Install air manifold TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 630 of 2000

EM–862AZ-FE ENGINE MECHANICAL – CYLINDER HEAD

EM

22. INSTALL ENGINE MOUNTING INSULATOR RH (See

page EM-41)

23. INSTALL RADIATOR RESERVOIR (See page EM-112)

24. INSTALL GENERATOR ASSEMBLY (See page CH-15)

25. INSTALL FAN AND GENERATOR V BELT (See page

EM-7)

26. INSTALL FRONT SUSPENSION MEMBER

REINFORCEMENT RH (See page EM-7)

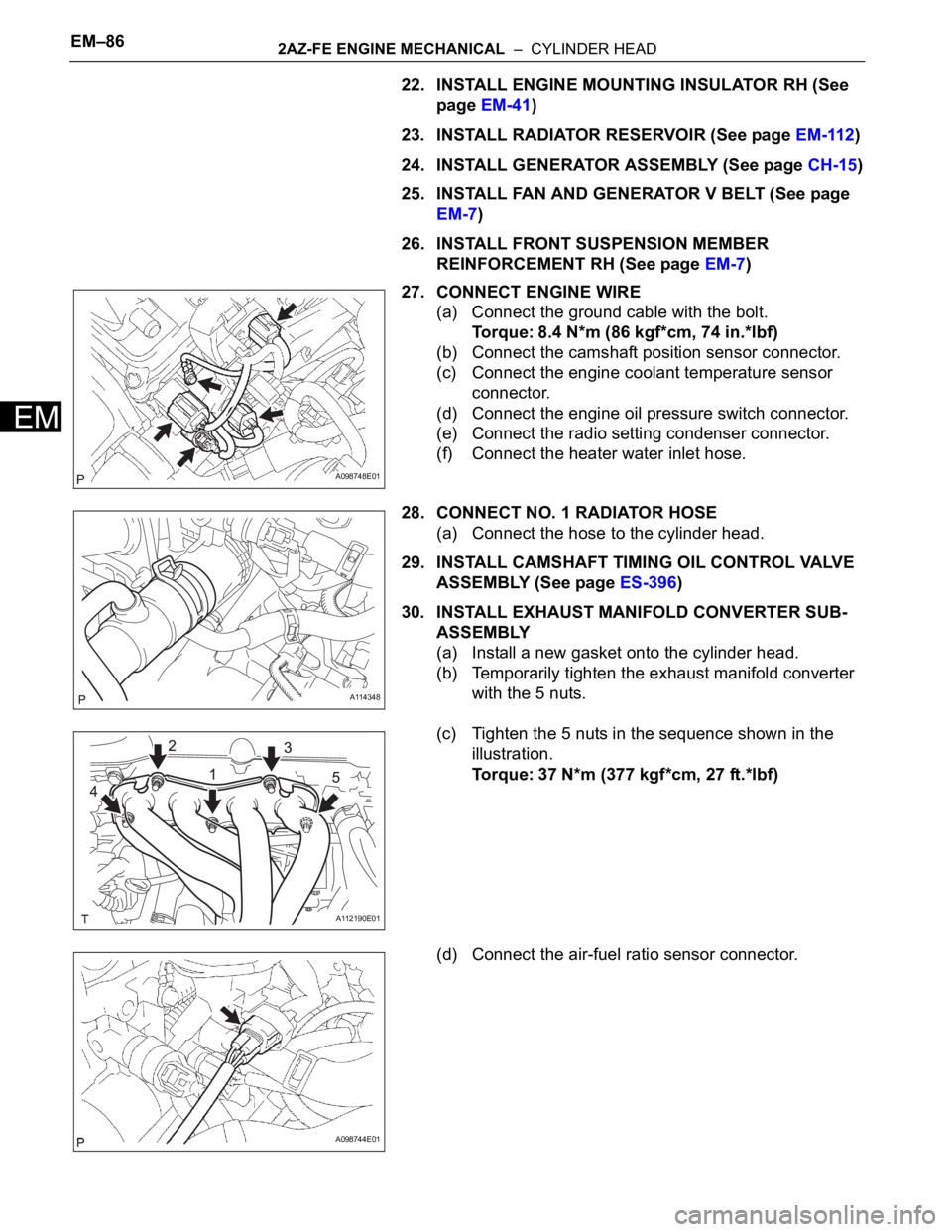

27. CONNECT ENGINE WIRE

(a) Connect the ground cable with the bolt.

Torque: 8.4 N*m (86 kgf*cm, 74 in.*lbf)

(b) Connect the camshaft position sensor connector.

(c) Connect the engine coolant temperature sensor

connector.

(d) Connect the engine oil pressure switch connector.

(e) Connect the radio setting condenser connector.

(f) Connect the heater water inlet hose.

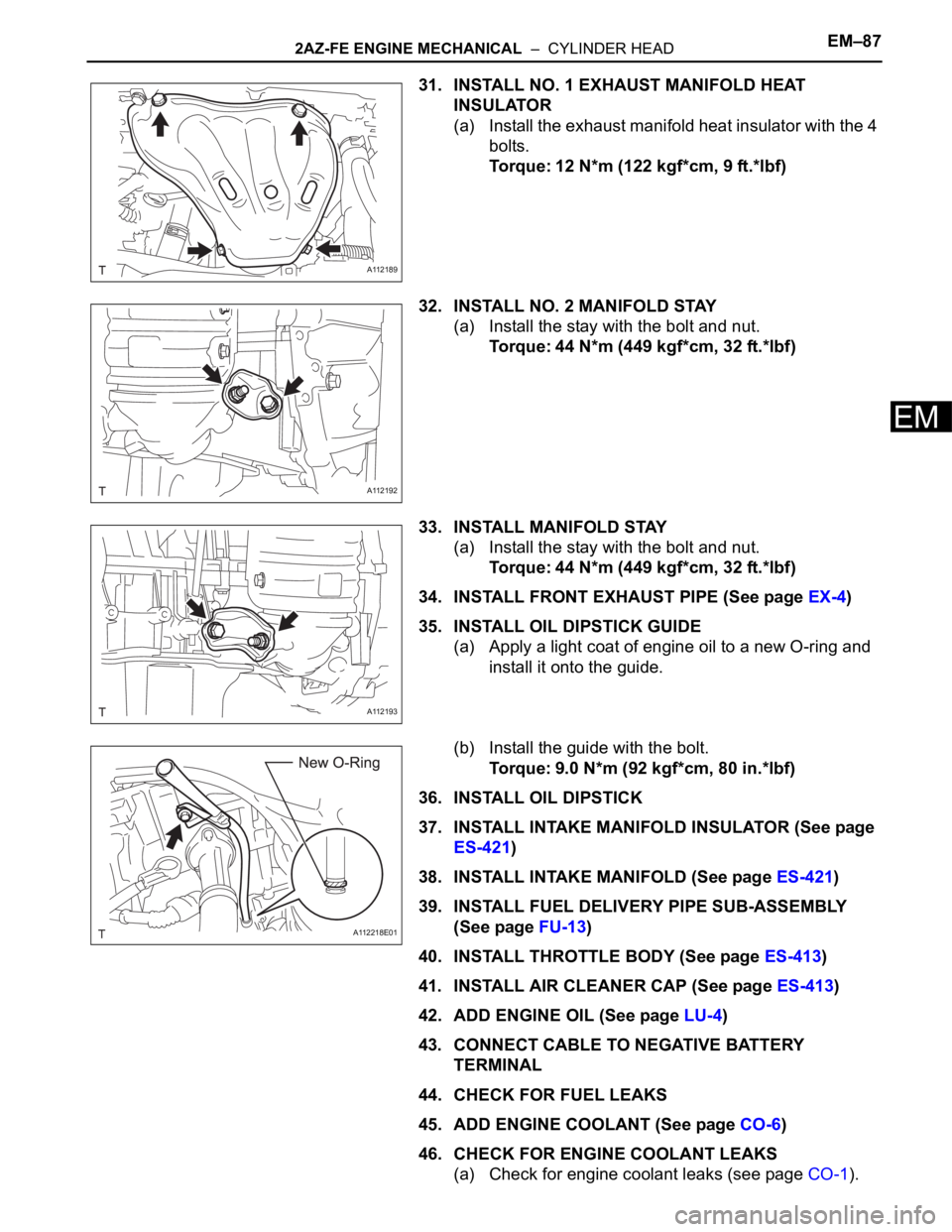

28. CONNECT NO. 1 RADIATOR HOSE

(a) Connect the hose to the cylinder head.

29. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY (See page ES-396)

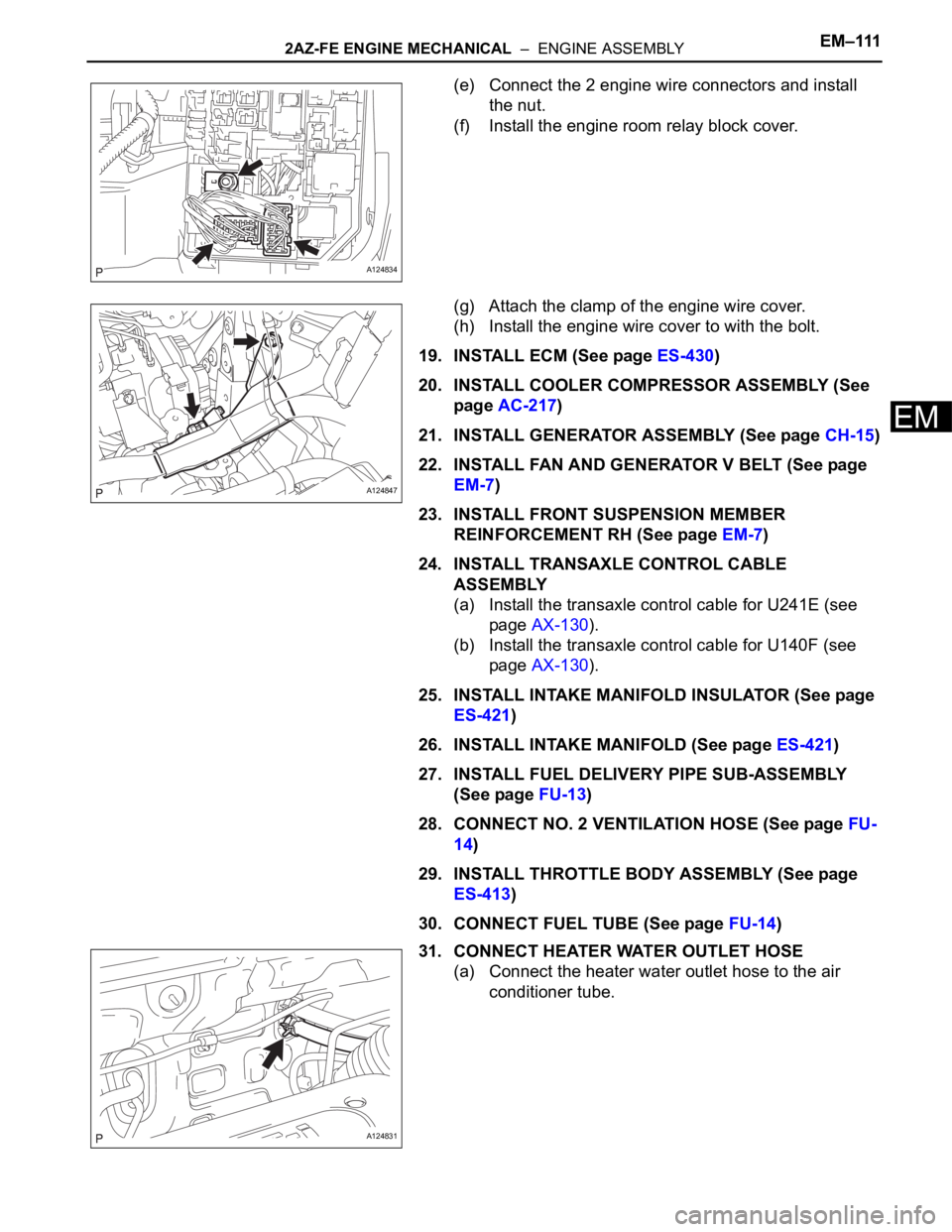

30. INSTALL EXHAUST MANIFOLD CONVERTER SUB-

ASSEMBLY

(a) Install a new gasket onto the cylinder head.

(b) Temporarily tighten the exhaust manifold converter

with the 5 nuts.

(c) Tighten the 5 nuts in the sequence shown in the

illustration.

Torque: 37 N*m (377 kgf*cm, 27 ft.*lbf)

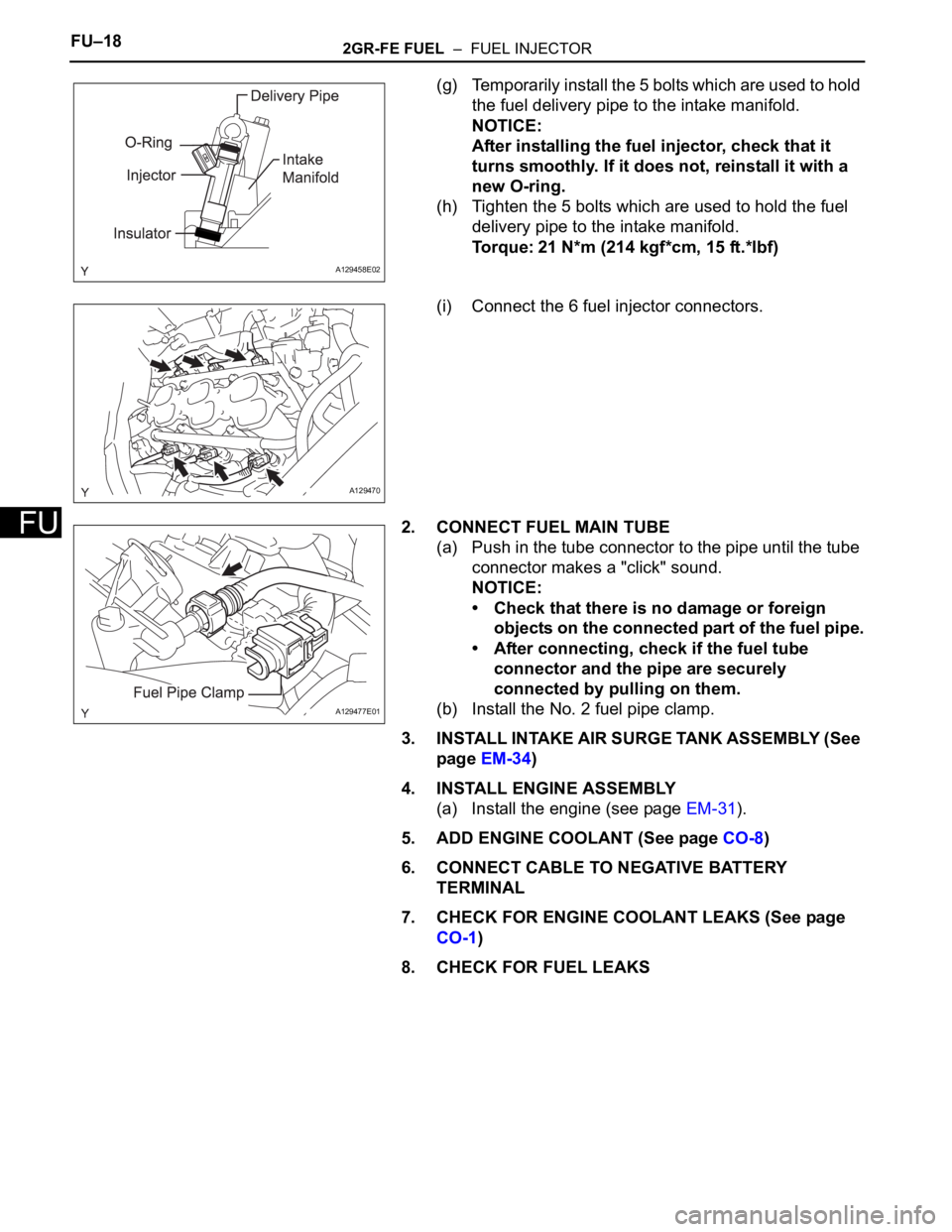

(d) Connect the air-fuel ratio sensor connector.

A098748E01

A114348

A112190E01

A098744E01

Page 631 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–87

EM

31. INSTALL NO. 1 EXHAUST MANIFOLD HEAT

INSULATOR

(a) Install the exhaust manifold heat insulator with the 4

bolts.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

32. INSTALL NO. 2 MANIFOLD STAY

(a) Install the stay with the bolt and nut.

Torque: 44 N*m (449 kgf*cm, 32 ft.*lbf)

33. INSTALL MANIFOLD STAY

(a) Install the stay with the bolt and nut.

Torque: 44 N*m (449 kgf*cm, 32 ft.*lbf)

34. INSTALL FRONT EXHAUST PIPE (See page EX-4)

35. INSTALL OIL DIPSTICK GUIDE

(a) Apply a light coat of engine oil to a new O-ring and

install it onto the guide.

(b) Install the guide with the bolt.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

36. INSTALL OIL DIPSTICK

37. INSTALL INTAKE MANIFOLD INSULATOR (See page

ES-421)

38. INSTALL INTAKE MANIFOLD (See page ES-421)

39. INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY

(See page FU-13)

40. INSTALL THROTTLE BODY (See page ES-413)

41. INSTALL AIR CLEANER CAP (See page ES-413)

42. ADD ENGINE OIL (See page LU-4)

43. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

44. CHECK FOR FUEL LEAKS

45. ADD ENGINE COOLANT (See page CO-6)

46. CHECK FOR ENGINE COOLANT LEAKS

(a) Check for engine coolant leaks (see page CO-1).

A112189

A112192

A112193

A112218E01

Page 646 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–111

EM

(e) Connect the 2 engine wire connectors and install

the nut.

(f) Install the engine room relay block cover.

(g) Attach the clamp of the engine wire cover.

(h) Install the engine wire cover to with the bolt.

19. INSTALL ECM (See page ES-430)

20. INSTALL COOLER COMPRESSOR ASSEMBLY (See

page AC-217)

21. INSTALL GENERATOR ASSEMBLY (See page CH-15)

22. INSTALL FAN AND GENERATOR V BELT (See page

EM-7)

23. INSTALL FRONT SUSPENSION MEMBER

REINFORCEMENT RH (See page EM-7)

24. INSTALL TRANSAXLE CONTROL CABLE

ASSEMBLY

(a) Install the transaxle control cable for U241E (see

page AX-130).

(b) Install the transaxle control cable for U140F (see

page AX-130).

25. INSTALL INTAKE MANIFOLD INSULATOR (See page

ES-421)

26. INSTALL INTAKE MANIFOLD (See page ES-421)

27. INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY

(See page FU-13)

28. CONNECT NO. 2 VENTILATION HOSE (See page FU-

14)

29. INSTALL THROTTLE BODY ASSEMBLY (See page

ES-413)

30. CONNECT FUEL TUBE (See page FU-14)

31. CONNECT HEATER WATER OUTLET HOSE

(a) Connect the heater water outlet hose to the air

conditioner tube.

A124834

A124847

A124831

Page 808 of 2000

FU–182GR-FE FUEL – FUEL INJECTOR

FU

(g) Temporarily install the 5 bolts which are used to hold

the fuel delivery pipe to the intake manifold.

NOTICE:

After installing the fuel injector, check that it

turns smoothly. If it does not, reinstall it with a

new O-ring.

(h) Tighten the 5 bolts which are used to hold the fuel

delivery pipe to the intake manifold.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(i) Connect the 6 fuel injector connectors.

2. CONNECT FUEL MAIN TUBE

(a) Push in the tube connector to the pipe until the tube

connector makes a "click" sound.

NOTICE:

• Check that there is no damage or foreign

objects on the connected part of the fuel pipe.

• After connecting, check if the fuel tube

connector and the pipe are securely

connected by pulling on them.

(b) Install the No. 2 fuel pipe clamp.

3. INSTALL INTAKE AIR SURGE TANK ASSEMBLY (See

page EM-34)

4. INSTALL ENGINE ASSEMBLY

(a) Install the engine (see page EM-31).

5. ADD ENGINE COOLANT (See page CO-8)

6. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

7. CHECK FOR ENGINE COOLANT LEAKS (See page

CO-1)

8. CHECK FOR FUEL LEAKS

A129458E02

A129470

A129477E01

Page 831 of 2000

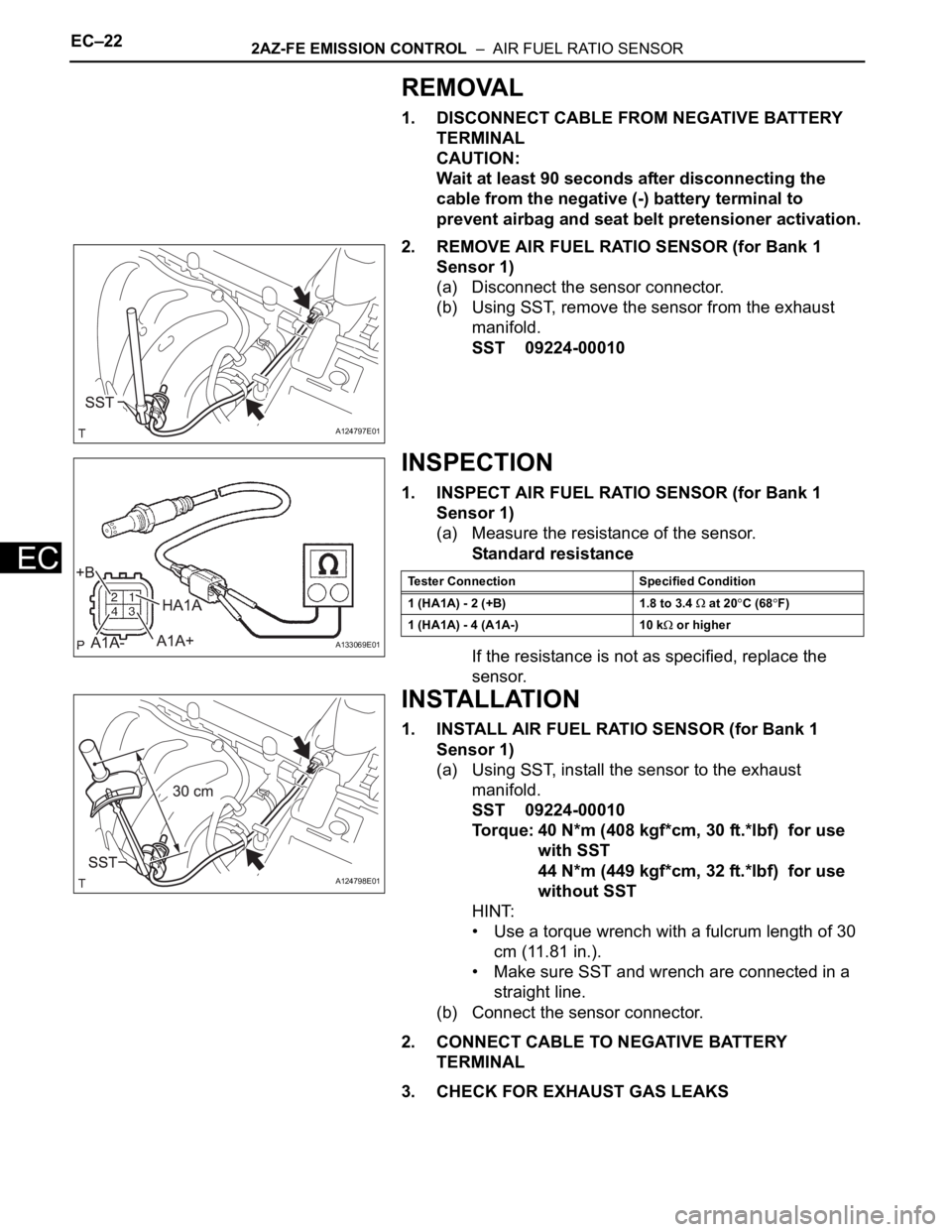

EC–222AZ-FE EMISSION CONTROL – AIR FUEL RATIO SENSOR

EC

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

2. REMOVE AIR FUEL RATIO SENSOR (for Bank 1

Sensor 1)

(a) Disconnect the sensor connector.

(b) Using SST, remove the sensor from the exhaust

manifold.

SST 09224-00010

INSPECTION

1. INSPECT AIR FUEL RATIO SENSOR (for Bank 1

Sensor 1)

(a) Measure the resistance of the sensor.

Standard resistance

If the resistance is not as specified, replace the

sensor.

INSTALLATION

1. INSTALL AIR FUEL RATIO SENSOR (for Bank 1

Sensor 1)

(a) Using SST, install the sensor to the exhaust

manifold.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use

with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use

without SST

HINT:

• Use a torque wrench with a fulcrum length of 30

cm (11.81 in.).

• Make sure SST and wrench are connected in a

straight line.

(b) Connect the sensor connector.

2. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

3. CHECK FOR EXHAUST GAS LEAKS

A124797E01

A133069E01

Tester Connection Specified Condition

1 (HA1A) - 2 (+B) 1.8 to 3.4

at 20C (68F)

1 (HA1A) - 4 (A1A-) 10 k

or higher

A124798E01

Page 838 of 2000

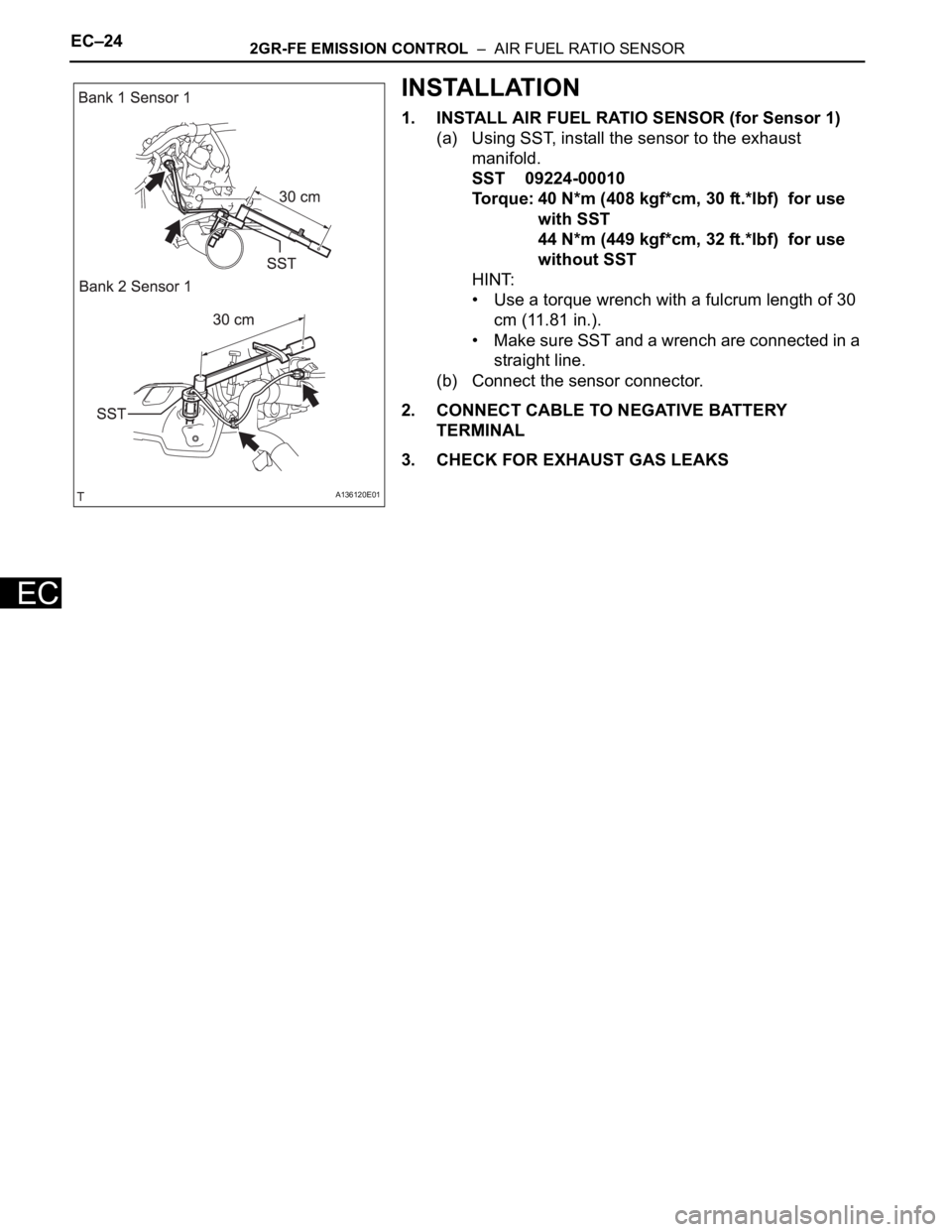

EC–242GR-FE EMISSION CONTROL – AIR FUEL RATIO SENSOR

EC

INSTALLATION

1. INSTALL AIR FUEL RATIO SENSOR (for Sensor 1)

(a) Using SST, install the sensor to the exhaust

manifold.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use

with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use

without SST

HINT:

• Use a torque wrench with a fulcrum length of 30

cm (11.81 in.).

• Make sure SST and a wrench are connected in a

straight line.

(b) Connect the sensor connector.

2. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

3. CHECK FOR EXHAUST GAS LEAKS

A136120E01