check engine TOYOTA SIENNA 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 314 of 3000

ES–102GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

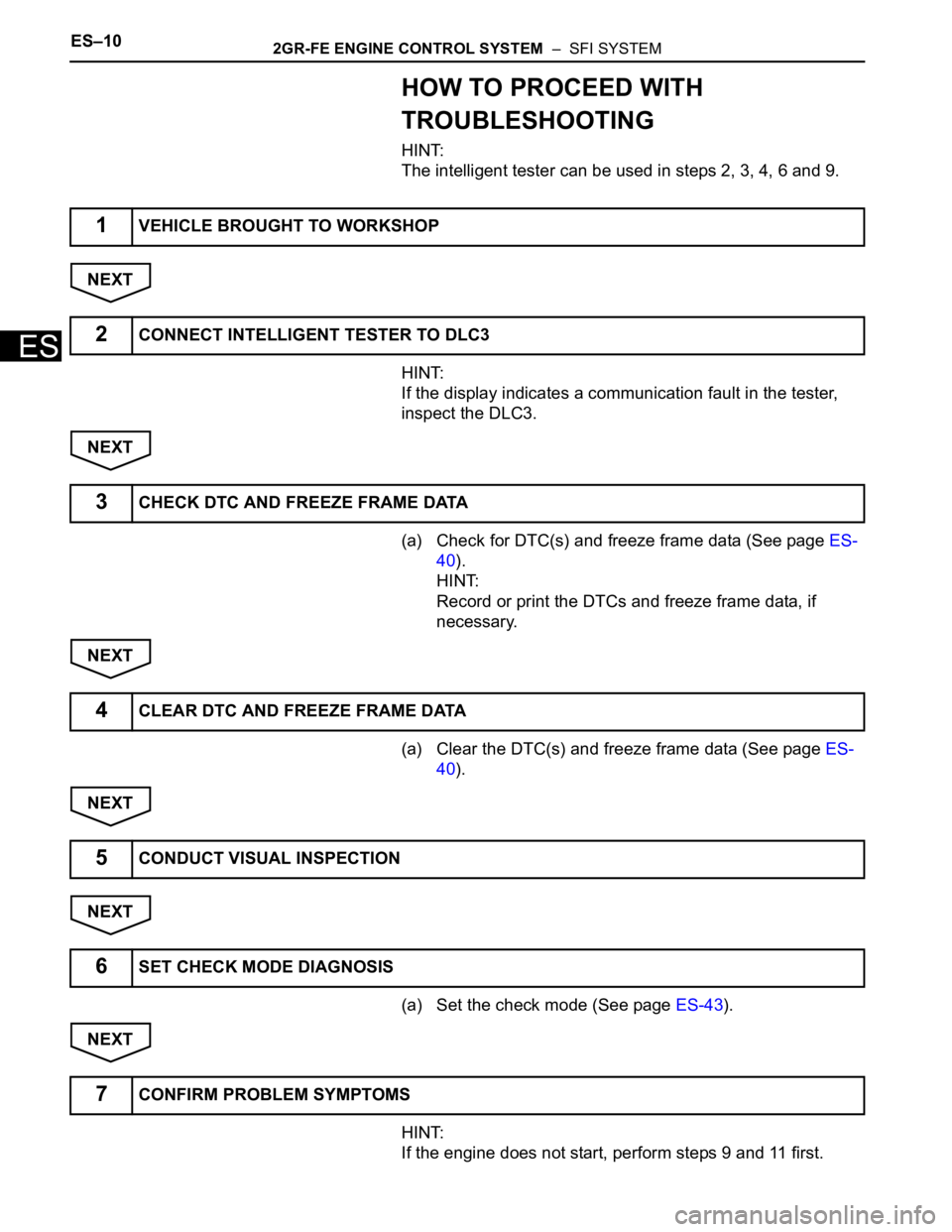

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

The intelligent tester can be used in steps 2, 3, 4, 6 and 9.

NEXT

HINT:

If the display indicates a communication fault in the tester,

inspect the DLC3.

NEXT

(a) Check for DTC(s) and freeze frame data (See page ES-

40).

HINT:

Record or print the DTCs and freeze frame data, if

necessary.

NEXT

(a) Clear the DTC(s) and freeze frame data (See page ES-

40).

NEXT

NEXT

(a) Set the check mode (See page ES-43).

NEXT

HINT:

If the engine does not start, perform steps 9 and 11 first.

1VEHICLE BROUGHT TO WORKSHOP

2CONNECT INTELLIGENT TESTER TO DLC3

3CHECK DTC AND FREEZE FRAME DATA

4CLEAR DTC AND FREEZE FRAME DATA

5CONDUCT VISUAL INSPECTION

6SET CHECK MODE DIAGNOSIS

7CONFIRM PROBLEM SYMPTOMS

Page 315 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–11

ES

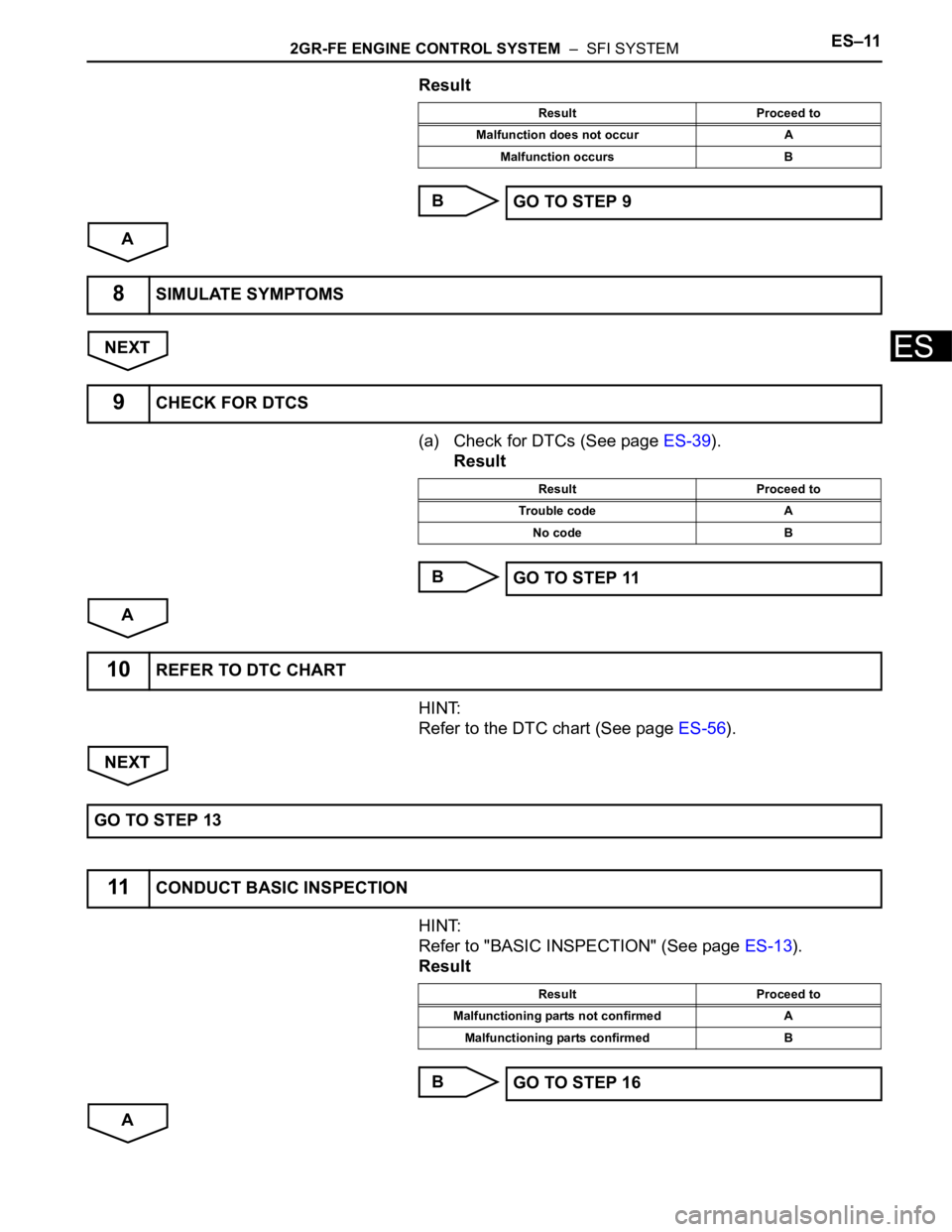

Result

B

A

NEXT

(a) Check for DTCs (See page ES-39).

Result

B

A

HINT:

Refer to the DTC chart (See page ES-56).

NEXT

HINT:

Refer to "BASIC INSPECTION" (See page ES-13).

Result

B

A

Result Proceed to

Malfunction does not occur A

Malfunction occurs B

GO TO STEP 9

8SIMULATE SYMPTOMS

9CHECK FOR DTCS

Result Proceed to

Trouble code A

No code B

GO TO STEP 11

10REFER TO DTC CHART

GO TO STEP 13

11CONDUCT BASIC INSPECTION

Result Proceed to

Malfunctioning parts not confirmed A

Malfunctioning parts confirmed B

GO TO STEP 16

Page 316 of 3000

ES–122GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

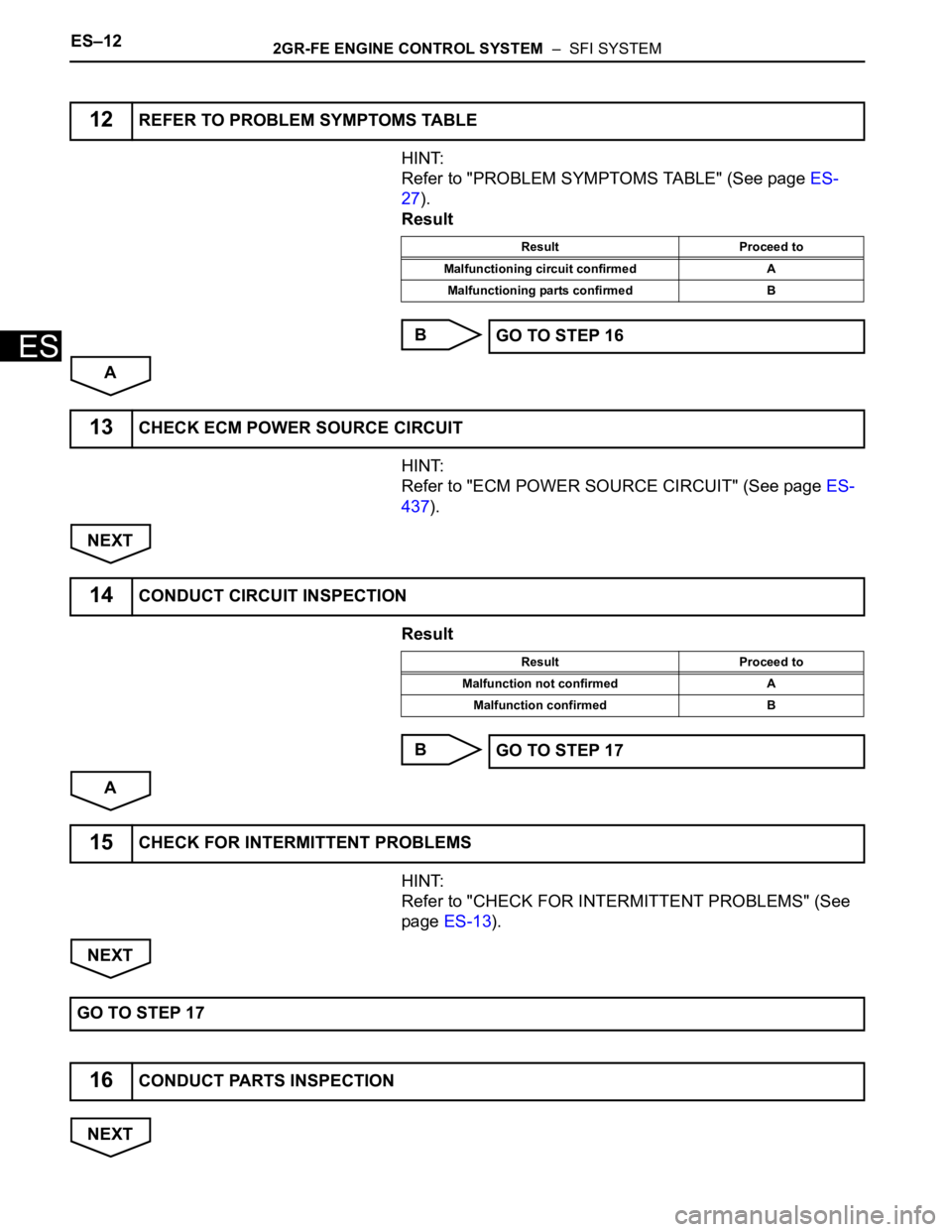

HINT:

Refer to "PROBLEM SYMPTOMS TABLE" (See page ES-

27).

Result

B

A

HINT:

Refer to "ECM POWER SOURCE CIRCUIT" (See page ES-

437).

NEXT

Result

B

A

HINT:

Refer to "CHECK FOR INTERMITTENT PROBLEMS" (See

page ES-13).

NEXT

NEXT

12REFER TO PROBLEM SYMPTOMS TABLE

Result Proceed to

Malfunctioning circuit confirmed A

Malfunctioning parts confirmed B

GO TO STEP 16

13CHECK ECM POWER SOURCE CIRCUIT

14CONDUCT CIRCUIT INSPECTION

Result Proceed to

Malfunction not confirmed A

Malfunction confirmed B

GO TO STEP 17

15CHECK FOR INTERMITTENT PROBLEMS

GO TO STEP 17

16CONDUCT PARTS INSPECTION

Page 319 of 3000

ES–22GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

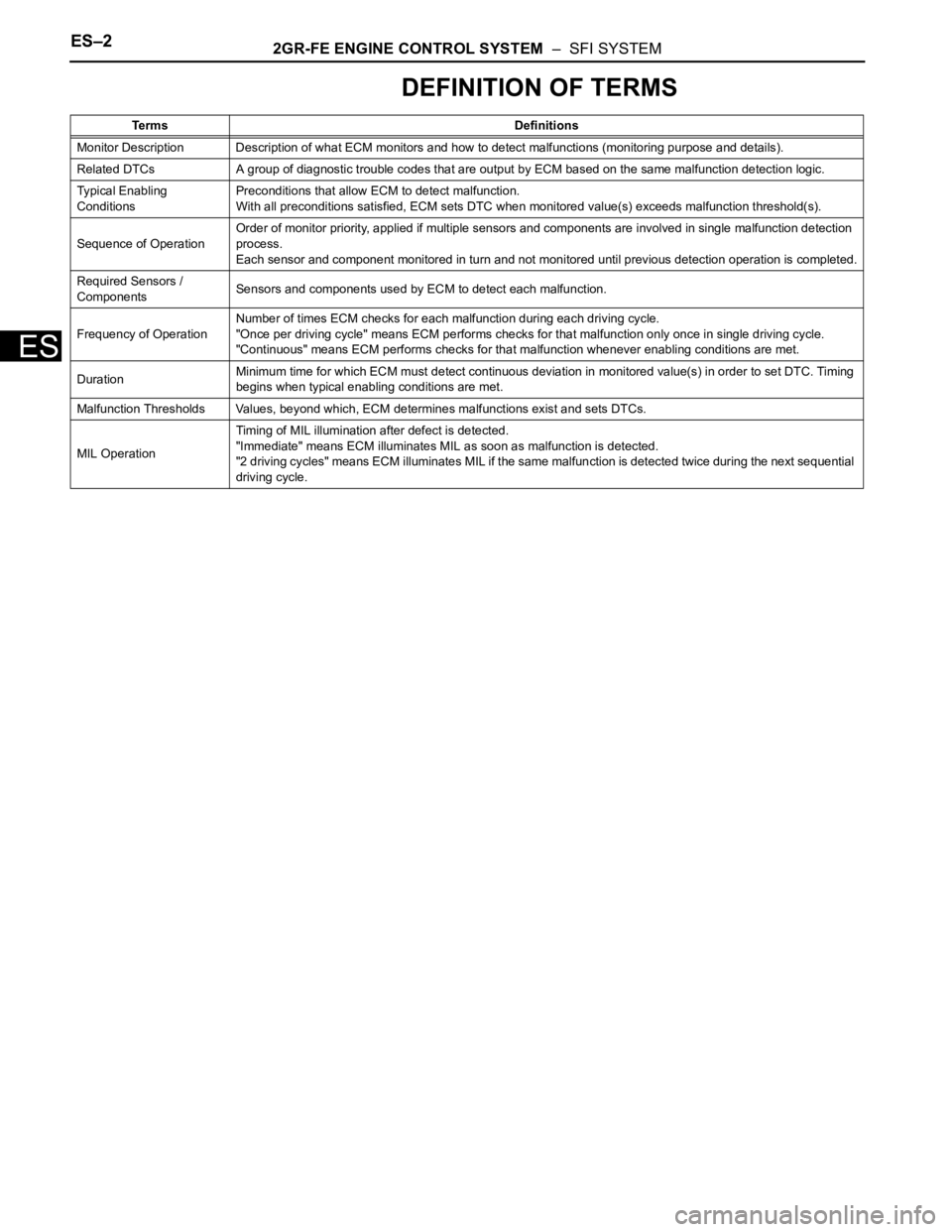

DEFINITION OF TERMS

Terms Definitions

Monitor Description Description of what ECM monitors and how to detect malfunctions (monitoring purpose and details).

Related DTCs A group of diagnostic trouble codes that are output by ECM based on the same malfunction detection logic.

Typical Enabling

ConditionsPreconditions that allow ECM to detect malfunction.

With all preconditions satisfied, ECM sets DTC when monitored value(s) exceeds malfunction threshold(s).

Sequence of OperationOrder of monitor priority, applied if multiple sensors and components are involved in single malfunction detection

process.

Each sensor and component monitored in turn and not monitored until previous detection operation is completed.

Required Sensors /

ComponentsSensors and components used by ECM to detect each malfunction.

Frequency of OperationNumber of times ECM checks for each malfunction during each driving cycle.

"Once per driving cycle" means ECM performs checks for that malfunction only once in single driving cycle.

"Continuous" means ECM performs checks for that malfunction whenever enabling conditions are met.

DurationMinimum time for which ECM must detect continuous deviation in monitored value(s) in order to set DTC. Timing

begins when typical enabling conditions are met.

Malfunction Thresholds Values, beyond which, ECM determines malfunctions exist and sets DTCs.

MIL OperationTiming of MIL illumination after defect is detected.

"Immediate" means ECM illuminates MIL as soon as malfunction is detected.

"2 driving cycles" means ECM illuminates MIL if the same malfunction is detected twice during the next sequential

driving cycle.

Page 321 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–253

ES

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

All:

Exhaust Camshaft Sensor Range Check / Rationality (While starting engine):

Exhaust Camshaft Sensor Range Check / Rationality (After starting engine):

Exhaust Camshaft Sensor Range Check (Chattering, Low voltage, High voltage):

TYPICAL MALFUNCTION THRESHOLDS

Exhaust Camshaft Sensor Range Check / Rationality (While starting engine):

Exhaust Camshaft Sensor Range Check / Rationality (After starting engine):

Exhaust Camshaft Sensor Range Check (Chattering):

Related DTCsP0365: Exhaust camshaft sensor (Bank 1) range check / rationality (while starting

engine)

P0365: Exhaust camshaft sensor (Bank 1) range check / rationality (after starting

engine)

P0365: Exhaust camshaft sensor (Bank 1) range check (chattering)

P0367: Exhaust camshaft sensor (Bank 1) range check (low voltage)

P0368: Exhaust camshaft sensor (Bank 1) range check (high voltage)

P0390: Exhaust camshaft sensor (Bank 2) range check / rationality (while starting

engine)

P0390: Exhaust camshaft sensor (Bank 2) range check / rationality (after starting

engine)

P0390: Exhaust camshaft sensor (Bank 2) range check (chattering)

P0392: Exhaust camshaft sensor (Bank 2) range check (low voltage)

P0393: Exhaust camshaft sensor (Bank 2) range check (high voltage)

Required Sensors / Components (Main) Exhaust camshaft sensor (Bank 1 and 2)

Required Sensors / Components (Related) Exhaust camshaft sensor

Frequency of Operation Continuous

Duration5 seconds: Exhaust camshaft sensor range check / rationality (After starting engine)

4 seconds: Others

MIL Operation2 driving cycles: Exhaust camshaft sensor range check / rationality (After starting

engine)

Immediate: Others

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentNone

Sta r t e r ON

Battery voltage while starter is ON at least once Less than 11 V

Engine RPM 600 rpm or more

Sta r t e r OF F

Battery voltage 8 V or more

Ignition Switch ON

Sta r t e r OF F

Ignition Switch ON and time after ignition switch is OFF

to ON2 seconds or more

Battery voltage 8 V or more

Exhaust camshaft sensor signal No signal

Exhaust camshaft sensor signal No signal

Exhaust camshaft sensor signal Less than 0.3 V, or more than 4.7 V

Page 322 of 3000

ES–2542GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

Exhaust Camshaft Sensor Range Check (Low voltage):

Exhaust Camshaft Sensor Range Check (High voltage):

WIRING DIAGRAM

Refer to DTC P0335 (See page ES-222).

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of

a malfunction.

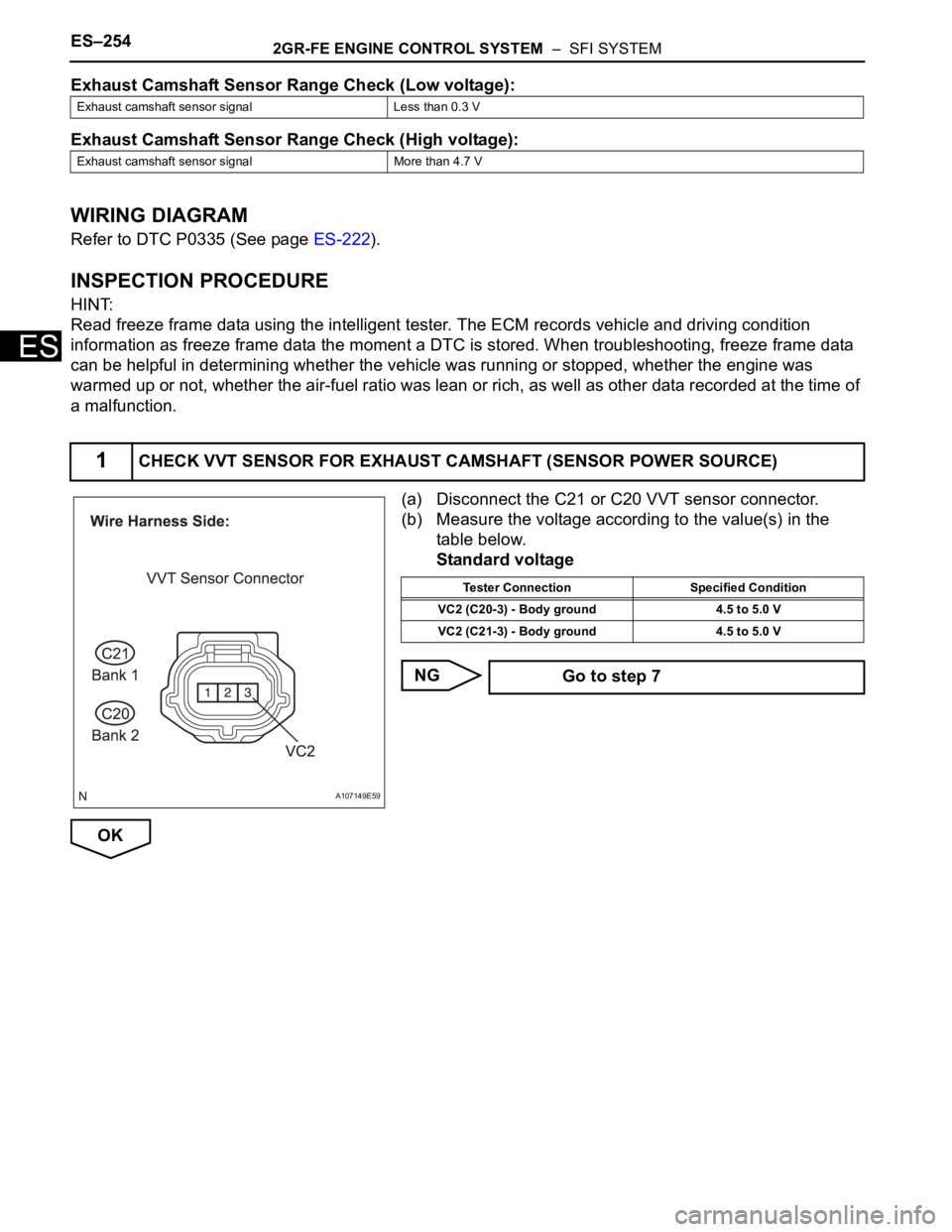

(a) Disconnect the C21 or C20 VVT sensor connector.

(b) Measure the voltage according to the value(s) in the

table below.

Standard voltage

NG

OK

Exhaust camshaft sensor signal Less than 0.3 V

Exhaust camshaft sensor signal More than 4.7 V

1CHECK VVT SENSOR FOR EXHAUST CAMSHAFT (SENSOR POWER SOURCE)

A107149E59

Tester Connection Specified Condition

VC2 (C20-3) - Body ground 4.5 to 5.0 V

VC2 (C21-3) - Body ground 4.5 to 5.0 V

Go to step 7

Page 323 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–255

ES

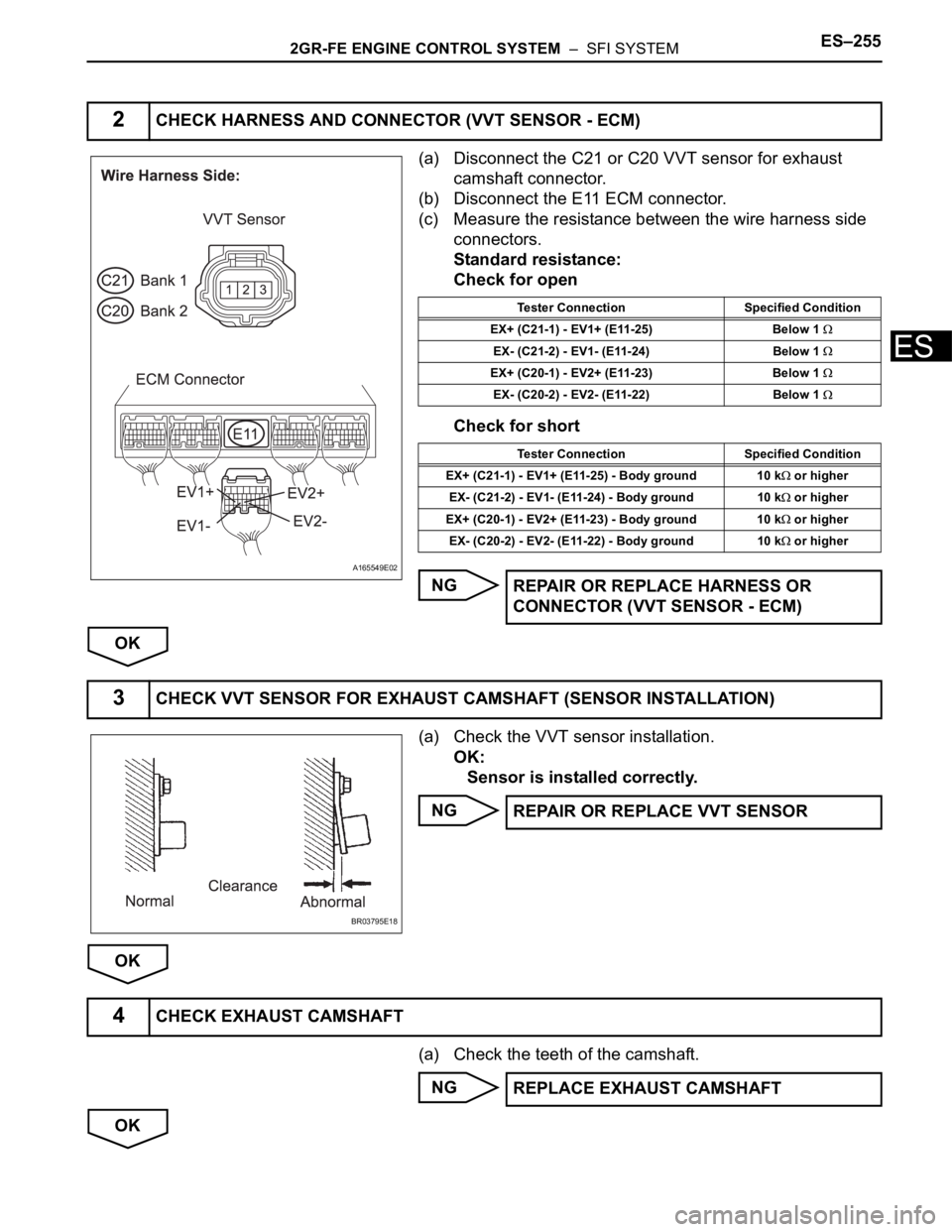

(a) Disconnect the C21 or C20 VVT sensor for exhaust

camshaft connector.

(b) Disconnect the E11 ECM connector.

(c) Measure the resistance between the wire harness side

connectors.

Standard resistance:

Check for open

Check for short

NG

OK

(a) Check the VVT sensor installation.

OK:

Sensor is installed correctly.

NG

OK

(a) Check the teeth of the camshaft.

NG

OK

2CHECK HARNESS AND CONNECTOR (VVT SENSOR - ECM)

A165549E02

Tester Connection Specified Condition

EX+ (C21-1) - EV1+ (E11-25) Below 1

EX- (C21-2) - EV1- (E11-24) Below 1

EX+ (C20-1) - EV2+ (E11-23) Below 1

EX- (C20-2) - EV2- (E11-22) Below 1

Tester Connection Specified Condition

EX+ (C21-1) - EV1+ (E11-25) - Body ground 10 k

or higher

EX- (C21-2) - EV1- (E11-24) - Body ground 10 k

or higher

EX+ (C20-1) - EV2+ (E11-23) - Body ground 10 k

or higher

EX- (C20-2) - EV2- (E11-22) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (VVT SENSOR - ECM)

3CHECK VVT SENSOR FOR EXHAUST CAMSHAFT (SENSOR INSTALLATION)

BR03795E18

REPAIR OR REPLACE VVT SENSOR

4CHECK EXHAUST CAMSHAFT

REPLACE EXHAUST CAMSHAFT

Page 324 of 3000

ES–2562GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

(a) Replace the VVT sensor (See page ES-509).

NEXT

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the intelligent tester on.

(d) Clear the DTCs.

(e) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC / INFO / PENDING CODES.

(f) Read the DTCs.

Result

HINT:

If the engine does not start, replace the ECM.

B

A

5REPLACE VVT SENSOR (FOR EXHAUST CAMSHAFT)

6CHECK WHETHER DTC OUTPUT RECURS

Display (DTC Output) Proceed to

No output A

P0365, P0352, P0353, P0354, P0355 or P0356 B

REPLACE ECM (See page ES-498)

END

Page 325 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–257

ES

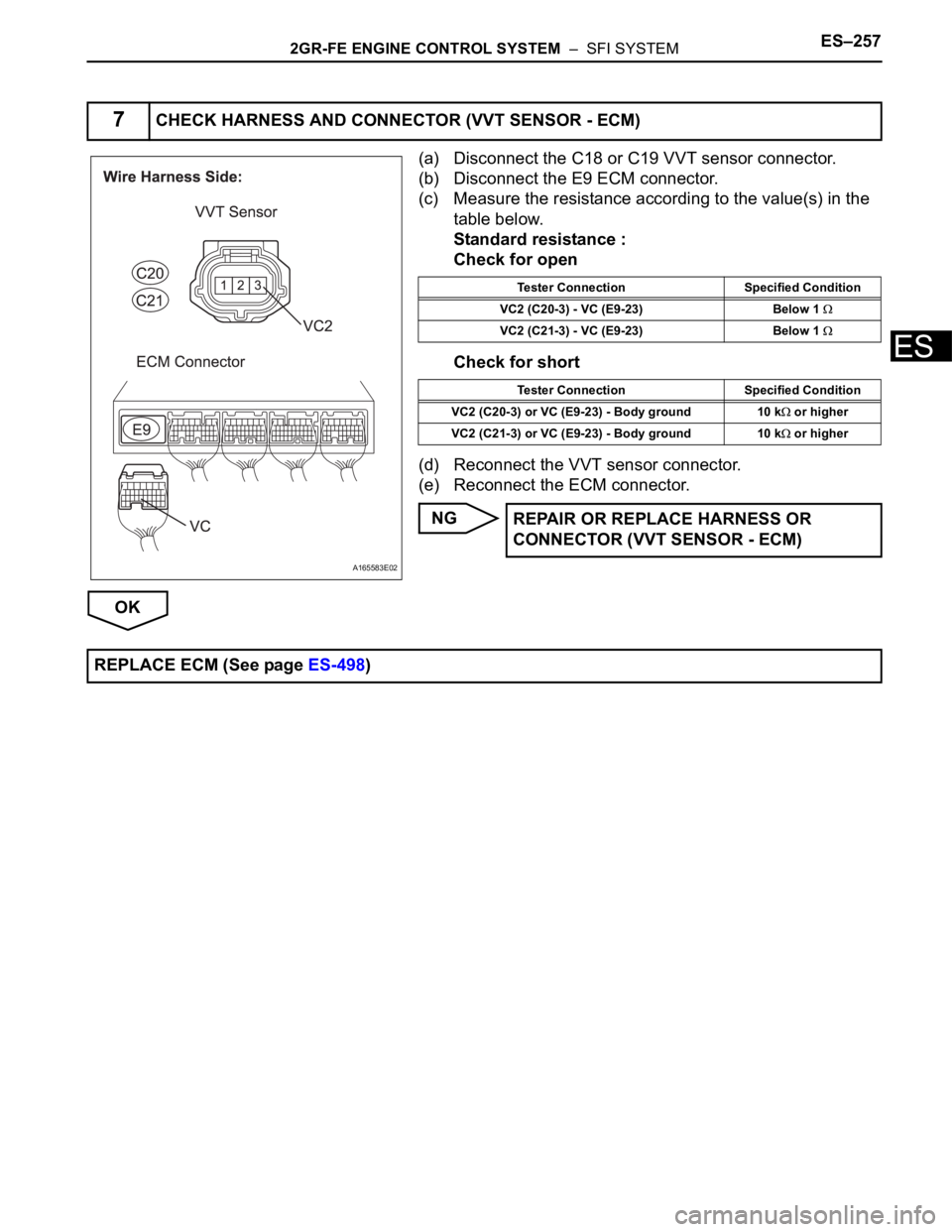

(a) Disconnect the C18 or C19 VVT sensor connector.

(b) Disconnect the E9 ECM connector.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance :

Check for open

Check for short

(d) Reconnect the VVT sensor connector.

(e) Reconnect the ECM connector.

NG

OK

7CHECK HARNESS AND CONNECTOR (VVT SENSOR - ECM)

A165583E02

Tester Connection Specified Condition

VC2 (C20-3) - VC (E9-23) Below 1

VC2 (C21-3) - VC (E9-23) Below 1

Tester Connection Specified Condition

VC2 (C20-3) or VC (E9-23) - Body ground 10 k

or higher

VC2 (C21-3) or VC (E9-23) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (VVT SENSOR - ECM)

REPLACE ECM (See page ES-498)

Page 327 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–259

ES

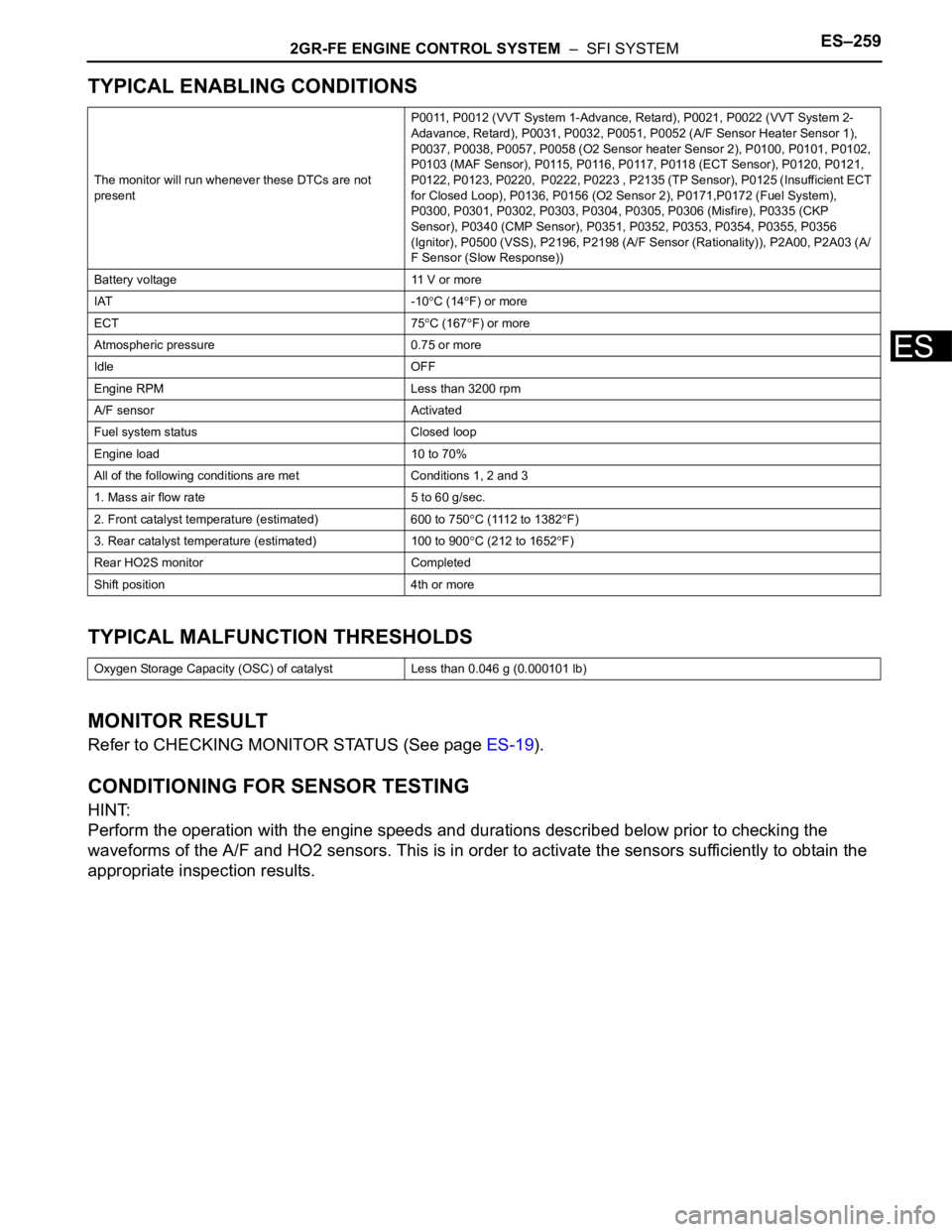

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

MONITOR RESULT

Refer to CHECKING MONITOR STATUS (See page ES-19).

CONDITIONING FOR SENSOR TESTING

HINT:

Perform the operation with the engine speeds and durations described below prior to checking the

waveforms of the A/F and HO2 sensors. This is in order to activate the sensors sufficiently to obtain the

appropriate inspection results.

The monitor will run whenever these DTCs are not

presentP0011, P0012 (VVT System 1-Advance, Retard), P0021, P0022 (VVT System 2-

Adavance, Retard), P0031, P0032, P0051, P0052 (A/F Sensor Heater Sensor 1),

P0037, P0038, P0057, P0058 (O2 Sensor heater Sensor 2), P0100, P0101, P0102,

P0103 (MAF Sensor), P0115, P0116, P0117, P0118 (ECT Sensor), P0120, P0121,

P0122, P0123, P0220, P0222, P0223 , P2135 (TP Sensor), P0125 (Insufficient ECT

for Closed Loop), P0136, P0156 (O2 Sensor 2), P0171,P0172 (Fuel System),

P0300, P0301, P0302, P0303, P0304, P0305, P0306 (Misfire), P0335 (CKP

Sensor), P0340 (CMP Sensor), P0351, P0352, P0353, P0354, P0355, P0356

(Ignitor), P0500 (VSS), P2196, P2198 (A/F Sensor (Rationality)), P2A00, P2A03 (A/

F Sensor (Slow Response))

Battery voltage 11 V or more

IAT -10

C (14F) or more

ECT 75

C (167F) or more

Atmospheric pressure 0.75 or more

Idle OFF

Engine RPM Less than 3200 rpm

A/F sensor Activated

Fuel system status Closed loop

Engine load 10 to 70%

All of the following conditions are met Conditions 1, 2 and 3

1. Mass air flow rate 5 to 60 g/sec.

2. Front catalyst temperature (estimated) 600 to 750

C (1112 to 1382F)

3. Rear catalyst temperature (estimated) 100 to 900

C (212 to 1652F)

Rear HO2S monitor Completed

Shift position 4th or more

Oxygen Storage Capacity (OSC) of catalyst Less than 0.046 g (0.000101 lb)