engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1884 of 3000

AX–168U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLY

AX

INSTALLATION

1. INSTALL TORQUE CONVERTER CLUTCH

ASSEMBLY

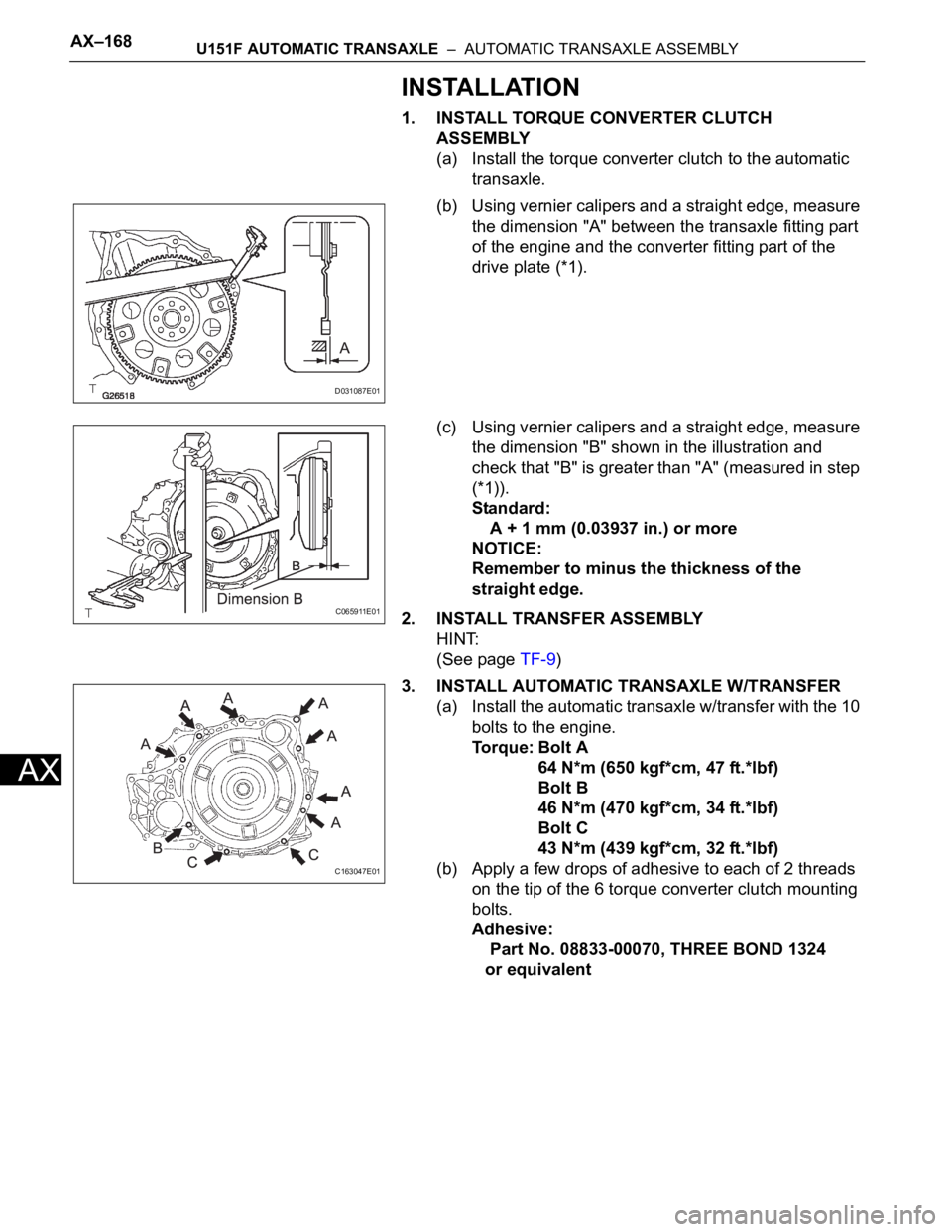

(a) Install the torque converter clutch to the automatic

transaxle.

(b) Using vernier calipers and a straight edge, measure

the dimension "A" between the transaxle fitting part

of the engine and the converter fitting part of the

drive plate (*1).

(c) Using vernier calipers and a straight edge, measure

the dimension "B" shown in the illustration and

check that "B" is greater than "A" (measured in step

(*1)).

Standard:

A + 1 mm (0.03937 in.) or more

NOTICE:

Remember to minus the thickness of the

straight edge.

2. INSTALL TRANSFER ASSEMBLY

HINT:

(See page TF-9)

3. INSTALL AUTOMATIC TRANSAXLE W/TRANSFER

(a) Install the automatic transaxle w/transfer with the 10

bolts to the engine.

To r q u e : B o l t A

64 N*m (650 kgf*cm, 47 ft.*lbf)

Bolt B

46 N*m (470 kgf*cm, 34 ft.*lbf)

Bolt C

43 N*m (439 kgf*cm, 32 ft.*lbf)

(b) Apply a few drops of adhesive to each of 2 threads

on the tip of the 6 torque converter clutch mounting

bolts.

Adhesive:

Part No. 08833-00070, THREE BOND 1324

or equivalent

D031087E01

C065911E01

C163047E01

Page 1885 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLYAX–169

AX

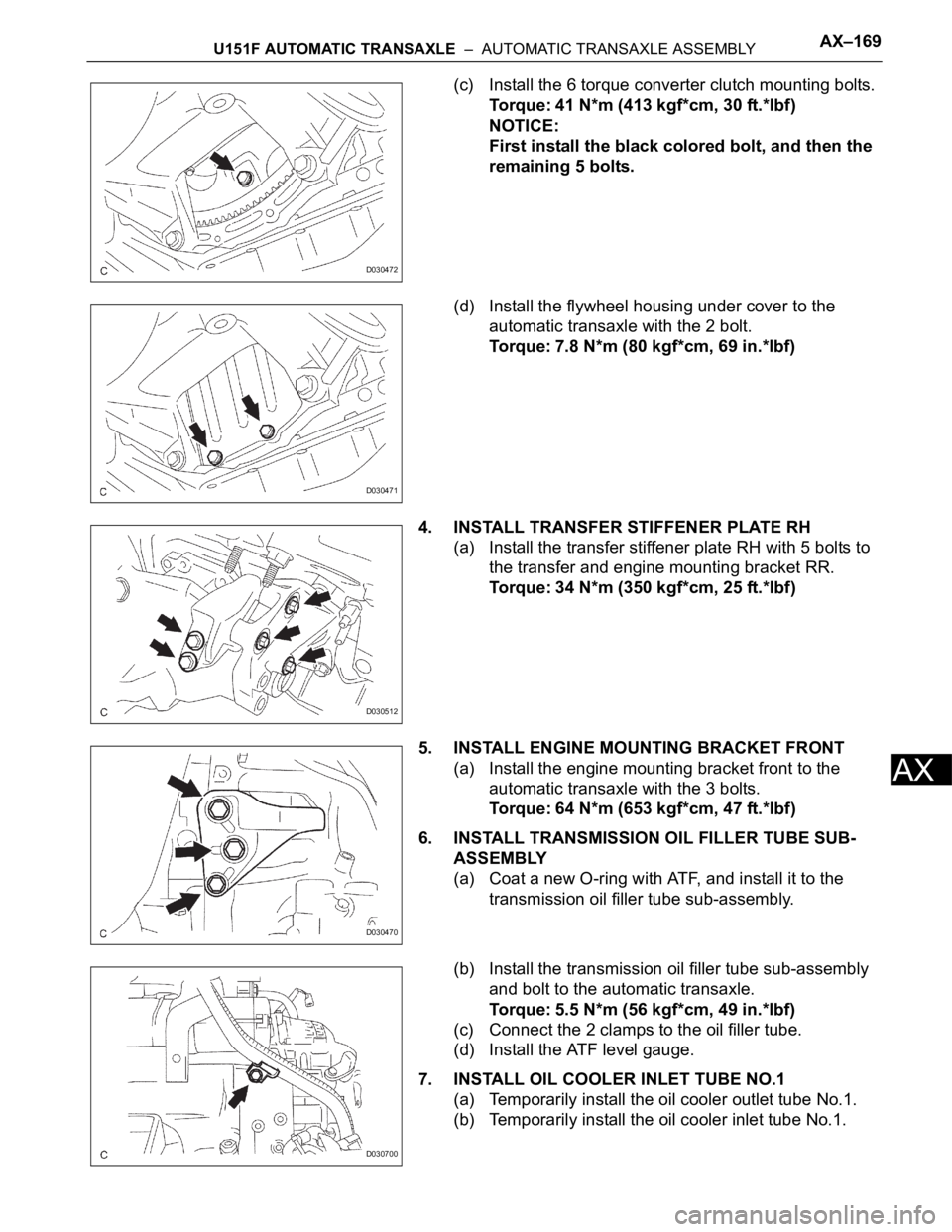

(c) Install the 6 torque converter clutch mounting bolts.

Torque: 41 N*m (413 kgf*cm, 30 ft.*lbf)

NOTICE:

First install the black colored bolt, and then the

remaining 5 bolts.

(d) Install the flywheel housing under cover to the

automatic transaxle with the 2 bolt.

Torque: 7.8 N*m (80 kgf*cm, 69 in.*lbf)

4. INSTALL TRANSFER STIFFENER PLATE RH

(a) Install the transfer stiffener plate RH with 5 bolts to

the transfer and engine mounting bracket RR.

Torque: 34 N*m (350 kgf*cm, 25 ft.*lbf)

5. INSTALL ENGINE MOUNTING BRACKET FRONT

(a) Install the engine mounting bracket front to the

automatic transaxle with the 3 bolts.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf)

6. INSTALL TRANSMISSION OIL FILLER TUBE SUB-

ASSEMBLY

(a) Coat a new O-ring with ATF, and install it to the

transmission oil filler tube sub-assembly.

(b) Install the transmission oil filler tube sub-assembly

and bolt to the automatic transaxle.

Torque: 5.5 N*m (56 kgf*cm, 49 in.*lbf)

(c) Connect the 2 clamps to the oil filler tube.

(d) Install the ATF level gauge.

7. INSTALL OIL COOLER INLET TUBE NO.1

(a) Temporarily install the oil cooler outlet tube No.1.

(b) Temporarily install the oil cooler inlet tube No.1.

D030472

D030471

D030512

D030470

D030700

Page 1887 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLYAX–171

AX

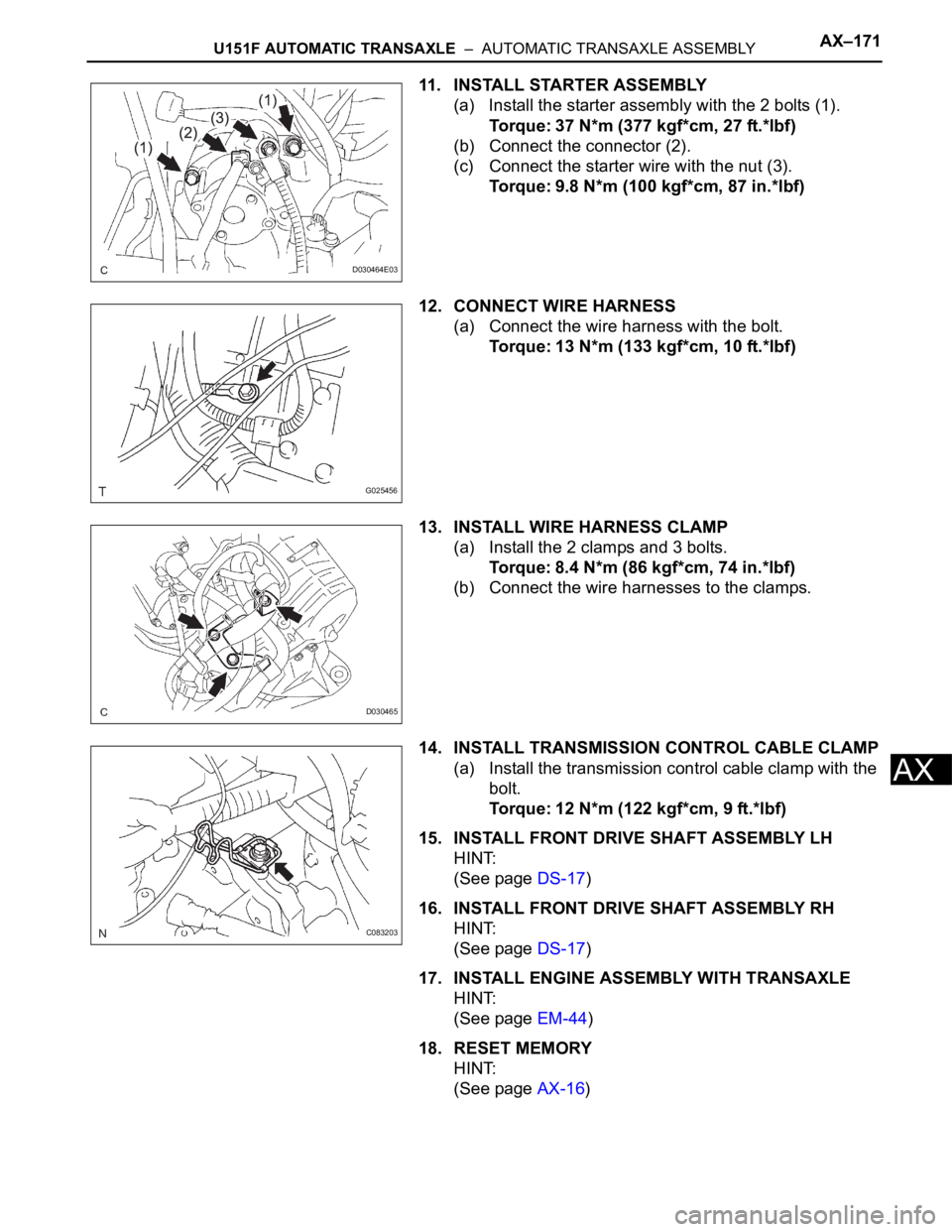

11. INSTALL STARTER ASSEMBLY

(a) Install the starter assembly with the 2 bolts (1).

Torque: 37 N*m (377 kgf*cm, 27 ft.*lbf)

(b) Connect the connector (2).

(c) Connect the starter wire with the nut (3).

Torque: 9.8 N*m (100 kgf*cm, 87 in.*lbf)

12. CONNECT WIRE HARNESS

(a) Connect the wire harness with the bolt.

Torque: 13 N*m (133 kgf*cm, 10 ft.*lbf)

13. INSTALL WIRE HARNESS CLAMP

(a) Install the 2 clamps and 3 bolts.

Torque: 8.4 N*m (86 kgf*cm, 74 in.*lbf)

(b) Connect the wire harnesses to the clamps.

14. INSTALL TRANSMISSION CONTROL CABLE CLAMP

(a) Install the transmission control cable clamp with the

bolt.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

15. INSTALL FRONT DRIVE SHAFT ASSEMBLY LH

HINT:

(See page DS-17)

16. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH

HINT:

(See page DS-17)

17. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

HINT:

(See page EM-44)

18. RESET MEMORY

HINT:

(See page AX-16)

D030464E03

G025456

D030465

C083203

Page 2031 of 3000

TF–8TRANSFER – TRANSFER ASSEMBLY

TF

REMOVAL

1. REMOVE ENGINE AND TRANSAXLE

HINT:

(See page EM-26)

2. REMOVE AUTOMATIC TRANSMISSION WITH

TRANSFER

HINT:

(See page AX-164)

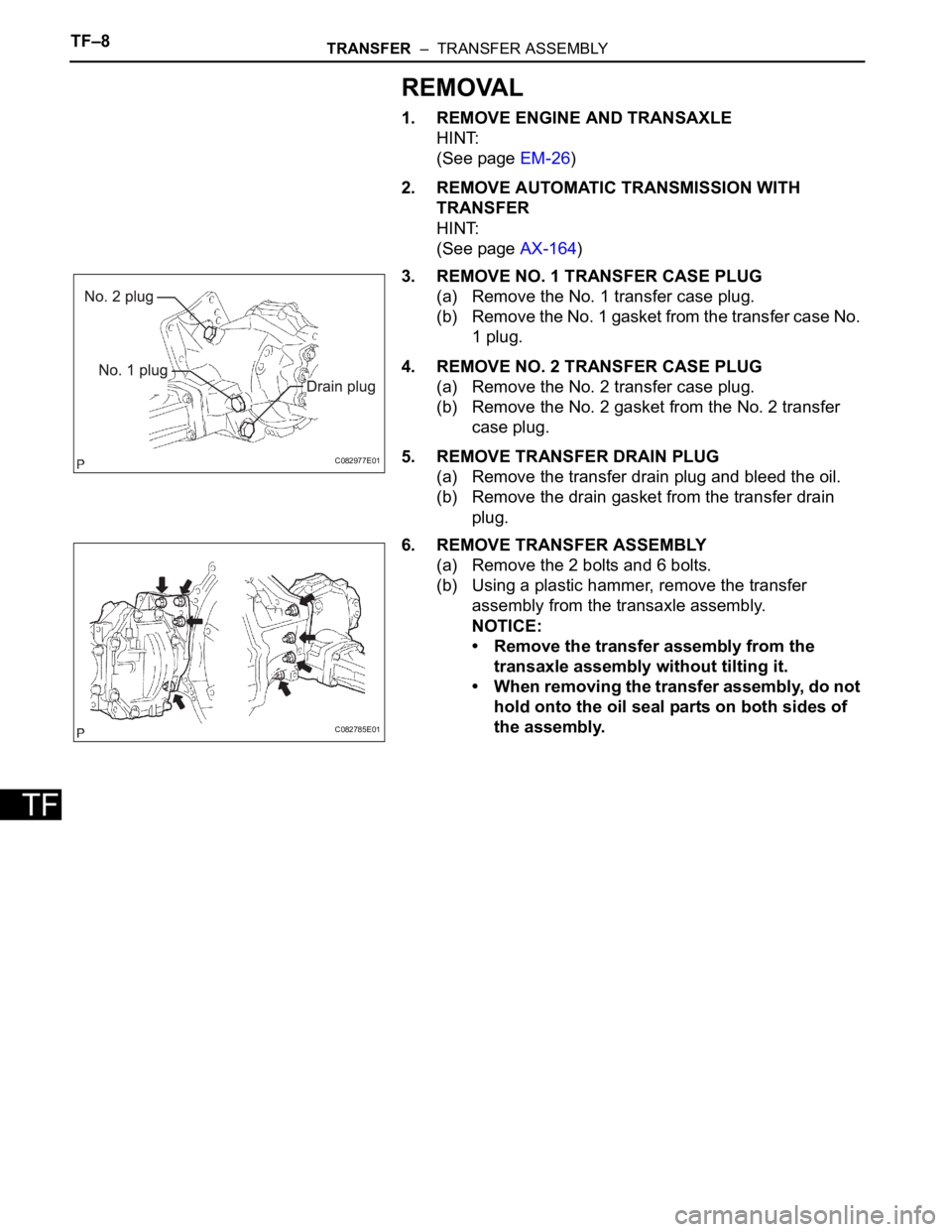

3. REMOVE NO. 1 TRANSFER CASE PLUG

(a) Remove the No. 1 transfer case plug.

(b) Remove the No. 1 gasket from the transfer case No.

1 plug.

4. REMOVE NO. 2 TRANSFER CASE PLUG

(a) Remove the No. 2 transfer case plug.

(b) Remove the No. 2 gasket from the No. 2 transfer

case plug.

5. REMOVE TRANSFER DRAIN PLUG

(a) Remove the transfer drain plug and bleed the oil.

(b) Remove the drain gasket from the transfer drain

plug.

6. REMOVE TRANSFER ASSEMBLY

(a) Remove the 2 bolts and 6 bolts.

(b) Using a plastic hammer, remove the transfer

assembly from the transaxle assembly.

NOTICE:

• Remove the transfer assembly from the

transaxle assembly without tilting it.

• When removing the transfer assembly, do not

hold onto the oil seal parts on both sides of

the assembly.

C082977E01

C082785E01

Page 2032 of 3000

TRANSFER – TRANSFER ASSEMBLYTF–9

TF

INSTALLATION

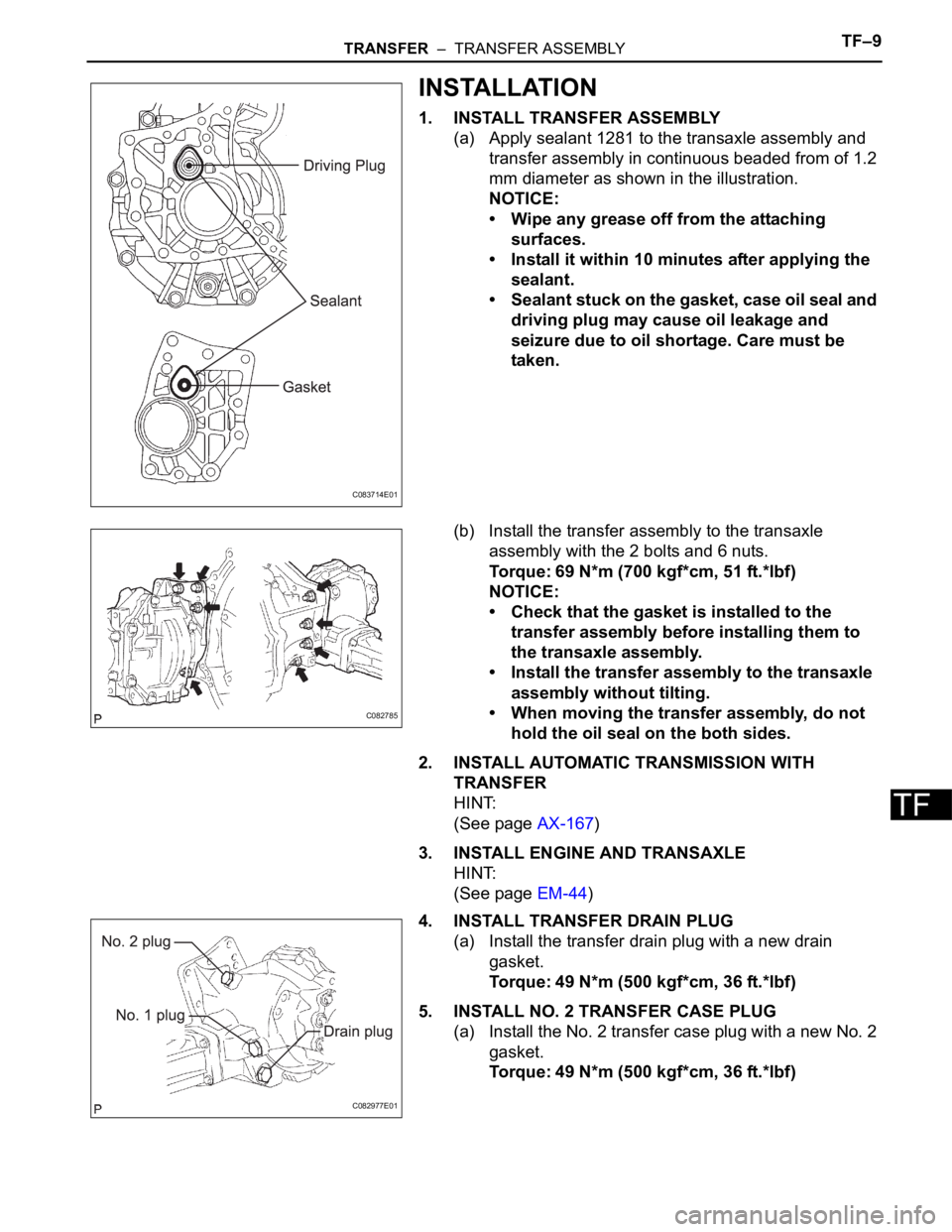

1. INSTALL TRANSFER ASSEMBLY

(a) Apply sealant 1281 to the transaxle assembly and

transfer assembly in continuous beaded from of 1.2

mm diameter as shown in the illustration.

NOTICE:

• Wipe any grease off from the attaching

surfaces.

• Install it within 10 minutes after applying the

sealant.

• Sealant stuck on the gasket, case oil seal and

driving plug may cause oil leakage and

seizure due to oil shortage. Care must be

taken.

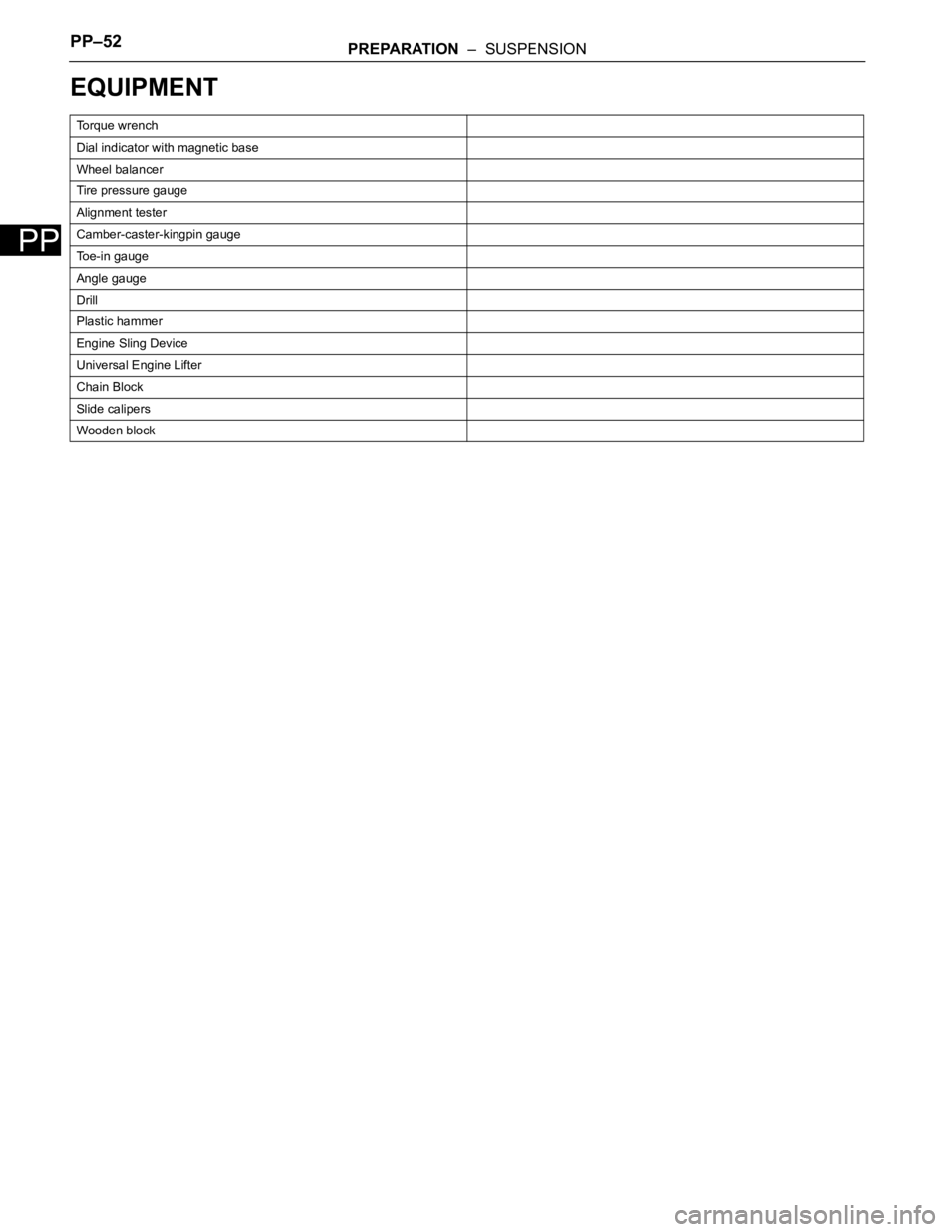

(b) Install the transfer assembly to the transaxle

assembly with the 2 bolts and 6 nuts.

Torque: 69 N*m (700 kgf*cm, 51 ft.*lbf)

NOTICE:

• Check that the gasket is installed to the

transfer assembly before installing them to

the transaxle assembly.

• Install the transfer assembly to the transaxle

assembly without tilting.

• When moving the transfer assembly, do not

hold the oil seal on the both sides.

2. INSTALL AUTOMATIC TRANSMISSION WITH

TRANSFER

HINT:

(See page AX-167)

3. INSTALL ENGINE AND TRANSAXLE

HINT:

(See page EM-44)

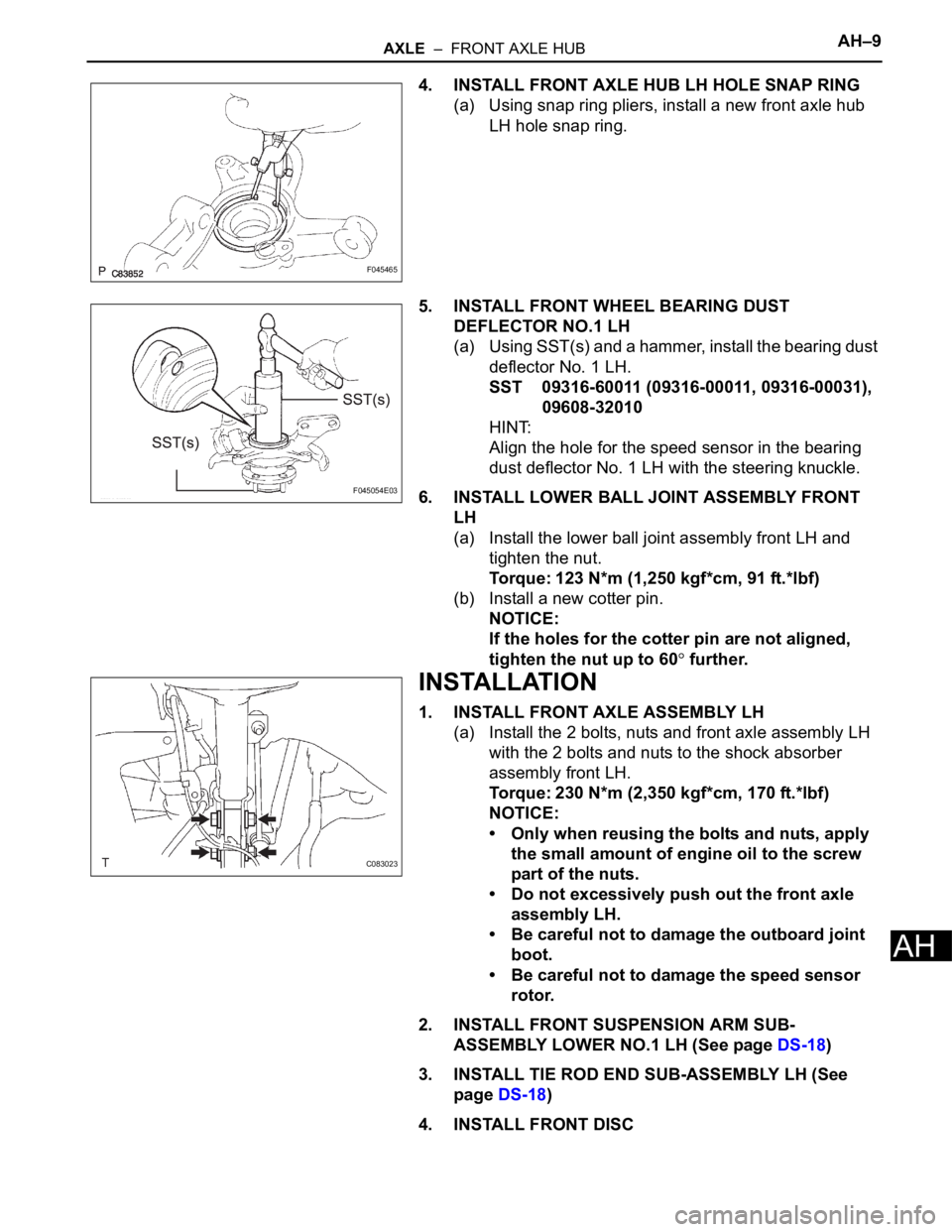

4. INSTALL TRANSFER DRAIN PLUG

(a) Install the transfer drain plug with a new drain

gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

5. INSTALL NO. 2 TRANSFER CASE PLUG

(a) Install the No. 2 transfer case plug with a new No. 2

gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

C083714E01

C082785

C082977E01

Page 2109 of 3000

PP–52PREPARATION – SUSPENSION

PP

EQUIPMENT

To r q u e w r e n c h

Dial indicator with magnetic base

Wheel balancer

Tire pressure gauge

Alignment tester

Camber-caster-kingpin gauge

Toe-in gauge

Angle gauge

Drill

Plastic hammer

Engine Sling Device

Universal Engine Lifter

Chain Block

Slide calipers

Wooden block

Page 2168 of 3000

AXLE – FRONT AXLE HUBAH–9

AH

4. INSTALL FRONT AXLE HUB LH HOLE SNAP RING

(a) Using snap ring pliers, install a new front axle hub

LH hole snap ring.

5. INSTALL FRONT WHEEL BEARING DUST

DEFLECTOR NO.1 LH

(a) Using SST(s) and a hammer, install the bearing dust

deflector No. 1 LH.

SST 09316-60011 (09316-00011, 09316-00031),

09608-32010

HINT:

Align the hole for the speed sensor in the bearing

dust deflector No. 1 LH with the steering knuckle.

6. INSTALL LOWER BALL JOINT ASSEMBLY FRONT

LH

(a) Install the lower ball joint assembly front LH and

tighten the nut.

Torque: 123 N*m (1,250 kgf*cm, 91 ft.*lbf)

(b) Install a new cotter pin.

NOTICE:

If the holes for the cotter pin are not aligned,

tighten the nut up to 60

further.

INSTALLATION

1. INSTALL FRONT AXLE ASSEMBLY LH

(a) Install the 2 bolts, nuts and front axle assembly LH

with the 2 bolts and nuts to the shock absorber

assembly front LH.

Torque: 230 N*m (2,350 kgf*cm, 170 ft.*lbf)

NOTICE:

• Only when reusing the bolts and nuts, apply

the small amount of engine oil to the screw

part of the nuts.

• Do not excessively push out the front axle

assembly LH.

• Be careful not to damage the outboard joint

boot.

• Be careful not to damage the speed sensor

rotor.

2. INSTALL FRONT SUSPENSION ARM SUB-

ASSEMBLY LOWER NO.1 LH (See page DS-18)

3. INSTALL TIE ROD END SUB-ASSEMBLY LH (See

page DS-18)

4. INSTALL FRONT DISC

F045465

F045054E03

C083023

Page 2191 of 3000

SUSPENSION – FRONT LOWER SUSPENSION ARMSP–21

SP

INSTALLATION

1. INSTALL FRONT SUSPENSION ARM SUB-

ASSEMBLY LOWER NO.1 LH

(a) Install the front lower arm bush stopper to the front

suspension arm sub-assembly lower No.1 LH.

(b) Install the bolt and nut to the rear side of the front

suspension arm sub-assembly lower No.1 LH.

Torque: 206 N*m (2,100 kgf*cm, 152 ft.*lbf)

(c) Install the 2 bolts on the front side of the front

suspension arm sub-assembly lower No.1 LH.

Torque: 200 N*m (2,040 kgf*cm, 148 ft.*lbf)

2. INSTALL TRANSVERSE ENGINE ENGINE

MOUNTING INSULATOR

(a) Install the transverse engine engine mounting

insulator with the 3 nuts.

Torque: 87 N*m (887 kgf*cm, 64 ft.*lbf)

3. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

HINT:

(See page EM-52)

F044965

F044964

C083387

Page 2207 of 3000

SP–20SUSPENSION – FRONT LOWER SUSPENSION ARM

SP

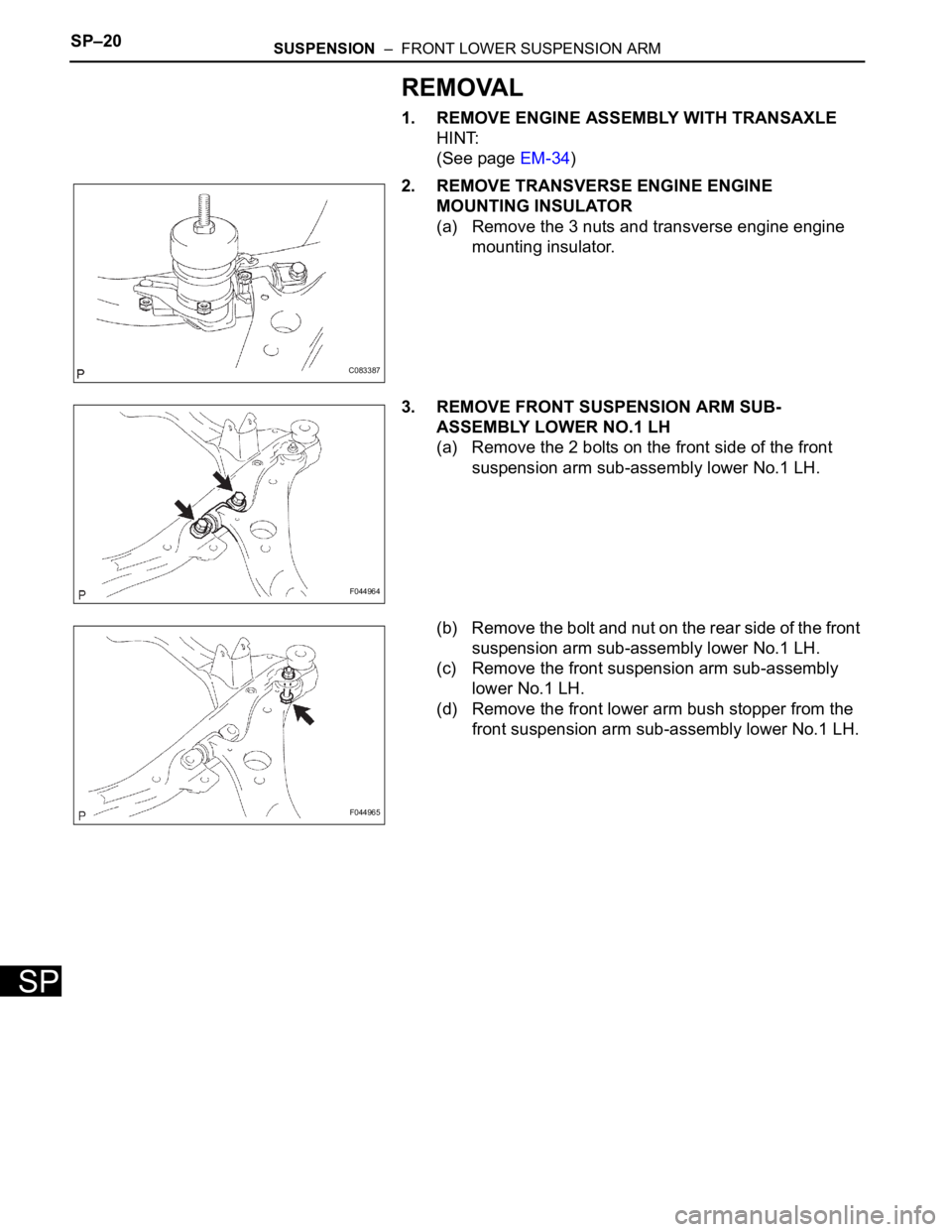

REMOVAL

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

HINT:

(See page EM-34)

2. REMOVE TRANSVERSE ENGINE ENGINE

MOUNTING INSULATOR

(a) Remove the 3 nuts and transverse engine engine

mounting insulator.

3. REMOVE FRONT SUSPENSION ARM SUB-

ASSEMBLY LOWER NO.1 LH

(a) Remove the 2 bolts on the front side of the front

suspension arm sub-assembly lower No.1 LH.

(b) Remove the bolt and nut on the rear side of the front

suspension arm sub-assembly lower No.1 LH.

(c) Remove the front suspension arm sub-assembly

lower No.1 LH.

(d) Remove the front lower arm bush stopper from the

front suspension arm sub-assembly lower No.1 LH.

C083387

F044964

F044965

Page 2283 of 3000

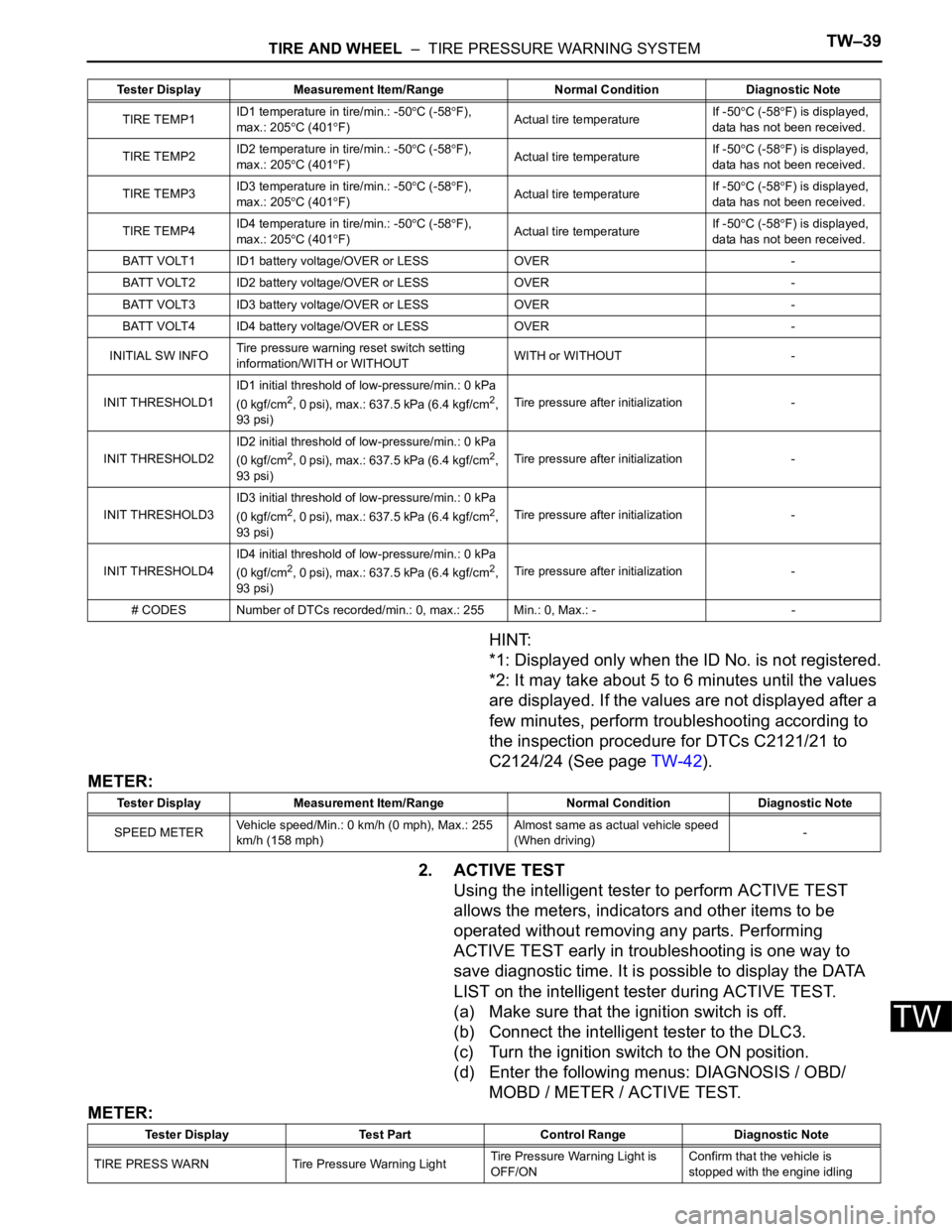

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEMTW–39

TW

HINT:

*1: Displayed only when the ID No. is not registered.

*2: It may take about 5 to 6 minutes until the values

are displayed. If the values are not displayed after a

few minutes, perform troubleshooting according to

the inspection procedure for DTCs C2121/21 to

C2124/24 (See page TW-42).

METER:

2. ACTIVE TEST

Using the intelligent tester to perform ACTIVE TEST

allows the meters, indicators and other items to be

operated without removing any parts. Performing

ACTIVE TEST early in troubleshooting is one way to

save diagnostic time. It is possible to display the DATA

LIST on the intelligent tester during ACTIVE TEST.

(a) Make sure that the ignition switch is off.

(b) Connect the intelligent tester to the DLC3.

(c) Turn the ignition switch to the ON position.

(d) Enter the following menus: DIAGNOSIS / OBD/

MOBD / METER / ACTIVE TEST.

METER:

TIRE TEMP1ID1 temperature in tire/min.: -50C (-58F),

max.: 205

C (401F)Actual tire temperatureIf -50

C (-58F) is displayed,

data has not been received.

TIRE TEMP2ID2 temperature in tire/min.: -50

C (-58F),

max.: 205

C (401F)Actual tire temperatureIf -50

C (-58F) is displayed,

data has not been received.

TIRE TEMP3ID3 temperature in tire/min.: -50

C (-58F),

max.: 205

C (401F)Actual tire temperatureIf -50

C (-58F) is displayed,

data has not been received.

TIRE TEMP4ID4 temperature in tire/min.: -50

C (-58F),

max.: 205

C (401F)Actual tire temperatureIf -50

C (-58F) is displayed,

data has not been received.

BATT VOLT1 ID1 battery voltage/OVER or LESS OVER -

BATT VOLT2 ID2 battery voltage/OVER or LESS OVER -

BATT VOLT3 ID3 battery voltage/OVER or LESS OVER -

BATT VOLT4 ID4 battery voltage/OVER or LESS OVER -

INITIAL SW INFOTire pressure warning reset switch setting

information/WITH or WITHOUTWITH or WITHOUT -

INIT THRESHOLD1ID1 initial threshold of low-pressure/min.: 0 kPa

(0 kgf/cm

2, 0 psi), max.: 637.5 kPa (6.4 kgf/cm2,

93 psi)Tire pressure after initialization -

INIT THRESHOLD2ID2 initial threshold of low-pressure/min.: 0 kPa

(0 kgf/cm

2, 0 psi), max.: 637.5 kPa (6.4 kgf/cm2,

93 psi)Tire pressure after initialization -

INIT THRESHOLD3ID3 initial threshold of low-pressure/min.: 0 kPa

(0 kgf/cm

2, 0 psi), max.: 637.5 kPa (6.4 kgf/cm2,

93 psi)Tire pressure after initialization -

INIT THRESHOLD4ID4 initial threshold of low-pressure/min.: 0 kPa

(0 kgf/cm

2, 0 psi), max.: 637.5 kPa (6.4 kgf/cm2,

93 psi)Tire pressure after initialization -

# CODES Number of DTCs recorded/min.: 0, max.: 255 Min.: 0, Max.: - - Tester Display Measurement Item/Range Normal Condition Diagnostic Note

Tester Display Measurement Item/Range Normal Condition Diagnostic Note

SPEED METERVehicle speed/Min.: 0 km/h (0 mph), Max.: 255

km/h (158 mph)Almost same as actual vehicle speed

(When driving)-

Tester Display Test Part Control Range Diagnostic Note

TIRE PRESS WARN Tire Pressure Warning LightTire Pressure Warning Light is

OFF/ONConfirm that the vehicle is

stopped with the engine idling