sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 461 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–155

ESHINT:

• When any of these DTCs are set, check the throttle valve opening angle by selecting the following

menu items on the intelligent tester: DIAGNOSIS / ENHANCED OBD II / DATA LIST / ETCS /

THROTTLE POS AND THROTTLE POS #2.

• THROTTLE POS denotes the VTA1 signal (expressed in percentages), and THROTTLE POS #2

denotes the VTA2 signal (expressed in voltages).

Reference (Normal Condition)

MONITOR DESCRIPTION

The ECM uses the Throttle Position (TP) sensor to monitor the throttle valve opening angle. There are

several checks that the ECM performs to confirm the proper operation of the TP sensor.

• A specific voltage difference is expected between the sensor terminals, VTA1 and VTA2, for each

throttle valve opening angle. If the difference between VTA1 and VTA2 is incorrect, the ECM interprets

this as a malfunction in the sensor, and sets a DTC.

• VTA1 and VTA2 each have a specific voltage range. If VTA1 or VTA2 is outside the normal operating

range, the ECM interprets this as a malfunction in the sensor, and sets a DTC.

• VTA1 and VTA2 should never be close to the same voltage level. If VTA1 is within 0.02 V of VTA2, the

ECM determines that there is a short circuit in the sensor, and sets a DTC.

If the malfunction is not repaired successfully, a DTC is set 2 seconds after the engine is next started.

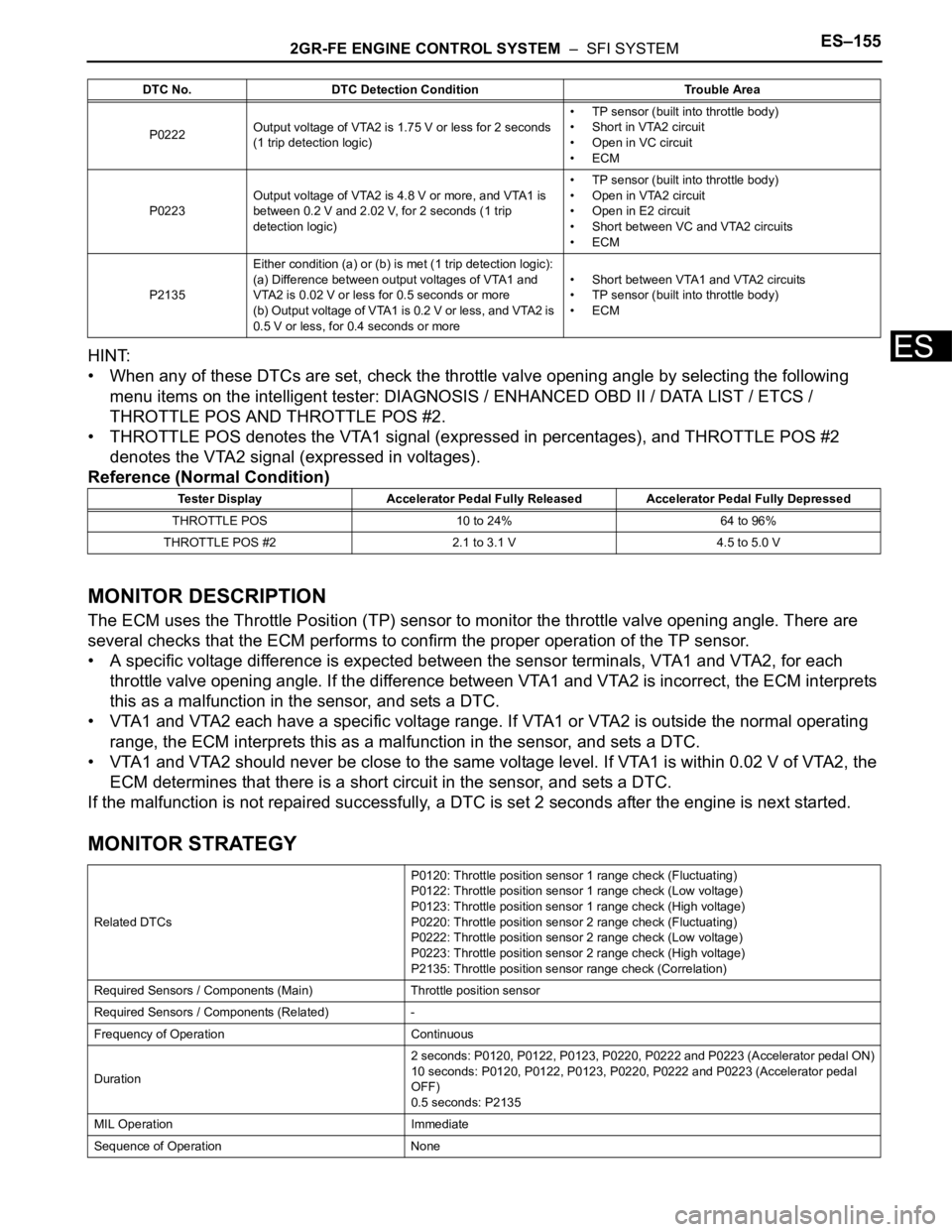

MONITOR STRATEGY

P0222Output voltage of VTA2 is 1.75 V or less for 2 seconds

(1 trip detection logic)• TP sensor (built into throttle body)

• Short in VTA2 circuit

• Open in VC circuit

•ECM

P0223Output voltage of VTA2 is 4.8 V or more, and VTA1 is

between 0.2 V and 2.02 V, for 2 seconds (1 trip

detection logic)• TP sensor (built into throttle body)

• Open in VTA2 circuit

• Open in E2 circuit

• Short between VC and VTA2 circuits

•ECM

P2135Either condition (a) or (b) is met (1 trip detection logic):

(a) Difference between output voltages of VTA1 and

VTA2 is 0.02 V or less for 0.5 seconds or more

(b) Output voltage of VTA1 is 0.2 V or less, and VTA2 is

0.5 V or less, for 0.4 seconds or more• Short between VTA1 and VTA2 circuits

• TP sensor (built into throttle body)

•ECM

Tester Display Accelerator Pedal Fully Released Accelerator Pedal Fully Depressed

THROTTLE POS 10 to 24% 64 to 96%

THROTTLE POS #2 2.1 to 3.1 V 4.5 to 5.0 V

Related DTCsP0120: Throttle position sensor 1 range check (Fluctuating)

P0122: Throttle position sensor 1 range check (Low voltage)

P0123: Throttle position sensor 1 range check (High voltage)

P0220: Throttle position sensor 2 range check (Fluctuating)

P0222: Throttle position sensor 2 range check (Low voltage)

P0223: Throttle position sensor 2 range check (High voltage)

P2135: Throttle position sensor range check (Correlation)

Required Sensors / Components (Main) Throttle position sensor

Required Sensors / Components (Related) -

Frequency of Operation Continuous

Duration2 seconds: P0120, P0122, P0123, P0220, P0222 and P0223 (Accelerator pedal ON)

10 seconds: P0120, P0122, P0123, P0220, P0222 and P0223 (Accelerator pedal

OFF)

0.5 seconds: P2135

MIL Operation Immediate

Sequence of Operation NoneDTC No. DTC Detection Condition Trouble Area

Page 464 of 3000

ES–1582GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

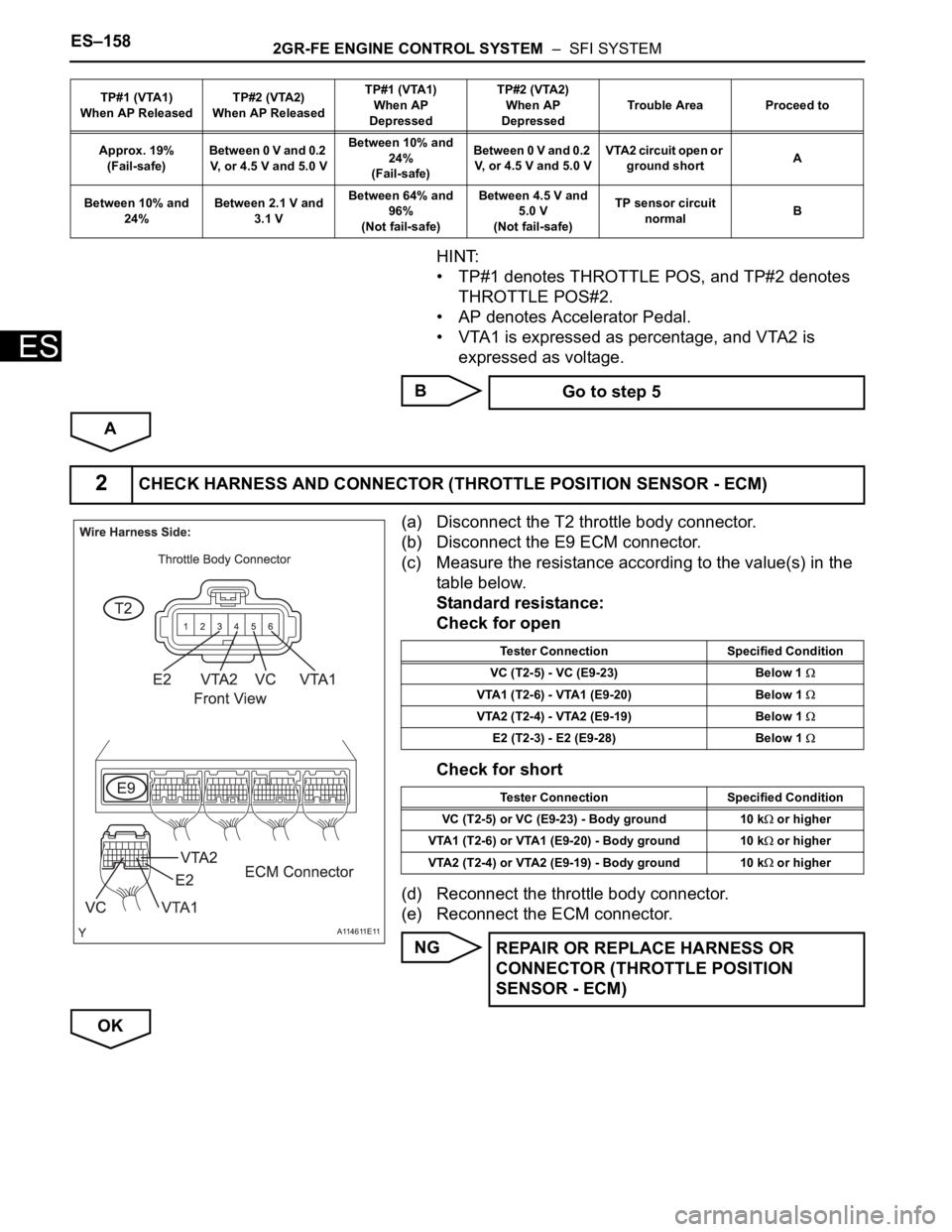

HINT:

• TP#1 denotes THROTTLE POS, and TP#2 denotes

THROTTLE POS#2.

• AP denotes Accelerator Pedal.

• VTA1 is expressed as percentage, and VTA2 is

expressed as voltage.

B

A

(a) Disconnect the T2 throttle body connector.

(b) Disconnect the E9 ECM connector.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Check for open

Check for short

(d) Reconnect the throttle body connector.

(e) Reconnect the ECM connector.

NG

OK

Approx. 19%

(Fail-safe)Between 0 V and 0.2

V, or 4.5 V and 5.0 VBetween 10% and

24%

(Fail-safe)B e t w e e n 0 V a n d 0 . 2

V, or 4.5 V and 5.0 VVTA2 circuit open or

ground shortA

Between 10% and

24%Between 2.1 V and

3.1 VBetween 64% and

96%

(Not fail-safe)Between 4.5 V and

5.0 V

(Not fail-safe)TP sensor circuit

normalB TP#1 (VTA1)

When AP ReleasedTP#2 (VTA2)

When AP ReleasedTP#1 (VTA1)

When AP

DepressedTP#2 (VTA2)

When AP

DepressedTrouble Area Proceed to

Go to step 5

2CHECK HARNESS AND CONNECTOR (THROTTLE POSITION SENSOR - ECM)

A114611E11

Tester Connection Specified Condition

VC (T2-5) - VC (E9-23) Below 1

VTA1 (T2-6) - VTA1 (E9-20) Below 1

VTA2 (T2-4) - VTA2 (E9-19) Below 1

E2 (T2-3) - E2 (E9-28) Below 1

Tester Connection Specified Condition

VC (T2-5) or VC (E9-23) - Body ground 10 k

or higher

VTA1 (T2-6) or VTA1 (E9-20) - Body ground 10 k

or higher

VTA2 (T2-4) or VTA2 (E9-19) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (THROTTLE POSITION

SENSOR - ECM)

Page 465 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–159

ES

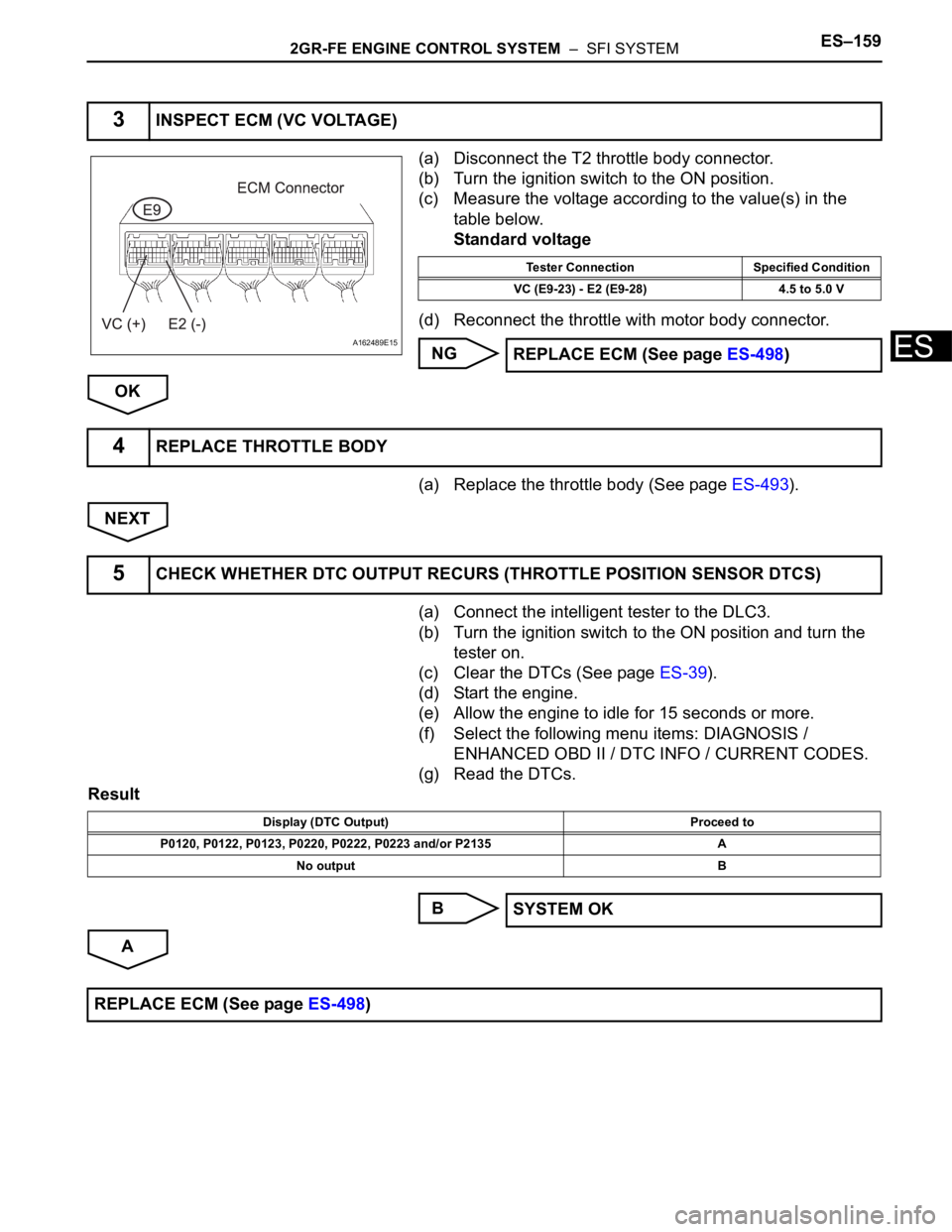

(a) Disconnect the T2 throttle body connector.

(b) Turn the ignition switch to the ON position.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

(d) Reconnect the throttle with motor body connector.

NG

OK

(a) Replace the throttle body (See page ES-493).

NEXT

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Clear the DTCs (See page ES-39).

(d) Start the engine.

(e) Allow the engine to idle for 15 seconds or more.

(f) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(g) Read the DTCs.

Result

B

A

3INSPECT ECM (VC VOLTAGE)

A162489E15

Tester Connection Specified Condition

VC (E9-23) - E2 (E9-28) 4.5 to 5.0 V

REPLACE ECM (See page ES-498)

4REPLACE THROTTLE BODY

5CHECK WHETHER DTC OUTPUT RECURS (THROTTLE POSITION SENSOR DTCS)

Display (DTC Output) Proceed to

P0120, P0122, P0123, P0220, P0222, P0223 and/or P2135 A

No output B

SYSTEM OK

REPLACE ECM (See page ES-498)

Page 466 of 3000

ES–1602GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

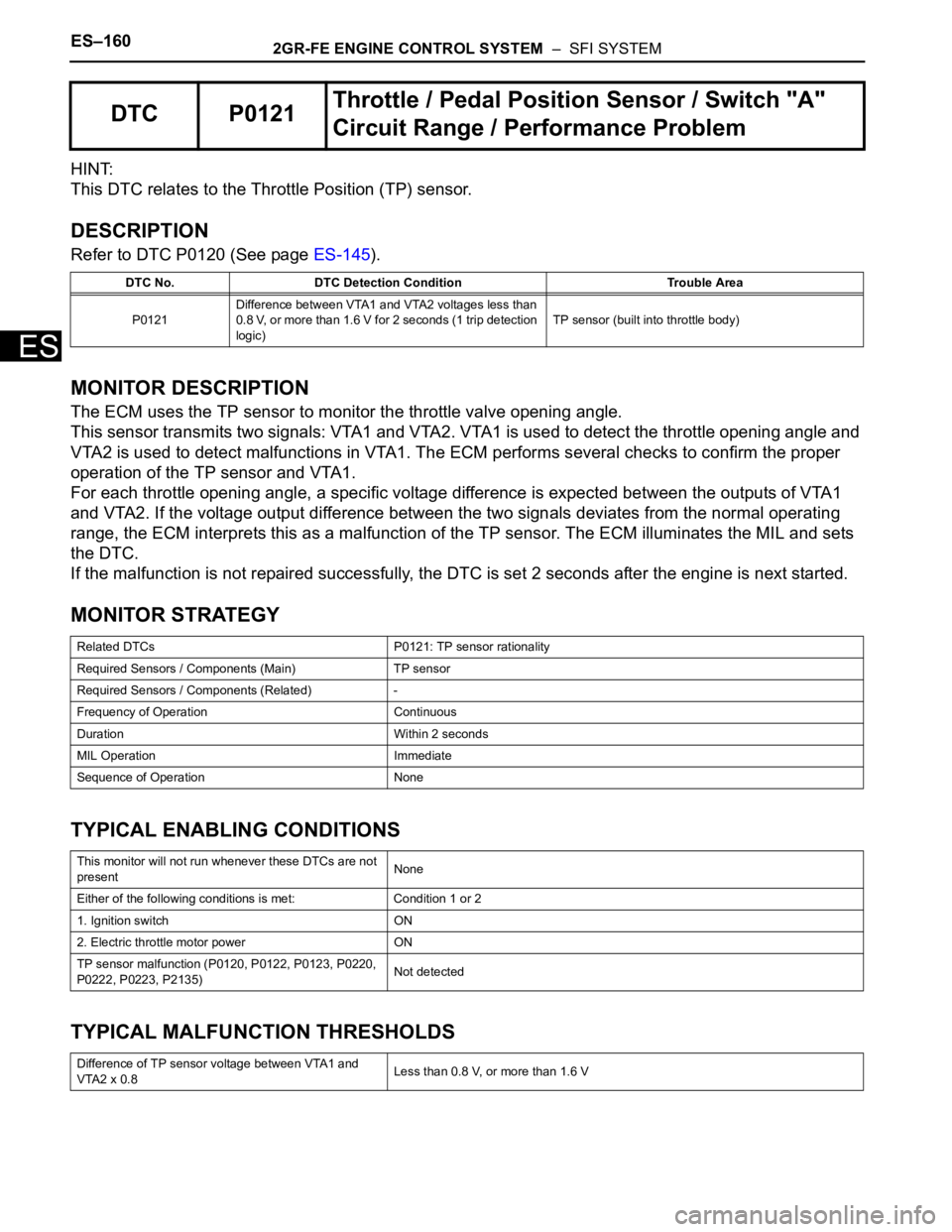

HINT:

This DTC relates to the Throttle Position (TP) sensor.

DESCRIPTION

Refer to DTC P0120 (See page ES-145).

MONITOR DESCRIPTION

The ECM uses the TP sensor to monitor the throttle valve opening angle.

This sensor transmits two signals: VTA1 and VTA2. VTA1 is used to detect the throttle opening angle and

VTA2 is used to detect malfunctions in VTA1. The ECM performs several checks to confirm the proper

operation of the TP sensor and VTA1.

For each throttle opening angle, a specific voltage difference is expected between the outputs of VTA1

and VTA2. If the voltage output difference between the two signals deviates from the normal operating

range, the ECM interprets this as a malfunction of the TP sensor. The ECM illuminates the MIL and sets

the DTC.

If the malfunction is not repaired successfully, the DTC is set 2 seconds after the engine is next started.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

DTC P0121Throttle / Pedal Position Sensor / Switch "A"

Circuit Range / Performance Problem

DTC No. DTC Detection Condition Trouble Area

P0121Difference between VTA1 and VTA2 voltages less than

0.8 V, or more than 1.6 V for 2 seconds (1 trip detection

logic)TP sensor (built into throttle body)

Related DTCs P0121: TP sensor rationality

Required Sensors / Components (Main) TP sensor

Required Sensors / Components (Related) -

Frequency of Operation Continuous

Duration Within 2 seconds

MIL Operation Immediate

Sequence of Operation None

This monitor will not run whenever these DTCs are not

presentNone

Either of the following conditions is met: Condition 1 or 2

1. Ignition switch ON

2. Electric throttle motor power ON

TP sensor malfunction (P0120, P0122, P0123, P0220,

P0222, P0223, P2135)Not detected

Difference of TP sensor voltage between VTA1 and

VTA2 x 0.8Less than 0.8 V, or more than 1.6 V

Page 468 of 3000

ES–1622GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

DESCRIPTION

Refer to DTC P0115 (See page ES-133).

MONITOR DESCRIPTION

The resistance of the ECT sensor varies in proportion to the actual ECT. The ECM supplies a constant

voltage to the sensor and monitors the signal output voltage of the sensor. The signal voltage output

varies according to the changing resistance of the sensor. After the engine is started, the ECT is

monitored through this signal. If the ECT sensor indicates that the engine is not yet warm enough for

closed-loop fuel control, despite a specified period of time having elapsed since the engine was started,

the ECM interprets this as a malfunction in the sensor or cooling system and sets the DTC.

Example:

The ECT is 0

C (32F) at engine start. After 5 minutes running time, the ECT sensor still indicates that the

engine is not warm enough to begin closed-loop fuel (air-fuel ratio feedback) control. The ECM interprets

this as a malfunction in the sensor or cooling system and sets the DTC.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

WIRING DIAGRAM

Refer to DTC P0115 (See page ES-134).

DTC P0125Insufficient Coolant Temperature for Closed

Loop Fuel Control

DTC No. DTC Detection Condition Trouble Area

P0125Engine coolant temperature (ECT) does not reach

closed-loop enabling temperature for 20 minutes (this

period varies with engine start ECT)• Cooling system

• Engine coolant temperature sensor

• Thermostat

Related DTCs P0125: Insufficient engine coolant temperature for closed-loop fuel control

Required Sensors / Components (Main) Thermostat, cooling system

Required Sensors / Components (Related) Engine coolant temperature sensor and mass air flow meter

Frequency of Operation Continuous

Duration78 seconds: Engine coolant temperature at engine start -8.34

C (17F) or more

131.3 seconds: Engine coolant temperature at engine start -19.45 to -8.34C (-3 to

17

F)

20 minutes: Engine coolant temperature at engine start less than -19.45

C (-3F)

MIL Operation 2 driving cycles

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentP0100, P0101, P0102, P0103 (MAF) sensor, P0110, P0111, P0112, P0113 (IAT

sensor), P0115, P0116, P0117, P0118 (ECT sensor)

Fuel cut OFF

Engine Running

Time until actual engine coolant temperature reaches

closed-loop fuel control enabling temperature78 seconds or more: Engine coolant temperature at engine start -8.34

C (17F) or

more

131.3 seconds or more: Engine coolant temperature at engine start -19.45 to -8.34

C

(-3 to 17

F)

20 minutes or more: Engine coolant temperature at engine start less than -19.45C (-

3

F)

Page 469 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–163

ES

INSPECTION PROCEDURE

HINT:

• If any of DTCs P0115, P0116, P0117 or P0118 are set simultaneously with DTC P0125, the Engine

Coolant Temperature (ECT) sensor may have an open or a short circuit. Troubleshoot those DTCs first.

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the

time of a malfunction.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(e) Read the DTCs.

Result

HINT:

If any DTCs other than P0125 are output, troubleshoot

those DTCs first.

B

A

(a) Remove the thermostat (See page CO-16).

(b) Check the valve opening temperature of the thermostat

(See page CO-17).

Standard:

80 to 84

C (176 to 183F)

HINT:

In addition to the above check, confirm that the valve is

completely closed when the temperature is below the

standard.

(c) Reinstall the thermostat (See page CO-17).

NG

OK

1CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0125)

Display (DTC Output) Proceed to

P0125 A

P0125 and other DTCs B

GO TO DTC CHART (See page ES-56)

2INSPECT THERMOSTAT

REPLACE THERMOSTAT (See page CO-16)

Page 470 of 3000

ES–1642GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

(a) Check for defects in the cooling system that might cause

the system to be too cold, such as abnormal radiator fan

operation or any modifications.

NG

OK

3CHECK COOLING SYSTEM

REPAIR OR REPLACE COOLING SYSTEM

REPLACE ENGINE COOLANT TEMPERATURE SENSOR (See page ES-516)

Page 471 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–165

ES

HINT:

This DTC relates to the thermostat.

DESCRIPTION

This DTC is set when the Engine Coolant Temperature (ECT) does not reach 75C (167F) despite

sufficient engine warm-up time.

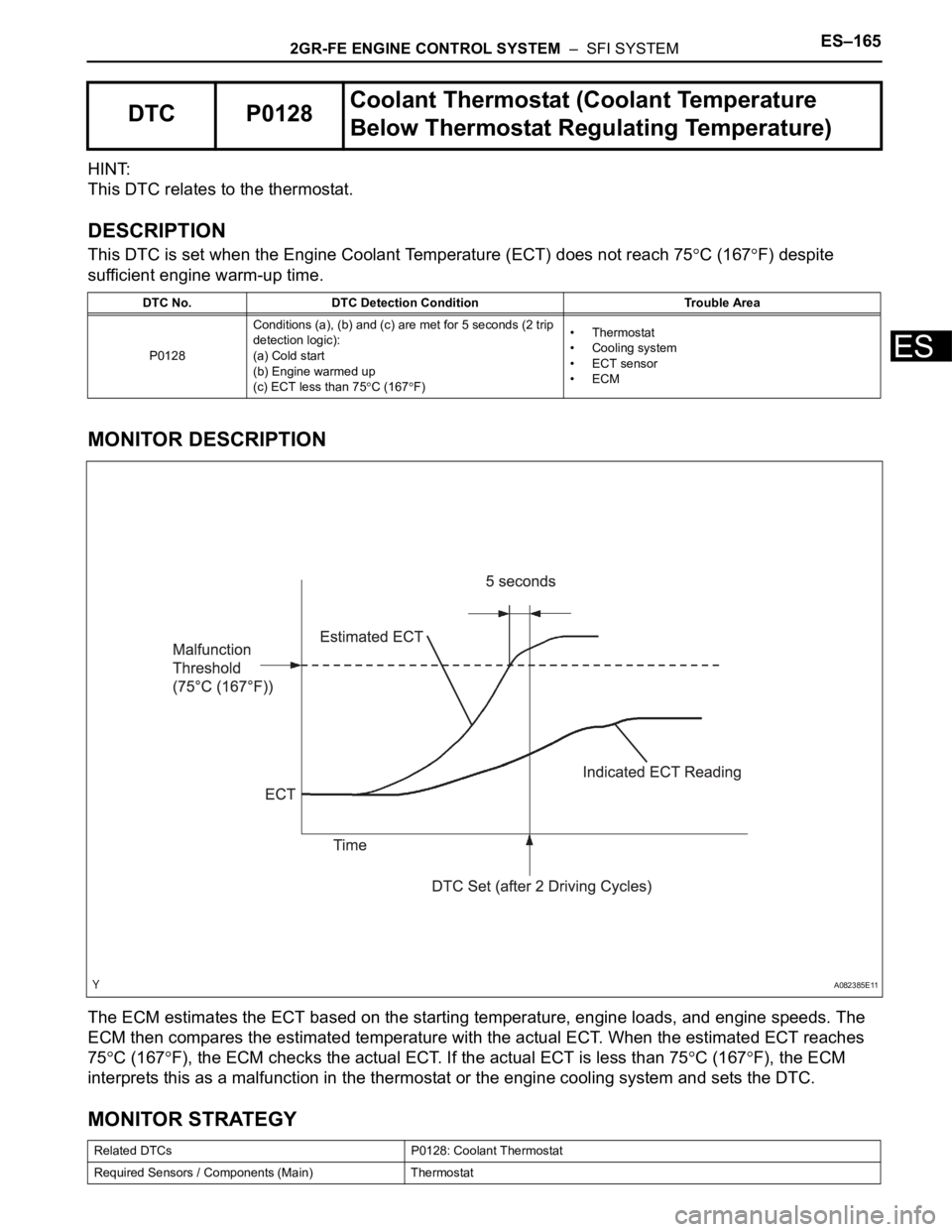

MONITOR DESCRIPTION

The ECM estimates the ECT based on the starting temperature, engine loads, and engine speeds. The

ECM then compares the estimated temperature with the actual ECT. When the estimated ECT reaches

75

C (167F), the ECM checks the actual ECT. If the actual ECT is less than 75C (167F), the ECM

interprets this as a malfunction in the thermostat or the engine cooling system and sets the DTC.

MONITOR STRATEGY

DTC P0128Coolant Thermostat (Coolant Temperature

Below Thermostat Regulating Temperature)

DTC No. DTC Detection Condition Trouble Area

P0128Conditions (a), (b) and (c) are met for 5 seconds (2 trip

detection logic):

(a) Cold start

(b) Engine warmed up

(c) ECT less than 75

C (167F)•Thermostat

• Cooling system

• ECT sensor

•ECM

Related DTCs P0128: Coolant Thermostat

Required Sensors / Components (Main) Thermostat

A082385E11

Page 472 of 3000

ES–1662GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

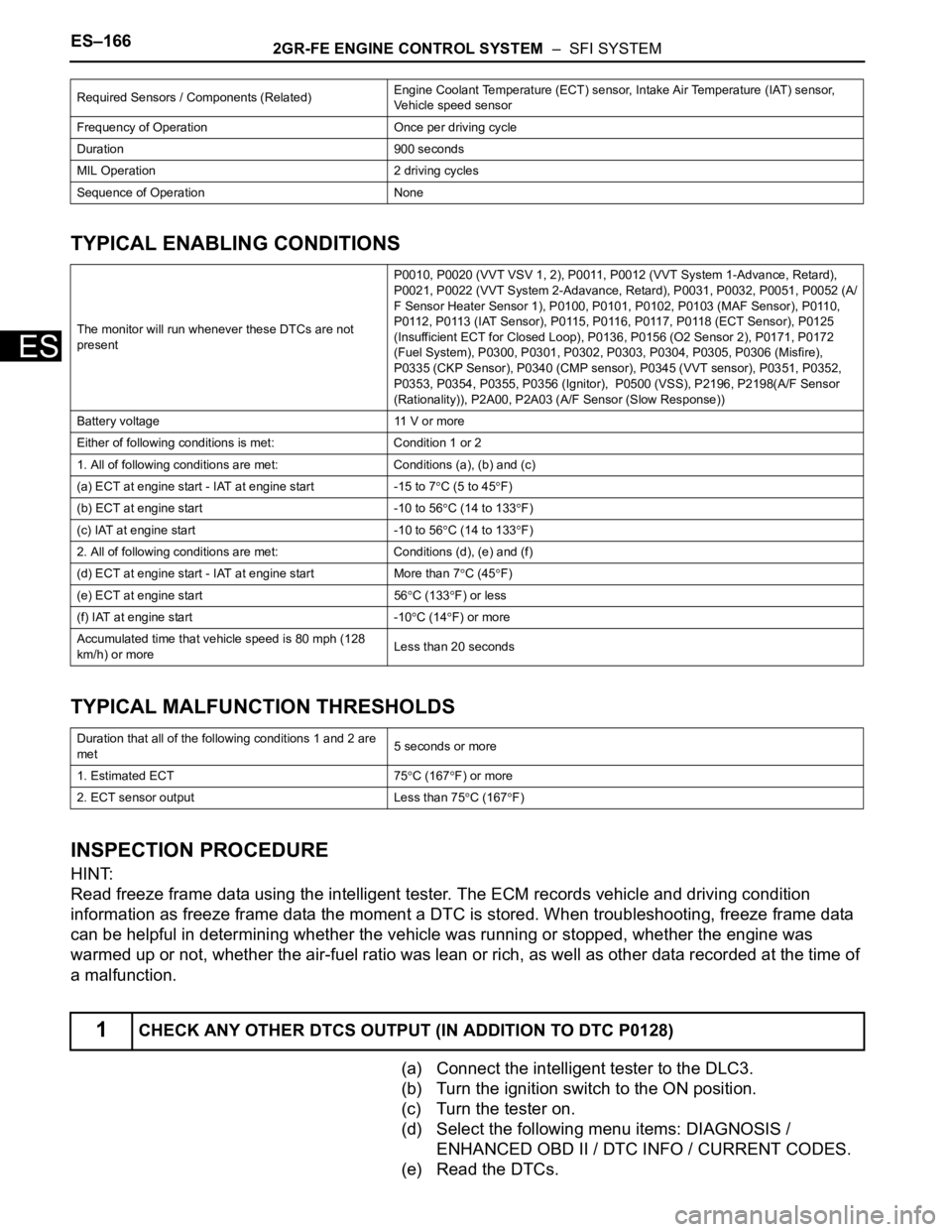

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of

a malfunction.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(e) Read the DTCs.

Required Sensors / Components (Related)Engine Coolant Temperature (ECT) sensor, Intake Air Temperature (IAT) sensor,

Vehicle speed sensor

Frequency of Operation Once per driving cycle

Duration 900 seconds

MIL Operation 2 driving cycles

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentP0010, P0020 (VVT VSV 1, 2), P0011, P0012 (VVT System 1-Advance, Retard),

P0021, P0022 (VVT System 2-Adavance, Retard), P0031, P0032, P0051, P0052 (A/

F Sensor Heater Sensor 1), P0100, P0101, P0102, P0103 (MAF Sensor), P0110,

P0112, P0113 (IAT Sensor), P0115, P0116, P0117, P0118 (ECT Sensor), P0125

(Insufficient ECT for Closed Loop), P0136, P0156 (O2 Sensor 2), P0171, P0172

(Fuel System), P0300, P0301, P0302, P0303, P0304, P0305, P0306 (Misfire),

P0335 (CKP Sensor), P0340 (CMP sensor), P0345 (VVT sensor), P0351, P0352,

P0353, P0354, P0355, P0356 (Ignitor), P0500 (VSS), P2196, P2198(A/F Sensor

(Rationality)), P2A00, P2A03 (A/F Sensor (Slow Response))

Battery voltage 11 V or more

Either of following conditions is met: Condition 1 or 2

1. All of following conditions are met: Conditions (a), (b) and (c)

(a) ECT at engine start - IAT at engine start -15 to 7

C (5 to 45F)

(b) ECT at engine start -10 to 56

C (14 to 133F)

(c) IAT at engine start -10 to 56

C (14 to 133F)

2. All of following conditions are met: Conditions (d), (e) and (f)

(d) ECT at engine start - IAT at engine start More than 7

C (45F)

(e) ECT at engine start 56

C (133F) or less

(f) IAT at engine start -10

C (14F) or more

Accumulated time that vehicle speed is 80 mph (128

km/h) or moreLess than 20 seconds

Duration that all of the following conditions 1 and 2 are

met5 seconds or more

1. Estimated ECT 75

C (167F) or more

2. ECT sensor output Less than 75

C (167F)

1CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0128)

Page 474 of 3000

ES–1682GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

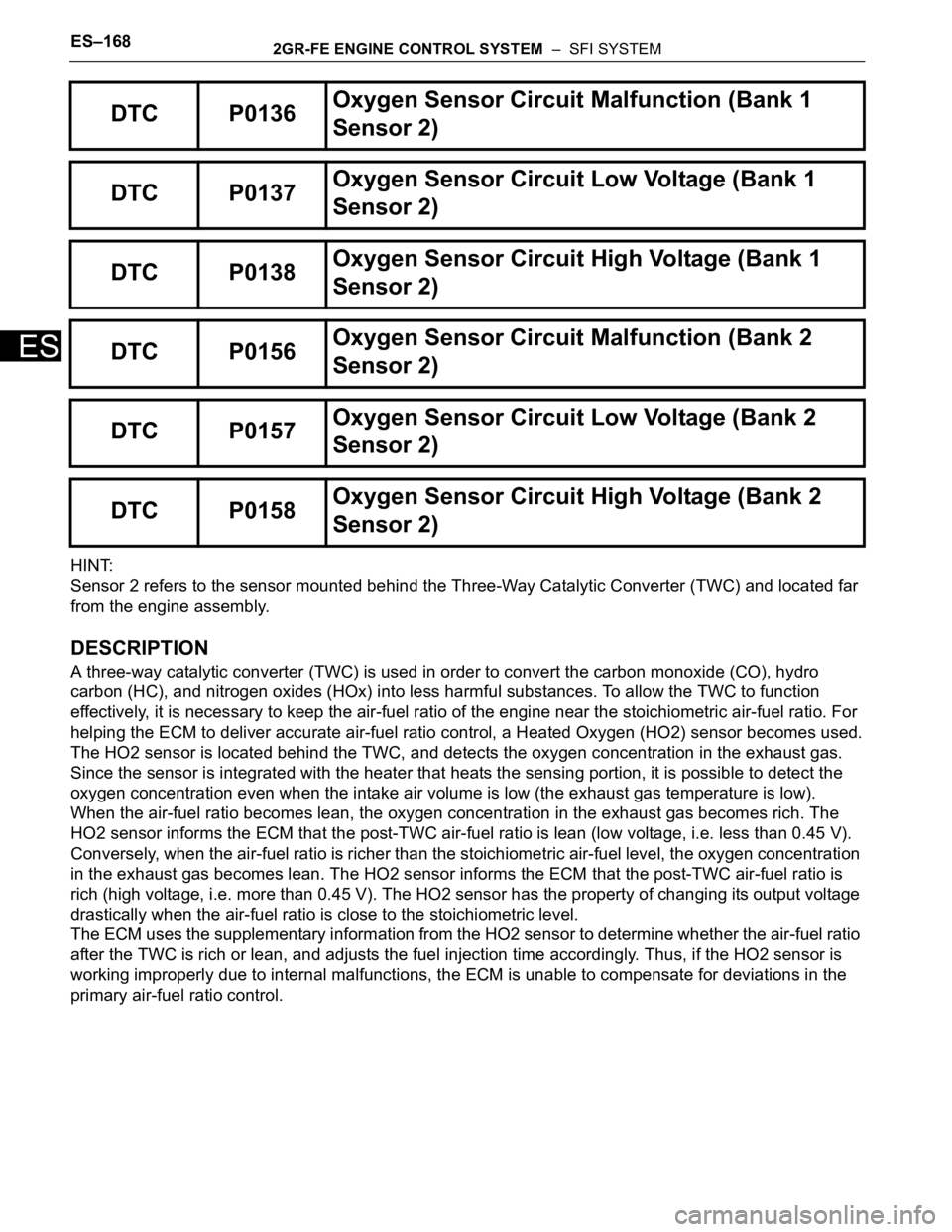

HINT:

Sensor 2 refers to the sensor mounted behind the Three-Way Catalytic Converter (TWC) and located far

from the engine assembly.

DESCRIPTION

A three-way catalytic converter (TWC) is used in order to convert the carbon monoxide (CO), hydro

carbon (HC), and nitrogen oxides (HOx) into less harmful substances. To allow the TWC to function

effectively, it is necessary to keep the air-fuel ratio of the engine near the stoichiometric air-fuel ratio. For

helping the ECM to deliver accurate air-fuel ratio control, a Heated Oxygen (HO2) sensor becomes used.

The HO2 sensor is located behind the TWC, and detects the oxygen concentration in the exhaust gas.

Since the sensor is integrated with the heater that heats the sensing portion, it is possible to detect the

oxygen concentration even when the intake air volume is low (the exhaust gas temperature is low).

When the air-fuel ratio becomes lean, the oxygen concentration in the exhaust gas becomes rich. The

HO2 sensor informs the ECM that the post-TWC air-fuel ratio is lean (low voltage, i.e. less than 0.45 V).

Conversely, when the air-fuel ratio is richer than the stoichiometric air-fuel level, the oxygen concentration

in the exhaust gas becomes lean. The HO2 sensor informs the ECM that the post-TWC air-fuel ratio is

rich (high voltage, i.e. more than 0.45 V). The HO2 sensor has the property of changing its output voltage

drastically when the air-fuel ratio is close to the stoichiometric level.

The ECM uses the supplementary information from the HO2 sensor to determine whether the air-fuel ratio

after the TWC is rich or lean, and adjusts the fuel injection time accordingly. Thus, if the HO2 sensor is

working improperly due to internal malfunctions, the ECM is unable to compensate for deviations in the

primary air-fuel ratio control.

DTC P0136Oxygen Sensor Circuit Malfunction (Bank 1

Sensor 2)

DTC P0137Oxygen Sensor Circuit Low Voltage (Bank 1

Sensor 2)

DTC P0138Oxygen Sensor Circuit High Voltage (Bank 1

Sensor 2)

DTC P0156Oxygen Sensor Circuit Malfunction (Bank 2

Sensor 2)

DTC P0157Oxygen Sensor Circuit Low Voltage (Bank 2

Sensor 2)

DTC P0158Oxygen Sensor Circuit High Voltage (Bank 2

Sensor 2)