wheel TOYOTA SIENNA 2007 Service Owners Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 2176 of 3000

AH–20AXLE – REAR AXLE HUB AND BEARING (for 4WD)

AH

REMOVAL

HINT:

Replace the RH side by the same procedures as the LH side.

1. REMOVE REAR WHEEL

2. REMOVE REAR AXLE SHAFT LH NUT (See page DS-

22)

3. SEPARATE REAR DISC BRAKE CALIPER

ASSEMBLY LH

(a) Removing the 2 bolts, separate the rear disc brake

caliper assembly LH.

4. REMOVE REAR DISC

5. SEPARATE SPEED SENSOR REAR LH

(a) Removing the bolt, separate the speed sensor rear

LH.

NOTICE:

• Be careful not to damage the speed sensor.

• Prevent foreign matter from attaching to the

speed sensor.

6. REMOVE REAR DRIVE SHAFT ASSEMBLY LH (See

page DS-22)

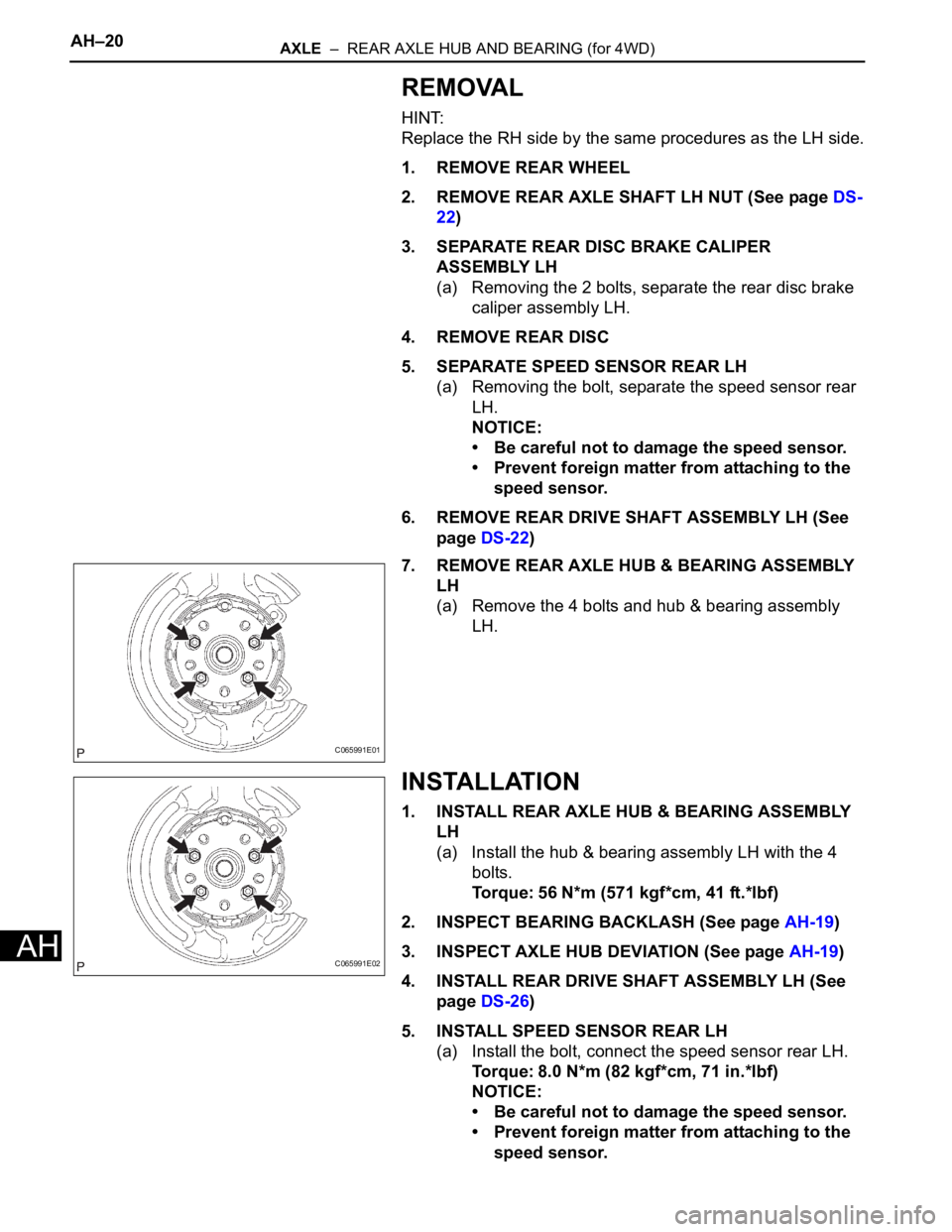

7. REMOVE REAR AXLE HUB & BEARING ASSEMBLY

LH

(a) Remove the 4 bolts and hub & bearing assembly

LH.

INSTALLATION

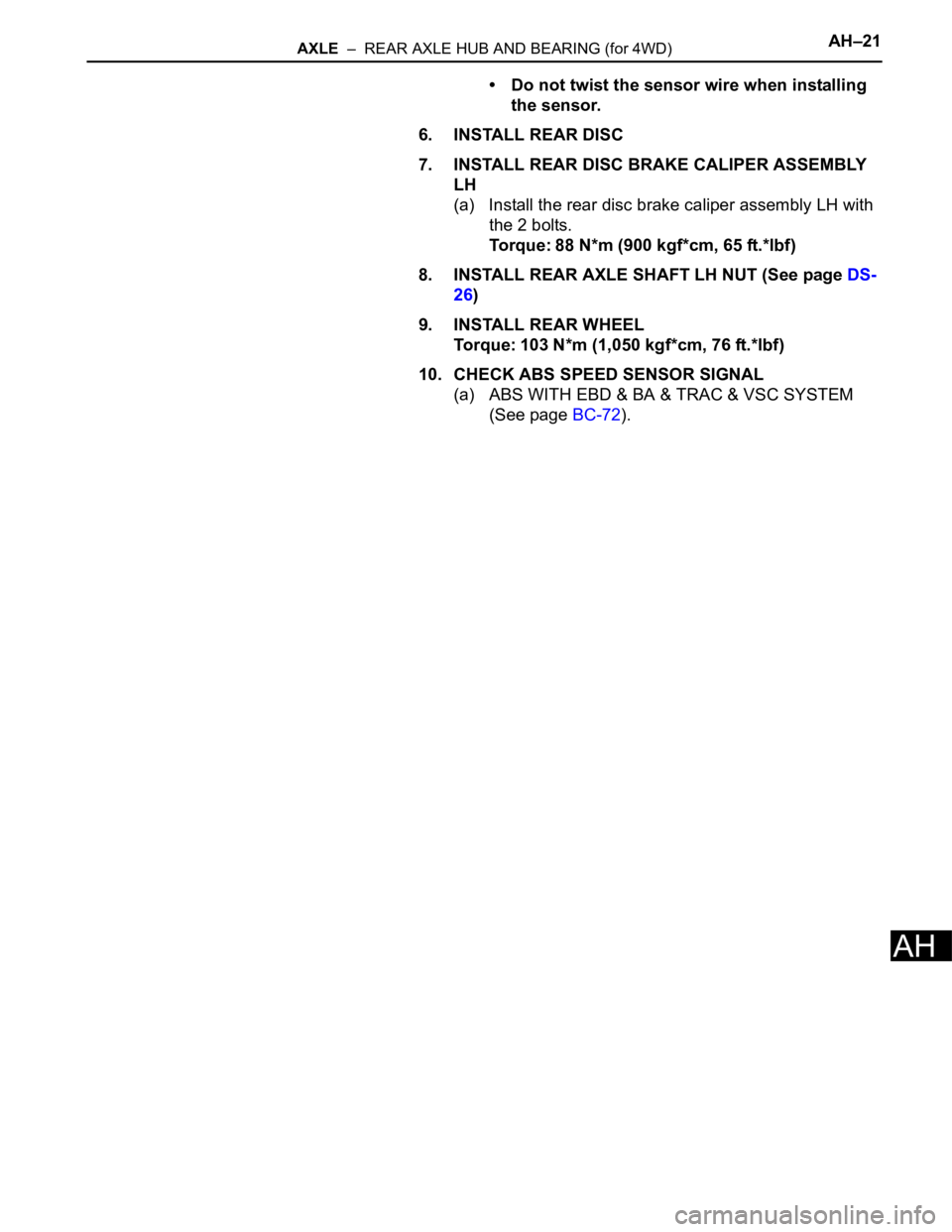

1. INSTALL REAR AXLE HUB & BEARING ASSEMBLY

LH

(a) Install the hub & bearing assembly LH with the 4

bolts.

Torque: 56 N*m (571 kgf*cm, 41 ft.*lbf)

2. INSPECT BEARING BACKLASH (See page AH-19)

3. INSPECT AXLE HUB DEVIATION (See page AH-19)

4. INSTALL REAR DRIVE SHAFT ASSEMBLY LH (See

page DS-26)

5. INSTALL SPEED SENSOR REAR LH

(a) Install the bolt, connect the speed sensor rear LH.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

NOTICE:

• Be careful not to damage the speed sensor.

• Prevent foreign matter from attaching to the

speed sensor.

C065991E01

C065991E02

Page 2177 of 3000

AXLE – REAR AXLE HUB AND BEARING (for 4WD)AH–21

AH

• Do not twist the sensor wire when installing

the sensor.

6. INSTALL REAR DISC

7. INSTALL REAR DISC BRAKE CALIPER ASSEMBLY

LH

(a) Install the rear disc brake caliper assembly LH with

the 2 bolts.

Torque: 88 N*m (900 kgf*cm, 65 ft.*lbf)

8. INSTALL REAR AXLE SHAFT LH NUT (See page DS-

26)

9. INSTALL REAR WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

10. CHECK ABS SPEED SENSOR SIGNAL

(a) ABS WITH EBD & BA & TRAC & VSC SYSTEM

(See page BC-72).

Page 2178 of 3000

SUSPENSION – FRONT SHOCK ABSORBER WITH COIL SPRINGSP–13

SP

REMOVAL

1. REMOVE FRONT WHEEL

2. REMOVE FRONT WIPER ARM HEAD CAP

HINT:

(See page WW-3)

3. REMOVE FR WIPER ARM RH

HINT:

(See page WW-3)

4. REMOVE FR WIPER ARM LH

HINT:

(See page WW-3)

5. REMOVE COWL TOP VENTILATOR LOUVER SUB-

ASSEMBLY

HINT:

(See page WW-3)

6. REMOVE WINDSHIELD WIPER MOTOR & LINK

ASSEMBLY

HINT:

(See page WW-3)

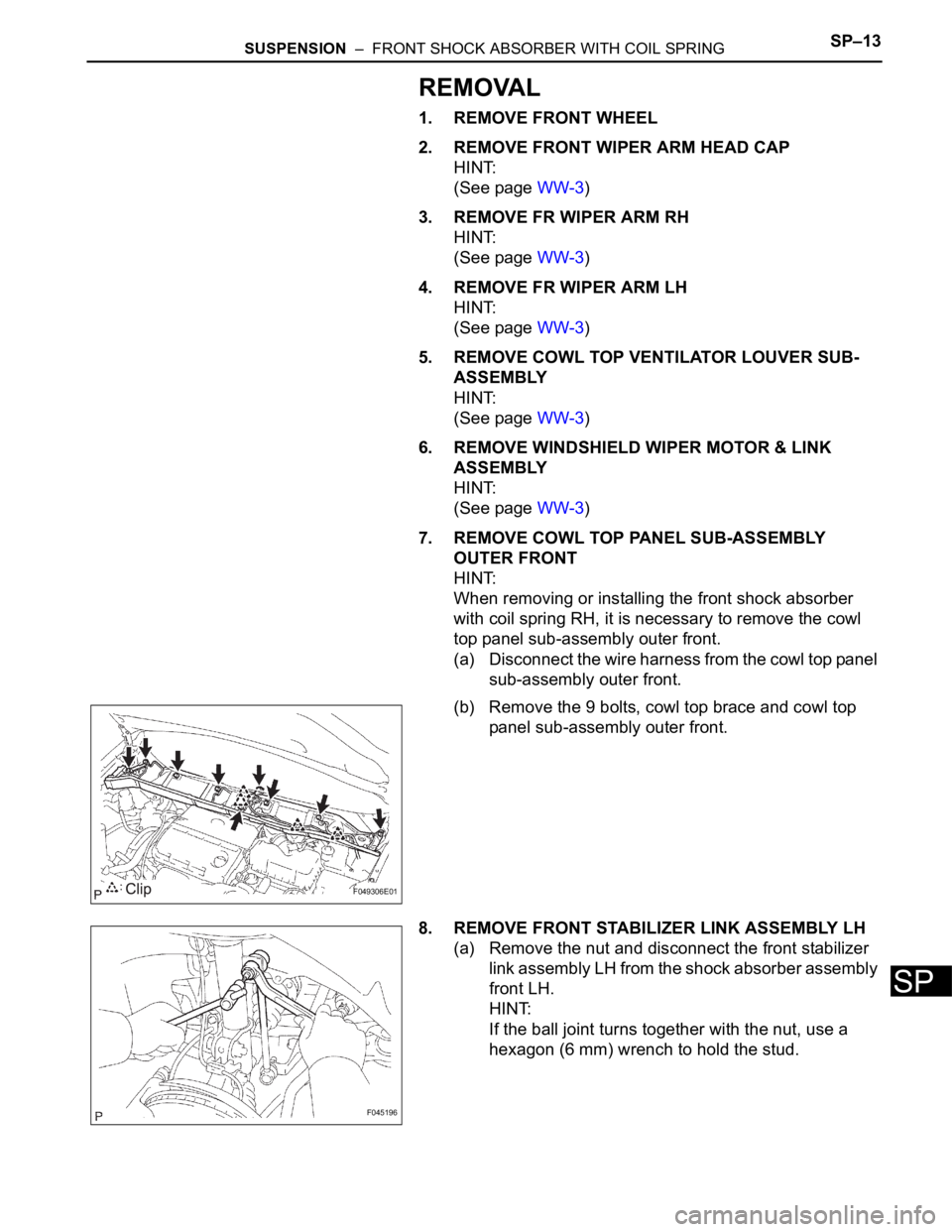

7. REMOVE COWL TOP PANEL SUB-ASSEMBLY

OUTER FRONT

HINT:

When removing or installing the front shock absorber

with coil spring RH, it is necessary to remove the cowl

top panel sub-assembly outer front.

(a) Disconnect the wire harness from the cowl top panel

sub-assembly outer front.

(b) Remove the 9 bolts, cowl top brace and cowl top

panel sub-assembly outer front.

8. REMOVE FRONT STABILIZER LINK ASSEMBLY LH

(a) Remove the nut and disconnect the front stabilizer

link assembly LH from the shock absorber assembly

front LH.

HINT:

If the ball joint turns together with the nut, use a

hexagon (6 mm) wrench to hold the stud.

F049306E01

F045196

Page 2184 of 3000

SUSPENSION – FRONT SHOCK ABSORBER WITH COIL SPRINGSP–19

SP

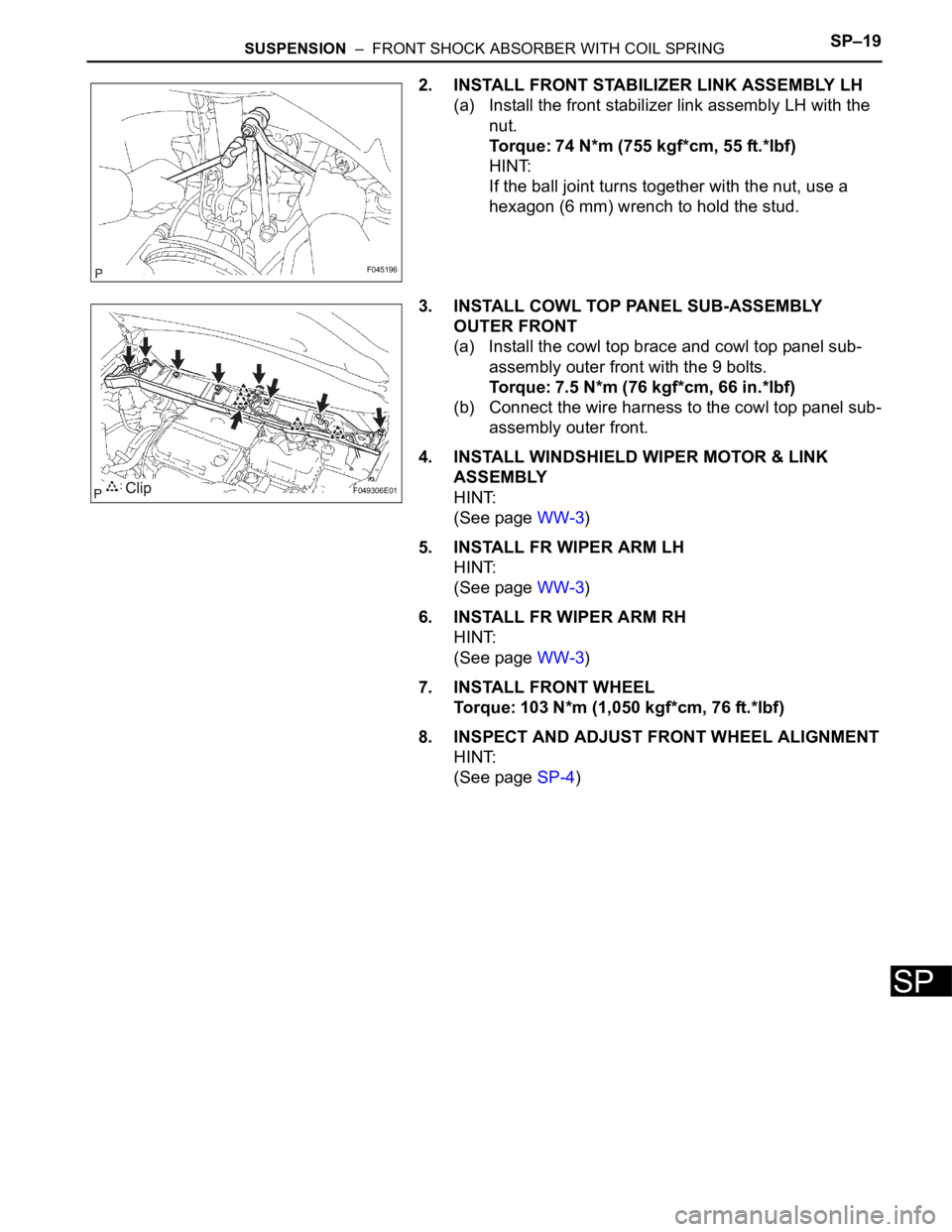

2. INSTALL FRONT STABILIZER LINK ASSEMBLY LH

(a) Install the front stabilizer link assembly LH with the

nut.

Torque: 74 N*m (755 kgf*cm, 55 ft.*lbf)

HINT:

If the ball joint turns together with the nut, use a

hexagon (6 mm) wrench to hold the stud.

3. INSTALL COWL TOP PANEL SUB-ASSEMBLY

OUTER FRONT

(a) Install the cowl top brace and cowl top panel sub-

assembly outer front with the 9 bolts.

Torque: 7.5 N*m (76 kgf*cm, 66 in.*lbf)

(b) Connect the wire harness to the cowl top panel sub-

assembly outer front.

4. INSTALL WINDSHIELD WIPER MOTOR & LINK

ASSEMBLY

HINT:

(See page WW-3)

5. INSTALL FR WIPER ARM LH

HINT:

(See page WW-3)

6. INSTALL FR WIPER ARM RH

HINT:

(See page WW-3)

7. INSTALL FRONT WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

8. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

HINT:

(See page SP-4)

F045196

F049306E01

Page 2186 of 3000

SP–4SUSPENSION – FRONT WHEEL ALIGNMENT

SP

FRONT WHEEL ALIGNMENT

ADJUSTMENT

NOTICE:

For vehicles equipped with VSC, if wheel alignment has

been adjusted, and if suspension or underbody

components have been removed/installed or replaced, be

sure to perform the following initialization procedure in

order for the system to function normally:

1. Disconnect the negative battery terminal for more

than 2 seconds.

2. Reconnect the negative battery terminal.

3. Perform zero point calibration of the yaw rate and

acceleration sensor and test mode inspection.

HINT:

(See page BC-70)

1. INSPECT TIRE

HINT:

(See page TW-2)

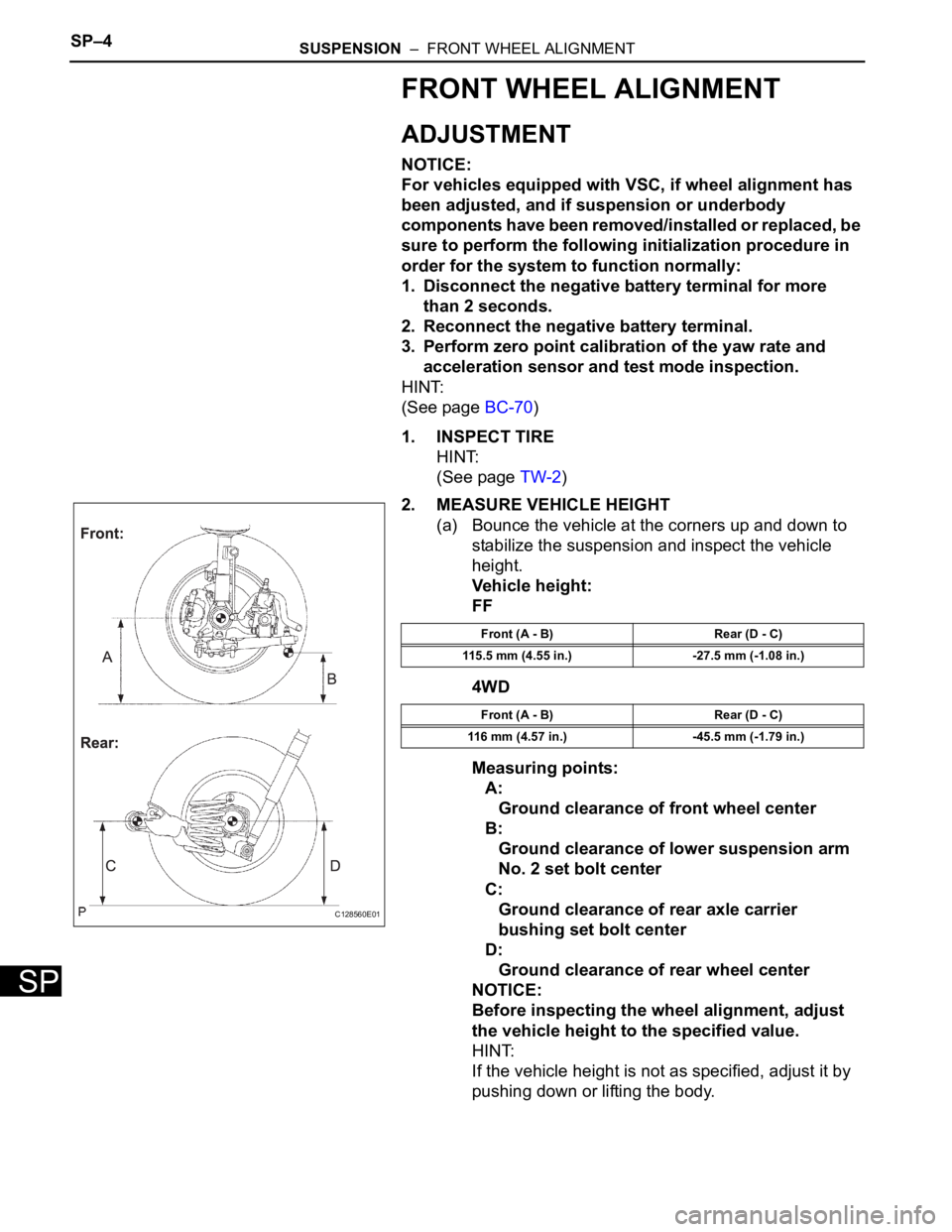

2. MEASURE VEHICLE HEIGHT

(a) Bounce the vehicle at the corners up and down to

stabilize the suspension and inspect the vehicle

height.

Vehicle height:

FF

4WD

Measuring points:

A:

Ground clearance of front wheel center

B:

Ground clearance of lower suspension arm

No. 2 set bolt center

C:

Ground clearance of rear axle carrier

bushing set bolt center

D:

Ground clearance of rear wheel center

NOTICE:

Before inspecting the wheel alignment, adjust

the vehicle height to the specified value.

HINT:

If the vehicle height is not as specified, adjust it by

pushing down or lifting the body.

C128560E01

Front (A - B) Rear (D - C)

115.5 mm (4.55 in.) -27.5 mm (-1.08 in.)

Front (A - B) Rear (D - C)

116 mm (4.57 in.) -45.5 mm (-1.79 in.)

Page 2187 of 3000

SUSPENSION – FRONT WHEEL ALIGNMENTSP–5

SP

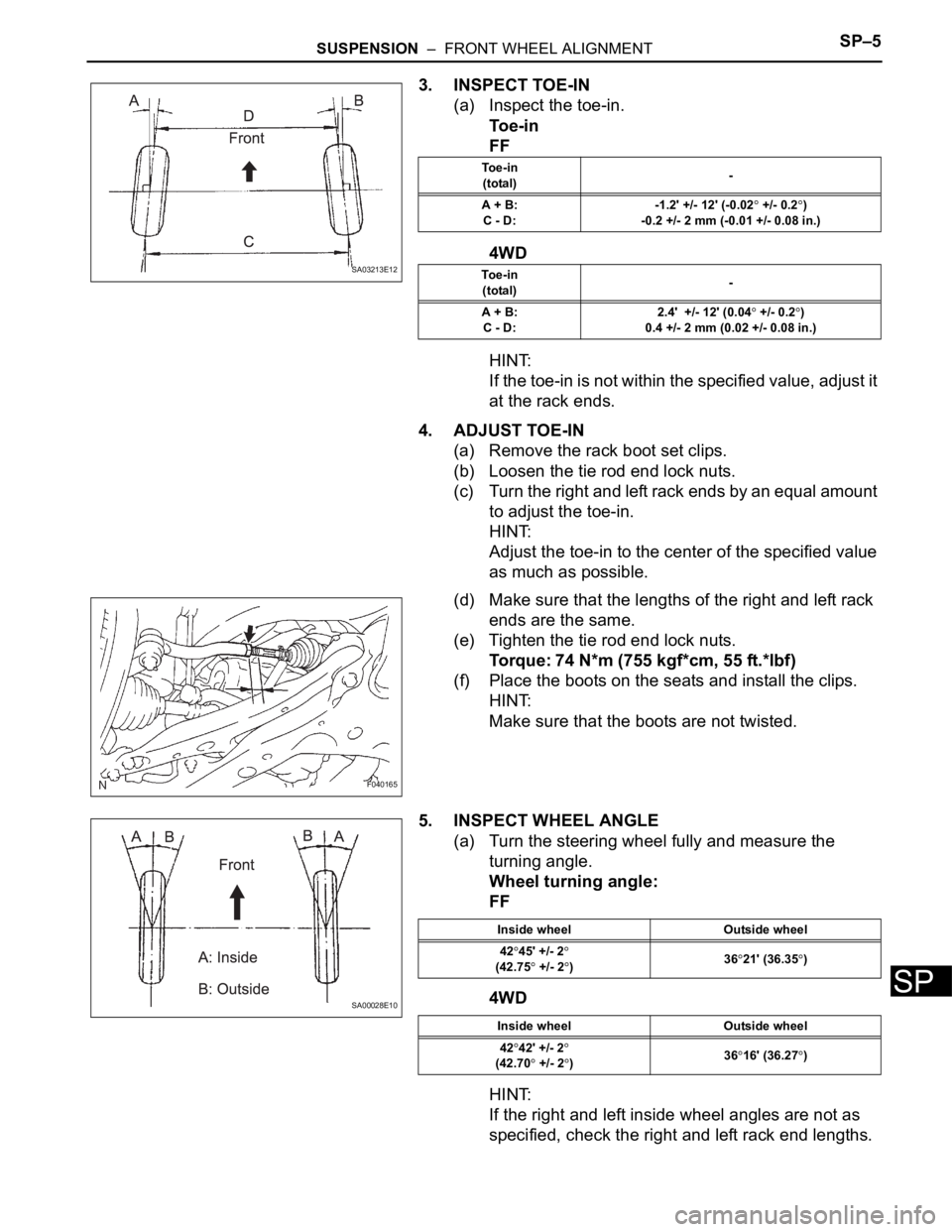

3. INSPECT TOE-IN

(a) Inspect the toe-in.

To e - i n

FF

4WD

HINT:

If the toe-in is not within the specified value, adjust it

at the rack ends.

4. ADJUST TOE-IN

(a) Remove the rack boot set clips.

(b) Loosen the tie rod end lock nuts.

(c) Turn the right and left rack ends by an equal amount

to adjust the toe-in.

HINT:

Adjust the toe-in to the center of the specified value

as much as possible.

(d) Make sure that the lengths of the right and left rack

ends are the same.

(e) Tighten the tie rod end lock nuts.

Torque: 74 N*m (755 kgf*cm, 55 ft.*lbf)

(f) Place the boots on the seats and install the clips.

HINT:

Make sure that the boots are not twisted.

5. INSPECT WHEEL ANGLE

(a) Turn the steering wheel fully and measure the

turning angle.

Wheel turning angle:

FF

4WD

HINT:

If the right and left inside wheel angles are not as

specified, check the right and left rack end lengths.

SA03213E12

To e - i n

(total)-

A + B:

C - D:-1.2' +/- 12' (-0.02

+/- 0.2)

-0.2 +/- 2 mm (-0.01 +/- 0.08 in.)

To e - i n

(total)-

A + B:

C - D:2.4' +/- 12' (0.04

+/- 0.2)

0.4 +/- 2 mm (0.02 +/- 0.08 in.)

F040165

SA00028E10

Inside wheel Outside wheel

42

45' +/- 2(42.75 +/- 2)3621' (36.35)

Inside wheel Outside wheel

42

42' +/- 2

(42.70 +/- 2)3616' (36.27)

Page 2188 of 3000

SP–6SUSPENSION – FRONT WHEEL ALIGNMENT

SP

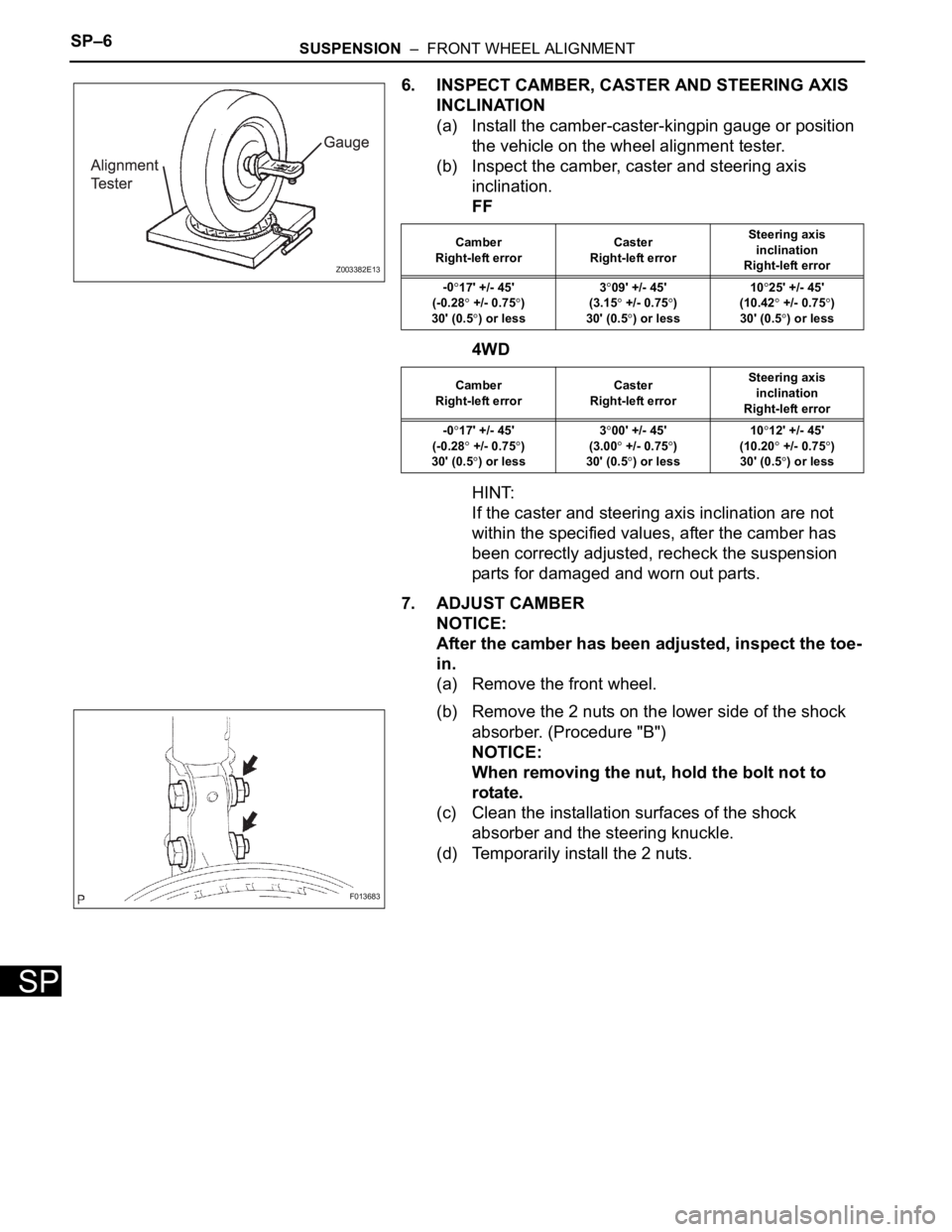

6. INSPECT CAMBER, CASTER AND STEERING AXIS

INCLINATION

(a) Install the camber-caster-kingpin gauge or position

the vehicle on the wheel alignment tester.

(b) Inspect the camber, caster and steering axis

inclination.

FF

4WD

HINT:

If the caster and steering axis inclination are not

within the specified values, after the camber has

been correctly adjusted, recheck the suspension

parts for damaged and worn out parts.

7. ADJUST CAMBER

NOTICE:

After the camber has been adjusted, inspect the toe-

in.

(a) Remove the front wheel.

(b) Remove the 2 nuts on the lower side of the shock

absorber. (Procedure "B")

NOTICE:

When removing the nut, hold the bolt not to

rotate.

(c) Clean the installation surfaces of the shock

absorber and the steering knuckle.

(d) Temporarily install the 2 nuts.

Z003382E13

Camber

Right-left errorCaster

Right-left errorSteering axis

inclination

Right-left error

-0

17' +/- 45'

(-0.28

+/- 0.75)

30' (0.5

) or less3

09' +/- 45'

(3.15

+/- 0.75)

30' (0.5

) or less10

25' +/- 45'

(10.42

+/- 0.75)

30' (0.5

) or less

Camber

Right-left errorCaster

Right-left errorSteering axis

inclination

Right-left error

-0

17' +/- 45'

(-0.28

+/- 0.75)

30' (0.5) or less3

00' +/- 45'

(3.00

+/- 0.75)

30' (0.5) or less10

12' +/- 45'

(10.20

+/- 0.75)

30' (0.5) or less

F013683

Page 2189 of 3000

SUSPENSION – FRONT WHEEL ALIGNMENTSP–7

SP

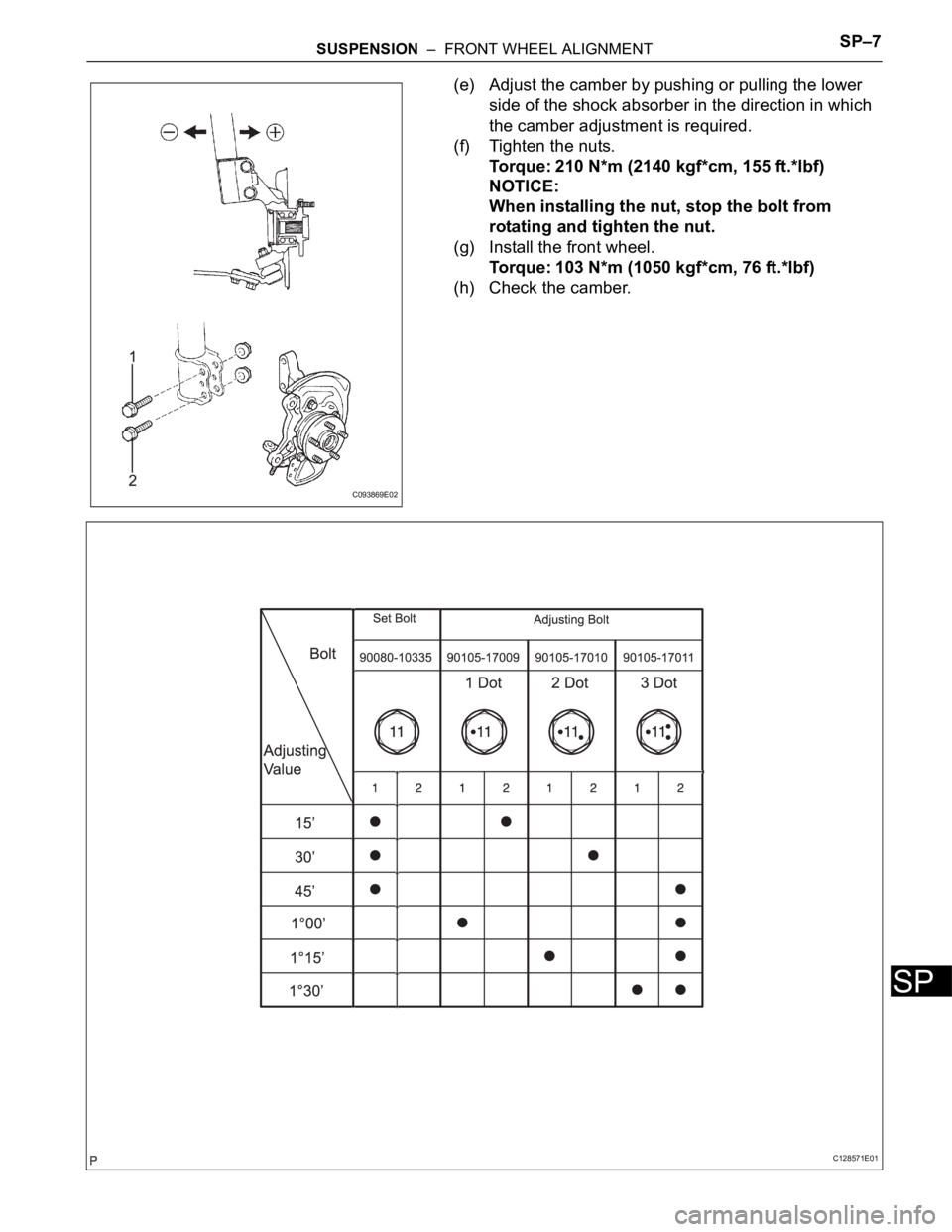

(e) Adjust the camber by pushing or pulling the lower

side of the shock absorber in the direction in which

the camber adjustment is required.

(f) Tighten the nuts.

Torque: 210 N*m (2140 kgf*cm, 155 ft.*lbf)

NOTICE:

When installing the nut, stop the bolt from

rotating and tighten the nut.

(g) Install the front wheel.

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

(h) Check the camber.

C093869E02

C128571E01

Page 2190 of 3000

SP–8SUSPENSION – FRONT WHEEL ALIGNMENT

SP

HINT:

• Adjust the camber to the center of the specified

value as much as possible.

• Adjusting value for the set bolts is 6' to 30' (0.1

to 0.5

).

• If the camber is not within the specified value,

using the following table, estimate how much

additional camber adjustment will be required,

and select the camber adjusting bolt.

NOTICE:

Tighten the adjusting bolt with a washer and a

new nut.

(i) Perform the procedure mentioned above again. At

procedure "B", replace 1 or 2 selected bolts.

HINT:

Replace one bolt at a time when replacing 2 bolts.

Page 2192 of 3000

SUSPENSION – REAR WHEEL ALIGNMENTSP–9

SP

REAR WHEEL ALIGNMENT

ADJUSTMENT

NOTICE:

For vehicles equipped with VSC, if wheel alignment has

been adjusted, and if suspension or underbody

components have been removed/installed or replaced, be

sure to perform the following initialization procedure in

order for the system to function normally:

1. Disconnect the negative battery terminal for more

than 2 seconds.

2. Reconnect the negative battery terminal.

3. Perform zero point calibration of the yaw rate and

acceleration sensor and test mode inspection.

HINT:

(See page BC-70)

1. INSPECT TIRE

HINT:

(See page TW-2)

2. MEASURE VEHICLE HEIGHT

NOTICE:

Before inspecting the wheel alignment, adjust the

vehicle height to the specified valve.

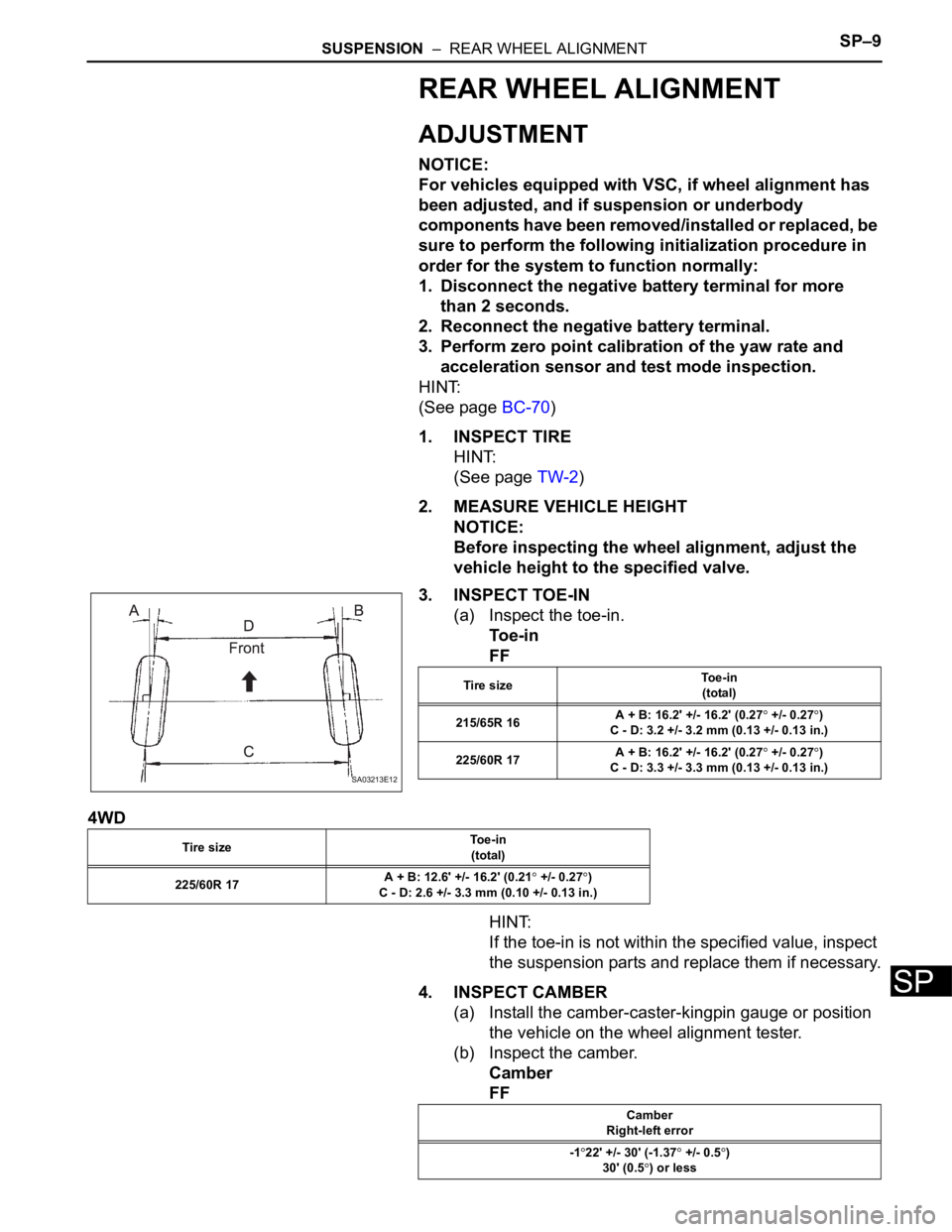

3. INSPECT TOE-IN

(a) Inspect the toe-in.

To e - i n

FF

4WD

HINT:

If the toe-in is not within the specified value, inspect

the suspension parts and replace them if necessary.

4. INSPECT CAMBER

(a) Install the camber-caster-kingpin gauge or position

the vehicle on the wheel alignment tester.

(b) Inspect the camber.

Camber

FF

SA03213E12

Tire sizeTo e - i n

(total)

215/65R 16A + B: 16.2' +/- 16.2' (0.27

+/- 0.27)

C - D: 3.2 +/- 3.2 mm (0.13 +/- 0.13 in.)

225/60R 17A + B: 16.2' +/- 16.2' (0.27

+/- 0.27)

C - D: 3.3 +/- 3.3 mm (0.13 +/- 0.13 in.)

Tire sizeTo e - i n

(total)

225/60R 17A + B: 12.6' +/- 16.2' (0.21

+/- 0.27)

C - D: 2.6 +/- 3.3 mm (0.10 +/- 0.13 in.)

Camber

Right-left error

-1

22' +/- 30' (-1.37 +/- 0.5)

30' (0.5

) or less