engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 333 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–405

ES

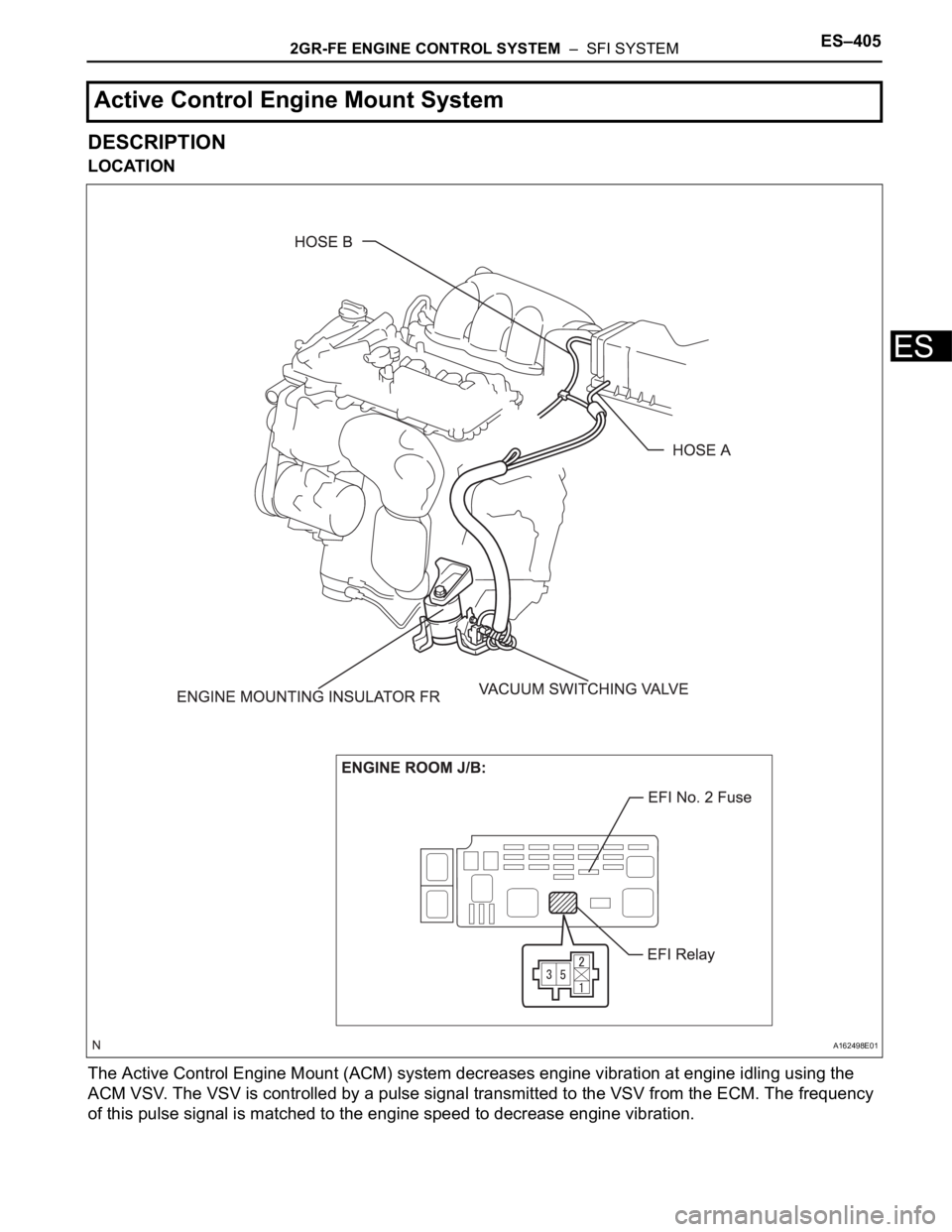

DESCRIPTION

LOCATION

The Active Control Engine Mount (ACM) system decreases engine vibration at engine idling using the

ACM VSV. The VSV is controlled by a pulse signal transmitted to the VSV from the ECM. The frequency

of this pulse signal is matched to the engine speed to decrease engine vibration.

Active Control Engine Mount System

A162498E01

Page 334 of 3000

ES–4062GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

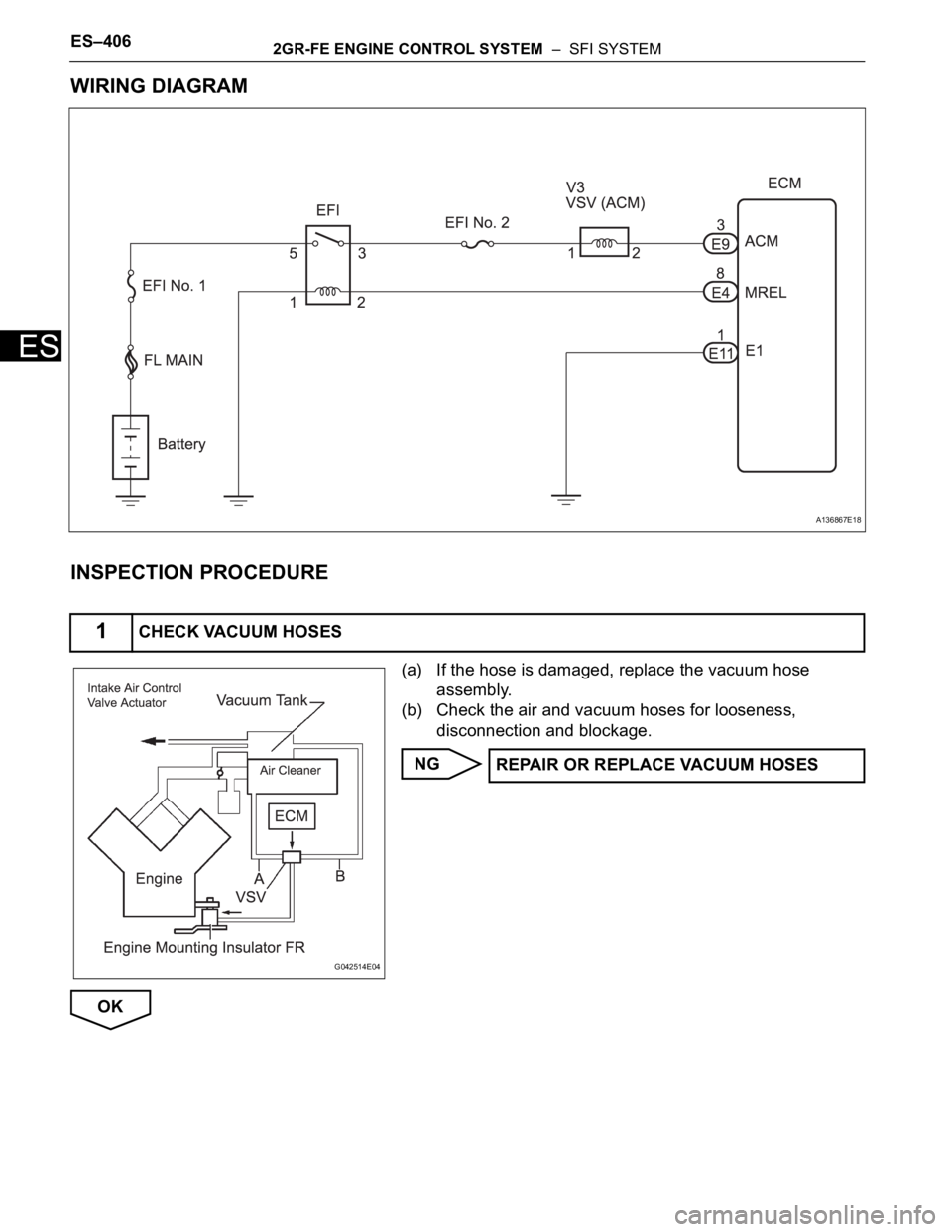

WIRING DIAGRAM

INSPECTION PROCEDURE

(a) If the hose is damaged, replace the vacuum hose

assembly.

(b) Check the air and vacuum hoses for looseness,

disconnection and blockage.

NG

OK

1CHECK VACUUM HOSES

A136867E18

G042514E04

REPAIR OR REPLACE VACUUM HOSES

Page 335 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–407

ES

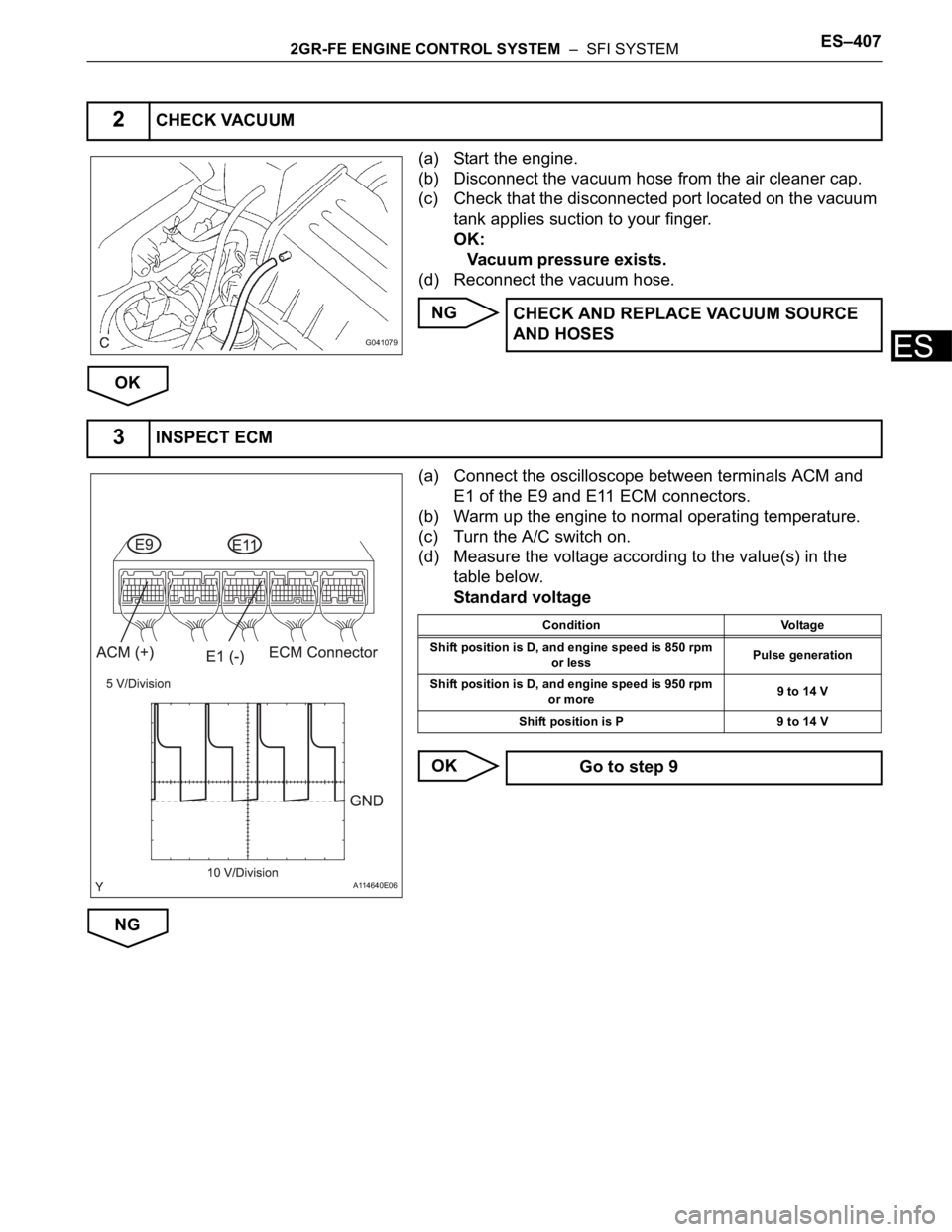

(a) Start the engine.

(b) Disconnect the vacuum hose from the air cleaner cap.

(c) Check that the disconnected port located on the vacuum

tank applies suction to your finger.

OK:

Vacuum pressure exists.

(d) Reconnect the vacuum hose.

NG

OK

(a) Connect the oscilloscope between terminals ACM and

E1 of the E9 and E11 ECM connectors.

(b) Warm up the engine to normal operating temperature.

(c) Turn the A/C switch on.

(d) Measure the voltage according to the value(s) in the

table below.

Standard voltage

OK

NG

2CHECK VACUUM

G041079

CHECK AND REPLACE VACUUM SOURCE

AND HOSES

3INSPECT ECM

A114640E06

Condition Voltage

Shift position is D, and engine speed is 850 rpm

or lessPulse generation

Shift position is D, and engine speed is 950 rpm

or more9 to 14 V

Shift position is P 9 to 14 V

Go to step 9

Page 336 of 3000

ES–4082GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

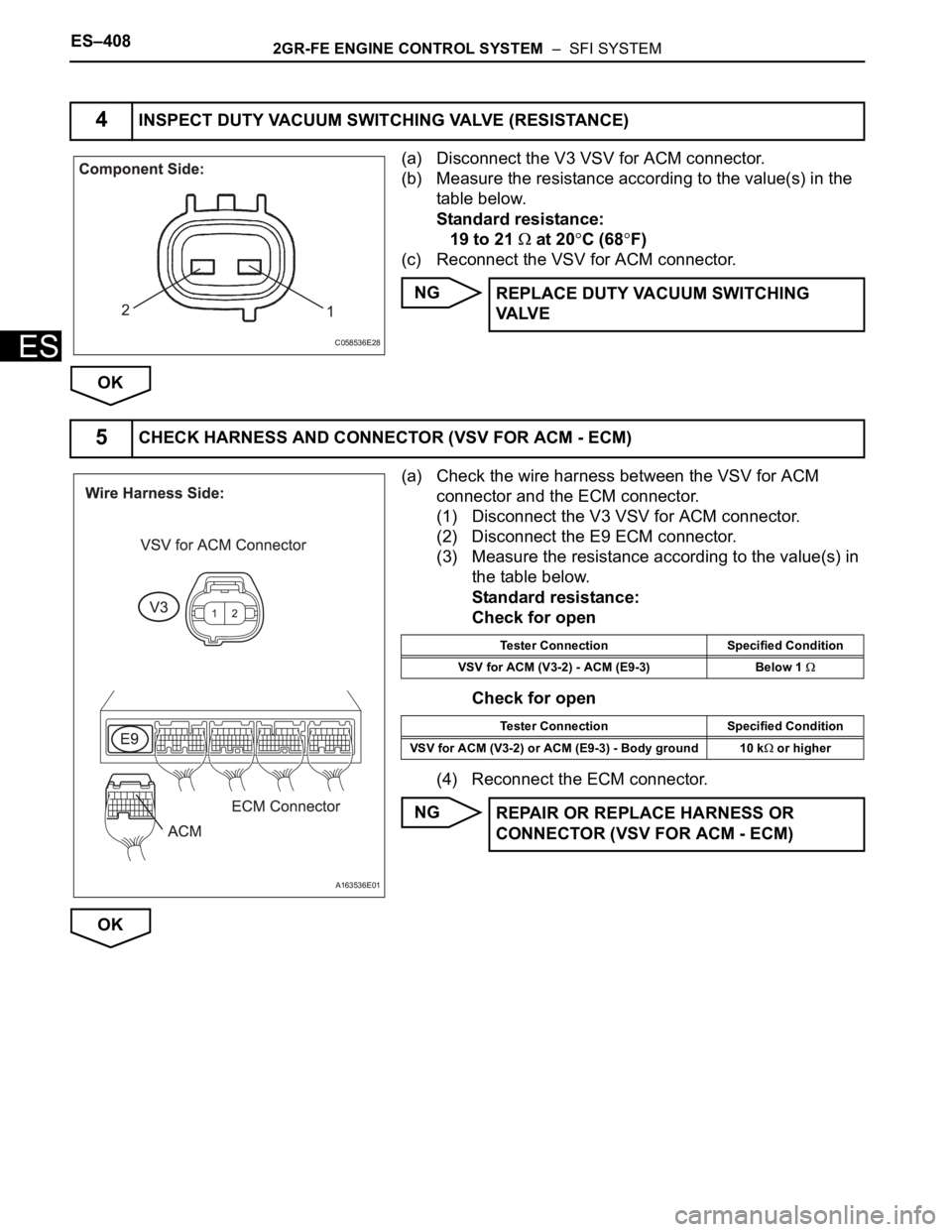

(a) Disconnect the V3 VSV for ACM connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

19 to 21

at 20C (68F)

(c) Reconnect the VSV for ACM connector.

NG

OK

(a) Check the wire harness between the VSV for ACM

connector and the ECM connector.

(1) Disconnect the V3 VSV for ACM connector.

(2) Disconnect the E9 ECM connector.

(3) Measure the resistance according to the value(s) in

the table below.

Standard resistance:

Check for open

Check for open

(4) Reconnect the ECM connector.

NG

OK

4INSPECT DUTY VACUUM SWITCHING VALVE (RESISTANCE)

C058536E28

REPLACE DUTY VACUUM SWITCHING

VA LV E

5CHECK HARNESS AND CONNECTOR (VSV FOR ACM - ECM)

A163536E01

Tester Connection Specified Condition

VSV for ACM (V3-2) - ACM (E9-3) Below 1

Tester Connection Specified Condition

VSV for ACM (V3-2) or ACM (E9-3) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (VSV FOR ACM - ECM)

Page 337 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–409

ES

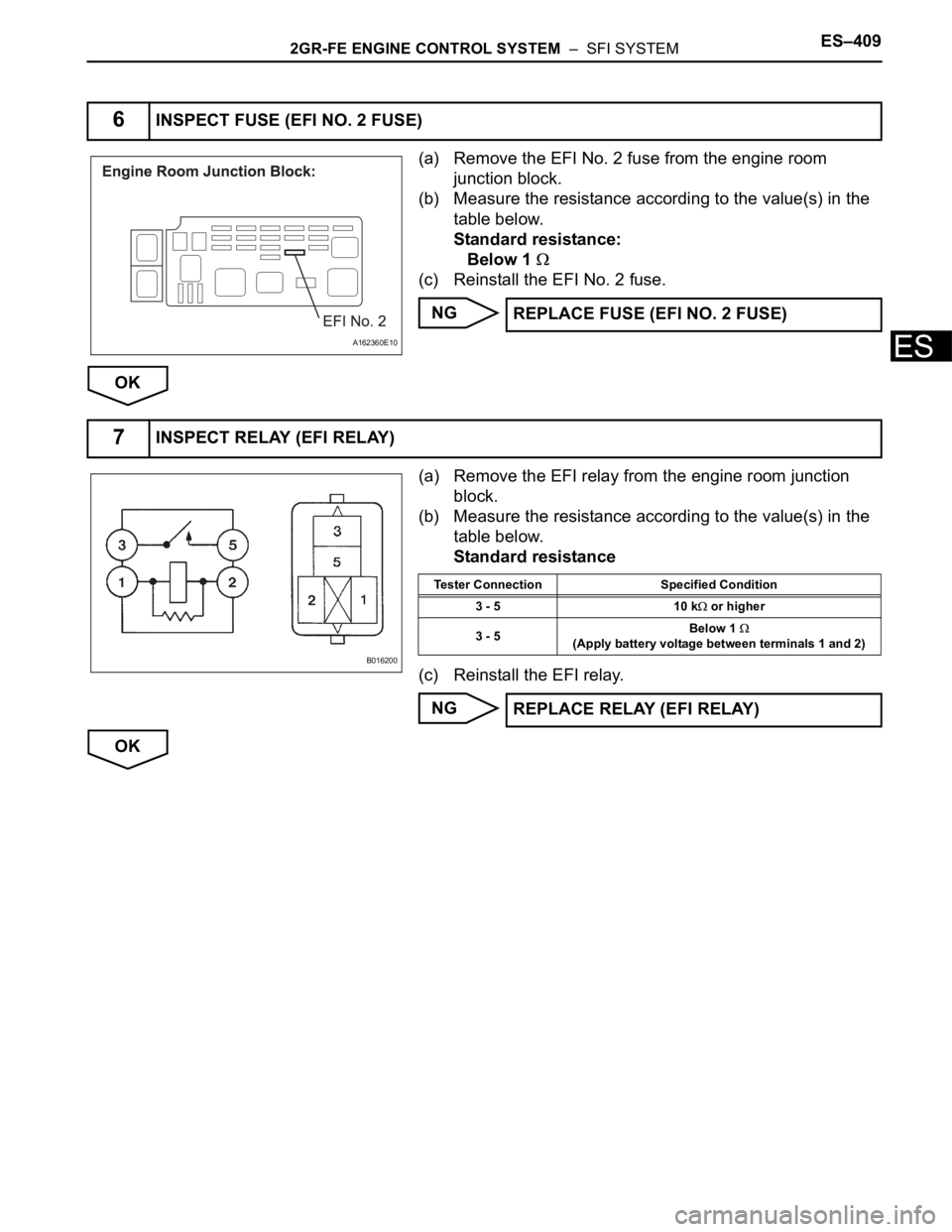

(a) Remove the EFI No. 2 fuse from the engine room

junction block.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Below 1

(c) Reinstall the EFI No. 2 fuse.

NG

OK

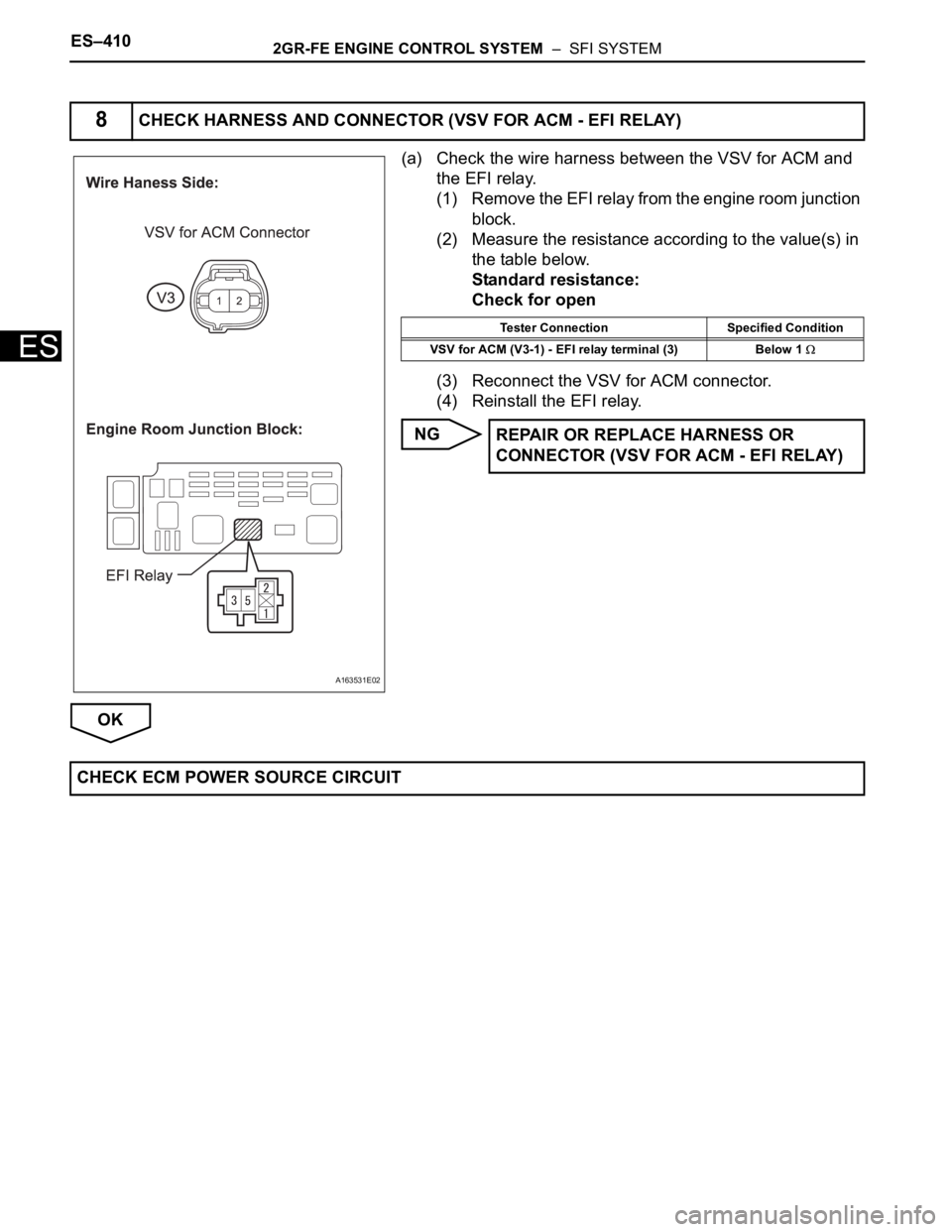

(a) Remove the EFI relay from the engine room junction

block.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(c) Reinstall the EFI relay.

NG

OK

6INSPECT FUSE (EFI NO. 2 FUSE)

A162360E10

REPLACE FUSE (EFI NO. 2 FUSE)

7INSPECT RELAY (EFI RELAY)

B016200

Tester Connection Specified Condition

3 - 5 10 k

or higher

3 - 5Below 1

(Apply battery voltage between terminals 1 and 2)

REPLACE RELAY (EFI RELAY)

Page 338 of 3000

ES–4102GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

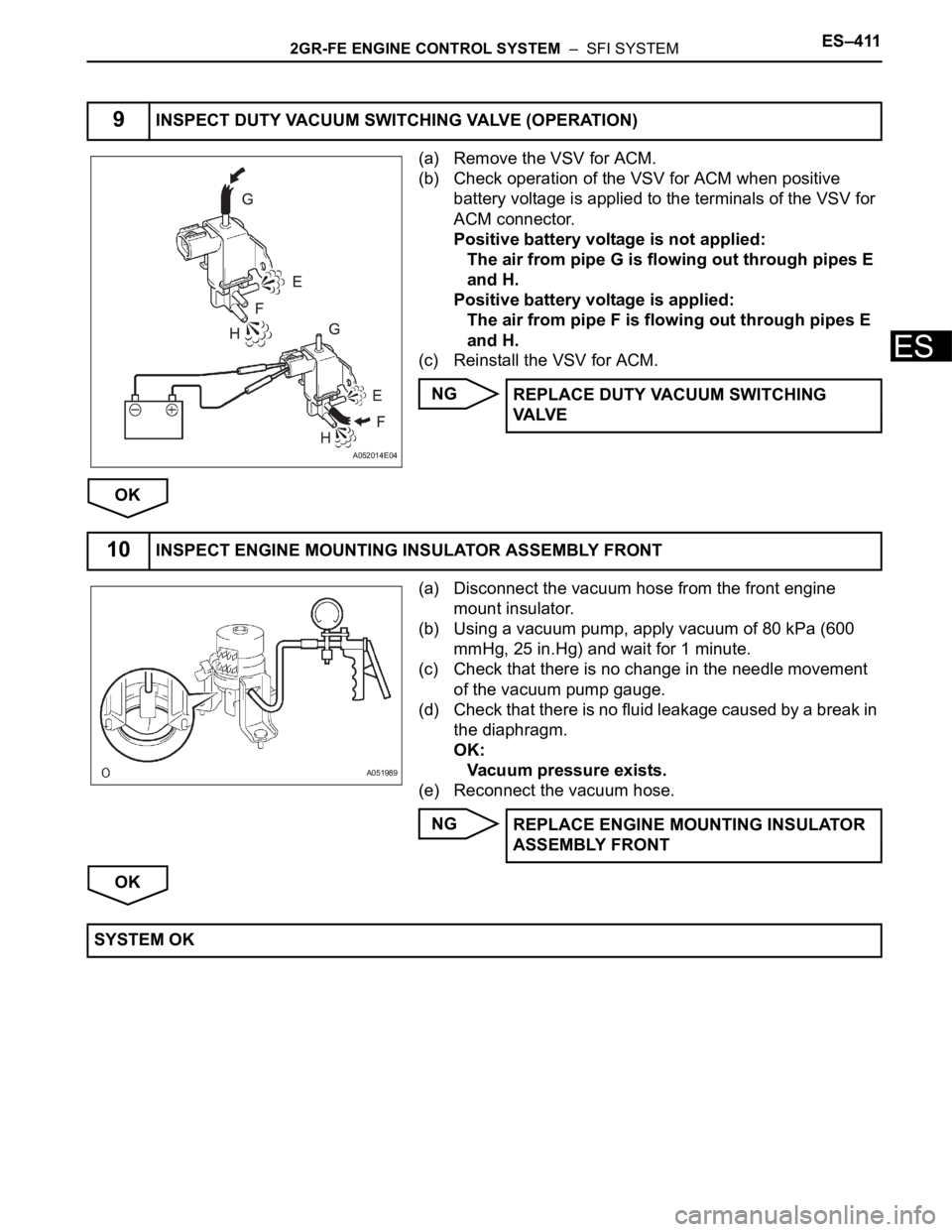

(a) Check the wire harness between the VSV for ACM and

the EFI relay.

(1) Remove the EFI relay from the engine room junction

block.

(2) Measure the resistance according to the value(s) in

the table below.

Standard resistance:

Check for open

(3) Reconnect the VSV for ACM connector.

(4) Reinstall the EFI relay.

NG

OK

8CHECK HARNESS AND CONNECTOR (VSV FOR ACM - EFI RELAY)

A163531E02

Tester Connection Specified Condition

VSV for ACM (V3-1) - EFI relay terminal (3) Below 1

REPAIR OR REPLACE HARNESS OR

CONNECTOR (VSV FOR ACM - EFI RELAY)

CHECK ECM POWER SOURCE CIRCUIT

Page 339 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–411

ES

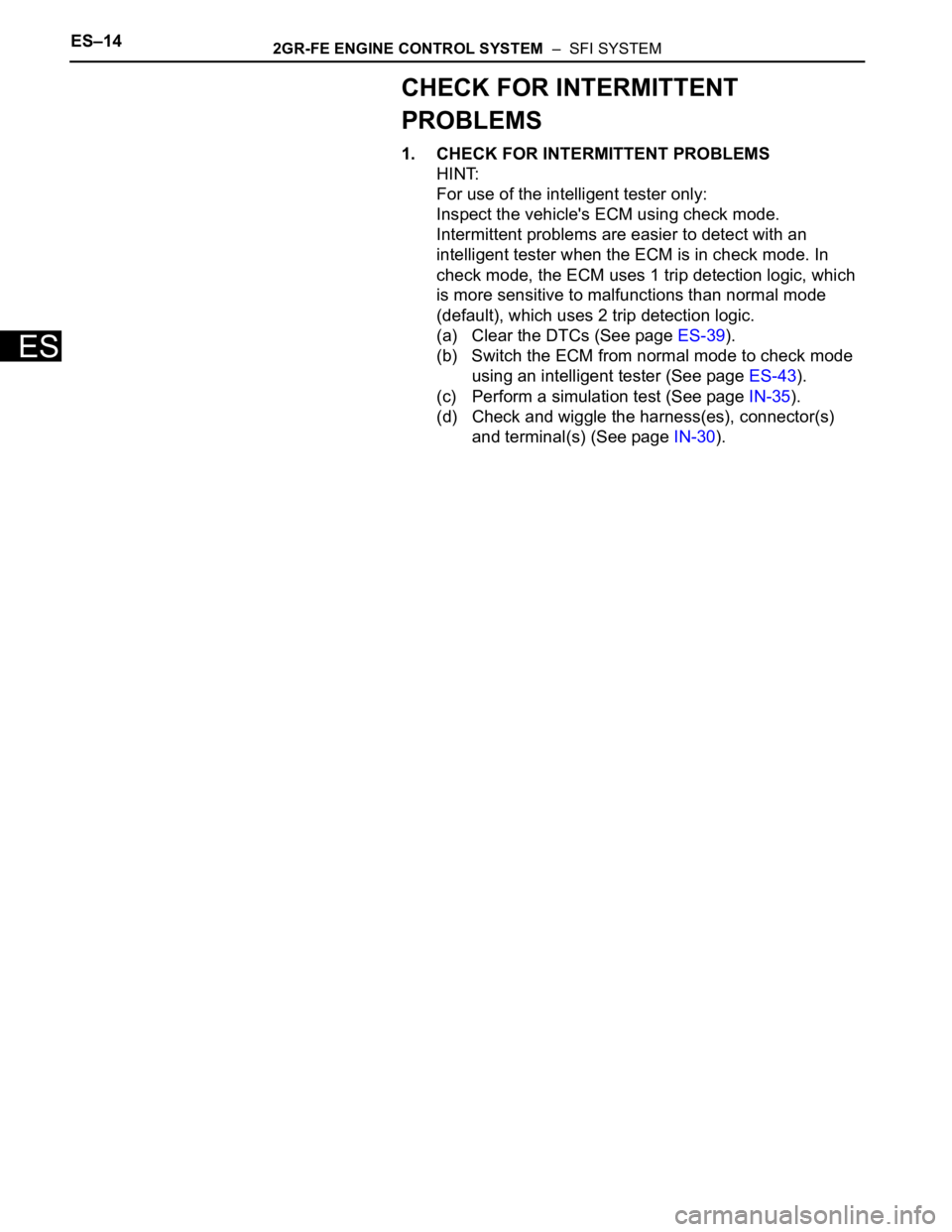

(a) Remove the VSV for ACM.

(b) Check operation of the VSV for ACM when positive

battery voltage is applied to the terminals of the VSV for

ACM connector.

Positive battery voltage is not applied:

The air from pipe G is flowing out through pipes E

and H.

Positive battery voltage is applied:

The air from pipe F is flowing out through pipes E

and H.

(c) Reinstall the VSV for ACM.

NG

OK

(a) Disconnect the vacuum hose from the front engine

mount insulator.

(b) Using a vacuum pump, apply vacuum of 80 kPa (600

mmHg, 25 in.Hg) and wait for 1 minute.

(c) Check that there is no change in the needle movement

of the vacuum pump gauge.

(d) Check that there is no fluid leakage caused by a break in

the diaphragm.

OK:

Vacuum pressure exists.

(e) Reconnect the vacuum hose.

NG

OK

9INSPECT DUTY VACUUM SWITCHING VALVE (OPERATION)

A052014E04

REPLACE DUTY VACUUM SWITCHING

VA LV E

10INSPECT ENGINE MOUNTING INSULATOR ASSEMBLY FRONT

A051989

REPLACE ENGINE MOUNTING INSULATOR

ASSEMBLY FRONT

SYSTEM OK

Page 340 of 3000

ES–142GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

CHECK FOR INTERMITTENT

PROBLEMS

1. CHECK FOR INTERMITTENT PROBLEMS

HINT:

For use of the intelligent tester only:

Inspect the vehicle's ECM using check mode.

Intermittent problems are easier to detect with an

intelligent tester when the ECM is in check mode. In

check mode, the ECM uses 1 trip detection logic, which

is more sensitive to malfunctions than normal mode

(default), which uses 2 trip detection logic.

(a) Clear the DTCs (See page ES-39).

(b) Switch the ECM from normal mode to check mode

using an intelligent tester (See page ES-43).

(c) Perform a simulation test (See page IN-35).

(d) Check and wiggle the harness(es), connector(s)

and terminal(s) (See page IN-30).

Page 341 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–15

ES

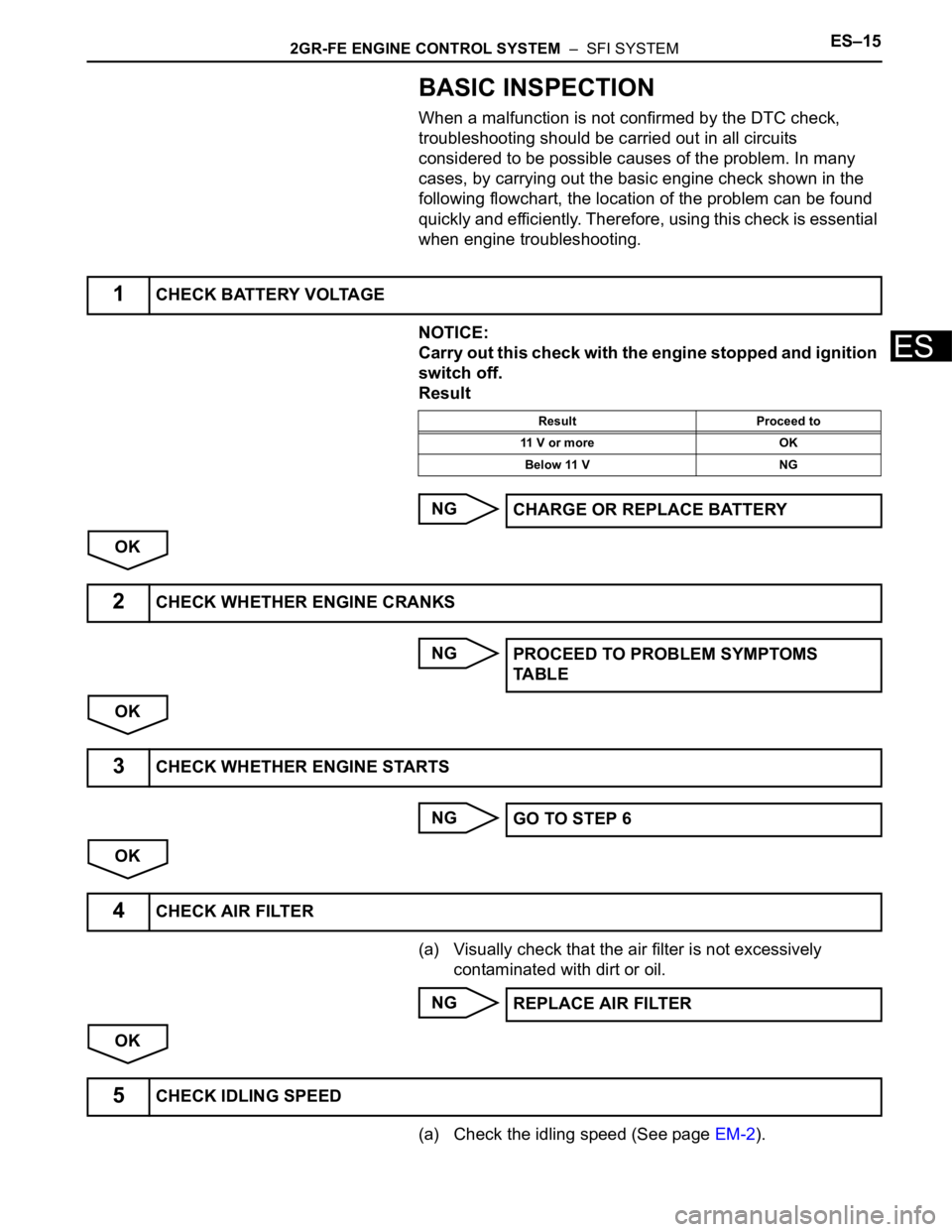

BASIC INSPECTION

When a malfunction is not confirmed by the DTC check,

troubleshooting should be carried out in all circuits

considered to be possible causes of the problem. In many

cases, by carrying out the basic engine check shown in the

following flowchart, the location of the problem can be found

quickly and efficiently. Therefore, using this check is essential

when engine troubleshooting.

NOTICE:

Carry out this check with the engine stopped and ignition

switch off.

Result

NG

OK

NG

OK

NG

OK

(a) Visually check that the air filter is not excessively

contaminated with dirt or oil.

NG

OK

(a) Check the idling speed (See page EM-2).

1CHECK BATTERY VOLTAGE

Result Proceed to

11 V or more OK

Below 11 V NG

CHARGE OR REPLACE BATTERY

2CHECK WHETHER ENGINE CRANKS

PROCEED TO PROBLEM SYMPTOMS

TA B L E

3CHECK WHETHER ENGINE STARTS

GO TO STEP 6

4CHECK AIR FILTER

REPLACE AIR FILTER

5CHECK IDLING SPEED

Page 342 of 3000

ES–162GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

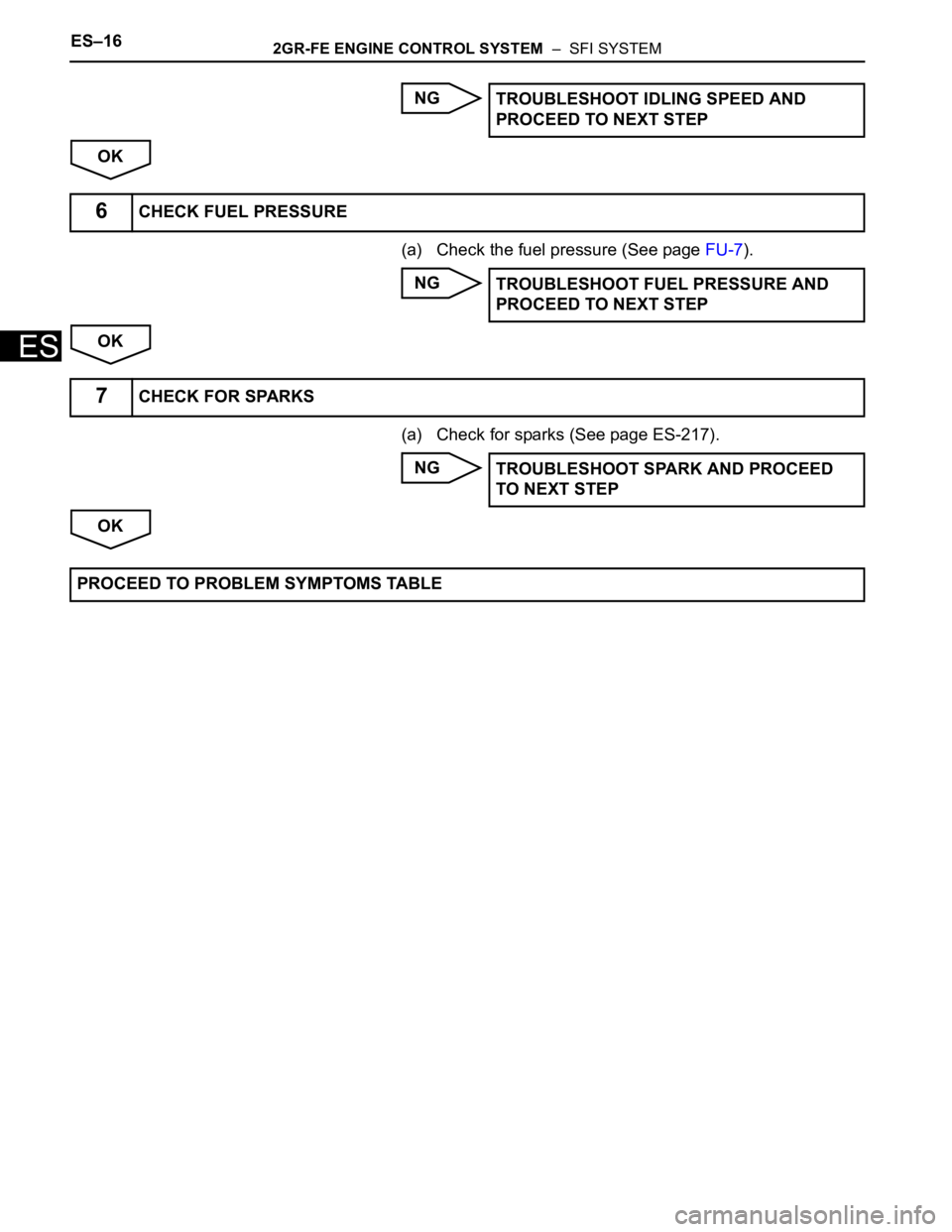

NG

OK

(a) Check the fuel pressure (See page FU-7).

NG

OK

(a) Check for sparks (See page ES-217).

NG

OKTROUBLESHOOT IDLING SPEED AND

PROCEED TO NEXT STEP

6CHECK FUEL PRESSURE

TROUBLESHOOT FUEL PRESSURE AND

PROCEED TO NEXT STEP

7CHECK FOR SPARKS

TROUBLESHOOT SPARK AND PROCEED

TO NEXT STEP

PROCEED TO PROBLEM SYMPTOMS TABLE