check oil TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 2023 of 3000

TRANSFER – TRANSFER UNITTF–33

TF

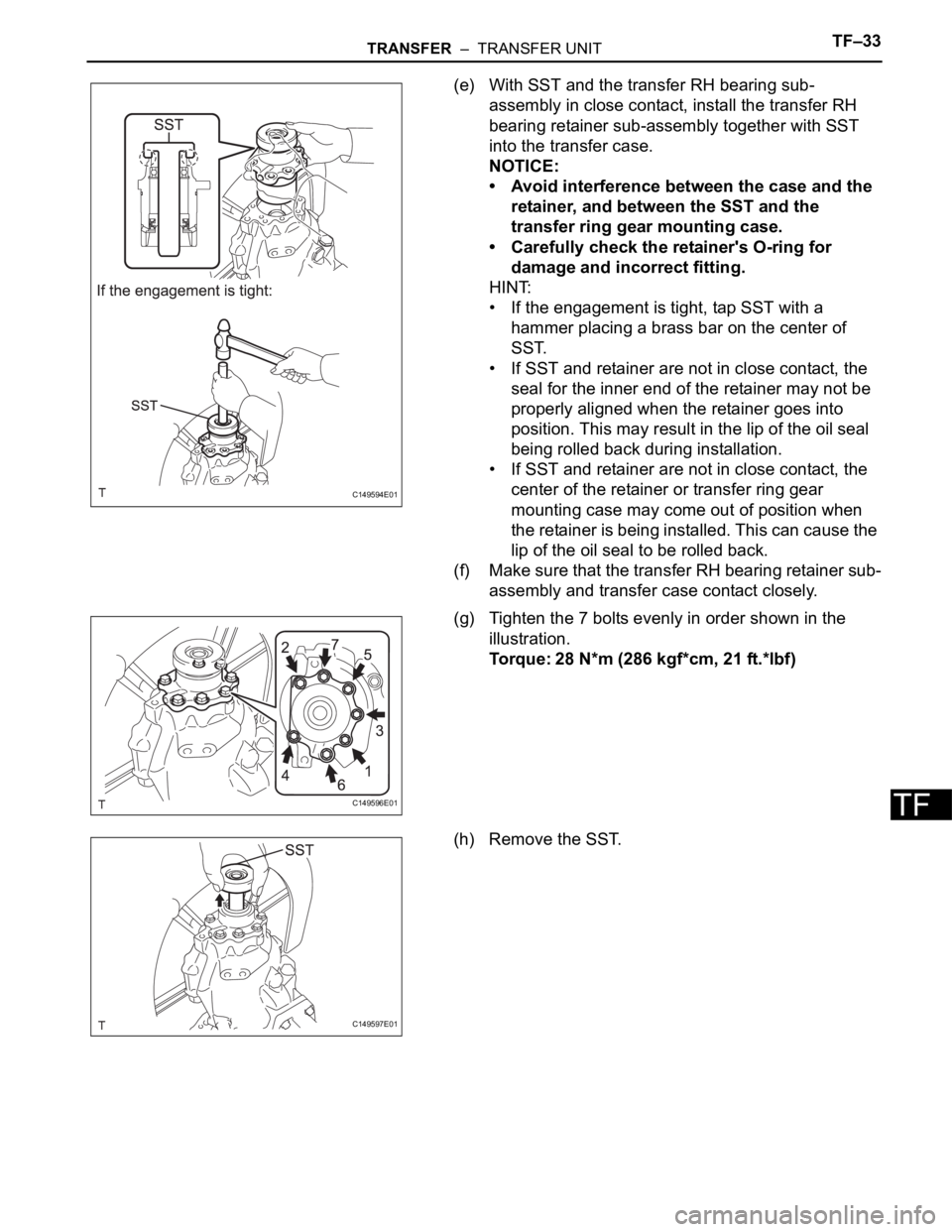

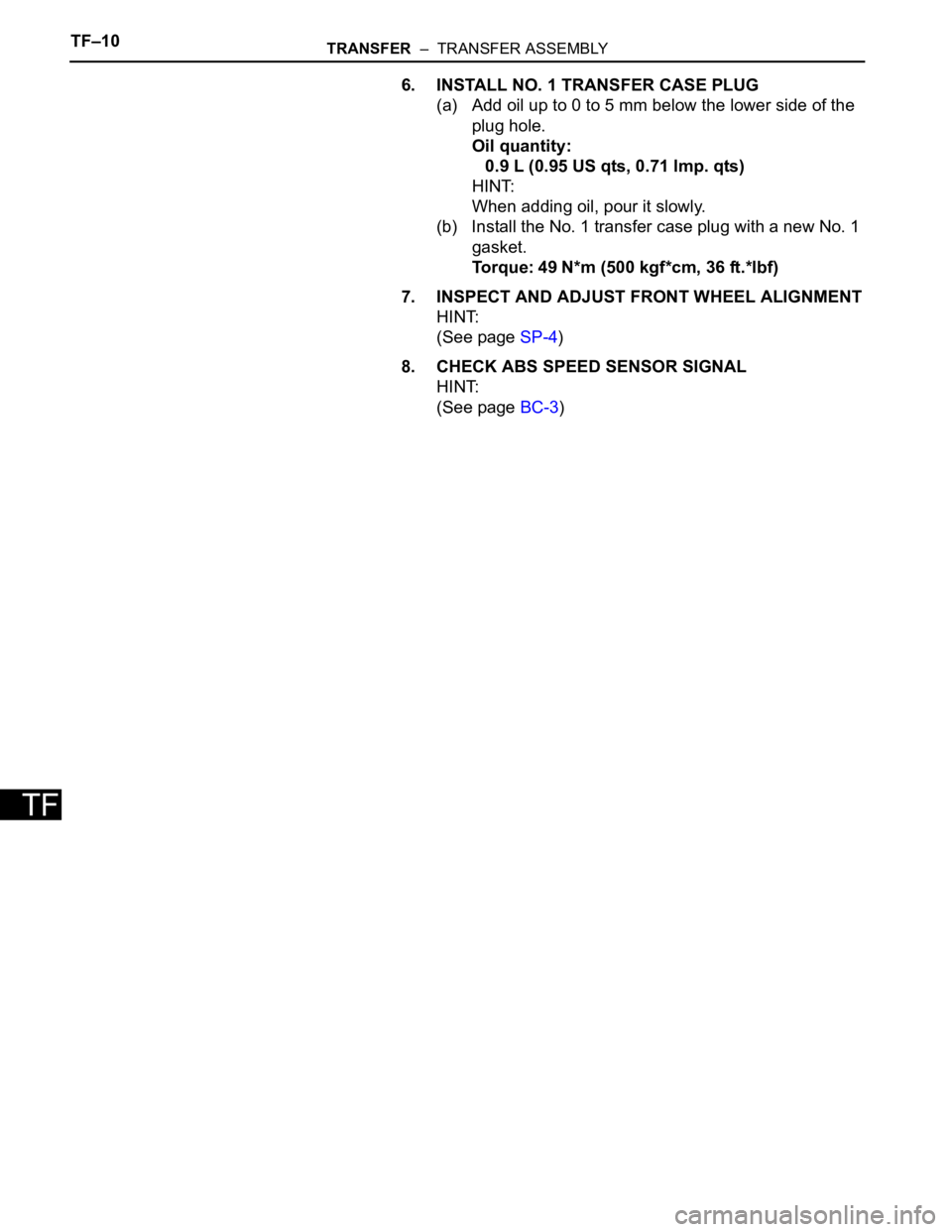

(e) With SST and the transfer RH bearing sub-

assembly in close contact, install the transfer RH

bearing retainer sub-assembly together with SST

into the transfer case.

NOTICE:

• Avoid interference between the case and the

retainer, and between the SST and the

transfer ring gear mounting case.

• Carefully check the retainer's O-ring for

damage and incorrect fitting.

HINT:

• If the engagement is tight, tap SST with a

hammer placing a brass bar on the center of

SST.

• If SST and retainer are not in close contact, the

seal for the inner end of the retainer may not be

properly aligned when the retainer goes into

position. This may result in the lip of the oil seal

being rolled back during installation.

• If SST and retainer are not in close contact, the

center of the retainer or transfer ring gear

mounting case may come out of position when

the retainer is being installed. This can cause the

lip of the oil seal to be rolled back.

(f) Make sure that the transfer RH bearing retainer sub-

assembly and transfer case contact closely.

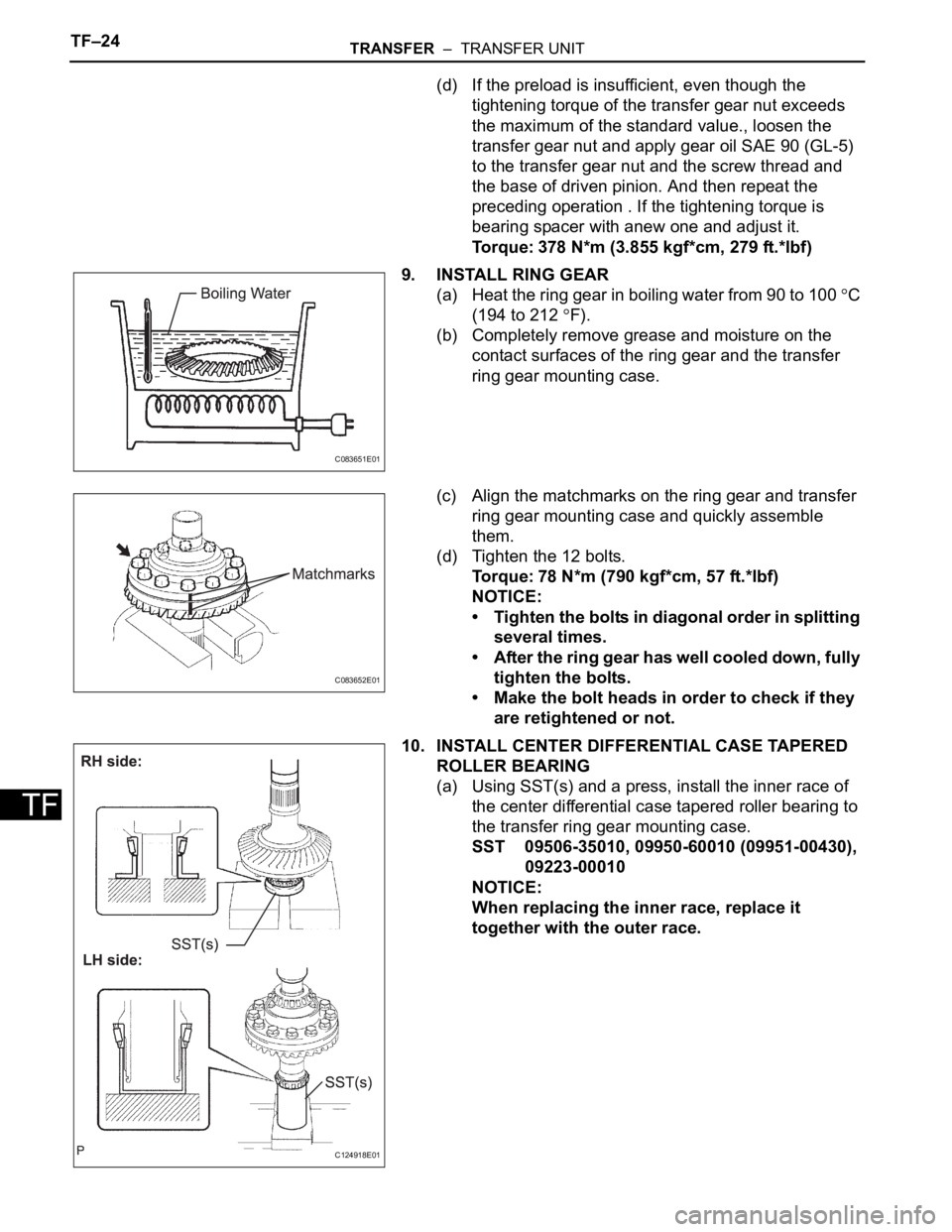

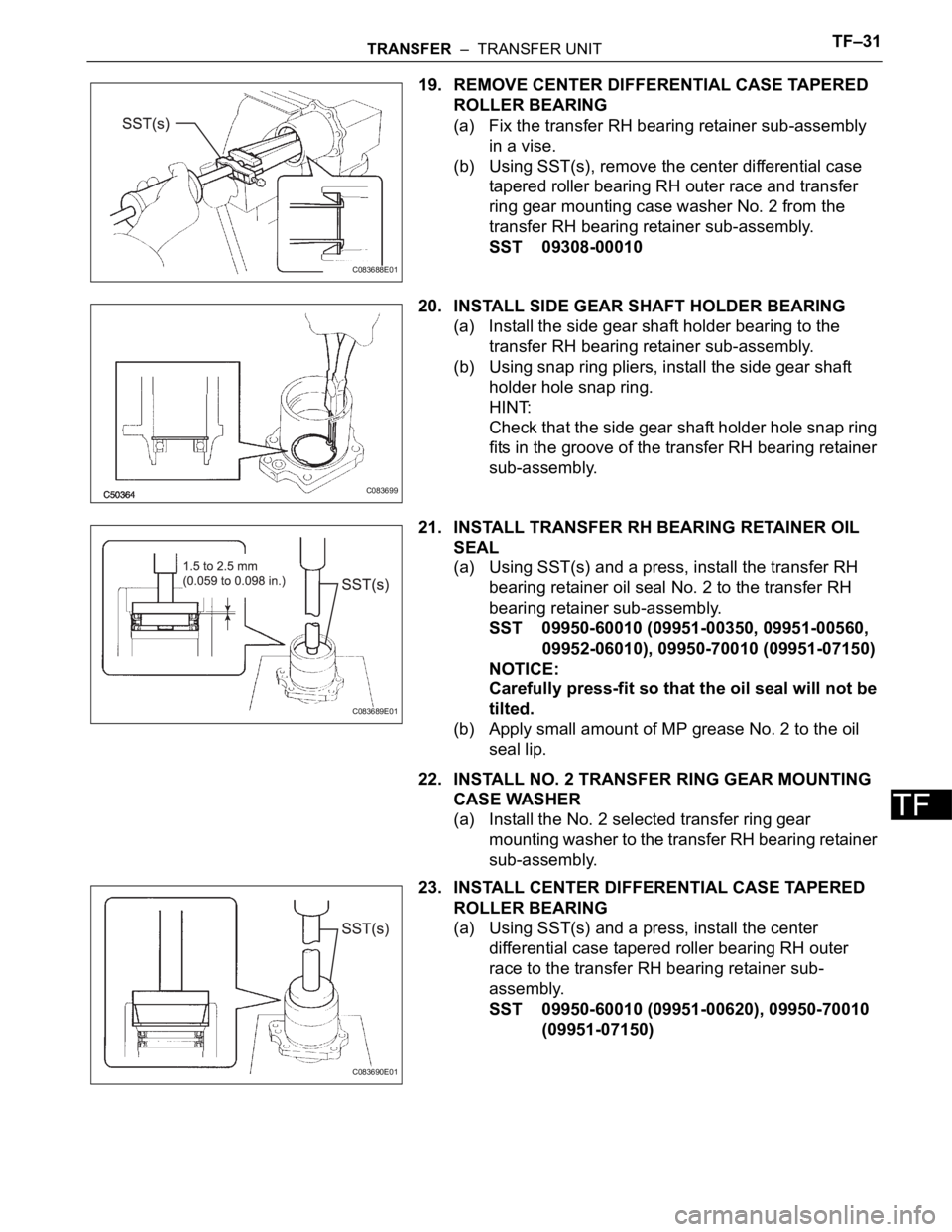

(g) Tighten the 7 bolts evenly in order shown in the

illustration.

Torque: 28 N*m (286 kgf*cm, 21 ft.*lbf)

(h) Remove the SST.

C149594E01

C149596E01

C149597E01

Page 2025 of 3000

TRANSFER – TRANSFER UNITTF–35

TF

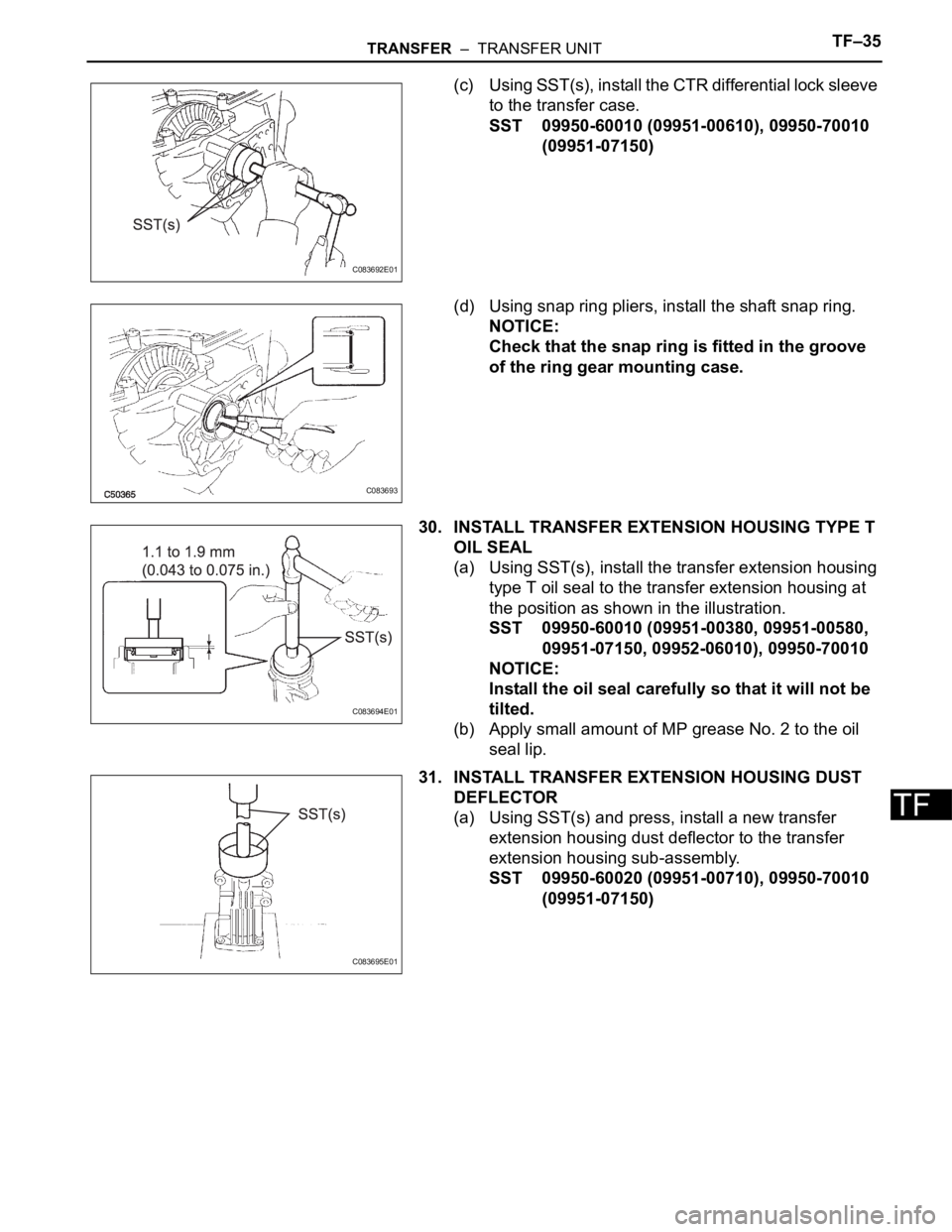

(c) Using SST(s), install the CTR differential lock sleeve

to the transfer case.

SST 09950-60010 (09951-00610), 09950-70010

(09951-07150)

(d) Using snap ring pliers, install the shaft snap ring.

NOTICE:

Check that the snap ring is fitted in the groove

of the ring gear mounting case.

30. INSTALL TRANSFER EXTENSION HOUSING TYPE T

OIL SEAL

(a) Using SST(s), install the transfer extension housing

type T oil seal to the transfer extension housing at

the position as shown in the illustration.

SST 09950-60010 (09951-00380, 09951-00580,

09951-07150, 09952-06010), 09950-70010

NOTICE:

Install the oil seal carefully so that it will not be

tilted.

(b) Apply small amount of MP grease No. 2 to the oil

seal lip.

31. INSTALL TRANSFER EXTENSION HOUSING DUST

DEFLECTOR

(a) Using SST(s) and press, install a new transfer

extension housing dust deflector to the transfer

extension housing sub-assembly.

SST 09950-60020 (09951-00710), 09950-70010

(09951-07150)

C083692E01

C083693

C083694E01

C083695E01

Page 2029 of 3000

TRANSFER – TRANSFER OILTF–3

TF

TRANSFER OIL

ON-VEHICLE INSPECTION

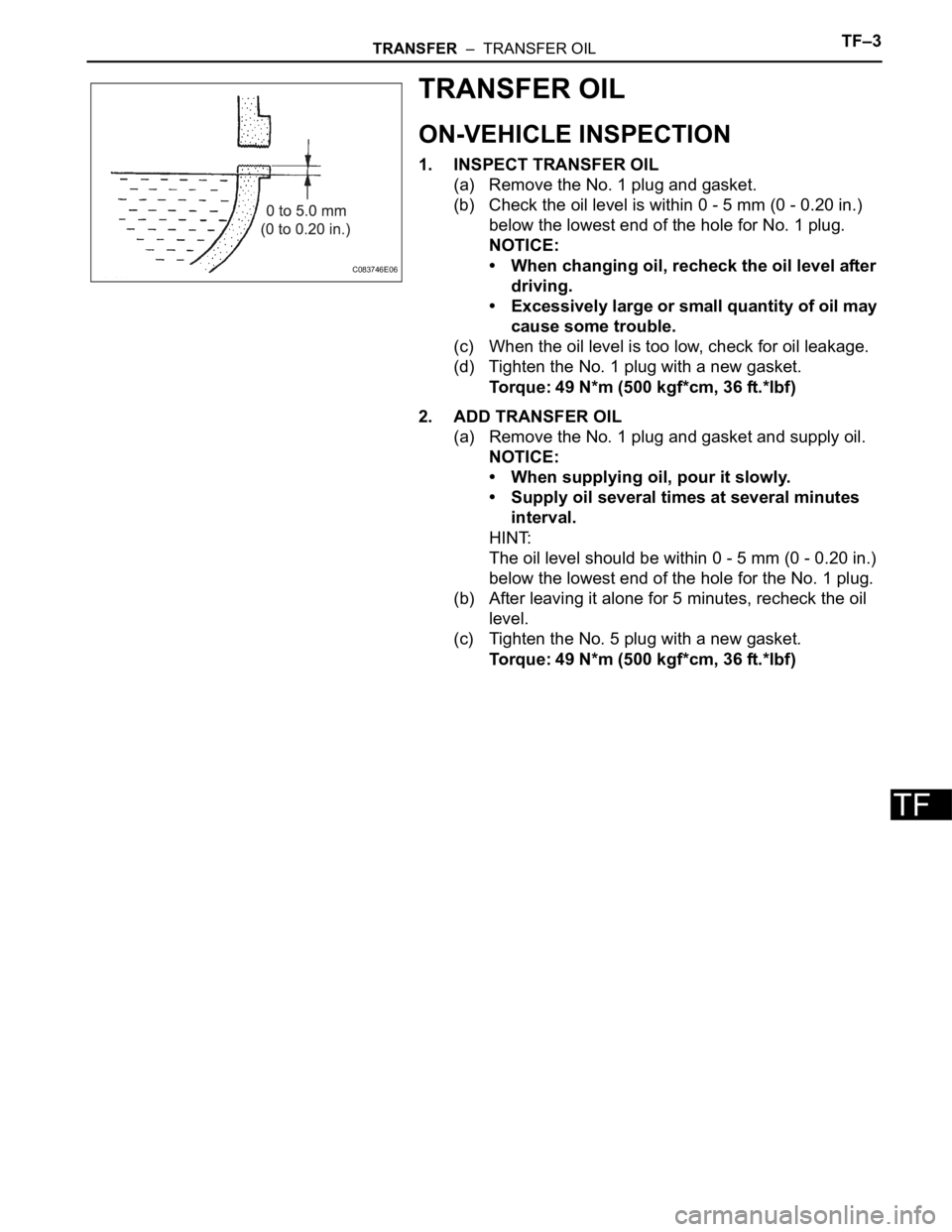

1. INSPECT TRANSFER OIL

(a) Remove the No. 1 plug and gasket.

(b) Check the oil level is within 0 - 5 mm (0 - 0.20 in.)

below the lowest end of the hole for No. 1 plug.

NOTICE:

• When changing oil, recheck the oil level after

driving.

• Excessively large or small quantity of oil may

cause some trouble.

(c) When the oil level is too low, check for oil leakage.

(d) Tighten the No. 1 plug with a new gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

2. ADD TRANSFER OIL

(a) Remove the No. 1 plug and gasket and supply oil.

NOTICE:

• When supplying oil, pour it slowly.

• Supply oil several times at several minutes

interval.

HINT:

The oil level should be within 0 - 5 mm (0 - 0.20 in.)

below the lowest end of the hole for the No. 1 plug.

(b) After leaving it alone for 5 minutes, recheck the oil

level.

(c) Tighten the No. 5 plug with a new gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

C083746E06

Page 2032 of 3000

TRANSFER – TRANSFER ASSEMBLYTF–9

TF

INSTALLATION

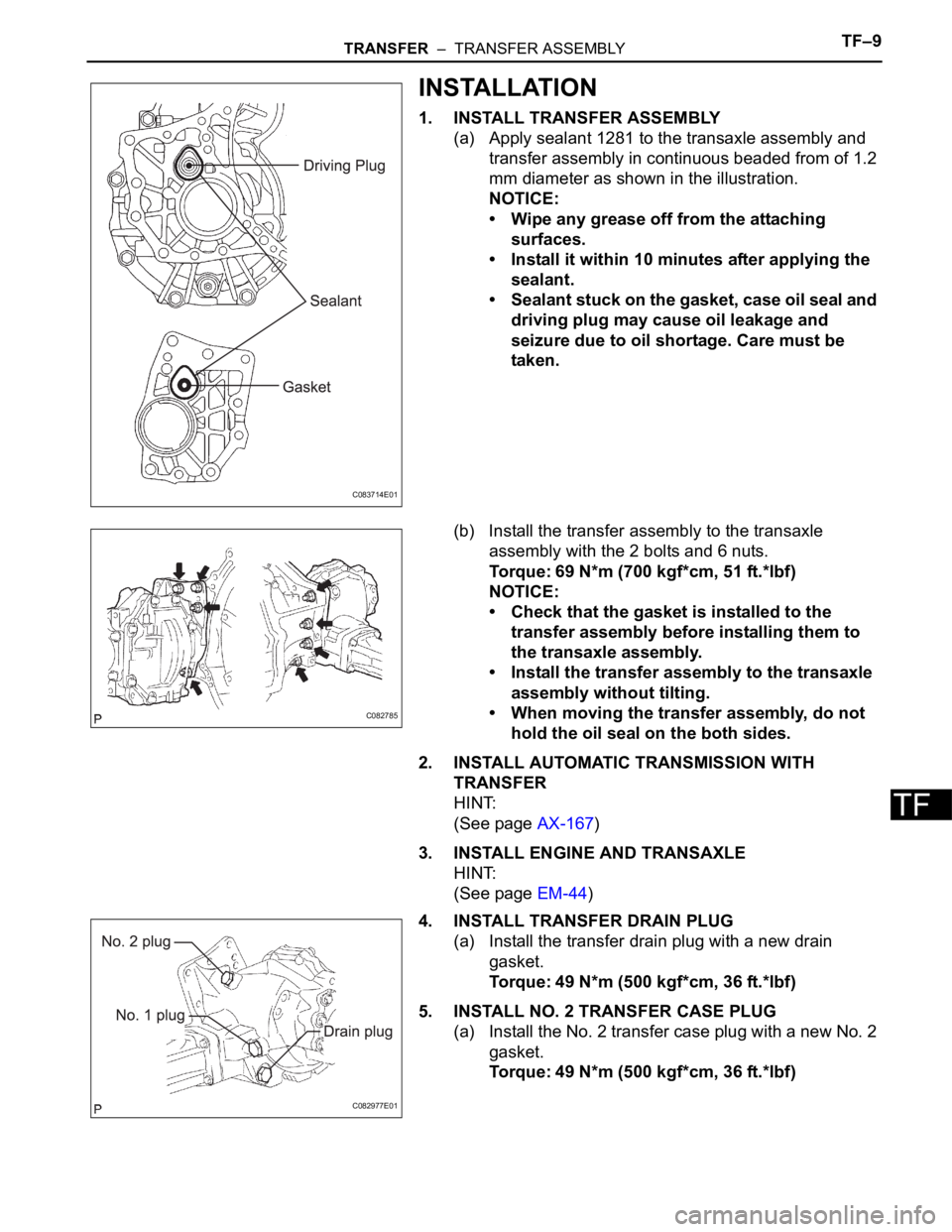

1. INSTALL TRANSFER ASSEMBLY

(a) Apply sealant 1281 to the transaxle assembly and

transfer assembly in continuous beaded from of 1.2

mm diameter as shown in the illustration.

NOTICE:

• Wipe any grease off from the attaching

surfaces.

• Install it within 10 minutes after applying the

sealant.

• Sealant stuck on the gasket, case oil seal and

driving plug may cause oil leakage and

seizure due to oil shortage. Care must be

taken.

(b) Install the transfer assembly to the transaxle

assembly with the 2 bolts and 6 nuts.

Torque: 69 N*m (700 kgf*cm, 51 ft.*lbf)

NOTICE:

• Check that the gasket is installed to the

transfer assembly before installing them to

the transaxle assembly.

• Install the transfer assembly to the transaxle

assembly without tilting.

• When moving the transfer assembly, do not

hold the oil seal on the both sides.

2. INSTALL AUTOMATIC TRANSMISSION WITH

TRANSFER

HINT:

(See page AX-167)

3. INSTALL ENGINE AND TRANSAXLE

HINT:

(See page EM-44)

4. INSTALL TRANSFER DRAIN PLUG

(a) Install the transfer drain plug with a new drain

gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

5. INSTALL NO. 2 TRANSFER CASE PLUG

(a) Install the No. 2 transfer case plug with a new No. 2

gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

C083714E01

C082785

C082977E01

Page 2033 of 3000

TF–10TRANSFER – TRANSFER ASSEMBLY

TF

6. INSTALL NO. 1 TRANSFER CASE PLUG

(a) Add oil up to 0 to 5 mm below the lower side of the

plug hole.

Oil quantity:

0.9 L (0.95 US qts, 0.71 lmp. qts)

HINT:

When adding oil, pour it slowly.

(b) Install the No. 1 transfer case plug with a new No. 1

gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

7. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

HINT:

(See page SP-4)

8. CHECK ABS SPEED SENSOR SIGNAL

HINT:

(See page BC-3)

Page 2047 of 3000

TF–24TRANSFER – TRANSFER UNIT

TF

(d) If the preload is insufficient, even though the

tightening torque of the transfer gear nut exceeds

the maximum of the standard value., loosen the

transfer gear nut and apply gear oil SAE 90 (GL-5)

to the transfer gear nut and the screw thread and

the base of driven pinion. And then repeat the

preceding operation . If the tightening torque is

bearing spacer with anew one and adjust it.

Torque: 378 N*m (3.855 kgf*cm, 279 ft.*lbf)

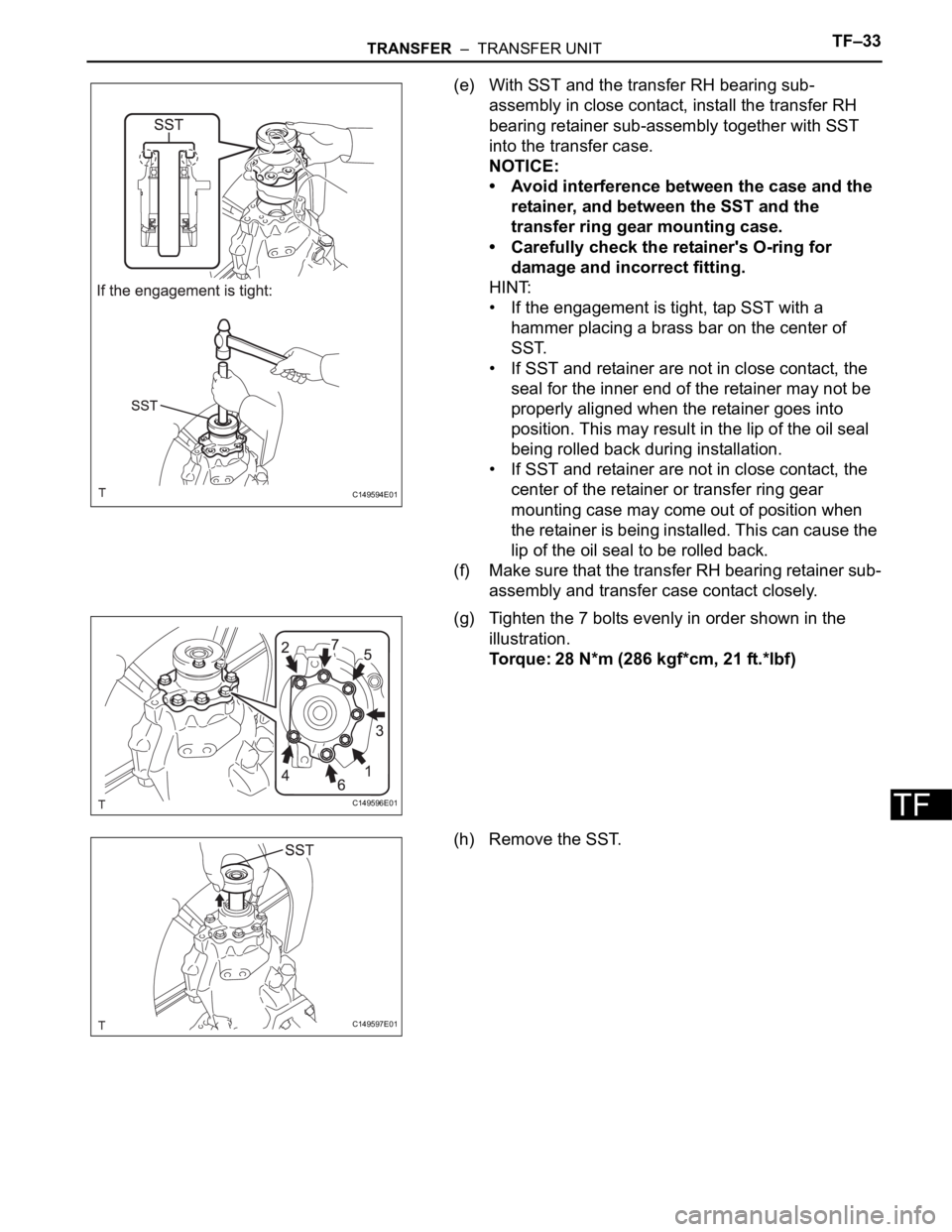

9. INSTALL RING GEAR

(a) Heat the ring gear in boiling water from 90 to 100

C

(194 to 212

F).

(b) Completely remove grease and moisture on the

contact surfaces of the ring gear and the transfer

ring gear mounting case.

(c) Align the matchmarks on the ring gear and transfer

ring gear mounting case and quickly assemble

them.

(d) Tighten the 12 bolts.

Torque: 78 N*m (790 kgf*cm, 57 ft.*lbf)

NOTICE:

• Tighten the bolts in diagonal order in splitting

several times.

• After the ring gear has well cooled down, fully

tighten the bolts.

• Make the bolt heads in order to check if they

are retightened or not.

10. INSTALL CENTER DIFFERENTIAL CASE TAPERED

ROLLER BEARING

(a) Using SST(s) and a press, install the inner race of

the center differential case tapered roller bearing to

the transfer ring gear mounting case.

SST 09506-35010, 09950-60010 (09951-00430),

09223-00010

NOTICE:

When replacing the inner race, replace it

together with the outer race.

C083651E01

C083652E01

C124918E01

Page 2054 of 3000

TRANSFER – TRANSFER UNITTF–31

TF

19. REMOVE CENTER DIFFERENTIAL CASE TAPERED

ROLLER BEARING

(a) Fix the transfer RH bearing retainer sub-assembly

in a vise.

(b) Using SST(s), remove the center differential case

tapered roller bearing RH outer race and transfer

ring gear mounting case washer No. 2 from the

transfer RH bearing retainer sub-assembly.

SST 09308-00010

20. INSTALL SIDE GEAR SHAFT HOLDER BEARING

(a) Install the side gear shaft holder bearing to the

transfer RH bearing retainer sub-assembly.

(b) Using snap ring pliers, install the side gear shaft

holder hole snap ring.

HINT:

Check that the side gear shaft holder hole snap ring

fits in the groove of the transfer RH bearing retainer

sub-assembly.

21. INSTALL TRANSFER RH BEARING RETAINER OIL

SEAL

(a) Using SST(s) and a press, install the transfer RH

bearing retainer oil seal No. 2 to the transfer RH

bearing retainer sub-assembly.

SST 09950-60010 (09951-00350, 09951-00560,

09952-06010), 09950-70010 (09951-07150)

NOTICE:

Carefully press-fit so that the oil seal will not be

tilted.

(b) Apply small amount of MP grease No. 2 to the oil

seal lip.

22. INSTALL NO. 2 TRANSFER RING GEAR MOUNTING

CASE WASHER

(a) Install the No. 2 selected transfer ring gear

mounting washer to the transfer RH bearing retainer

sub-assembly.

23. INSTALL CENTER DIFFERENTIAL CASE TAPERED

ROLLER BEARING

(a) Using SST(s) and a press, install the center

differential case tapered roller bearing RH outer

race to the transfer RH bearing retainer sub-

assembly.

SST 09950-60010 (09951-00620), 09950-70010

(09951-07150)

C083688E01

C083699

C083689E01

C083690E01

Page 2056 of 3000

TRANSFER – TRANSFER UNITTF–33

TF

(e) With SST and the transfer RH bearing sub-

assembly in close contact, install the transfer RH

bearing retainer sub-assembly together with SST

into the transfer case.

NOTICE:

• Avoid interference between the case and the

retainer, and between the SST and the

transfer ring gear mounting case.

• Carefully check the retainer's O-ring for

damage and incorrect fitting.

HINT:

• If the engagement is tight, tap SST with a

hammer placing a brass bar on the center of

SST.

• If SST and retainer are not in close contact, the

seal for the inner end of the retainer may not be

properly aligned when the retainer goes into

position. This may result in the lip of the oil seal

being rolled back during installation.

• If SST and retainer are not in close contact, the

center of the retainer or transfer ring gear

mounting case may come out of position when

the retainer is being installed. This can cause the

lip of the oil seal to be rolled back.

(f) Make sure that the transfer RH bearing retainer sub-

assembly and transfer case contact closely.

(g) Tighten the 7 bolts evenly in order shown in the

illustration.

Torque: 28 N*m (286 kgf*cm, 21 ft.*lbf)

(h) Remove the SST.

C149594E01

C149596E01

C149597E01

Page 2058 of 3000

TRANSFER – TRANSFER UNITTF–35

TF

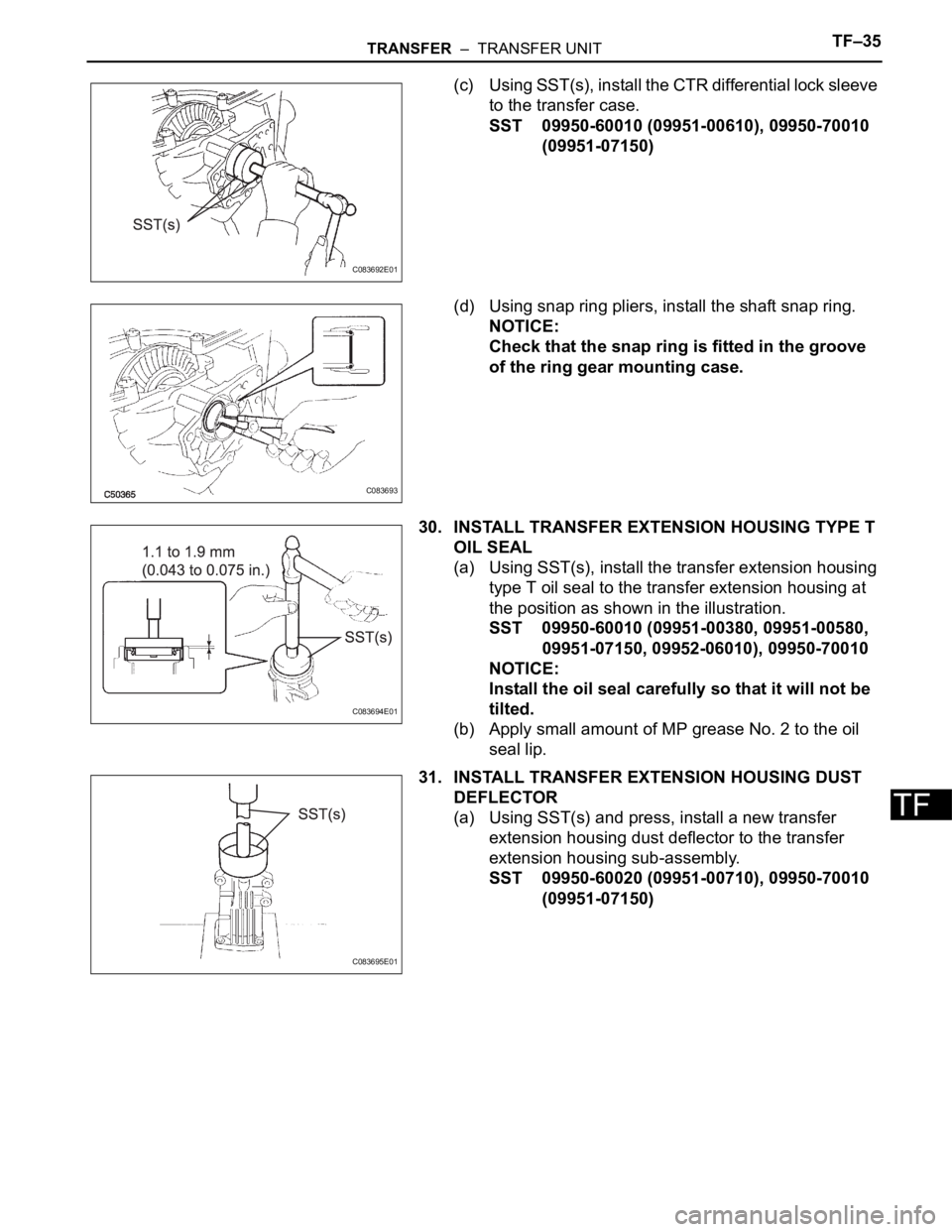

(c) Using SST(s), install the CTR differential lock sleeve

to the transfer case.

SST 09950-60010 (09951-00610), 09950-70010

(09951-07150)

(d) Using snap ring pliers, install the shaft snap ring.

NOTICE:

Check that the snap ring is fitted in the groove

of the ring gear mounting case.

30. INSTALL TRANSFER EXTENSION HOUSING TYPE T

OIL SEAL

(a) Using SST(s), install the transfer extension housing

type T oil seal to the transfer extension housing at

the position as shown in the illustration.

SST 09950-60010 (09951-00380, 09951-00580,

09951-07150, 09952-06010), 09950-70010

NOTICE:

Install the oil seal carefully so that it will not be

tilted.

(b) Apply small amount of MP grease No. 2 to the oil

seal lip.

31. INSTALL TRANSFER EXTENSION HOUSING DUST

DEFLECTOR

(a) Using SST(s) and press, install a new transfer

extension housing dust deflector to the transfer

extension housing sub-assembly.

SST 09950-60020 (09951-00710), 09950-70010

(09951-07150)

C083692E01

C083693

C083694E01

C083695E01

Page 2069 of 3000

PROPELLER SHAFT – PROPELLER SHAFT ASSEMBLY (for 4WD)PR–9

PR

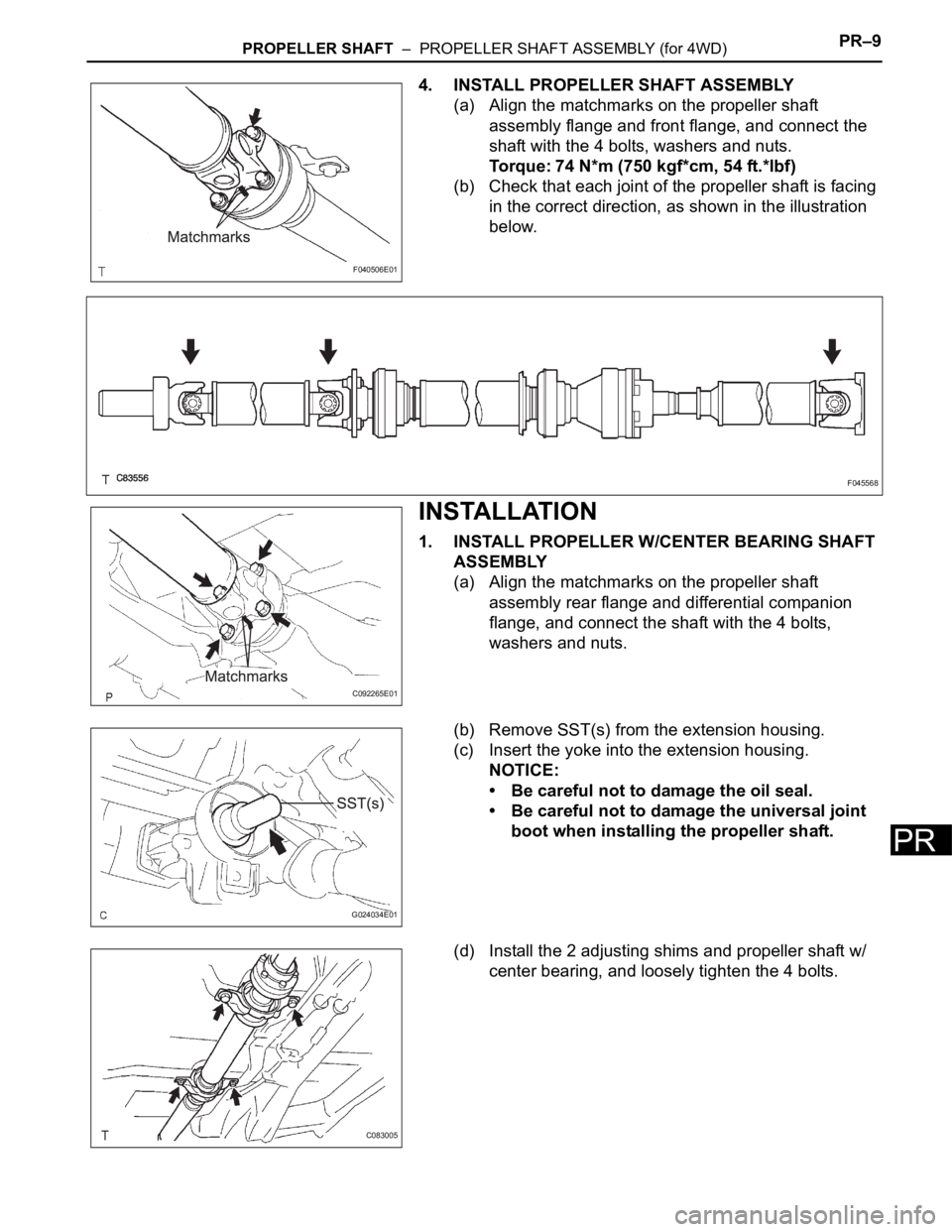

4. INSTALL PROPELLER SHAFT ASSEMBLY

(a) Align the matchmarks on the propeller shaft

assembly flange and front flange, and connect the

shaft with the 4 bolts, washers and nuts.

Torque: 74 N*m (750 kgf*cm, 54 ft.*lbf)

(b) Check that each joint of the propeller shaft is facing

in the correct direction, as shown in the illustration

below.

INSTALLATION

1. INSTALL PROPELLER W/CENTER BEARING SHAFT

ASSEMBLY

(a) Align the matchmarks on the propeller shaft

assembly rear flange and differential companion

flange, and connect the shaft with the 4 bolts,

washers and nuts.

(b) Remove SST(s) from the extension housing.

(c) Insert the yoke into the extension housing.

NOTICE:

• Be careful not to damage the oil seal.

• Be careful not to damage the universal joint

boot when installing the propeller shaft.

(d) Install the 2 adjusting shims and propeller shaft w/

center bearing, and loosely tighten the 4 bolts.

F040506E01

F045568

C092265E01

G024034E01

C083005