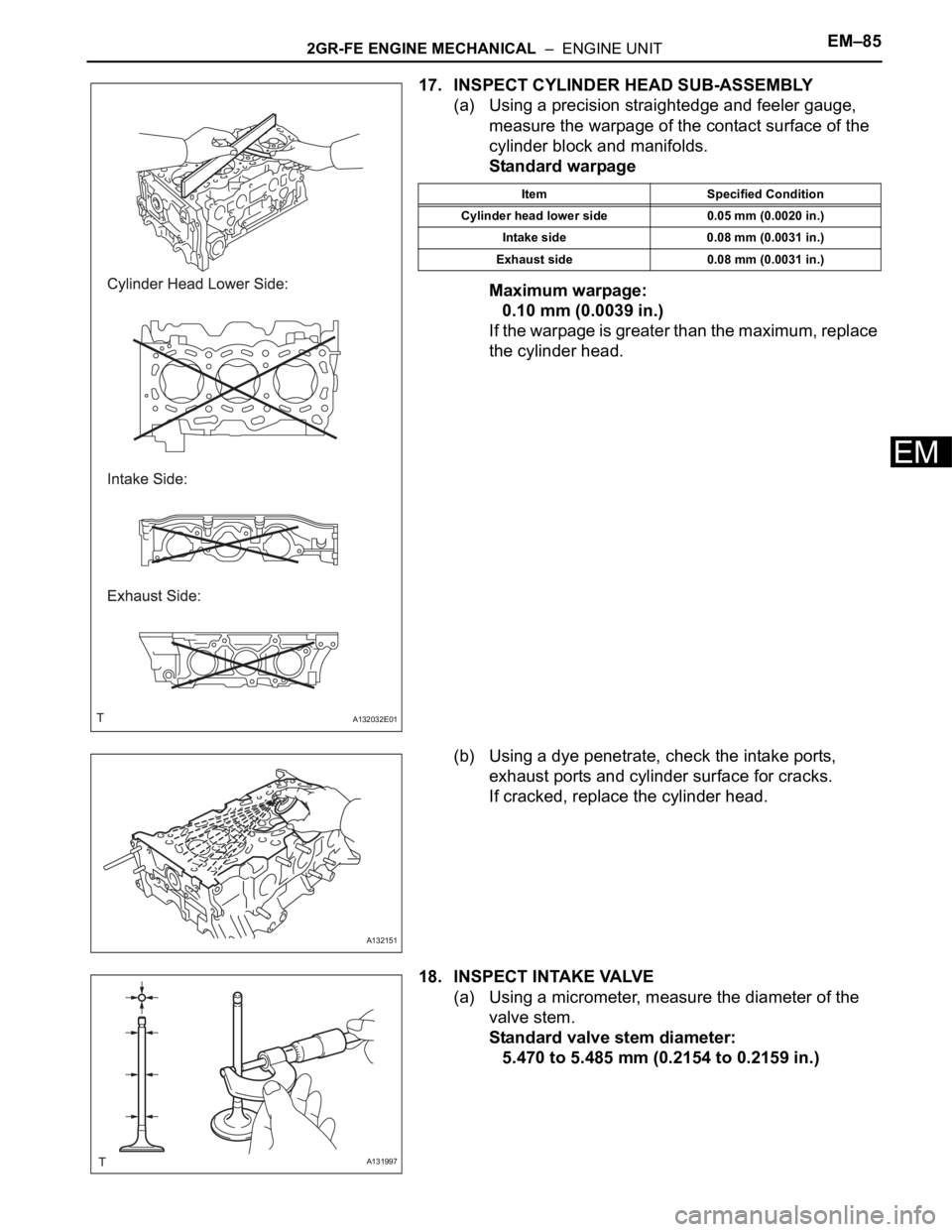

14. INSPECT CHAIN TENSIONER SLIPPER

(a) Measure the worn depth of the chain tensioner

slipper.

Maximum depth:

1.0 mm (0.039 in.)

If the depth is greater than the maximum, replace

the chain tensioner slipper.

15. INSPECT NO. 1 CHAIN VIBRATION DAMPER

(a) Measure the worn depth of the chain vibration

damper.

Maximum depth:

1.0 mm (0.039 in.)

If the depth is greater than the maximum, replace

the chain vibration damper.

16. INSPECT NO. 2 CHAIN VIBRATION DAMPER

(a) Measure the worn depth of the chain vibration

damper.

Maximum depth:

1.0 mm (0.039 in.)

If the depth is greater than the maximum, replace

the chain vibration damper.

A129744E02

A129745E02

A129746E02

Page 722 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–85

EM

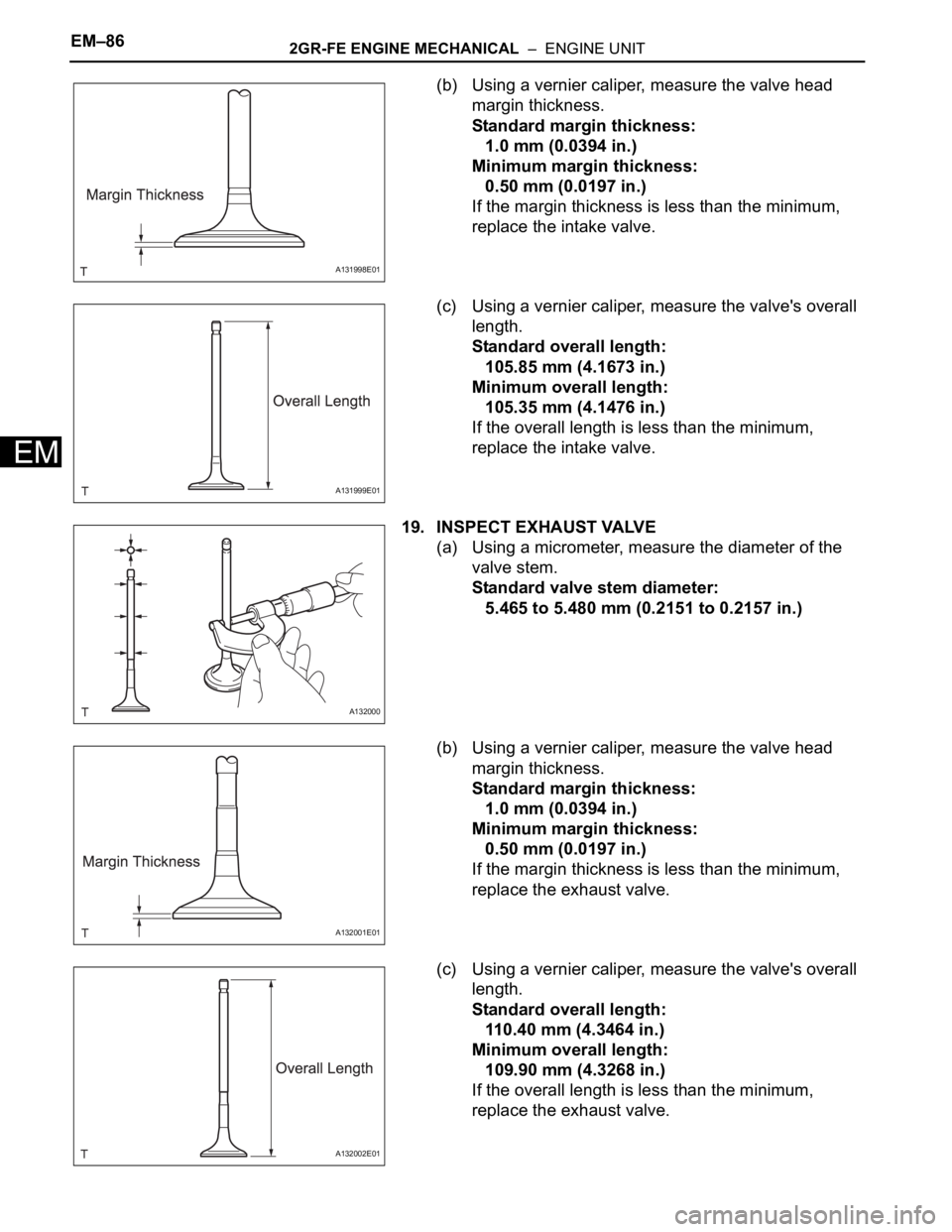

17. INSPECT CYLINDER HEAD SUB-ASSEMBLY

(a) Using a precision straightedge and feeler gauge,

measure the warpage of the contact surface of the

cylinder block and manifolds.

Standard warpage

Maximum warpage:

0.10 mm (0.0039 in.)

If the warpage is greater than the maximum, replace

the cylinder head.

(b) Using a dye penetrate, check the intake ports,

exhaust ports and cylinder surface for cracks.

If cracked, replace the cylinder head.

18. INSPECT INTAKE VALVE

(a) Using a micrometer, measure the diameter of the

valve stem.

Standard valve stem diameter:

5.470 to 5.485 mm (0.2154 to 0.2159 in.)

A132032E01

Item Specified Condition

Cylinder head lower side 0.05 mm (0.0020 in.)

Intake side 0.08 mm (0.0031 in.)

Exhaust side 0.08 mm (0.0031 in.)

A132151

A131997

Page 723 of 2000

EM–862GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

(b) Using a vernier caliper, measure the valve head

margin thickness.

Standard margin thickness:

1.0 mm (0.0394 in.)

Minimum margin thickness:

0.50 mm (0.0197 in.)

If the margin thickness is less than the minimum,

replace the intake valve.

(c) Using a vernier caliper, measure the valve's overall

length.

Standard overall length:

105.85 mm (4.1673 in.)

Minimum overall length:

105.35 mm (4.1476 in.)

If the overall length is less than the minimum,

replace the intake valve.

19. INSPECT EXHAUST VALVE

(a) Using a micrometer, measure the diameter of the

valve stem.

Standard valve stem diameter:

5.465 to 5.480 mm (0.2151 to 0.2157 in.)

(b) Using a vernier caliper, measure the valve head

margin thickness.

Standard margin thickness:

1.0 mm (0.0394 in.)

Minimum margin thickness:

0.50 mm (0.0197 in.)

If the margin thickness is less than the minimum,

replace the exhaust valve.

(c) Using a vernier caliper, measure the valve's overall

length.

Standard overall length:

110.40 mm (4.3464 in.)

Minimum overall length:

109.90 mm (4.3268 in.)

If the overall length is less than the minimum,

replace the exhaust valve.

A131998E01

A131999E01

A132000

A132001E01

A132002E01

Page 724 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–87

EM

20. INSPECT INTAKE VALVE SEAT

(a) Apply a light coat of Prussian blue to the valve face.

(b) Lightly press the valve face against the valve seat.

(c) Check the valve face and valve seat by using the

following procedure.

(1) If Prussian blue appears around the entire

valve face, the valve face is concentric. If not,

replace the valve.

(2) If Prussian blue appears around the entire

valve seat, the guide and valve face are

concentric. If not, resurface the valve seat.

(3) Check that the valve seat contacts in the

middle of the valve face with the width between

1.1 and 1.5 mm (0.043 and 0.059 in.).

21. INSPECT EXHAUST VALVE SEAT

(a) Apply a light coat of Prussian blue to the valve face.

(b) Lightly press the valve face against the valve seat.

(c) Check the valve face and valve seat by using the

following procedure.

(1) If Prussian blue appears around the entire

valve face, the valve face is concentric. If not,

replace the valve.

(2) If Prussian blue appears around the entire

valve seat, the guide and valve face are

concentric. If not, resurface the valve seat.

(3) Check that the valve seat contacts in the

middle of the valve face with the width between

1.2 and 1.6 mm (0.047 and 0.063 in.).

22. INSPECT INNER COMPRESSION SPRING

(a) Using a vernier caliper, measure the free length of

the inner compression spring.

Standard free length:

45.46 mm (1.7898 in.)

If the free length is not as specified, replace the

spring.

(b) Using a steel square, measure the deviation of the

inner compression spring.

Maximum deviation:

1.0 mm (0.039 in.)

Maximum angle (reference):

2

If the deviation is greater than the maximum,

replace the spring.

A132152E01

A132152E01

A101392

A101393E02

Page 725 of 2000

EM–882GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

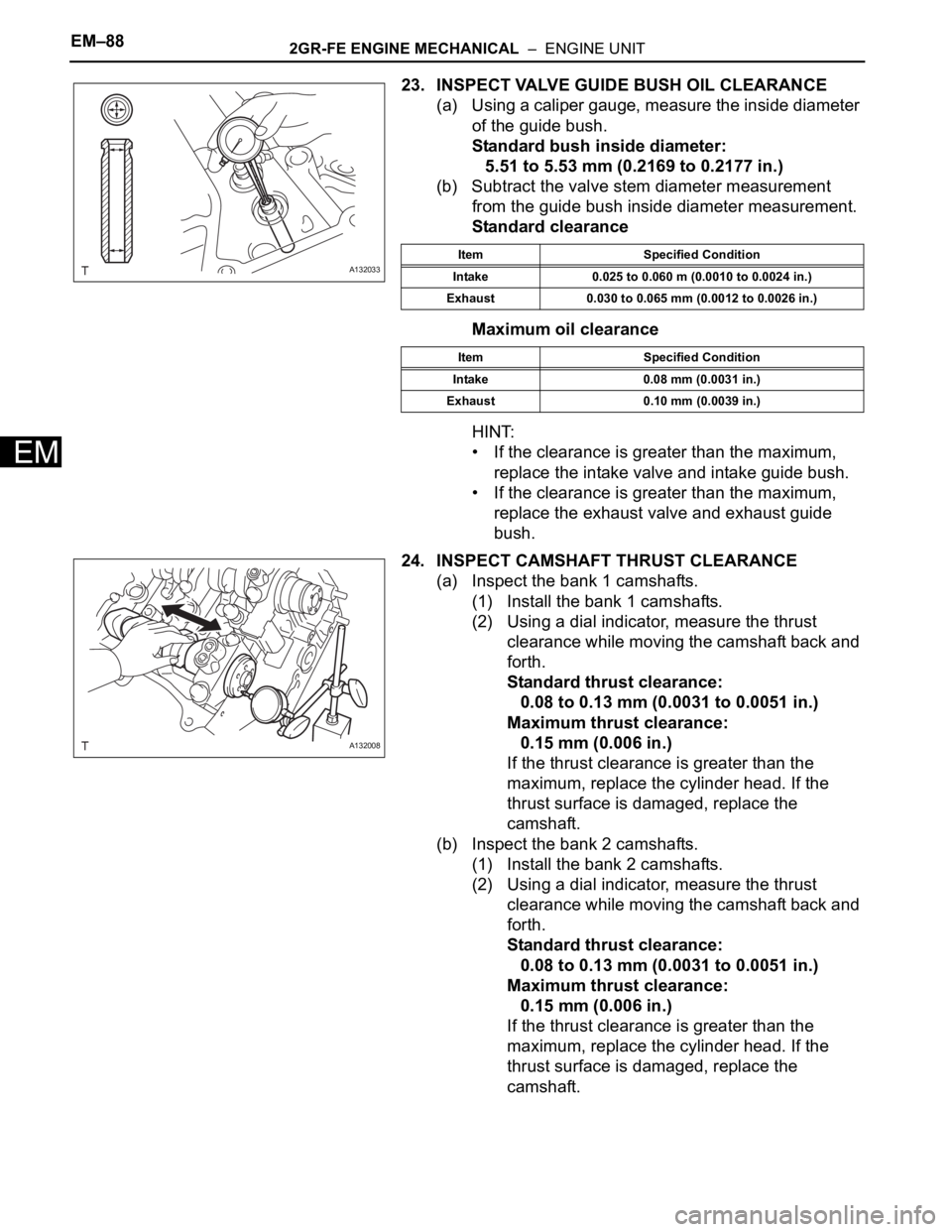

23. INSPECT VALVE GUIDE BUSH OIL CLEARANCE

(a) Using a caliper gauge, measure the inside diameter

of the guide bush.

Standard bush inside diameter:

5.51 to 5.53 mm (0.2169 to 0.2177 in.)

(b) Subtract the valve stem diameter measurement

from the guide bush inside diameter measurement.

Standard clearance

Maximum oil clearance

HINT:

• If the clearance is greater than the maximum,

replace the intake valve and intake guide bush.

• If the clearance is greater than the maximum,

replace the exhaust valve and exhaust guide

bush.

24. INSPECT CAMSHAFT THRUST CLEARANCE

(a) Inspect the bank 1 camshafts.

(1) Install the bank 1 camshafts.

(2) Using a dial indicator, measure the thrust

clearance while moving the camshaft back and

forth.

Standard thrust clearance:

0.08 to 0.13 mm (0.0031 to 0.0051 in.)

Maximum thrust clearance:

0.15 mm (0.006 in.)

If the thrust clearance is greater than the

maximum, replace the cylinder head. If the

thrust surface is damaged, replace the

camshaft.

(b) Inspect the bank 2 camshafts.

(1) Install the bank 2 camshafts.

(2) Using a dial indicator, measure the thrust

clearance while moving the camshaft back and

forth.

Standard thrust clearance:

0.08 to 0.13 mm (0.0031 to 0.0051 in.)

Maximum thrust clearance:

0.15 mm (0.006 in.)

If the thrust clearance is greater than the

maximum, replace the cylinder head. If the

thrust surface is damaged, replace the

camshaft.

A132033Item Specified Condition

Intake 0.025 to 0.060 m (0.0010 to 0.0024 in.)

Exhaust 0.030 to 0.065 mm (0.0012 to 0.0026 in.)

Item Specified Condition

Intake 0.08 mm (0.0031 in.)

Exhaust 0.10 mm (0.0039 in.)

A132008