engine TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 977 of 2000

U140F AUTOMATIC TRANSAXLE – DIFFERENTIAL OIL SEALAX–145

AX

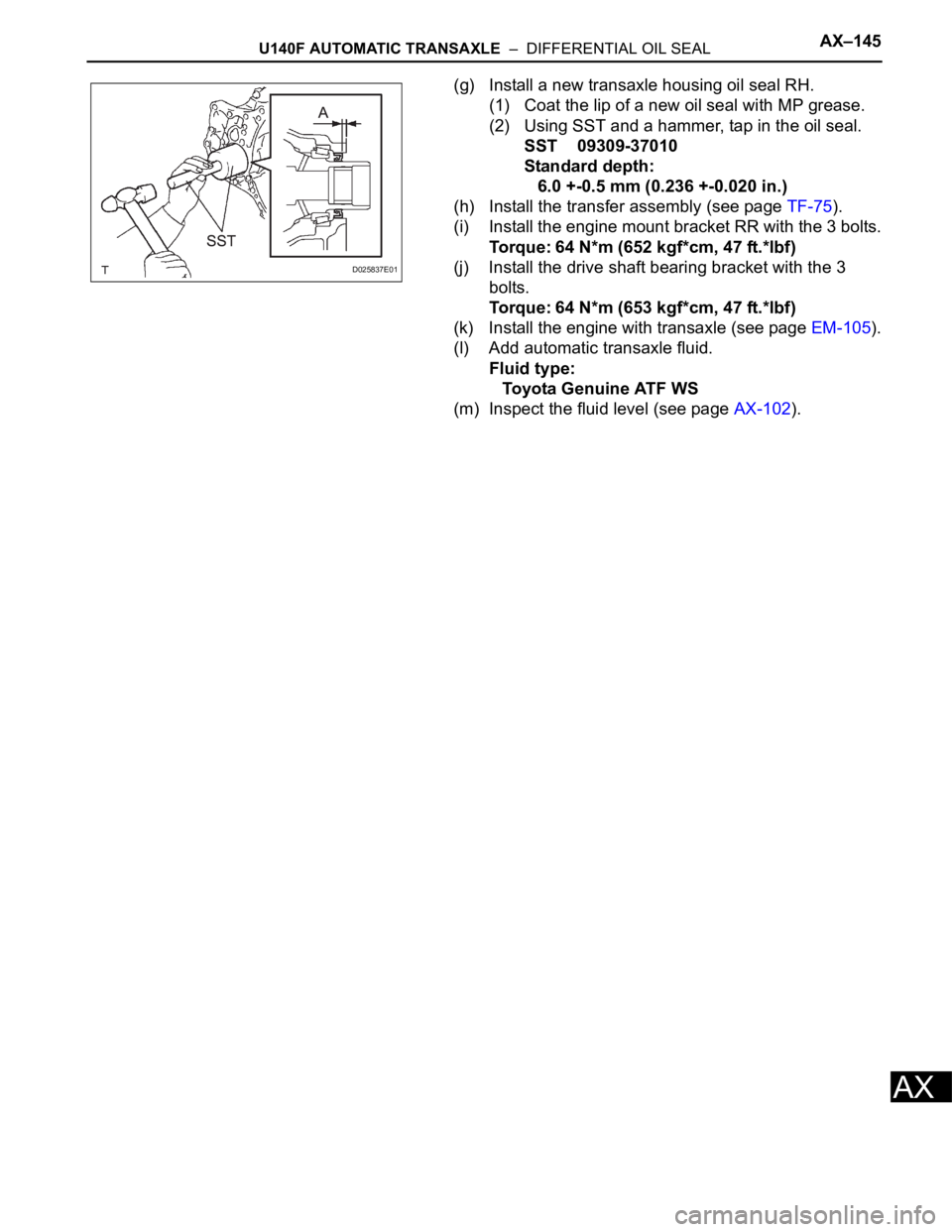

(g) Install a new transaxle housing oil seal RH.

(1) Coat the lip of a new oil seal with MP grease.

(2) Using SST and a hammer, tap in the oil seal.

SST 09309-37010

Standard depth:

6.0 +-0.5 mm (0.236 +-0.020 in.)

(h) Install the transfer assembly (see page TF-75).

(i) Install the engine mount bracket RR with the 3 bolts.

Torque: 64 N*m (652 kgf*cm, 47 ft.*lbf)

(j) Install the drive shaft bearing bracket with the 3

bolts.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf)

(k) Install the engine with transaxle (see page EM-105).

(l) Add automatic transaxle fluid.

Fluid type:

Toyota Genuine ATF WS

(m) Inspect the fluid level (see page AX-102).

D025837E01

Page 979 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLYAX–151

AX

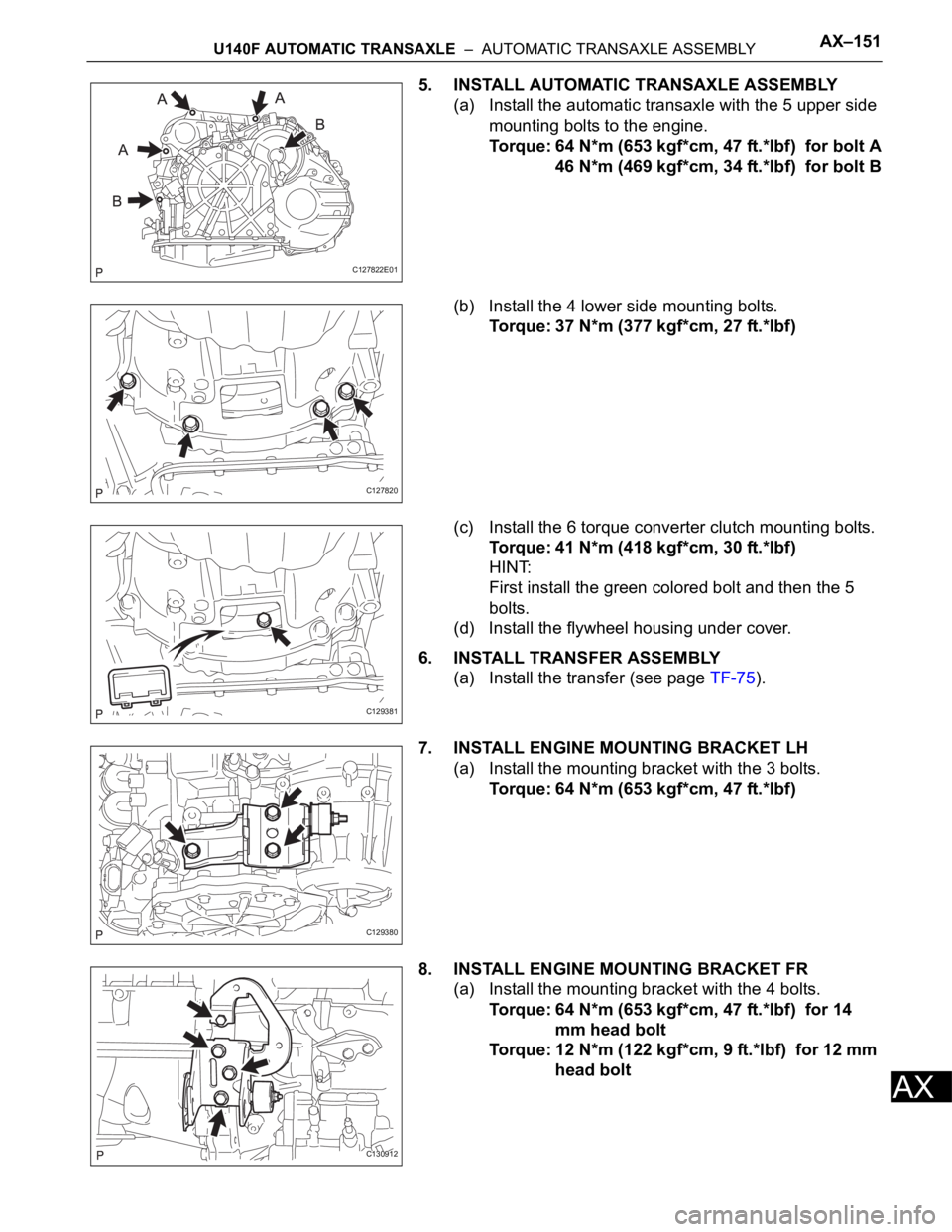

5. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY

(a) Install the automatic transaxle with the 5 upper side

mounting bolts to the engine.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf) for bolt A

46 N*m (469 kgf*cm, 34 ft.*lbf) for bolt B

(b) Install the 4 lower side mounting bolts.

Torque: 37 N*m (377 kgf*cm, 27 ft.*lbf)

(c) Install the 6 torque converter clutch mounting bolts.

Torque: 41 N*m (418 kgf*cm, 30 ft.*lbf)

HINT:

First install the green colored bolt and then the 5

bolts.

(d) Install the flywheel housing under cover.

6. INSTALL TRANSFER ASSEMBLY

(a) Install the transfer (see page TF-75).

7. INSTALL ENGINE MOUNTING BRACKET LH

(a) Install the mounting bracket with the 3 bolts.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf)

8. INSTALL ENGINE MOUNTING BRACKET FR

(a) Install the mounting bracket with the 4 bolts.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf) for 14

mm head bolt

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf) for 12 mm

head bolt

C127822E01

C127820

C129381

C129380

C130912

Page 980 of 2000

AX–152U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLY

AX

9. INSTALL ENGINE MOUNTING BRACKET RR

(a) Install the mounting bracket with the 3 bolts.

Torque: 45 N*m (459 kgf*cm, 33 ft.*lbf)

10. INSTALL TRANSMISSION OIL COOLER

(a) Install the oil cooler (see page AX-127).

11. CONNECT WIRE HARNESS

(a) Connect the wire harness clamps.

(b) Connect the 2 speed sensor connectors.

(c) Connect the transaxle wire connector.

(d) Connect the park/neutral position switch connector.

12. INSTALL STARTER ASSEMBLY

(a) Install the starter with the 2 bolts.

Torque: 37 N*m (377 kgf*cm, 27 ft.*lbf)

(b) Connect the starter wire with the nut.

Torque: 13 N*m (133 kgf*cm, 10 ft.*lbf)

(c) Connect the starter connector.

(d) Install the terminal nut and cover the nut with the

cap.

Torque: 9.8 N*m (100 kgf*cm, 7 in.*lbf)

13. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

(a) Install the engine with transaxle. (see page EM-

105).

14. ADD AUTOMATIC TRANSAXLE FLUID

Fluid type:

Toyota Genuine ATF WS

15. INSPECT AUTOMATIC TRANSAXLE FLUID

(a) Inspect the automatic transaxle fluid (see page AX-

102).

16. PERFORM RESET MEMORY

(a) Perform the RESET MEMORY procedures (A/T

initialization) (see page AX-18).

C130913

C127821

A124921

A124920

Page 1026 of 2000

AX–10U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

SYSTEM DESCRIPTION

1. SYSTEM DESCRIPTION

(a) The Electronic Controlled Automatic Transaxle

(ECT) is an automatic transaxle that electronically

controls shift timing using the Engine Control

Module (ECM). The ECM detects electrical signals

that indicate engine and driving conditions, and

controls the shift point based on driver habits and

road conditions. As a result, fuel efficiency and

power transaxle performance are improved.

Shift shock is reduced by controlling the engine and

transaxle simultaneously.

In addition, the ECT has the following features:

• Diagnostic function.

• Fail-safe function when a malfunction occurs.

Page 1031 of 2000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–15

AX

ROAD TEST

1. PROBLEM SYMPTOM CONFIRMATION

(a) Based on the result of the customer problem

analysis, try to reproduce the symptoms. If the

problem is that the transaxle does not shift up, shift

down, or the shift point is too high or too low,

conduct the following road test referring to the

automatic shift schedule and simulate the problem

symptoms.

2. ROAD TEST

NOTICE:

Perform the test at the normal operating ATF

temperature of 50 to 80

C (122 to 176F).

(a) D position test:

Move the shift lever to D and fully depress the

accelerator pedal. Check the following:

(1) Check up-shift operation.

Check that the 1

2, 2 3, 3 4 and 4 5th

up-shifts take place at the shift point shown in

the automatic shift schedule (see page SS-43).

HINT:

5th Gear Up-shift Prohibition Control

• Engine coolant temperature is 55

C (131F)

or less and vehicle speed is at 80 km/h (50

mph) or less.

• ATF temperature is -2

C (28F) or less.

4th Gear Up-shift Prohibition Control

• Engine coolant temperature is 47

C (117F)

or less and vehicle speed is at 55 km/h (34

mph) or less.

5th and 4th Gear Lock-up Prohibition Control

• Brake pedal is depressed.

• Accelerator pedal is released.

• Engine coolant temperature is 60

C (140F)

or less.

(2) Check for shift shock and slip.

Check for shock and slip at the 1

2, 2 3, 3

4 and 4 5th up-shifts.

(3) Check for abnormal noise and vibration.

Check for abnormal noise and vibration when

up-shifting from 1

2, 2 3, 3 4 and 4

5th while driving with the shift lever on D, and

check while driving in the lock-up condition.

HINT:

The check for the cause of abnormal noise and

vibration must be done thoroughly as it could

also be due to loss of balance in the differential,

torque converter clutch, etc.

Page 1032 of 2000

AX–16U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

(4) Check kick-down operation.

While driving the vehicle in the 2nd, 3rd, 4th and

5th gears with the shift lever on D, check that the

possible kick-down vehicle speed limits for 2

1, 3

2, 4 3 and 5 4 kick-downs conform

to those indicated in the automatic shift schedule

(see page SS-43).

(5) Check for abnormal shock and slip at kick-down.

(6) Check the lock-up mechanism.

• Drive the vehicle in the 5th gear with the shift

lever on D. Maintain a steady speed (lock-up

ON).

• Lightly depress the accelerator pedal and

check that the engine speed does not change

abruptly.

HINT:

• There is no lock-up in the 1st, 2nd and 3rd

gear.

• 4th lock-up operates while uphill-downhill

control is active with the shift lever on D.

• If there is a sudden increase in engine speed,

there is no lock-up.

(b) 4 (O/D OFF) position test:

Move the shift lever to 4 and fully depress the

accelerator pedal. Check the following:

(1) Check up-shift operation.

Check that the 1

2, 2 3 and 3 4 up-shifts

take place and that the shifts point conforms to

the automatic shift schedule (see page SS-43).

HINT:

There is no 5th up-shift in the 4 position.

(2) Check engine braking.

While driving the vehicle in the 4th gear with the

shift lever on 4, release the accelerator pedal

and check the engine braking effect.

(3) Check for abnormal noise during acceleration

and deceleration, and for shock at up-shift and

down-shift.

(c) 3 position test:

Move the shift lever to 3 and fully depress the

accelerator pedal. Check the following:

(1) Check up-shift operation.

Check that the 1

2 and 2 3 up-shifts take

place and that the shifts point conforms to the

automatic shift schedule (see page SS-43).

HINT:

There is no 3rd up-shift and lock-up in the 3

position.

(2) Check engine braking.

While driving the vehicle in the 3rd gear with the

shift lever on 3, release the accelerator pedal

and check the engine braking effect.

Page 1033 of 2000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–17

AX

(3) Check for abnormal noise during acceleration

and deceleration, and for shock at up-shift and

down-shift.

(d) 2 position test:

Move the shift lever to 2 and fully depress the

accelerator pedal. Check the following:

(1) Check up-shift operation.

Check that the 1

2 up-shifts take place and

that the shift point conforms to the automatic

shift schedule (see page SS-43).

HINT:

There is no 3rd up-shift and lock-up when the

shift lever is on 2.

(2) Check engine braking.

While driving the vehicle in the 2nd gear with the

shift lever on 2, release the accelerator pedal

and check the engine braking effect.

(3) Check for abnormal noise during acceleration

and deceleration, and for shock at up-shift and

down-shift.

(e) L position test:

Move the shift lever to L and fully depress the

accelerator pedal. Check the following:

(1) Check no up-shift.

While driving the vehicle with the shift lever on L,

check that there is no up-shift to 2nd gear.

HINT:

There is no lock-up in L.

(2) Check engine braking.

While driving the vehicle with the shift lever on L,

release the accelerator pedal and check the

engine braking effect.

(3) Check for abnormal noises during acceleration

and deceleration.

(f) R position test:

Move the shift lever to R and lightly depress the

accelerator pedal. Check that the vehicle moves

backward without any abnormal noise or vibration.

CAUTION:

Before conducting this test, ensure that no

people or obstacles are in the test area.

(g) P position test:

Stop the vehicle on an incline (more than 5

). Then

move the shift lever to P and release the parking

brake. Check that the parking lock pawl holds the

vehicle in place.

(h) Uphill/downhill control function test:

(1) Check that the gear does not up-shift to the 4th

or 5th gear while the vehicle is driving uphill.

(2) Check that the gear automatically down-shifts

from 5

4 or from 4 3 when the brake is

applied while the vehicle is driving downhill.

Page 1034 of 2000

AX–18U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

MECHANICAL SYSTEM TESTS

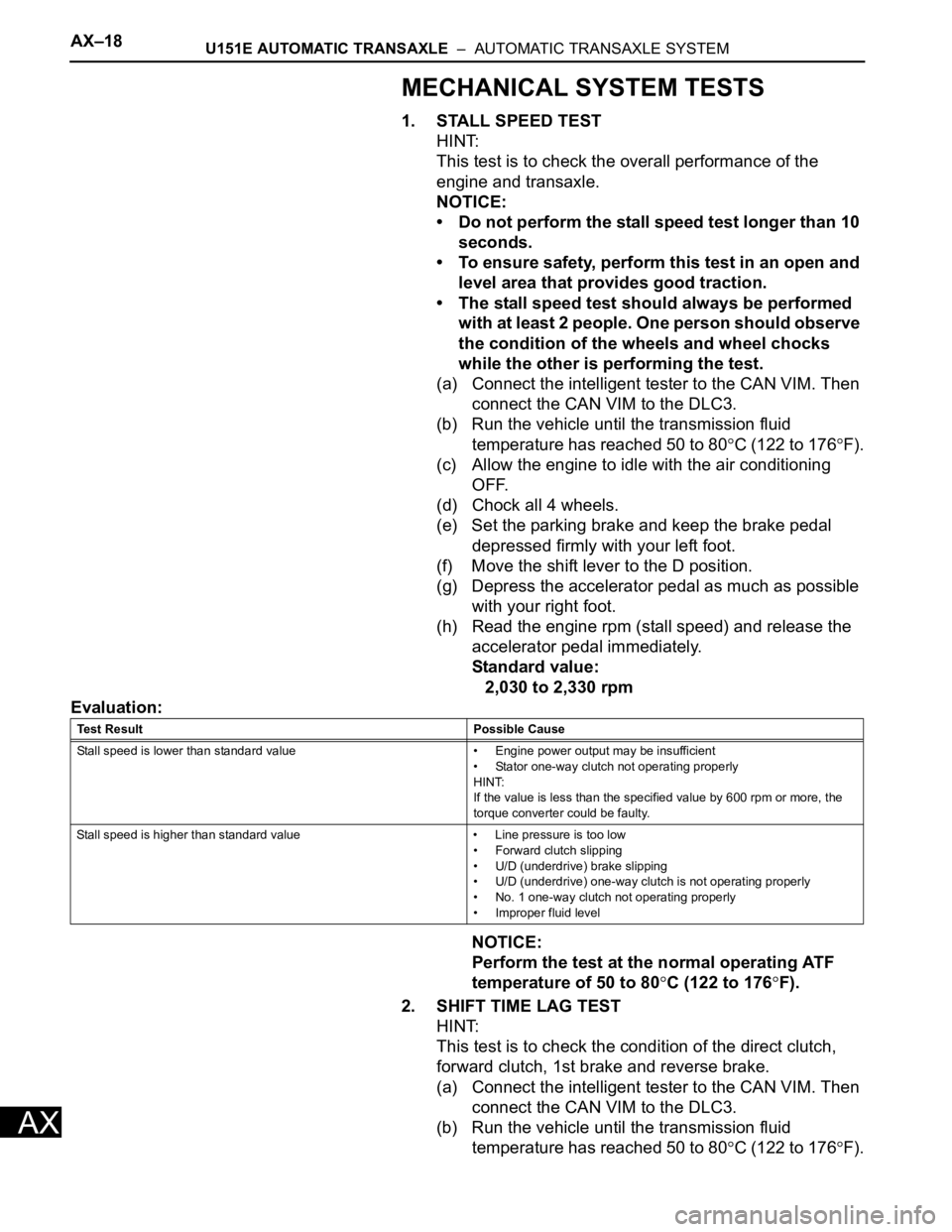

1. STALL SPEED TEST

HINT:

This test is to check the overall performance of the

engine and transaxle.

NOTICE:

• Do not perform the stall speed test longer than 10

seconds.

• To ensure safety, perform this test in an open and

level area that provides good traction.

• The stall speed test should always be performed

with at least 2 people. One person should observe

the condition of the wheels and wheel chocks

while the other is performing the test.

(a) Connect the intelligent tester to the CAN VIM. Then

connect the CAN VIM to the DLC3.

(b) Run the vehicle until the transmission fluid

temperature has reached 50 to 80

C (122 to 176F).

(c) Allow the engine to idle with the air conditioning

OFF.

(d) Chock all 4 wheels.

(e) Set the parking brake and keep the brake pedal

depressed firmly with your left foot.

(f) Move the shift lever to the D position.

(g) Depress the accelerator pedal as much as possible

with your right foot.

(h) Read the engine rpm (stall speed) and release the

accelerator pedal immediately.

Standard value:

2,030 to 2,330 rpm

Evaluation:

NOTICE:

Perform the test at the normal operating ATF

temperature of 50 to 80

C (122 to 176F).

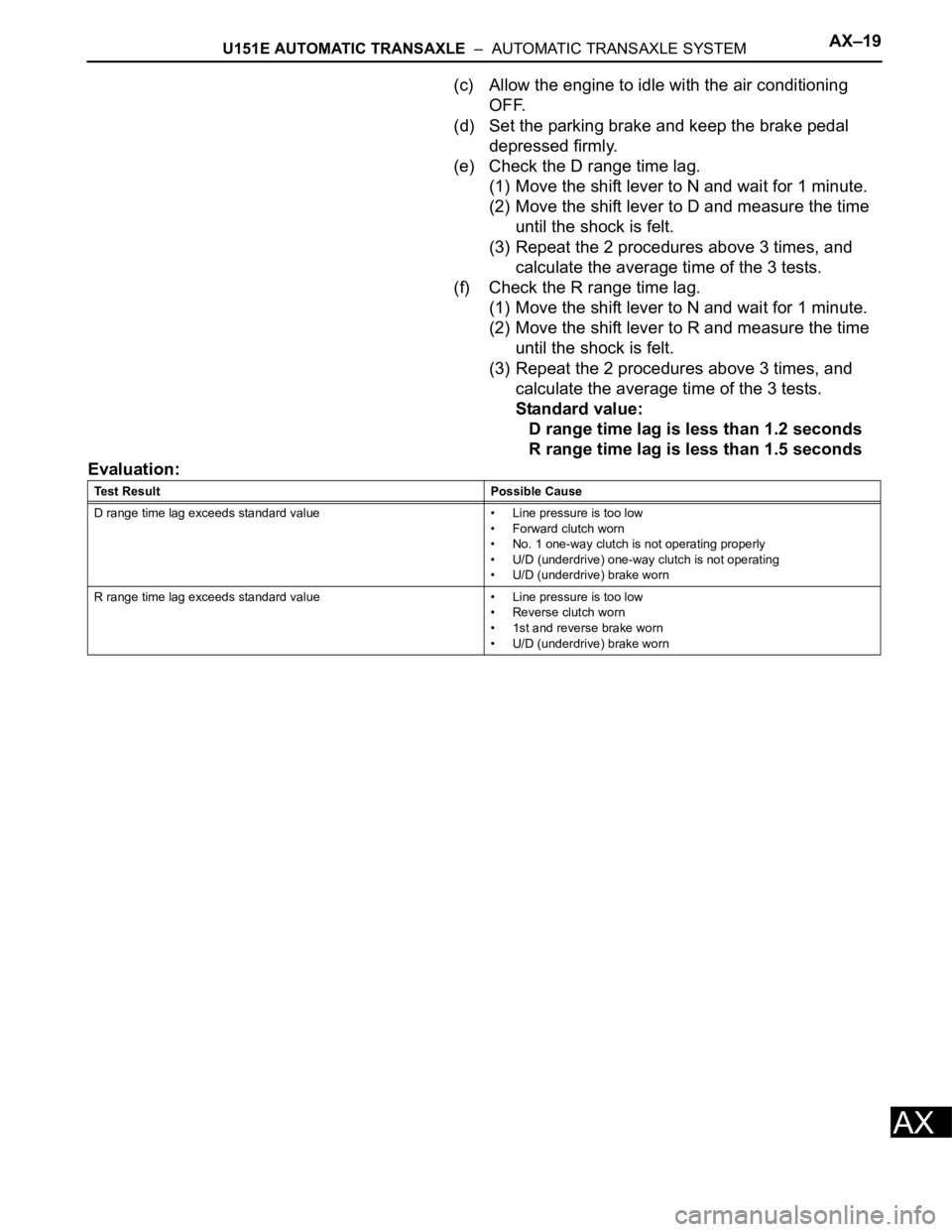

2. SHIFT TIME LAG TEST

HINT:

This test is to check the condition of the direct clutch,

forward clutch, 1st brake and reverse brake.

(a) Connect the intelligent tester to the CAN VIM. Then

connect the CAN VIM to the DLC3.

(b) Run the vehicle until the transmission fluid

temperature has reached 50 to 80

C (122 to 176F).

Test Result Possible Cause

Stall speed is lower than standard value • Engine power output may be insufficient

• Stator one-way clutch not operating properly

HINT:

If the value is less than the specified value by 600 rpm or more, the

torque converter could be faulty.

Stall speed is higher than standard value • Line pressure is too low

• Forward clutch slipping

• U/D (underdrive) brake slipping

• U/D (underdrive) one-way clutch is not operating properly

• No. 1 one-way clutch not operating properly

• Improper fluid level

Page 1035 of 2000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–19

AX

(c) Allow the engine to idle with the air conditioning

OFF.

(d) Set the parking brake and keep the brake pedal

depressed firmly.

(e) Check the D range time lag.

(1) Move the shift lever to N and wait for 1 minute.

(2) Move the shift lever to D and measure the time

until the shock is felt.

(3) Repeat the 2 procedures above 3 times, and

calculate the average time of the 3 tests.

(f) Check the R range time lag.

(1) Move the shift lever to N and wait for 1 minute.

(2) Move the shift lever to R and measure the time

until the shock is felt.

(3) Repeat the 2 procedures above 3 times, and

calculate the average time of the 3 tests.

Standard value:

D range time lag is less than 1.2 seconds

R range time lag is less than 1.5 seconds

Evaluation:

Test Result Possible Cause

D range time lag exceeds standard value • Line pressure is too low

• Forward clutch worn

• No. 1 one-way clutch is not operating properly

• U/D (underdrive) one-way clutch is not operating

• U/D (underdrive) brake worn

R range time lag exceeds standard value • Line pressure is too low

• Reverse clutch worn

• 1st and reverse brake worn

• U/D (underdrive) brake worn

Page 1036 of 2000

AX–20U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

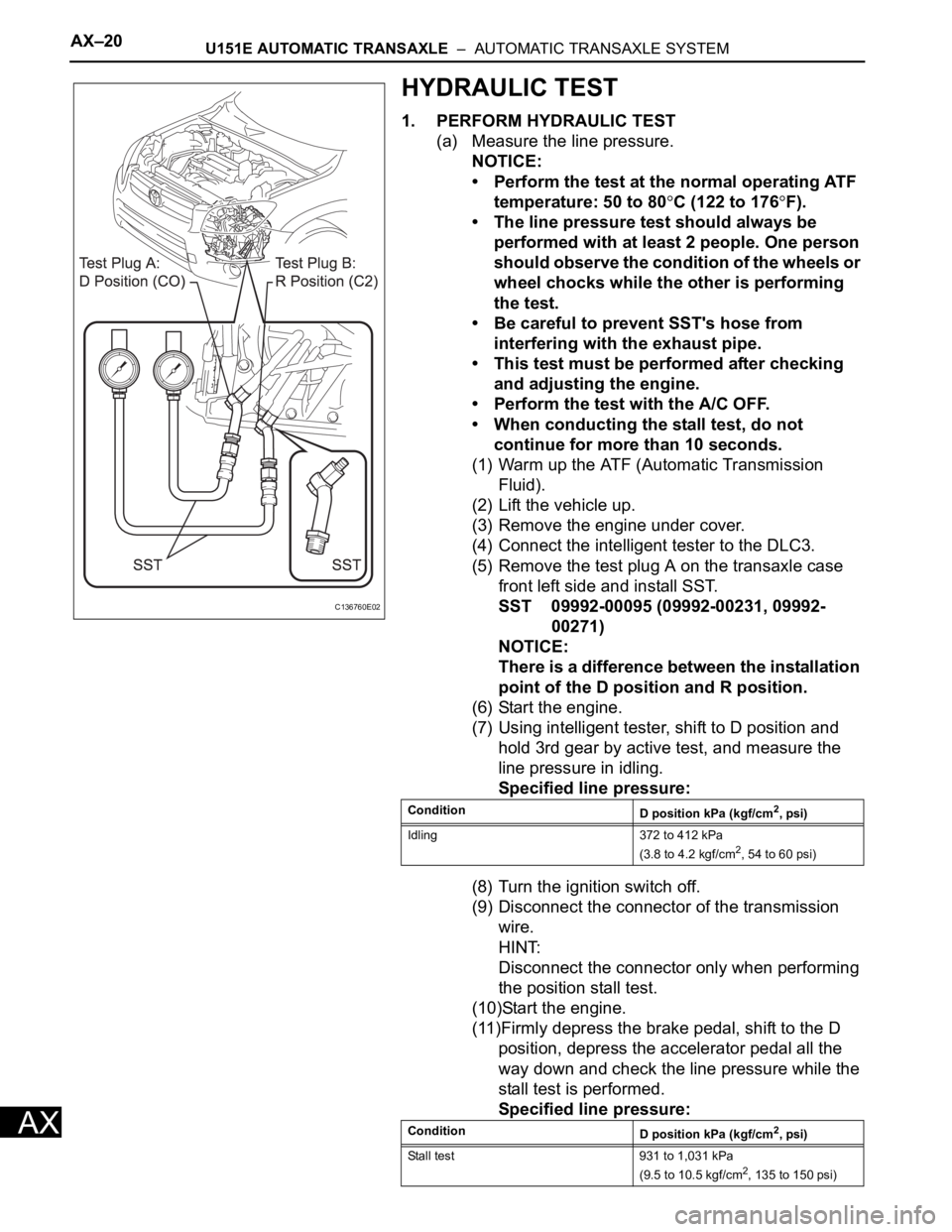

HYDRAULIC TEST

1. PERFORM HYDRAULIC TEST

(a) Measure the line pressure.

NOTICE:

• Perform the test at the normal operating ATF

temperature: 50 to 80

C (122 to 176F).

• The line pressure test should always be

performed with at least 2 people. One person

should observe the condition of the wheels or

wheel chocks while the other is performing

the test.

• Be careful to prevent SST's hose from

interfering with the exhaust pipe.

• This test must be performed after checking

and adjusting the engine.

• Perform the test with the A/C OFF.

• When conducting the stall test, do not

continue for more than 10 seconds.

(1) Warm up the ATF (Automatic Transmission

Fluid).

(2) Lift the vehicle up.

(3) Remove the engine under cover.

(4) Connect the intelligent tester to the DLC3.

(5) Remove the test plug A on the transaxle case

front left side and install SST.

SST 09992-00095 (09992-00231, 09992-

00271)

NOTICE:

There is a difference between the installation

point of the D position and R position.

(6) Start the engine.

(7) Using intelligent tester, shift to D position and

hold 3rd gear by active test, and measure the

line pressure in idling.

Specified line pressure:

(8) Turn the ignition switch off.

(9) Disconnect the connector of the transmission

wire.

HINT:

Disconnect the connector only when performing

the position stall test.

(10)Start the engine.

(11)Firmly depress the brake pedal, shift to the D

position, depress the accelerator pedal all the

way down and check the line pressure while the

stall test is performed.

Specified line pressure:

C136760E02

Condition

D position kPa (kgf/cm2, psi)

Idling 372 to 412 kPa

(3.8 to 4.2 kgf/cm

2, 54 to 60 psi)

Condition

D position kPa (kgf/cm

2, psi)

Stall test 931 to 1,031 kPa

(9.5 to 10.5 kgf/cm

2, 135 to 150 psi)