check oil TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 2074 of 3000

DS–20DRIVE SHAFT – FRONT DRIVE SHAFT

DS

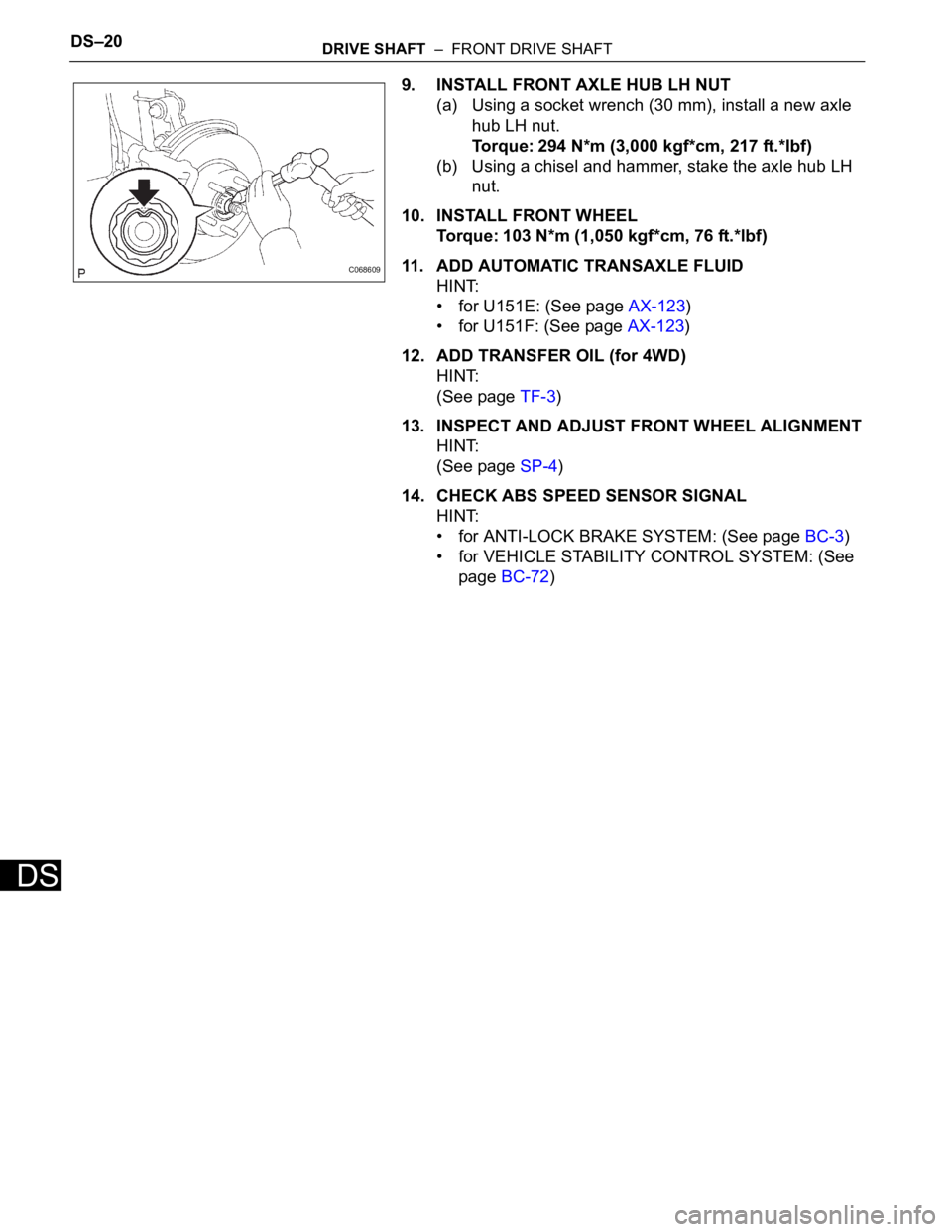

9. INSTALL FRONT AXLE HUB LH NUT

(a) Using a socket wrench (30 mm), install a new axle

hub LH nut.

Torque: 294 N*m (3,000 kgf*cm, 217 ft.*lbf)

(b) Using a chisel and hammer, stake the axle hub LH

nut.

10. INSTALL FRONT WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

11. ADD AUTOMATIC TRANSAXLE FLUID

HINT:

• for U151E: (See page AX-123)

• for U151F: (See page AX-123)

12. ADD TRANSFER OIL (for 4WD)

HINT:

(See page TF-3)

13. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

HINT:

(See page SP-4)

14. CHECK ABS SPEED SENSOR SIGNAL

HINT:

• for ANTI-LOCK BRAKE SYSTEM: (See page BC-3)

• for VEHICLE STABILITY CONTROL SYSTEM: (See

page BC-72)

C068609

Page 2095 of 3000

DS–20DRIVE SHAFT – FRONT DRIVE SHAFT

DS

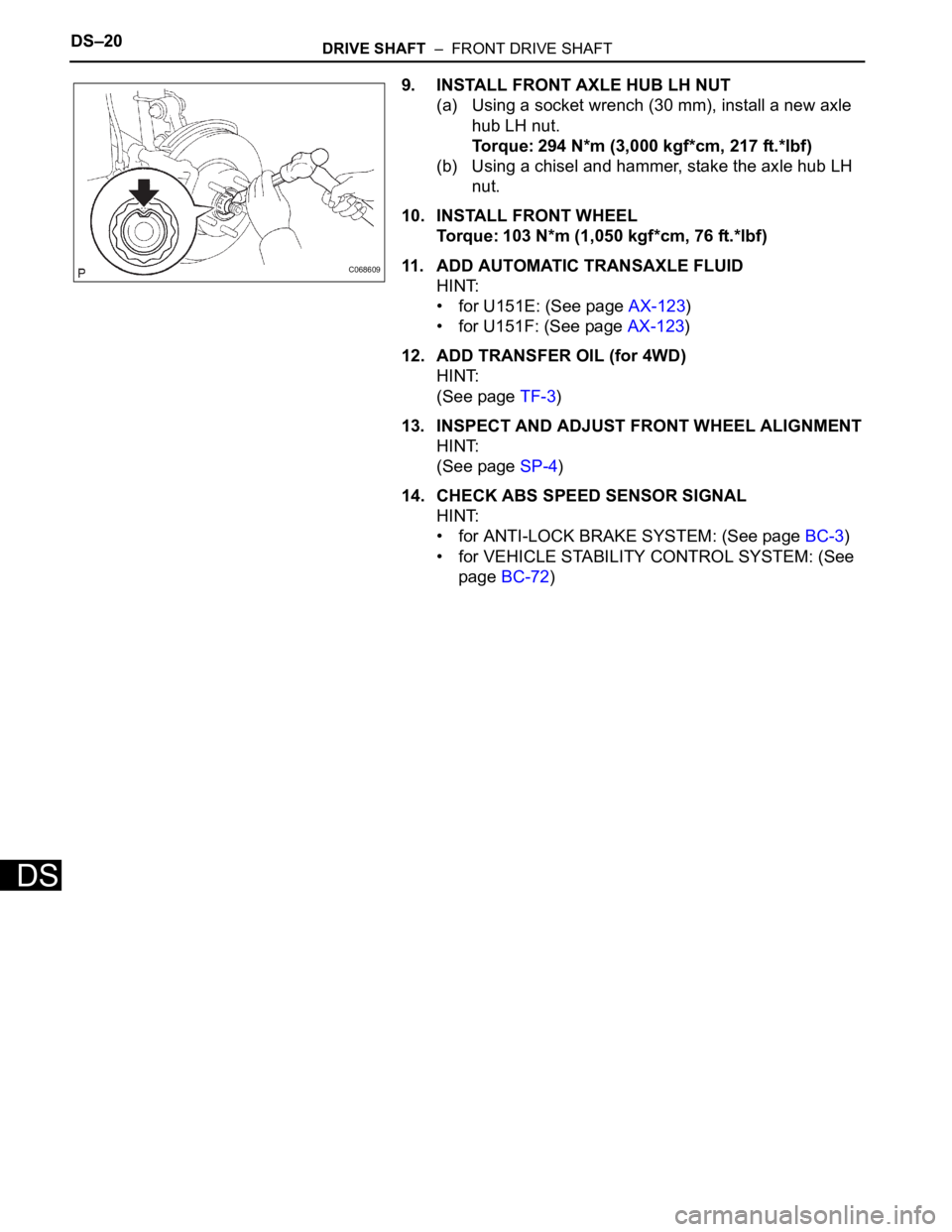

9. INSTALL FRONT AXLE HUB LH NUT

(a) Using a socket wrench (30 mm), install a new axle

hub LH nut.

Torque: 294 N*m (3,000 kgf*cm, 217 ft.*lbf)

(b) Using a chisel and hammer, stake the axle hub LH

nut.

10. INSTALL FRONT WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

11. ADD AUTOMATIC TRANSAXLE FLUID

HINT:

• for U151E: (See page AX-123)

• for U151F: (See page AX-123)

12. ADD TRANSFER OIL (for 4WD)

HINT:

(See page TF-3)

13. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

HINT:

(See page SP-4)

14. CHECK ABS SPEED SENSOR SIGNAL

HINT:

• for ANTI-LOCK BRAKE SYSTEM: (See page BC-3)

• for VEHICLE STABILITY CONTROL SYSTEM: (See

page BC-72)

C068609

Page 2096 of 3000

DRIVE SHAFT – REAR DRIVE SHAFT (for 4WD)DS–27

DS

INSTALLATION

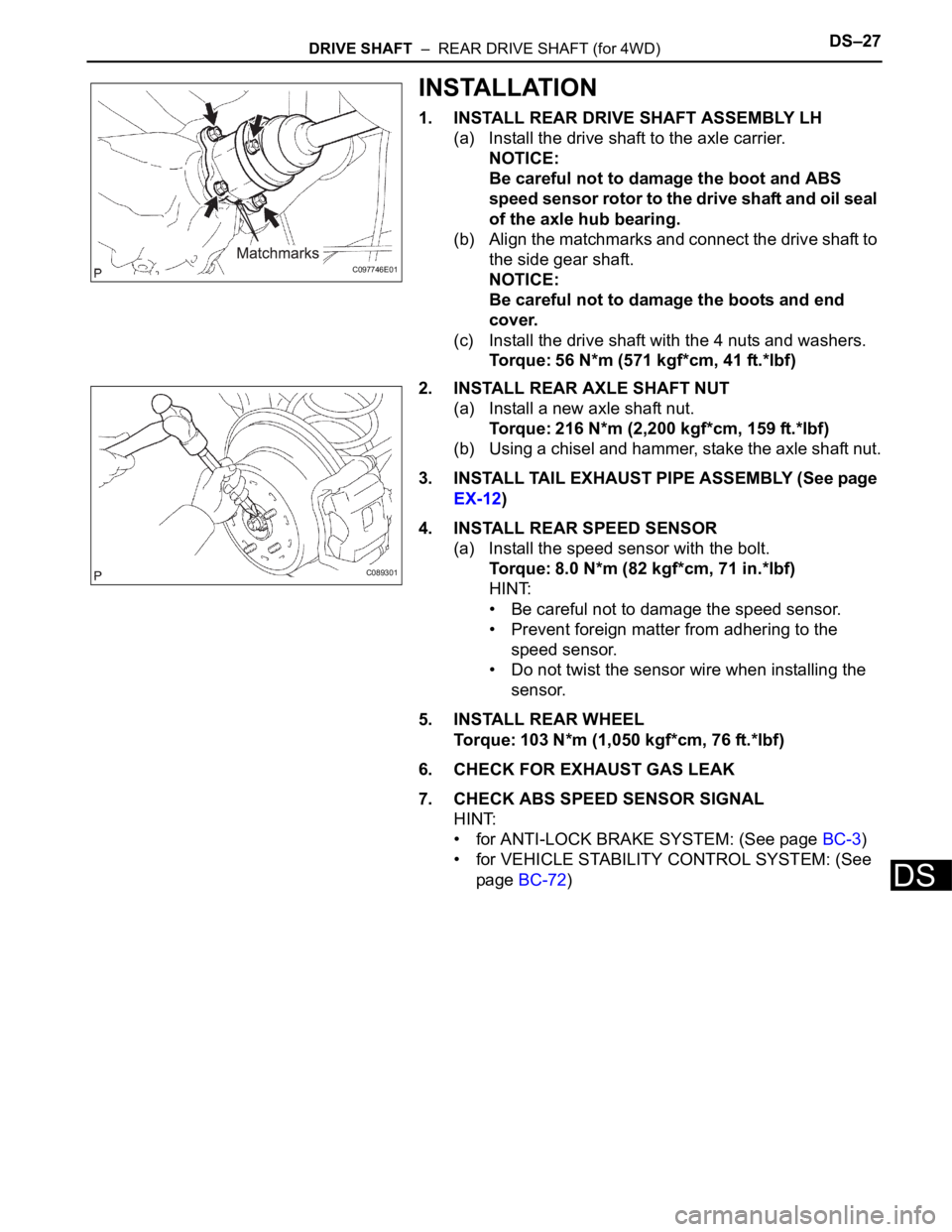

1. INSTALL REAR DRIVE SHAFT ASSEMBLY LH

(a) Install the drive shaft to the axle carrier.

NOTICE:

Be careful not to damage the boot and ABS

speed sensor rotor to the drive shaft and oil seal

of the axle hub bearing.

(b) Align the matchmarks and connect the drive shaft to

the side gear shaft.

NOTICE:

Be careful not to damage the boots and end

cover.

(c) Install the drive shaft with the 4 nuts and washers.

Torque: 56 N*m (571 kgf*cm, 41 ft.*lbf)

2. INSTALL REAR AXLE SHAFT NUT

(a) Install a new axle shaft nut.

Torque: 216 N*m (2,200 kgf*cm, 159 ft.*lbf)

(b) Using a chisel and hammer, stake the axle shaft nut.

3. INSTALL TAIL EXHAUST PIPE ASSEMBLY (See page

EX-12)

4. INSTALL REAR SPEED SENSOR

(a) Install the speed sensor with the bolt.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

HINT:

• Be careful not to damage the speed sensor.

• Prevent foreign matter from adhering to the

speed sensor.

• Do not twist the sensor wire when installing the

sensor.

5. INSTALL REAR WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

6. CHECK FOR EXHAUST GAS LEAK

7. CHECK ABS SPEED SENSOR SIGNAL

HINT:

• for ANTI-LOCK BRAKE SYSTEM: (See page BC-3)

• for VEHICLE STABILITY CONTROL SYSTEM: (See

page BC-72)

C097746E01

C089301

Page 2100 of 3000

DRIVE SHAFT – REAR DRIVE SHAFT (for 4WD)DS–27

DS

INSTALLATION

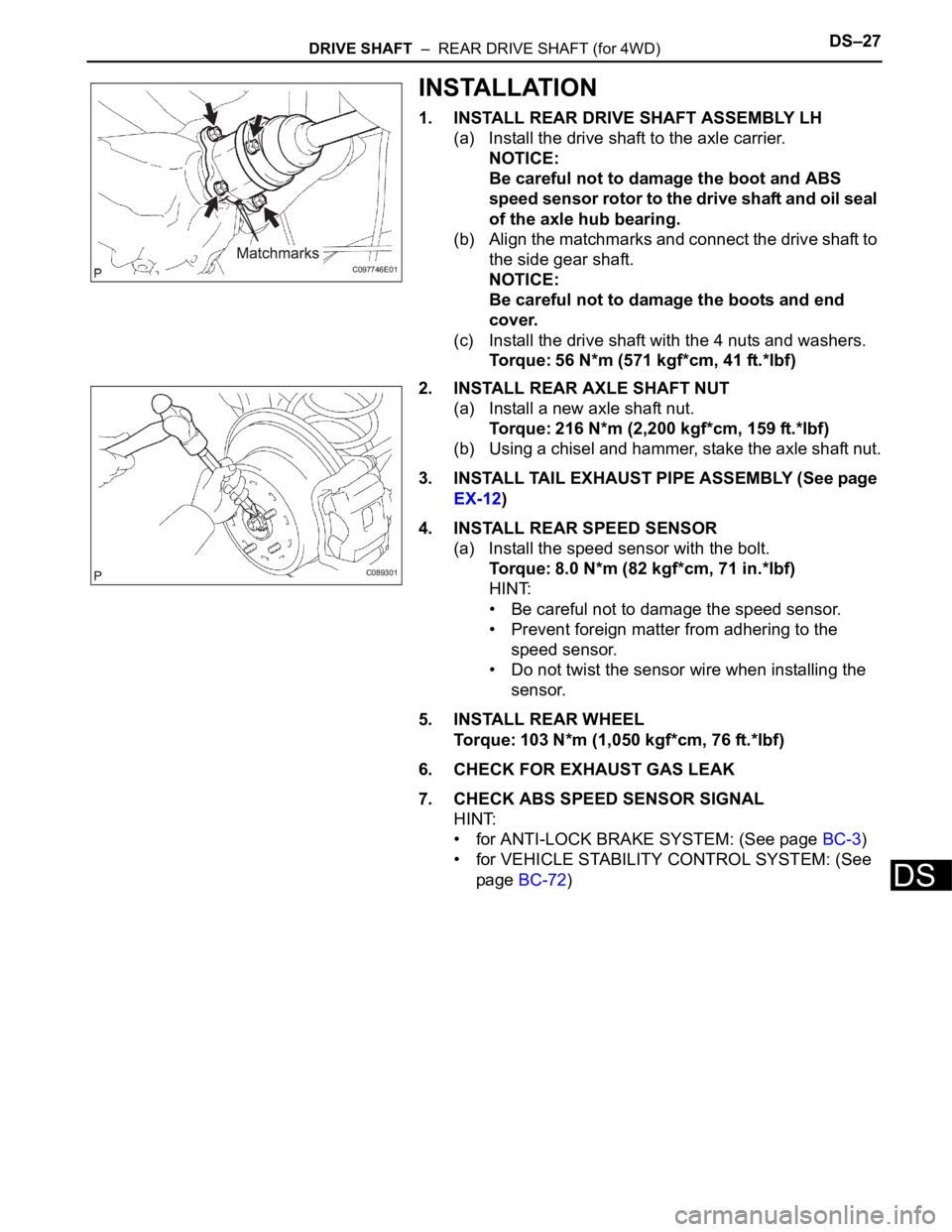

1. INSTALL REAR DRIVE SHAFT ASSEMBLY LH

(a) Install the drive shaft to the axle carrier.

NOTICE:

Be careful not to damage the boot and ABS

speed sensor rotor to the drive shaft and oil seal

of the axle hub bearing.

(b) Align the matchmarks and connect the drive shaft to

the side gear shaft.

NOTICE:

Be careful not to damage the boots and end

cover.

(c) Install the drive shaft with the 4 nuts and washers.

Torque: 56 N*m (571 kgf*cm, 41 ft.*lbf)

2. INSTALL REAR AXLE SHAFT NUT

(a) Install a new axle shaft nut.

Torque: 216 N*m (2,200 kgf*cm, 159 ft.*lbf)

(b) Using a chisel and hammer, stake the axle shaft nut.

3. INSTALL TAIL EXHAUST PIPE ASSEMBLY (See page

EX-12)

4. INSTALL REAR SPEED SENSOR

(a) Install the speed sensor with the bolt.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

HINT:

• Be careful not to damage the speed sensor.

• Prevent foreign matter from adhering to the

speed sensor.

• Do not twist the sensor wire when installing the

sensor.

5. INSTALL REAR WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

6. CHECK FOR EXHAUST GAS LEAK

7. CHECK ABS SPEED SENSOR SIGNAL

HINT:

• for ANTI-LOCK BRAKE SYSTEM: (See page BC-3)

• for VEHICLE STABILITY CONTROL SYSTEM: (See

page BC-72)

C097746E01

C089301

Page 2114 of 3000

DF–16DIFFERENTIAL – REAR DIFFERENTIAL CARRIER

DF

DISASSEMBLY

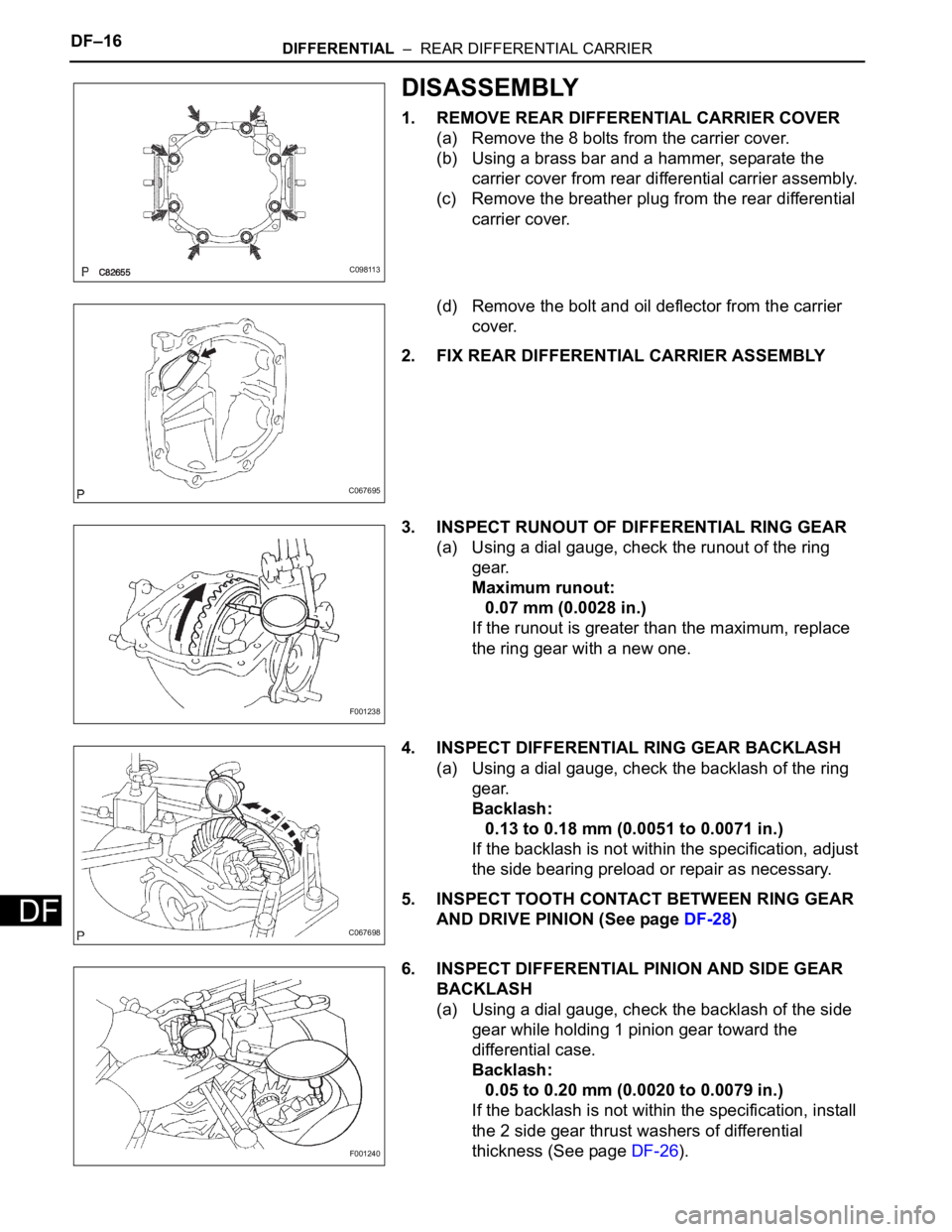

1. REMOVE REAR DIFFERENTIAL CARRIER COVER

(a) Remove the 8 bolts from the carrier cover.

(b) Using a brass bar and a hammer, separate the

carrier cover from rear differential carrier assembly.

(c) Remove the breather plug from the rear differential

carrier cover.

(d) Remove the bolt and oil deflector from the carrier

cover.

2. FIX REAR DIFFERENTIAL CARRIER ASSEMBLY

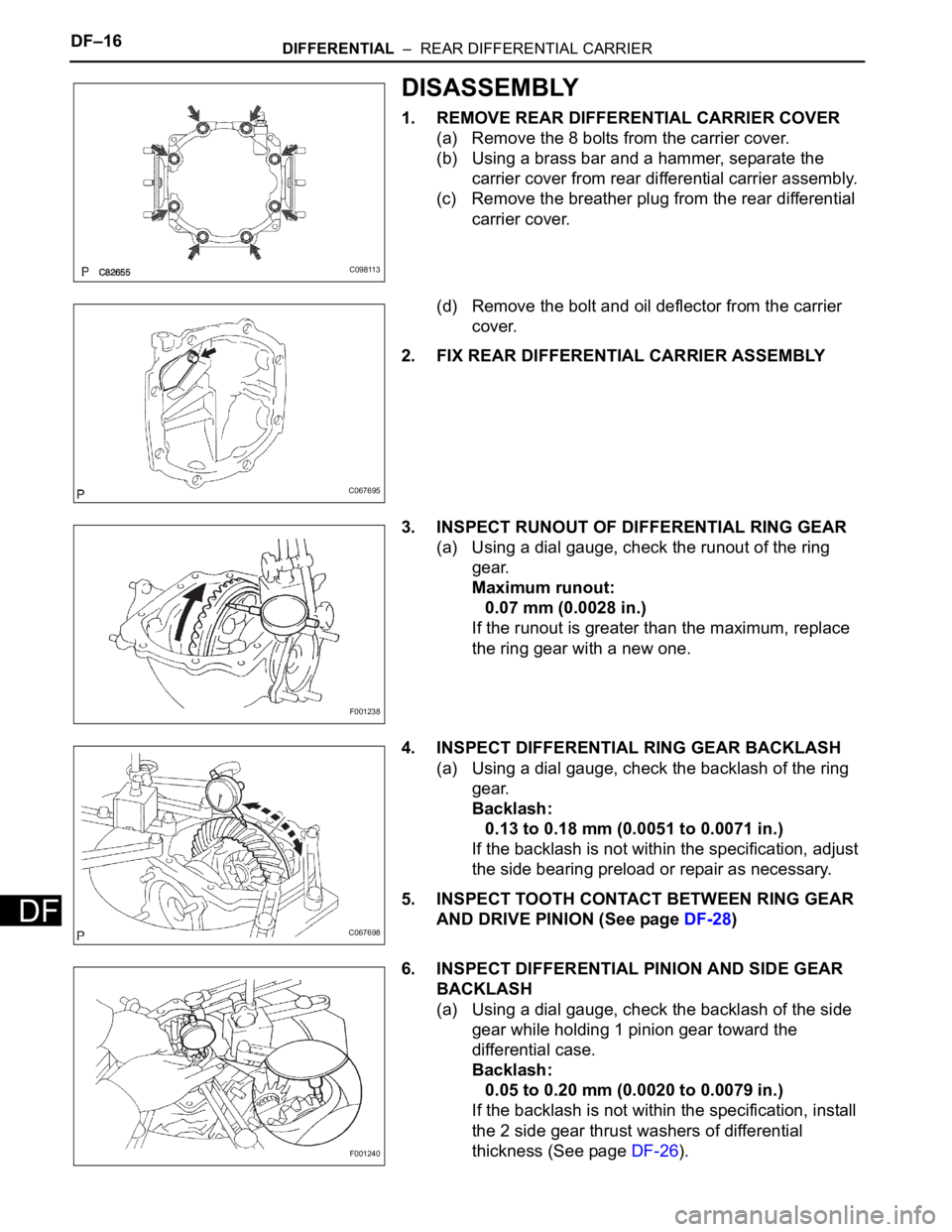

3. INSPECT RUNOUT OF DIFFERENTIAL RING GEAR

(a) Using a dial gauge, check the runout of the ring

gear.

Maximum runout:

0.07 mm (0.0028 in.)

If the runout is greater than the maximum, replace

the ring gear with a new one.

4. INSPECT DIFFERENTIAL RING GEAR BACKLASH

(a) Using a dial gauge, check the backlash of the ring

gear.

Backlash:

0.13 to 0.18 mm (0.0051 to 0.0071 in.)

If the backlash is not within the specification, adjust

the side bearing preload or repair as necessary.

5. INSPECT TOOTH CONTACT BETWEEN RING GEAR

AND DRIVE PINION (See page DF-28)

6. INSPECT DIFFERENTIAL PINION AND SIDE GEAR

BACKLASH

(a) Using a dial gauge, check the backlash of the side

gear while holding 1 pinion gear toward the

differential case.

Backlash:

0.05 to 0.20 mm (0.0020 to 0.0079 in.)

If the backlash is not within the specification, install

the 2 side gear thrust washers of differential

thickness (See page DF-26).

C098113

C067695

F001238

C067698

F001240

Page 2130 of 3000

DF–32DIFFERENTIAL – REAR DIFFERENTIAL CARRIER

DF

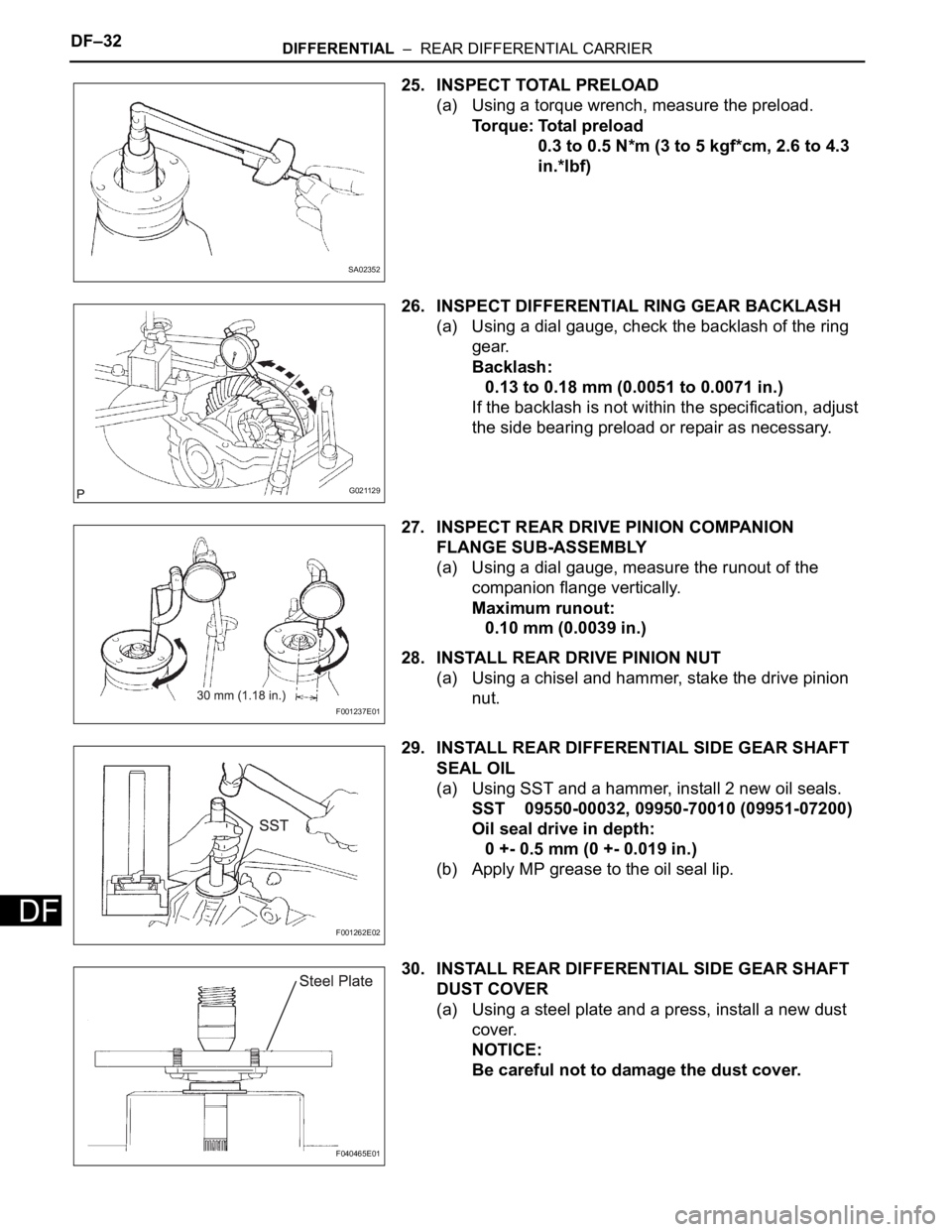

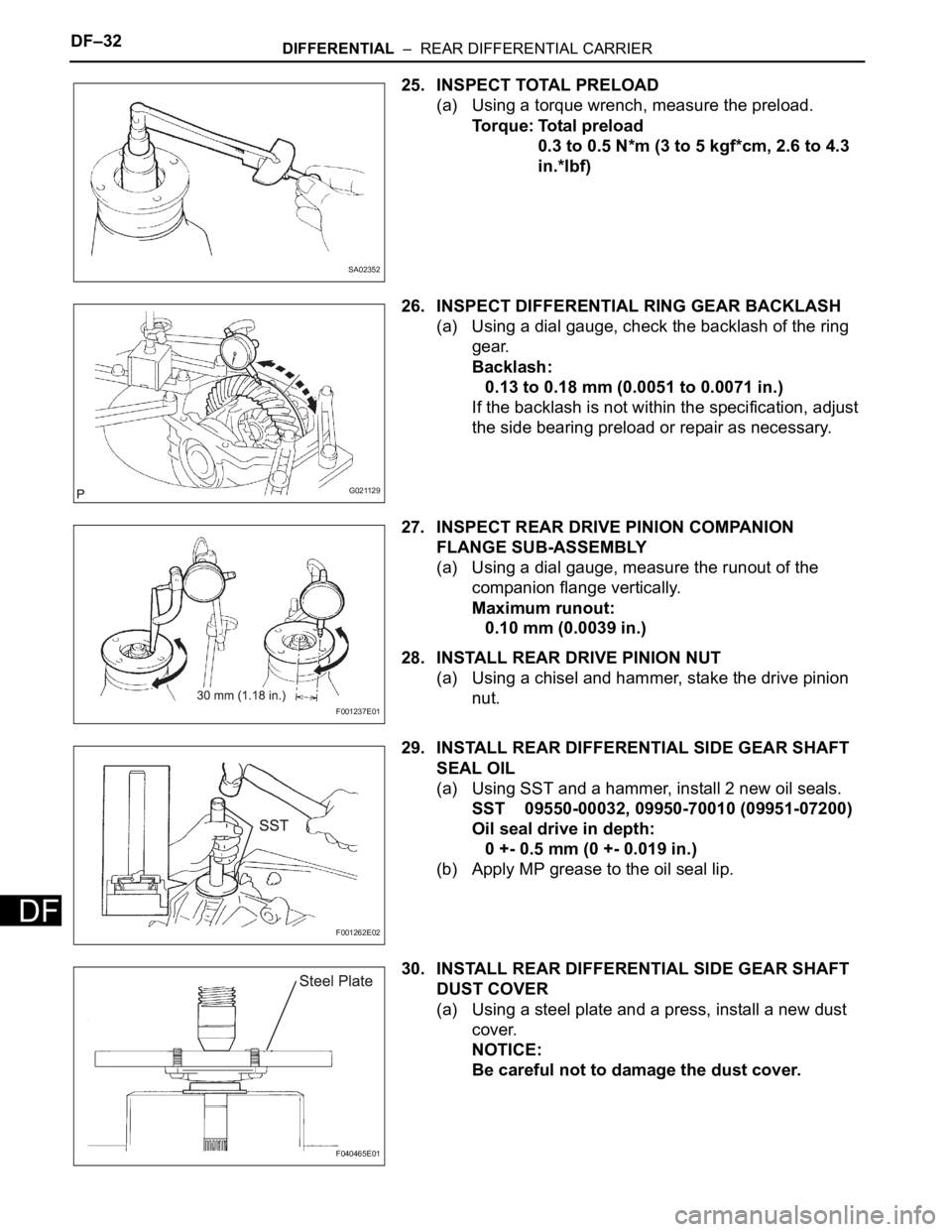

25. INSPECT TOTAL PRELOAD

(a) Using a torque wrench, measure the preload.

Torque: Total preload

0.3 to 0.5 N*m (3 to 5 kgf*cm, 2.6 to 4.3

in.*lbf)

26. INSPECT DIFFERENTIAL RING GEAR BACKLASH

(a) Using a dial gauge, check the backlash of the ring

gear.

Backlash:

0.13 to 0.18 mm (0.0051 to 0.0071 in.)

If the backlash is not within the specification, adjust

the side bearing preload or repair as necessary.

27. INSPECT REAR DRIVE PINION COMPANION

FLANGE SUB-ASSEMBLY

(a) Using a dial gauge, measure the runout of the

companion flange vertically.

Maximum runout:

0.10 mm (0.0039 in.)

28. INSTALL REAR DRIVE PINION NUT

(a) Using a chisel and hammer, stake the drive pinion

nut.

29. INSTALL REAR DIFFERENTIAL SIDE GEAR SHAFT

SEAL OIL

(a) Using SST and a hammer, install 2 new oil seals.

SST 09550-00032, 09950-70010 (09951-07200)

Oil seal drive in depth:

0 +- 0.5 mm (0 +- 0.019 in.)

(b) Apply MP grease to the oil seal lip.

30. INSTALL REAR DIFFERENTIAL SIDE GEAR SHAFT

DUST COVER

(a) Using a steel plate and a press, install a new dust

cover.

NOTICE:

Be careful not to damage the dust cover.

SA02352

G021129

F001237E01

F001262E02

F040465E01

Page 2133 of 3000

DIFFERENTIAL – DIFFERENTIAL OILDF–3

DF

DIFFERENTIAL OIL

ADJUSTMENT

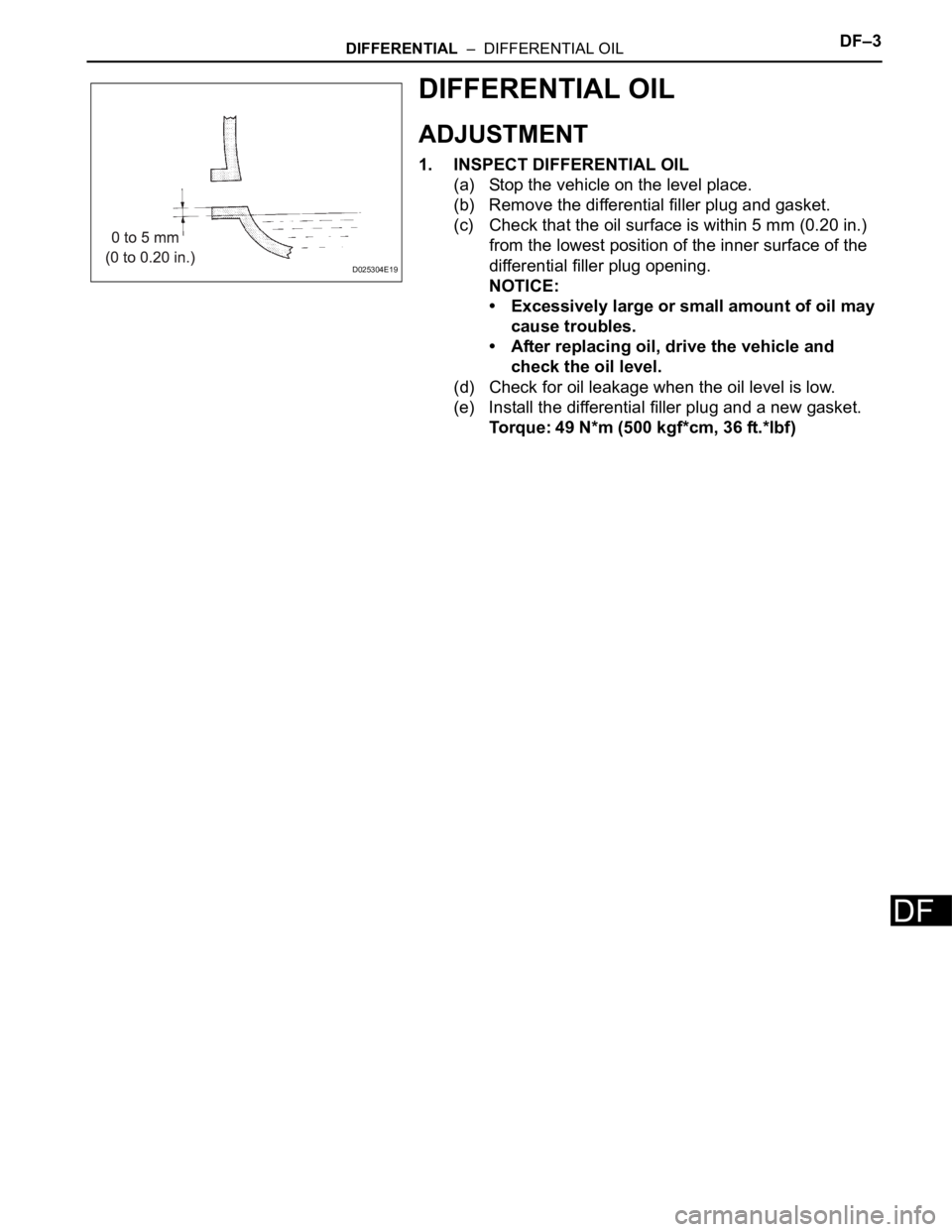

1. INSPECT DIFFERENTIAL OIL

(a) Stop the vehicle on the level place.

(b) Remove the differential filler plug and gasket.

(c) Check that the oil surface is within 5 mm (0.20 in.)

from the lowest position of the inner surface of the

differential filler plug opening.

NOTICE:

• Excessively large or small amount of oil may

cause troubles.

• After replacing oil, drive the vehicle and

check the oil level.

(d) Check for oil leakage when the oil level is low.

(e) Install the differential filler plug and a new gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

D025304E19

Page 2138 of 3000

DF–16DIFFERENTIAL – REAR DIFFERENTIAL CARRIER

DF

DISASSEMBLY

1. REMOVE REAR DIFFERENTIAL CARRIER COVER

(a) Remove the 8 bolts from the carrier cover.

(b) Using a brass bar and a hammer, separate the

carrier cover from rear differential carrier assembly.

(c) Remove the breather plug from the rear differential

carrier cover.

(d) Remove the bolt and oil deflector from the carrier

cover.

2. FIX REAR DIFFERENTIAL CARRIER ASSEMBLY

3. INSPECT RUNOUT OF DIFFERENTIAL RING GEAR

(a) Using a dial gauge, check the runout of the ring

gear.

Maximum runout:

0.07 mm (0.0028 in.)

If the runout is greater than the maximum, replace

the ring gear with a new one.

4. INSPECT DIFFERENTIAL RING GEAR BACKLASH

(a) Using a dial gauge, check the backlash of the ring

gear.

Backlash:

0.13 to 0.18 mm (0.0051 to 0.0071 in.)

If the backlash is not within the specification, adjust

the side bearing preload or repair as necessary.

5. INSPECT TOOTH CONTACT BETWEEN RING GEAR

AND DRIVE PINION (See page DF-28)

6. INSPECT DIFFERENTIAL PINION AND SIDE GEAR

BACKLASH

(a) Using a dial gauge, check the backlash of the side

gear while holding 1 pinion gear toward the

differential case.

Backlash:

0.05 to 0.20 mm (0.0020 to 0.0079 in.)

If the backlash is not within the specification, install

the 2 side gear thrust washers of differential

thickness (See page DF-26).

C098113

C067695

F001238

C067698

F001240

Page 2154 of 3000

DF–32DIFFERENTIAL – REAR DIFFERENTIAL CARRIER

DF

25. INSPECT TOTAL PRELOAD

(a) Using a torque wrench, measure the preload.

Torque: Total preload

0.3 to 0.5 N*m (3 to 5 kgf*cm, 2.6 to 4.3

in.*lbf)

26. INSPECT DIFFERENTIAL RING GEAR BACKLASH

(a) Using a dial gauge, check the backlash of the ring

gear.

Backlash:

0.13 to 0.18 mm (0.0051 to 0.0071 in.)

If the backlash is not within the specification, adjust

the side bearing preload or repair as necessary.

27. INSPECT REAR DRIVE PINION COMPANION

FLANGE SUB-ASSEMBLY

(a) Using a dial gauge, measure the runout of the

companion flange vertically.

Maximum runout:

0.10 mm (0.0039 in.)

28. INSTALL REAR DRIVE PINION NUT

(a) Using a chisel and hammer, stake the drive pinion

nut.

29. INSTALL REAR DIFFERENTIAL SIDE GEAR SHAFT

SEAL OIL

(a) Using SST and a hammer, install 2 new oil seals.

SST 09550-00032, 09950-70010 (09951-07200)

Oil seal drive in depth:

0 +- 0.5 mm (0 +- 0.019 in.)

(b) Apply MP grease to the oil seal lip.

30. INSTALL REAR DIFFERENTIAL SIDE GEAR SHAFT

DUST COVER

(a) Using a steel plate and a press, install a new dust

cover.

NOTICE:

Be careful not to damage the dust cover.

SA02352

G021129

F001237E01

F001262E02

F040465E01

Page 2180 of 3000

SUSPENSION – FRONT SHOCK ABSORBER WITH COIL SPRINGSP–15

SP

DISASSEMBLY

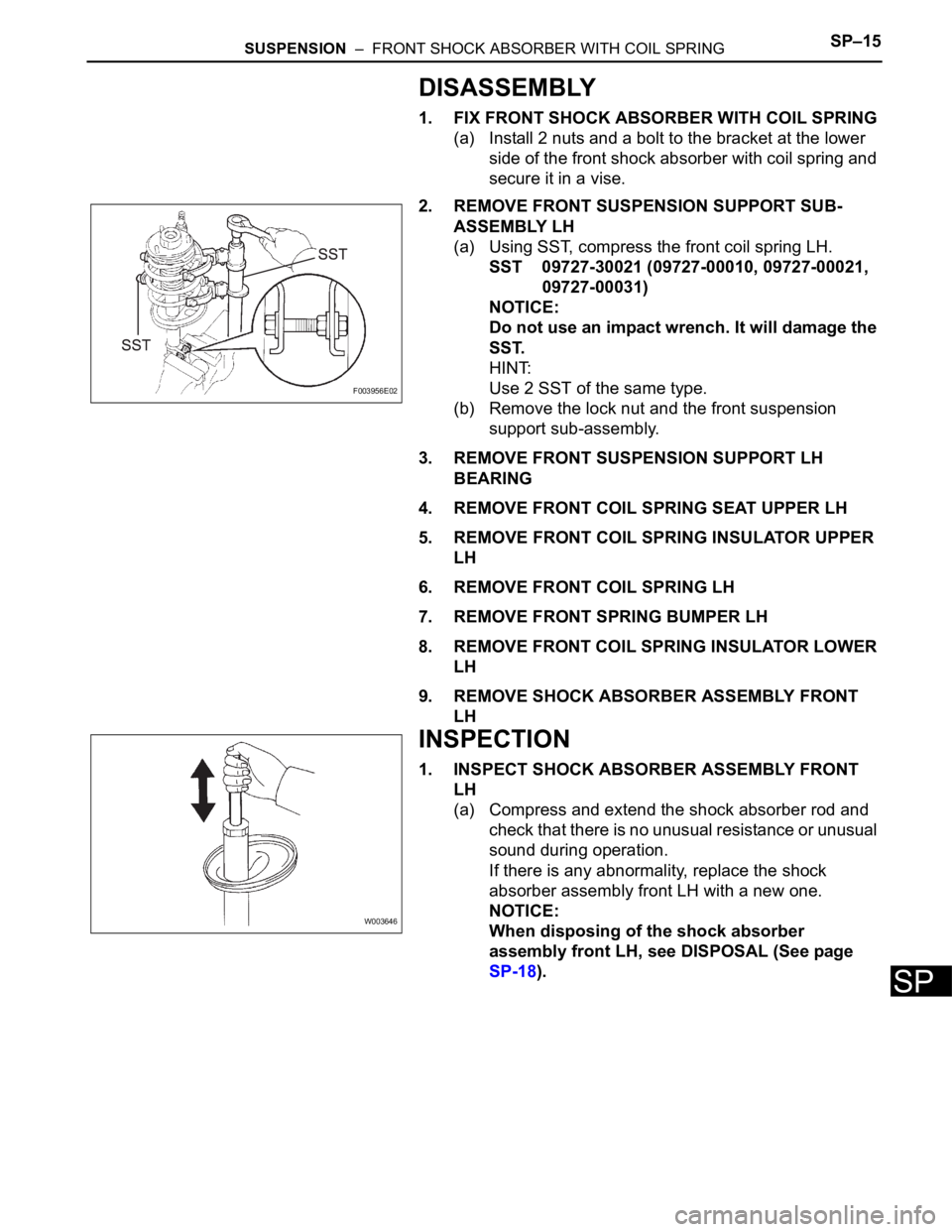

1. FIX FRONT SHOCK ABSORBER WITH COIL SPRING

(a) Install 2 nuts and a bolt to the bracket at the lower

side of the front shock absorber with coil spring and

secure it in a vise.

2. REMOVE FRONT SUSPENSION SUPPORT SUB-

ASSEMBLY LH

(a) Using SST, compress the front coil spring LH.

SST 09727-30021 (09727-00010, 09727-00021,

09727-00031)

NOTICE:

Do not use an impact wrench. It will damage the

SST.

HINT:

Use 2 SST of the same type.

(b) Remove the lock nut and the front suspension

support sub-assembly.

3. REMOVE FRONT SUSPENSION SUPPORT LH

BEARING

4. REMOVE FRONT COIL SPRING SEAT UPPER LH

5. REMOVE FRONT COIL SPRING INSULATOR UPPER

LH

6. REMOVE FRONT COIL SPRING LH

7. REMOVE FRONT SPRING BUMPER LH

8. REMOVE FRONT COIL SPRING INSULATOR LOWER

LH

9. REMOVE SHOCK ABSORBER ASSEMBLY FRONT

LH

INSPECTION

1. INSPECT SHOCK ABSORBER ASSEMBLY FRONT

LH

(a) Compress and extend the shock absorber rod and

check that there is no unusual resistance or unusual

sound during operation.

If there is any abnormality, replace the shock

absorber assembly front LH with a new one.

NOTICE:

When disposing of the shock absorber

assembly front LH, see DISPOSAL (See page

SP-18).

F003956E02

W003646