Rele TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 51 of 2000

ENGINE - 2AZ-FE ENGINE

Service Tip

The canister pump module performs the EVAP leak check. This check is done approximately five

hours after the engine is turned off. So you may hear sound coming from underneath the luggage

compartment for several minutes. It does not indicate a malfunction.

The pinpoint pressure test procedure is carried out by pressurizing the fresh air line that runs from

the pump module to the air filler neck. For details, refer to the 2006 RAV4 Repair Manual (Pub.

No. RM01M1U).

EG-54

10. EVAP (evaporative Emission) Control System

General

The EVAP (evaporative emission) control system prevents the vapor gas that is created in the fuel tank from

being released directly into the atmosphere.

The canister stores the vapor gas that has been created in the fuel tank.

The ECM controls the purge VSV in accordance with the driving conditions in order to direct the vapor

gas into the engine, where it is burned.

In this system, the ECM checks the evaporative emission leak and outputs DTC (Diagnostic Trouble

Code) in the event of a malfunction. An EVAP (evaporative emission) leak check consists of an

application of a vacuum pressure to the system and monitoring the changes in the system pressure in order

to detect a leakage.

This system consists of the purge VSV, canister, refueling valve, canister pump module, and ECM.

The ORVR (Onboard Refueling Vapor Recovery) function is provided in the refueling valve.

The canister pressure sensor has been included to the canister pump module.

The canister filter has been provided on the fresh air line. This canister filter is maintenance-free.

The followings are the typical conditions for enabling an EVAP leak check:

Typical Enabling

Condition

Five hours have elapsed after the engine has been turned OFF*.

Altitude: Below 2400 m (8000 feet)

Battery voltage: 10.5 V or more

Ignition switch: OFF

Engine coolant temperature: 4.4 to 35C (40 to 95F)

Intake air temperature: 4.4 to 35C (40 to 95F)

*: If engine coolant temperature does not drop below 35C (95F), this time should be extended to 7hours.

Even after that, if the temperature is not less than 35

C (95F), the time should be extended to 9.5 hours.

Page 167 of 2000

IN–22INTRODUCTION – REPAIR INSTRUCTION

IN

VEHICLE LIFT AND SUPPORT

LOCATIONS

1. NOTICE ABOUT VEHICLE CONDITION WHEN

JACKING UP VEHICLE

(a) The vehicle must be unloaded before jacking up /

lifting up the vehicle. Never jack up / lift up a heavily

loaded vehicle.

(b) When removing heavy parts such as the engine and

transmission, the center of gravity of the vehicle

may shift. To stabilize the vehicle, place a balance

weight in a location where it will not roll or shift, or

use a mission jack to hold the jacking support.

2. NOTICE FOR USING 4 POST LIFT

(a) Follow the safety procedures outlined in the lift

instruction manual.

(b) Use precautionary measures to prevent the free

wheel beam from damaging tires or wheels.

(c) Use wheel chocks to secure the vehicle.

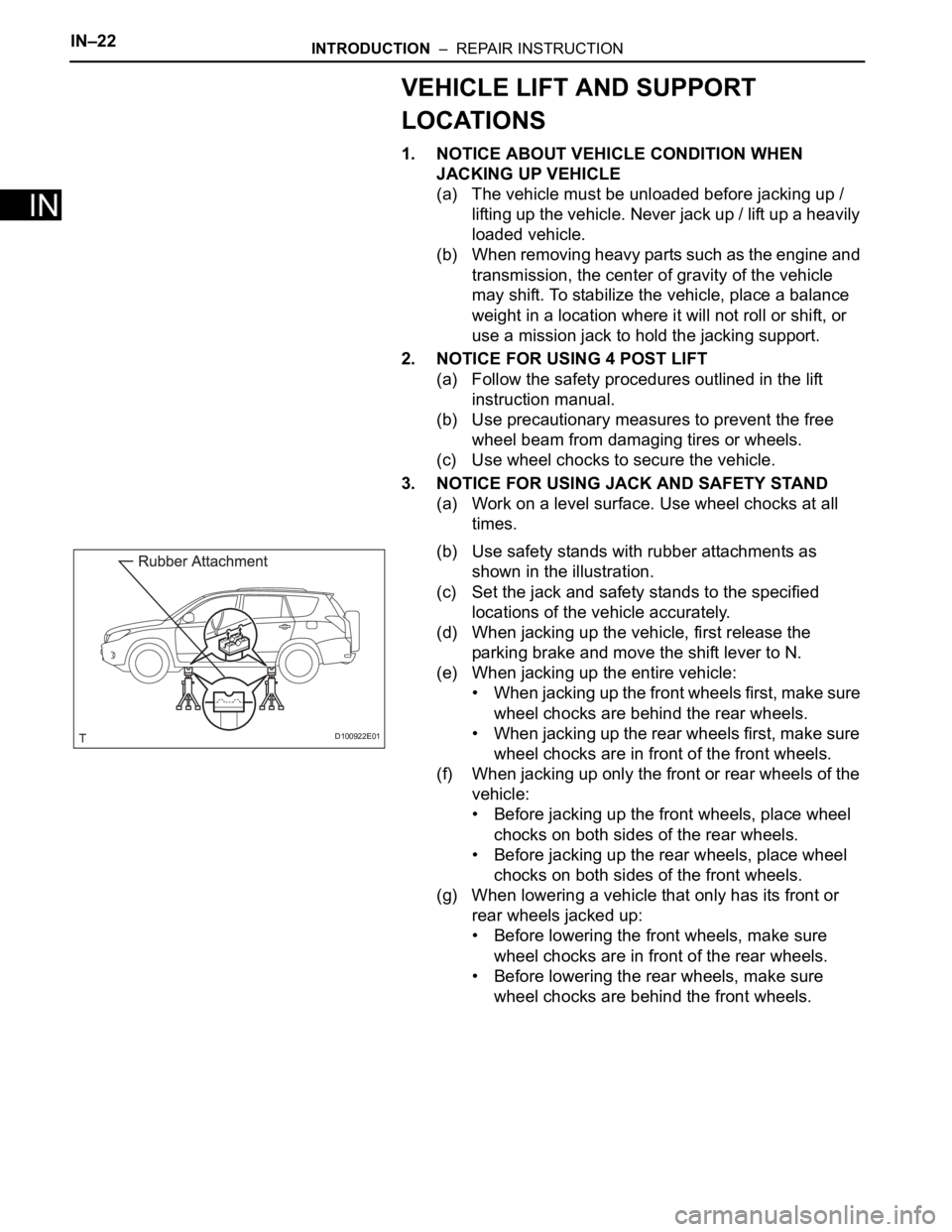

3. NOTICE FOR USING JACK AND SAFETY STAND

(a) Work on a level surface. Use wheel chocks at all

times.

(b) Use safety stands with rubber attachments as

shown in the illustration.

(c) Set the jack and safety stands to the specified

locations of the vehicle accurately.

(d) When jacking up the vehicle, first release the

parking brake and move the shift lever to N.

(e) When jacking up the entire vehicle:

• When jacking up the front wheels first, make sure

wheel chocks are behind the rear wheels.

• When jacking up the rear wheels first, make sure

wheel chocks are in front of the front wheels.

(f) When jacking up only the front or rear wheels of the

vehicle:

• Before jacking up the front wheels, place wheel

chocks on both sides of the rear wheels.

• Before jacking up the rear wheels, place wheel

chocks on both sides of the front wheels.

(g) When lowering a vehicle that only has its front or

rear wheels jacked up:

• Before lowering the front wheels, make sure

wheel chocks are in front of the rear wheels.

• Before lowering the rear wheels, make sure

wheel chocks are behind the front wheels.

D100922E01

Page 209 of 2000

IN–26INTRODUCTION – REPAIR INSTRUCTION

IN

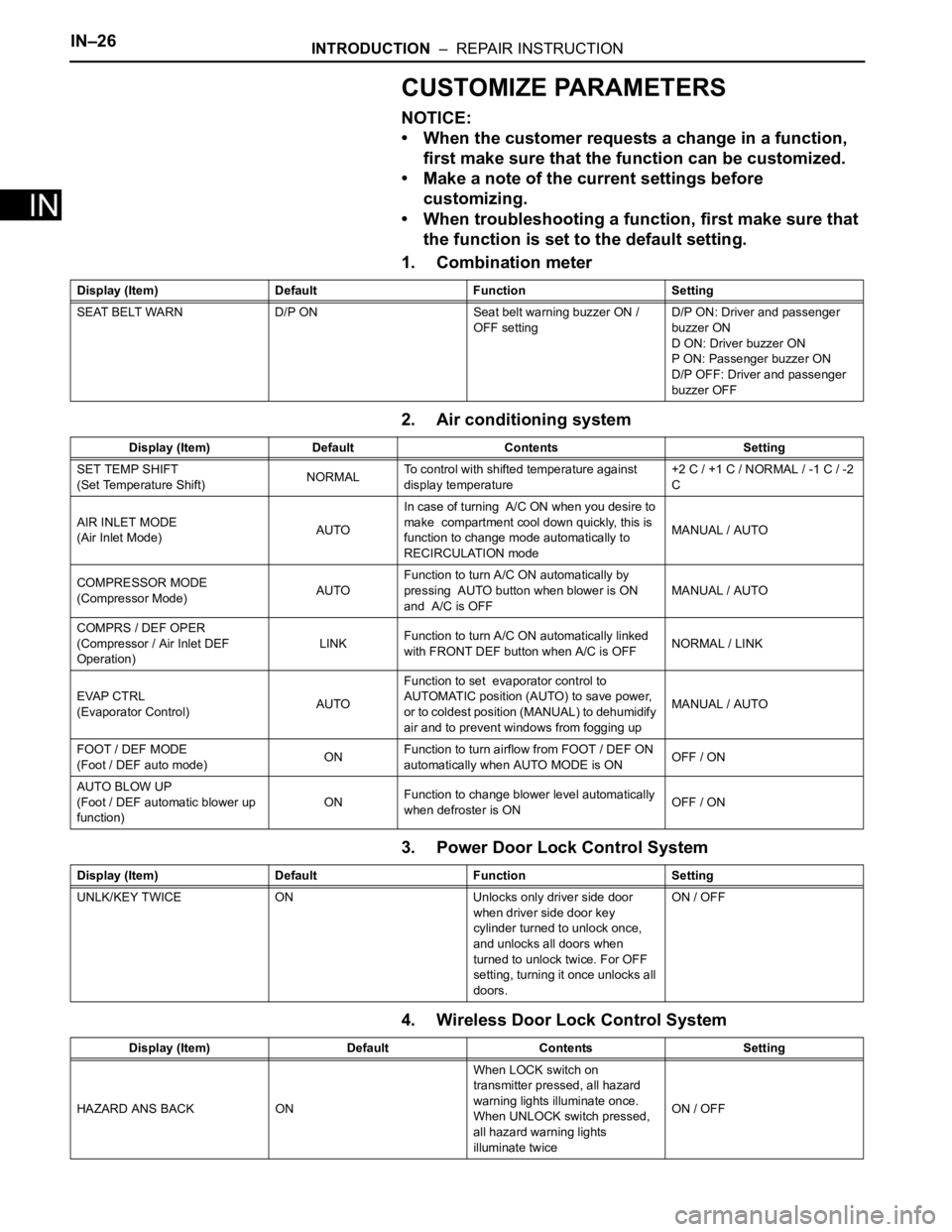

CUSTOMIZE PARAMETERS

NOTICE:

• When the customer requests a change in a function,

first make sure that the function can be customized.

• Make a note of the current settings before

customizing.

• When troubleshooting a function, first make sure that

the function is set to the default setting.

1. Combination meter

2. Air conditioning system

3. Power Door Lock Control System

4. Wireless Door Lock Control System

Display (Item) Default Function Setting

SEAT BELT WARN D/P ON Seat belt warning buzzer ON /

OFF settingD/P ON: Driver and passenger

buzzer ON

D ON: Driver buzzer ON

P ON: Passenger buzzer ON

D/P OFF: Driver and passenger

buzzer OFF

Display (Item) Default Contents Setting

SET TEMP SHIFT

(Set Temperature Shift)NORMALTo control with shifted temperature against

display temperature+2 C / +1 C / NORMAL / -1 C / -2

C

AIR INLET MODE

(Air Inlet Mode)AUTOIn case of turning A/C ON when you desire to

make compartment cool down quickly, this is

function to change mode automatically to

RECIRCULATION modeMANUAL / AUTO

COMPRESSOR MODE

(Compressor Mode)AUTOFunction to turn A/C ON automatically by

pressing AUTO button when blower is ON

and A/C is OFFMANUAL / AUTO

COMPRS / DEF OPER

(Compressor / Air Inlet DEF

Operation)LINKFunction to turn A/C ON automatically linked

with FRONT DEF button when A/C is OFFNORMAL / LINK

EVAP CTRL

(Evaporator Control)AUTOFunction to set evaporator control to

AUTOMATIC position (AUTO) to save power,

or to coldest position (MANUAL) to dehumidify

air and to prevent windows from fogging upMANUAL / AUTO

FOOT / DEF MODE

(Foot / DEF auto mode)ONFunction to turn airflow from FOOT / DEF ON

automatically when AUTO MODE is ONOFF / ON

AUTO BLOW UP

(Foot / DEF automatic blower up

function)ONFunction to change blower level automatically

when defroster is ONOFF / ON

Display (Item) Default Function Setting

UNLK/KEY TWICE ON Unlocks only driver side door

when driver side door key

cylinder turned to unlock once,

and unlocks all doors when

turned to unlock twice. For OFF

setting, turning it once unlocks all

doors.ON / OFF

Display (Item) Default Contents Setting

HAZARD ANS BACK ONWhen LOCK switch on

transmitter pressed, all hazard

warning lights illuminate once.

When UNLOCK switch pressed,

all hazard warning lights

illuminate twiceON / OFF

Page 210 of 2000

INTRODUCTION – REPAIR INSTRUCTIONIN–27

IN

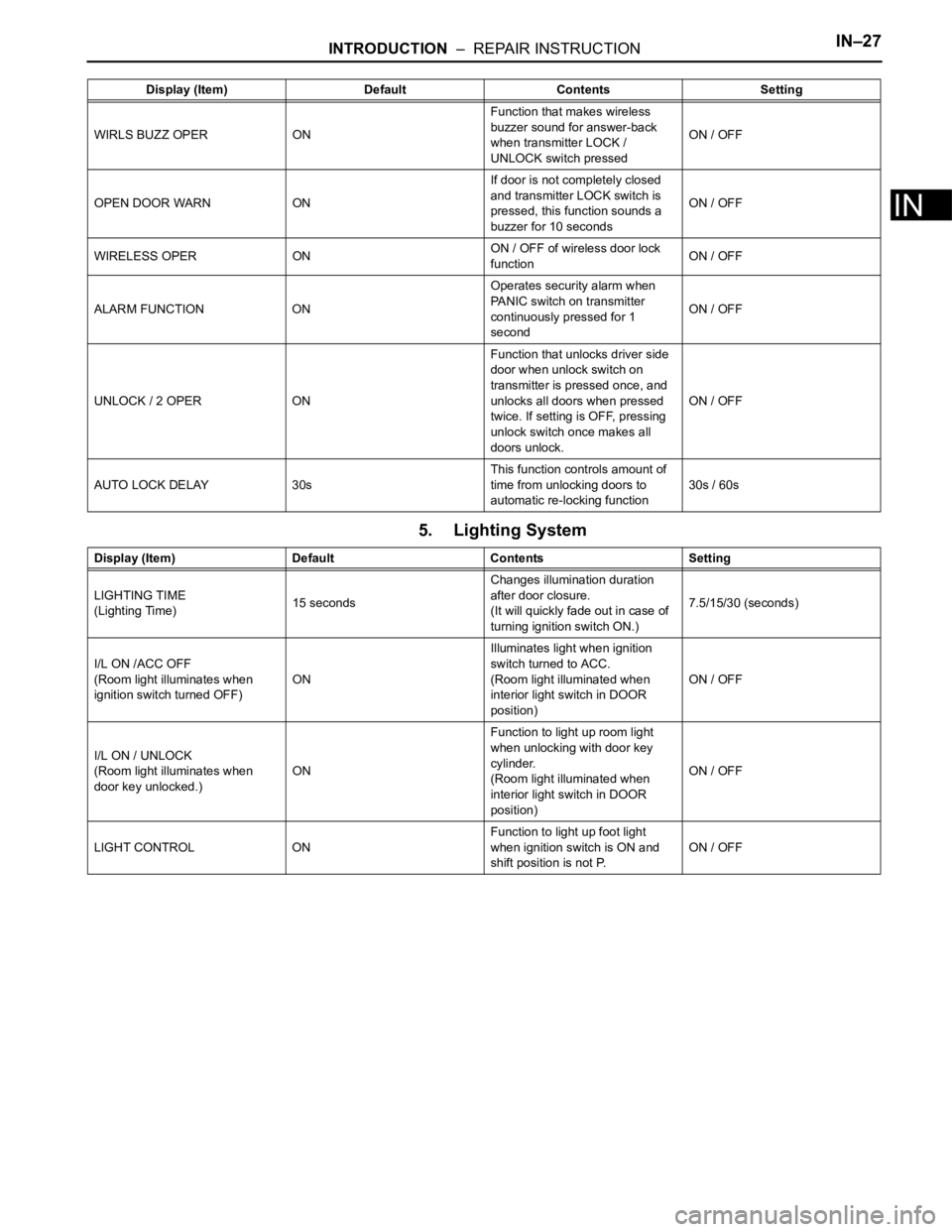

5. Lighting System

WIRLS BUZZ OPER ONFunction that makes wireless

buzzer sound for answer-back

when transmitter LOCK /

UNLOCK switch pressedON / OFF

OPEN DOOR WARN ONIf door is not completely closed

and transmitter LOCK switch is

pressed, this function sounds a

buzzer for 10 secondsON / OFF

WIRELESS OPER ONON / OFF of wireless door lock

functionON / OFF

ALARM FUNCTION ONOperates security alarm when

PANIC switch on transmitter

continuously pressed for 1

secondON / OFF

UNLOCK / 2 OPER ONFunction that unlocks driver side

door when unlock switch on

transmitter is pressed once, and

unlocks all doors when pressed

twice. If setting is OFF, pressing

unlock switch once makes all

doors unlock.ON / OFF

AUTO LOCK DELAY 30sThis function controls amount of

time from unlocking doors to

automatic re-locking function30s / 60s Display (Item) Default Contents Setting

Display (Item) Default Contents Setting

LIGHTING TIME

(Lighting Time)15 secondsChanges illumination duration

after door closure.

(It will quickly fade out in case of

turning ignition switch ON.)7.5/15/30 (seconds)

I/L ON /ACC OFF

(Room light illuminates when

ignition switch turned OFF)ONIlluminates light when ignition

switch turned to ACC.

(Room light illuminated when

interior light switch in DOOR

position)ON / OFF

I/L ON / UNLOCK

(Room light illuminates when

door key unlocked.)ONFunction to light up room light

when unlocking with door key

cylinder.

(Room light illuminated when

interior light switch in DOOR

position)ON / OFF

LIGHT CONTROL ONFunction to light up foot light

when ignition switch is ON and

shift position is not P.ON / OFF

Page 215 of 2000

IN–38INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN

ELECTRONIC CIRCUIT INSPECTION

PROCEDURE

1. BASIC INSPECTION

(a) WHEN MEASURING RESISTANCE OF

ELECTRONIC PARTS

(1) Unless otherwise stated, all resistance

measurements should be made at an ambient

temperature of 20

C (68F). Resistance

measurements may be inaccurate if measured

at high temperatures, i.e. immediately after the

vehicle has been running. Measurements should

be made after the engine has cooled down.

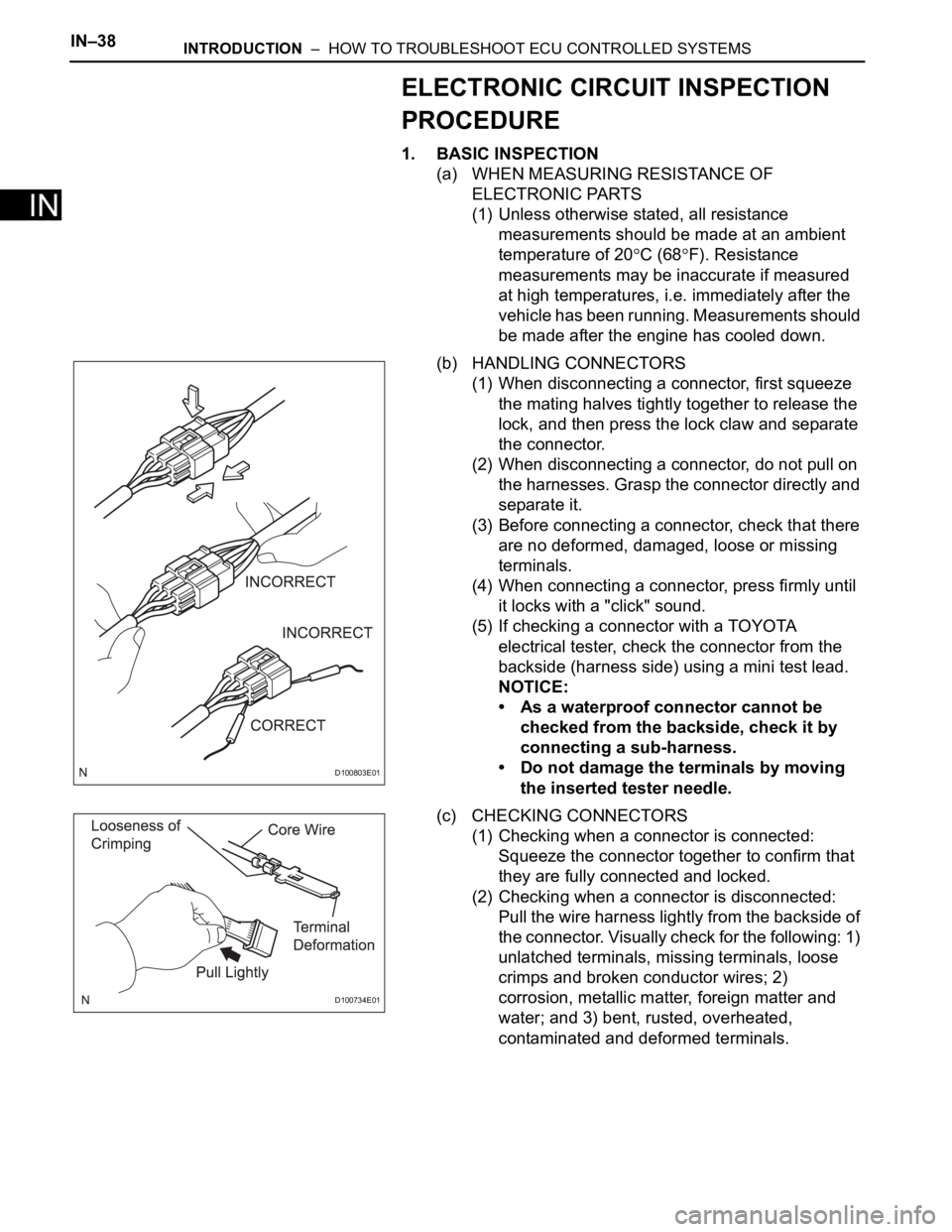

(b) HANDLING CONNECTORS

(1) When disconnecting a connector, first squeeze

the mating halves tightly together to release the

lock, and then press the lock claw and separate

the connector.

(2) When disconnecting a connector, do not pull on

the harnesses. Grasp the connector directly and

separate it.

(3) Before connecting a connector, check that there

are no deformed, damaged, loose or missing

terminals.

(4) When connecting a connector, press firmly until

it locks with a "click" sound.

(5) If checking a connector with a TOYOTA

electrical tester, check the connector from the

backside (harness side) using a mini test lead.

NOTICE:

• As a waterproof connector cannot be

checked from the backside, check it by

connecting a sub-harness.

• Do not damage the terminals by moving

the inserted tester needle.

(c) CHECKING CONNECTORS

(1) Checking when a connector is connected:

Squeeze the connector together to confirm that

they are fully connected and locked.

(2) Checking when a connector is disconnected:

Pull the wire harness lightly from the backside of

the connector. Visually check for the following: 1)

unlatched terminals, missing terminals, loose

crimps and broken conductor wires; 2)

corrosion, metallic matter, foreign matter and

water; and 3) bent, rusted, overheated,

contaminated and deformed terminals.

D100803E01

D100734E01

Page 227 of 2000

2AZ-FE EMISSION CONTROL – EMISSION CONTROL SYSTEMEC–7

EC

ON-VEHICLE INSPECTION

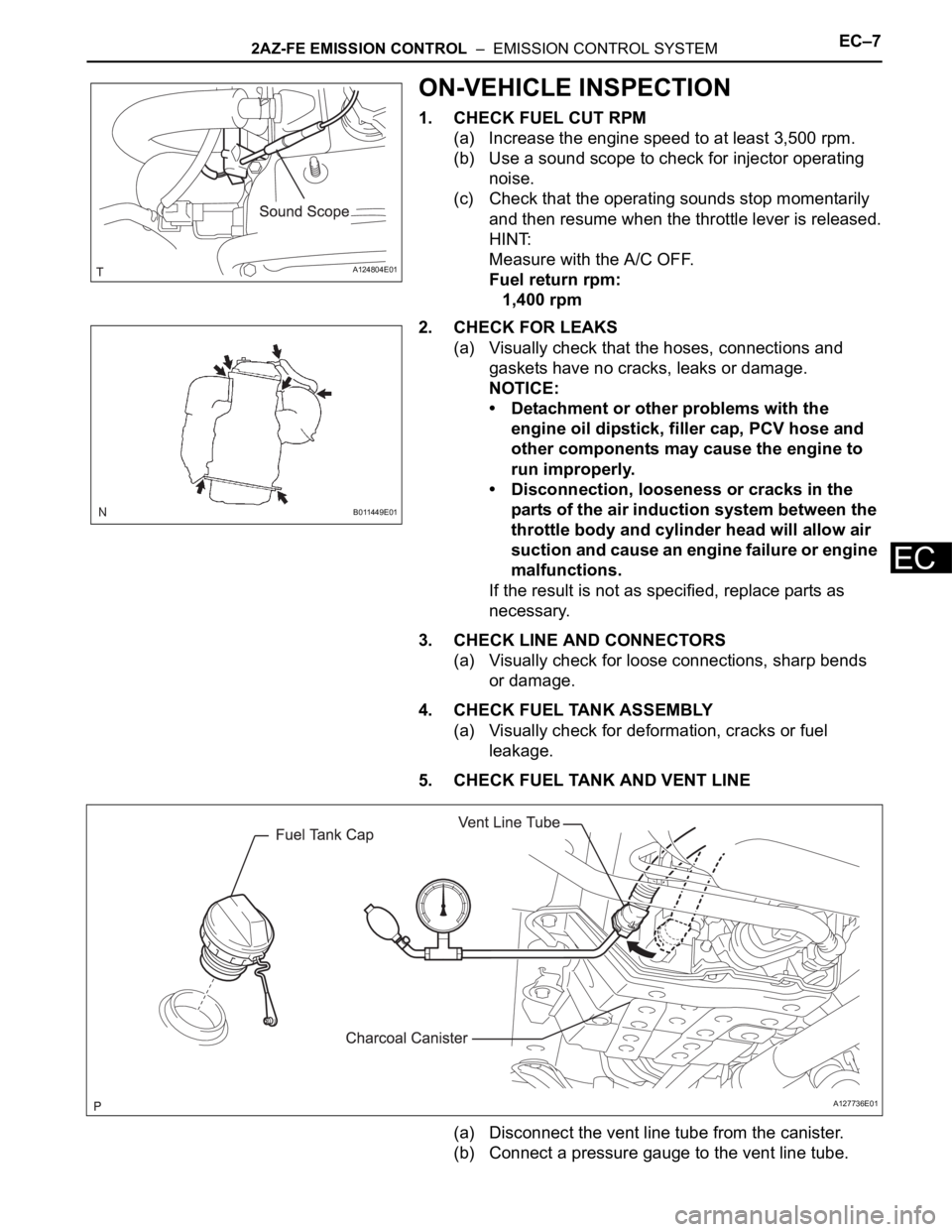

1. CHECK FUEL CUT RPM

(a) Increase the engine speed to at least 3,500 rpm.

(b) Use a sound scope to check for injector operating

noise.

(c) Check that the operating sounds stop momentarily

and then resume when the throttle lever is released.

HINT:

Measure with the A/C OFF.

Fuel return rpm:

1,400 rpm

2. CHECK FOR LEAKS

(a) Visually check that the hoses, connections and

gaskets have no cracks, leaks or damage.

NOTICE:

• Detachment or other problems with the

engine oil dipstick, filler cap, PCV hose and

other components may cause the engine to

run improperly.

• Disconnection, looseness or cracks in the

parts of the air induction system between the

throttle body and cylinder head will allow air

suction and cause an engine failure or engine

malfunctions.

If the result is not as specified, replace parts as

necessary.

3. CHECK LINE AND CONNECTORS

(a) Visually check for loose connections, sharp bends

or damage.

4. CHECK FUEL TANK ASSEMBLY

(a) Visually check for deformation, cracks or fuel

leakage.

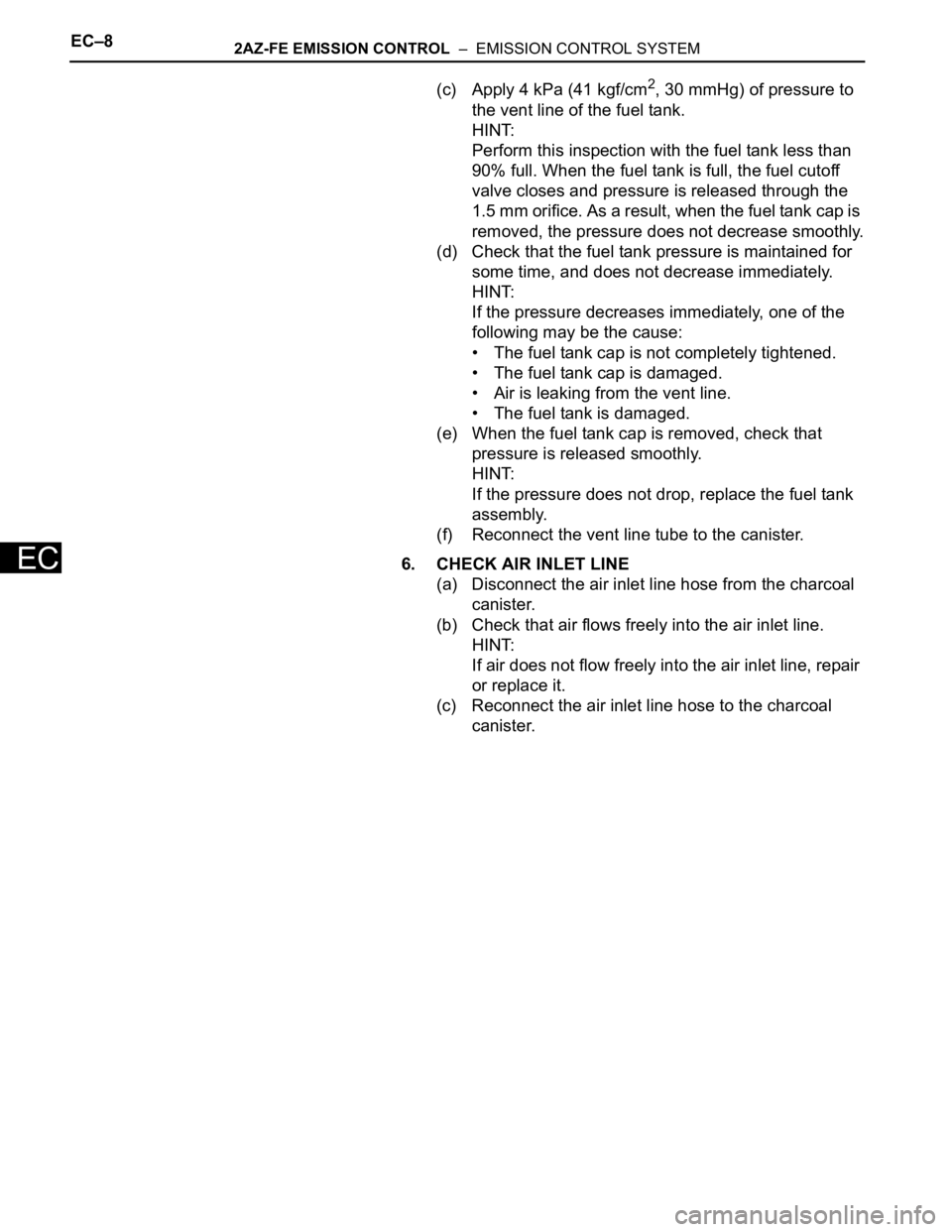

5. CHECK FUEL TANK AND VENT LINE

(a) Disconnect the vent line tube from the canister.

(b) Connect a pressure gauge to the vent line tube.

A124804E01

B011449E01

A127736E01

Page 228 of 2000

EC–82AZ-FE EMISSION CONTROL – EMISSION CONTROL SYSTEM

EC

(c) Apply 4 kPa (41 kgf/cm2, 30 mmHg) of pressure to

the vent line of the fuel tank.

HINT:

Perform this inspection with the fuel tank less than

90% full. When the fuel tank is full, the fuel cutoff

valve closes and pressure is released through the

1.5 mm orifice. As a result, when the fuel tank cap is

removed, the pressure does not decrease smoothly.

(d) Check that the fuel tank pressure is maintained for

some time, and does not decrease immediately.

HINT:

If the pressure decreases immediately, one of the

following may be the cause:

• The fuel tank cap is not completely tightened.

• The fuel tank cap is damaged.

• Air is leaking from the vent line.

• The fuel tank is damaged.

(e) When the fuel tank cap is removed, check that

pressure is released smoothly.

HINT:

If the pressure does not drop, replace the fuel tank

assembly.

(f) Reconnect the vent line tube to the canister.

6. CHECK AIR INLET LINE

(a) Disconnect the air inlet line hose from the charcoal

canister.

(b) Check that air flows freely into the air inlet line.

HINT:

If air does not flow freely into the air inlet line, repair

or replace it.

(c) Reconnect the air inlet line hose to the charcoal

canister.

Page 349 of 2000

AX–138U140F AUTOMATIC TRANSAXLE – FLOOR SHIFT ASSEMBLY

AX

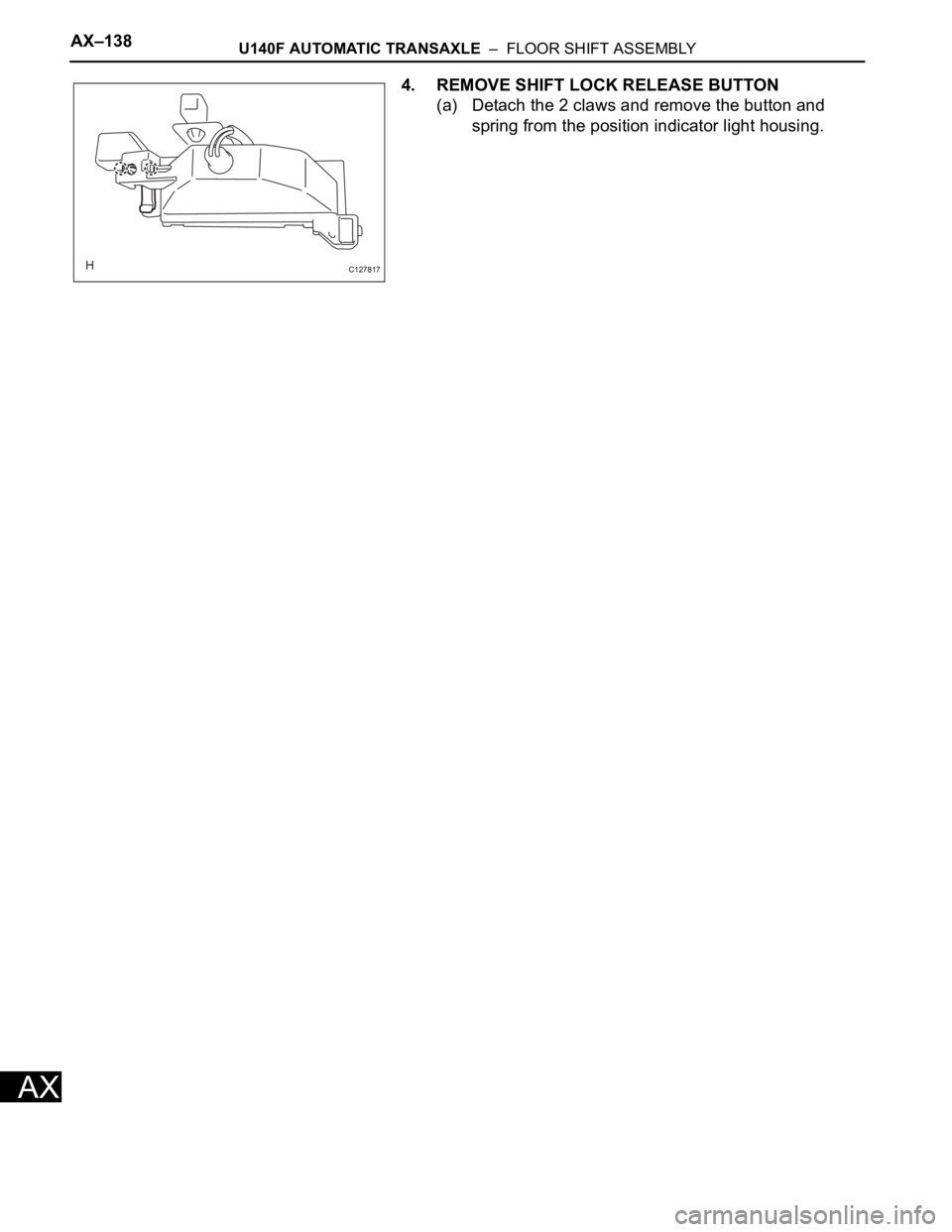

4. REMOVE SHIFT LOCK RELEASE BUTTON

(a) Detach the 2 claws and remove the button and

spring from the position indicator light housing.

C127817

Page 357 of 2000

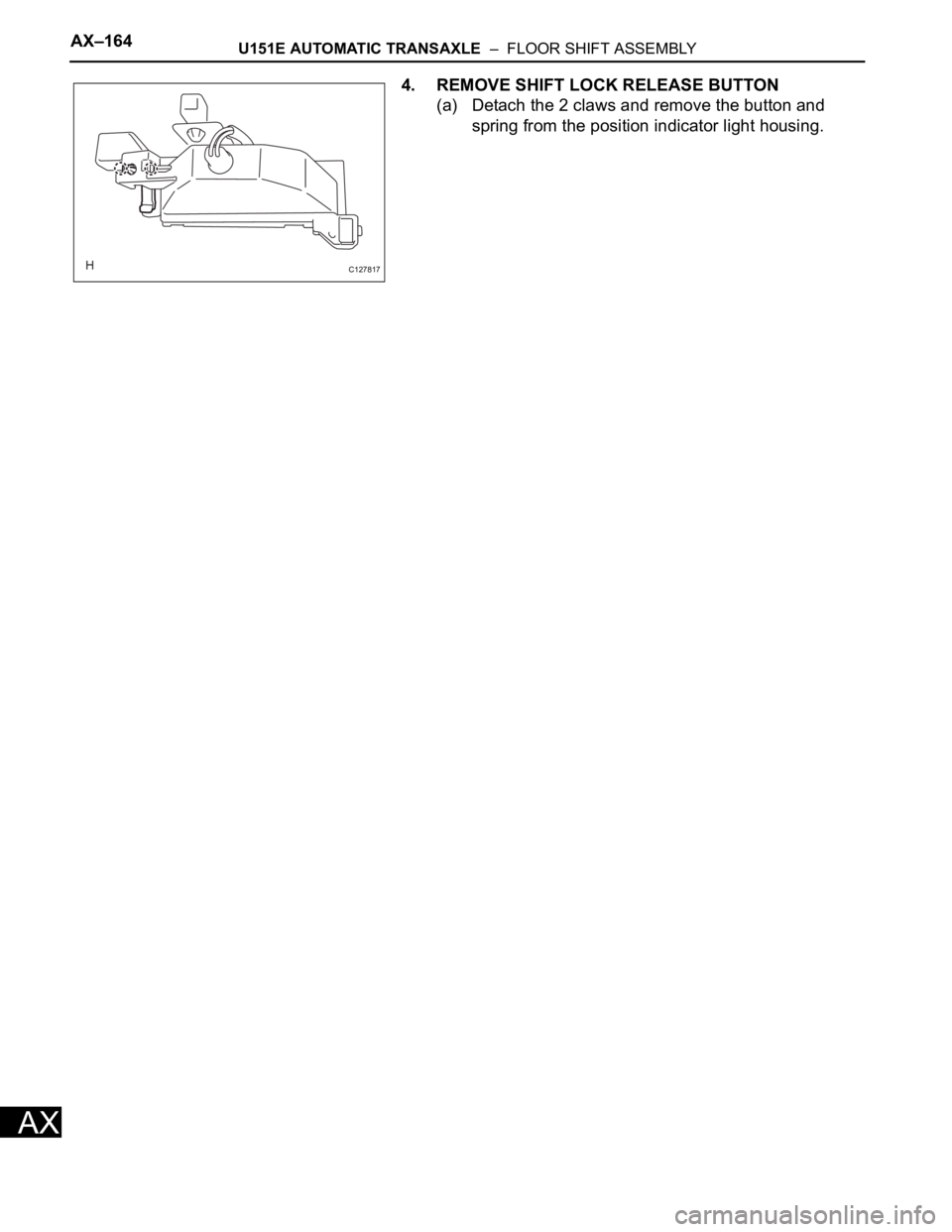

AX–164U151E AUTOMATIC TRANSAXLE – FLOOR SHIFT ASSEMBLY

AX

4. REMOVE SHIFT LOCK RELEASE BUTTON

(a) Detach the 2 claws and remove the button and

spring from the position indicator light housing.

C127817

Page 363 of 2000

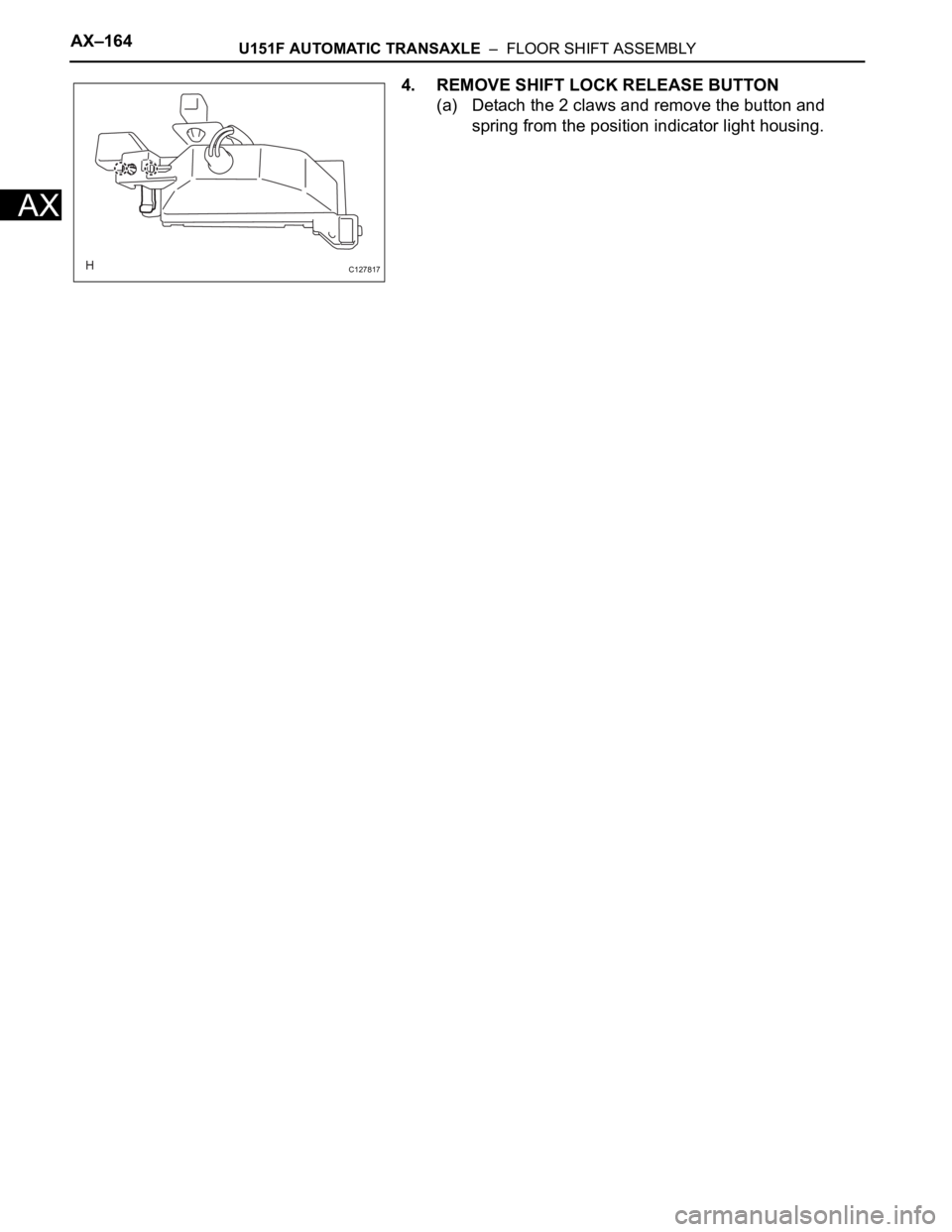

AX–164U151F AUTOMATIC TRANSAXLE – FLOOR SHIFT ASSEMBLY

AX

4. REMOVE SHIFT LOCK RELEASE BUTTON

(a) Detach the 2 claws and remove the button and

spring from the position indicator light housing.

C127817