check engine TOYOTA SIENNA 2007 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 58 of 3000

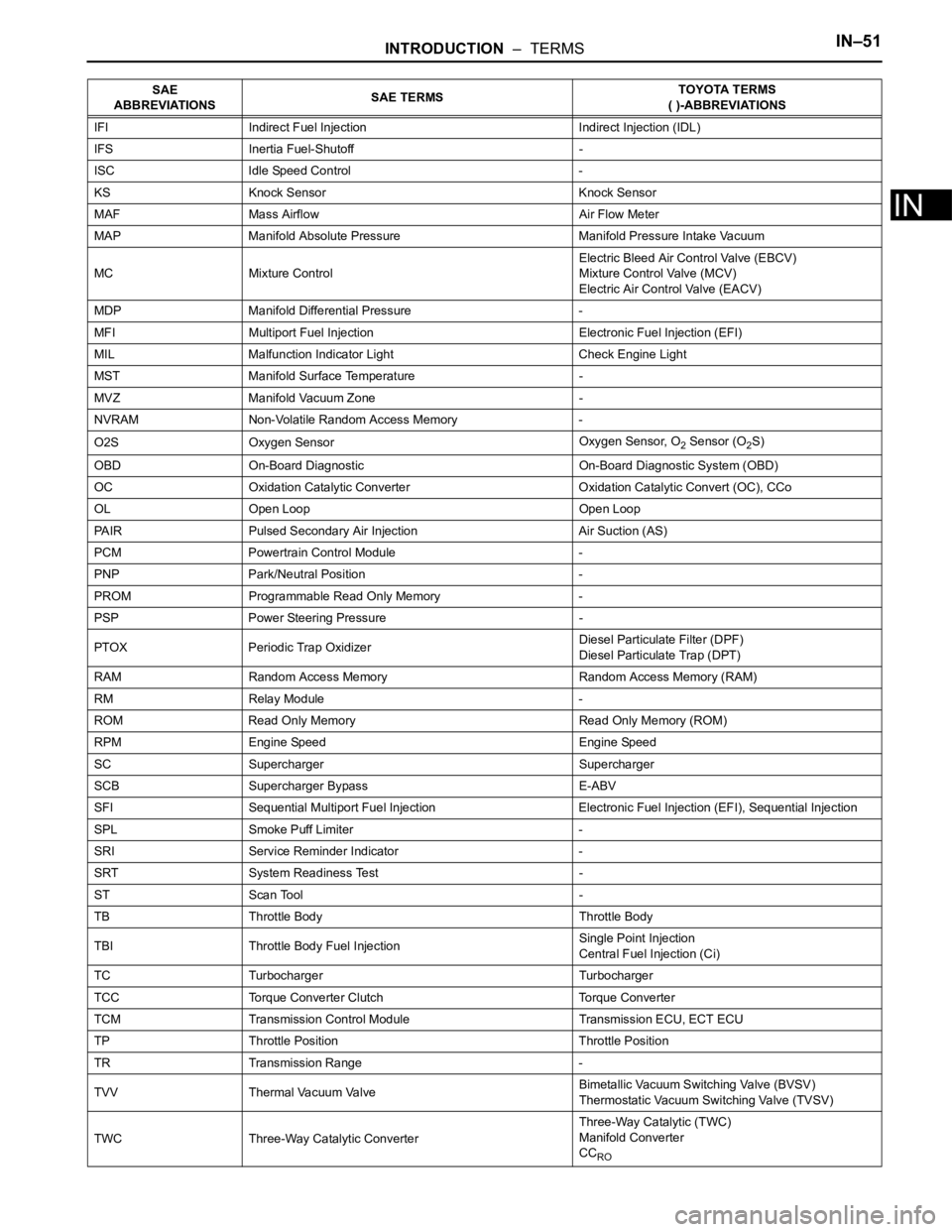

INTRODUCTION – TERMSIN–51

IN

IFI Indirect Fuel Injection Indirect Injection (IDL)

IFS Inertia Fuel-Shutoff -

ISC Idle Speed Control -

KS Knock Sensor Knock Sensor

MAF Mass Airflow Air Flow Meter

MAP Manifold Absolute Pressure Manifold Pressure Intake Vacuum

MC Mixture ControlElectric Bleed Air Control Valve (EBCV)

Mixture Control Valve (MCV)

Electric Air Control Valve (EACV)

MDP Manifold Differential Pressure -

MFI Multiport Fuel Injection Electronic Fuel Injection (EFI)

MIL Malfunction Indicator Light Check Engine Light

MST Manifold Surface Temperature -

MVZ Manifold Vacuum Zone -

NVRAM Non-Volatile Random Access Memory -

O2S Oxygen SensorOxygen Sensor, O

2 Sensor (O2S)

OBD On-Board Diagnostic On-Board Diagnostic System (OBD)

OC Oxidation Catalytic Converter Oxidation Catalytic Convert (OC), CCo

OL Open Loop Open Loop

PAIR Pulsed Secondary Air Injection Air Suction (AS)

PCM Powertrain Control Module -

PNP Park/Neutral Position -

PROM Programmable Read Only Memory -

PSP Power Steering Pressure -

PTOX Periodic Trap OxidizerDiesel Particulate Filter (DPF)

Diesel Particulate Trap (DPT)

RAM Random Access Memory Random Access Memory (RAM)

RM Relay Module -

ROM Read Only Memory Read Only Memory (ROM)

RPM Engine Speed Engine Speed

SC Supercharger Supercharger

SCB Supercharger Bypass E-ABV

SFI Sequential Multiport Fuel Injection Electronic Fuel Injection (EFI), Sequential Injection

SPL Smoke Puff Limiter -

SRI Service Reminder Indicator -

SRT System Readiness Test -

ST Scan Tool -

TB Throttle Body Throttle Body

TBI Throttle Body Fuel InjectionSingle Point Injection

Central Fuel Injection (Ci)

TC Turbocharger Turbocharger

TCC Torque Converter Clutch Torque Converter

TCM Transmission Control Module Transmission ECU, ECT ECU

TP Throttle Position Throttle Position

TR Transmission Range -

TVV Thermal Vacuum ValveBimetallic Vacuum Switching Valve (BVSV)

Thermostatic Vacuum Switching Valve (TVSV)

TWC Three-Way Catalytic ConverterThree-Way Catalytic (TWC)

Manifold Converter

CC

RO

SAE

ABBREVIATIONSSAE TERMSTOYOTA TERMS

( )-ABBREVIATIONS

Page 61 of 3000

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMSIN–31

IN

ELECTRONIC CIRCUIT INSPECTION

PROCEDURE

1. BASIC INSPECTION

(a) WHEN MEASURING RESISTANCE OF

ELECTRONIC PARTS

(1) Unless otherwise stated, all resistance

measurements should be made at an ambient

temperature of 20

C (68F). Resistance

measurements may be inaccurate if measured

at high temperatures, i.e. immediately after the

vehicle has been running. Measurements should

be made after the engine has cooled down.

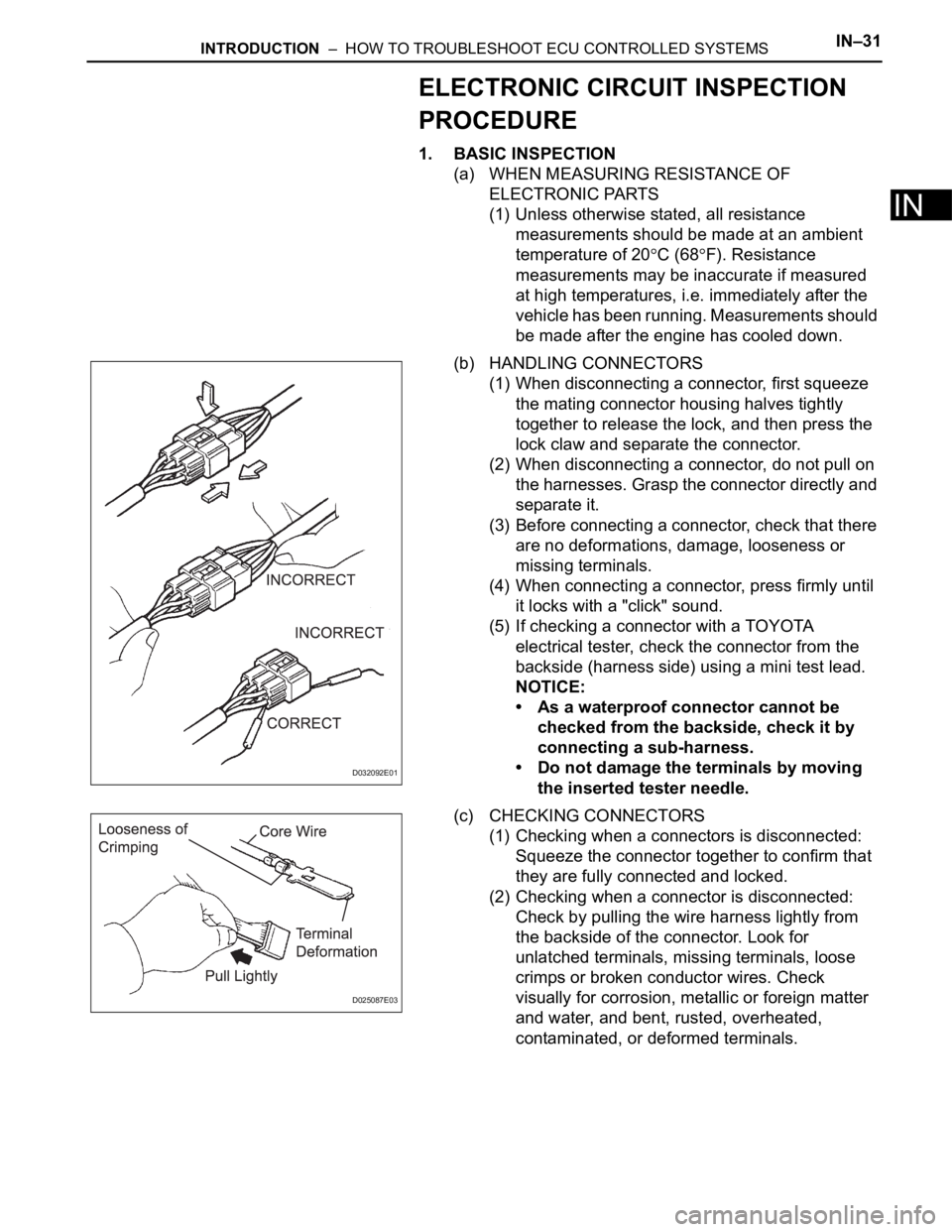

(b) HANDLING CONNECTORS

(1) When disconnecting a connector, first squeeze

the mating connector housing halves tightly

together to release the lock, and then press the

lock claw and separate the connector.

(2) When disconnecting a connector, do not pull on

the harnesses. Grasp the connector directly and

separate it.

(3) Before connecting a connector, check that there

are no deformations, damage, looseness or

missing terminals.

(4) When connecting a connector, press firmly until

it locks with a "click" sound.

(5) If checking a connector with a TOYOTA

electrical tester, check the connector from the

backside (harness side) using a mini test lead.

NOTICE:

• As a waterproof connector cannot be

checked from the backside, check it by

connecting a sub-harness.

• Do not damage the terminals by moving

the inserted tester needle.

(c) CHECKING CONNECTORS

(1) Checking when a connectors is disconnected:

Squeeze the connector together to confirm that

they are fully connected and locked.

(2) Checking when a connector is disconnected:

Check by pulling the wire harness lightly from

the backside of the connector. Look for

unlatched terminals, missing terminals, loose

crimps or broken conductor wires. Check

visually for corrosion, metallic or foreign matter

and water, and bent, rusted, overheated,

contaminated, or deformed terminals.

D032092E01

D025087E03

Page 64 of 3000

IN–34INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN

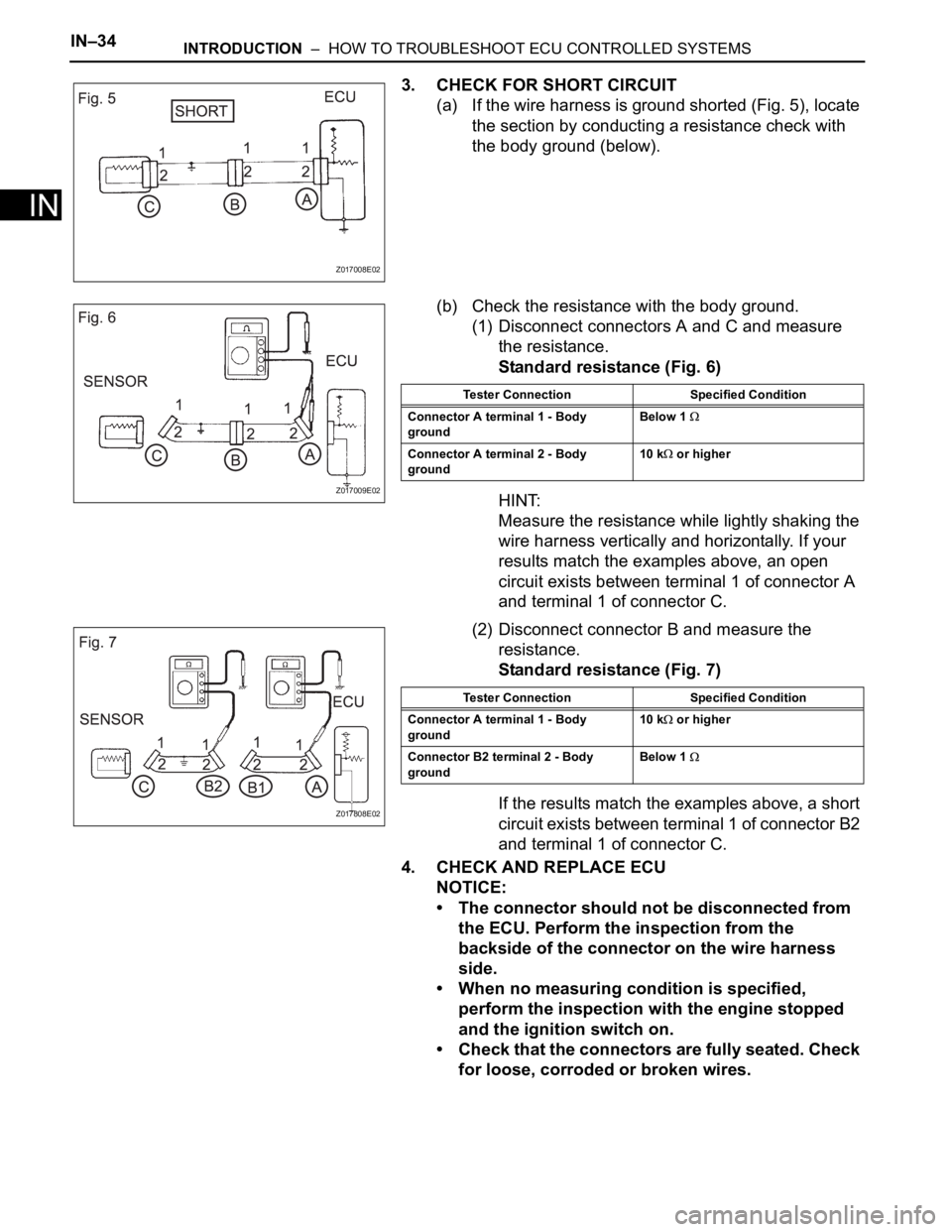

3. CHECK FOR SHORT CIRCUIT

(a) If the wire harness is ground shorted (Fig. 5), locate

the section by conducting a resistance check with

the body ground (below).

(b) Check the resistance with the body ground.

(1) Disconnect connectors A and C and measure

the resistance.

Standard resistance (Fig. 6)

HINT:

Measure the resistance while lightly shaking the

wire harness vertically and horizontally. If your

results match the examples above, an open

circuit exists between terminal 1 of connector A

and terminal 1 of connector C.

(2) Disconnect connector B and measure the

resistance.

Standard resistance (Fig. 7)

If the results match the examples above, a short

circuit exists between terminal 1 of connector B2

and terminal 1 of connector C.

4. CHECK AND REPLACE ECU

NOTICE:

• The connector should not be disconnected from

the ECU. Perform the inspection from the

backside of the connector on the wire harness

side.

• When no measuring condition is specified,

perform the inspection with the engine stopped

and the ignition switch on.

• Check that the connectors are fully seated. Check

for loose, corroded or broken wires.

Z017008E02

Z017009E02

Tester Connection Specified Condition

Connector A terminal 1 - Body

groundBelow 1

Connector A terminal 2 - Body

ground10 k or higher

Z017808E02

Tester Connection Specified Condition

Connector A terminal 1 - Body

ground10 k

or higher

Connector B2 terminal 2 - Body

ground Below 1

Page 66 of 3000

IN–36INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN

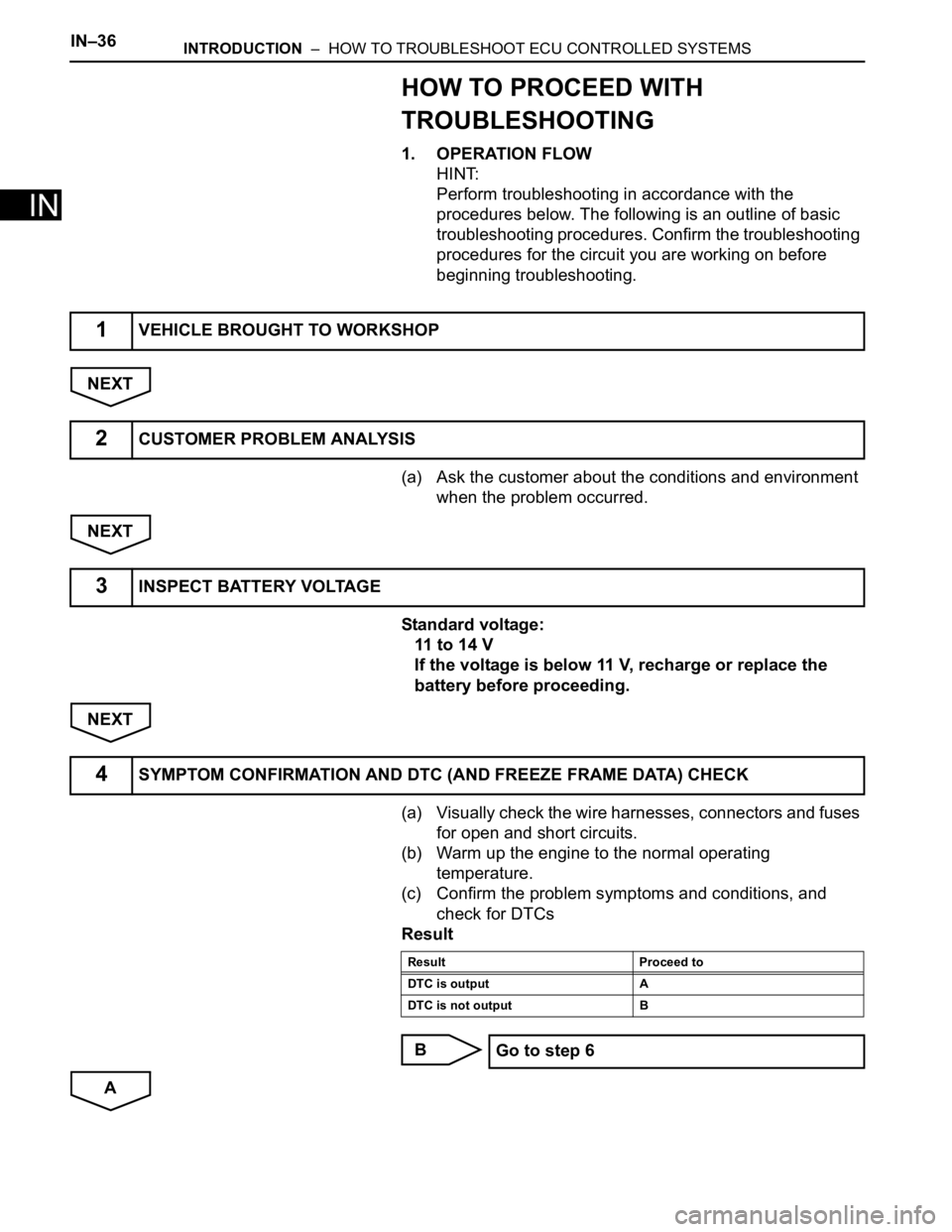

HOW TO PROCEED WITH

TROUBLESHOOTING

1. OPERATION FLOW

HINT:

Perform troubleshooting in accordance with the

procedures below. The following is an outline of basic

troubleshooting procedures. Confirm the troubleshooting

procedures for the circuit you are working on before

beginning troubleshooting.

NEXT

(a) Ask the customer about the conditions and environment

when the problem occurred.

NEXT

Standard voltage:

11 to 14 V

If the voltage is below 11 V, recharge or replace the

battery before proceeding.

NEXT

(a) Visually check the wire harnesses, connectors and fuses

for open and short circuits.

(b) Warm up the engine to the normal operating

temperature.

(c) Confirm the problem symptoms and conditions, and

check for DTCs

Result

B

A

1VEHICLE BROUGHT TO WORKSHOP

2CUSTOMER PROBLEM ANALYSIS

3INSPECT BATTERY VOLTAGE

4SYMPTOM CONFIRMATION AND DTC (AND FREEZE FRAME DATA) CHECK

Result Proceed to

DTC is output A

DTC is not output B

Go to step 6

Page 69 of 3000

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMSIN–39

IN

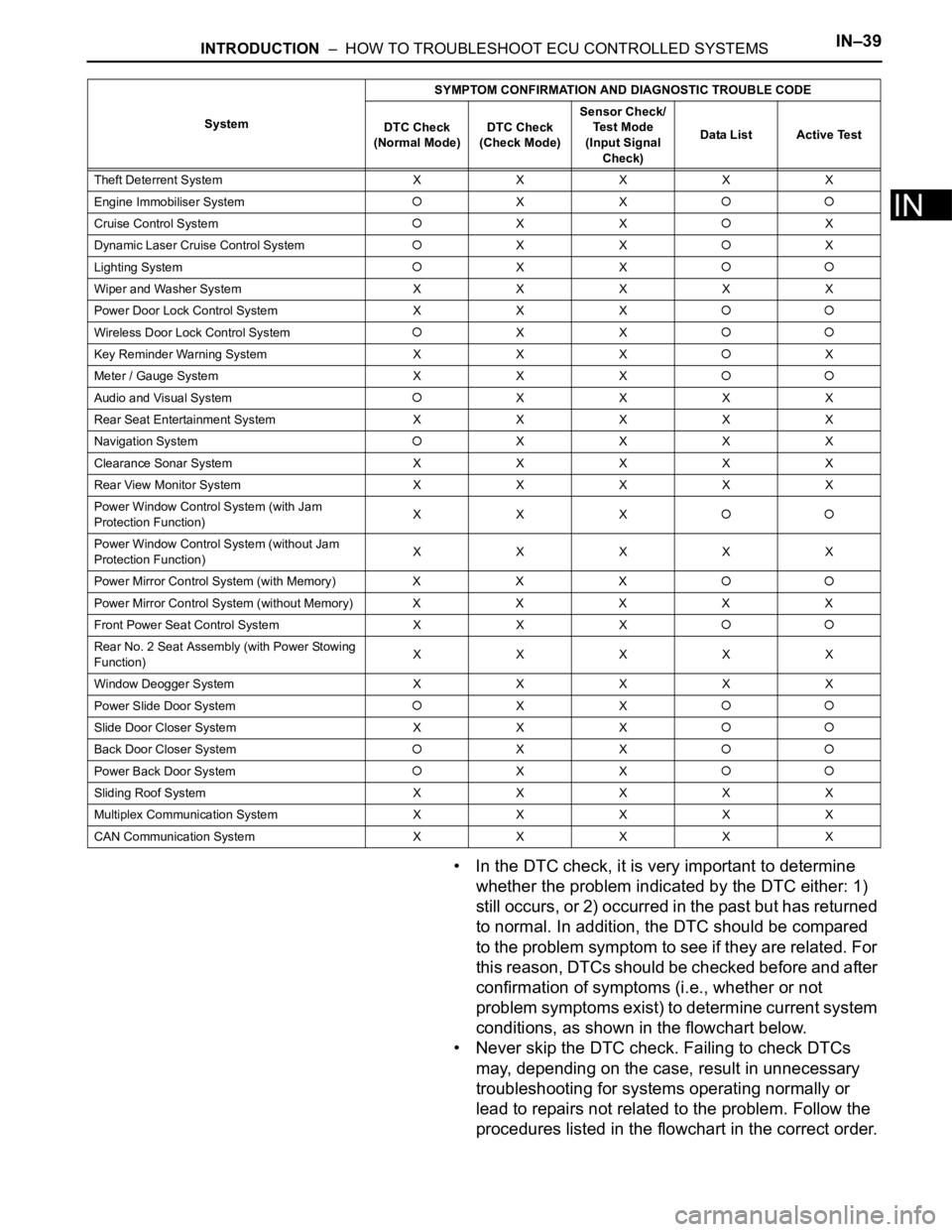

• In the DTC check, it is very important to determine

whether the problem indicated by the DTC either: 1)

still occurs, or 2) occurred in the past but has returned

to normal. In addition, the DTC should be compared

to the problem symptom to see if they are related. For

this reason, DTCs should be checked before and after

confirmation of symptoms (i.e., whether or not

problem symptoms exist) to determine current system

conditions, as shown in the flowchart below.

• Never skip the DTC check. Failing to check DTCs

may, depending on the case, result in unnecessary

troubleshooting for systems operating normally or

lead to repairs not related to the problem. Follow the

procedures listed in the flowchart in the correct order.

Theft Deterrent System XXXXX

Engine Immobiliser System

XX

Cruise Control SystemXXX

Dynamic Laser Cruise Control System

XXX

Lighting System

XX

Wiper and Washer SystemXXXXX

Power Door Lock Control System X X X

Wireless Door Lock Control SystemXX

Key Reminder Warning System X X XX

Meter / Gauge System X X X

Audio and Visual SystemXXXX

Rear Seat Entertainment System XXXXX

Navigation System

XXXX

Clearance Sonar SystemXXXXX

Rear View Monitor System XXXXX

Power Window Control System (with Jam

Protection Function)XXX

Power Window Control System (without Jam

Protection Function)XXXXX

Power Mirror Control System (with Memory) X X X

Power Mirror Control System (without Memory)XXXXX

Front Power Seat Control System X X X

Rear No. 2 Seat Assembly (with Power Stowing

Function)XXXXX

Window Deogger SystemXXXXX

Power Slide Door System

XX

Slide Door Closer System X X X

Back Door Closer SystemXX

Power Back Door SystemXX

Sliding Roof System XXXXX

Multiplex Communication System XXXXX

CAN Communication System XXXXXSystemSYMPTOM CONFIRMATION AND DIAGNOSTIC TROUBLE CODE

DTC Check

(Normal Mode)DTC Check

(Check Mode)Sensor Check/

Test Mode

(Input Signal

Check)Data List Active Test

Page 71 of 3000

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMSIN–41

IN

If a DTC was displayed in the initial DTC check, the

problem may have occurred in a wire harness or

connector in that circuit in the past. Check the wire

harness and connectors.

B

A

The problem still occurs in a place other than the diagnostic

circuit (the DTC displayed first is either for a past problem or

a secondary problem).

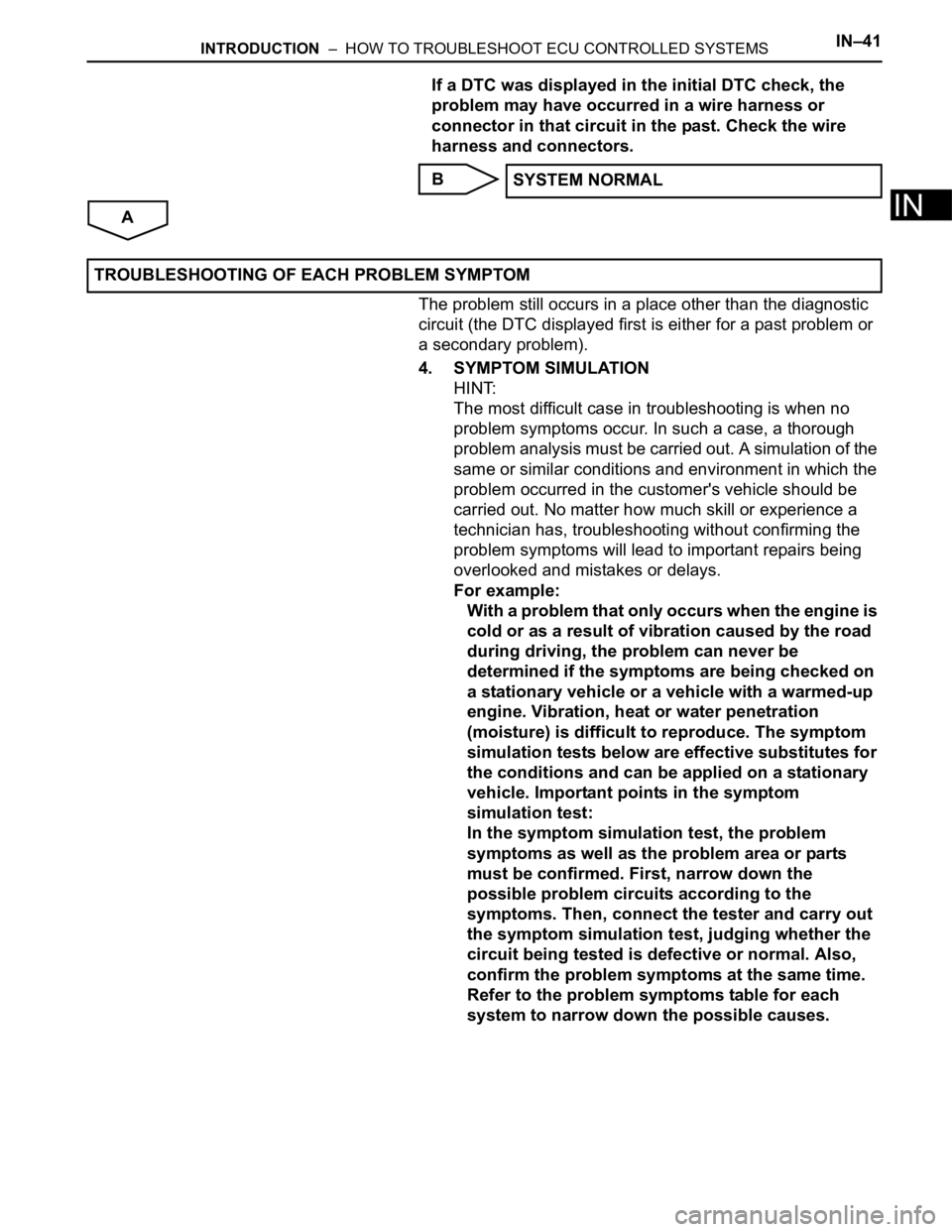

4. SYMPTOM SIMULATION

HINT:

The most difficult case in troubleshooting is when no

problem symptoms occur. In such a case, a thorough

problem analysis must be carried out. A simulation of the

same or similar conditions and environment in which the

problem occurred in the customer's vehicle should be

carried out. No matter how much skill or experience a

technician has, troubleshooting without confirming the

problem symptoms will lead to important repairs being

overlooked and mistakes or delays.

For example:

With a problem that only occurs when the engine is

cold or as a result of vibration caused by the road

during driving, the problem can never be

determined if the symptoms are being checked on

a stationary vehicle or a vehicle with a warmed-up

engine. Vibration, heat or water penetration

(moisture) is difficult to reproduce. The symptom

simulation tests below are effective substitutes for

the conditions and can be applied on a stationary

vehicle. Important points in the symptom

simulation test:

In the symptom simulation test, the problem

symptoms as well as the problem area or parts

must be confirmed. First, narrow down the

possible problem circuits according to the

symptoms. Then, connect the tester and carry out

the symptom simulation test, judging whether the

circuit being tested is defective or normal. Also,

confirm the problem symptoms at the same time.

Refer to the problem symptoms table for each

system to narrow down the possible causes.SYSTEM NORMAL

TROUBLESHOOTING OF EACH PROBLEM SYMPTOM

Page 72 of 3000

IN–42INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN

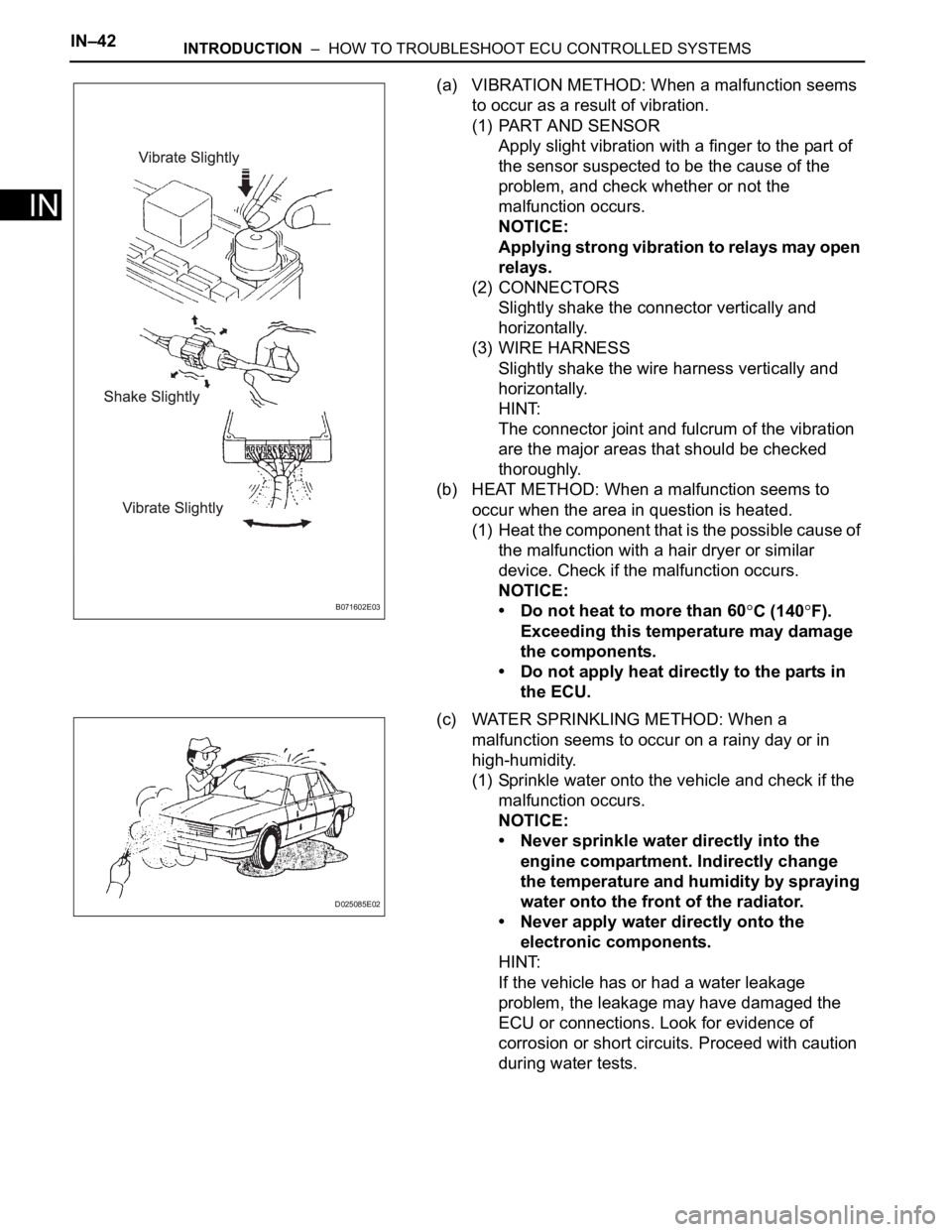

(a) VIBRATION METHOD: When a malfunction seems

to occur as a result of vibration.

(1) PART AND SENSOR

Apply slight vibration with a finger to the part of

the sensor suspected to be the cause of the

problem, and check whether or not the

malfunction occurs.

NOTICE:

Applying strong vibration to relays may open

relays.

(2) CONNECTORS

Slightly shake the connector vertically and

horizontally.

(3) WIRE HARNESS

Slightly shake the wire harness vertically and

horizontally.

HINT:

The connector joint and fulcrum of the vibration

are the major areas that should be checked

thoroughly.

(b) HEAT METHOD: When a malfunction seems to

occur when the area in question is heated.

(1) Heat the component that is the possible cause of

the malfunction with a hair dryer or similar

device. Check if the malfunction occurs.

NOTICE:

• Do not heat to more than 60

C (140F).

Exceeding this temperature may damage

the components.

• Do not apply heat directly to the parts in

the ECU.

(c) WATER SPRINKLING METHOD: When a

malfunction seems to occur on a rainy day or in

high-humidity.

(1) Sprinkle water onto the vehicle and check if the

malfunction occurs.

NOTICE:

• Never sprinkle water directly into the

engine compartment. Indirectly change

the temperature and humidity by spraying

water onto the front of the radiator.

• Never apply water directly onto the

electronic components.

HINT:

If the vehicle has or had a water leakage

problem, the leakage may have damaged the

ECU or connections. Look for evidence of

corrosion or short circuits. Proceed with caution

during water tests.B071602E03

D025085E02

Page 76 of 3000

2GR-FE COOLING – COOLING FAN SYSTEMCO–5

CO

ON-VEHICLE INSPECTION

1. INSPECT COOLING FAN SYSTEM

(a) Put the vehicle in the following conditions:

(1) The engine switch is off.

(2) The coolant temperature is less than 95

C

(203

F).

(3) The battery voltage is between 9 and 14 V.

(4) The A/C switch is OFF.

(b) Clamp the 400 A probe of an ammeter over the M+

wire of each cooling fan motor.

(c) Turn the ignition switch to the ON position and wait

for approximately 10 seconds. Check that the fan

stops.

(d) Start the engine. Check that the fan stops with the

engine idling.

HINT:

• Make sure that the radiator engine coolant

temperature is less than 95

C (203F).

• Turn the A/C switch OFF.

(e) Check that the fan operates when the A/C switch is

turned ON (MAX COOL and the magnetic clutch is

operating).

Standard current

HINT:

The coolant temperature is less than 95

C (203F).

(f) Check that the fan operates when the engine

coolant temperature sensor connector is

disconnected.

Standard current

Item Specified Condition

No. 1 cooling fan motor 5 to 14 A

No. 2 cooling fan motor 4 to 12 A

Item Specified Condition

No. 1 cooling fan motor 5 to 19 A

No. 2 cooling fan motor 4 to 16 A

Page 77 of 3000

CO–62GR-FE COOLING – COOLING FAN SYSTEM

CO

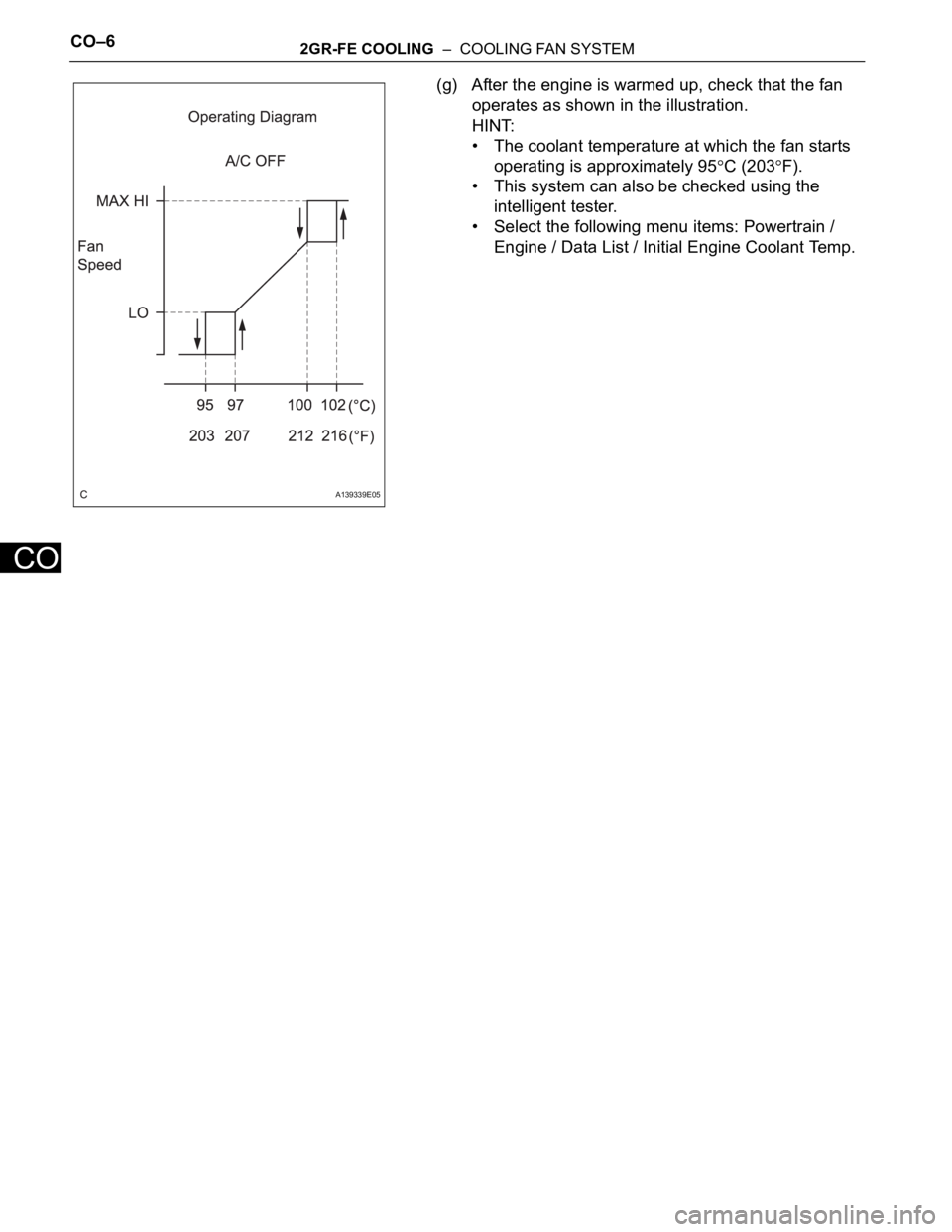

(g) After the engine is warmed up, check that the fan

operates as shown in the illustration.

HINT:

• The coolant temperature at which the fan starts

operating is approximately 95

C (203F).

• This system can also be checked using the

intelligent tester.

• Select the following menu items: Powertrain /

Engine / Data List / Initial Engine Coolant Temp.

A139339E05

Page 80 of 3000

IG–62GR-FE IGNITION – IGNITION COIL AND SPARK PLUG

IG

ON-VEHICLE INSPECTION

NOTICE:

In this section, the terms "cold" and "hot" refer to the

temperature of the coils. "Cold" means approximately -

10

C (14F) to 50C (122F). "Hot" means approximately

50

C (122F) to 100C (212F).

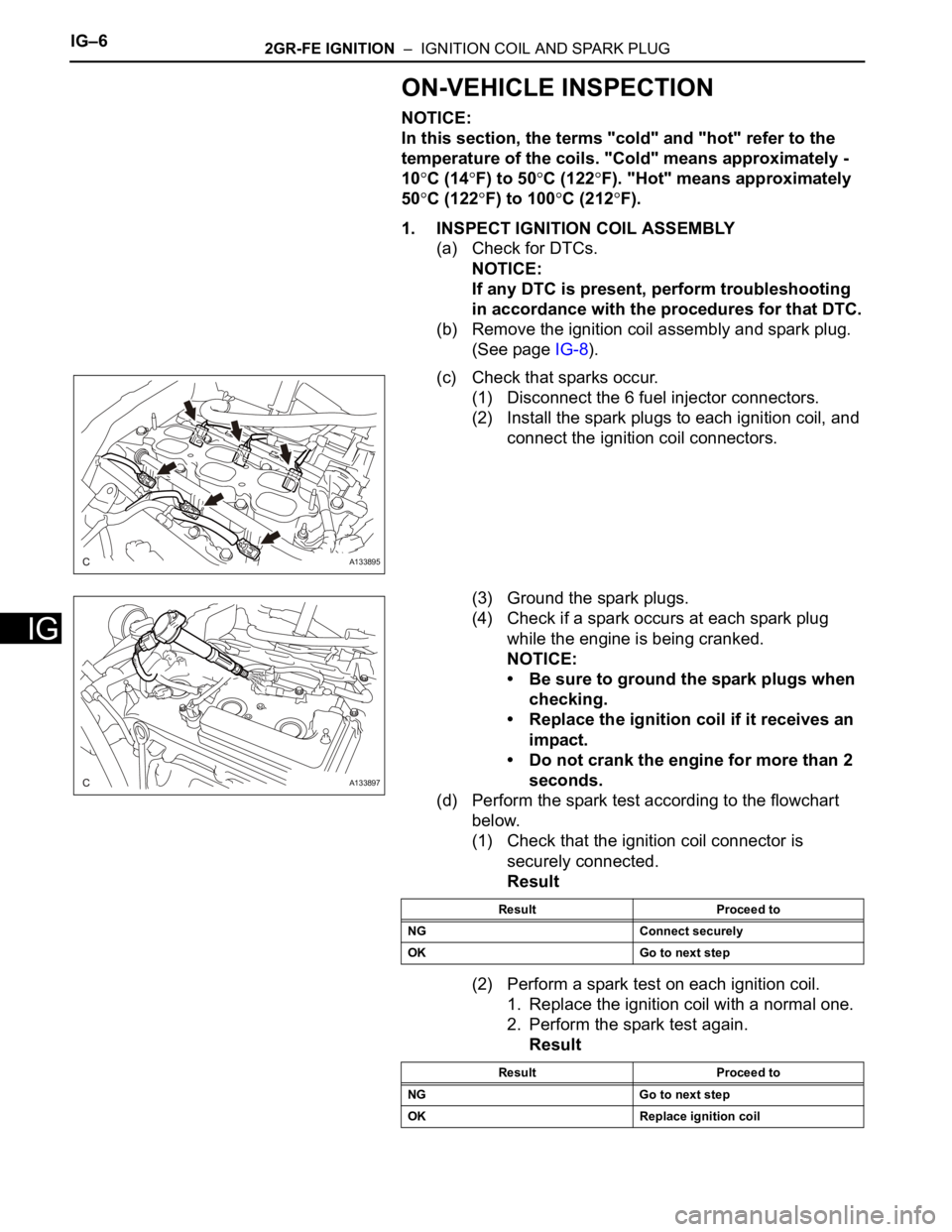

1. INSPECT IGNITION COIL ASSEMBLY

(a) Check for DTCs.

NOTICE:

If any DTC is present, perform troubleshooting

in accordance with the procedures for that DTC.

(b) Remove the ignition coil assembly and spark plug.

(See page IG-8).

(c) Check that sparks occur.

(1) Disconnect the 6 fuel injector connectors.

(2) Install the spark plugs to each ignition coil, and

connect the ignition coil connectors.

(3) Ground the spark plugs.

(4) Check if a spark occurs at each spark plug

while the engine is being cranked.

NOTICE:

• Be sure to ground the spark plugs when

checking.

• Replace the ignition coil if it receives an

impact.

• Do not crank the engine for more than 2

seconds.

(d) Perform the spark test according to the flowchart

below.

(1) Check that the ignition coil connector is

securely connected.

Result

(2) Perform a spark test on each ignition coil.

1. Replace the ignition coil with a normal one.

2. Perform the spark test again.

Result

A133895

A133897

Result Proceed to

NG Connect securely

OK Go to next step

Result Proceed to

NG Go to next step

OK Replace ignition coil