engine TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 877 of 2000

2GR-FE LUBRICATION – OIL PUMPLU–17

LU

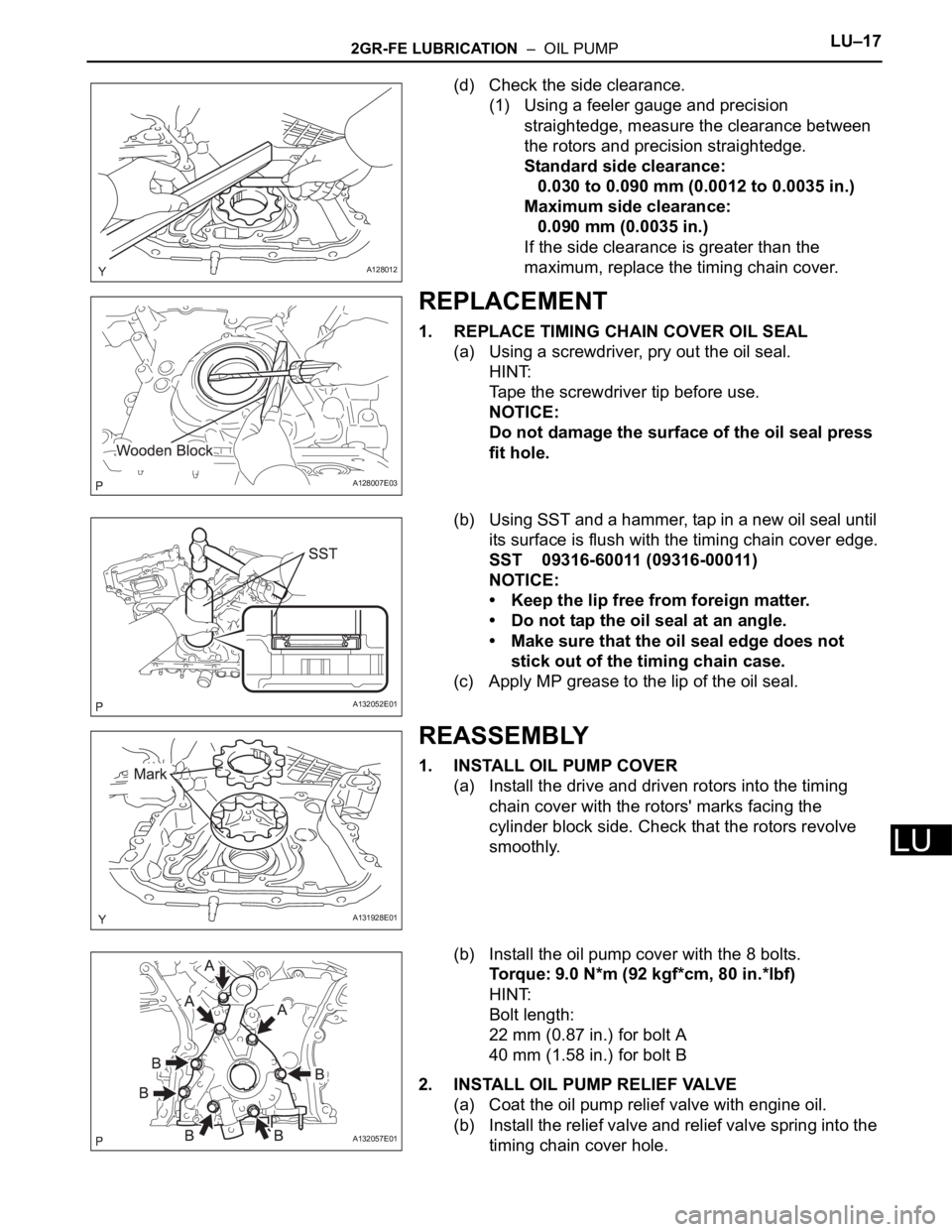

(d) Check the side clearance.

(1) Using a feeler gauge and precision

straightedge, measure the clearance between

the rotors and precision straightedge.

Standard side clearance:

0.030 to 0.090 mm (0.0012 to 0.0035 in.)

Maximum side clearance:

0.090 mm (0.0035 in.)

If the side clearance is greater than the

maximum, replace the timing chain cover.

REPLACEMENT

1. REPLACE TIMING CHAIN COVER OIL SEAL

(a) Using a screwdriver, pry out the oil seal.

HINT:

Tape the screwdriver tip before use.

NOTICE:

Do not damage the surface of the oil seal press

fit hole.

(b) Using SST and a hammer, tap in a new oil seal until

its surface is flush with the timing chain cover edge.

SST 09316-60011 (09316-00011)

NOTICE:

• Keep the lip free from foreign matter.

• Do not tap the oil seal at an angle.

• Make sure that the oil seal edge does not

stick out of the timing chain case.

(c) Apply MP grease to the lip of the oil seal.

REASSEMBLY

1. INSTALL OIL PUMP COVER

(a) Install the drive and driven rotors into the timing

chain cover with the rotors' marks facing the

cylinder block side. Check that the rotors revolve

smoothly.

(b) Install the oil pump cover with the 8 bolts.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

HINT:

Bolt length:

22 mm (0.87 in.) for bolt A

40 mm (1.58 in.) for bolt B

2. INSTALL OIL PUMP RELIEF VALVE

(a) Coat the oil pump relief valve with engine oil.

(b) Install the relief valve and relief valve spring into the

timing chain cover hole.

A128012

A128007E03

A132052E01

A131928E01

A132057E01

Page 879 of 2000

2GR-FE LUBRICATION – OIL PUMPLU–19

LU

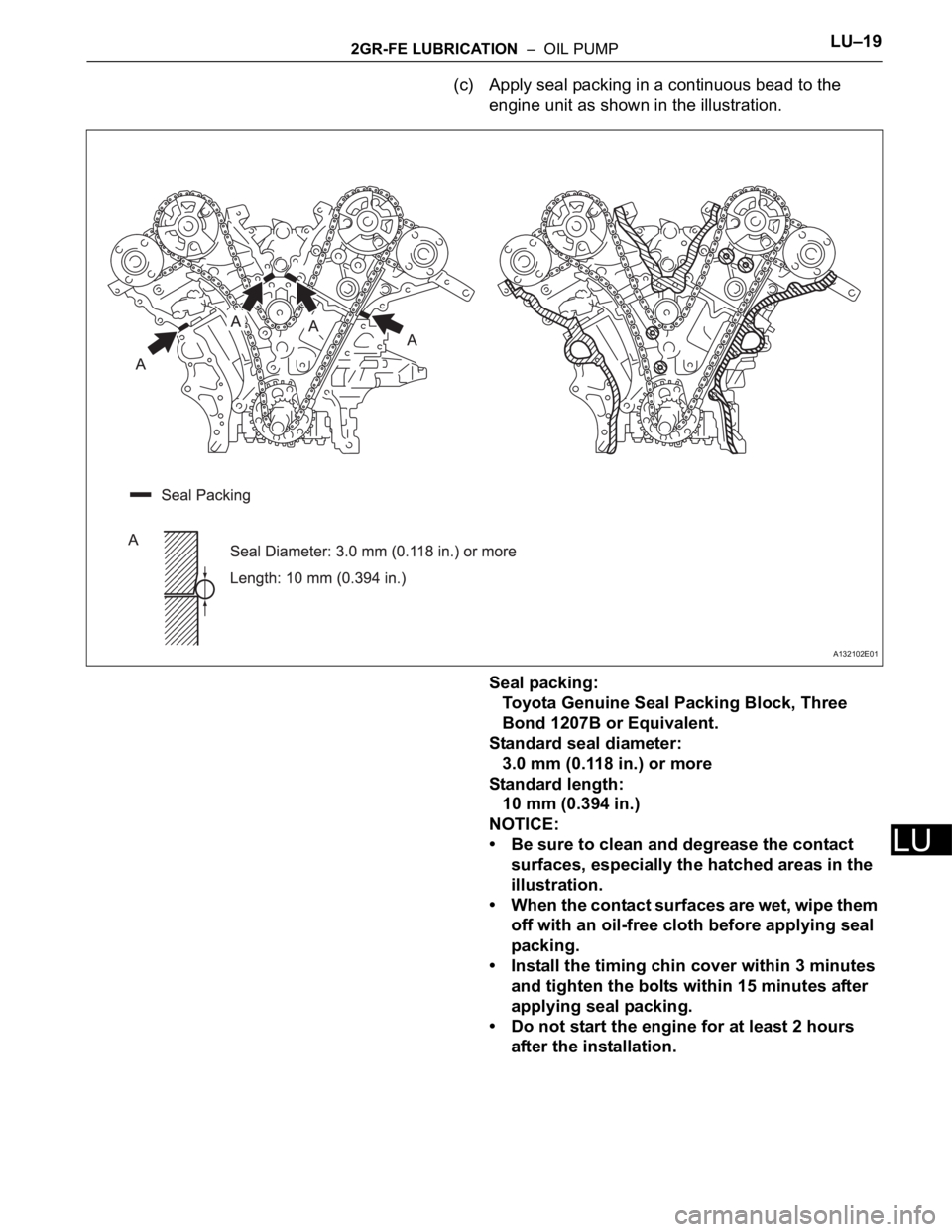

(c) Apply seal packing in a continuous bead to the

engine unit as shown in the illustration.

Seal packing:

Toyota Genuine Seal Packing Block, Three

Bond 1207B or Equivalent.

Standard seal diameter:

3.0 mm (0.118 in.) or more

Standard length:

10 mm (0.394 in.)

NOTICE:

• Be sure to clean and degrease the contact

surfaces, especially the hatched areas in the

illustration.

• When the contact surfaces are wet, wipe them

off with an oil-free cloth before applying seal

packing.

• Install the timing chin cover within 3 minutes

and tighten the bolts within 15 minutes after

applying seal packing.

• Do not start the engine for at least 2 hours

after the installation.

A132102E01

Page 881 of 2000

2GR-FE LUBRICATION – OIL PUMPLU–21

LU

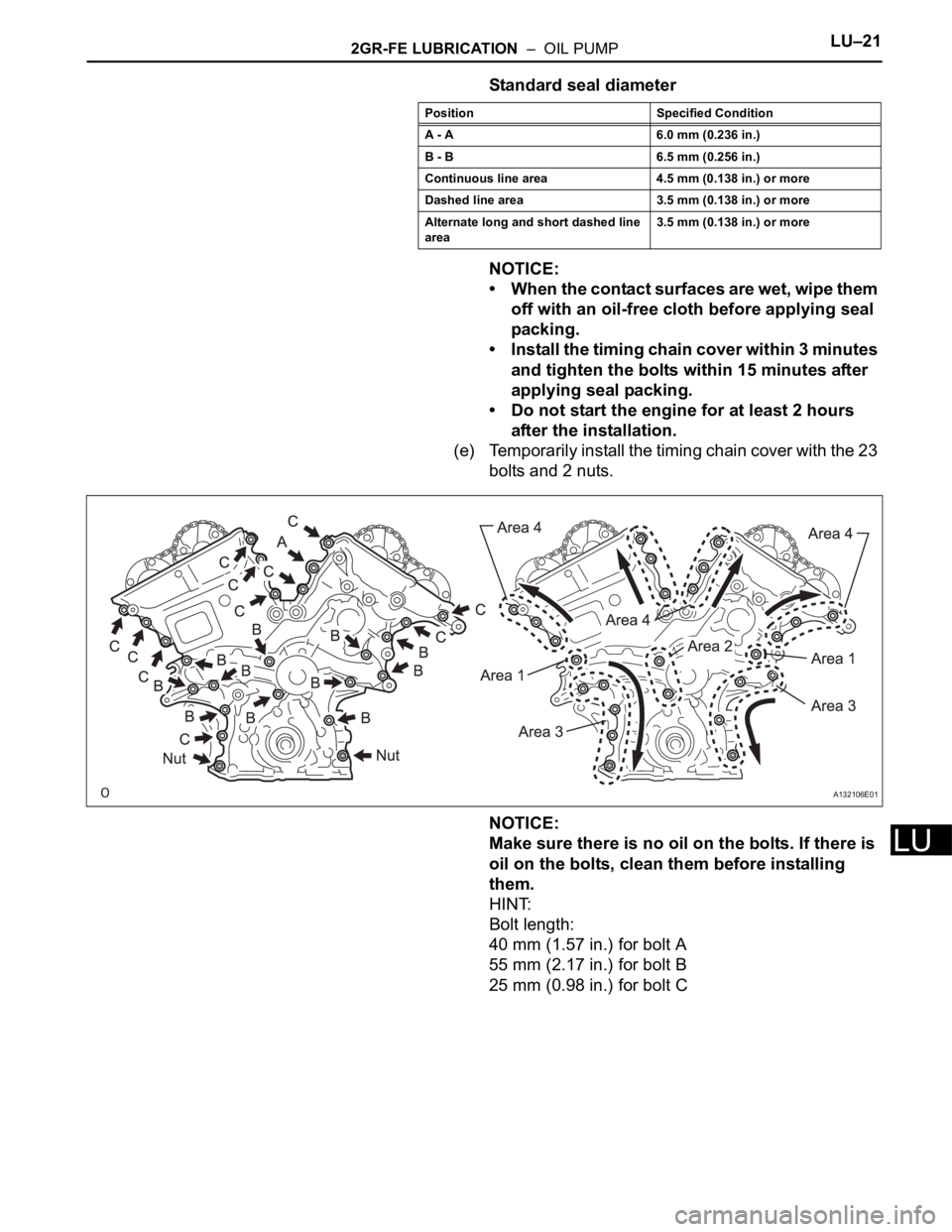

Standard seal diameter

NOTICE:

• When the contact surfaces are wet, wipe them

off with an oil-free cloth before applying seal

packing.

• Install the timing chain cover within 3 minutes

and tighten the bolts within 15 minutes after

applying seal packing.

• Do not start the engine for at least 2 hours

after the installation.

(e) Temporarily install the timing chain cover with the 23

bolts and 2 nuts.

NOTICE:

Make sure there is no oil on the bolts. If there is

oil on the bolts, clean them before installing

them.

HINT:

Bolt length:

40 mm (1.57 in.) for bolt A

55 mm (2.17 in.) for bolt B

25 mm (0.98 in.) for bolt C

Position Specified Condition

A - A 6.0 mm (0.236 in.)

B - B 6.5 mm (0.256 in.)

Continuous line area 4.5 mm (0.138 in.) or more

Dashed line area 3.5 mm (0.138 in.) or more

Alternate long and short dashed line

area3.5 mm (0.138 in.) or more

A132106E01

Page 882 of 2000

LU–222GR-FE LUBRICATION – OIL PUMP

LU

(f) Tighten the bolts in this order: Area 1, Area 2, Area

3, Area 4.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf) for Area

1, 2 bolt

21 N*m (214 kgf*cm, 15 ft.*lbf) for Area 3

bolt, nut

43 N*m (438 kgf*cm, 32 ft.*lbf) for Area 4

bolt A

21 N*m (214 kgf*cm, 15 ft.*lbf) for Area 4

except bolt A

2. INSTALL CRANKSHAFT PULLEY (See page EM-126)

3. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

(for Bank 2) (See page EM-127)

4. INSTALL NO. 1 OIL PIPE (See page EM-128)

5. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

(for Bank 1) (See page EM-127)

6. INSTALL OIL PIPE (See page EM-127)

7. INSTALL WATER INLET HOUSING (See page CO-14)

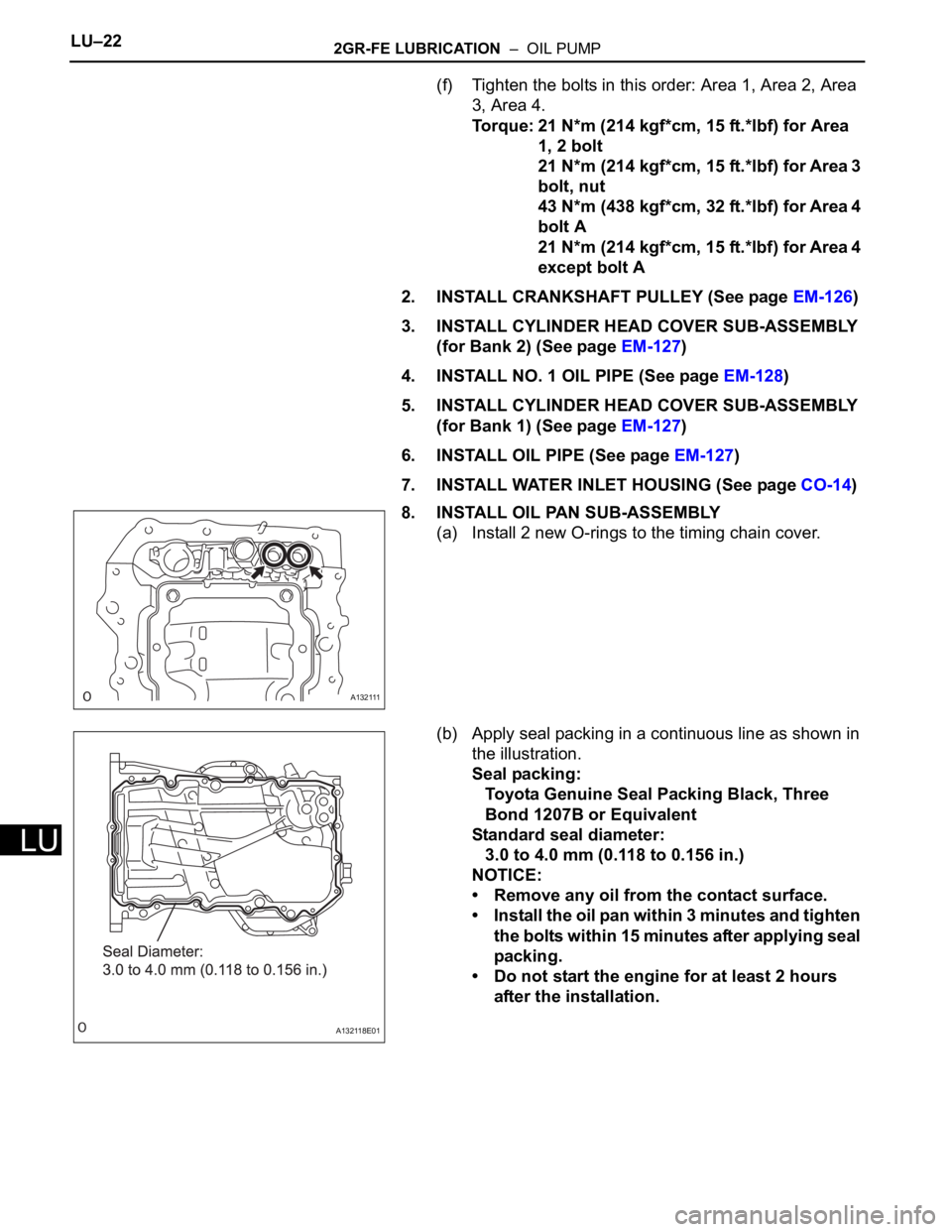

8. INSTALL OIL PAN SUB-ASSEMBLY

(a) Install 2 new O-rings to the timing chain cover.

(b) Apply seal packing in a continuous line as shown in

the illustration.

Seal packing:

Toyota Genuine Seal Packing Black, Three

Bond 1207B or Equivalent

Standard seal diameter:

3.0 to 4.0 mm (0.118 to 0.156 in.)

NOTICE:

• Remove any oil from the contact surface.

• Install the oil pan within 3 minutes and tighten

the bolts within 15 minutes after applying seal

packing.

• Do not start the engine for at least 2 hours

after the installation.

A132111

A132118E01

Page 883 of 2000

2GR-FE LUBRICATION – OIL PUMPLU–23

LU

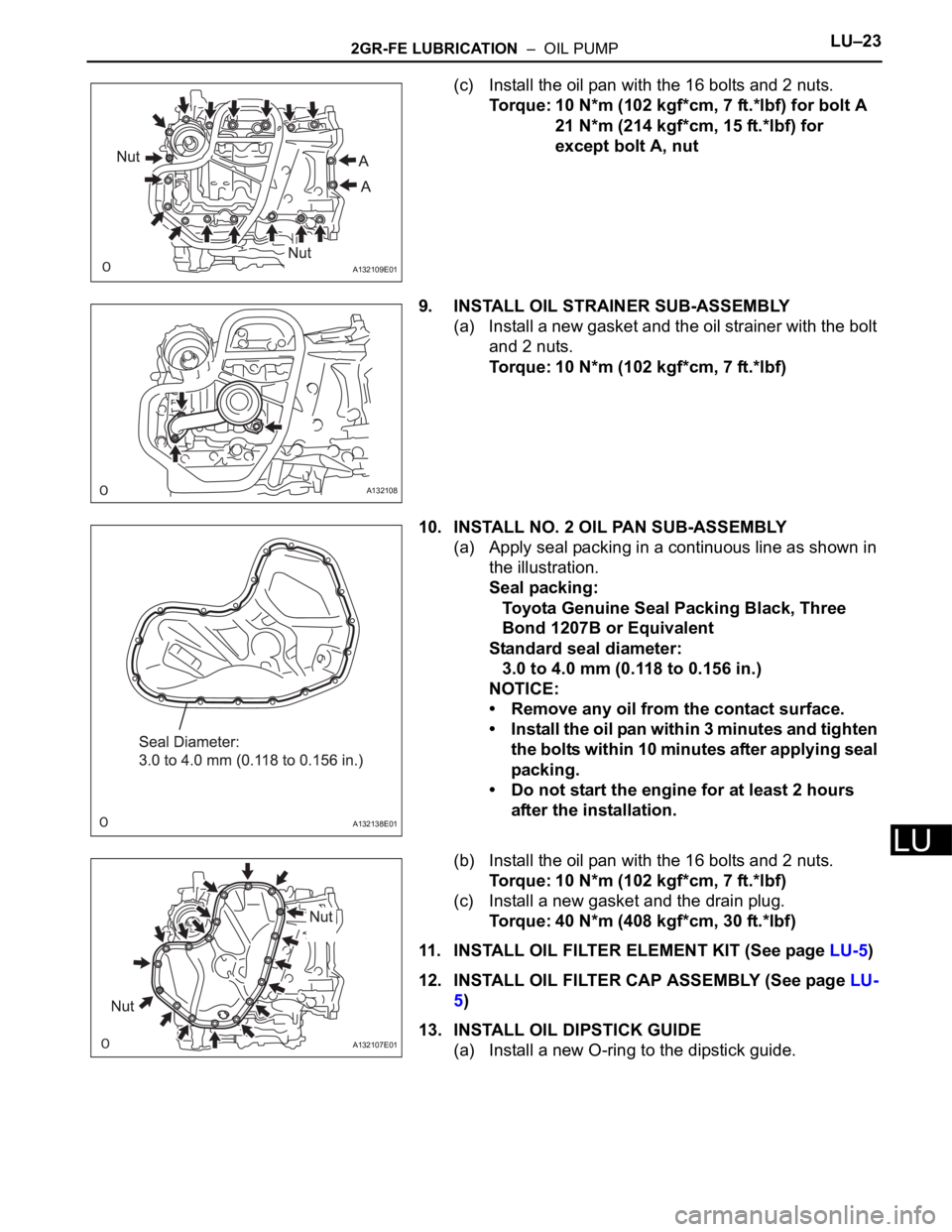

(c) Install the oil pan with the 16 bolts and 2 nuts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf) for bolt A

21 N*m (214 kgf*cm, 15 ft.*lbf) for

except bolt A, nut

9. INSTALL OIL STRAINER SUB-ASSEMBLY

(a) Install a new gasket and the oil strainer with the bolt

and 2 nuts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

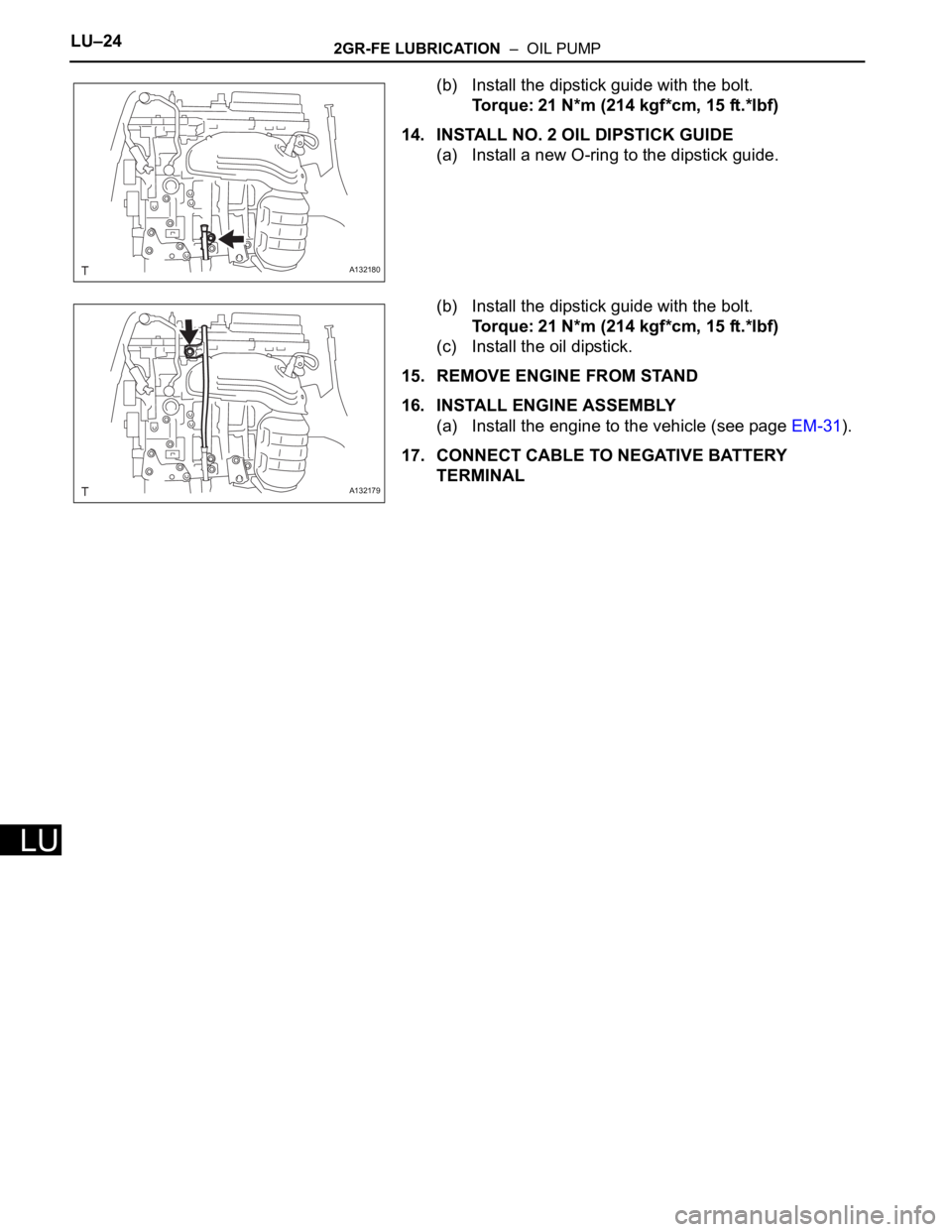

10. INSTALL NO. 2 OIL PAN SUB-ASSEMBLY

(a) Apply seal packing in a continuous line as shown in

the illustration.

Seal packing:

Toyota Genuine Seal Packing Black, Three

Bond 1207B or Equivalent

Standard seal diameter:

3.0 to 4.0 mm (0.118 to 0.156 in.)

NOTICE:

• Remove any oil from the contact surface.

• Install the oil pan within 3 minutes and tighten

the bolts within 10 minutes after applying seal

packing.

• Do not start the engine for at least 2 hours

after the installation.

(b) Install the oil pan with the 16 bolts and 2 nuts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(c) Install a new gasket and the drain plug.

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf)

11. INSTALL OIL FILTER ELEMENT KIT (See page LU-5)

12. INSTALL OIL FILTER CAP ASSEMBLY (See page LU-

5)

13. INSTALL OIL DIPSTICK GUIDE

(a) Install a new O-ring to the dipstick guide.

A132109E01

A132108

A132138E01

A132107E01

Page 884 of 2000

LU–242GR-FE LUBRICATION – OIL PUMP

LU

(b) Install the dipstick guide with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

14. INSTALL NO. 2 OIL DIPSTICK GUIDE

(a) Install a new O-ring to the dipstick guide.

(b) Install the dipstick guide with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(c) Install the oil dipstick.

15. REMOVE ENGINE FROM STAND

16. INSTALL ENGINE ASSEMBLY

(a) Install the engine to the vehicle (see page EM-31).

17. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

A132180

A132179

Page 885 of 2000

2AZ-FE IGNITION – IGNITION SYSTEMIG–5

IG

ON-VEHICLE INSPECTION

1. CHECK IGNITION COIL ASSEMBLY AND PERFORM

SPARK TEST

NOTICE:

In this section, the terms "cold" and "hot" refer to

the temperature of the coils. "Cold" means

approximately -10 to 50

C (14 to 122F). "Hot" means

approximately 50 to 100

C (122 to 212F).

(a) Check the DTCs.

NOTICE:

If a DTC is present, perform troubleshooting in

accordance with the procedure for that DTC.

(b) Check that sparks occur.

(1) Remove the No. 1 engine cover.

(2) Remove the bolt and ignition coil.

(3) Using a 16 mm spark plug wrench, remove the

spark plug.

(4) Disconnect the 4 fuel injector connectors.

(5) Install the spark plug into the ignition coil, and

then connect the ignition coil connectors.

(6) Ground the spark plug.

(7) Check that sparks occur at the spark plug while

the engine is being cranked.

NOTICE:

• Be sure to ground the spark plugs when

checking them.

• If the ignition coil has been struck or

dropped, replace it.

• Do not crank the engine for more than 2

seconds.

If sparks do not occur, Perform the spark test.

(8) Using a 16 mm plug wrench, install the spark

plug.

Torque: 25 N*m (254 kgf*cm, 18 ft.*lbf)

A124849E01

A097448E01

A124396

Page 886 of 2000

IG–62AZ-FE IGNITION – IGNITION SYSTEM

IG

(9) Install the ignition coil with the bolt.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

(10) Connect the 4 fuel injector connectors.

(11) Install the No. 1 engine cover.

(c) Spark test flow chart.

(1) Check that the ignition coil connector is

securely connected.

Result

(2) Perform the spark test on each ignition coil.

1. Replace the ignition coil with a normal one.

2. Perform the spark test again.

Result

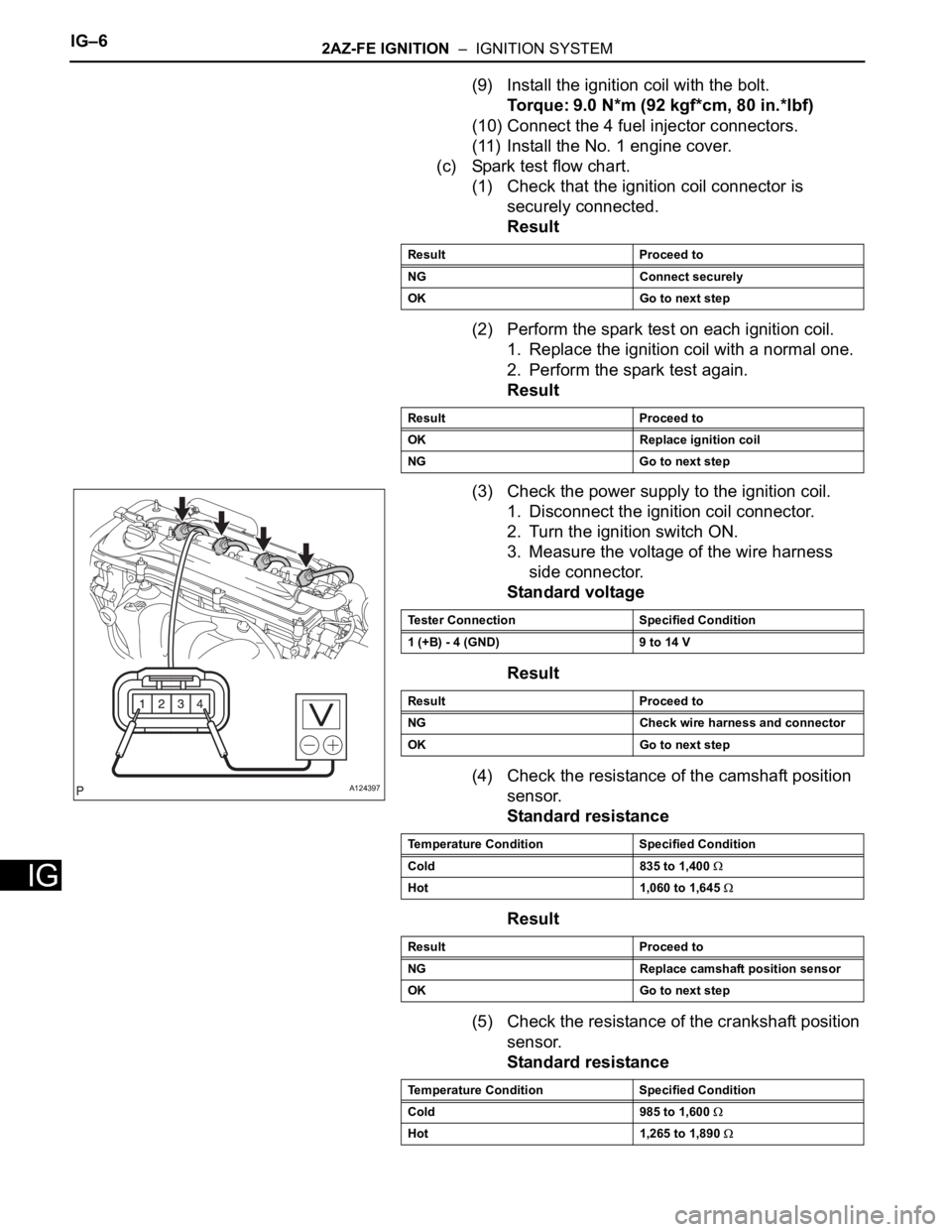

(3) Check the power supply to the ignition coil.

1. Disconnect the ignition coil connector.

2. Turn the ignition switch ON.

3. Measure the voltage of the wire harness

side connector.

Standard voltage

Result

(4) Check the resistance of the camshaft position

sensor.

Standard resistance

Result

(5) Check the resistance of the crankshaft position

sensor.

Standard resistance

Result Proceed to

NG Connect securely

OK Go to next step

Result Proceed to

OK Replace ignition coil

NG Go to next step

A124397

Tester Connection Specified Condition

1 (+B) - 4 (GND) 9 to 14 V

Result Proceed to

NG Check wire harness and connector

OK Go to next step

Temperature Condition Specified Condition

Cold 835 to 1,400

Hot 1,060 to 1,645

Result Proceed to

NG Replace camshaft position sensor

OK Go to next step

Temperature Condition Specified Condition

Cold 985 to 1,600

Hot 1,265 to 1,890

Page 887 of 2000

2AZ-FE IGNITION – IGNITION SYSTEMIG–7

IG

Result

(6) Check the IGT signal from the ECM.

Result

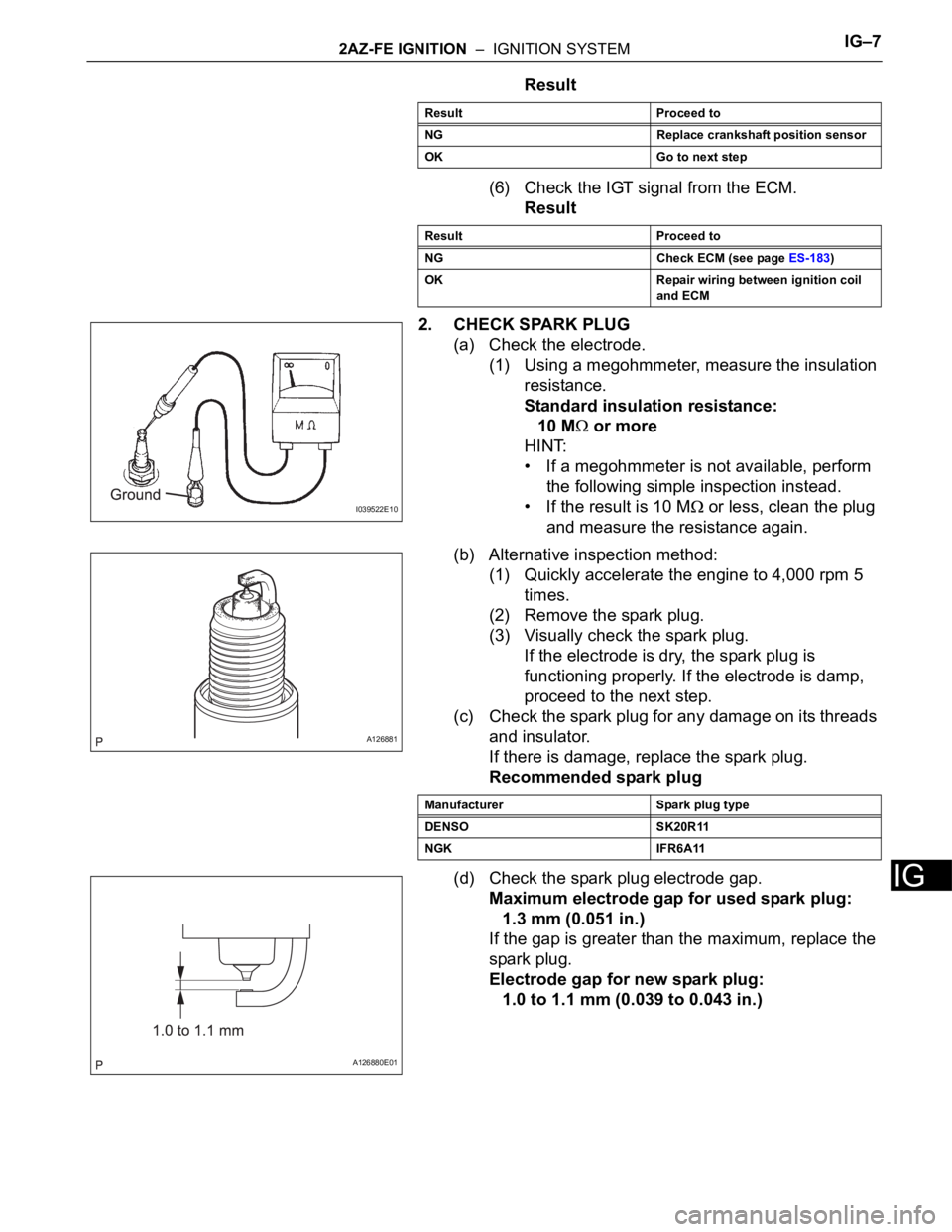

2. CHECK SPARK PLUG

(a) Check the electrode.

(1) Using a megohmmeter, measure the insulation

resistance.

Standard insulation resistance:

10 M

or more

HINT:

• If a megohmmeter is not available, perform

the following simple inspection instead.

• If the result is 10 M

or less, clean the plug

and measure the resistance again.

(b) Alternative inspection method:

(1) Quickly accelerate the engine to 4,000 rpm 5

times.

(2) Remove the spark plug.

(3) Visually check the spark plug.

If the electrode is dry, the spark plug is

functioning properly. If the electrode is damp,

proceed to the next step.

(c) Check the spark plug for any damage on its threads

and insulator.

If there is damage, replace the spark plug.

Recommended spark plug

(d) Check the spark plug electrode gap.

Maximum electrode gap for used spark plug:

1.3 mm (0.051 in.)

If the gap is greater than the maximum, replace the

spark plug.

Electrode gap for new spark plug:

1.0 to 1.1 mm (0.039 to 0.043 in.)

Result Proceed to

NG Replace crankshaft position sensor

OK Go to next step

Result Proceed to

NG Check ECM (see page ES-183)

OK Repair wiring between ignition coil

and ECM

I039522E10

A126881

Manufacturer Spark plug type

DENSO SK20R11

NGK IFR6A11

A126880E01

Page 895 of 2000

2GR-FE IGNITION – IGNITION SYSTEMIG–5

IG

ON-VEHICLE INSPECTION

1. CHECK IGNITION COIL ASSEMBLY AND PERFORM

SPARK TEST

NOTICE:

In this section, the terms "Cold" and "Hot" refer to

the temperature of the sensor. "Cold" means

approximately -10 to 50

C (14 to 122F). "Hot" means

approximately 50 to 100

C (122 to 212F).

(a) Check the DTCs.

NOTICE:

If a DTC is present, perform troubleshooting in

accordance with the procedure for that DTC.

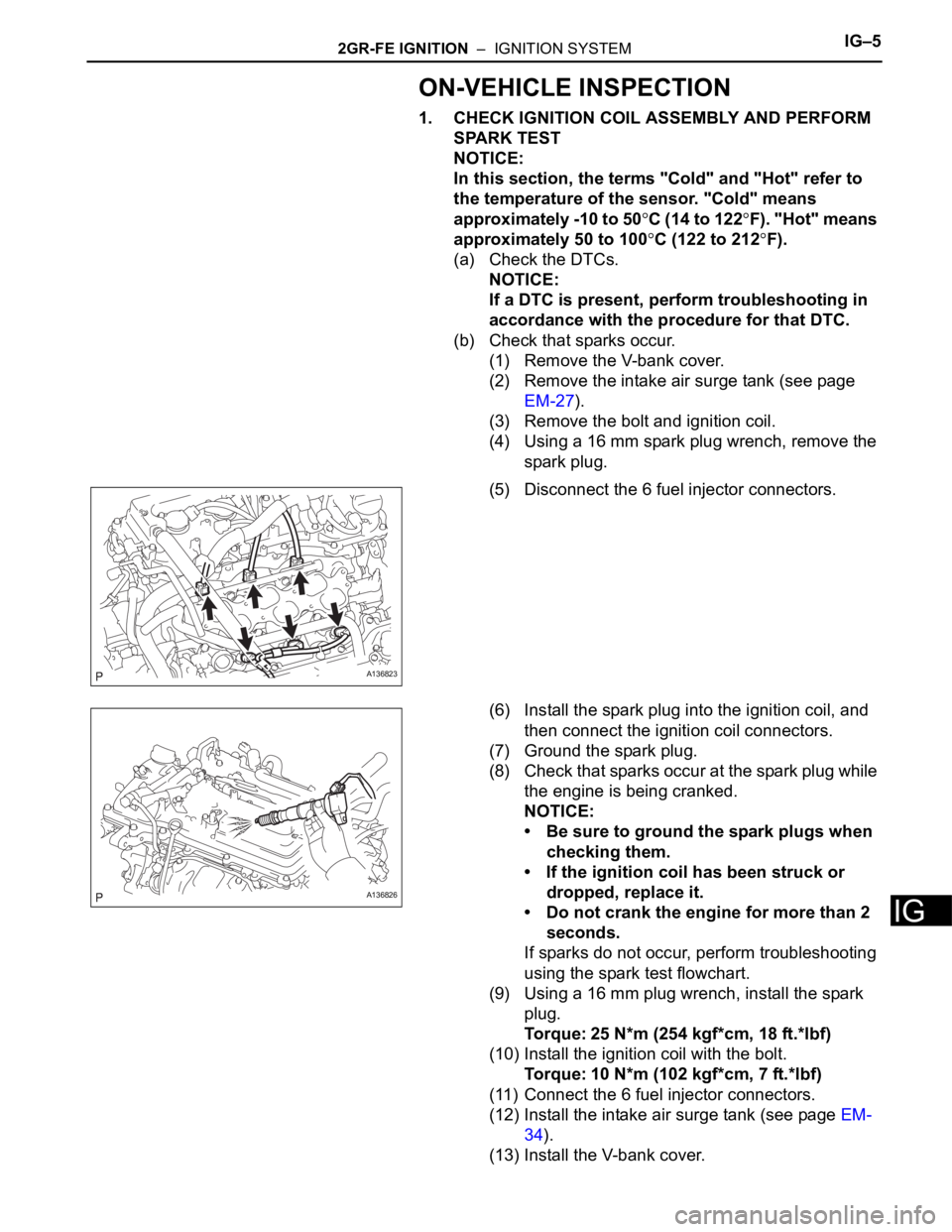

(b) Check that sparks occur.

(1) Remove the V-bank cover.

(2) Remove the intake air surge tank (see page

EM-27).

(3) Remove the bolt and ignition coil.

(4) Using a 16 mm spark plug wrench, remove the

spark plug.

(5) Disconnect the 6 fuel injector connectors.

(6) Install the spark plug into the ignition coil, and

then connect the ignition coil connectors.

(7) Ground the spark plug.

(8) Check that sparks occur at the spark plug while

the engine is being cranked.

NOTICE:

• Be sure to ground the spark plugs when

checking them.

• If the ignition coil has been struck or

dropped, replace it.

• Do not crank the engine for more than 2

seconds.

If sparks do not occur, perform troubleshooting

using the spark test flowchart.

(9) Using a 16 mm plug wrench, install the spark

plug.

Torque: 25 N*m (254 kgf*cm, 18 ft.*lbf)

(10) Install the ignition coil with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(11) Connect the 6 fuel injector connectors.

(12) Install the intake air surge tank (see page EM-

34).

(13) Install the V-bank cover.

A136823

A136826