sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 497 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–191

ES

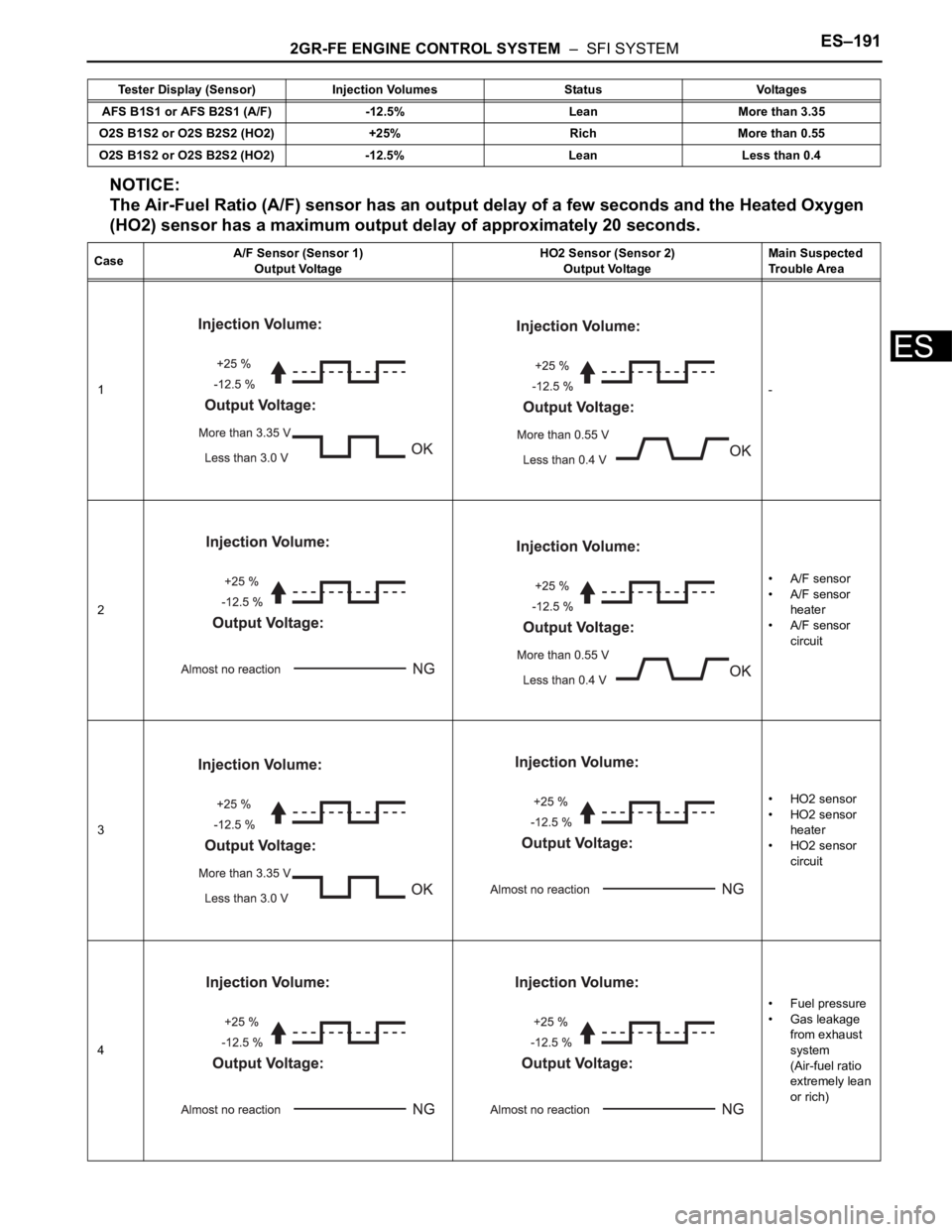

NOTICE:

The Air-Fuel Ratio (A/F) sensor has an output delay of a few seconds and the Heated Oxygen

(HO2) sensor has a maximum output delay of approximately 20 seconds.

AFS B1S1 or AFS B2S1 (A/F) -12.5% Lean More than 3.35

O2S B1S2 or O2S B2S2 (HO2) +25% Rich More than 0.55

O2S B1S2 or O2S B2S2 (HO2) -12.5% Lean Less than 0.4

CaseA/F Sensor (Sensor 1)

Output VoltageHO2 Sensor (Sensor 2)

Output VoltageMain Suspected

Trouble Area

1-

2•A/F sensor

•A/F sensor

heater

•A/F sensor

circuit

3•HO2 sensor

• HO2 sensor

heater

• HO2 sensor

circuit

4• Fuel pressure

• Gas leakage

from exhaust

system

(Air-fuel ratio

extremely lean

or rich) Tester Display (Sensor) Injection Volumes Status Voltages

Page 498 of 3000

ES–1922GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

– Following the A/F CONTROL procedure enables technicians to check and graph the voltage outputs

of both the A/F and HO2 sensors.

– To display the graph, select the following menu items on the tester: DIAGNOSIS / ENHANCED OBD

II / ACTIVE TEST / A/F CONTROL / USER DATA / AFS B1S1 and O2S B1S2 or AFS B2S1 and

O2S B2S2. Press the YES button and then the ENTER button. Then press the F4 button.

HINT:

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving

condition information as freeze frame data the moment a DTC is stored. When troubleshooting,

freeze frame data can be helpful in determining whether the vehicle was running or stopped,

whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as

other data recorded at the time of a malfunction.

• A low A/F sensor voltage could be caused by a rich air-fuel mixture. Check for conditions that

would cause the engine to run rich.

• A high A/F sensor voltage could be caused by a lean air-fuel mixture. Check for conditions that

would cause the engine to run lean.

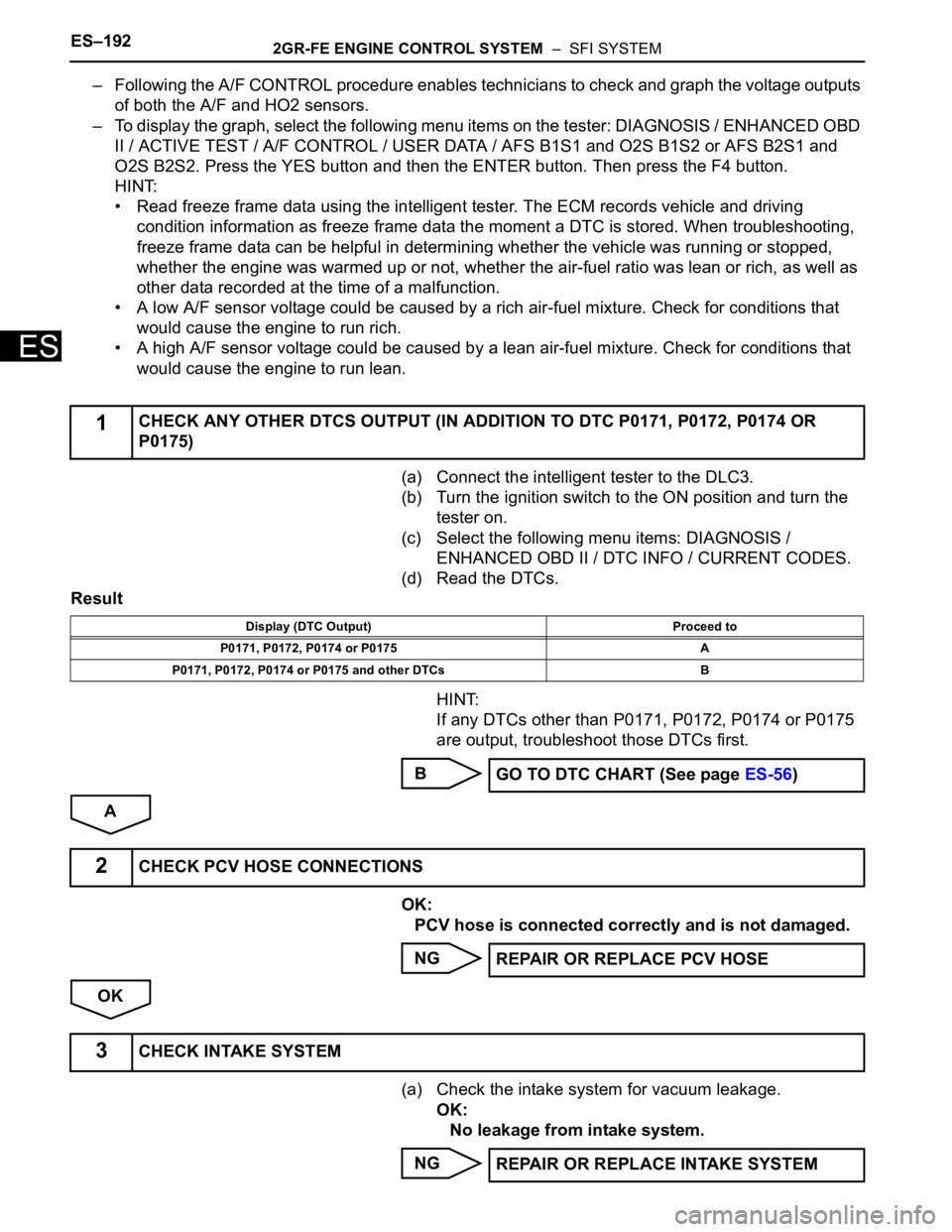

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(d) Read the DTCs.

Result

HINT:

If any DTCs other than P0171, P0172, P0174 or P0175

are output, troubleshoot those DTCs first.

B

A

OK:

PCV hose is connected correctly and is not damaged.

NG

OK

(a) Check the intake system for vacuum leakage.

OK:

No leakage from intake system.

NG

1CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0171, P0172, P0174 OR

P0175)

Display (DTC Output) Proceed to

P0171, P0172, P0174 or P0175 A

P0171, P0172, P0174 or P0175 and other DTCs B

GO TO DTC CHART (See page ES-56)

2CHECK PCV HOSE CONNECTIONS

REPAIR OR REPLACE PCV HOSE

3CHECK INTAKE SYSTEM

REPAIR OR REPLACE INTAKE SYSTEM

Page 499 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–193

ES

OK

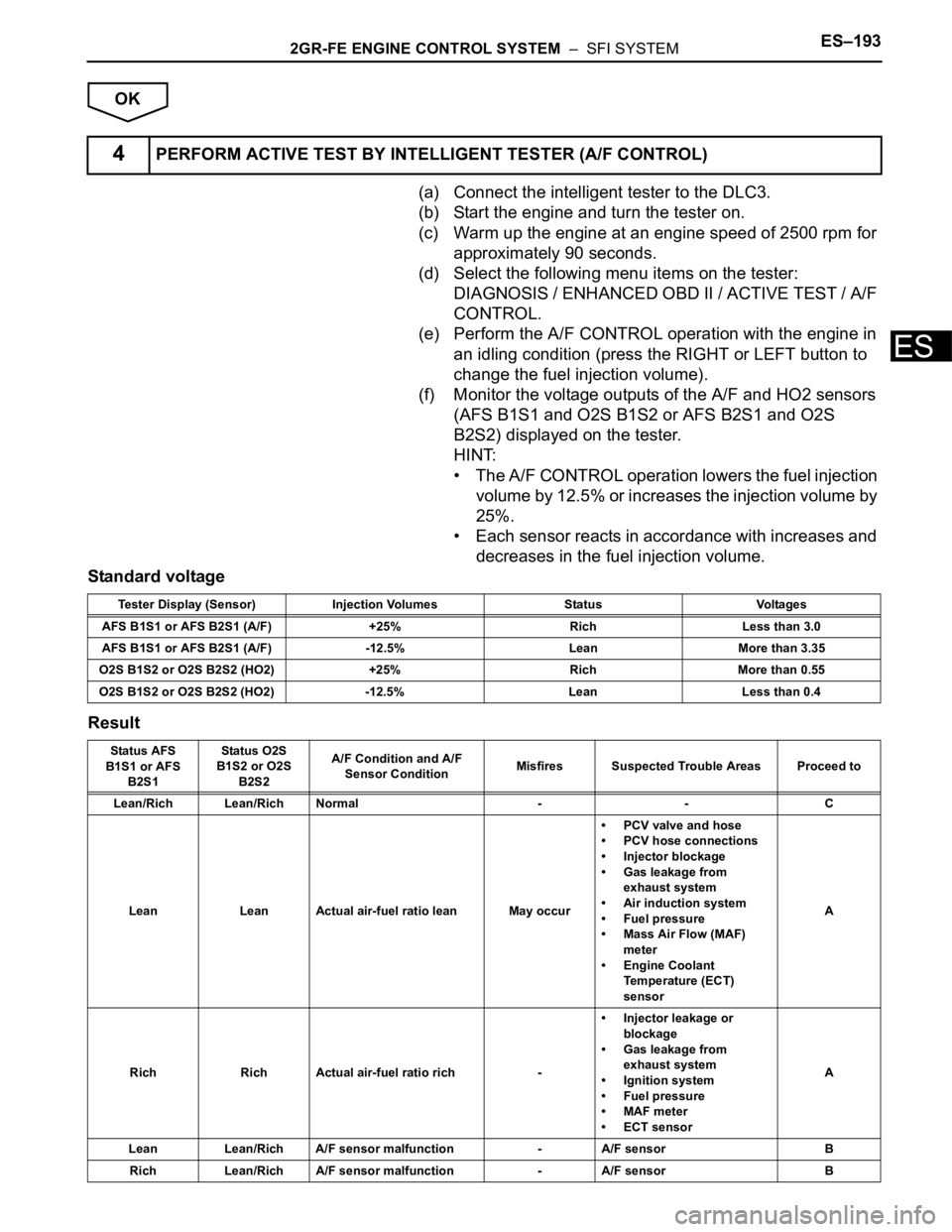

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and turn the tester on.

(c) Warm up the engine at an engine speed of 2500 rpm for

approximately 90 seconds.

(d) Select the following menu items on the tester:

DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / A/F

CONTROL.

(e) Perform the A/F CONTROL operation with the engine in

an idling condition (press the RIGHT or LEFT button to

change the fuel injection volume).

(f) Monitor the voltage outputs of the A/F and HO2 sensors

(AFS B1S1 and O2S B1S2 or AFS B2S1 and O2S

B2S2) displayed on the tester.

HINT:

• The A/F CONTROL operation lowers the fuel injection

volume by 12.5% or increases the injection volume by

25%.

• Each sensor reacts in accordance with increases and

decreases in the fuel injection volume.

Standard voltage

Result

4PERFORM ACTIVE TEST BY INTELLIGENT TESTER (A/F CONTROL)

Tester Display (Sensor) Injection Volumes Status Voltages

AFS B1S1 or AFS B2S1 (A/F) +25% Rich Less than 3.0

AFS B1S1 or AFS B2S1 (A/F) -12.5% Lean More than 3.35

O2S B1S2 or O2S B2S2 (HO2) +25% Rich More than 0.55

O2S B1S2 or O2S B2S2 (HO2) -12.5% Lean Less than 0.4

Status AFS

B1S1 or AFS

B2S1Status O2S

B1S2 or O2S

B2S2A/F Condition and A/F

Sensor ConditionMisfires Suspected Trouble Areas Proceed to

Lean/Rich Lean/Rich Normal - - C

Lean Lean Actual air-fuel ratio lean May occur• PCV valve and hose

• PCV hose connections

• Injector blockage

• Gas leakage from

exhaust system

• Air induction system

• Fuel pressure

• Mass Air Flow (MAF)

meter

• Engine Coolant

Temperature (ECT)

sensorA

Rich Rich Actual air-fuel ratio rich -• Injector leakage or

blockage

• Gas leakage from

exhaust system

• Ignition system

• Fuel pressure

• MAF meter

• ECT sensorA

Lean Lean/Rich A/F sensor malfunction - A/F sensor B

Rich Lean/Rich A/F sensor malfunction - A/F sensor B

Page 500 of 3000

ES–1942GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

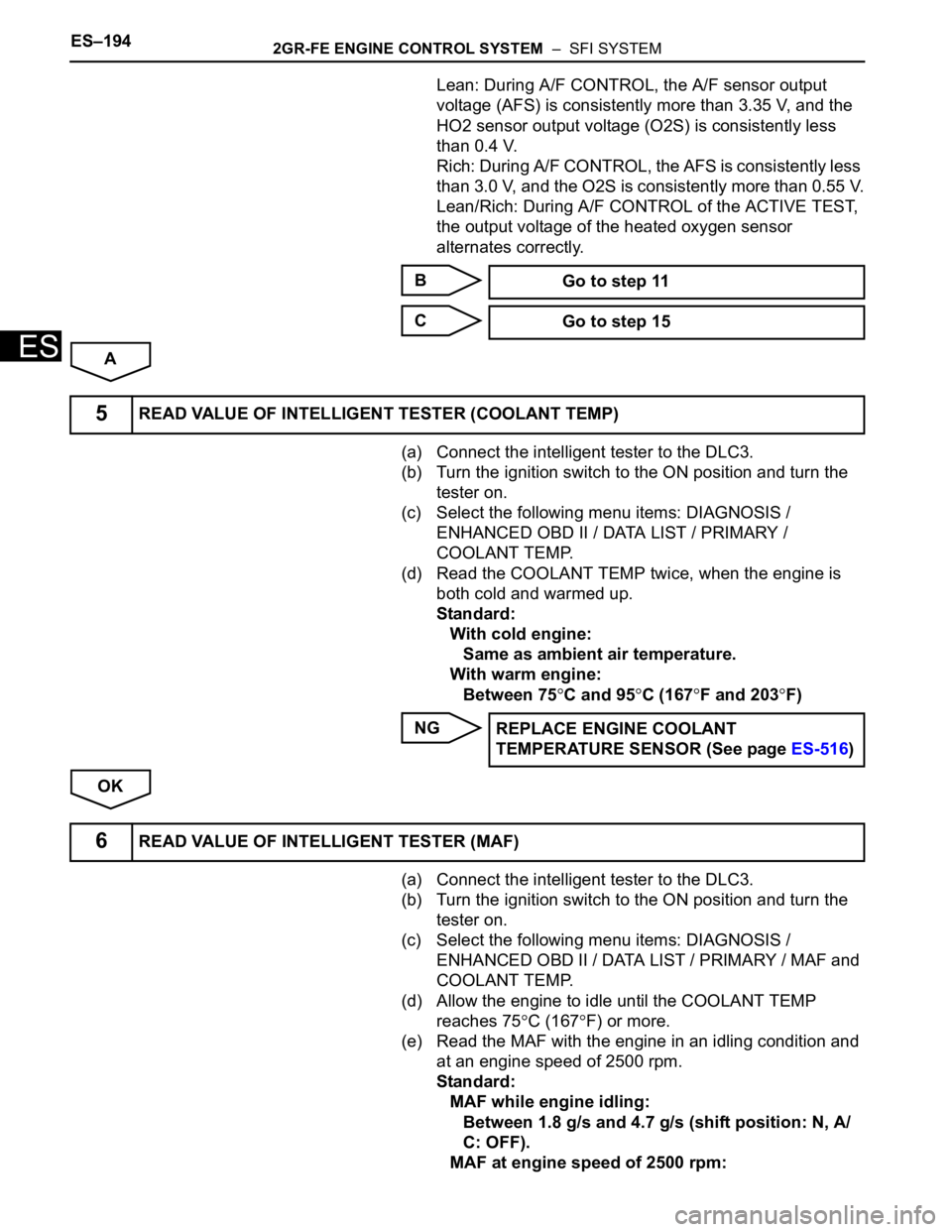

Lean: During A/F CONTROL, the A/F sensor output

voltage (AFS) is consistently more than 3.35 V, and the

HO2 sensor output voltage (O2S) is consistently less

than 0.4 V.

Rich: During A/F CONTROL, the AFS is consistently less

than 3.0 V, and the O2S is consistently more than 0.55 V.

Lean/Rich: During A/F CONTROL of the ACTIVE TEST,

the output voltage of the heated oxygen sensor

alternates correctly.

B

C

A

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / PRIMARY /

COOLANT TEMP.

(d) Read the COOLANT TEMP twice, when the engine is

both cold and warmed up.

Standard:

With cold engine:

Same as ambient air temperature.

With warm engine:

Between 75

C and 95C (167F and 203F)

NG

OK

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / PRIMARY / MAF and

COOLANT TEMP.

(d) Allow the engine to idle until the COOLANT TEMP

reaches 75

C (167F) or more.

(e) Read the MAF with the engine in an idling condition and

at an engine speed of 2500 rpm.

Standard:

MAF while engine idling:

Between 1.8 g/s and 4.7 g/s (shift position: N, A/

C: OFF).

MAF at engine speed of 2500 rpm: Go to step 11

Go to step 15

5READ VALUE OF INTELLIGENT TESTER (COOLANT TEMP)

REPLACE ENGINE COOLANT

TEMPERATURE SENSOR (See page ES-516)

6READ VALUE OF INTELLIGENT TESTER (MAF)

Page 502 of 3000

ES–1962GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

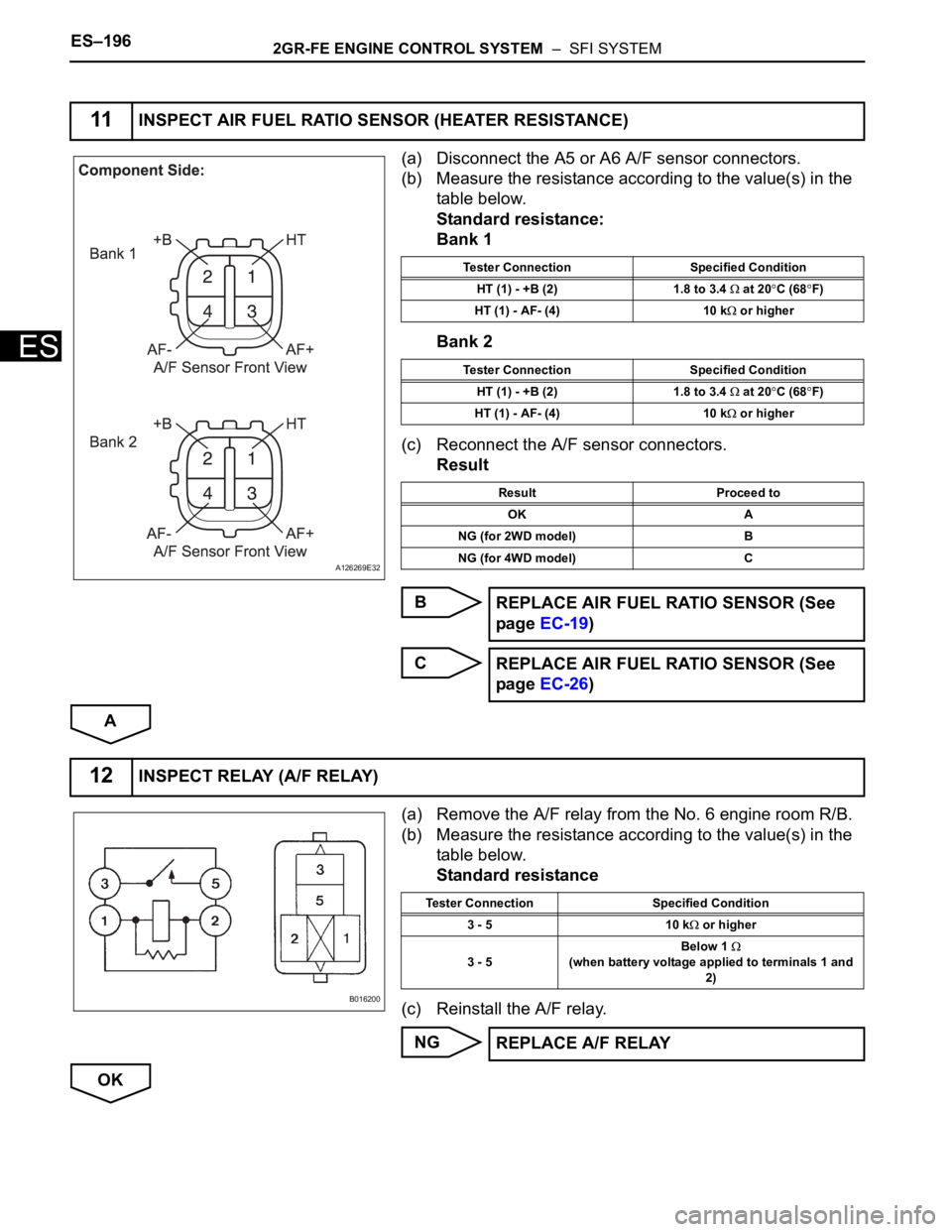

(a) Disconnect the A5 or A6 A/F sensor connectors.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Bank 1

Bank 2

(c) Reconnect the A/F sensor connectors.

Result

B

C

A

(a) Remove the A/F relay from the No. 6 engine room R/B.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(c) Reinstall the A/F relay.

NG

OK

11INSPECT AIR FUEL RATIO SENSOR (HEATER RESISTANCE)

A126269E32

Tester Connection Specified Condition

HT (1) - +B (2) 1.8 to 3.4

at 20C (68F)

HT (1) - AF- (4) 10 k

or higher

Tester Connection Specified Condition

HT (1) - +B (2) 1.8 to 3.4

at 20C (68F)

HT (1) - AF- (4) 10 k

or higher

Result Proceed to

OK A

NG (for 2WD model) B

NG (for 4WD model) C

REPLACE AIR FUEL RATIO SENSOR (See

page EC-19)

REPLACE AIR FUEL RATIO SENSOR (See

page EC-26)

12INSPECT RELAY (A/F RELAY)

B016200

Tester Connection Specified Condition

3 - 5 10 k

or higher

3 - 5Below 1

(when battery voltage applied to terminals 1 and

2)

REPLACE A/F RELAY

Page 503 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–197

ES

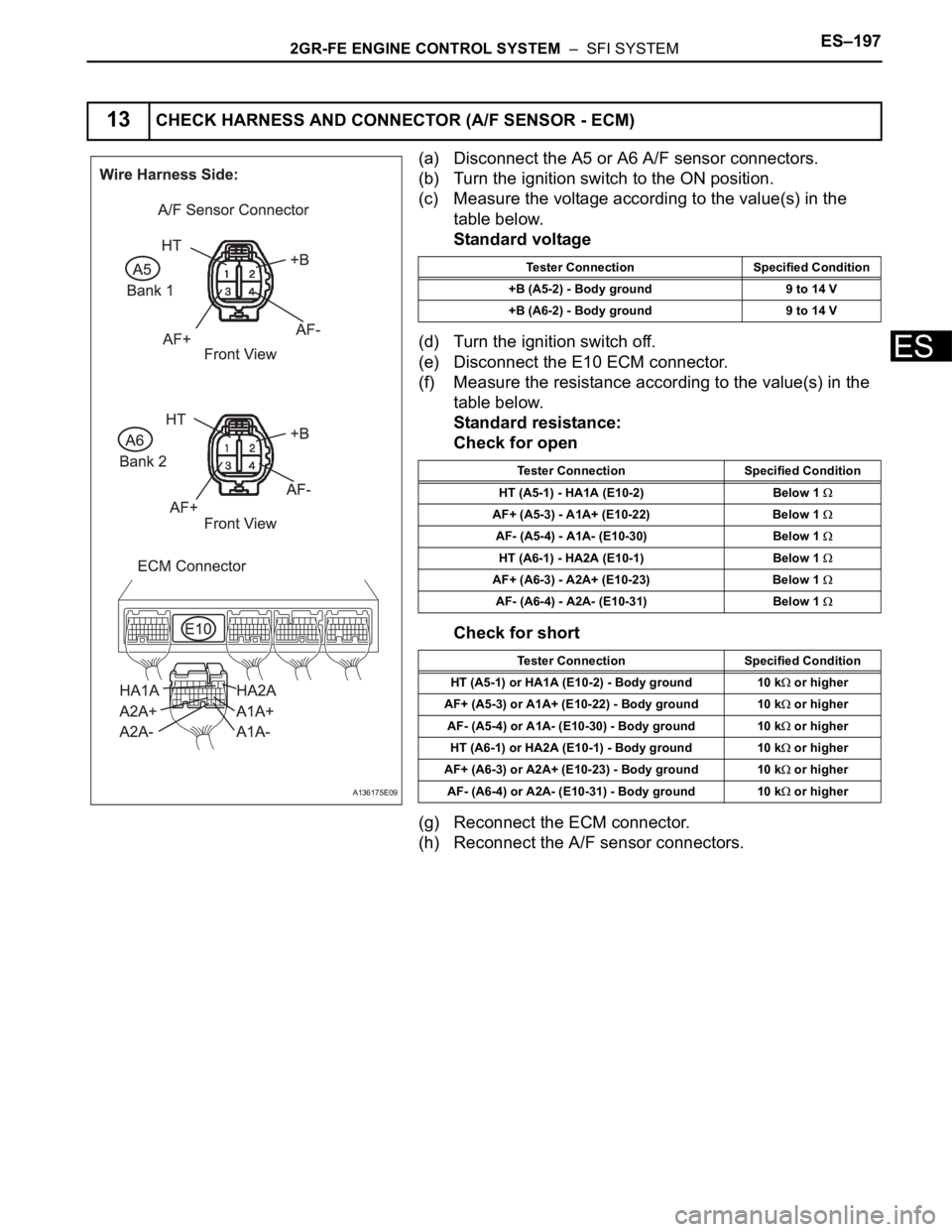

(a) Disconnect the A5 or A6 A/F sensor connectors.

(b) Turn the ignition switch to the ON position.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

(d) Turn the ignition switch off.

(e) Disconnect the E10 ECM connector.

(f) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Check for open

Check for short

(g) Reconnect the ECM connector.

(h) Reconnect the A/F sensor connectors.

13CHECK HARNESS AND CONNECTOR (A/F SENSOR - ECM)

A136175E09

Tester Connection Specified Condition

+B (A5-2) - Body ground 9 to 14 V

+B (A6-2) - Body ground 9 to 14 V

Tester Connection Specified Condition

HT (A5-1) - HA1A (E10-2) Below 1

AF+ (A5-3) - A1A+ (E10-22) Below 1

AF- (A5-4) - A1A- (E10-30) Below 1

HT (A6-1) - HA2A (E10-1) Below 1

AF+ (A6-3) - A2A+ (E10-23) Below 1

AF- (A6-4) - A2A- (E10-31) Below 1

Tester Connection Specified Condition

HT (A5-1) or HA1A (E10-2) - Body ground 10 k

or higher

AF+ (A5-3) or A1A+ (E10-22) - Body ground 10 k

or higher

AF- (A5-4) or A1A- (E10-30) - Body ground 10 k

or higher

HT (A6-1) or HA2A (E10-1) - Body ground 10 k

or higher

AF+ (A6-3) or A2A+ (E10-23) - Body ground 10 k

or higher

AF- (A6-4) or A2A- (E10-31) - Body ground 10 k

or higher

Page 504 of 3000

ES–1982GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

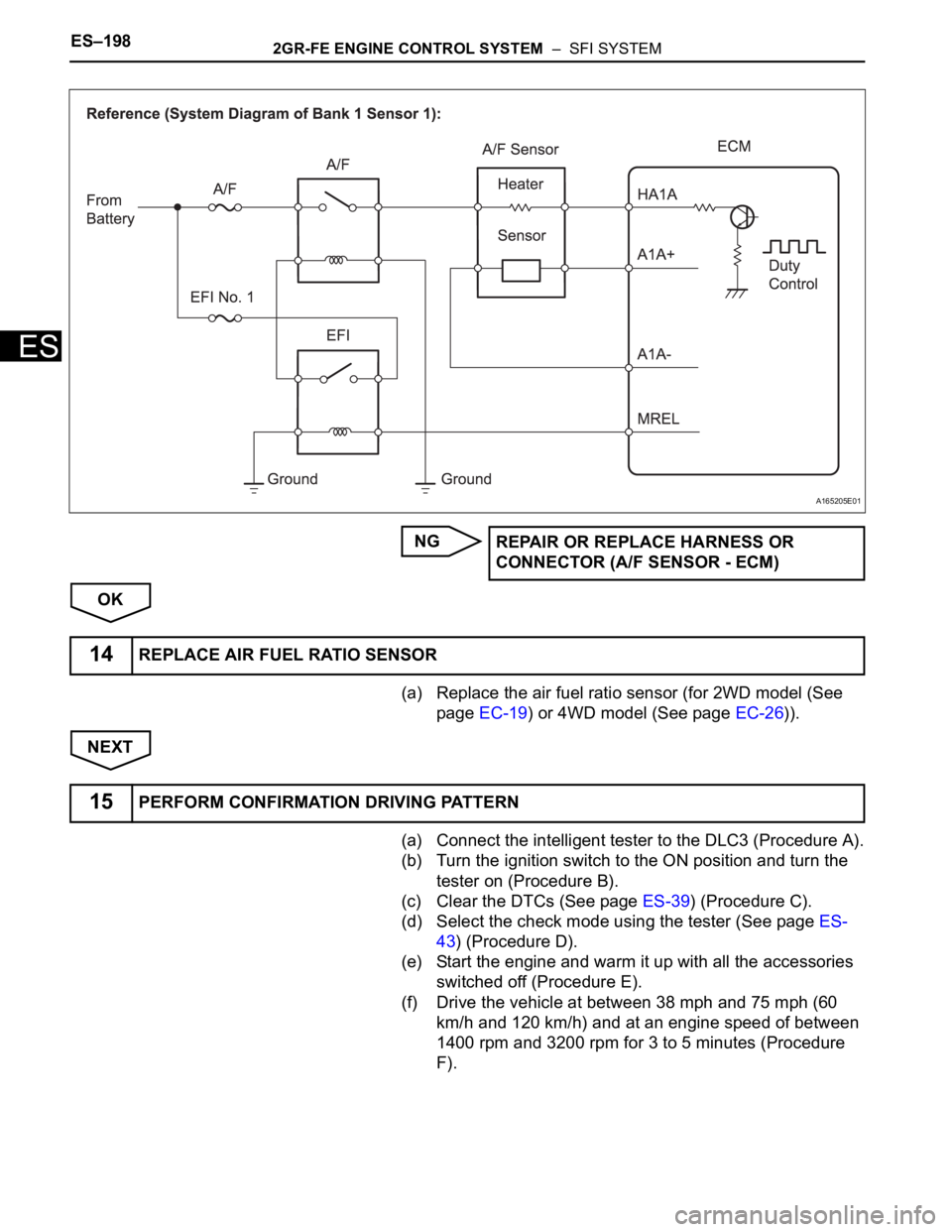

NG

OK

(a) Replace the air fuel ratio sensor (for 2WD model (See

page EC-19) or 4WD model (See page EC-26)).

NEXT

(a) Connect the intelligent tester to the DLC3 (Procedure A).

(b) Turn the ignition switch to the ON position and turn the

tester on (Procedure B).

(c) Clear the DTCs (See page ES-39) (Procedure C).

(d) Select the check mode using the tester (See page ES-

43) (Procedure D).

(e) Start the engine and warm it up with all the accessories

switched off (Procedure E).

(f) Drive the vehicle at between 38 mph and 75 mph (60

km/h and 120 km/h) and at an engine speed of between

1400 rpm and 3200 rpm for 3 to 5 minutes (Procedure

F).

A165205E01

REPAIR OR REPLACE HARNESS OR

CONNECTOR (A/F SENSOR - ECM)

14REPLACE AIR FUEL RATIO SENSOR

15PERFORM CONFIRMATION DRIVING PATTERN

Page 510 of 3000

ES–2042GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

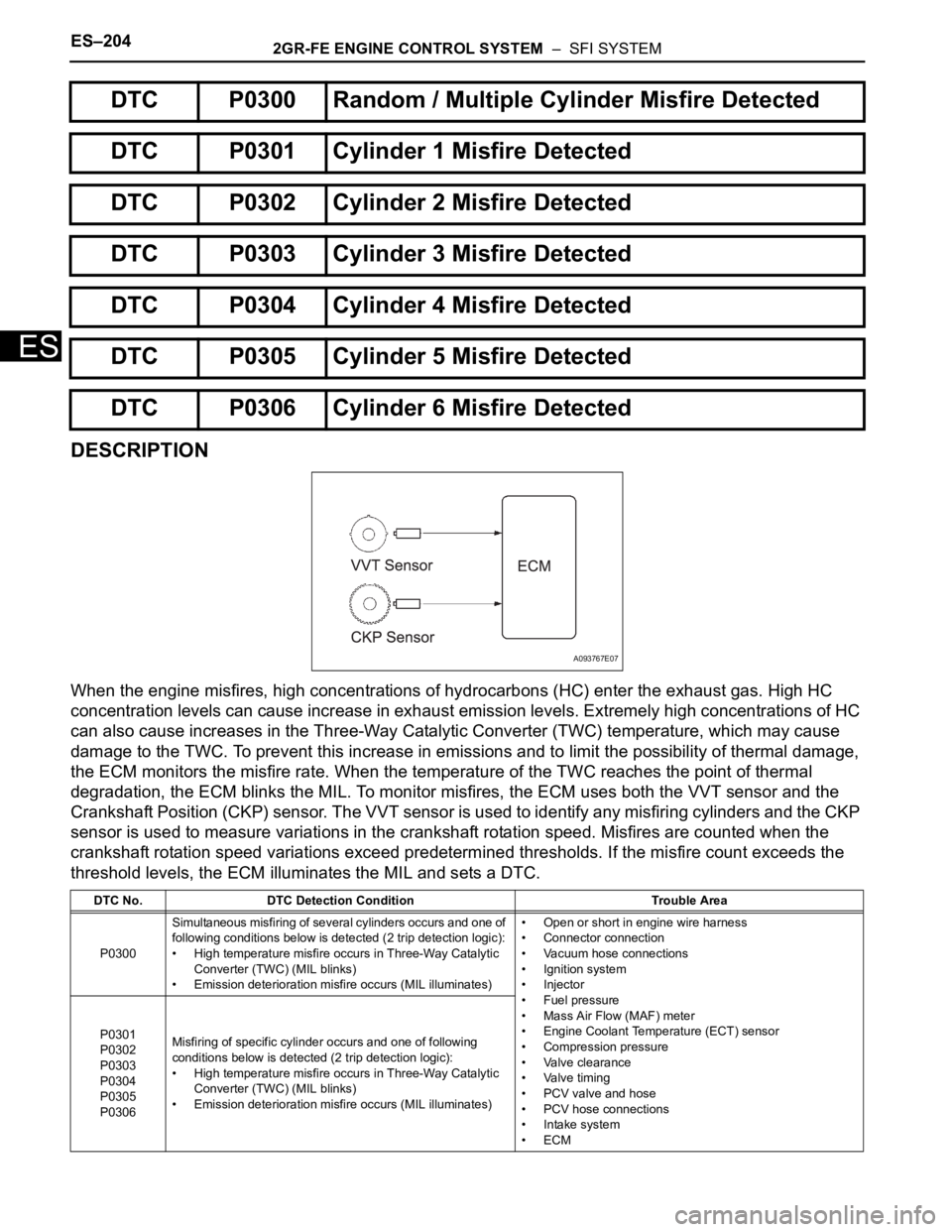

DESCRIPTION

When the engine misfires, high concentrations of hydrocarbons (HC) enter the exhaust gas. High HC

concentration levels can cause increase in exhaust emission levels. Extremely high concentrations of HC

can also cause increases in the Three-Way Catalytic Converter (TWC) temperature, which may cause

damage to the TWC. To prevent this increase in emissions and to limit the possibility of thermal damage,

the ECM monitors the misfire rate. When the temperature of the TWC reaches the point of thermal

degradation, the ECM blinks the MIL. To monitor misfires, the ECM uses both the VVT sensor and the

Crankshaft Position (CKP) sensor. The VVT sensor is used to identify any misfiring cylinders and the CKP

sensor is used to measure variations in the crankshaft rotation speed. Misfires are counted when the

crankshaft rotation speed variations exceed predetermined thresholds. If the misfire count exceeds the

threshold levels, the ECM illuminates the MIL and sets a DTC.

DTC P0300 Random / Multiple Cylinder Misfire Detected

DTC P0301 Cylinder 1 Misfire Detected

DTC P0302 Cylinder 2 Misfire Detected

DTC P0303 Cylinder 3 Misfire Detected

DTC P0304 Cylinder 4 Misfire Detected

DTC P0305 Cylinder 5 Misfire Detected

DTC P0306 Cylinder 6 Misfire Detected

DTC No. DTC Detection Condition Trouble Area

P0300Simultaneous misfiring of several cylinders occurs and one of

following conditions below is detected (2 trip detection logic):

• High temperature misfire occurs in Three-Way Catalytic

Converter (TWC) (MIL blinks)

• Emission deterioration misfire occurs (MIL illuminates)• Open or short in engine wire harness

• Connector connection

• Vacuum hose connections

• Ignition system

• Injector

• Fuel pressure

• Mass Air Flow (MAF) meter

• Engine Coolant Temperature (ECT) sensor

• Compression pressure

• Valve clearance

• Valve timing

• PCV valve and hose

• PCV hose connections

• Intake system

•ECM P0301

P0302

P0303

P0304

P0305

P0306Misfiring of specific cylinder occurs and one of following

conditions below is detected (2 trip detection logic):

• High temperature misfire occurs in Three-Way Catalytic

Converter (TWC) (MIL blinks)

• Emission deterioration misfire occurs (MIL illuminates)

A093767E07

Page 511 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–205

ES

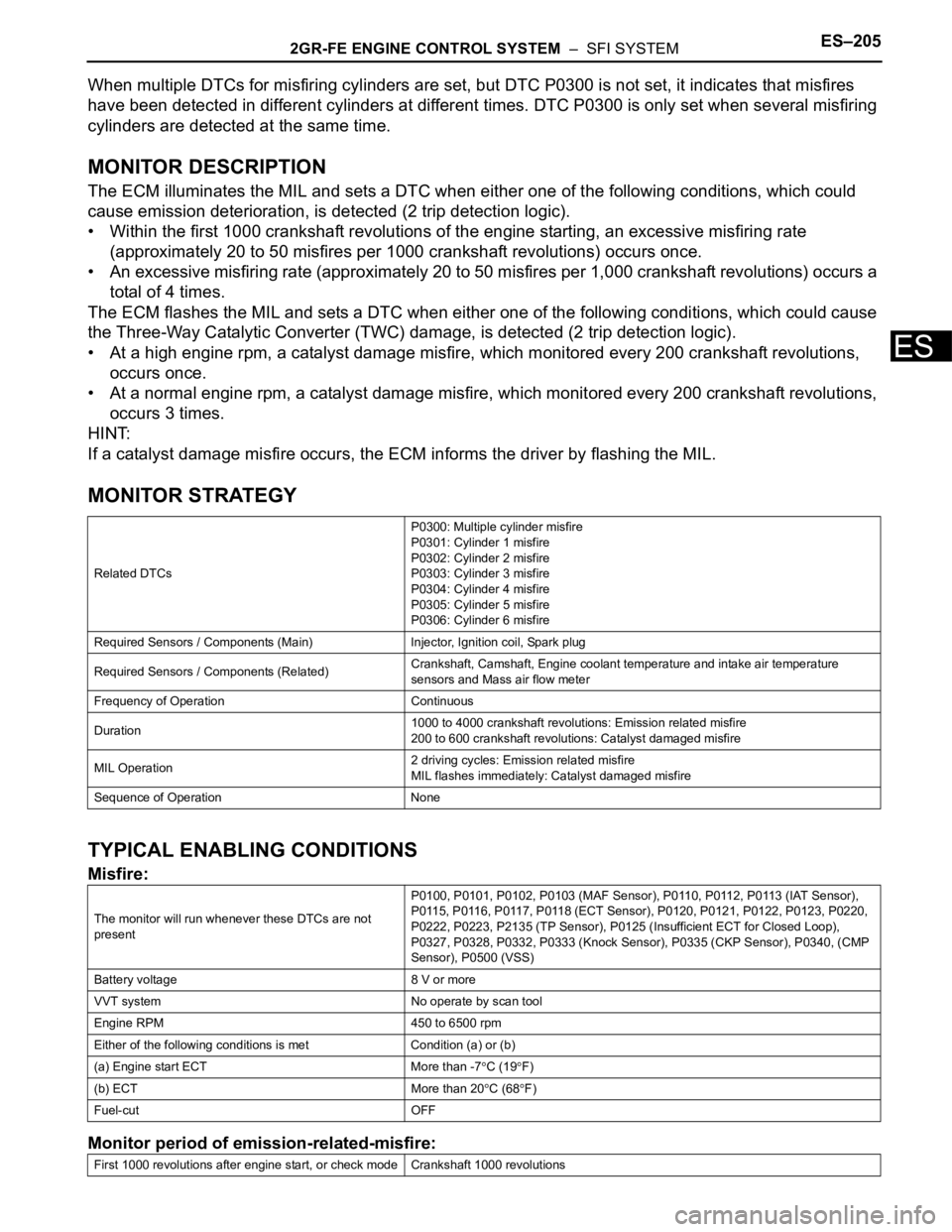

When multiple DTCs for misfiring cylinders are set, but DTC P0300 is not set, it indicates that misfires

have been detected in different cylinders at different times. DTC P0300 is only set when several misfiring

cylinders are detected at the same time.

MONITOR DESCRIPTION

The ECM illuminates the MIL and sets a DTC when either one of the following conditions, which could

cause emission deterioration, is detected (2 trip detection logic).

• Within the first 1000 crankshaft revolutions of the engine starting, an excessive misfiring rate

(approximately 20 to 50 misfires per 1000 crankshaft revolutions) occurs once.

• An excessive misfiring rate (approximately 20 to 50 misfires per 1,000 crankshaft revolutions) occurs a

total of 4 times.

The ECM flashes the MIL and sets a DTC when either one of the following conditions, which could cause

the Three-Way Catalytic Converter (TWC) damage, is detected (2 trip detection logic).

• At a high engine rpm, a catalyst damage misfire, which monitored every 200 crankshaft revolutions,

occurs once.

• At a normal engine rpm, a catalyst damage misfire, which monitored every 200 crankshaft revolutions,

occurs 3 times.

HINT:

If a catalyst damage misfire occurs, the ECM informs the driver by flashing the MIL.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

Misfire:

Monitor period of emission-related-misfire:

Related DTCsP0300: Multiple cylinder misfire

P0301: Cylinder 1 misfire

P0302: Cylinder 2 misfire

P0303: Cylinder 3 misfire

P0304: Cylinder 4 misfire

P0305: Cylinder 5 misfire

P0306: Cylinder 6 misfire

Required Sensors / Components (Main) Injector, Ignition coil, Spark plug

Required Sensors / Components (Related)Crankshaft, Camshaft, Engine coolant temperature and intake air temperature

sensors and Mass air flow meter

Frequency of Operation Continuous

Duration1000 to 4000 crankshaft revolutions: Emission related misfire

200 to 600 crankshaft revolutions: Catalyst damaged misfire

MIL Operation2 driving cycles: Emission related misfire

MIL flashes immediately: Catalyst damaged misfire

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentP0100, P0101, P0102, P0103 (MAF Sensor), P0110, P0112, P0113 (IAT Sensor),

P0115, P0116, P0117, P0118 (ECT Sensor), P0120, P0121, P0122, P0123, P0220,

P0222, P0223, P2135 (TP Sensor), P0125 (Insufficient ECT for Closed Loop),

P0327, P0328, P0332, P0333 (Knock Sensor), P0335 (CKP Sensor), P0340, (CMP

Sensor), P0500 (VSS)

Battery voltage 8 V or more

VVT system No operate by scan tool

Engine RPM 450 to 6500 rpm

Either of the following conditions is met Condition (a) or (b)

(a) Engine start ECT More than -7

C (19F)

(b) ECT More than 20

C (68F)

Fuel-cut OFF

First 1000 revolutions after engine start, or check mode Crankshaft 1000 revolutions

Page 520 of 3000

ES–2142GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

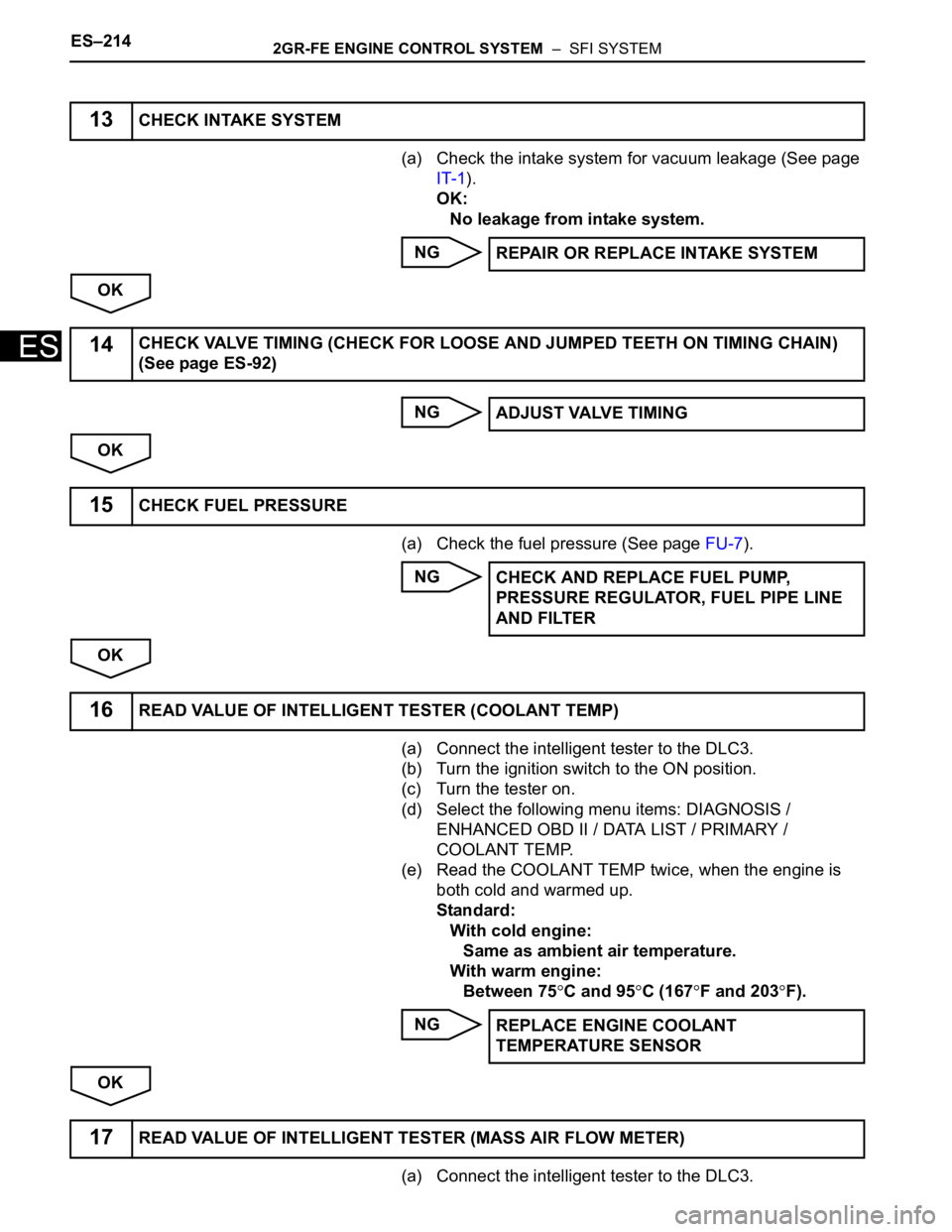

(a) Check the intake system for vacuum leakage (See page

IT-1).

OK:

No leakage from intake system.

NG

OK

NG

OK

(a) Check the fuel pressure (See page FU-7).

NG

OK

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / PRIMARY /

COOLANT TEMP.

(e) Read the COOLANT TEMP twice, when the engine is

both cold and warmed up.

Standard:

With cold engine:

Same as ambient air temperature.

With warm engine:

Between 75

C and 95C (167F and 203F).

NG

OK

(a) Connect the intelligent tester to the DLC3.

13CHECK INTAKE SYSTEM

REPAIR OR REPLACE INTAKE SYSTEM

14CHECK VALVE TIMING (CHECK FOR LOOSE AND JUMPED TEETH ON TIMING CHAIN)

(See page ES-92)

ADJUST VALVE TIMING

15CHECK FUEL PRESSURE

CHECK AND REPLACE FUEL PUMP,

PRESSURE REGULATOR, FUEL PIPE LINE

AND FILTER

16READ VALUE OF INTELLIGENT TESTER (COOLANT TEMP)

REPLACE ENGINE COOLANT

TEMPERATURE SENSOR

17READ VALUE OF INTELLIGENT TESTER (MASS AIR FLOW METER)