check engine light TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 182 of 2000

MAINTENANCE – UNDER HOODMA–7

MA

GENERAL MAINTENANCE

(2006/01- )

1. GENERAL NOTES

• Maintenance requirements vary depending on the

country.

• Check the maintenance schedule in the owner's

manual supplement.

• Following the maintenance schedule is mandatory.

• Determine the appropriate time to service the vehicle

using either miles driven or time elapsed, whichever

reaches the specification first.

• Maintain similar intervals between periodic

maintenance, unless otherwise noted.

• Failing to check each vehicle part could lead to poor

engine performance and increase exhaust emissions.

2. WINDSHIELD WASHER FLUID

(a) Check that there is sufficient fluid in the tank.

3. ENGINE COOLANT LEVEL

(a) Check that the coolant level is between the "FULL"

and "LOW" lines on the see-through reservoir.

4. RADIATOR AND HOSES

(a) Check that the front of the radiator is clean and not

blocked by leaves, dirt or bugs.

(b) Check the hoses for cracks, kinks, rot or loose

connections.

5. BATTERY ELECTROLYTE LEVEL

(a) Check that the electrolyte level of all the battery

cells is between the upper and lower level lines on

the case.

HINT:

If the electrolyte level is difficult to see, lightly shake

the vehicle.

6. BRAKE FLUID LEVEL

(a) Check that the brake fluid levels are near the upper

level lines on the see-through reservoirs.

7. ENGINE DRIVE BELT

(a) Check the drive belt for fraying, cracks, wear or

oiliness.

8. ENGINE OIL LEVEL

(a) Check the level on the dipstick with the engine

stopped.

9. AUTOMATIC TRANSAXLE FLUID LEVEL

10. EXHAUST SYSTEM

(a) Check for unusual exhaust sounds or abnormal

exhaust fumes. Inspect the cause and repair it.

Type See procedures

U151E See page AX-126

U151F See page AX-126

Page 215 of 2000

IN–38INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN

ELECTRONIC CIRCUIT INSPECTION

PROCEDURE

1. BASIC INSPECTION

(a) WHEN MEASURING RESISTANCE OF

ELECTRONIC PARTS

(1) Unless otherwise stated, all resistance

measurements should be made at an ambient

temperature of 20

C (68F). Resistance

measurements may be inaccurate if measured

at high temperatures, i.e. immediately after the

vehicle has been running. Measurements should

be made after the engine has cooled down.

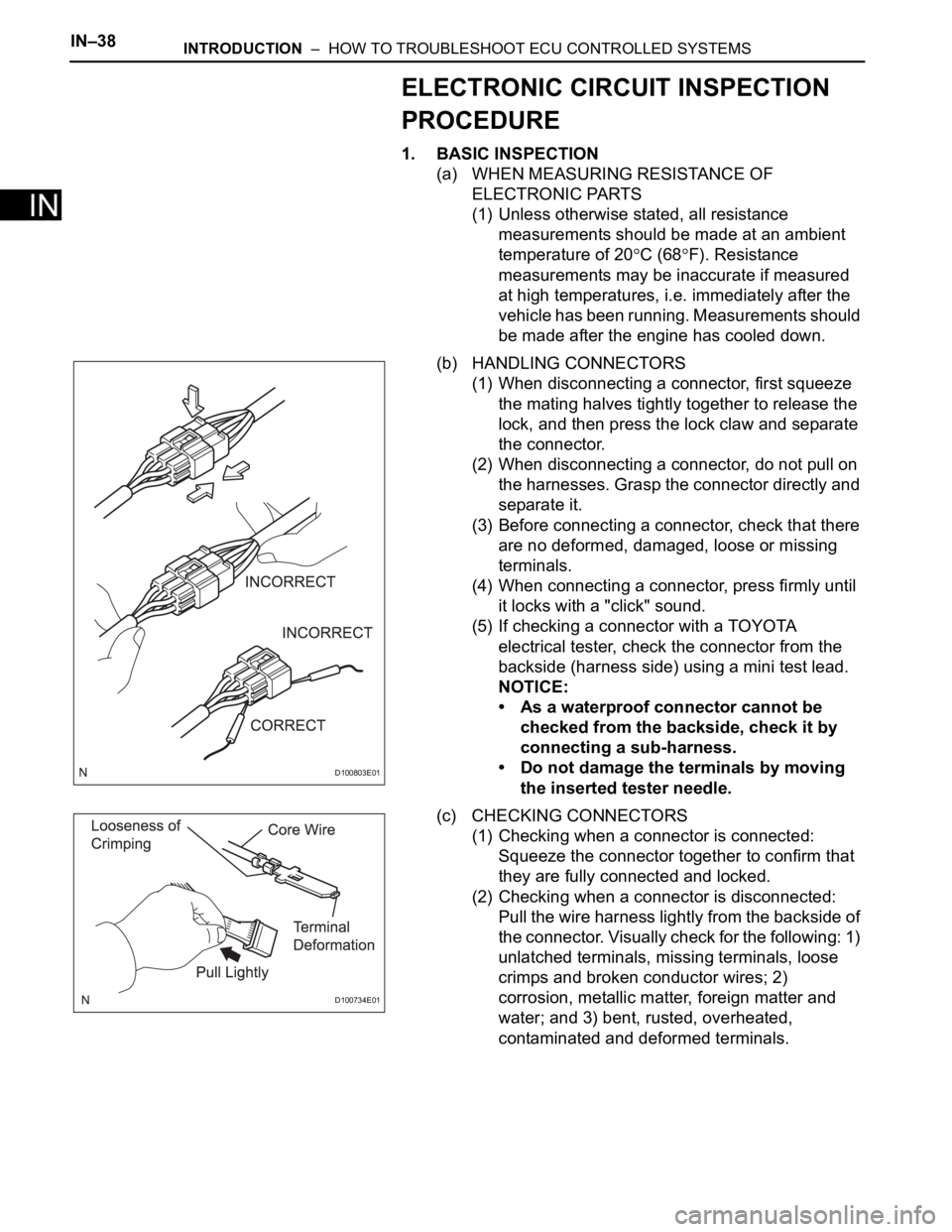

(b) HANDLING CONNECTORS

(1) When disconnecting a connector, first squeeze

the mating halves tightly together to release the

lock, and then press the lock claw and separate

the connector.

(2) When disconnecting a connector, do not pull on

the harnesses. Grasp the connector directly and

separate it.

(3) Before connecting a connector, check that there

are no deformed, damaged, loose or missing

terminals.

(4) When connecting a connector, press firmly until

it locks with a "click" sound.

(5) If checking a connector with a TOYOTA

electrical tester, check the connector from the

backside (harness side) using a mini test lead.

NOTICE:

• As a waterproof connector cannot be

checked from the backside, check it by

connecting a sub-harness.

• Do not damage the terminals by moving

the inserted tester needle.

(c) CHECKING CONNECTORS

(1) Checking when a connector is connected:

Squeeze the connector together to confirm that

they are fully connected and locked.

(2) Checking when a connector is disconnected:

Pull the wire harness lightly from the backside of

the connector. Visually check for the following: 1)

unlatched terminals, missing terminals, loose

crimps and broken conductor wires; 2)

corrosion, metallic matter, foreign matter and

water; and 3) bent, rusted, overheated,

contaminated and deformed terminals.

D100803E01

D100734E01

Page 218 of 2000

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMSIN–41

IN

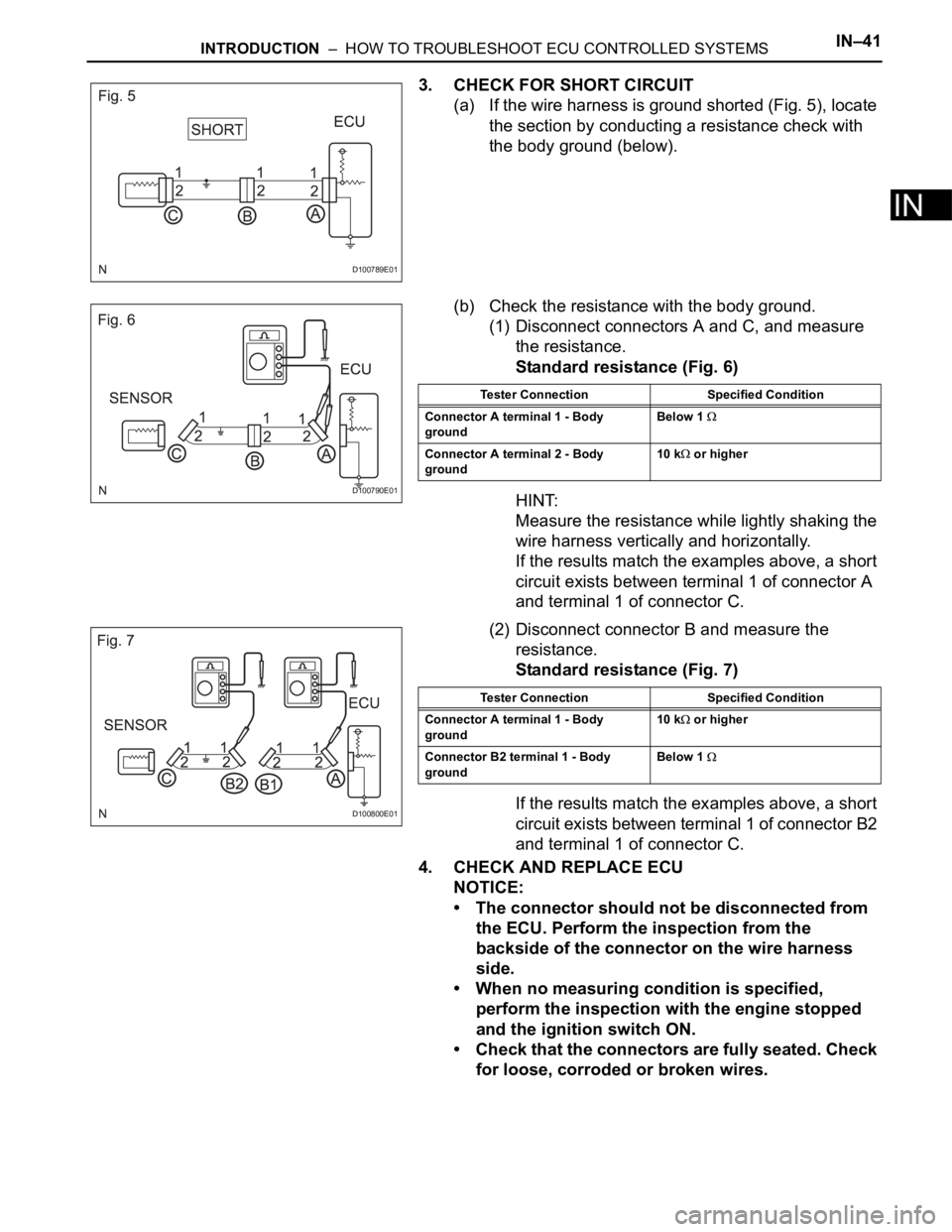

3. CHECK FOR SHORT CIRCUIT

(a) If the wire harness is ground shorted (Fig. 5), locate

the section by conducting a resistance check with

the body ground (below).

(b) Check the resistance with the body ground.

(1) Disconnect connectors A and C, and measure

the resistance.

Standard resistance (Fig. 6)

HINT:

Measure the resistance while lightly shaking the

wire harness vertically and horizontally.

If the results match the examples above, a short

circuit exists between terminal 1 of connector A

and terminal 1 of connector C.

(2) Disconnect connector B and measure the

resistance.

Standard resistance (Fig. 7)

If the results match the examples above, a short

circuit exists between terminal 1 of connector B2

and terminal 1 of connector C.

4. CHECK AND REPLACE ECU

NOTICE:

• The connector should not be disconnected from

the ECU. Perform the inspection from the

backside of the connector on the wire harness

side.

• When no measuring condition is specified,

perform the inspection with the engine stopped

and the ignition switch ON.

• Check that the connectors are fully seated. Check

for loose, corroded or broken wires.

D100789E01

D100790E01

Tester Connection Specified Condition

Connector A terminal 1 - Body

groundBelow 1

Connector A terminal 2 - Body

ground10 k or higher

D100800E01

Tester Connection Specified Condition

Connector A terminal 1 - Body

ground10 k

or higher

Connector B2 terminal 1 - Body

ground Below 1

Page 339 of 2000

CH–42AZ-FE CHARGING – CHARGING SYSTEM

CH

ON-VEHICLE INSPECTION

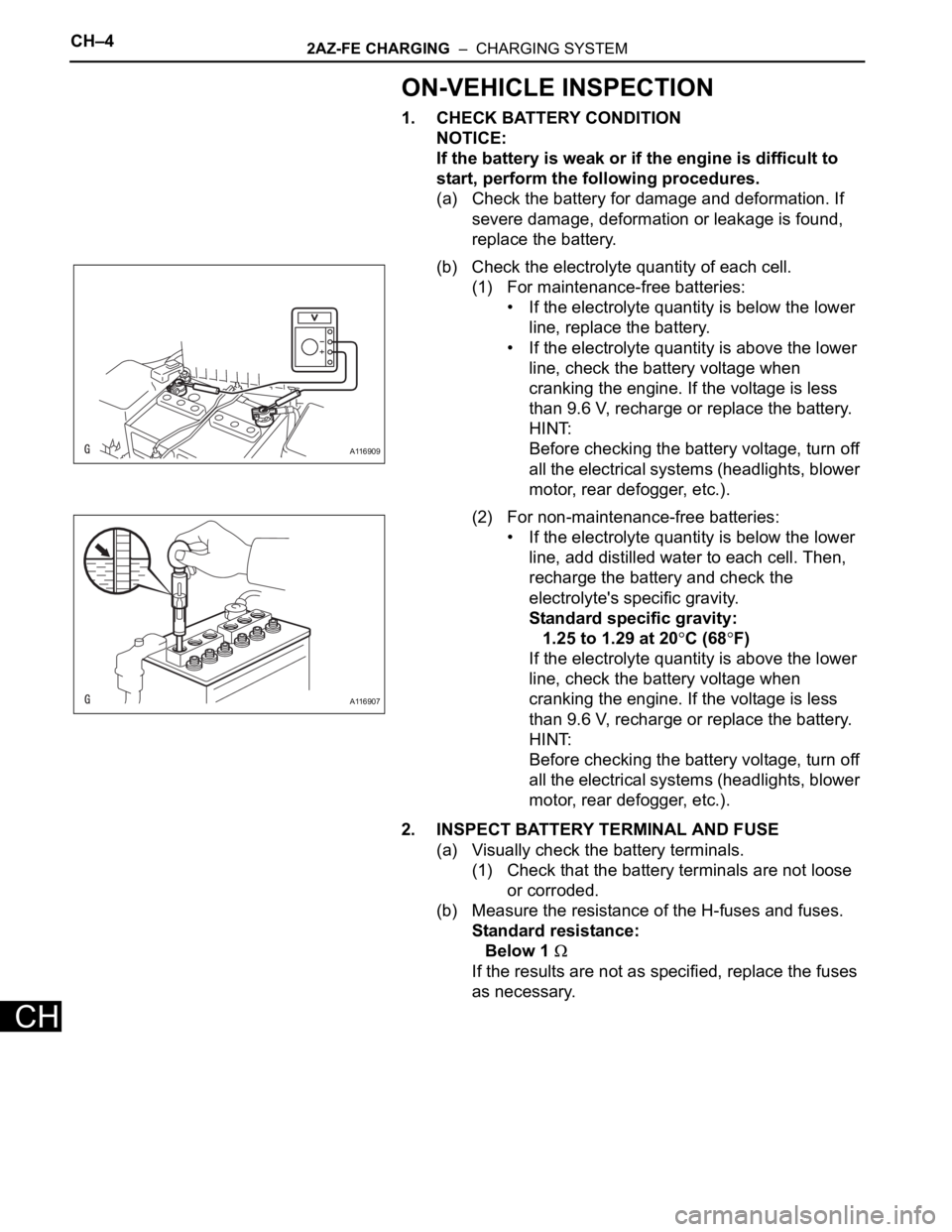

1. CHECK BATTERY CONDITION

NOTICE:

If the battery is weak or if the engine is difficult to

start, perform the following procedures.

(a) Check the battery for damage and deformation. If

severe damage, deformation or leakage is found,

replace the battery.

(b) Check the electrolyte quantity of each cell.

(1) For maintenance-free batteries:

• If the electrolyte quantity is below the lower

line, replace the battery.

• If the electrolyte quantity is above the lower

line, check the battery voltage when

cranking the engine. If the voltage is less

than 9.6 V, recharge or replace the battery.

HINT:

Before checking the battery voltage, turn off

all the electrical systems (headlights, blower

motor, rear defogger, etc.).

(2) For non-maintenance-free batteries:

• If the electrolyte quantity is below the lower

line, add distilled water to each cell. Then,

recharge the battery and check the

electrolyte's specific gravity.

Standard specific gravity:

1.25 to 1.29 at 20

C (68F)

If the electrolyte quantity is above the lower

line, check the battery voltage when

cranking the engine. If the voltage is less

than 9.6 V, recharge or replace the battery.

HINT:

Before checking the battery voltage, turn off

all the electrical systems (headlights, blower

motor, rear defogger, etc.).

2. INSPECT BATTERY TERMINAL AND FUSE

(a) Visually check the battery terminals.

(1) Check that the battery terminals are not loose

or corroded.

(b) Measure the resistance of the H-fuses and fuses.

Standard resistance:

Below 1

If the results are not as specified, replace the fuses

as necessary.

A116909

A116907

Page 340 of 2000

2AZ-FE CHARGING – CHARGING SYSTEMCH–5

CH

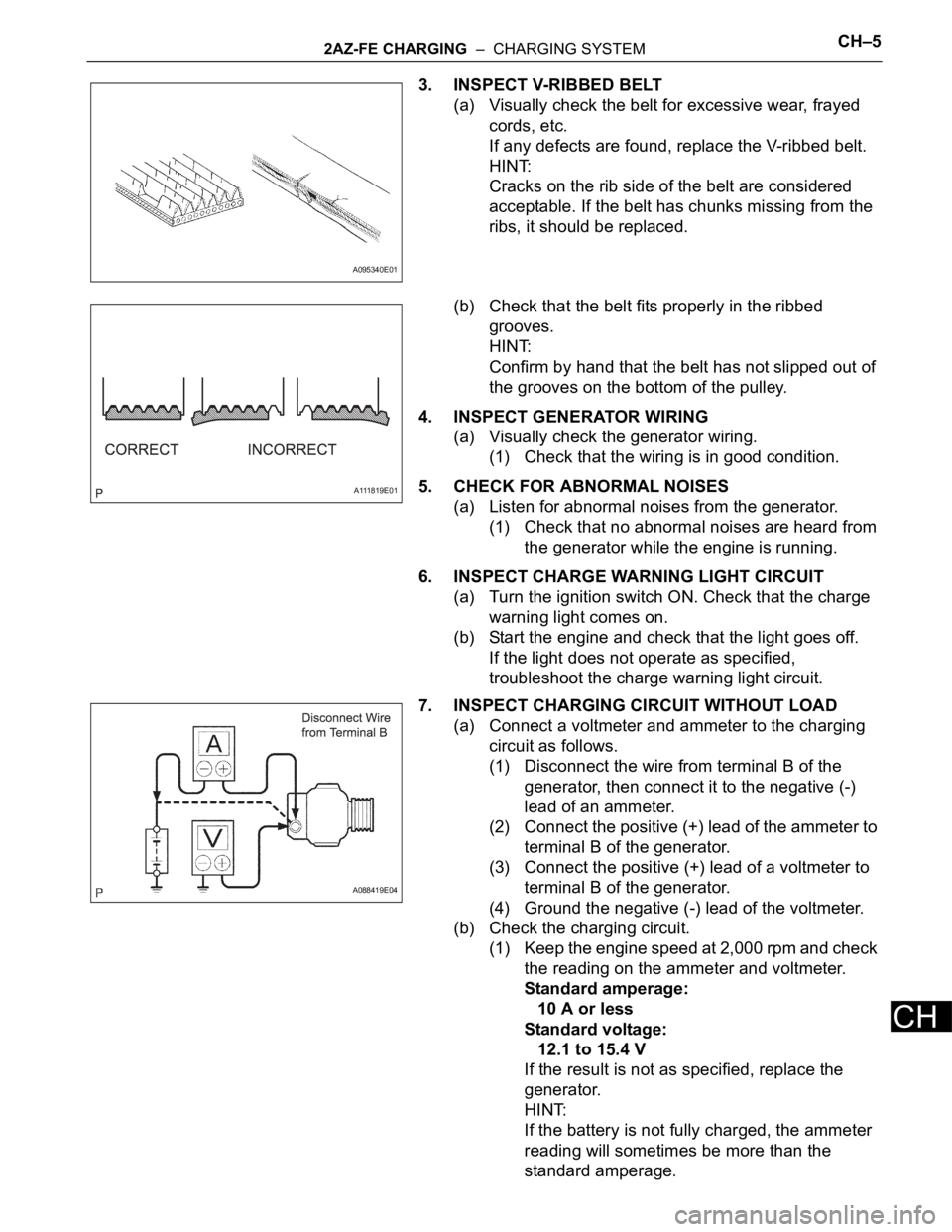

3. INSPECT V-RIBBED BELT

(a) Visually check the belt for excessive wear, frayed

cords, etc.

If any defects are found, replace the V-ribbed belt.

HINT:

Cracks on the rib side of the belt are considered

acceptable. If the belt has chunks missing from the

ribs, it should be replaced.

(b) Check that the belt fits properly in the ribbed

grooves.

HINT:

Confirm by hand that the belt has not slipped out of

the grooves on the bottom of the pulley.

4. INSPECT GENERATOR WIRING

(a) Visually check the generator wiring.

(1) Check that the wiring is in good condition.

5. CHECK FOR ABNORMAL NOISES

(a) Listen for abnormal noises from the generator.

(1) Check that no abnormal noises are heard from

the generator while the engine is running.

6. INSPECT CHARGE WARNING LIGHT CIRCUIT

(a) Turn the ignition switch ON. Check that the charge

warning light comes on.

(b) Start the engine and check that the light goes off.

If the light does not operate as specified,

troubleshoot the charge warning light circuit.

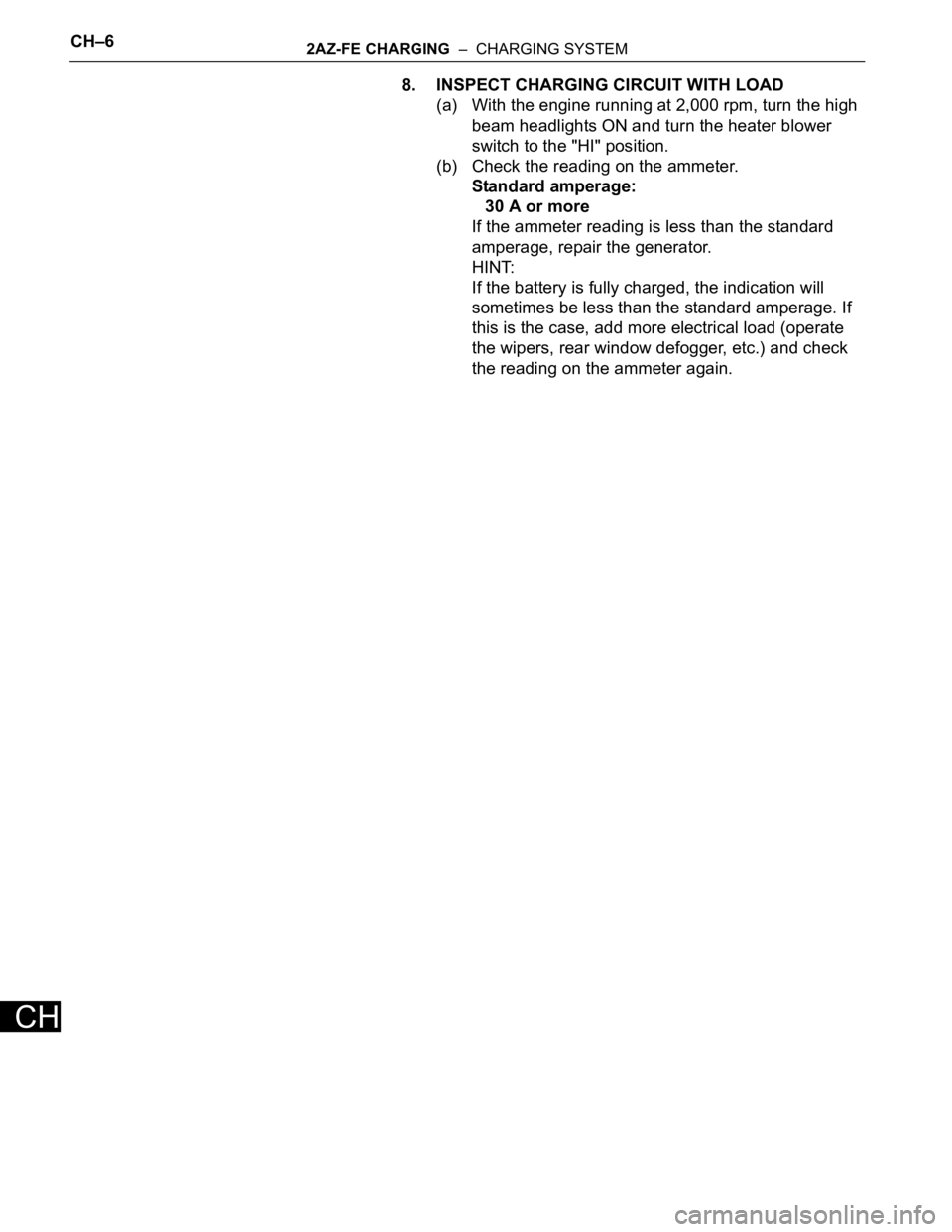

7. INSPECT CHARGING CIRCUIT WITHOUT LOAD

(a) Connect a voltmeter and ammeter to the charging

circuit as follows.

(1) Disconnect the wire from terminal B of the

generator, then connect it to the negative (-)

lead of an ammeter.

(2) Connect the positive (+) lead of the ammeter to

terminal B of the generator.

(3) Connect the positive (+) lead of a voltmeter to

terminal B of the generator.

(4) Ground the negative (-) lead of the voltmeter.

(b) Check the charging circuit.

(1) Keep the engine speed at 2,000 rpm and check

the reading on the ammeter and voltmeter.

Standard amperage:

10 A or less

Standard voltage:

12.1 to 15.4 V

If the result is not as specified, replace the

generator.

HINT:

If the battery is not fully charged, the ammeter

reading will sometimes be more than the

standard amperage.

A095340E01

A111819E01

A088419E04

Page 341 of 2000

CH–62AZ-FE CHARGING – CHARGING SYSTEM

CH

8. INSPECT CHARGING CIRCUIT WITH LOAD

(a) With the engine running at 2,000 rpm, turn the high

beam headlights ON and turn the heater blower

switch to the "HI" position.

(b) Check the reading on the ammeter.

Standard amperage:

30 A or more

If the ammeter reading is less than the standard

amperage, repair the generator.

HINT:

If the battery is fully charged, the indication will

sometimes be less than the standard amperage. If

this is the case, add more electrical load (operate

the wipers, rear window defogger, etc.) and check

the reading on the ammeter again.

Page 497 of 2000

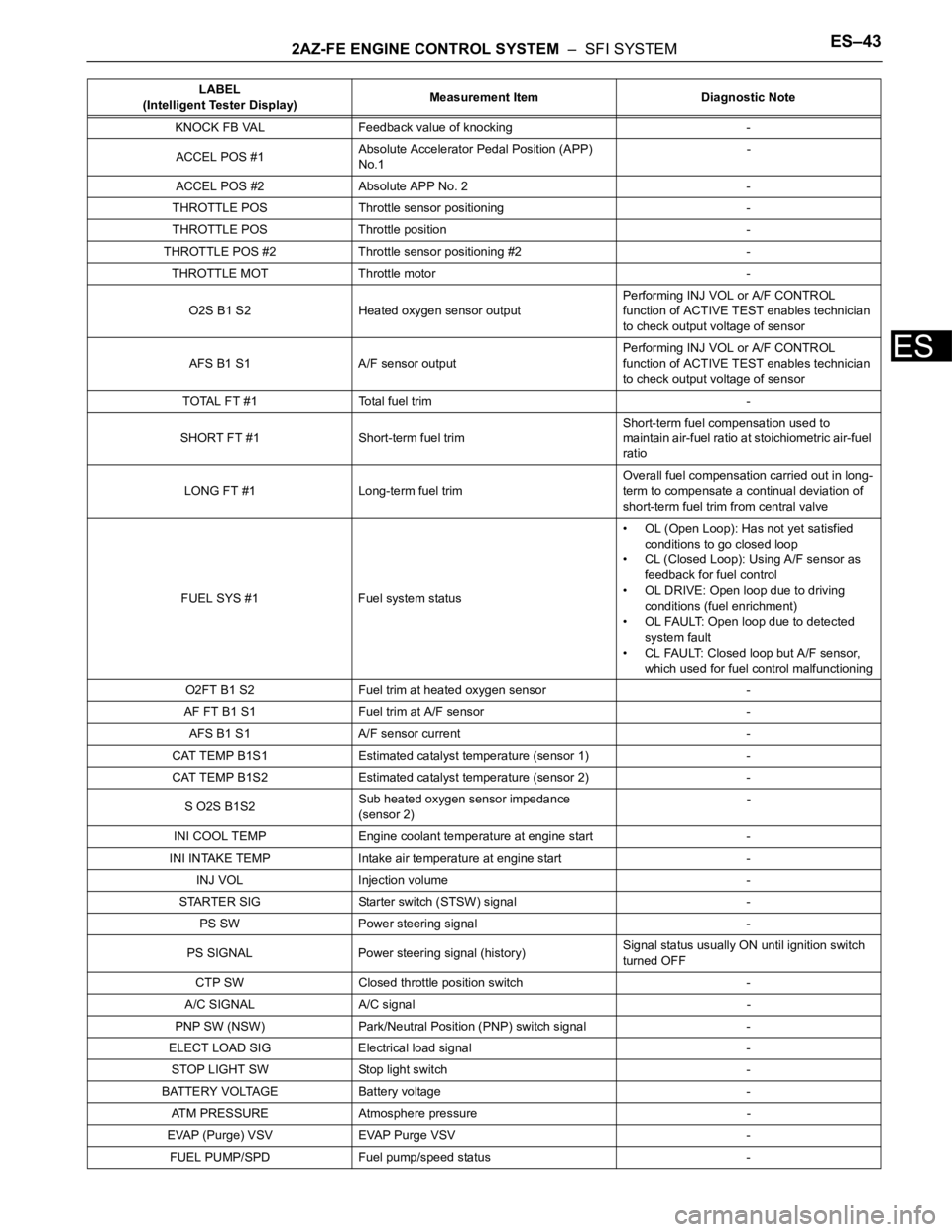

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–43

ES

KNOCK FB VAL Feedback value of knocking -

ACCEL POS #1Absolute Accelerator Pedal Position (APP)

No.1-

ACCEL POS #2 Absolute APP No. 2 -

THROTTLE POS Throttle sensor positioning -

THROTTLE POS Throttle position -

THROTTLE POS #2 Throttle sensor positioning #2 -

THROTTLE MOT Throttle motor -

O2S B1 S2 Heated oxygen sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check output voltage of sensor

AFS B1 S1 A/F sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check output voltage of sensor

TOTAL FT #1 Total fuel trim -

SHORT FT #1 Short-term fuel trimShort-term fuel compensation used to

maintain air-fuel ratio at stoichiometric air-fuel

ratio

LONG FT #1 Long-term fuel trimOverall fuel compensation carried out in long-

term to compensate a continual deviation of

short-term fuel trim from central valve

FUEL SYS #1 Fuel system status• OL (Open Loop): Has not yet satisfied

conditions to go closed loop

• CL (Closed Loop): Using A/F sensor as

feedback for fuel control

• OL DRIVE: Open loop due to driving

conditions (fuel enrichment)

• OL FAULT: Open loop due to detected

system fault

• CL FAULT: Closed loop but A/F sensor,

which used for fuel control malfunctioning

O2FT B1 S2 Fuel trim at heated oxygen sensor -

AF FT B1 S1 Fuel trim at A/F sensor -

AFS B1 S1 A/F sensor current -

CAT TEMP B1S1 Estimated catalyst temperature (sensor 1) -

CAT TEMP B1S2 Estimated catalyst temperature (sensor 2) -

S O2S B1S2Sub heated oxygen sensor impedance

(sensor 2)-

INI COOL TEMP Engine coolant temperature at engine start -

INI INTAKE TEMP Intake air temperature at engine start -

INJ VOL Injection volume -

STARTER SIG Starter switch (STSW) signal -

PS SW Power steering signal -

PS SIGNAL Power steering signal (history)Signal status usually ON until ignition switch

turned OFF

CTP SW Closed throttle position switch -

A/C SIGNAL A/C signal -

PNP SW (NSW) Park/Neutral Position (PNP) switch signal -

ELECT LOAD SIG Electrical load signal -

STOP LIGHT SW Stop light switch -

BATTERY VOLTAGE Battery voltage -

ATM PRESSURE Atmosphere pressure -

EVAP (Purge) VSV EVAP Purge VSV -

FUEL PUMP/SPD Fuel pump/speed status -LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

Page 571 of 2000

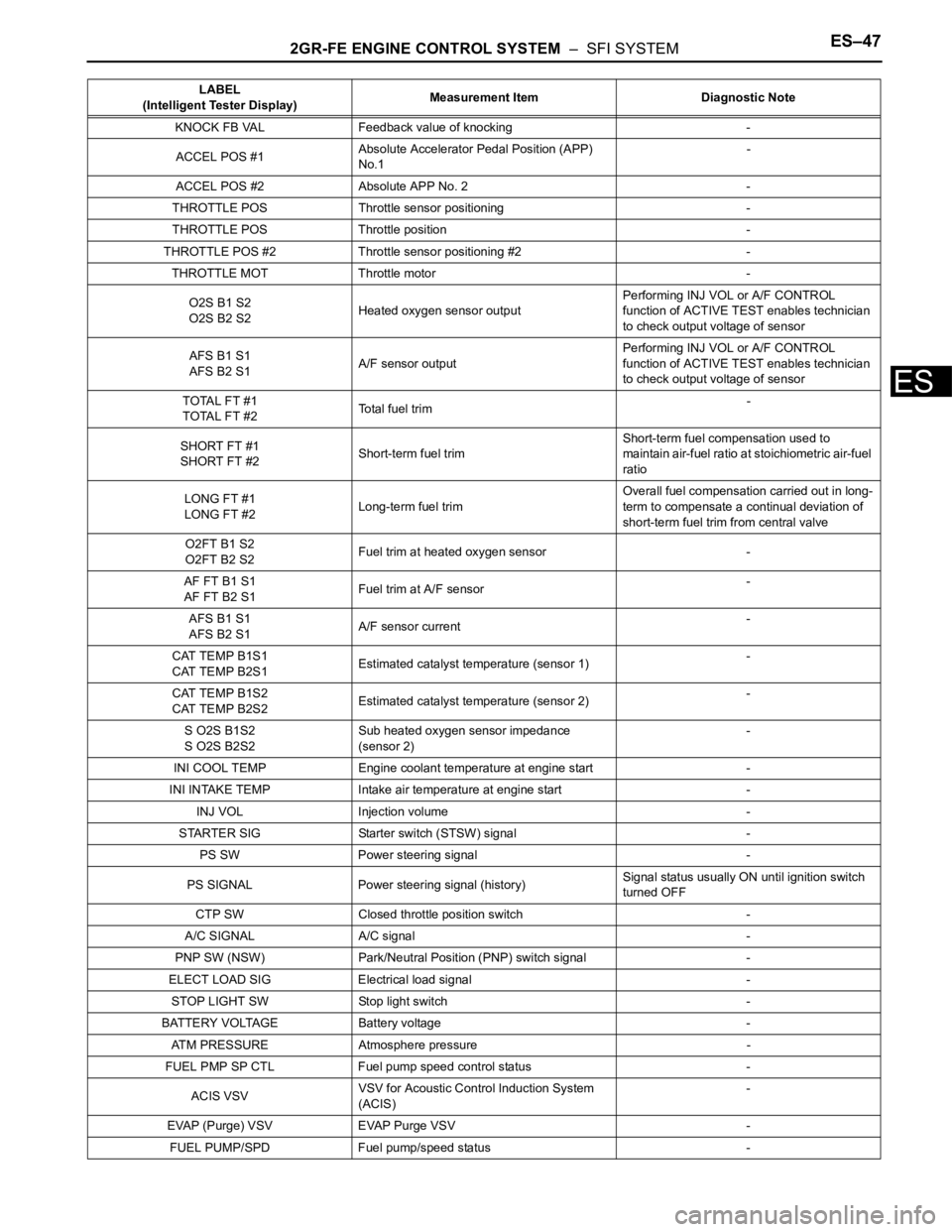

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–47

ES

KNOCK FB VAL Feedback value of knocking -

ACCEL POS #1Absolute Accelerator Pedal Position (APP)

No.1-

ACCEL POS #2 Absolute APP No. 2 -

THROTTLE POS Throttle sensor positioning -

THROTTLE POS Throttle position -

THROTTLE POS #2 Throttle sensor positioning #2 -

THROTTLE MOT Throttle motor -

O2S B1 S2

O2S B2 S2Heated oxygen sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check output voltage of sensor

AFS B1 S1

AFS B2 S1A/F sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check output voltage of sensor

TOTAL FT #1

TOTAL FT #2Total fuel trim -

SHORT FT #1

SHORT FT #2Short-term fuel trimShort-term fuel compensation used to

maintain air-fuel ratio at stoichiometric air-fuel

ratio

LONG FT #1

LONG FT #2Long-term fuel trimOverall fuel compensation carried out in long-

term to compensate a continual deviation of

short-term fuel trim from central valve

O2FT B1 S2

O2FT B2 S2Fuel trim at heated oxygen sensor -

AF FT B1 S1

AF FT B2 S1Fuel trim at A/F sensor-

AFS B1 S1

AFS B2 S1A/F sensor current-

CAT TEMP B1S1

CAT TEMP B2S1Estimated catalyst temperature (sensor 1)-

CAT TEMP B1S2

CAT TEMP B2S2Estimated catalyst temperature (sensor 2)-

S O2S B1S2

S O2S B2S2Sub heated oxygen sensor impedance

(sensor 2)-

INI COOL TEMP Engine coolant temperature at engine start -

INI INTAKE TEMP Intake air temperature at engine start -

INJ VOL Injection volume -

STARTER SIG Starter switch (STSW) signal -

PS SW Power steering signal -

PS SIGNAL Power steering signal (history)Signal status usually ON until ignition switch

turned OFF

CTP SW Closed throttle position switch -

A/C SIGNAL A/C signal -

PNP SW (NSW) Park/Neutral Position (PNP) switch signal -

ELECT LOAD SIG Electrical load signal -

STOP LIGHT SW Stop light switch -

BATTERY VOLTAGE Battery voltage -

ATM PRESSURE Atmosphere pressure -

FUEL PMP SP CTL Fuel pump speed control status -

ACIS VSVVSV for Acoustic Control Induction System

(ACIS)-

EVAP (Purge) VSV EVAP Purge VSV -

FUEL PUMP/SPD Fuel pump/speed status -LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

Page 610 of 2000

EM–662AZ-FE ENGINE MECHANICAL – CYLINDER HEAD

EM

INSPECTION

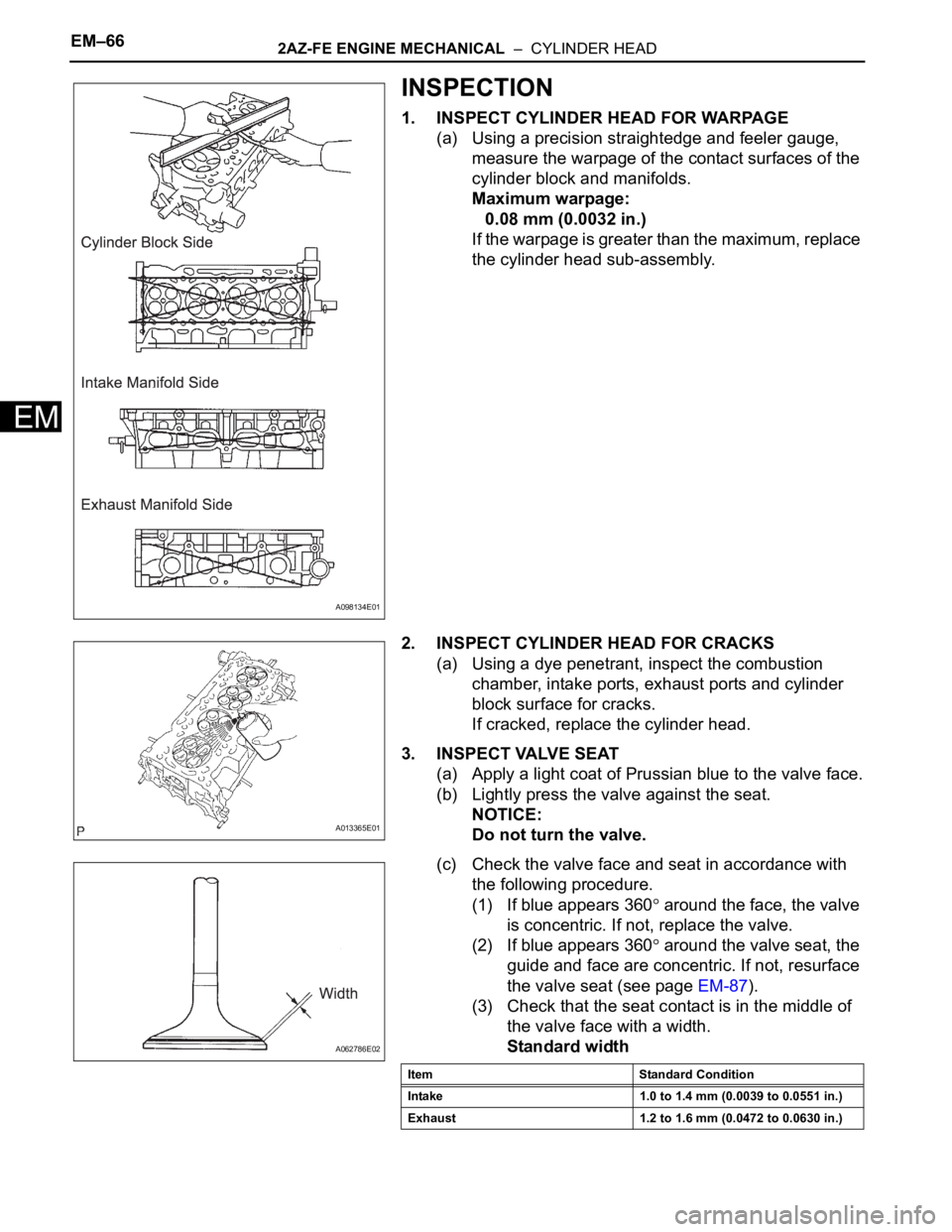

1. INSPECT CYLINDER HEAD FOR WARPAGE

(a) Using a precision straightedge and feeler gauge,

measure the warpage of the contact surfaces of the

cylinder block and manifolds.

Maximum warpage:

0.08 mm (0.0032 in.)

If the warpage is greater than the maximum, replace

the cylinder head sub-assembly.

2. INSPECT CYLINDER HEAD FOR CRACKS

(a) Using a dye penetrant, inspect the combustion

chamber, intake ports, exhaust ports and cylinder

block surface for cracks.

If cracked, replace the cylinder head.

3. INSPECT VALVE SEAT

(a) Apply a light coat of Prussian blue to the valve face.

(b) Lightly press the valve against the seat.

NOTICE:

Do not turn the valve.

(c) Check the valve face and seat in accordance with

the following procedure.

(1) If blue appears 360

around the face, the valve

is concentric. If not, replace the valve.

(2) If blue appears 360

around the valve seat, the

guide and face are concentric. If not, resurface

the valve seat (see page EM-87).

(3) Check that the seat contact is in the middle of

the valve face with a width.

Standard width

A098134E01

A013365E01

A062786E02

Item Standard Condition

Intake 1.0 to 1.4 mm (0.0039 to 0.0551 in.)

Exhaust 1.2 to 1.6 mm (0.0472 to 0.0630 in.)

Page 628 of 2000

EM–842AZ-FE ENGINE MECHANICAL – CYLINDER HEAD

EM

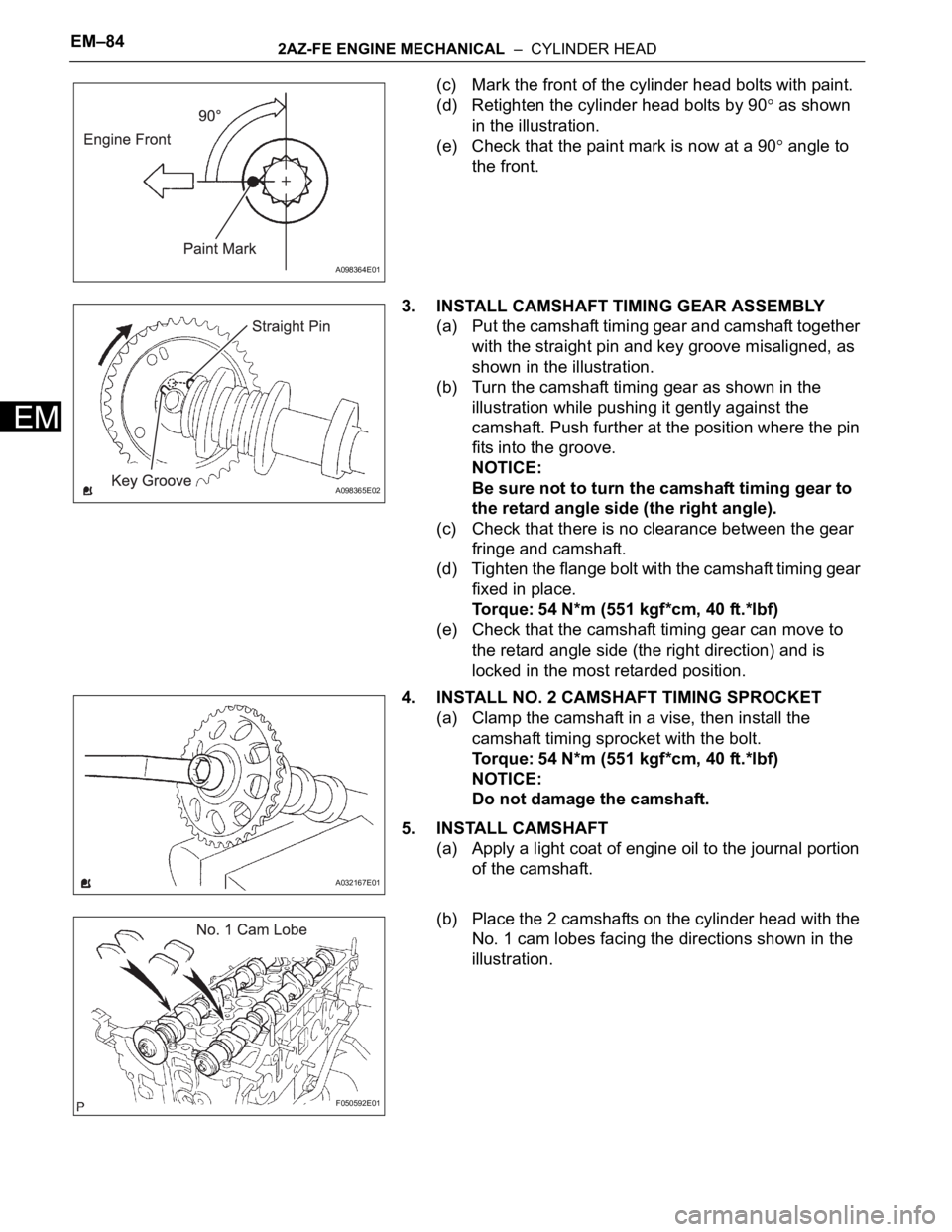

(c) Mark the front of the cylinder head bolts with paint.

(d) Retighten the cylinder head bolts by 90

as shown

in the illustration.

(e) Check that the paint mark is now at a 90

angle to

the front.

3. INSTALL CAMSHAFT TIMING GEAR ASSEMBLY

(a) Put the camshaft timing gear and camshaft together

with the straight pin and key groove misaligned, as

shown in the illustration.

(b) Turn the camshaft timing gear as shown in the

illustration while pushing it gently against the

camshaft. Push further at the position where the pin

fits into the groove.

NOTICE:

Be sure not to turn the camshaft timing gear to

the retard angle side (the right angle).

(c) Check that there is no clearance between the gear

fringe and camshaft.

(d) Tighten the flange bolt with the camshaft timing gear

fixed in place.

Torque: 54 N*m (551 kgf*cm, 40 ft.*lbf)

(e) Check that the camshaft timing gear can move to

the retard angle side (the right direction) and is

locked in the most retarded position.

4. INSTALL NO. 2 CAMSHAFT TIMING SPROCKET

(a) Clamp the camshaft in a vise, then install the

camshaft timing sprocket with the bolt.

Torque: 54 N*m (551 kgf*cm, 40 ft.*lbf)

NOTICE:

Do not damage the camshaft.

5. INSTALL CAMSHAFT

(a) Apply a light coat of engine oil to the journal portion

of the camshaft.

(b) Place the 2 camshafts on the cylinder head with the

No. 1 cam lobes facing the directions shown in the

illustration.

A098364E01

A098365E02

A032167E01

F050592E01