sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 522 of 3000

ES–2162GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / PRIMARY /

COOLANT TEMP.

(e) Read the COOLANT TEMP twice, when the engine is

both cold and warmed up.

Standard:

With cold engine:

Same as ambient air temperature.

With warm engine:

Between 75

C and 95C (167F and 203F).

NG

OK

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / PRIMARY / MAF and

COOLANT TEMP.

(e) Allow the engine to idle until the COOLANT TEMP

reaches 75

C (167F) or more.

(f) Read the MAF with the engine in an idling condition and

at an engine speed of 2500 rpm.

Standard:

MAF while engine is idling:

Between 1.8 g/s and 4.7 g/s (shift position: N, A/

C: OFF).

MAF at engine speed of 2500 rpm:

Between 7.4 g/s and 18.9 g/s (shift position: N, A/

C: OFF).

NG

OK

21READ VALUE OF INTELLIGENT TESTER (COOLANT TEMP)

REPLACE ENGINE COOLANT

TEMPERATURE SENSOR

22READ VALUE OF INTELLIGENT TESTER (MASS AIR FLOW METER)

REPLACE MASS AIR FLOW METER

Page 527 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–221

ESDESCRIPTION

A flat type knock sensor (non-resonant type) has a structure that can detect vibrations over a wide band of

frequencies: between approximately 6 kHz and 15 kHz.

Knock sensors are fitted onto the engine block to detect engine knocking.

The knock sensor contains a piezoelectric element which generates a voltage when the engine block

vibrates due to knocking. Any occurrence of engine knocking can be suppressed by delaying the ignition

timing.

HINT:

When any of DTCs P0327, P0328, P0332 and P0333 are set, the ECM enters fail-safe mode. During fail-

safe mode, the ignition timing is delayed to its maximum retardation. Fail-safe mode continues until the

ignition switch is turned off.

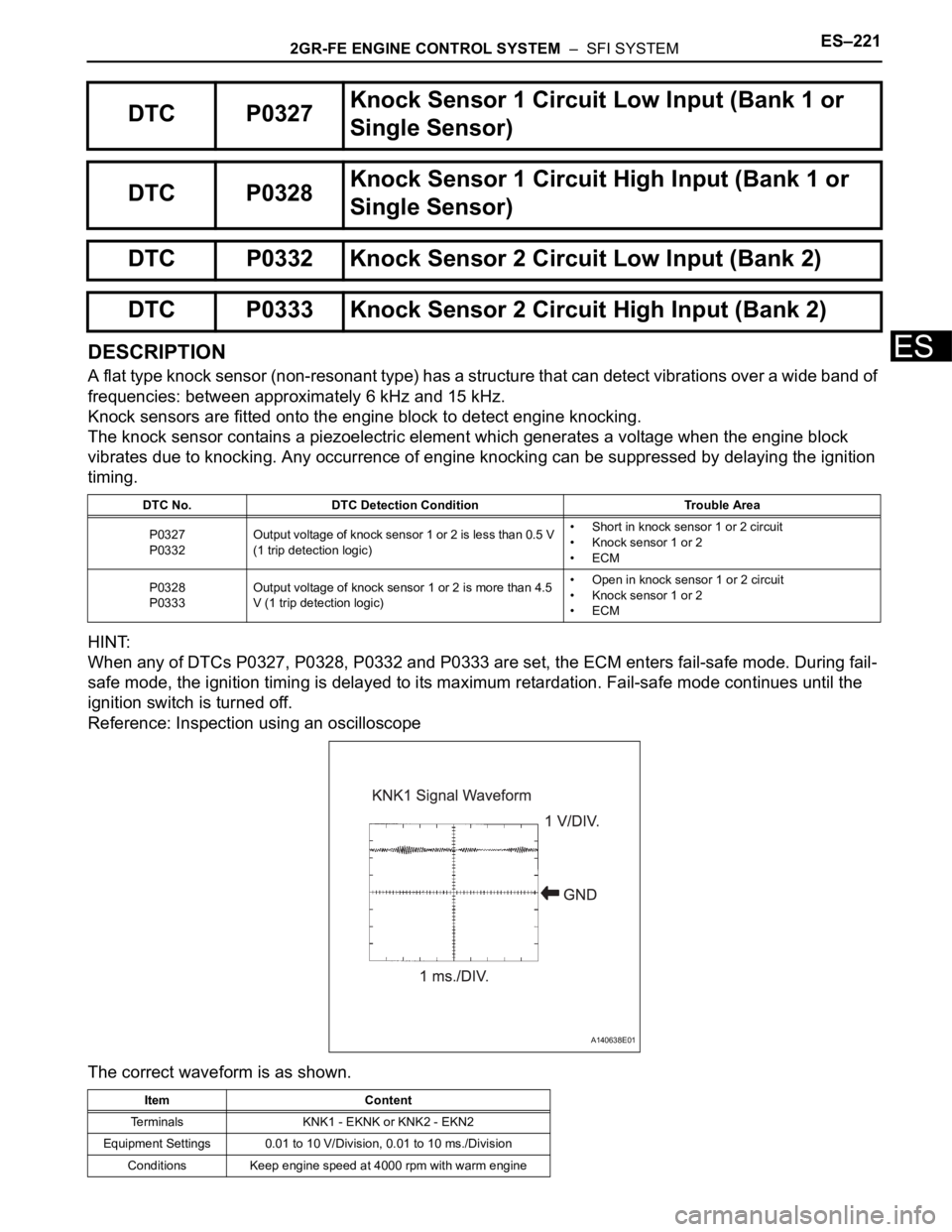

Reference: Inspection using an oscilloscope

The correct waveform is as shown.

DTC P0327Knock Sensor 1 Circuit Low Input (Bank 1 or

Single Sensor)

DTC P0328Knock Sensor 1 Circuit High Input (Bank 1 or

Single Sensor)

DTC P0332 Knock Sensor 2 Circuit Low Input (Bank 2)

DTC P0333 Knock Sensor 2 Circuit High Input (Bank 2)

DTC No. DTC Detection Condition Trouble Area

P0327

P0332Output voltage of knock sensor 1 or 2 is less than 0.5 V

(1 trip detection logic)• Short in knock sensor 1 or 2 circuit

• Knock sensor 1 or 2

•ECM

P0328

P0333Output voltage of knock sensor 1 or 2 is more than 4.5

V (1 trip detection logic)• Open in knock sensor 1 or 2 circuit

• Knock sensor 1 or 2

•ECM

Item Content

Terminals KNK1 - EKNK or KNK2 - EKN2

Equipment Settings 0.01 to 10 V/Division, 0.01 to 10 ms./Division

Conditions Keep engine speed at 4000 rpm with warm engine

A140638E01

Page 528 of 3000

ES–2222GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

MONITOR DESCRIPTION

The knock sensor, located on the cylinder block, detects spark knock. When a spark knock occurs, the

piezoelectric element of the sensor vibrates. When the ECM detects a voltage in this frequency range, it

retards the ignition timing to suppress the spark knock.

The ECM also senses background engine noise with the knock sensor and uses this noise to check for

faults in the sensor. If the knock sensor signal level is too low for more than 10 seconds, or if the knock

sensor output voltage is outside the normal range, the ECM interprets this as a fault in the knock sensor

and sets a DTC.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

Knock Sensor Range Check (Low voltage) P0327 and P0332:

Knock Sensor Range Check (High voltage) P0328 and P0333:

Related DTCsP0327: Knock sensor (Bank 1) open/short (Low voltage)

P0328: Knock sensor (Bank 1) open/short (High voltage)

P0332: Knock sensor (Bank 2) open/short (Low voltage)

P0333: Knock sensor (Bank 2) open/short (High voltage)

Required Sensors / Components (Main) Knock sensor (Bank 1 and 2)

Required Sensors / Components (Related) -

Frequency of Operation Continuous

Duration 1 second

MIL Operation Immediate

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentNone

Battery voltage 10.5 V or more

Time after engine start 5 seconds or more

Ignition switch ON

Starter OFF

Knock sensor voltage Less than 0.5 V

Knock sensor voltage More than 4.5 V

Page 529 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–223

ES

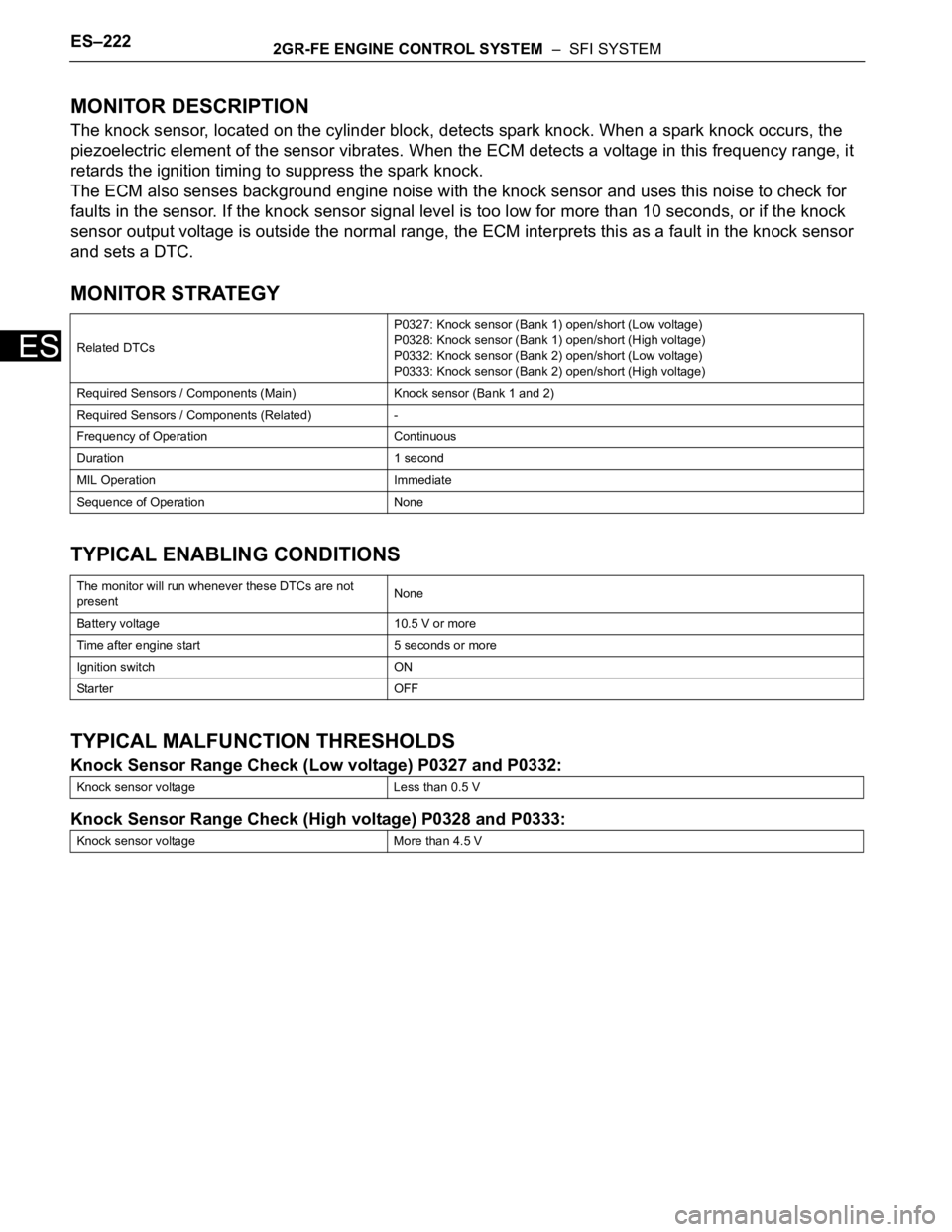

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

• DTCs P0327 and P0328 are for the bank 1 knock sensor circuit.

• DTCs P0332 and P0333 are for the bank 2 knock sensor circuit.

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the

time of a malfunction.

A136096E05

Page 530 of 3000

ES–2242GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

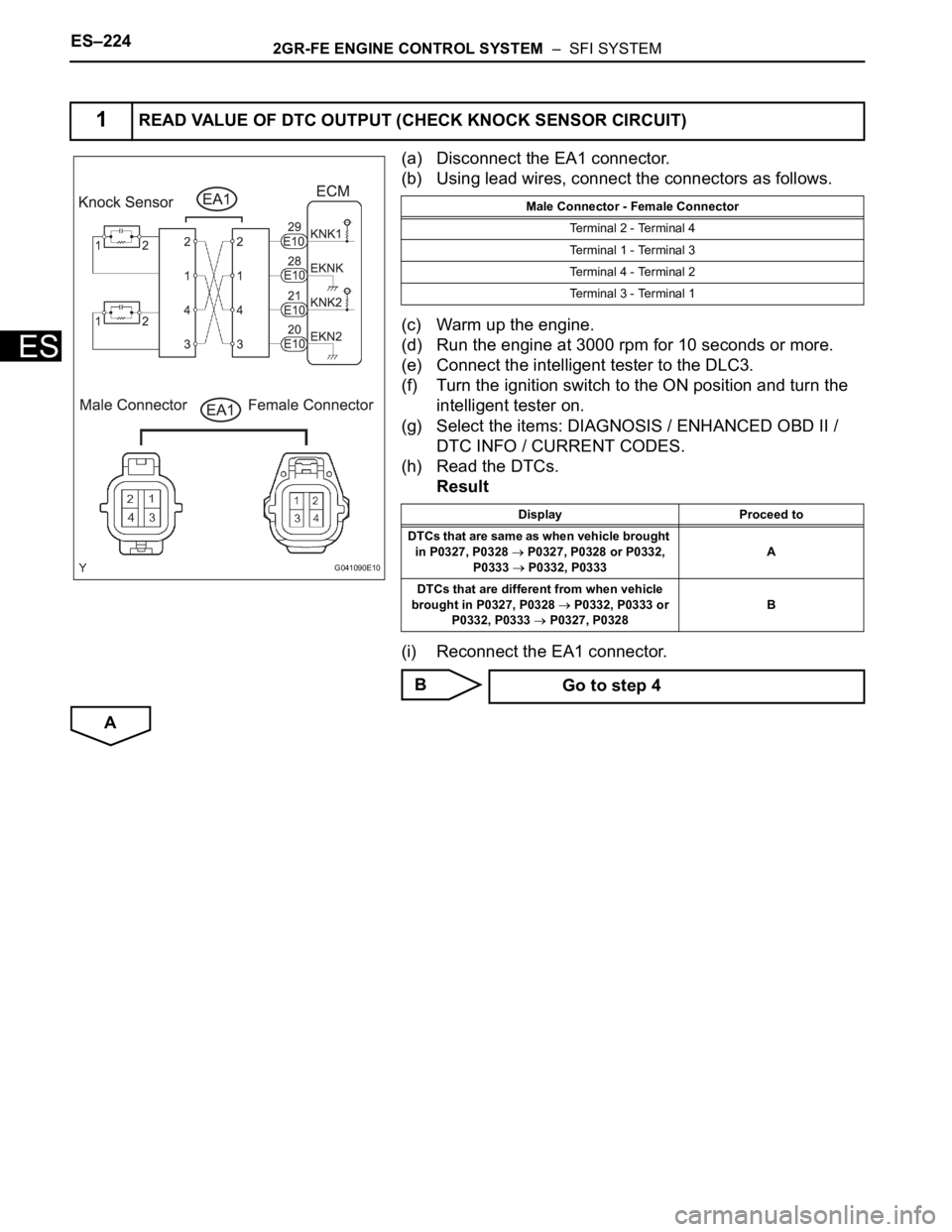

(a) Disconnect the EA1 connector.

(b) Using lead wires, connect the connectors as follows.

(c) Warm up the engine.

(d) Run the engine at 3000 rpm for 10 seconds or more.

(e) Connect the intelligent tester to the DLC3.

(f) Turn the ignition switch to the ON position and turn the

intelligent tester on.

(g) Select the items: DIAGNOSIS / ENHANCED OBD II /

DTC INFO / CURRENT CODES.

(h) Read the DTCs.

Result

(i) Reconnect the EA1 connector.

B

A

1READ VALUE OF DTC OUTPUT (CHECK KNOCK SENSOR CIRCUIT)

G041090E10

Male Connector - Female Connector

Terminal 2 - Terminal 4

Terminal 1 - Terminal 3

Terminal 4 - Terminal 2

Terminal 3 - Terminal 1

Display Proceed to

DTCs that are same as when vehicle brought

in P0327, P0328

P0327, P0328 or P0332,

P0333

P0332, P0333A

DTCs that are different from when vehicle

brought in P0327, P0328

P0332, P0333 or

P0332, P0333 P0327, P0328B

Go to step 4

Page 532 of 3000

ES–2262GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

OK

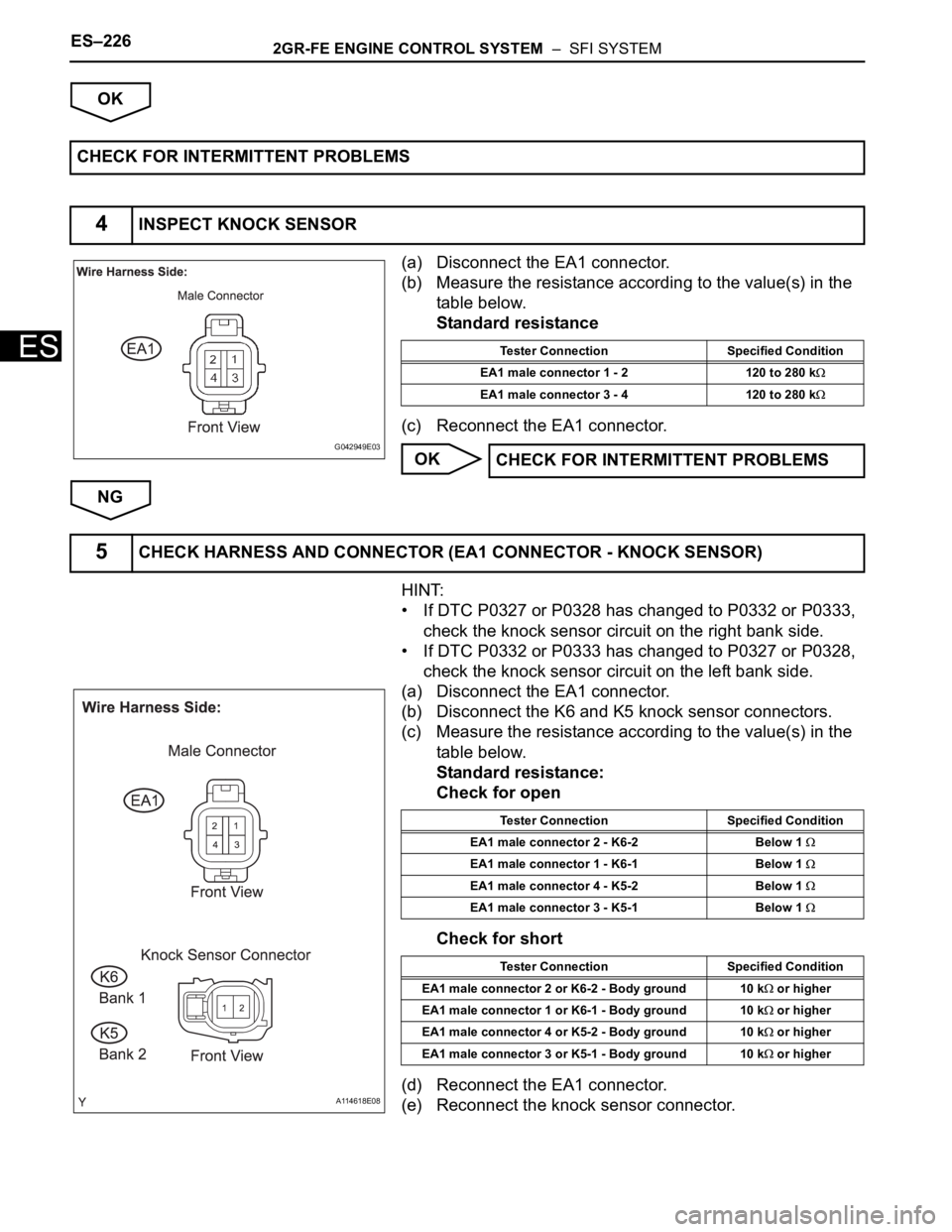

(a) Disconnect the EA1 connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(c) Reconnect the EA1 connector.

OK

NG

HINT:

• If DTC P0327 or P0328 has changed to P0332 or P0333,

check the knock sensor circuit on the right bank side.

• If DTC P0332 or P0333 has changed to P0327 or P0328,

check the knock sensor circuit on the left bank side.

(a) Disconnect the EA1 connector.

(b) Disconnect the K6 and K5 knock sensor connectors.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Check for open

Check for short

(d) Reconnect the EA1 connector.

(e) Reconnect the knock sensor connector. CHECK FOR INTERMITTENT PROBLEMS

4INSPECT KNOCK SENSOR

G042949E03

Tester Connection Specified Condition

EA1 male connector 1 - 2 120 to 280 k

EA1 male connector 3 - 4 120 to 280 k

CHECK FOR INTERMITTENT PROBLEMS

5CHECK HARNESS AND CONNECTOR (EA1 CONNECTOR - KNOCK SENSOR)

A114618E08

Tester Connection Specified Condition

EA1 male connector 2 - K6-2 Below 1

EA1 male connector 1 - K6-1 Below 1

EA1 male connector 4 - K5-2 Below 1

EA1 male connector 3 - K5-1 Below 1

Tester Connection Specified Condition

EA1 male connector 2 or K6-2 - Body ground 10 k

or higher

EA1 male connector 1 or K6-1 - Body ground 10 k

or higher

EA1 male connector 4 or K5-2 - Body ground 10 k

or higher

EA1 male connector 3 or K5-1 - Body ground 10 k

or higher

Page 533 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–227

ES

NG

OKREPAIR OR REPLACE HARNESS OR

CONNECTOR (EA1 CONNECTOR - KNOCK

SENSOR)

REPLACE KNOCK SENSOR (See page ES-520)

Page 534 of 3000

ES–2282GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

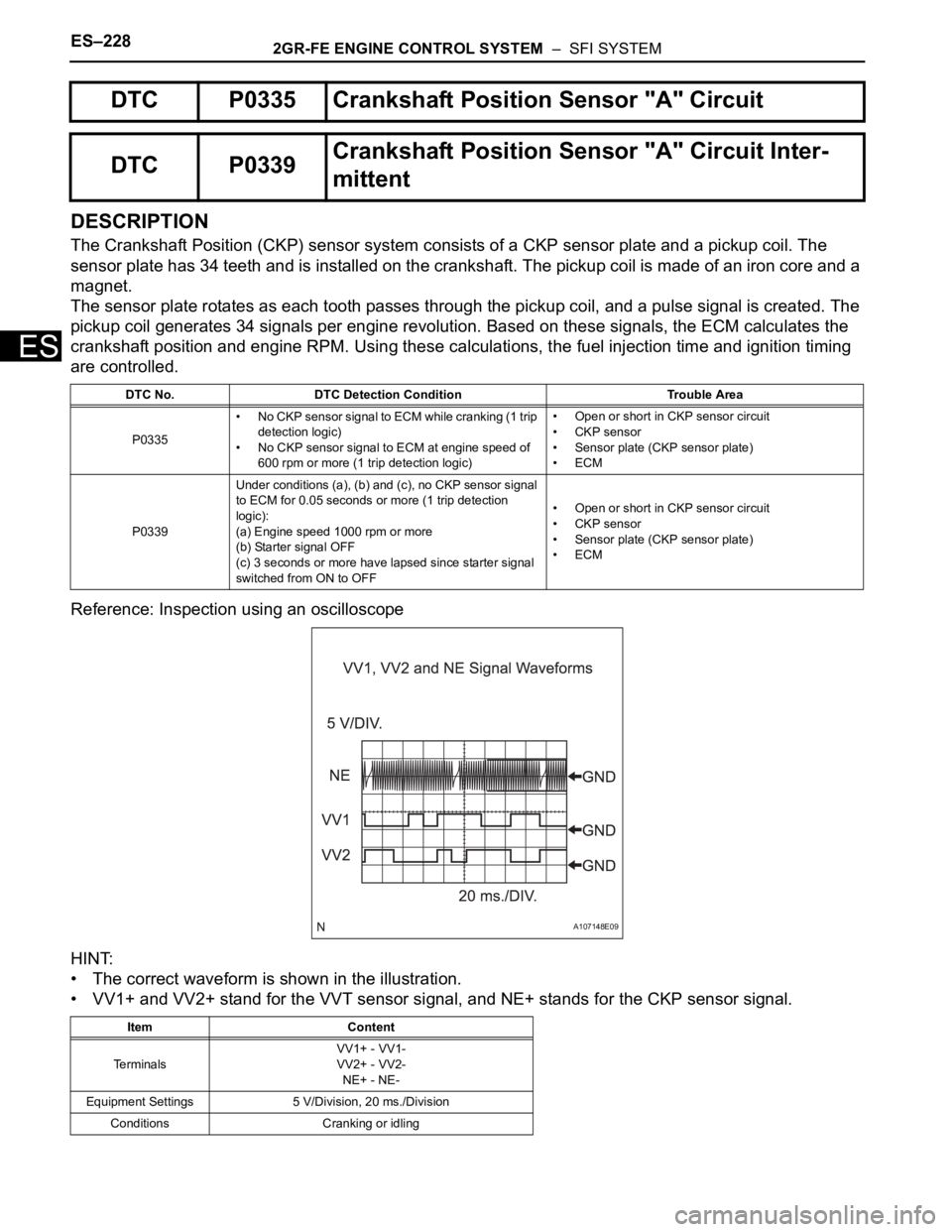

DESCRIPTION

The Crankshaft Position (CKP) sensor system consists of a CKP sensor plate and a pickup coil. The

sensor plate has 34 teeth and is installed on the crankshaft. The pickup coil is made of an iron core and a

magnet.

The sensor plate rotates as each tooth passes through the pickup coil, and a pulse signal is created. The

pickup coil generates 34 signals per engine revolution. Based on these signals, the ECM calculates the

crankshaft position and engine RPM. Using these calculations, the fuel injection time and ignition timing

are controlled.

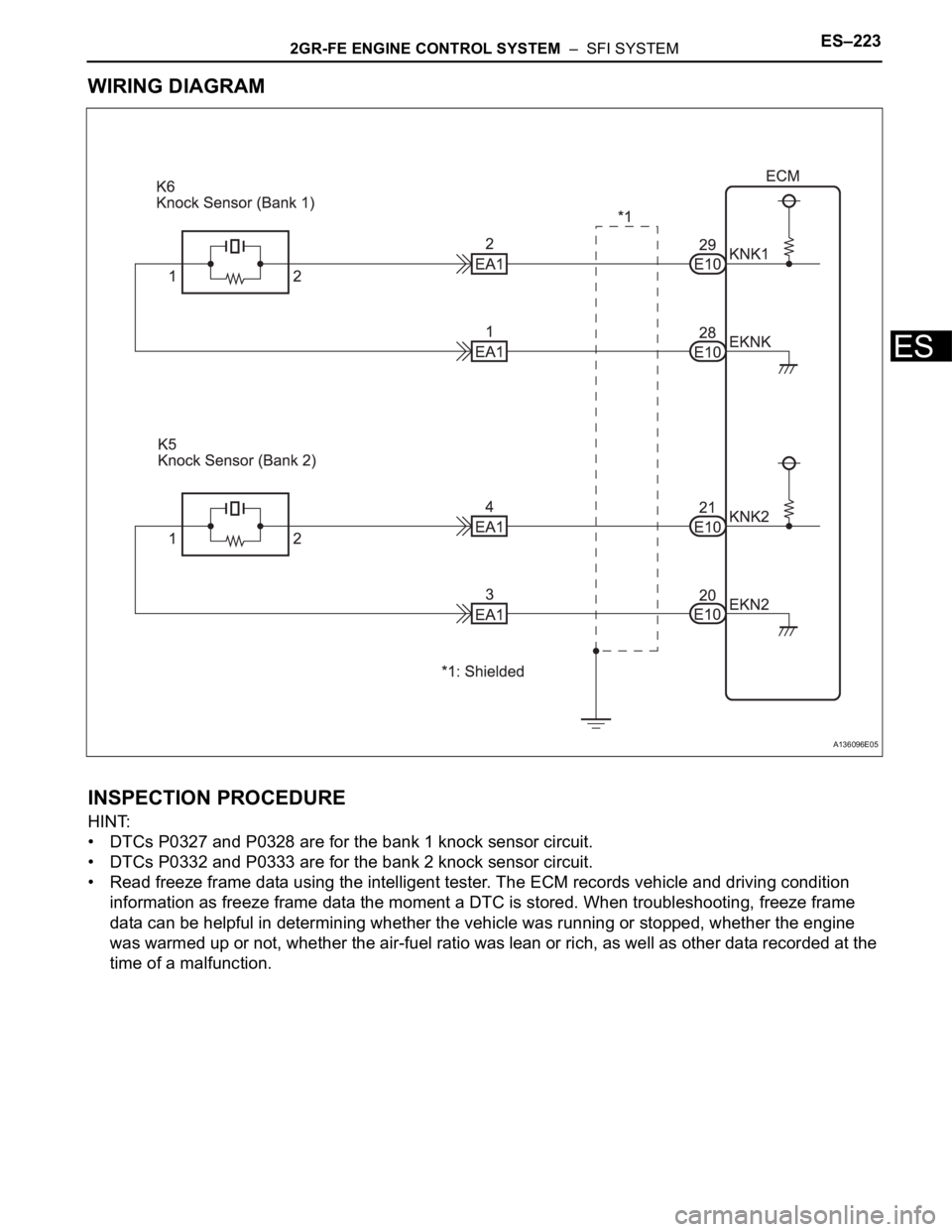

Reference: Inspection using an oscilloscope

HINT:

• The correct waveform is shown in the illustration.

• VV1+ and VV2+ stand for the VVT sensor signal, and NE+ stands for the CKP sensor signal.

DTC P0335 Crankshaft Position Sensor "A" Circuit

DTC P0339Crankshaft Position Sensor "A" Circuit Inter-

mittent

DTC No. DTC Detection Condition Trouble Area

P0335• No CKP sensor signal to ECM while cranking (1 trip

detection logic)

• No CKP sensor signal to ECM at engine speed of

600 rpm or more (1 trip detection logic)• Open or short in CKP sensor circuit

• CKP sensor

• Sensor plate (CKP sensor plate)

•ECM

P0339Under conditions (a), (b) and (c), no CKP sensor signal

to ECM for 0.05 seconds or more (1 trip detection

logic):

(a) Engine speed 1000 rpm or more

(b) Starter signal OFF

(c) 3 seconds or more have lapsed since starter signal

switched from ON to OFF• Open or short in CKP sensor circuit

• CKP sensor

• Sensor plate (CKP sensor plate)

•ECM

Item Content

Te r m i n a l sVV1+ - VV1-

VV2+ - VV2-

NE+ - NE-

Equipment Settings 5 V/Division, 20 ms./Division

Conditions Cranking or idling

A107148E09

Page 535 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–229

ES

MONITOR DESCRIPTION

If there is no signal from the CKP sensor despite the engine revolving, the ECM interprets this as a

malfunction of the sensor.

If the malfunction is not repaired successfully, a DTC is set 10 seconds after the engine is next started.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

All:

Crankshaft Position Sensor Range Check during Cranking P0335:

Crankshaft Position Sensor Range Check during Engine Running P0335:

TYPICAL MALFUNCTION THRESHOLDS

Crankshaft Position Sensor Range Check during Cranking P0335:

Crankshaft Position Sensor Range Check during Engine Running P0335:

COMPONENT OPERATING RANGE

Related DTCsP0335: Crankshaft position sensor range check during cranking

P0335: Crankshaft position sensor range check during engine running

Required Sensors / Components (Main) Crankshaft Position (CKP) sensor

Required Sensors / Components (Related) -

Frequency of Operation Continuous

Duration 3 times

MIL Operation Immediate

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentNone

Sta r t e r OF F

Ignition switch ON

Battery voltage 7 V or more

Minimum battery voltage while starter ON Less than 11 V

Number of VVT sensor signal pulse 6 times

CMP sensor circuit fail Not detected

Engine speed 600 rpm or more

Sta r t e r OF F

Time after starter from ON to OFF 3 seconds or more

Number of crankshaft position sensor signal pulse 132 or less, or 174 or more

CKP sensor signal No signal

CKP sensor• CKP sensor output voltage fluctuates while crankshaft is revolving

• 34 CKP sensor signals per crankshaft revolution

Page 537 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–231

ES

INSPECTION PROCEDURE

HINT:

• If no problem is found by this diagnostic troubleshooting procedure, troubleshoot the engine

mechanical systems.

• Check the engine speed. The engine speed can be checked by using the intelligent tester. Perform the

following procedure:

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine.

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / DATA LIST / PRIMARY /

ENGINE SPD.

The engine speed may be indicated as zero despite the engine revolving normally. This is caused

by a lack of NE signals from the Crankshaft Position (CKP) sensor. Alternatively, the engine speed

may be indicated as lower than the actual engine speed, if the CKP sensor voltage output is

insufficient.

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the

time of a malfunction.

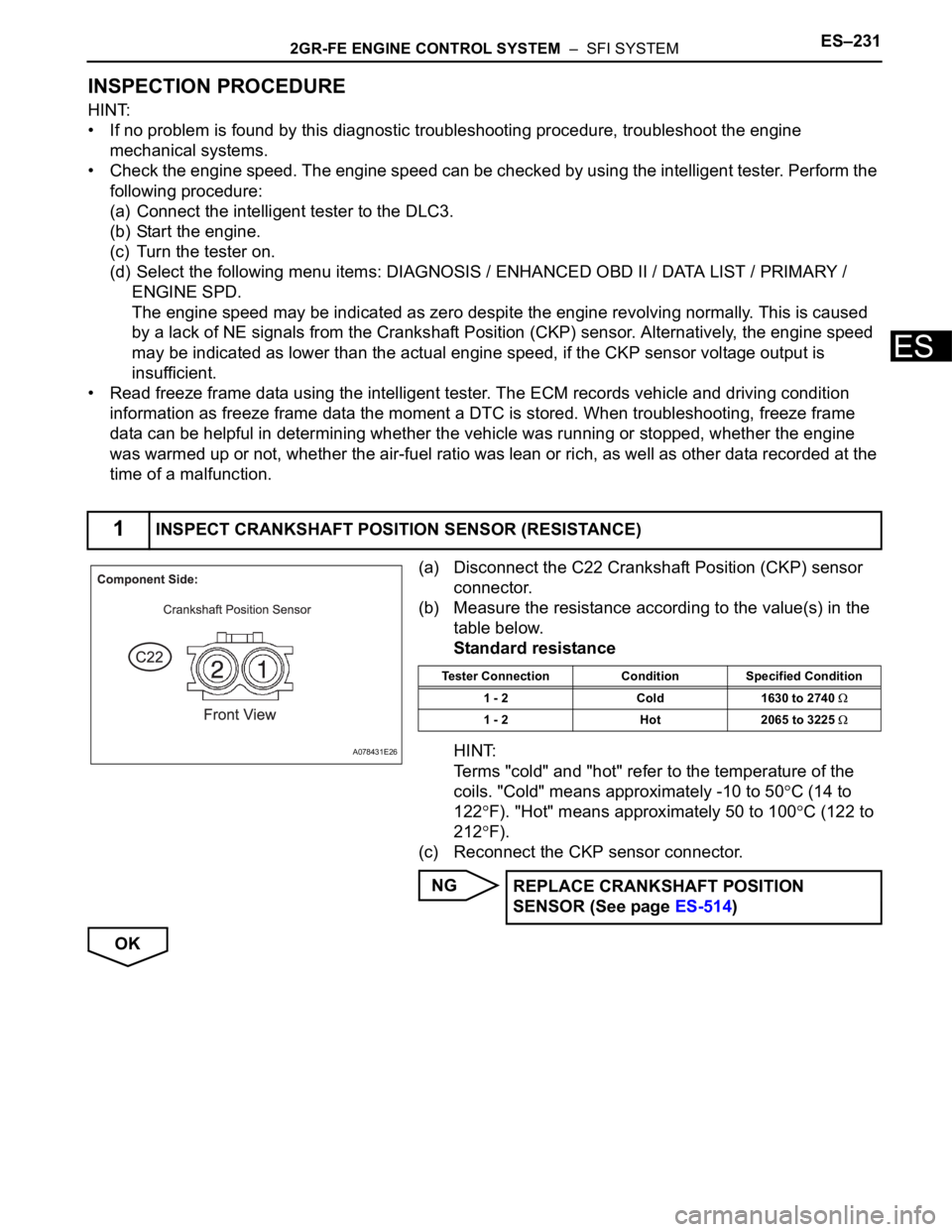

(a) Disconnect the C22 Crankshaft Position (CKP) sensor

connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

HINT:

Terms "cold" and "hot" refer to the temperature of the

coils. "Cold" means approximately -10 to 50

C (14 to

122

F). "Hot" means approximately 50 to 100C (122 to

212

F).

(c) Reconnect the CKP sensor connector.

NG

OK

1INSPECT CRANKSHAFT POSITION SENSOR (RESISTANCE)

A078431E26

Tester Connection Condition Specified Condition

1 - 2 Cold 1630 to 2740

1 - 2 Hot 2065 to 3225

REPLACE CRANKSHAFT POSITION

SENSOR (See page ES-514)