engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 2357 of 3000

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEMTW–39

TW

HINT:

*1: Displayed only when the ID No. is not registered.

*2: It may take about 5 to 6 minutes until the values

are displayed. If the values are not displayed after a

few minutes, perform troubleshooting according to

the inspection procedure for DTCs C2121/21 to

C2124/24 (See page TW-42).

METER:

2. ACTIVE TEST

Using the intelligent tester to perform ACTIVE TEST

allows the meters, indicators and other items to be

operated without removing any parts. Performing

ACTIVE TEST early in troubleshooting is one way to

save diagnostic time. It is possible to display the DATA

LIST on the intelligent tester during ACTIVE TEST.

(a) Make sure that the ignition switch is off.

(b) Connect the intelligent tester to the DLC3.

(c) Turn the ignition switch to the ON position.

(d) Enter the following menus: DIAGNOSIS / OBD/

MOBD / METER / ACTIVE TEST.

METER:

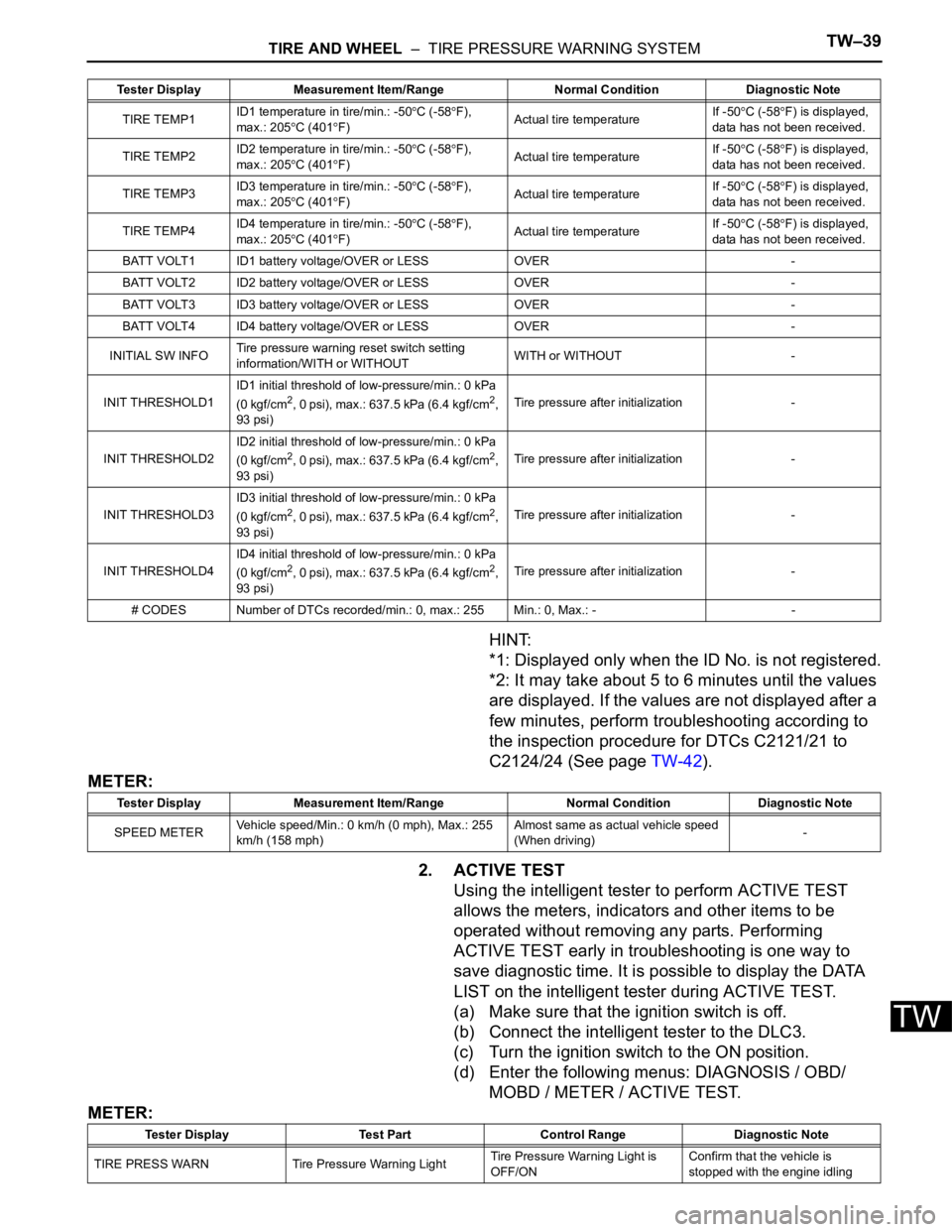

TIRE TEMP1ID1 temperature in tire/min.: -50C (-58F),

max.: 205

C (401F)Actual tire temperatureIf -50

C (-58F) is displayed,

data has not been received.

TIRE TEMP2ID2 temperature in tire/min.: -50

C (-58F),

max.: 205

C (401F)Actual tire temperatureIf -50

C (-58F) is displayed,

data has not been received.

TIRE TEMP3ID3 temperature in tire/min.: -50

C (-58F),

max.: 205

C (401F)Actual tire temperatureIf -50

C (-58F) is displayed,

data has not been received.

TIRE TEMP4ID4 temperature in tire/min.: -50

C (-58F),

max.: 205

C (401F)Actual tire temperatureIf -50

C (-58F) is displayed,

data has not been received.

BATT VOLT1 ID1 battery voltage/OVER or LESS OVER -

BATT VOLT2 ID2 battery voltage/OVER or LESS OVER -

BATT VOLT3 ID3 battery voltage/OVER or LESS OVER -

BATT VOLT4 ID4 battery voltage/OVER or LESS OVER -

INITIAL SW INFOTire pressure warning reset switch setting

information/WITH or WITHOUTWITH or WITHOUT -

INIT THRESHOLD1ID1 initial threshold of low-pressure/min.: 0 kPa

(0 kgf/cm

2, 0 psi), max.: 637.5 kPa (6.4 kgf/cm2,

93 psi)Tire pressure after initialization -

INIT THRESHOLD2ID2 initial threshold of low-pressure/min.: 0 kPa

(0 kgf/cm

2, 0 psi), max.: 637.5 kPa (6.4 kgf/cm2,

93 psi)Tire pressure after initialization -

INIT THRESHOLD3ID3 initial threshold of low-pressure/min.: 0 kPa

(0 kgf/cm

2, 0 psi), max.: 637.5 kPa (6.4 kgf/cm2,

93 psi)Tire pressure after initialization -

INIT THRESHOLD4ID4 initial threshold of low-pressure/min.: 0 kPa

(0 kgf/cm

2, 0 psi), max.: 637.5 kPa (6.4 kgf/cm2,

93 psi)Tire pressure after initialization -

# CODES Number of DTCs recorded/min.: 0, max.: 255 Min.: 0, Max.: - - Tester Display Measurement Item/Range Normal Condition Diagnostic Note

Tester Display Measurement Item/Range Normal Condition Diagnostic Note

SPEED METERVehicle speed/Min.: 0 km/h (0 mph), Max.: 255

km/h (158 mph)Almost same as actual vehicle speed

(When driving)-

Tester Display Test Part Control Range Diagnostic Note

TIRE PRESS WARN Tire Pressure Warning LightTire Pressure Warning Light is

OFF/ONConfirm that the vehicle is

stopped with the engine idling

Page 2368 of 3000

BC–4BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

TEST MODE PROCEDURE

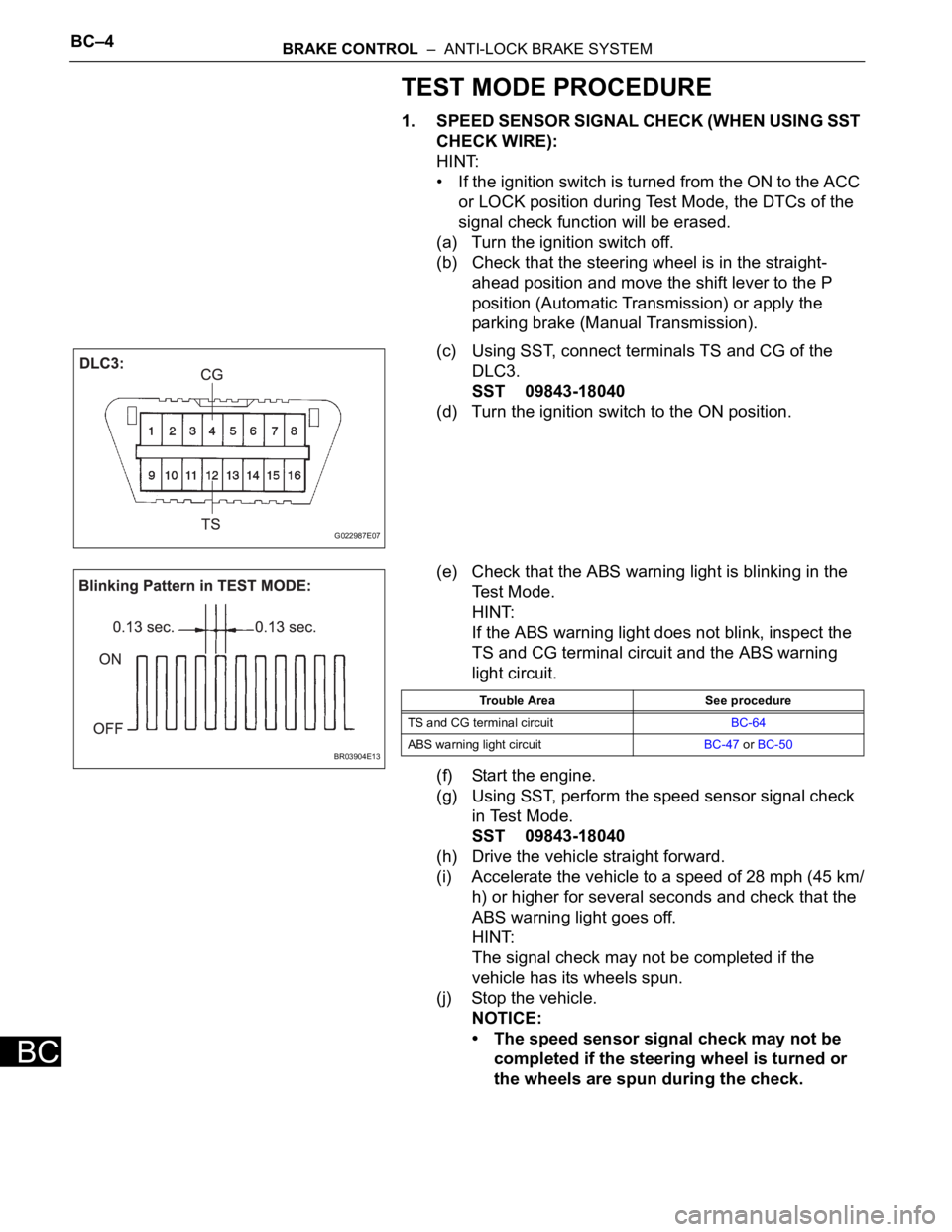

1. SPEED SENSOR SIGNAL CHECK (WHEN USING SST

CHECK WIRE):

HINT:

• If the ignition switch is turned from the ON to the ACC

or LOCK position during Test Mode, the DTCs of the

signal check function will be erased.

(a) Turn the ignition switch off.

(b) Check that the steering wheel is in the straight-

ahead position and move the shift lever to the P

position (Automatic Transmission) or apply the

parking brake (Manual Transmission).

(c) Using SST, connect terminals TS and CG of the

DLC3.

SST 09843-18040

(d) Turn the ignition switch to the ON position.

(e) Check that the ABS warning light is blinking in the

Test Mode.

HINT:

If the ABS warning light does not blink, inspect the

TS and CG terminal circuit and the ABS warning

light circuit.

(f) Start the engine.

(g) Using SST, perform the speed sensor signal check

in Test Mode.

SST 09843-18040

(h) Drive the vehicle straight forward.

(i) Accelerate the vehicle to a speed of 28 mph (45 km/

h) or higher for several seconds and check that the

ABS warning light goes off.

HINT:

The signal check may not be completed if the

vehicle has its wheels spun.

(j) Stop the vehicle.

NOTICE:

• The speed sensor signal check may not be

completed if the steering wheel is turned or

the wheels are spun during the check.

G022987E07

BR03904E13

Trouble Area See procedure

TS and CG terminal circuitBC-64

ABS warning light circuitBC-47 or BC-50

Page 2371 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–7

BC

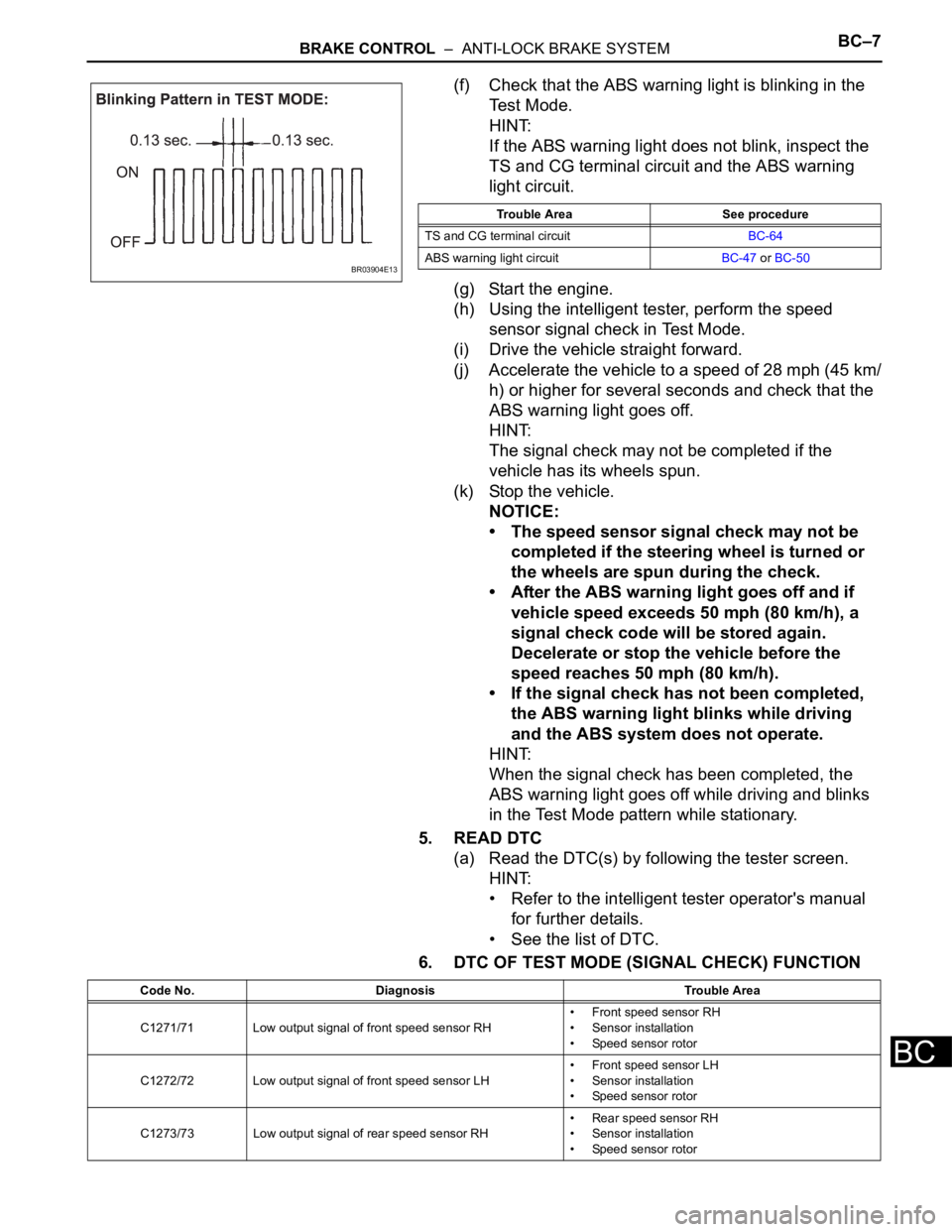

(f) Check that the ABS warning light is blinking in the

Test Mode.

HINT:

If the ABS warning light does not blink, inspect the

TS and CG terminal circuit and the ABS warning

light circuit.

(g) Start the engine.

(h) Using the intelligent tester, perform the speed

sensor signal check in Test Mode.

(i) Drive the vehicle straight forward.

(j) Accelerate the vehicle to a speed of 28 mph (45 km/

h) or higher for several seconds and check that the

ABS warning light goes off.

HINT:

The signal check may not be completed if the

vehicle has its wheels spun.

(k) Stop the vehicle.

NOTICE:

• The speed sensor signal check may not be

completed if the steering wheel is turned or

the wheels are spun during the check.

• After the ABS warning light goes off and if

vehicle speed exceeds 50 mph (80 km/h), a

signal check code will be stored again.

Decelerate or stop the vehicle before the

speed reaches 50 mph (80 km/h).

• If the signal check has not been completed,

the ABS warning light blinks while driving

and the ABS system does not operate.

HINT:

When the signal check has been completed, the

ABS warning light goes off while driving and blinks

in the Test Mode pattern while stationary.

5. READ DTC

(a) Read the DTC(s) by following the tester screen.

HINT:

• Refer to the intelligent tester operator's manual

for further details.

• See the list of DTC.

6. DTC OF TEST MODE (SIGNAL CHECK) FUNCTION

BR03904E13

Trouble Area See procedure

TS and CG terminal circuitBC-64

ABS warning light circuitBC-47 or BC-50

Code No. Diagnosis Trouble Area

C1271/71 Low output signal of front speed sensor RH• Front speed sensor RH

• Sensor installation

• Speed sensor rotor

C1272/72 Low output signal of front speed sensor LH• Front speed sensor LH

• Sensor installation

• Speed sensor rotor

C1273/73 Low output signal of rear speed sensor RH• Rear speed sensor RH

• Sensor installation

• Speed sensor rotor

Page 2393 of 3000

BC–32BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

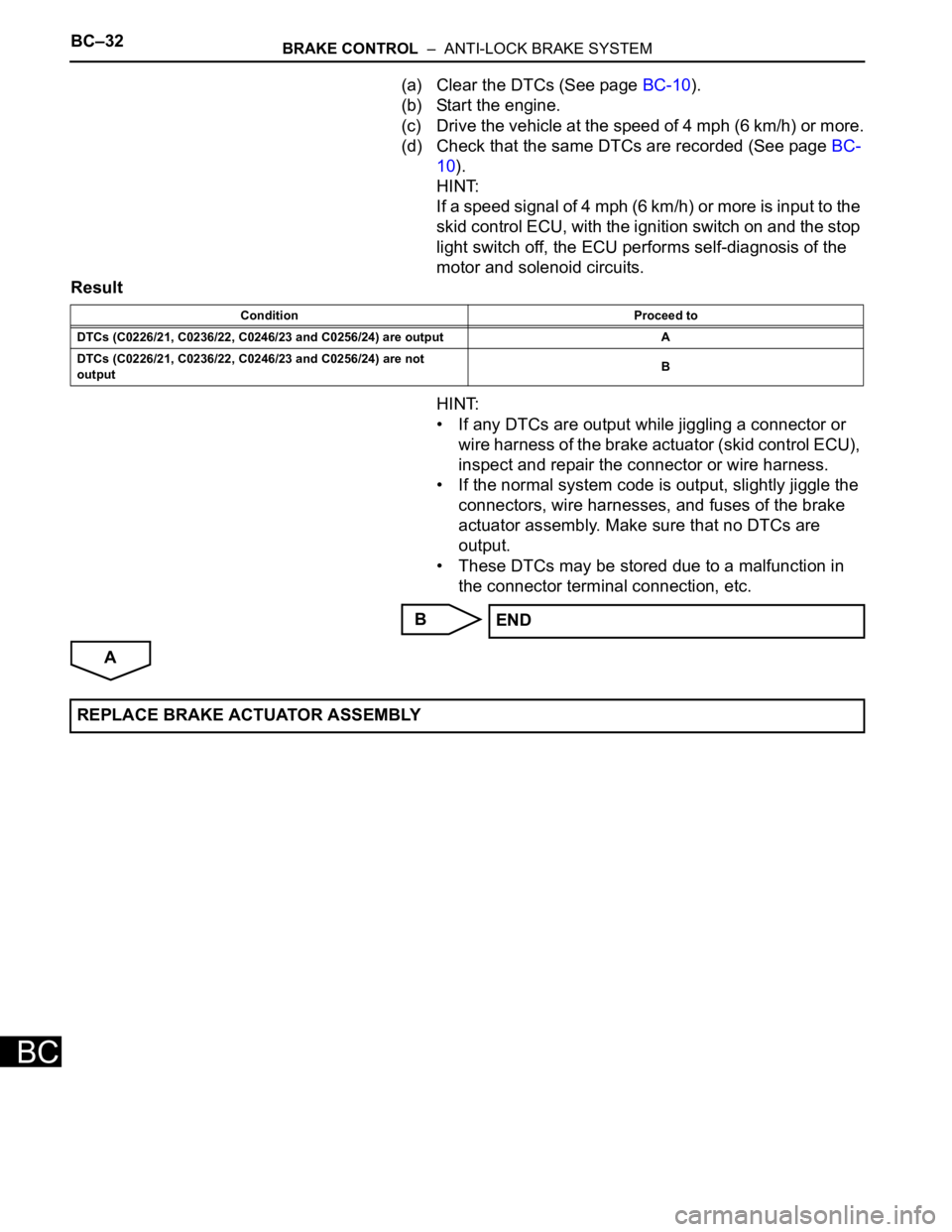

(a) Clear the DTCs (See page BC-10).

(b) Start the engine.

(c) Drive the vehicle at the speed of 4 mph (6 km/h) or more.

(d) Check that the same DTCs are recorded (See page BC-

10).

HINT:

If a speed signal of 4 mph (6 km/h) or more is input to the

skid control ECU, with the ignition switch on and the stop

light switch off, the ECU performs self-diagnosis of the

motor and solenoid circuits.

Result

HINT:

• If any DTCs are output while jiggling a connector or

wire harness of the brake actuator (skid control ECU),

inspect and repair the connector or wire harness.

• If the normal system code is output, slightly jiggle the

connectors, wire harnesses, and fuses of the brake

actuator assembly. Make sure that no DTCs are

output.

• These DTCs may be stored due to a malfunction in

the connector terminal connection, etc.

B

A

Condition Proceed to

DTCs (C0226/21, C0236/22, C0246/23 and C0256/24) are output A

DTCs (C0226/21, C0236/22, C0246/23 and C0256/24) are not

outputB

END

REPLACE BRAKE ACTUATOR ASSEMBLY

Page 2395 of 3000

BC–34BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

NG

OK

(a) Install the ABS 1 fuse.

(b) Disconnect the skid control ECU connector.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

NG

OK

(a) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Reconnect the skid control ECU connector.

(b) Connect the intelligent tester to the DLC3.

(c) Turn the ignition switch to the ON position and turn the

intelligent tester main switch on.

(d) Start the engine.

(e) Select the ACTIVE TEST mode on the intelligent tester.

ABS:REPLACE FUSE (ABS 1 FUSE)

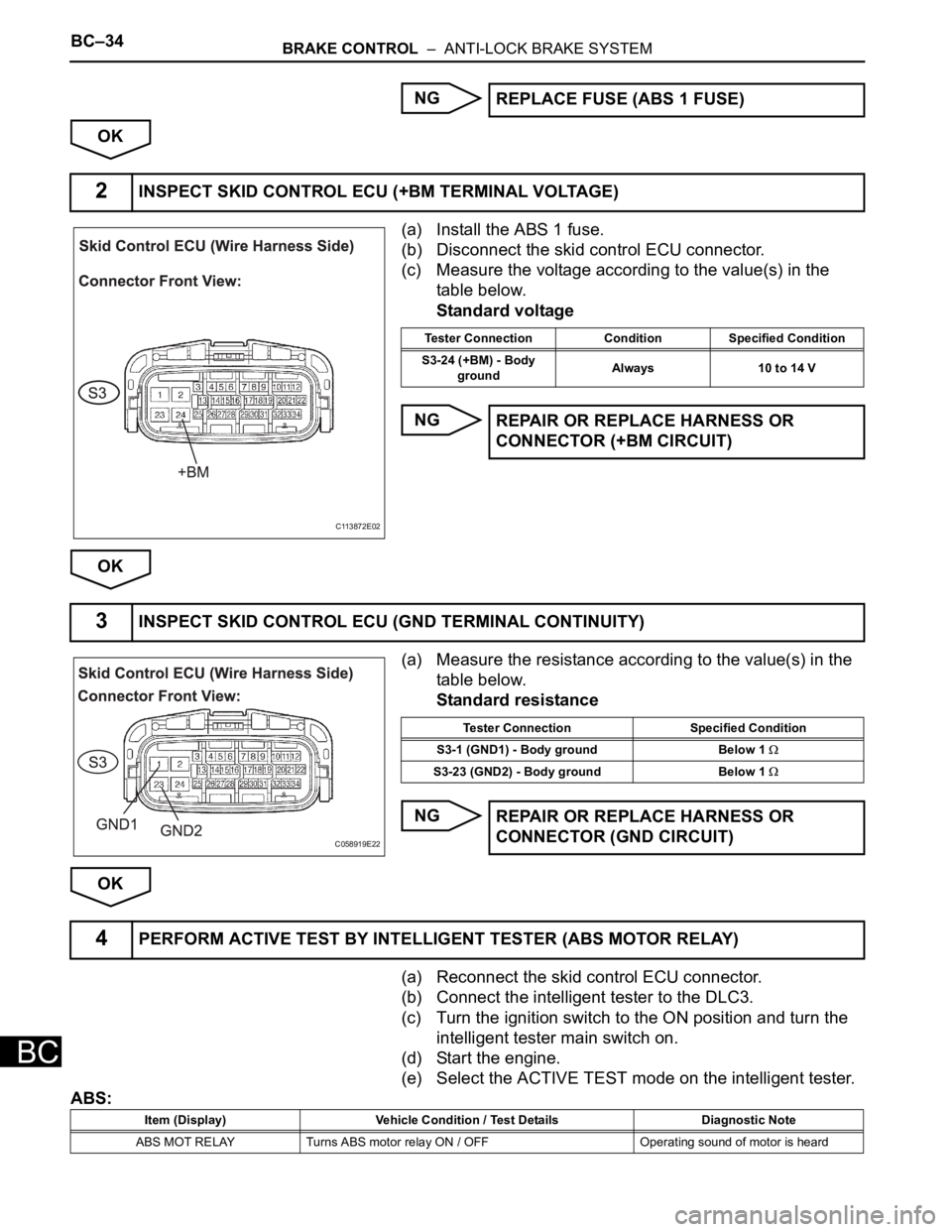

2INSPECT SKID CONTROL ECU (+BM TERMINAL VOLTAGE)

C113872E02

Tester Connection Condition Specified Condition

S3-24 (+BM) - Body

groundAlways 10 to 14 V

REPAIR OR REPLACE HARNESS OR

CONNECTOR (+BM CIRCUIT)

3INSPECT SKID CONTROL ECU (GND TERMINAL CONTINUITY)

C058919E22

Tester Connection Specified Condition

S3-1 (GND1) - Body ground Below 1

S3-23 (GND2) - Body ground Below 1

REPAIR OR REPLACE HARNESS OR

CONNECTOR (GND CIRCUIT)

4PERFORM ACTIVE TEST BY INTELLIGENT TESTER (ABS MOTOR RELAY)

Item (Display) Vehicle Condition / Test Details Diagnostic Note

ABS MOT RELAY Turns ABS motor relay ON / OFF Operating sound of motor is heard

Page 2396 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–35

BC

(f) Check operating sound of the ABS motor when

operating it with the intelligent tester.

OK:

The operating sound of the ABS motor is heard.

NG

OK

(a) Clear the DTCs (See page BC-10).

(b) Start the engine.

(c) Drive the vehicle at the speed of 6 km/h (4 mph) or more.

(d) Check that the same DTCs are recorded (See page BC-

10).

HINT:

• Reinstall the sensors, connectors, etc. and restore the

vehicle to its prior condition before rechecking for

DTCs.

• If a speed signal of 6 km/h (4 mph) or more is input to

the skid control ECU, with the ignition switch on and

the stop light switch off, the ECU performs self-

diagnosis of the motor and solenoid circuits.

Result

HINT:

• If any DTCs are output while jiggling a connector or

wire harness of the brake actuator (skid control ECU),

inspect and repair the connector or wire harness.

• If the normal system code is output, slightly jiggle the

connectors, wire harnesses, and fuses of the brake

actuator assembly. Make sure that no DTCs are

output.

• These DTCs may be stored due to a malfunction in

the connector terminal connection, etc.

B

AREPLACE BRAKE ACTUATOR ASSEMBLY

5RECONFIRM DTC

Condition Proceed to

DTCs (C0273/13 and C0274/14) are output A

DTCs (C0273/13 and C0274/14) are not output B

END

REPLACE BRAKE ACTUATOR ASSEMBLY

Page 2398 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–37

BC

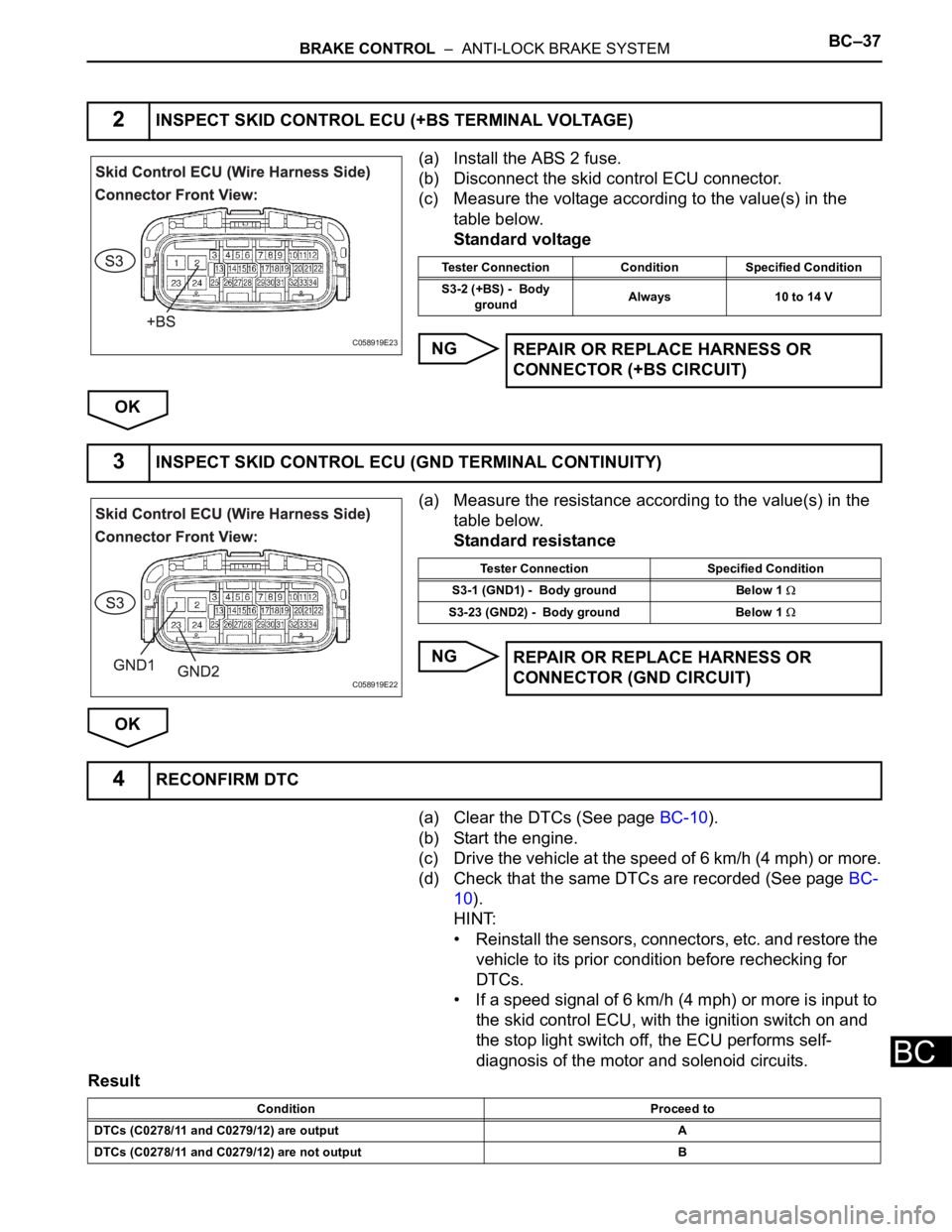

(a) Install the ABS 2 fuse.

(b) Disconnect the skid control ECU connector.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

NG

OK

(a) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Clear the DTCs (See page BC-10).

(b) Start the engine.

(c) Drive the vehicle at the speed of 6 km/h (4 mph) or more.

(d) Check that the same DTCs are recorded (See page BC-

10).

HINT:

• Reinstall the sensors, connectors, etc. and restore the

vehicle to its prior condition before rechecking for

DTCs.

• If a speed signal of 6 km/h (4 mph) or more is input to

the skid control ECU, with the ignition switch on and

the stop light switch off, the ECU performs self-

diagnosis of the motor and solenoid circuits.

Result

2INSPECT SKID CONTROL ECU (+BS TERMINAL VOLTAGE)

C058919E23

Tester Connection Condition Specified Condition

S3-2 (+BS) - Body

groundAlways 10 to 14 V

REPAIR OR REPLACE HARNESS OR

CONNECTOR (+BS CIRCUIT)

3INSPECT SKID CONTROL ECU (GND TERMINAL CONTINUITY)

C058919E22

Tester Connection Specified Condition

S3-1 (GND1) - Body ground Below 1

S3-23 (GND2) - Body ground Below 1

REPAIR OR REPLACE HARNESS OR

CONNECTOR (GND CIRCUIT)

4RECONFIRM DTC

Condition Proceed to

DTCs (C0278/11 and C0279/12) are output A

DTCs (C0278/11 and C0279/12) are not output B

Page 2401 of 3000

BC–40BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

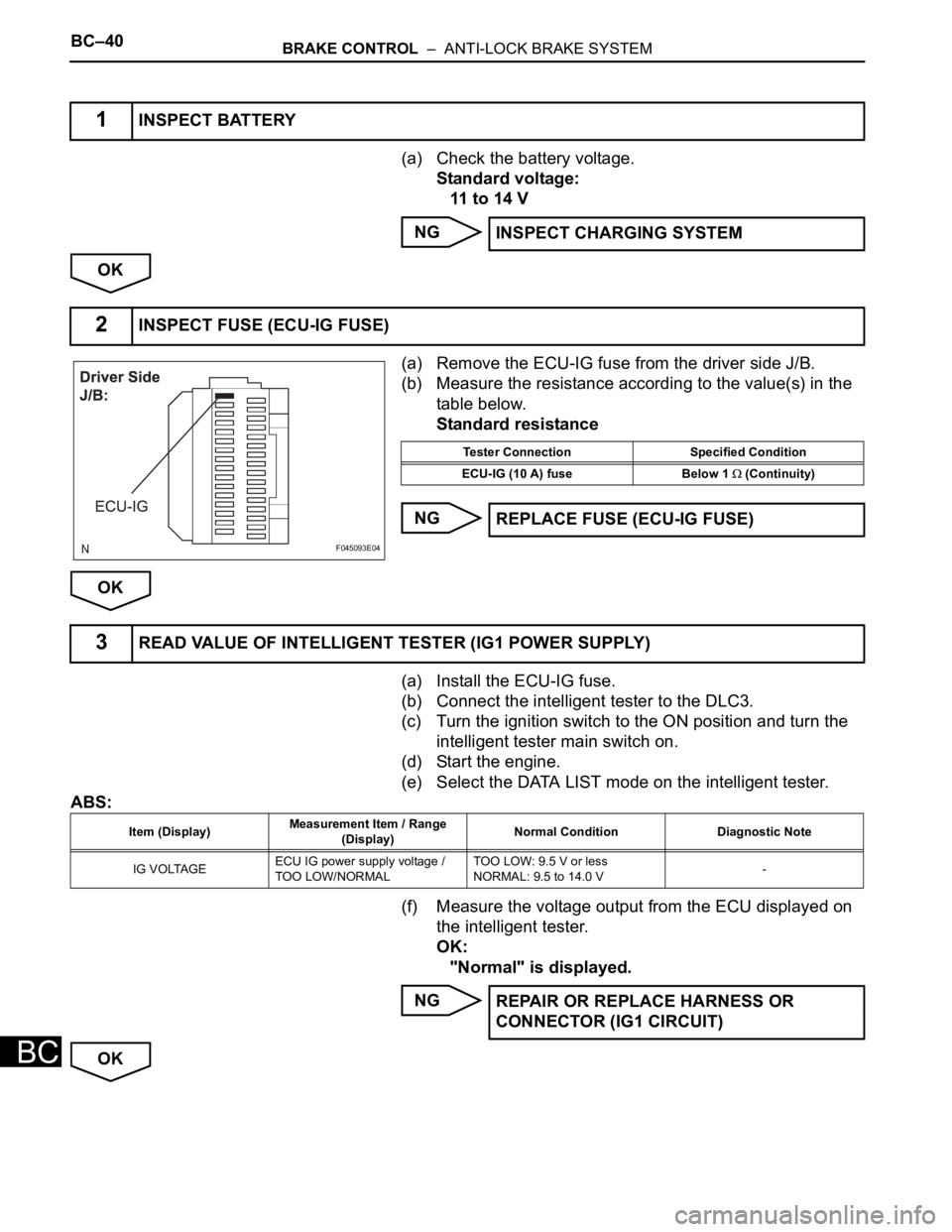

(a) Check the battery voltage.

Standard voltage:

11 to 14 V

NG

OK

(a) Remove the ECU-IG fuse from the driver side J/B.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Install the ECU-IG fuse.

(b) Connect the intelligent tester to the DLC3.

(c) Turn the ignition switch to the ON position and turn the

intelligent tester main switch on.

(d) Start the engine.

(e) Select the DATA LIST mode on the intelligent tester.

ABS:

(f) Measure the voltage output from the ECU displayed on

the intelligent tester.

OK:

"Normal" is displayed.

NG

OK

1INSPECT BATTERY

INSPECT CHARGING SYSTEM

2INSPECT FUSE (ECU-IG FUSE)

F045093E04

Tester Connection Specified Condition

ECU-IG (10 A) fuse Below 1

(Continuity)

REPLACE FUSE (ECU-IG FUSE)

3READ VALUE OF INTELLIGENT TESTER (IG1 POWER SUPPLY)

Item (Display)Measurement Item / Range

(Display)Normal Condition Diagnostic Note

IG VOLTAGEECU IG power supply voltage /

TOO LOW/NORMALTOO LOW: 9.5 V or less

NORMAL: 9.5 to 14.0 V-

REPAIR OR REPLACE HARNESS OR

CONNECTOR (IG1 CIRCUIT)

Page 2408 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–47

BC

DESCRIPTION

The motor relay (semiconductor relay) is housed in the brake actuator assembly and drives the pump

motor based on a signal from the skid control ECU.

WIRING DIAGRAM

Refer to DTCs C0273/13 and C0274/14 (See page BC-31).

INSPECTION PROCEDURE

HINT:

After step 1 is complete, start the inspection from step 2 when using the intelligent tester, and from step 3

when not using the intelligent tester.

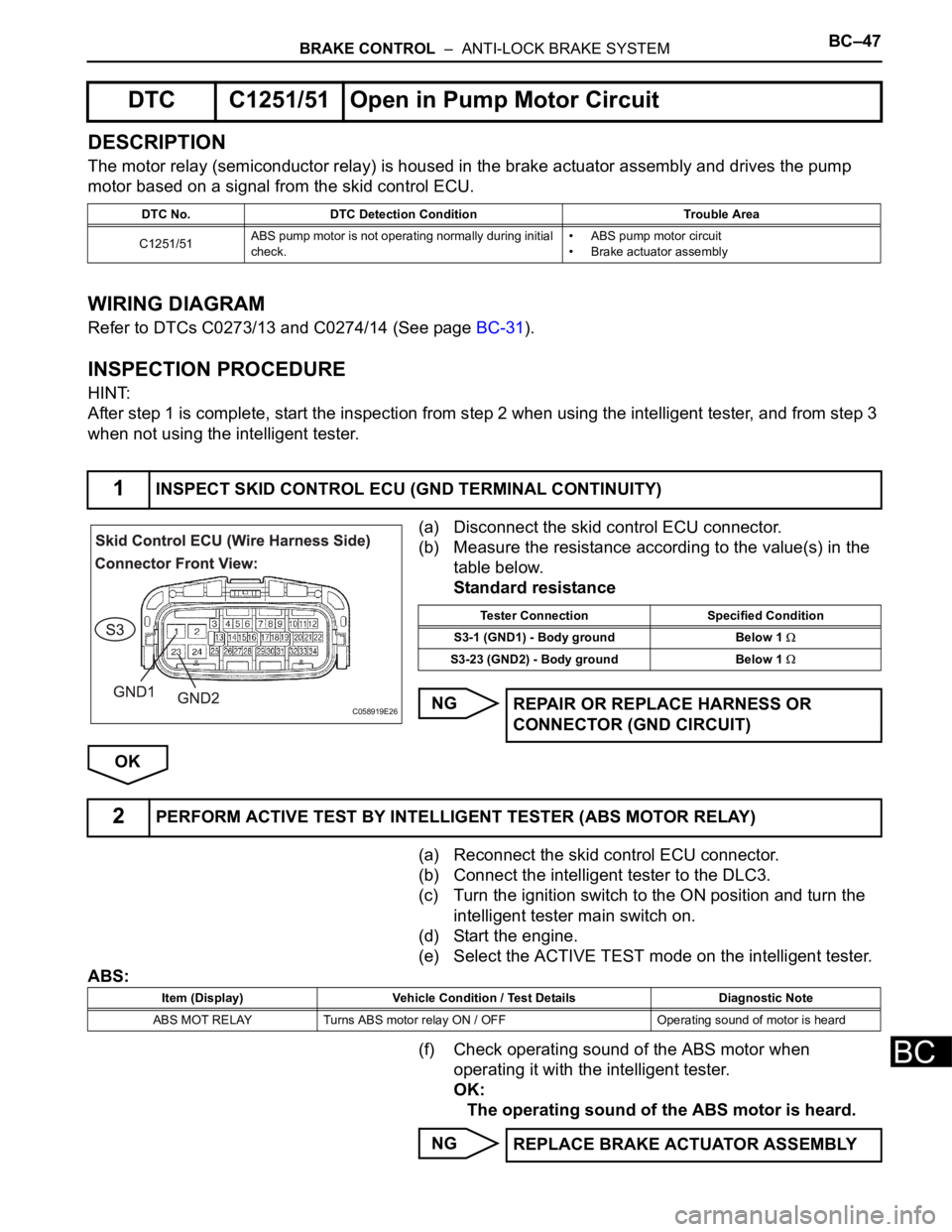

(a) Disconnect the skid control ECU connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Reconnect the skid control ECU connector.

(b) Connect the intelligent tester to the DLC3.

(c) Turn the ignition switch to the ON position and turn the

intelligent tester main switch on.

(d) Start the engine.

(e) Select the ACTIVE TEST mode on the intelligent tester.

ABS:

(f) Check operating sound of the ABS motor when

operating it with the intelligent tester.

OK:

The operating sound of the ABS motor is heard.

NG

DTC C1251/51 Open in Pump Motor Circuit

DTC No. DTC Detection Condition Trouble Area

C1251/51ABS pump motor is not operating normally during initial

check.• ABS pump motor circuit

• Brake actuator assembly

1INSPECT SKID CONTROL ECU (GND TERMINAL CONTINUITY)

C058919E26

Tester Connection Specified Condition

S3-1 (GND1) - Body ground Below 1

S3-23 (GND2) - Body ground Below 1

REPAIR OR REPLACE HARNESS OR

CONNECTOR (GND CIRCUIT)

2PERFORM ACTIVE TEST BY INTELLIGENT TESTER (ABS MOTOR RELAY)

Item (Display) Vehicle Condition / Test Details Diagnostic Note

ABS MOT RELAY Turns ABS motor relay ON / OFF Operating sound of motor is heard

REPLACE BRAKE ACTUATOR ASSEMBLY

Page 2409 of 3000

BC–48BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

OK

(a) Clear the DTCs (See page BC-10).

(b) Start the engine.

(c) Drive the vehicle at the speed of 6 km/h (4 mph) or more.

(d) Check that the same DTC is recorded (See page BC-

10).

HINT:

• Reinstall the sensors, connectors, etc. and restore the

vehicle to its prior condition before rechecking for

DTCs.

• If a speed signal of 6 km/h (4 mph) or more is input to

the skid control ECU, with the ignition switch on and

the stop light switch off, the ECU performs self-

diagnosis of the motor and solenoid circuits.

Result

HINT:

• If any DTCs are output while jiggling a connector or

wire harness of the brake actuator (skid control ECU),

inspect and repair the connector or wire harness.

• If the normal system code is output, slightly jiggle the

connectors, wire harnesses, and fuses of the brake

actuator assembly. Make sure that no DTCs are

output.

• These DTCs may be stored due to a malfunction in

the connector terminal connection, etc.

B

A

3RECONFIRM DTC

Condition Proceed to

DTC (C1251/51) is outputA

DTC (C1251/51) not outputB

END

REPLACE BRAKE ACTUATOR ASSEMBLY