wheel TOYOTA SIENNA 2007 Service Workshop Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1356 of 3000

CH–162GR-FE CHARGING – GENERATOR

CH

REMOVAL

1. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

2. REMOVE FRONT WHEEL RH

3. REMOVE NO. 1 ENGINE UNDER COVER (See page

EM-26)

4. REMOVE FRONT FENDER APRON SEAL RH (See

page EM-26)

5. DRAIN ENGINE COOLANT (See page CO-6)

6. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

7. REMOVE BATTERY (See page EM-26)

8. REMOVE FRONT BUMPER ASSEMBLY (See page

ET-3)

9. REMOVE FRONT BUMPER ENERGY ABSORBER

10. REMOVE NO. 1 AIR CLEANER INLET (See page EM-

28)

11. DISCONNECT RADIATOR RESERVE TANK HOSE OR

PIPE (See page CO-28)

12. DISCONNECT NO. 1 RADIATOR HOSE (See page CO-

28)

13. DISCONNECT NO. 2 RADIATOR HOSE (See page CO-

29)

14. REMOVE HOOD LOCK RELEASE LEVER

PROTECTOR (See page CO-29)

15. REMOVE HOOD LOCK ASSEMBLY (See page CO-29)

16. REMOVE HOOD LOCK SUPPORT SUB-ASSEMBLY

(See page CO-29)

17. DISCONNECT COOLING FAN ECU CONNECTOR

(See page CO-30)

18. REMOVE RADIATOR UPPER SUPPORT SUB-

ASSEMBLY (See page CO-30)

19. DISCONNECT NO. 2 OIL COOLER OUTLET TUBE

SUB-ASSEMBLY (See page CO-31)

20. REMOVE HEADLIGHT ASSEMBLY RH (See page LI-

69)

21. REMOVE RADIATOR SIDE DEFLECTOR RH (See

page CO-31)

22. REMOVE HEADLIGHT BRACKET RH (See page CO-

32)

23. REMOVE PRESSURE FEED TUBE ASSEMBLY (See

page CO-32)

Page 1369 of 3000

2GR-FE CHARGING – GENERATORCH–29

CH

18. CONNECT RADIATOR RESERVE TANK HOSE OR

PIPE (See page CO-44)

19. INSTALL NO. 1 AIR CLEANER INLET (See page EM-

59)

20. INSTALL FRONT BUMPER ENERGY ABSORBER

21. INSTALL FRONT BUMPER ASSEMBLY (See page ET-

9)

22. INSTALL BATTERY (See page EM-59)

23. INSTALL NO. 2 AIR CLEANER INLET (See page EM-

60)

24. ADD ENGINE COOLANT (See page CO-7)

25. INSPECT FOR COOLANT LEAK (See page CO-1)

26. ADD AUTOMATIC TRANSAXLE FLUID

27. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

28. INSTALL FRONT FENDER APRON SEAL RH (See

page EM-62)

29. INSTALL NO. 1 ENGINE UNDER COVER (See page

EM-63)

30. INSTALL FRONT WHEEL RH

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

31. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-63)

32. VEHICLE PREPARATION FOR HEADLIGHT AIM

ADJUSTMENT (See page LI-71)

33. PREPARATION FOR HEADLIGHT AIMING (Using a

tester) (See page LI-71)

34. PREPARATION FOR HEADLIGHT AIMING (Using a

Screen) (See page LI-72)

35. HEADLIGHT AIMING INSPECTION (See page LI-74)

36. HEADLIGHT AIMING ADJUSTMENT (See page LI-75)

37. VEHICLE PREPARATION FOR FOG LIGHT AIM

ADJUSTMENT (w/ Fog Light) (See page LI-82)

38. PREPARATION FOR FOG LIGHT AIMING (Using a

Screen) (w/ Fog Light) (See page LI-83)

39. FOG LIGHT AIMING INSPECTION (w/ Fog Light) (See

page LI-74)

40. FOG LIGHT AIMING ADJUSTMENT (w/ Fog Light)

(See page LI-85)

Page 1378 of 3000

2GR-FE CHARGING – GENERATORCH–29

CH

18. CONNECT RADIATOR RESERVE TANK HOSE OR

PIPE (See page CO-44)

19. INSTALL NO. 1 AIR CLEANER INLET (See page EM-

59)

20. INSTALL FRONT BUMPER ENERGY ABSORBER

21. INSTALL FRONT BUMPER ASSEMBLY (See page ET-

9)

22. INSTALL BATTERY (See page EM-59)

23. INSTALL NO. 2 AIR CLEANER INLET (See page EM-

60)

24. ADD ENGINE COOLANT (See page CO-7)

25. INSPECT FOR COOLANT LEAK (See page CO-1)

26. ADD AUTOMATIC TRANSAXLE FLUID

27. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

28. INSTALL FRONT FENDER APRON SEAL RH (See

page EM-62)

29. INSTALL NO. 1 ENGINE UNDER COVER (See page

EM-63)

30. INSTALL FRONT WHEEL RH

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

31. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-63)

32. VEHICLE PREPARATION FOR HEADLIGHT AIM

ADJUSTMENT (See page LI-71)

33. PREPARATION FOR HEADLIGHT AIMING (Using a

tester) (See page LI-71)

34. PREPARATION FOR HEADLIGHT AIMING (Using a

Screen) (See page LI-72)

35. HEADLIGHT AIMING INSPECTION (See page LI-74)

36. HEADLIGHT AIMING ADJUSTMENT (See page LI-75)

37. VEHICLE PREPARATION FOR FOG LIGHT AIM

ADJUSTMENT (w/ Fog Light) (See page LI-82)

38. PREPARATION FOR FOG LIGHT AIMING (Using a

Screen) (w/ Fog Light) (See page LI-83)

39. FOG LIGHT AIMING INSPECTION (w/ Fog Light) (See

page LI-74)

40. FOG LIGHT AIMING ADJUSTMENT (w/ Fog Light)

(See page LI-85)

Page 1390 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–13

AX

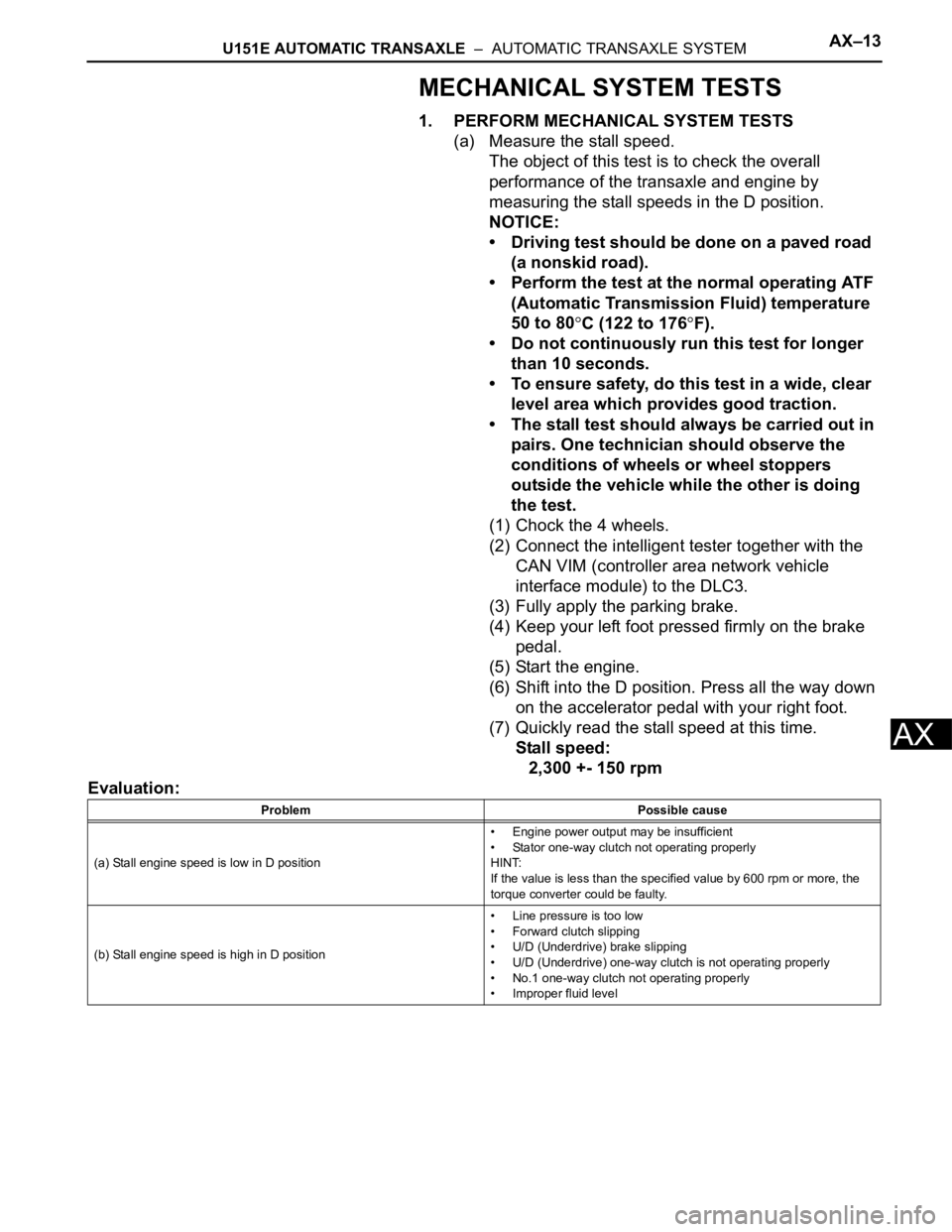

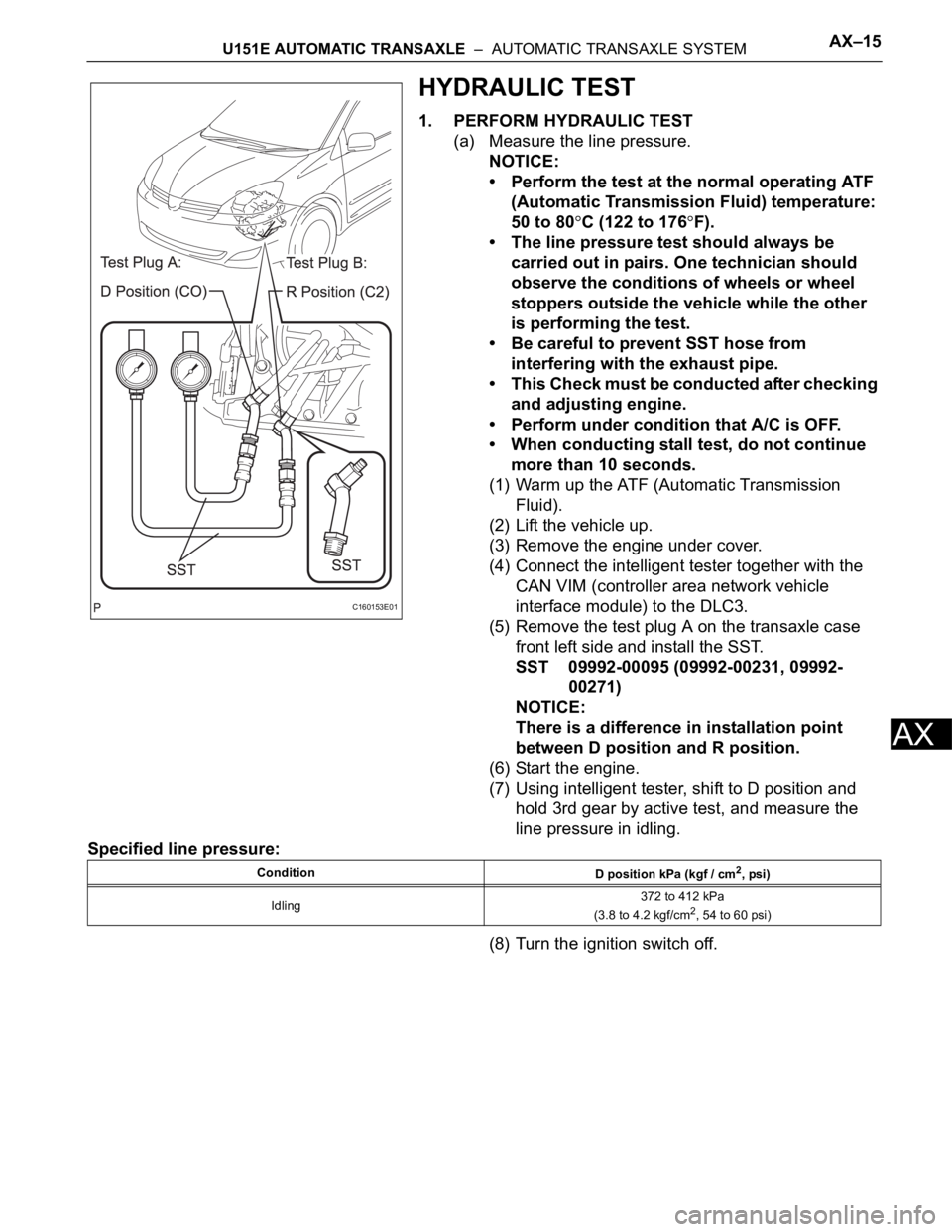

MECHANICAL SYSTEM TESTS

1. PERFORM MECHANICAL SYSTEM TESTS

(a) Measure the stall speed.

The object of this test is to check the overall

performance of the transaxle and engine by

measuring the stall speeds in the D position.

NOTICE:

• Driving test should be done on a paved road

(a nonskid road).

• Perform the test at the normal operating ATF

(Automatic Transmission Fluid) temperature

50 to 80

C (122 to 176F).

• Do not continuously run this test for longer

than 10 seconds.

• To ensure safety, do this test in a wide, clear

level area which provides good traction.

• The stall test should always be carried out in

pairs. One technician should observe the

conditions of wheels or wheel stoppers

outside the vehicle while the other is doing

the test.

(1) Chock the 4 wheels.

(2) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(3) Fully apply the parking brake.

(4) Keep your left foot pressed firmly on the brake

pedal.

(5) Start the engine.

(6) Shift into the D position. Press all the way down

on the accelerator pedal with your right foot.

(7) Quickly read the stall speed at this time.

Stall speed:

2,300 +- 150 rpm

Evaluation:

Problem Possible cause

(a) Stall engine speed is low in D position• Engine power output may be insufficient

• Stator one-way clutch not operating properly

HINT:

If the value is less than the specified value by 600 rpm or more, the

torque converter could be faulty.

(b) Stall engine speed is high in D position• Line pressure is too low

• Forward clutch slipping

• U/D (Underdrive) brake slipping

• U/D (Underdrive) one-way clutch is not operating properly

• No.1 one-way clutch not operating properly

• Improper fluid level

Page 1392 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–15

AX

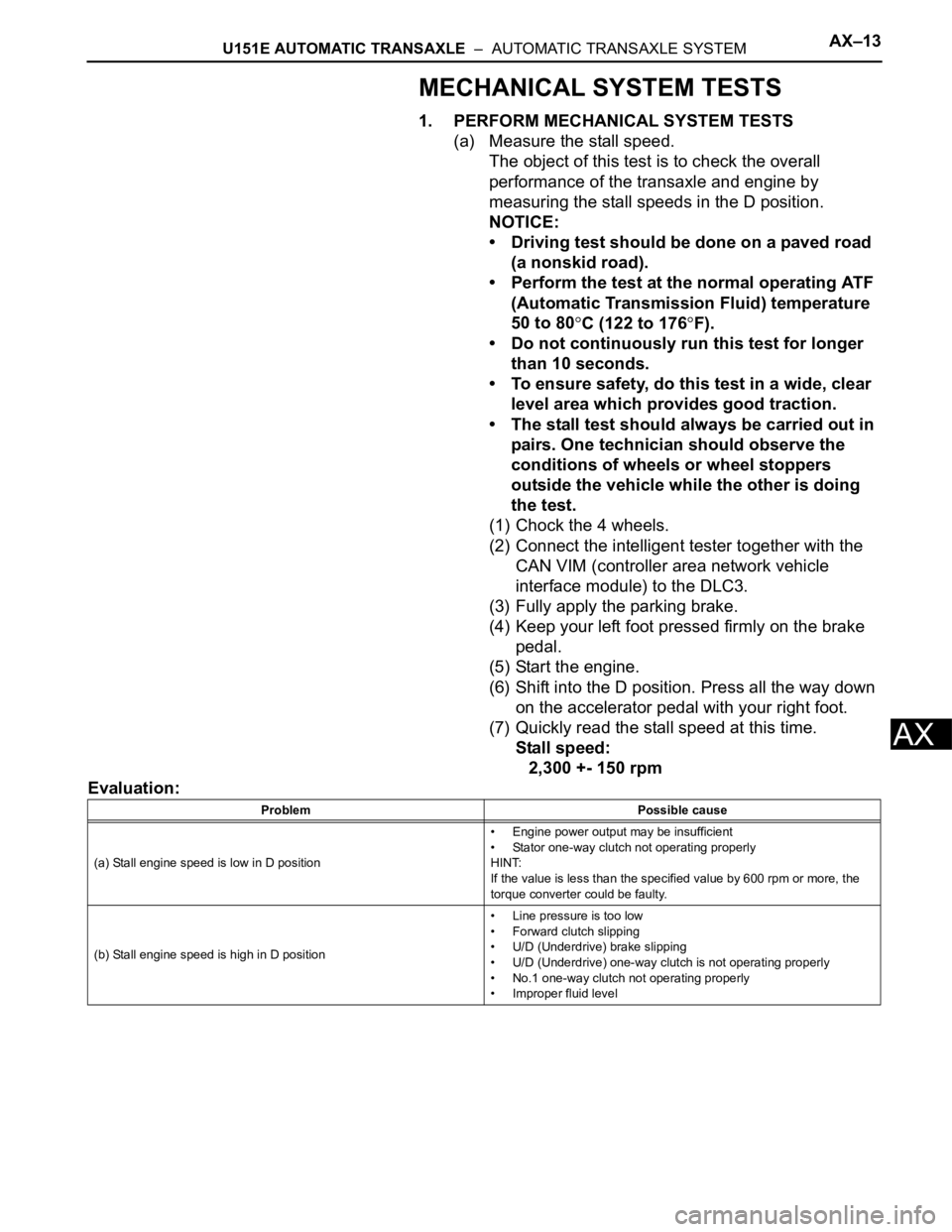

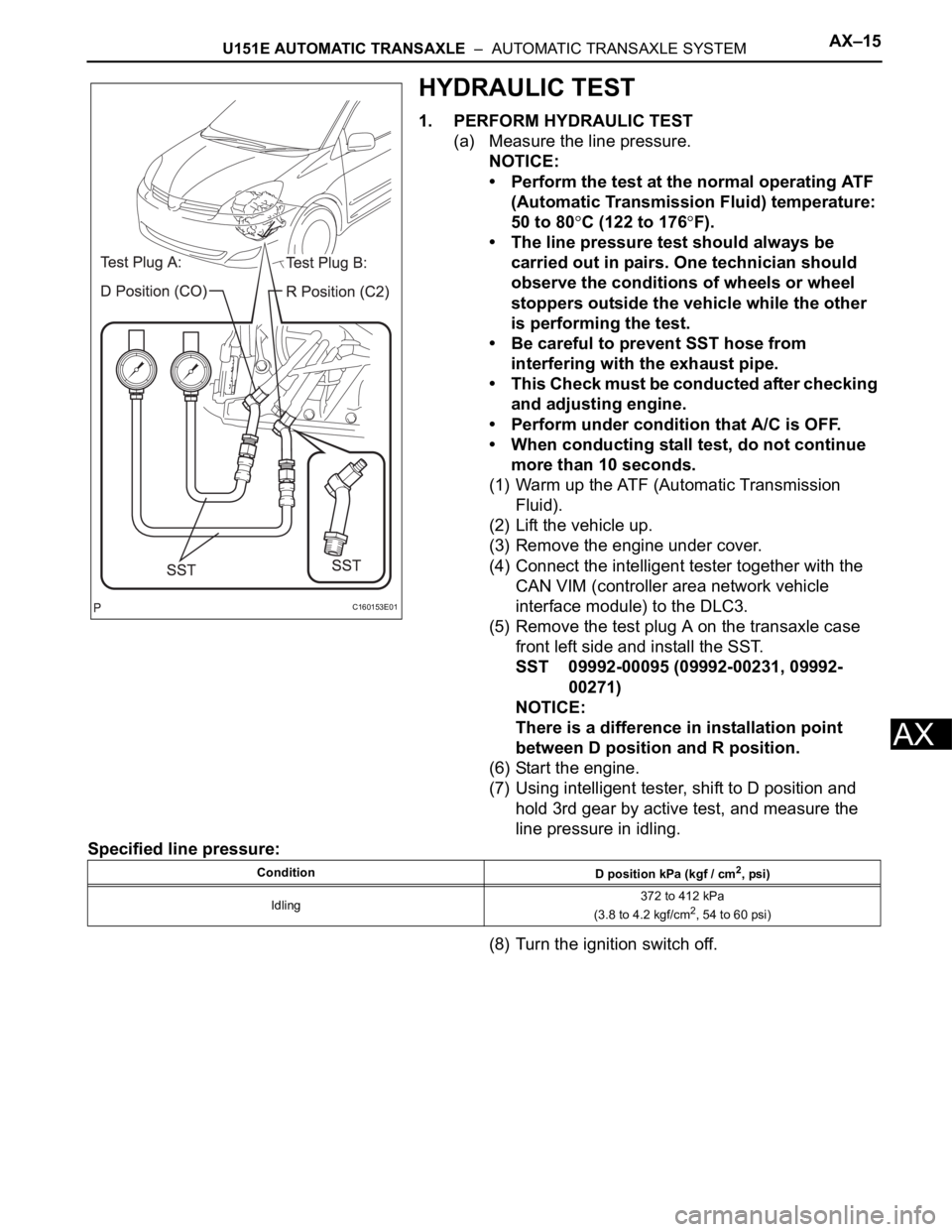

HYDRAULIC TEST

1. PERFORM HYDRAULIC TEST

(a) Measure the line pressure.

NOTICE:

• Perform the test at the normal operating ATF

(Automatic Transmission Fluid) temperature:

50 to 80

C (122 to 176F).

• The line pressure test should always be

carried out in pairs. One technician should

observe the conditions of wheels or wheel

stoppers outside the vehicle while the other

is performing the test.

• Be careful to prevent SST hose from

interfering with the exhaust pipe.

• This Check must be conducted after checking

and adjusting engine.

• Perform under condition that A/C is OFF.

• When conducting stall test, do not continue

more than 10 seconds.

(1) Warm up the ATF (Automatic Transmission

Fluid).

(2) Lift the vehicle up.

(3) Remove the engine under cover.

(4) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(5) Remove the test plug A on the transaxle case

front left side and install the SST.

SST 09992-00095 (09992-00231, 09992-

00271)

NOTICE:

There is a difference in installation point

between D position and R position.

(6) Start the engine.

(7) Using intelligent tester, shift to D position and

hold 3rd gear by active test, and measure the

line pressure in idling.

Specified line pressure:

(8) Turn the ignition switch off.

C160153E01

Condition

D position kPa (kgf / cm2, psi)

Idling372 to 412 kPa

(3.8 to 4.2 kgf/cm

2, 54 to 60 psi)

Page 1500 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–13

AX

MECHANICAL SYSTEM TESTS

1. PERFORM MECHANICAL SYSTEM TESTS

(a) Measure the stall speed.

The object of this test is to check the overall

performance of the transaxle and engine by

measuring the stall speeds in the D position.

NOTICE:

• Driving test should be done on a paved road

(a nonskid road).

• Perform the test at the normal operating ATF

(Automatic Transmission Fluid) temperature

50 to 80

C (122 to 176F).

• Do not continuously run this test for longer

than 10 seconds.

• To ensure safety, do this test in a wide, clear

level area which provides good traction.

• The stall test should always be carried out in

pairs. One technician should observe the

conditions of wheels or wheel stoppers

outside the vehicle while the other is doing

the test.

(1) Chock the 4 wheels.

(2) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(3) Fully apply the parking brake.

(4) Keep your left foot pressed firmly on the brake

pedal.

(5) Start the engine.

(6) Shift into the D position. Press all the way down

on the accelerator pedal with your right foot.

(7) Quickly read the stall speed at this time.

Stall speed:

2,300 +- 150 rpm

Evaluation:

Problem Possible cause

(a) Stall engine speed is low in D position• Engine power output may be insufficient

• Stator one-way clutch not operating properly

HINT:

If the value is less than the specified value by 600 rpm or more, the

torque converter could be faulty.

(b) Stall engine speed is high in D position• Line pressure is too low

• Forward clutch slipping

• U/D (Underdrive) brake slipping

• U/D (Underdrive) one-way clutch is not operating properly

• No.1 one-way clutch not operating properly

• Improper fluid level

Page 1502 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–15

AX

HYDRAULIC TEST

1. PERFORM HYDRAULIC TEST

(a) Measure the line pressure.

NOTICE:

• Perform the test at the normal operating ATF

(Automatic Transmission Fluid) temperature:

50 to 80

C (122 to 176F).

• The line pressure test should always be

carried out in pairs. One technician should

observe the conditions of wheels or wheel

stoppers outside the vehicle while the other

is performing the test.

• Be careful to prevent SST hose from

interfering with the exhaust pipe.

• This Check must be conducted after checking

and adjusting engine.

• Perform under condition that A/C is OFF.

• When conducting stall test, do not continue

more than 10 seconds.

(1) Warm up the ATF (Automatic Transmission

Fluid).

(2) Lift the vehicle up.

(3) Remove the engine under cover.

(4) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(5) Remove the test plug A on the transaxle case

front left side and install the SST.

SST 09992-00095 (09992-00231, 09992-

00271)

NOTICE:

There is a difference in installation point

between D position and R position.

(6) Start the engine.

(7) Using intelligent tester, shift to D position and

hold 3rd gear by active test, and measure the

line pressure in idling.

Specified line pressure:

(8) Turn the ignition switch off.

C160153E01

Condition

D position kPa (kgf / cm2, psi)

Idling372 to 412 kPa

(3.8 to 4.2 kgf/cm

2, 54 to 60 psi)

Page 1554 of 3000

U151E AUTOMATIC TRANSAXLE – DIFFERENTIAL OIL SEALAX–159

AX

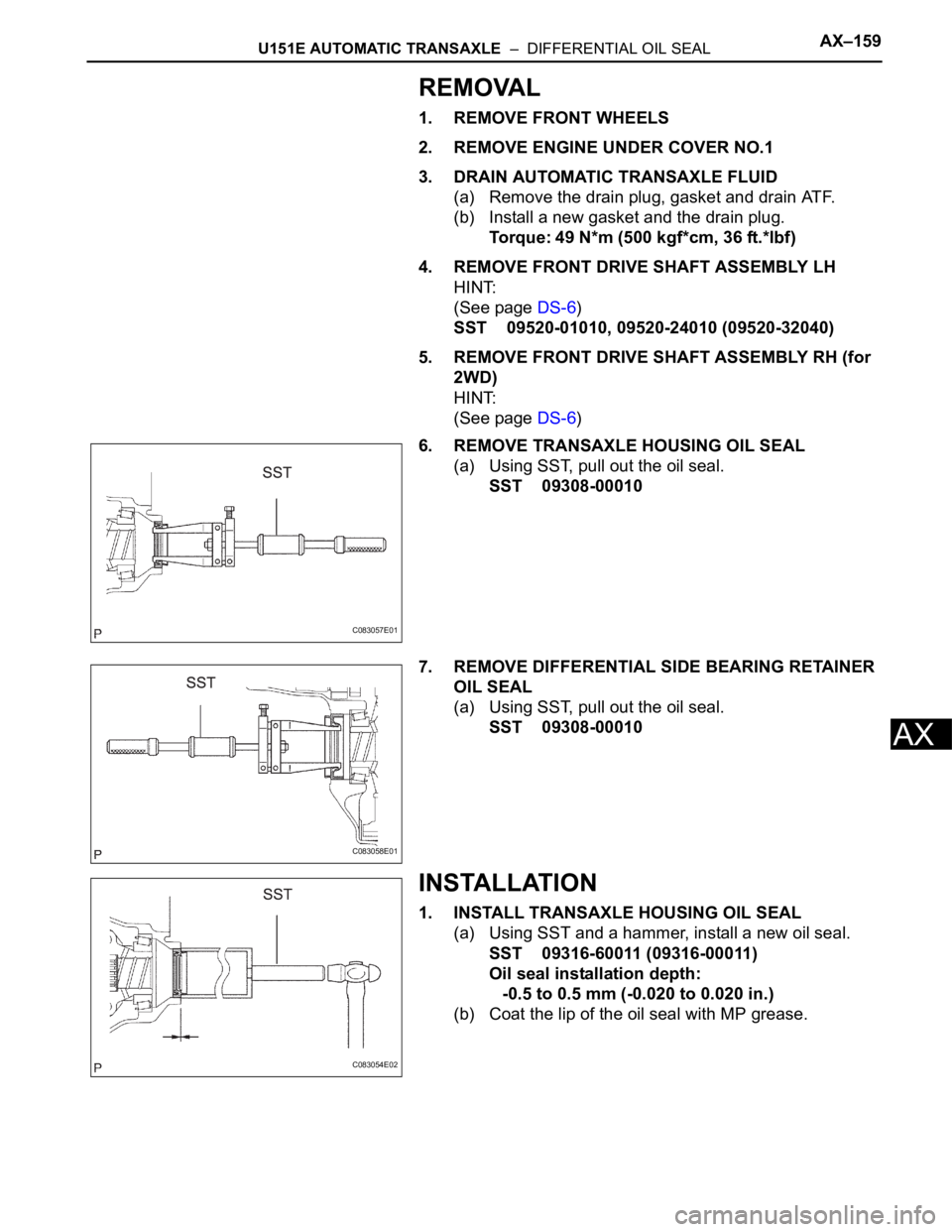

REMOVAL

1. REMOVE FRONT WHEELS

2. REMOVE ENGINE UNDER COVER NO.1

3. DRAIN AUTOMATIC TRANSAXLE FLUID

(a) Remove the drain plug, gasket and drain ATF.

(b) Install a new gasket and the drain plug.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

4. REMOVE FRONT DRIVE SHAFT ASSEMBLY LH

HINT:

(See page DS-6)

SST 09520-01010, 09520-24010 (09520-32040)

5. REMOVE FRONT DRIVE SHAFT ASSEMBLY RH (for

2WD)

HINT:

(See page DS-6)

6. REMOVE TRANSAXLE HOUSING OIL SEAL

(a) Using SST, pull out the oil seal.

SST 09308-00010

7. REMOVE DIFFERENTIAL SIDE BEARING RETAINER

OIL SEAL

(a) Using SST, pull out the oil seal.

SST 09308-00010

INSTALLATION

1. INSTALL TRANSAXLE HOUSING OIL SEAL

(a) Using SST and a hammer, install a new oil seal.

SST 09316-60011 (09316-00011)

Oil seal installation depth:

-0.5 to 0.5 mm (-0.020 to 0.020 in.)

(b) Coat the lip of the oil seal with MP grease.

C083057E01

C083058E01

C083054E02

Page 1555 of 3000

AX–160U151E AUTOMATIC TRANSAXLE – DIFFERENTIAL OIL SEAL

AX

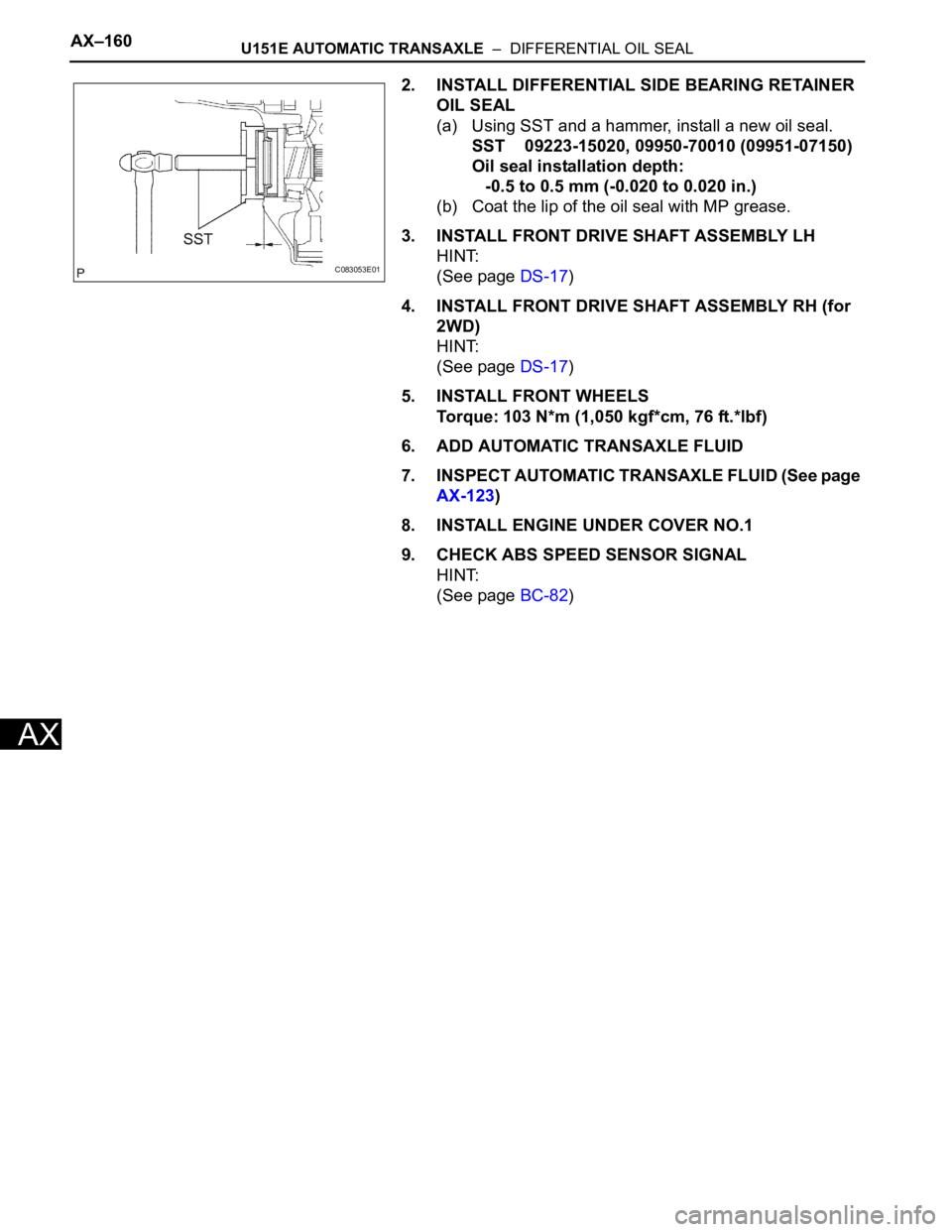

2. INSTALL DIFFERENTIAL SIDE BEARING RETAINER

OIL SEAL

(a) Using SST and a hammer, install a new oil seal.

SST 09223-15020, 09950-70010 (09951-07150)

Oil seal installation depth:

-0.5 to 0.5 mm (-0.020 to 0.020 in.)

(b) Coat the lip of the oil seal with MP grease.

3. INSTALL FRONT DRIVE SHAFT ASSEMBLY LH

HINT:

(See page DS-17)

4. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH (for

2WD)

HINT:

(See page DS-17)

5. INSTALL FRONT WHEELS

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

6. ADD AUTOMATIC TRANSAXLE FLUID

7. INSPECT AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

8. INSTALL ENGINE UNDER COVER NO.1

9. CHECK ABS SPEED SENSOR SIGNAL

HINT:

(See page BC-82)

C083053E01

Page 1582 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLYAX–165

AX

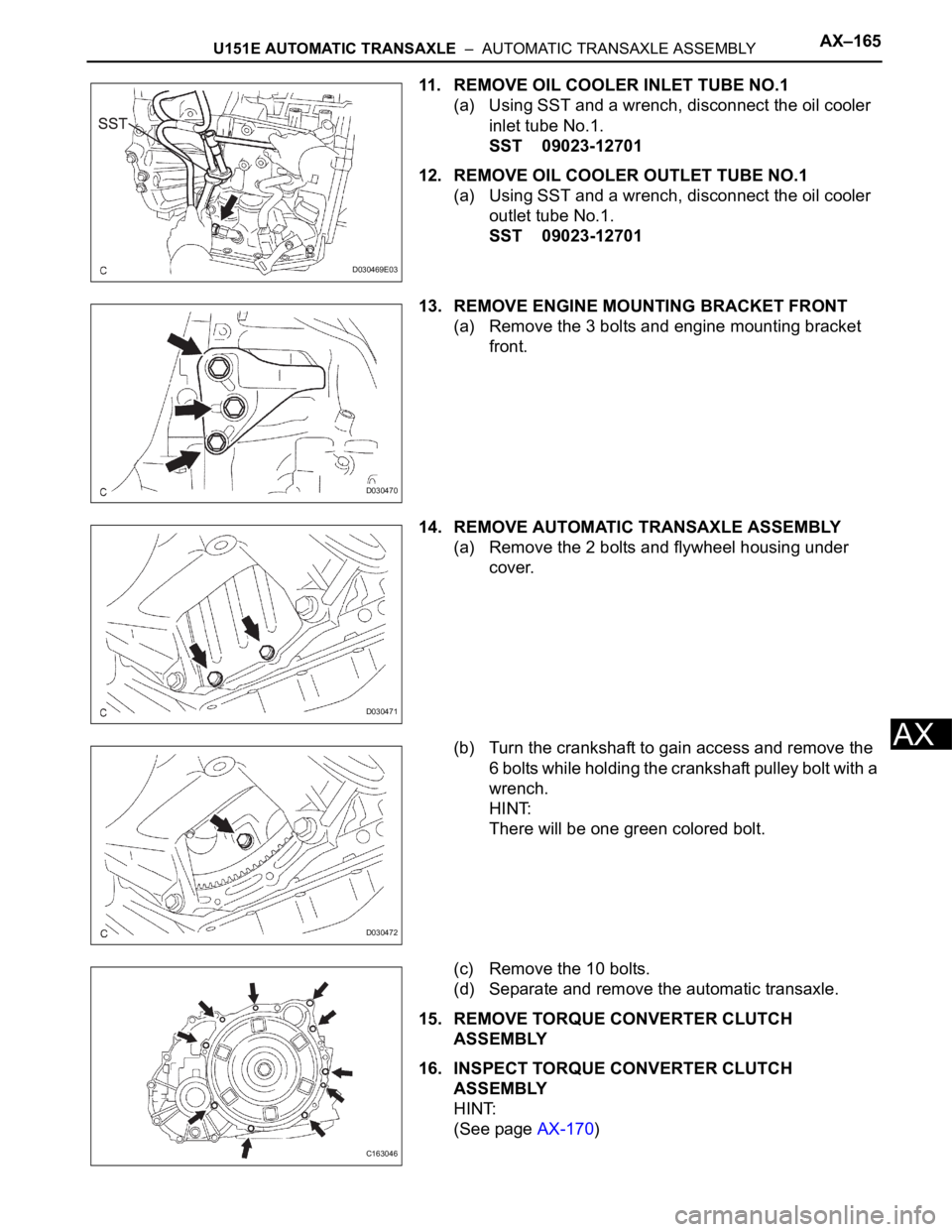

11. REMOVE OIL COOLER INLET TUBE NO.1

(a) Using SST and a wrench, disconnect the oil cooler

inlet tube No.1.

SST 09023-12701

12. REMOVE OIL COOLER OUTLET TUBE NO.1

(a) Using SST and a wrench, disconnect the oil cooler

outlet tube No.1.

SST 09023-12701

13. REMOVE ENGINE MOUNTING BRACKET FRONT

(a) Remove the 3 bolts and engine mounting bracket

front.

14. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY

(a) Remove the 2 bolts and flywheel housing under

cover.

(b) Turn the crankshaft to gain access and remove the

6 bolts while holding the crankshaft pulley bolt with a

wrench.

HINT:

There will be one green colored bolt.

(c) Remove the 10 bolts.

(d) Separate and remove the automatic transaxle.

15. REMOVE TORQUE CONVERTER CLUTCH

ASSEMBLY

16. INSPECT TORQUE CONVERTER CLUTCH

ASSEMBLY

HINT:

(See page AX-170)

D030469E03

D030470

D030471

D030472

C163046