relay TOYOTA RAV4 2006 Service Service Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1619 of 2000

POWER STEERING – ELECTRONIC POWER STEERING SYSTEMPS–19

PS

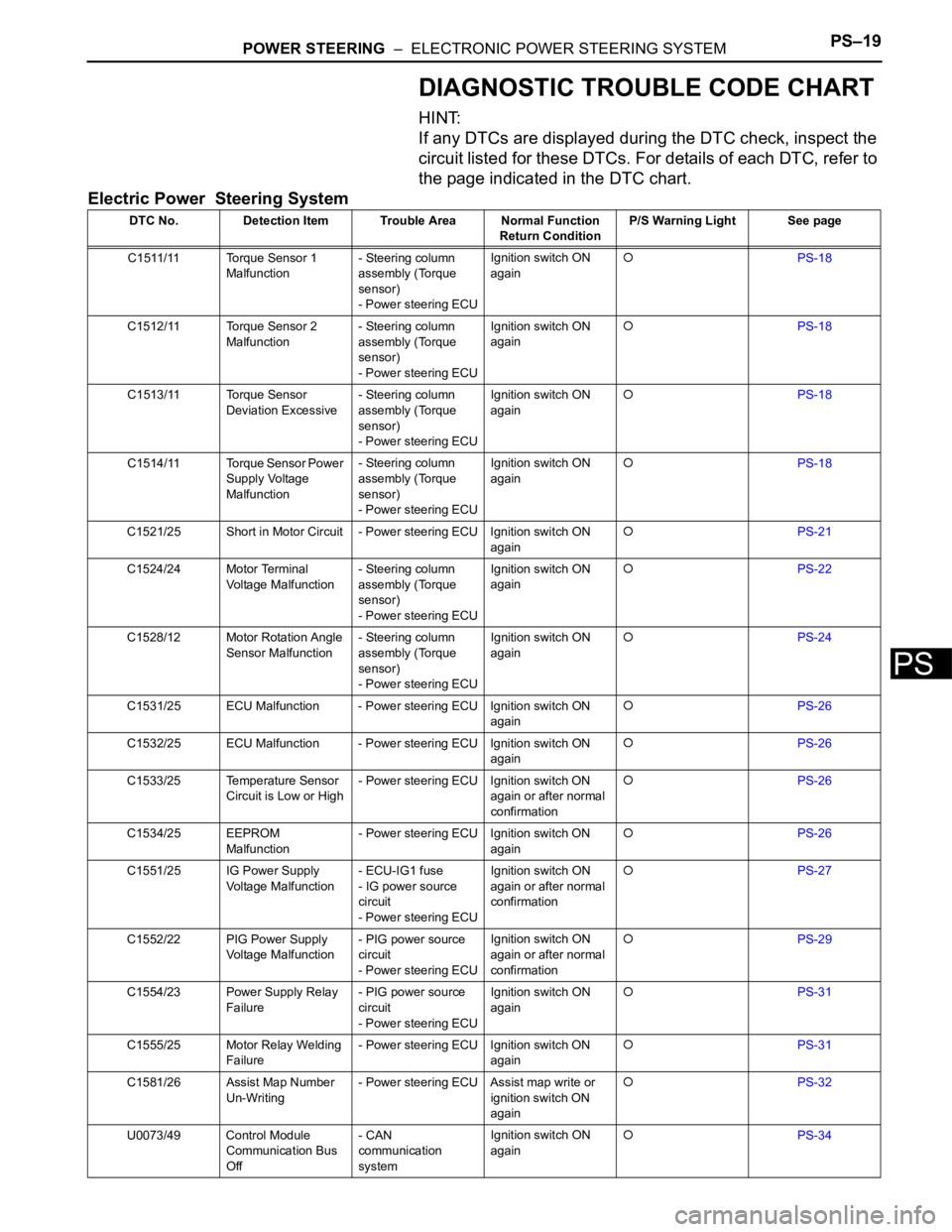

DIAGNOSTIC TROUBLE CODE CHART

HINT:

If any DTCs are displayed during the DTC check, inspect the

circuit listed for these DTCs. For details of each DTC, refer to

the page indicated in the DTC chart.

Electric Power Steering System

DTC No. Detection Item Trouble Area Normal Function

Return ConditionP/S Warning Light See page

C1511/11 Torque Sensor 1

Malfunction- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-18

C1512/11 Torque Sensor 2

Malfunction- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-18

C1513/11 Torque Sensor

Deviation Excessive- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-18

C1514/11 Torque Sensor Power

Supply Voltage

Malfunction- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-18

C1521/25 Short in Motor Circuit - Power steering ECU Ignition switch ON

again

PS-21

C1524/24 Motor Terminal

Voltage Malfunction- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-22

C1528/12 Motor Rotation Angle

Sensor Malfunction- Steering column

assembly (Torque

sensor)

- Power steering ECUIgnition switch ON

again

PS-24

C1531/25 ECU Malfunction - Power steering ECU Ignition switch ON

again

PS-26

C1532/25 ECU Malfunction - Power steering ECU Ignition switch ON

again

PS-26

C1533/25 Temperature Sensor

Circuit is Low or High- Power steering ECU Ignition switch ON

again or after normal

confirmation

PS-26

C1534/25 EEPROM

Malfunction- Power steering ECU Ignition switch ON

again

PS-26

C1551/25 IG Power Supply

Voltage Malfunction- ECU-IG1 fuse

- IG power source

circuit

- Power steering ECUIgnition switch ON

again or after normal

confirmation

PS-27

C1552/22 PIG Power Supply

Voltage Malfunction- PIG power source

circuit

- Power steering ECUIgnition switch ON

again or after normal

confirmation

PS-29

C1554/23 Power Supply Relay

Failure- PIG power source

circuit

- Power steering ECUIgnition switch ON

again

PS-31

C1555/25 Motor Relay Welding

Failure- Power steering ECU Ignition switch ON

again

PS-31

C1581/26 Assist Map Number

Un-Writing- Power steering ECU Assist map write or

ignition switch ON

again

PS-32

U0073/49 Control Module

Communication Bus

Off- CAN

communication

systemIgnition switch ON

again

PS-34

Page 1629 of 2000

POWER STEERING – ELECTRONIC POWER STEERING SYSTEMPS–29

PS

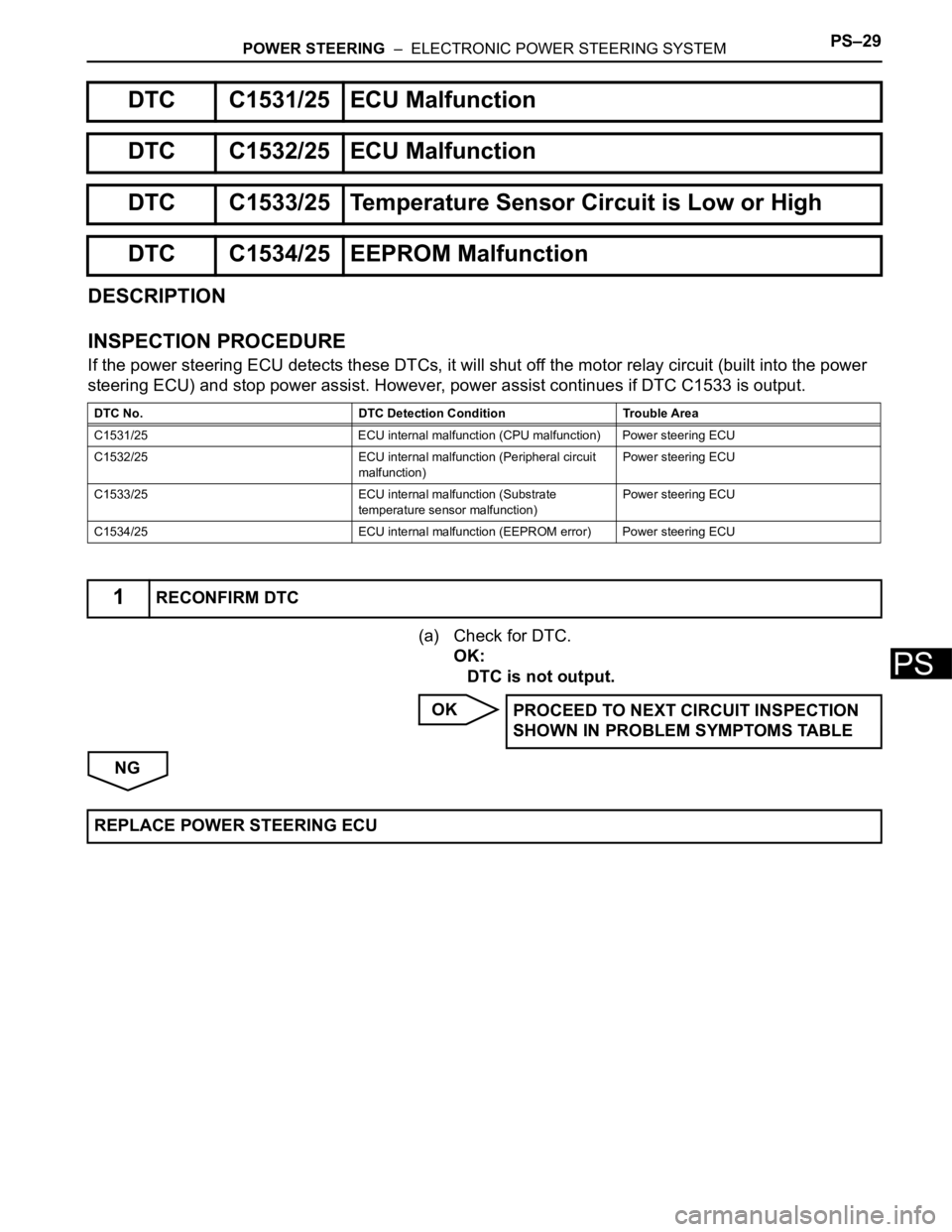

DESCRIPTION

INSPECTION PROCEDURE

If the power steering ECU detects these DTCs, it will shut off the motor relay circuit (built into the power

steering ECU) and stop power assist. However, power assist continues if DTC C1533 is output.

(a) Check for DTC.

OK:

DTC is not output.

OK

NG

DTC C1531/25 ECU Malfunction

DTC C1532/25 ECU Malfunction

DTC C1533/25 Temperature Sensor Circuit is Low or High

DTC C1534/25 EEPROM Malfunction

DTC No. DTC Detection Condition Trouble Area

C1531/25 ECU internal malfunction (CPU malfunction) Power steering ECU

C1532/25 ECU internal malfunction (Peripheral circuit

malfunction)Power steering ECU

C1533/25 ECU internal malfunction (Substrate

temperature sensor malfunction)Power steering ECU

C1534/25 ECU internal malfunction (EEPROM error) Power steering ECU

1RECONFIRM DTC

PROCEED TO NEXT CIRCUIT INSPECTION

SHOWN IN PROBLEM SYMPTOMS TABLE

REPLACE POWER STEERING ECU

Page 1632 of 2000

PS–32POWER STEERING – ELECTRONIC POWER STEERING SYSTEM

PS

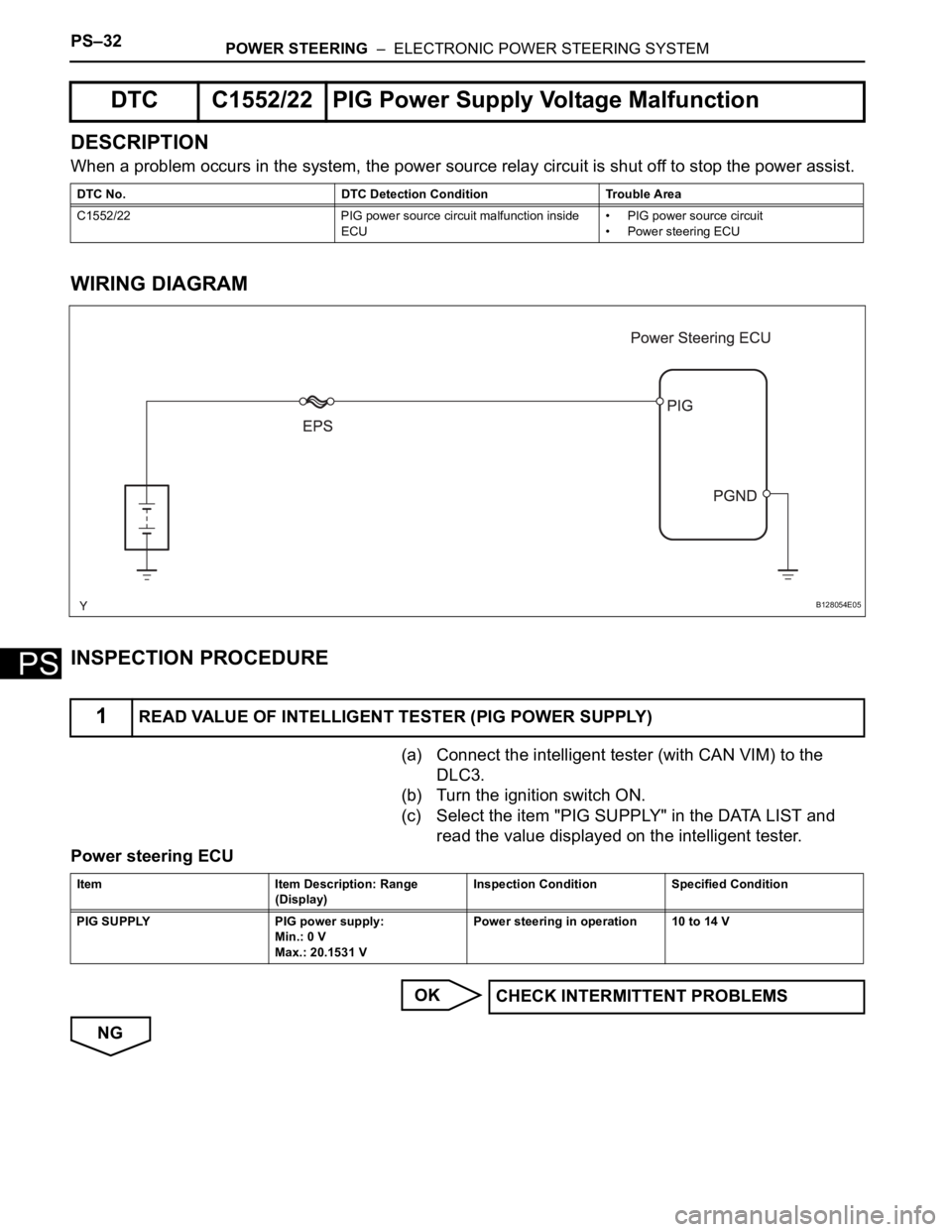

DESCRIPTION

When a problem occurs in the system, the power source relay circuit is shut off to stop the power assist.

WIRING DIAGRAM

INSPECTION PROCEDURE

(a) Connect the intelligent tester (with CAN VIM) to the

DLC3.

(b) Turn the ignition switch ON.

(c) Select the item "PIG SUPPLY" in the DATA LIST and

read the value displayed on the intelligent tester.

Power steering ECU

OK

NG

DTC C1552/22 PIG Power Supply Voltage Malfunction

DTC No. DTC Detection Condition Trouble Area

C1552/22 PIG power source circuit malfunction inside

ECU• PIG power source circuit

• Power steering ECU

1READ VALUE OF INTELLIGENT TESTER (PIG POWER SUPPLY)

B128054E05

Item Item Description: Range

(Display)Inspection Condition Specified Condition

PIG SUPPLY PIG power supply:

Min.: 0 V

Max.: 20.1531 VPower steering in operation 10 to 14 V

CHECK INTERMITTENT PROBLEMS

Page 1650 of 2000

AC–22AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)

AC

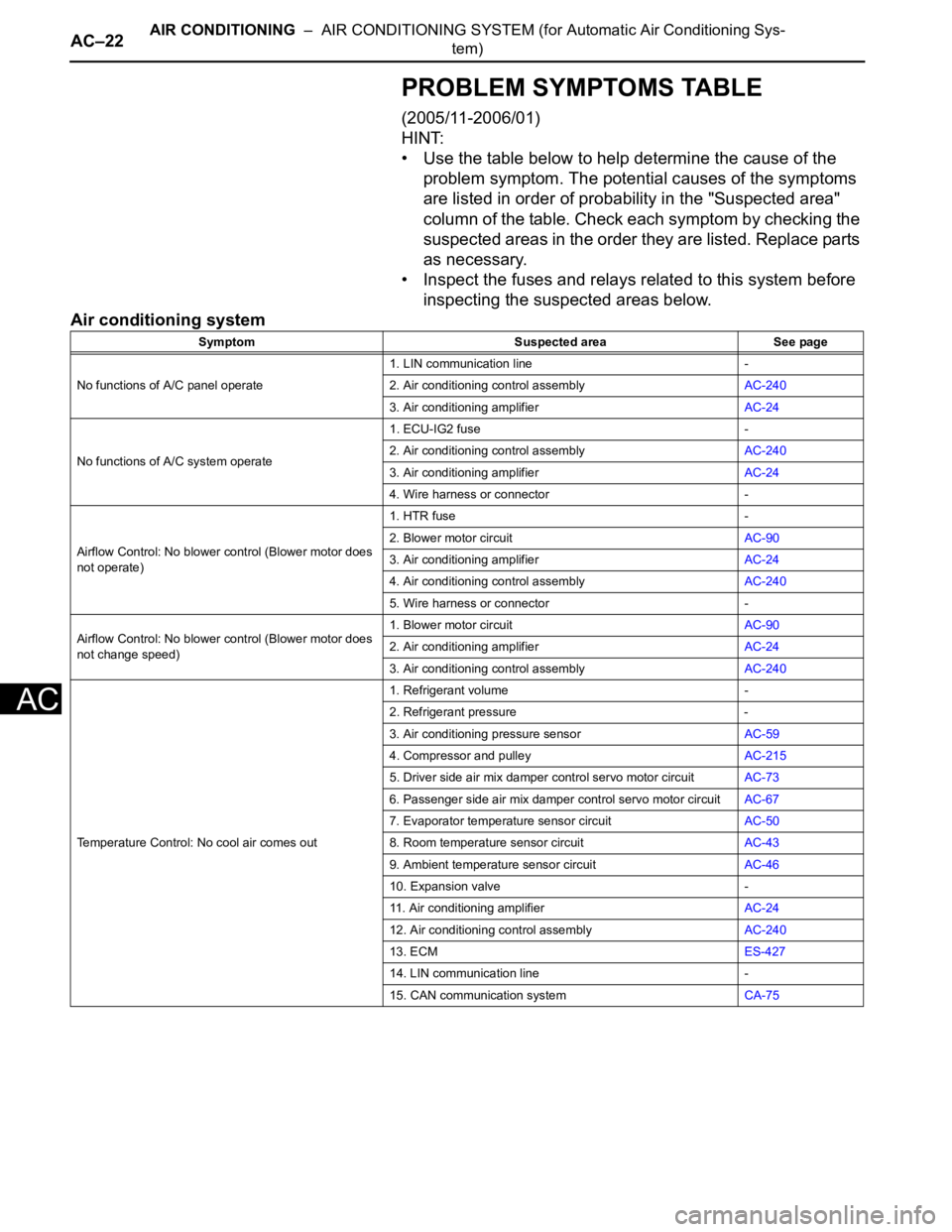

PROBLEM SYMPTOMS TABLE

(2005/11-2006/01)

HINT:

• Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Replace parts

as necessary.

• Inspect the fuses and relays related to this system before

inspecting the suspected areas below.

Air conditioning system

Symptom Suspected area See page

No functions of A/C panel operate1. LIN communication line -

2. Air conditioning control assemblyAC-240

3. Air conditioning amplifierAC-24

No functions of A/C system operate1. ECU-IG2 fuse -

2. Air conditioning control assemblyAC-240

3. Air conditioning amplifierAC-24

4. Wire harness or connector -

Airflow Control: No blower control (Blower motor does

not operate)1. HTR fuse -

2. Blower motor circuitAC-90

3. Air conditioning amplifierAC-24

4. Air conditioning control assemblyAC-240

5. Wire harness or connector -

Airflow Control: No blower control (Blower motor does

not change speed)1. Blower motor circuitAC-90

2. Air conditioning amplifierAC-24

3. Air conditioning control assemblyAC-240

Temperature Control: No cool air comes out1. Refrigerant volume -

2. Refrigerant pressure -

3. Air conditioning pressure sensorAC-59

4. Compressor and pulleyAC-215

5. Driver side air mix damper control servo motor circuitAC-73

6. Passenger side air mix damper control servo motor circuitAC-67

7. Evaporator temperature sensor circuitAC-50

8. Room temperature sensor circuitAC-43

9. Ambient temperature sensor circuitAC-46

10. Expansion valve -

11. Air conditioning amplifierAC-24

12. Air conditioning control assemblyAC-240

13. ECMES-427

14. LIN communication line -

15. CAN communication systemCA-75

Page 1652 of 2000

AC–24AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)

AC

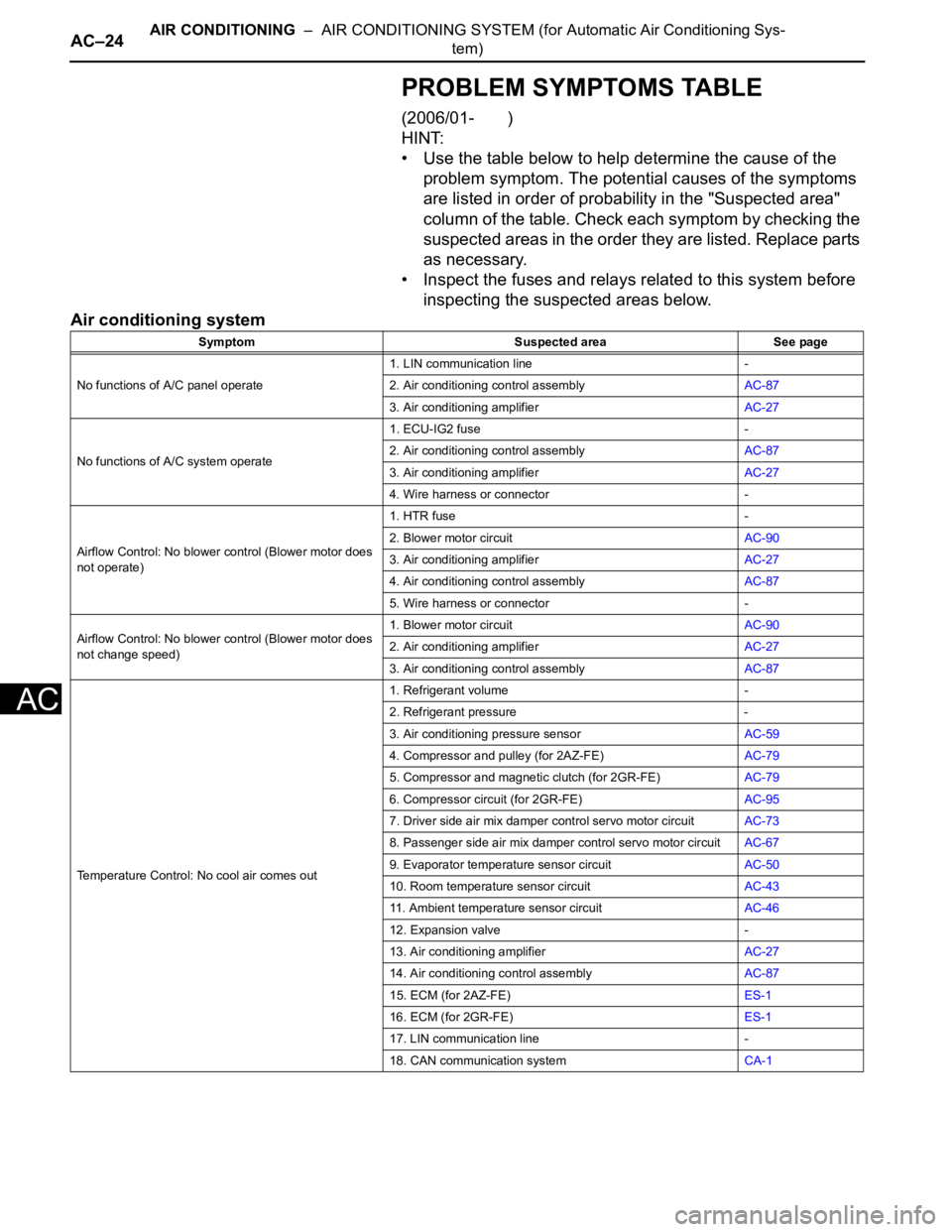

PROBLEM SYMPTOMS TABLE

(2006/01- )

HINT:

• Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Replace parts

as necessary.

• Inspect the fuses and relays related to this system before

inspecting the suspected areas below.

Air conditioning system

Symptom Suspected area See page

No functions of A/C panel operate1. LIN communication line -

2. Air conditioning control assemblyAC-87

3. Air conditioning amplifierAC-27

No functions of A/C system operate1. ECU-IG2 fuse -

2. Air conditioning control assemblyAC-87

3. Air conditioning amplifierAC-27

4. Wire harness or connector -

Airflow Control: No blower control (Blower motor does

not operate)1. HTR fuse -

2. Blower motor circuitAC-90

3. Air conditioning amplifierAC-27

4. Air conditioning control assemblyAC-87

5. Wire harness or connector -

Airflow Control: No blower control (Blower motor does

not change speed)1. Blower motor circuitAC-90

2. Air conditioning amplifierAC-27

3. Air conditioning control assemblyAC-87

Temperature Control: No cool air comes out1. Refrigerant volume -

2. Refrigerant pressure -

3. Air conditioning pressure sensorAC-59

4. Compressor and pulley (for 2AZ-FE)AC-79

5. Compressor and magnetic clutch (for 2GR-FE)AC-79

6. Compressor circuit (for 2GR-FE)AC-95

7. Driver side air mix damper control servo motor circuitAC-73

8. Passenger side air mix damper control servo motor circuitAC-67

9. Evaporator temperature sensor circuitAC-50

10. Room temperature sensor circuitAC-43

11. Ambient temperature sensor circuitAC-46

12. Expansion valve -

13. Air conditioning amplifierAC-27

14. Air conditioning control assemblyAC-87

15. ECM (for 2AZ-FE)ES-1

16. ECM (for 2GR-FE)ES-1

17. LIN communication line -

18. CAN communication systemCA-1

Page 1658 of 2000

AC–30AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)

AC

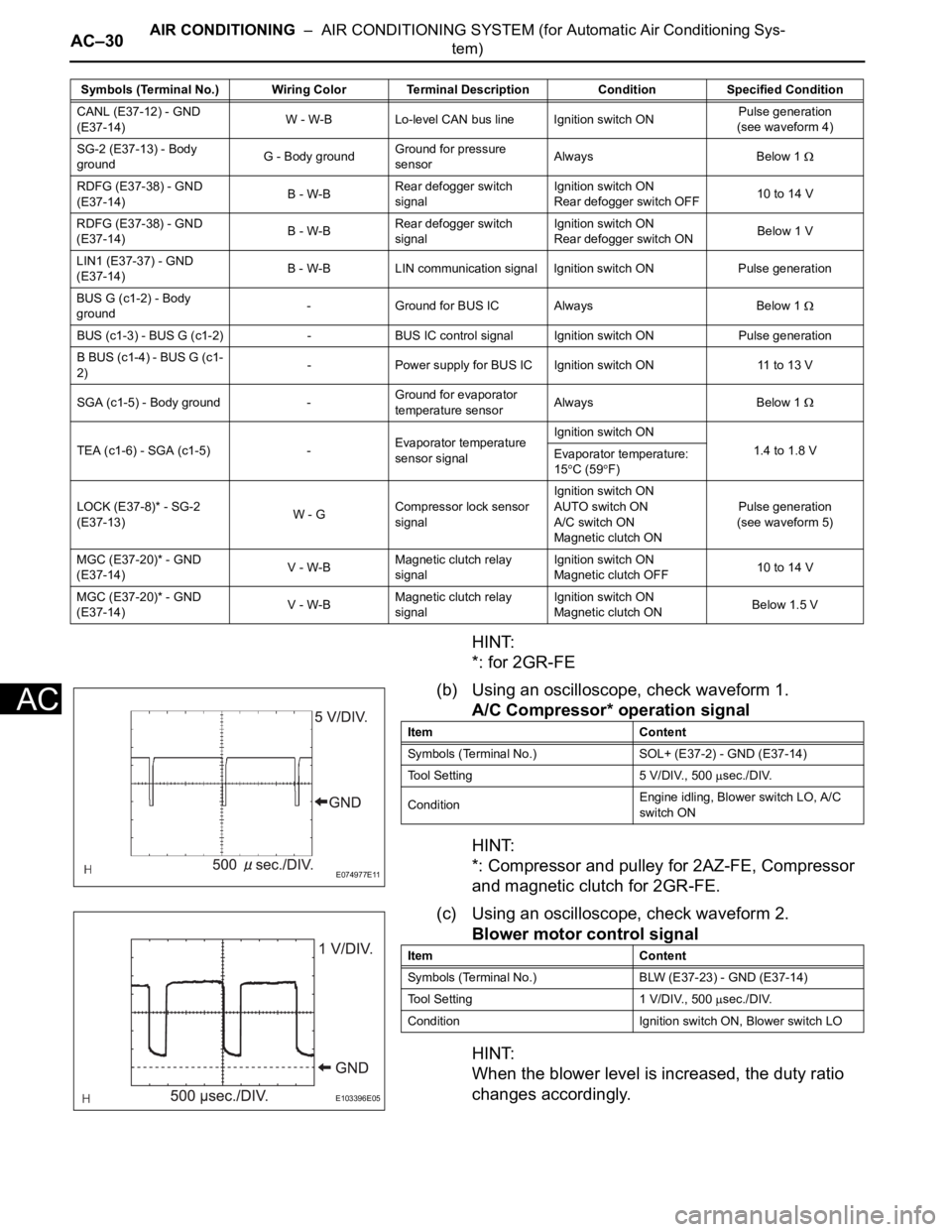

HINT:

*: for 2GR-FE

(b) Using an oscilloscope, check waveform 1.

A/C Compressor* operation signal

HINT:

*: Compressor and pulley for 2AZ-FE, Compressor

and magnetic clutch for 2GR-FE.

(c) Using an oscilloscope, check waveform 2.

Blower motor control signal

HINT:

When the blower level is increased, the duty ratio

changes accordingly.

CANL (E37-12) - GND

(E37-14)W - W-B Lo-level CAN bus line Ignition switch ONPulse generation

(see waveform 4)

SG-2 (E37-13) - Body

groundG - Body groundGround for pressure

sensorAlways Below 1

RDFG (E37-38) - GND

(E37-14)B - W-BRear defogger switch

signalIgnition switch ON

Rear defogger switch OFF10 to 14 V

RDFG (E37-38) - GND

(E37-14)B - W-BRear defogger switch

signalIgnition switch ON

Rear defogger switch ONBelow 1 V

LIN1 (E37-37) - GND

(E37-14)B - W-B LIN communication signal Ignition switch ON Pulse generation

BUS G (c1-2) - Body

ground- Ground for BUS IC Always Below 1

BUS (c1-3) - BUS G (c1-2) - BUS IC control signal Ignition switch ON Pulse generation

B BUS (c1-4) - BUS G (c1-

2)- Power supply for BUS IC Ignition switch ON 11 to 13 V

SGA (c1-5) - Body ground -Ground for evaporator

temperature sensorAlways Below 1

TEA (c1-6) - SGA (c1-5) -Evaporator temperature

sensor signalIgnition switch ON

1.4 to 1.8 V

Evaporator temperature:

15

C (59F)

LOCK (E37-8)* - SG-2

(E37-13)W - GCompressor lock sensor

signalIgnition switch ON

AUTO switch ON

A/C switch ON

Magnetic clutch ONPulse generation

(see waveform 5)

MGC (E37-20)* - GND

(E37-14)V - W-BMagnetic clutch relay

signalIgnition switch ON

Magnetic clutch OFF10 to 14 V

MGC (E37-20)* - GND

(E37-14)V - W-BMagnetic clutch relay

signalIgnition switch ON

Magnetic clutch ONBelow 1.5 V Symbols (Terminal No.) Wiring Color Terminal Description ConditionSpecified Condition

E074977E11

Item Content

Symbols (Terminal No.) SOL+ (E37-2) - GND (E37-14)

Tool Setting 5 V/DIV., 500

sec./DIV.

ConditionEngine idling, Blower switch LO, A/C

switch ON

E103396E05

Item Content

Symbols (Terminal No.) BLW (E37-23) - GND (E37-14)

Tool Setting 1 V/DIV., 500

sec./DIV.

Condition Ignition switch ON, Blower switch LO

Page 1689 of 2000

RS–40SUPPLEMENTAL RESTRAINT SYSTEM – AIRBAG SYSTEM

RS

3. SYMPTOM SIMULATION

HINT:

The most difficult case in troubleshooting is when no

problem symptoms occur. In such a case, a through

problem analysis must be carried out. A simulation of the

same or similar conditions and environment in which the

problem occurred in the customer's vehicle should be

carried out. No matter how much skill or experience a

technician has, troubleshooting without confirming the

problem symptoms will lead to important repairs being

overlooked and mistakes or delays.

This leads to a standstill in troubleshooting.

(a) Simulation method: When vibration seems to be the

major cause

HINT:

Perform this method only during the primary check

period (for approximately 6 seconds after the

ignition switch is turned ON).

(1) Use your finger to slightly vibrate the part of the

sensor considered to be the problem cause, and

check whether the malfunction recurs.

HINT:

Wiggling the relays too strongly may result in

open relays.

(2) Gently wiggle the connector.

(3) Slightly shake the wire harness vertically and

horizontally.

The connector joint and fulcrum of the vibration

are the major areas to be checked thoroughly.

4. FUNCTION OF SRS WARNING LIGHT

(a) Primary check

(1) Turn the ignition switch off. Wait for at least 2

seconds, then turn the ignition switch ON. The

SRS warning light comes on for approximately 6

seconds and the SRS airbag system diagnosis

(including the seat belt pretensioner) is

performed.

HINT:

If any malfunctions are detected during the

primary check, the SRS warning light remains

on even after the primary check period has

elapsed.

(b) Constant check

(1) After the primary check, the center airbag sensor

constantly monitors the SRS airbag system for

trouble.

HINT:

If any malfunctions are detected during the

constant check, the center airbag sensor

functions as follows:

• The SRS warning light comes on.

H100146E01

Page 1750 of 2000

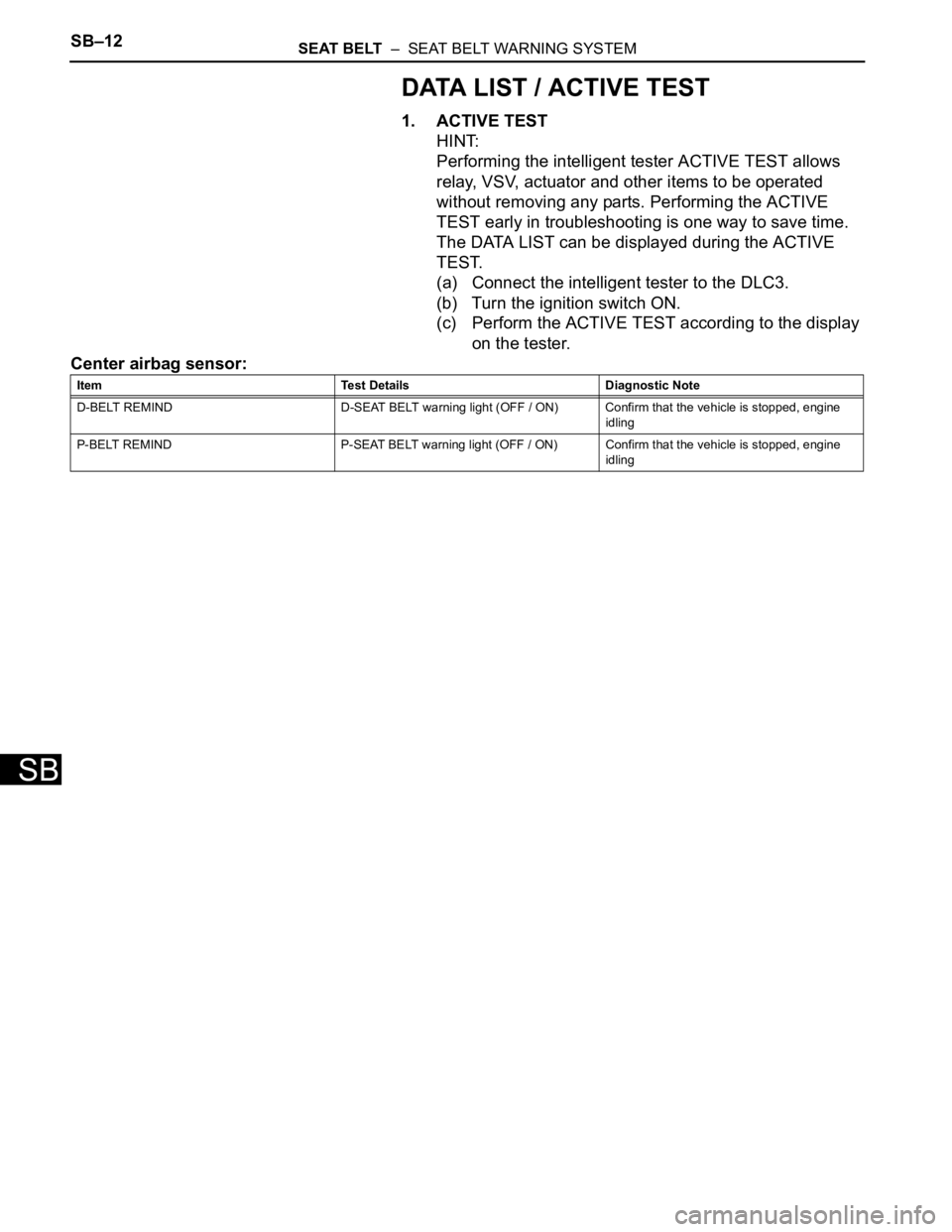

SB–12SEAT BELT – SEAT BELT WARNING SYSTEM

SB

DATA LIST / ACTIVE TEST

1. ACTIVE TEST

HINT:

Performing the intelligent tester ACTIVE TEST allows

relay, VSV, actuator and other items to be operated

without removing any parts. Performing the ACTIVE

TEST early in troubleshooting is one way to save time.

The DATA LIST can be displayed during the ACTIVE

TEST.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch ON.

(c) Perform the ACTIVE TEST according to the display

on the tester.

Center airbag sensor:

Item Test Details Diagnostic Note

D-BELT REMIND D-SEAT BELT warning light (OFF / ON) Confirm that the vehicle is stopped, engine

idling

P-BELT REMIND P-SEAT BELT warning light (OFF / ON) Confirm that the vehicle is stopped, engine

idling

Page 1784 of 2000

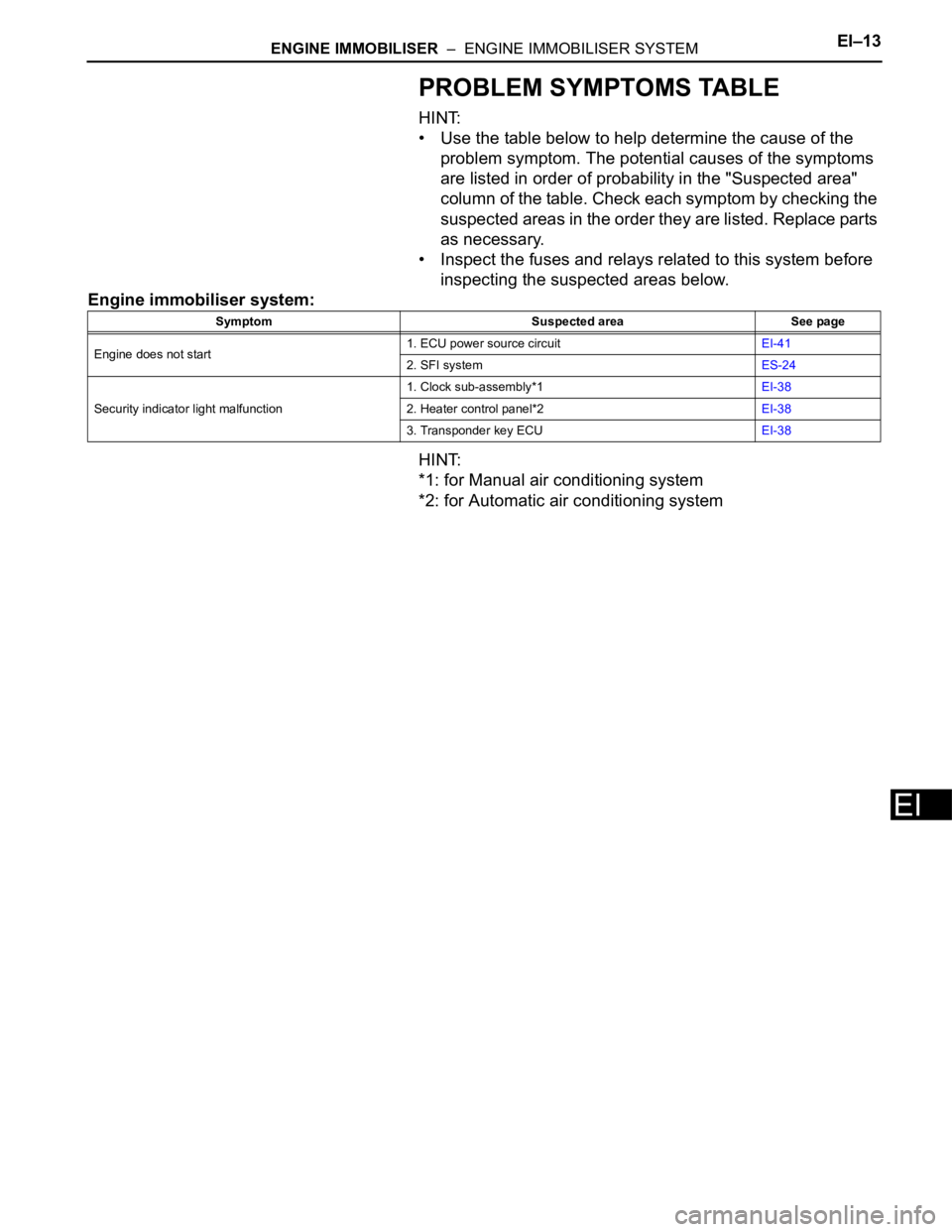

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEMEI–13

EI

PROBLEM SYMPTOMS TABLE

HINT:

• Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Replace parts

as necessary.

• Inspect the fuses and relays related to this system before

inspecting the suspected areas below.

Engine immobiliser system:

HINT:

*1: for Manual air conditioning system

*2: for Automatic air conditioning system

Symptom Suspected area See page

Engine does not start1. ECU power source circuitEI-41

2. SFI systemES-24

Security indicator light malfunction1. Clock sub-assembly*1EI-38

2. Heater control panel*2EI-38

3. Transponder key ECUEI-38

Page 1793 of 2000

EI–22ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM

EI

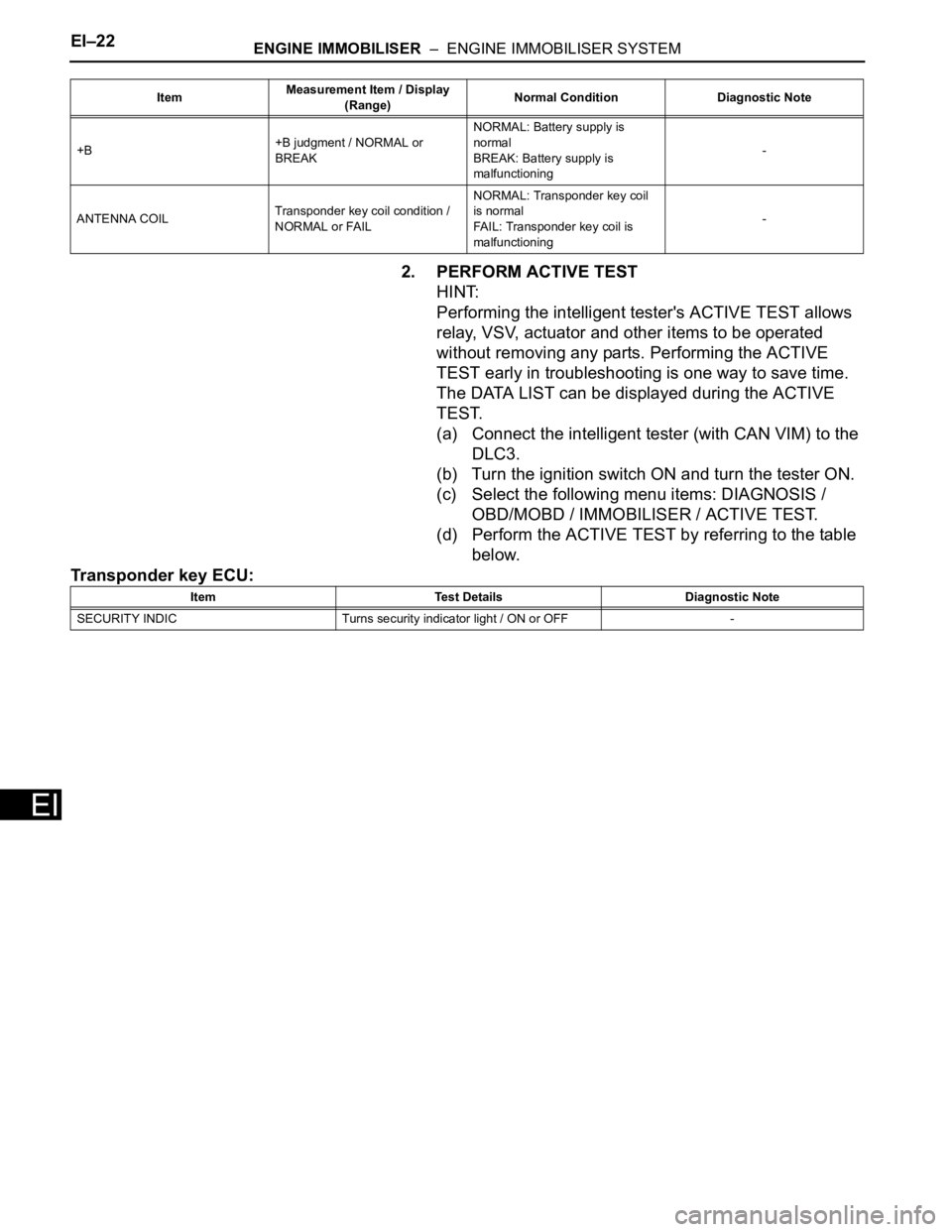

2. PERFORM ACTIVE TEST

HINT:

Performing the intelligent tester's ACTIVE TEST allows

relay, VSV, actuator and other items to be operated

without removing any parts. Performing the ACTIVE

TEST early in troubleshooting is one way to save time.

The DATA LIST can be displayed during the ACTIVE

TEST.

(a) Connect the intelligent tester (with CAN VIM) to the

DLC3.

(b) Turn the ignition switch ON and turn the tester ON.

(c) Select the following menu items: DIAGNOSIS /

OBD/MOBD / IMMOBILISER / ACTIVE TEST.

(d) Perform the ACTIVE TEST by referring to the table

below.

Transponder key ECU:

+B+B judgment / NORMAL or

BREAKNORMAL: Battery supply is

normal

BREAK: Battery supply is

malfunctioning-

ANTENNA COILTransponder key coil condition /

NORMAL or FAILNORMAL: Transponder key coil

is normal

FAIL: Transponder key coil is

malfunctioning- ItemMeasurement Item / Display

(Range)Normal Condition Diagnostic Note

Item Test Details Diagnostic Note

SECURITY INDIC Turns security indicator light / ON or OFF -