fuel pump TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 19 of 2000

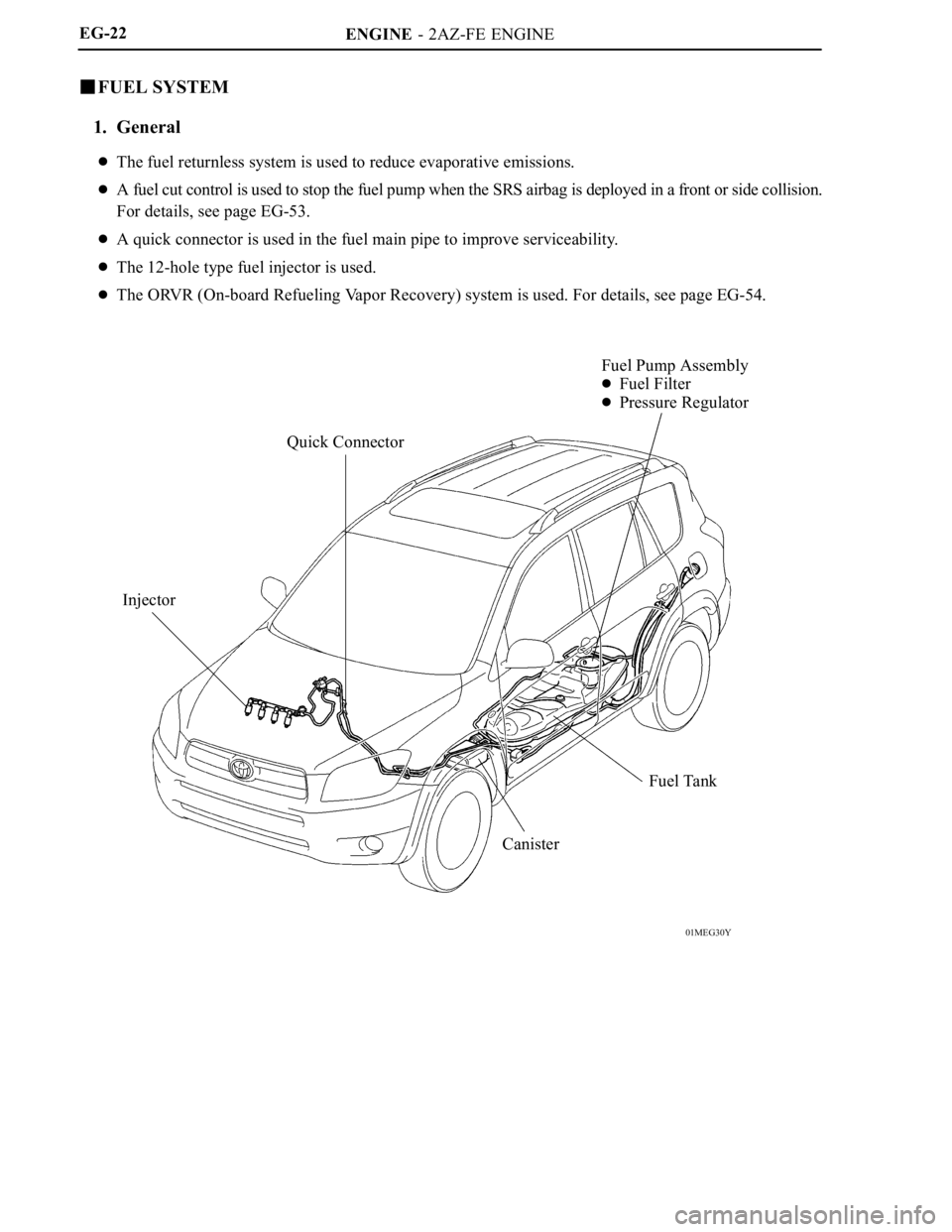

ENGINE - 2AZ-FE ENGINE

01MEG30Y

Fuel Pump Assembly

Fuel Filter

Pressure Regulator

Quick Connector

Injector

Fuel Tank

Canister EG-22

FUEL SYSTEM

1. General

The fuel returnless system is used to reduce evaporative emissions.

A fuel cut control is used to stop the fuel pump when the SRS airbag is deployed in a front or side collision.

For details, see page EG-53.

A quick connector is used in the fuel main pipe to improve serviceability.

The 12-hole type fuel injector is used.

The ORVR (On-board Refueling Vapor Recovery) system is used. For details, see page EG-54.

Page 20 of 2000

ENGINE - 2AZ-FE ENGINE

185EG16

Pulsation

Dumper

Pressure Regulator

Fuel Pump

AssemblyFuel Tank

Fuel Filter

Fuel Pump

DR011EG18

EG-23

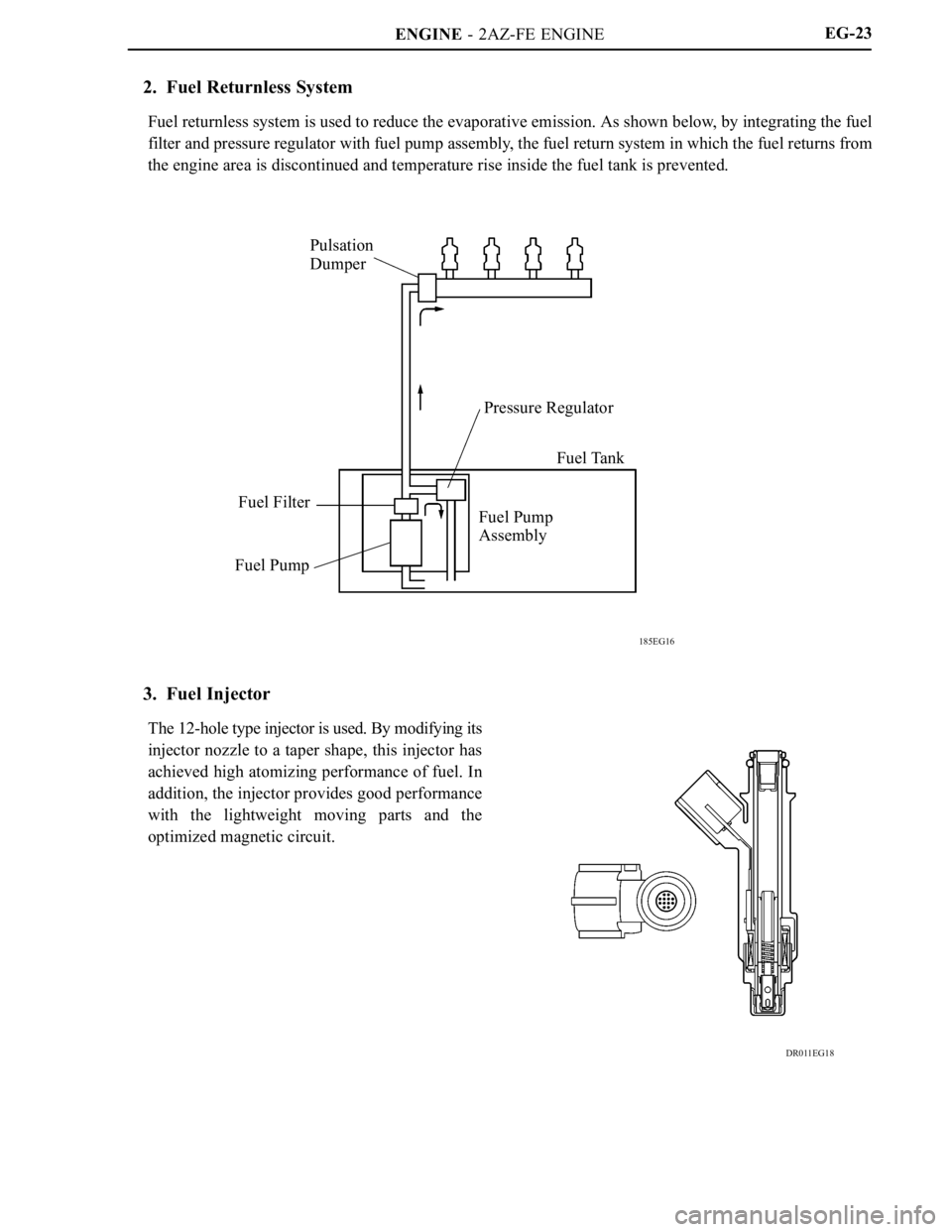

2. Fuel Returnless System

Fuel returnless system is used to reduce the evaporative emission. As shown below, by integrating the fuel

filter and pressure regulator with fuel pump assembly, the fuel return system in which the fuel returns from

the engine area is discontinued and temperature rise inside the fuel tank is prevented.

3. Fuel Injector

The 12-hole type injector is used. By modifying its

injector nozzle to a taper shape, this injector has

achieved high atomizing performance of fuel. In

addition, the injector provides good performance

with the lightweight moving parts and the

optimized magnetic circuit.

Page 27 of 2000

ENGINE - 2AZ-FE ENGINE EG-30

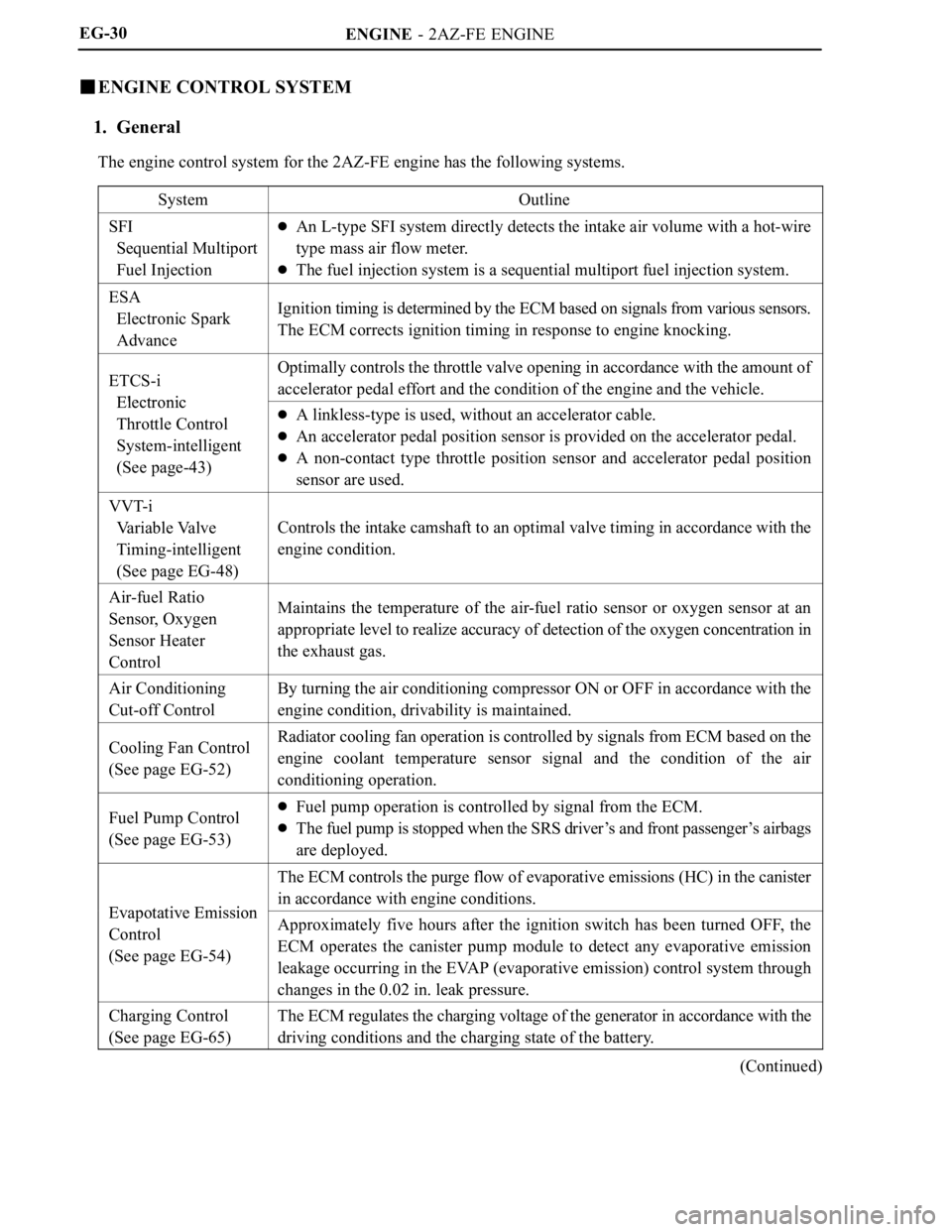

ENGINE CONTROL SYSTEM

1. General

The engine control system for the 2AZ-FE engine has the following systems.

System

Outline

SFI

Sequential Multiport

Fuel InjectionAn L-type SFI system directly detects the intake air volume with a hot-wire

type mass air flow meter.

The fuel injection system is a sequential multiport fuel injection system.

ESA

Electronic Spark

AdvanceIgnition timing is determined by the ECM based on signals from various sensors.

The ECM corrects ignition timing in response to engine knocking.

ETCS-i

Electronic

Optimally controls the throttle valve opening in accordance with the amount of

accelerator pedal effort and the condition of the engine and the vehicle.

Electronic

Throttle Control

System-intelligent

(See page-43)A linkless-type is used, without an accelerator cable.

An accelerator pedal position sensor is provided on the accelerator pedal.

A non-contact type throttle position sensor and accelerator pedal position

sensor are used.

VVT-i

Va r i a b l e Va l v e

Timing-intelligent

(See page EG-48)

Controls the intake camshaft to an optimal valve timing in accordance with the

engine condition.

Air-fuel Ratio

Sensor, Oxygen

Sensor Heater

ControlMaintains the temperature of the air-fuel ratio sensor or oxygen sensor at an

appropriate level to realize accuracy of detection of the oxygen concentration in

the exhaust gas.

Air Conditioning

Cut-off ControlBy turning the air conditioning compressor ON or OFF in accordance with the

engine condition, drivability is maintained.

Cooling Fan Control

(See page EG-52)Radiator cooling fan operation is controlled by signals from ECM based on the

engine coolant temperature sensor signal and the condition of the air

conditioning operation.

Fuel Pump Control

(See page EG-53)Fuel pump operation is controlled by signal from the ECM.

The fuel pump is stopped when the SRS driver’s and front passenger’s airbags

are deployed.

Evapotative Emission

The ECM controls the purge flow of evaporative emissions (HC) in the canister

in accordance with engine conditions.

Evapotative Emission

Control

(See page EG-54)Approximately five hours after the ignition switch has been turned OFF, the

ECM operates the canister pump module to detect any evaporative emission

leakage occurring in the EVAP (evaporative emission) control system through

changes in the 0.02 in. leak pressure.

Charging Control

(See page EG-65)The ECM regulates the charging voltage of the generator in accordance with the

driving conditions and the charging state of the battery.

(Continued)

Page 29 of 2000

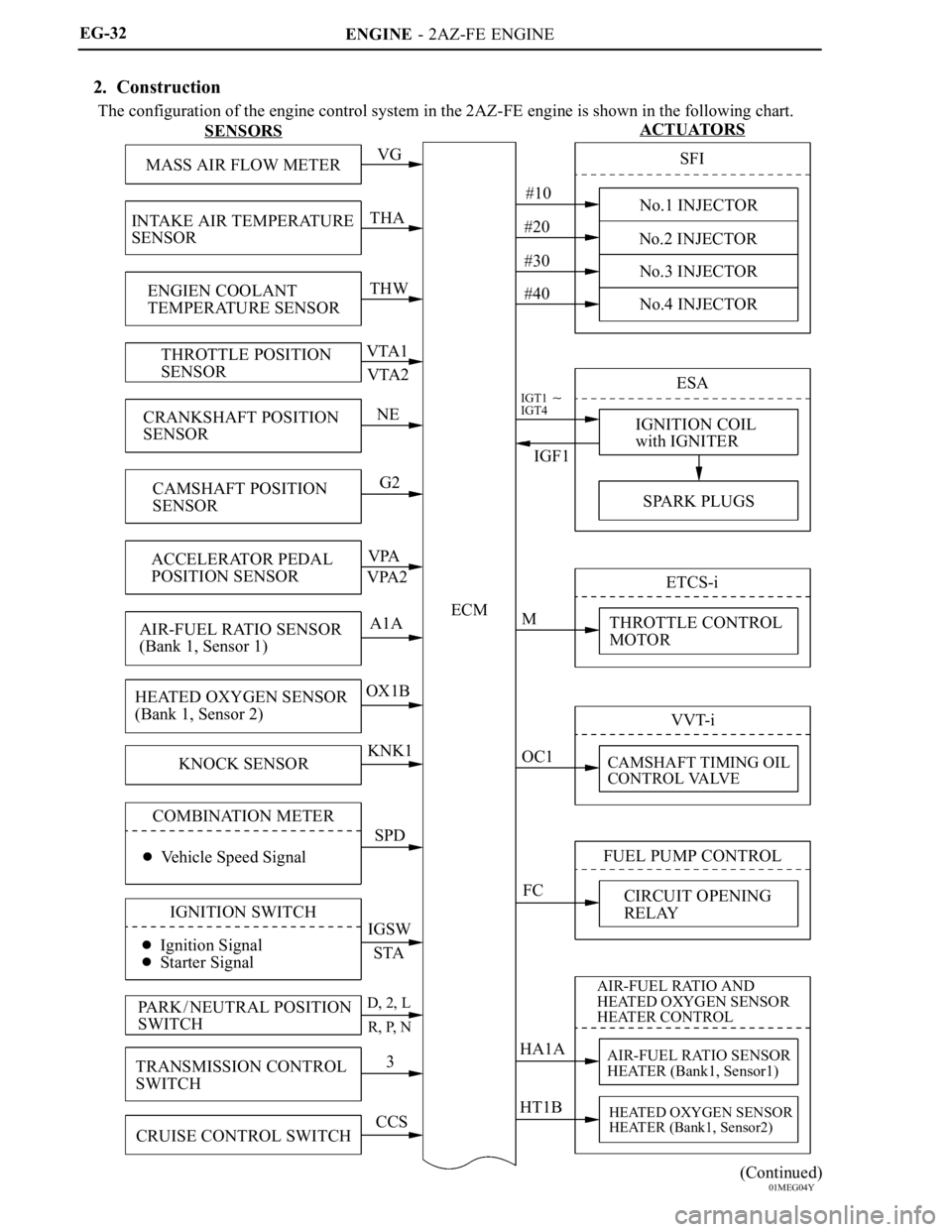

ENGINE - 2AZ-FE ENGINE

01MEG04Y

SENSORSACTUATORS

MASS AIR FLOW METER

INTAKE AIR TEMPERATURE

SENSOR

ENGIEN COOLANT

TEMPERATURE SENSOR

THROTTLE POSITION

SENSOR

CRANKSHAFT POSITION

SENSOR

CAMSHAFT POSITION

SENSOR

ACCELERATOR PEDAL

POSITION SENSOR

AIR-FUEL RATIO SENSOR

(Bank 1, Sensor 1)

HEATED OXYGEN SENSOR

(Bank 1, Sensor 2)

KNOCK SENSOR

COMBINATION METER

Vehicle Speed Signal

IGNITION SWITCH

Ignition Signal

Starter Signal

PA R K / N E U T R A L P O S I T I O N

SWITCH

TRANSMISSION CONTROL

SWITCH

CRUISE CONTROL SWITCHVG

THA

THW

VTA1

VTA2

NE

G2

VPA

VPA2

A1A

OX1B

KNK1

SPD

IGSW

STA

D, 2, L

R, P, N

3

CCSECM#10

#20

#30

#40

IGT1 IGT4

IGF1

M

OC1

FC

HA1A

HT1BSFI

No.1 INJECTOR

No.2 INJECTOR

No.3 INJECTOR

No.4 INJECTOR

ESA

IGNITION COIL

with IGNITER

SPARK PLUGS

ETCS-i

THROTTLE CONTROL

MOTOR

VVT-i

CAMSHAFT TIMING OIL

CONTROL VALVE

FUEL PUMP CONTROL

CIRCUIT OPENING

RELAY

AIR-FUEL RATIO AND

HEATED OXYGEN SENSOR

HEATER CONTROL

AIR-FUEL RATIO SENSOR

HEATER (Bank1, Sensor1)

HEATED OXYGEN SENSOR

HEATER (Bank1, Sensor2)

EG-32

2. Construction

The configuration of the engine control system in the 2AZ-FE engine is shown in the following chart.

(Continued)

Page 31 of 2000

ENGINE - 2AZ-FE ENGINE

01MEG09Y

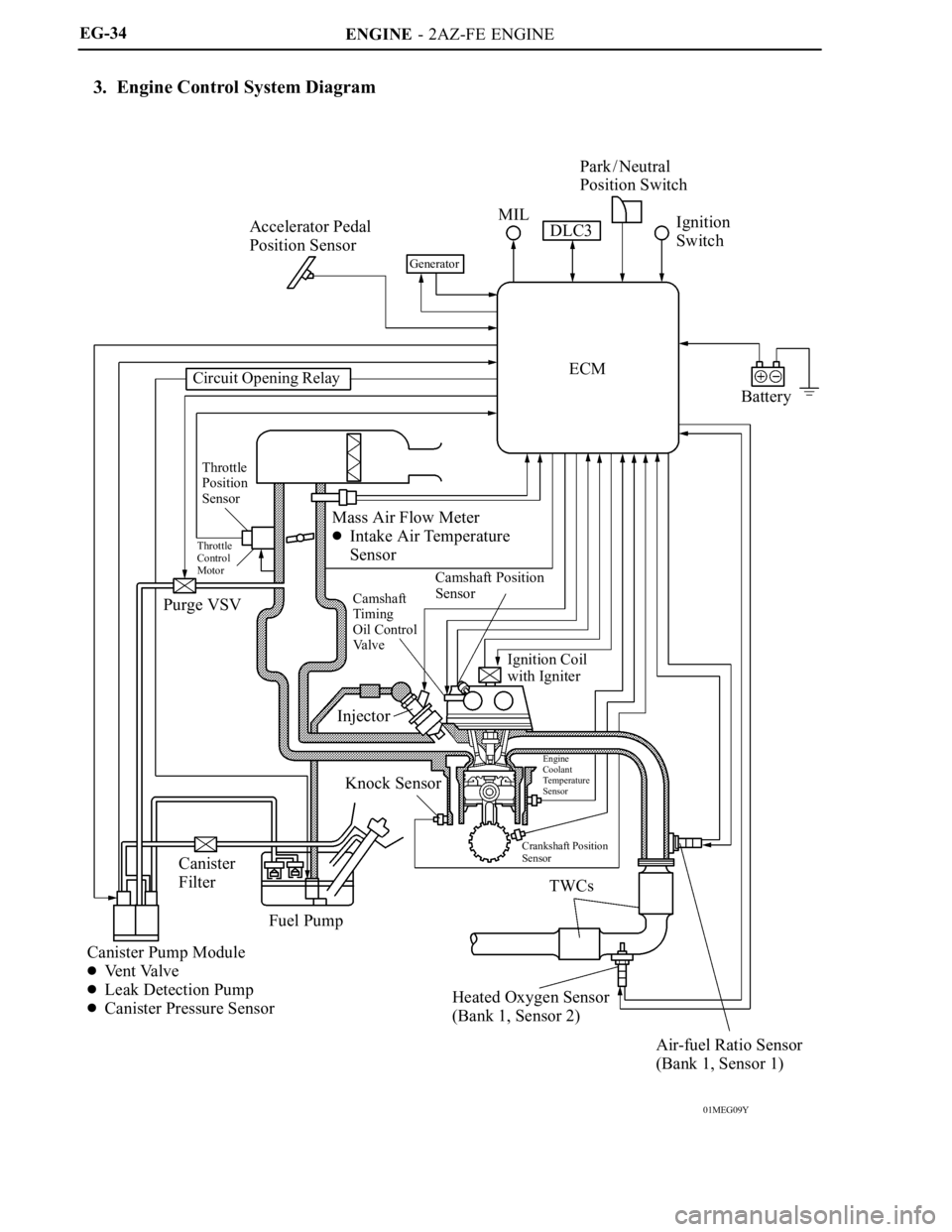

Accelerator Pedal

Position Sensor

Generator

MIL

DLC3Park / Neutral

Position Switch

Ignition

Switch

Circuit Opening RelayECM

Battery

Throttle

Position

Sensor

Throttle

Control

Motor

Purge VSVMass Air Flow Meter

Intake Air Temperature

Sensor

Camshaft Position

Sensor

Camshaft

Timing

Oil Control

Va l v e

Ignition Coil

with Igniter

Injector

Knock Sensor

Engine

Coolant

Temperature

Sensor

Crankshaft Position

Sensor

Canister

Filter

Fuel Pump

Canister Pump Module

Ve n t Va l v e

Leak Detection Pump

Canister Pressure SensorTWCs

Heated Oxygen Sensor

(Bank 1, Sensor 2)

Air-fuel Ratio Sensor

(Bank 1, Sensor 1) EG-34

3. Engine Control System Diagram

Page 32 of 2000

ENGINE - 2AZ-FE ENGINE

01MEG31Y

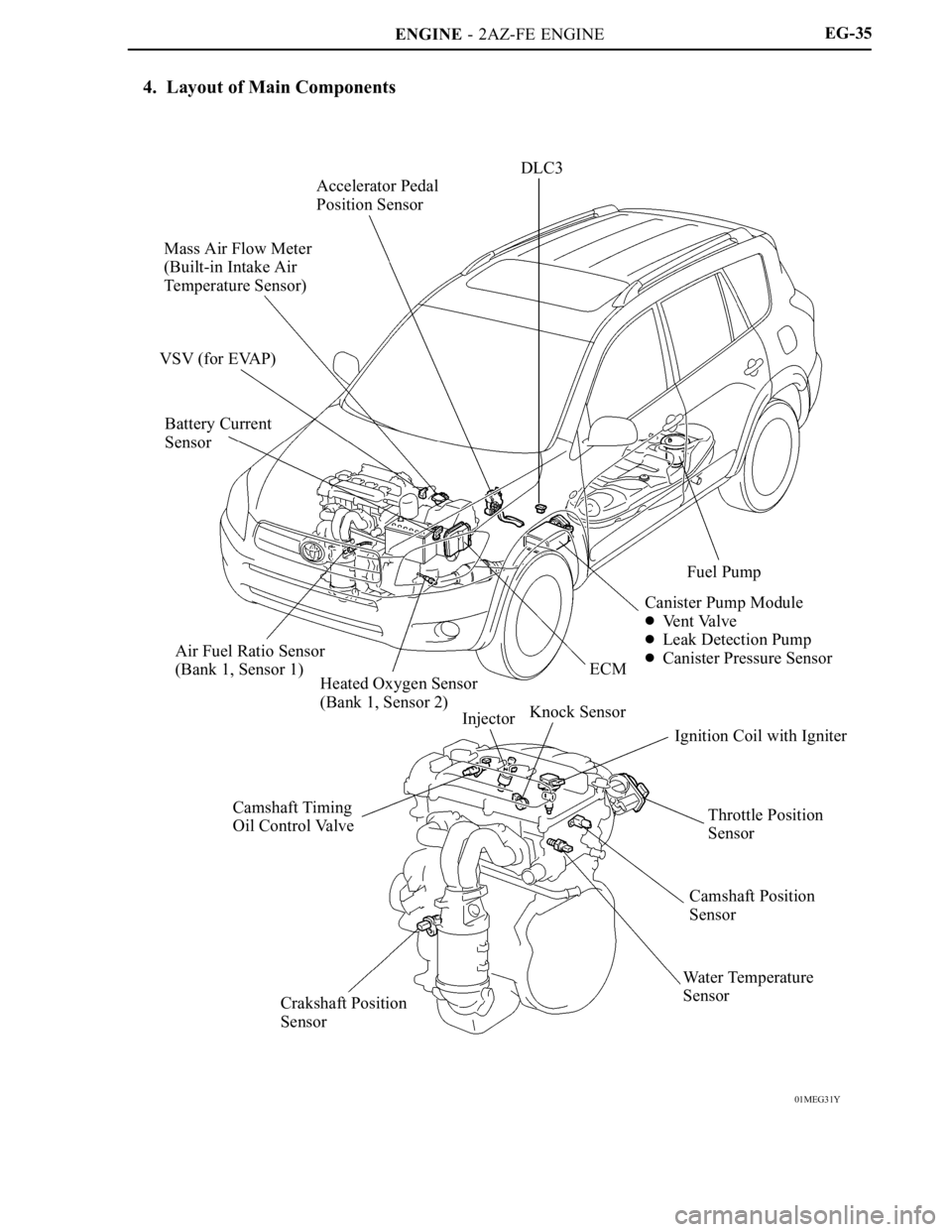

DLC3

Accelerator Pedal

Position Sensor

Mass Air Flow Meter

(Built-in Intake Air

Temperature Sensor)

VSV (for EVAP)

Battery Current

Sensor

Fuel Pump

Canister Pump Module

Ve n t Va l v e

Leak Detection Pump

Canister Pressure Sensor

ECM

Heated Oxygen Sensor

(Bank 1, Sensor 2) Air Fuel Ratio Sensor

(Bank 1, Sensor 1)

Camshaft Timing

Oil Control ValveInjectorKnock Sensor

Ignition Coil with Igniter

Throttle Position

Sensor

Camshaft Position

Sensor

Water Temperature

Sensor

Crakshaft Position

SensorEG-35

4. Layout of Main Components

Page 46 of 2000

ENGINE - 2AZ-FE ENGINE

185EG48

185EG49

185EG50

287EG34

185EG48

185EG48

TDCLatest Timing

EX IN

BDC

To Advance Side

EX IN

EX IN

To Advance Side

EX IN

To Retard Side

Latest Timing

EX IN

Latest Timing

EX INEG-49

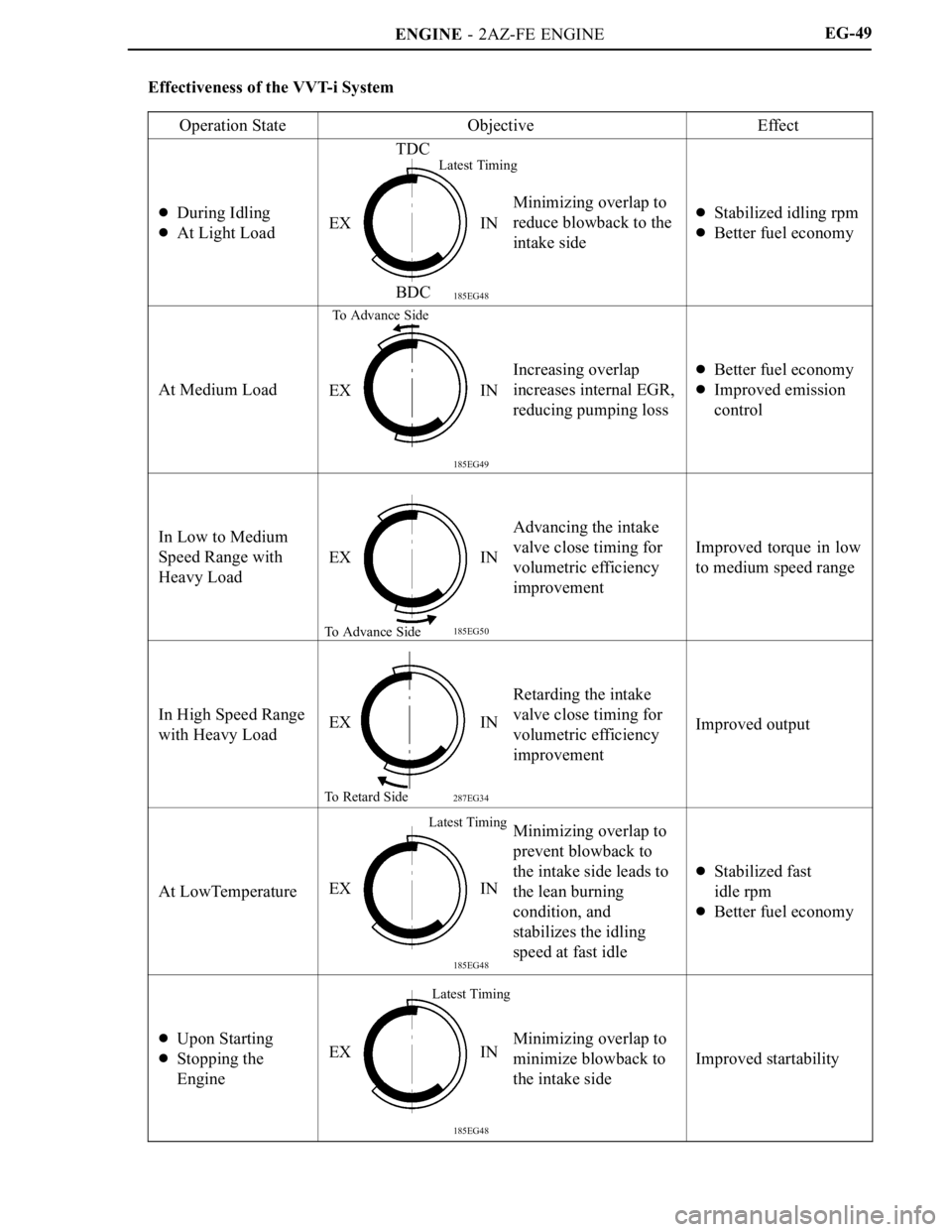

Effectiveness of the VVT-i System

Operation State

ObjectiveEffect

During Idling

At Light Load

Minimizing overlap to

reduce blowback to the

intake sideStabilized idling rpm

Better fuel economy

At Medium Load

Increasing overlap

increases internal EGR,

reducing pumping lossBetter fuel economy

Improved emission

control

In Low to Medium

Speed Range with

Heavy LoadAdvancing the intake

valve close timing for

volumetric efficiency

improvement

Improved torque in low

to medium speed range

In High Speed Range

with Heavy Load

Retarding the intake

valve close timing for

volumetric efficiency

improvement

Improved output

At LowTemperature

Minimizing overlap to

prevent blowback to

the intake side leads to

the lean burning

condition, and

stabilizes the idling

speed at fast idle

Stabilized fast

idle rpm

Better fuel economy

Upon Starting

Stopping the

Engine

Minimizing overlap to

minimize blowback to

the intake side

Improved startability

Page 50 of 2000

ENGINE - 2AZ-FE ENGINE

00REG18Y

Front Airbag

Sensor

(RH and LH)

Curtain Shield

Airbag Sensor*

(RH and LH)Airbag

Sensor

Side Airbag

Sensor*

(RH or LH)ECMCircuit

Opening

Relay

Fuel

Pump

Motor

: CANEG-53

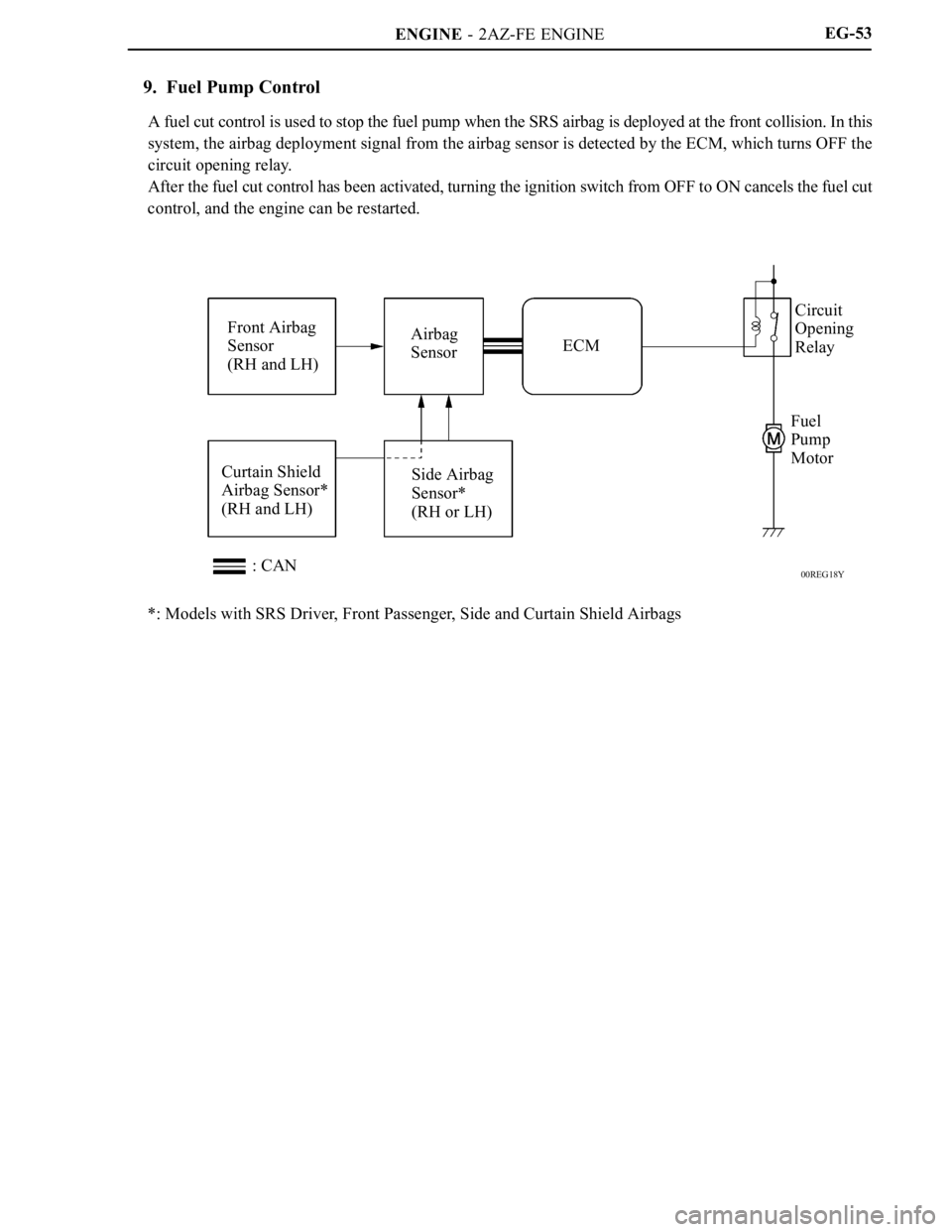

9. Fuel Pump Control

A fuel cut control is used to stop the fuel pump when the SRS airbag is deployed at the front collision. In this

system, the airbag deployment signal from the airbag sensor is detected by the ECM, which turns OFF the

circuit opening relay.

After the fuel cut control has been activated, turning the ignition switch from OFF to ON cancels the fuel cut

control, and the engine can be restarted.

*: Models with SRS Driver, Front Passenger, Side and Curtain Shield Airbags

Page 51 of 2000

ENGINE - 2AZ-FE ENGINE

Service Tip

The canister pump module performs the EVAP leak check. This check is done approximately five

hours after the engine is turned off. So you may hear sound coming from underneath the luggage

compartment for several minutes. It does not indicate a malfunction.

The pinpoint pressure test procedure is carried out by pressurizing the fresh air line that runs from

the pump module to the air filler neck. For details, refer to the 2006 RAV4 Repair Manual (Pub.

No. RM01M1U).

EG-54

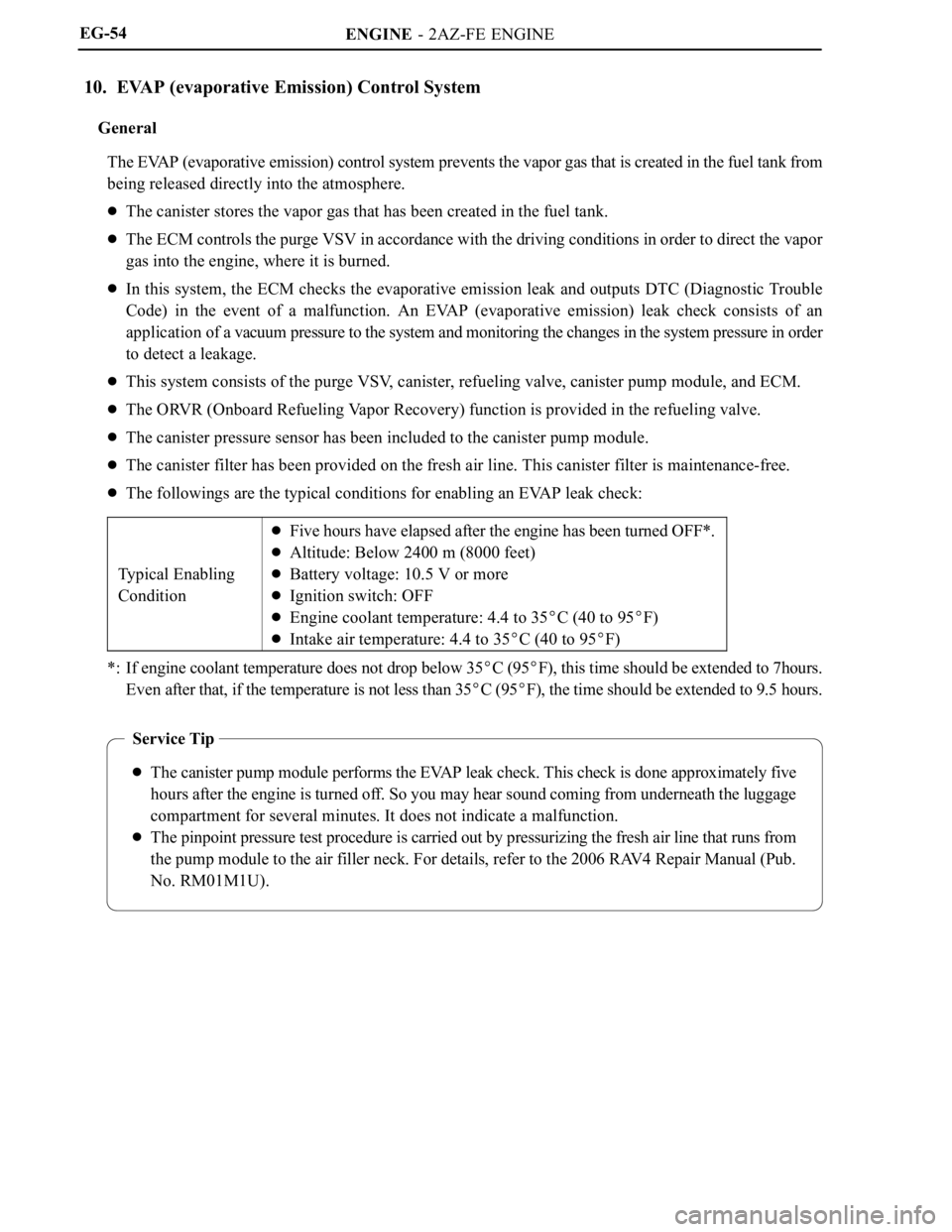

10. EVAP (evaporative Emission) Control System

General

The EVAP (evaporative emission) control system prevents the vapor gas that is created in the fuel tank from

being released directly into the atmosphere.

The canister stores the vapor gas that has been created in the fuel tank.

The ECM controls the purge VSV in accordance with the driving conditions in order to direct the vapor

gas into the engine, where it is burned.

In this system, the ECM checks the evaporative emission leak and outputs DTC (Diagnostic Trouble

Code) in the event of a malfunction. An EVAP (evaporative emission) leak check consists of an

application of a vacuum pressure to the system and monitoring the changes in the system pressure in order

to detect a leakage.

This system consists of the purge VSV, canister, refueling valve, canister pump module, and ECM.

The ORVR (Onboard Refueling Vapor Recovery) function is provided in the refueling valve.

The canister pressure sensor has been included to the canister pump module.

The canister filter has been provided on the fresh air line. This canister filter is maintenance-free.

The followings are the typical conditions for enabling an EVAP leak check:

Typical Enabling

Condition

Five hours have elapsed after the engine has been turned OFF*.

Altitude: Below 2400 m (8000 feet)

Battery voltage: 10.5 V or more

Ignition switch: OFF

Engine coolant temperature: 4.4 to 35C (40 to 95F)

Intake air temperature: 4.4 to 35C (40 to 95F)

*: If engine coolant temperature does not drop below 35C (95F), this time should be extended to 7hours.

Even after that, if the temperature is not less than 35

C (95F), the time should be extended to 9.5 hours.

Page 52 of 2000

ENGINE - 2AZ-FE ENGINE

00REG22Y

To Intake Manifold

Purge VSV

Purge Air

Line

ECMFuel Tank

Canister Filter

Fresh Air LineRefueling Valve

Canister Pump Module

Ve n t

Va l v e

Leak Detection Pump

& Pump Motor

Canister

Pressure SensorCanisterP M

EG-55

System Diagram

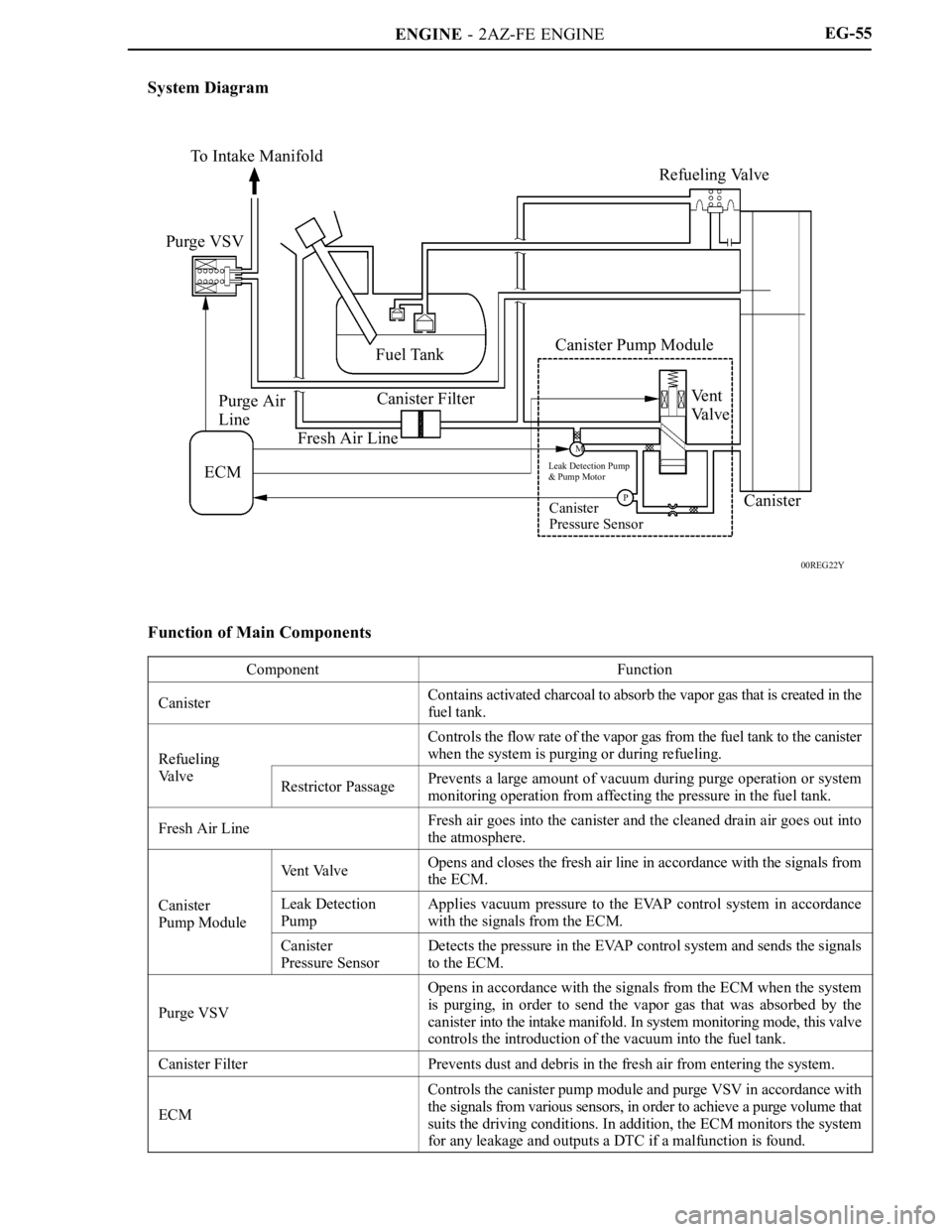

Function of Main Components

ComponentFunction

CanisterContains activated charcoal to absorb the vapor gas that is created in the

fuel tank.

Refueling

Controls the flow rate of the vapor gas from the fuel tank to the canister

when the system is purging or during refueling.

Refueling

Va l v eRestrictor PassagePrevents a large amount of vacuum during purge operation or system

monitoring operation from affecting the pressure in the fuel tank.

Fresh Air LineFresh air goes into the canister and the cleaned drain air goes out into

the atmosphere.

Vent ValveOpens and closes the fresh air line in accordance with the signals from

the ECM.

Canister

Pump ModuleLeak Detection

PumpApplies vacuum pressure to the EVAP control system in accordance

with the signals from the ECM.

p

Canister

Pressure SensorDetects the pressure in the EVAP control system and sends the signals

to the ECM.

Purge VSV

Opens in accordance with the signals from the ECM when the system

is purging, in order to send the vapor gas that was absorbed by the

canister into the intake manifold. In system monitoring mode, this valve

controls the introduction of the vacuum into the fuel tank.

Canister FilterPrevents dust and debris in the fresh air from entering the system.

ECM

Controls the canister pump module and purge VSV in accordance with

the signals from various sensors, in order to achieve a purge volume that

suits the driving conditions. In addition, the ECM monitors the system

for any leakage and outputs a DTC if a malfunction is found.