check engine TOYOTA SIENNA 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 81 of 3000

2GR-FE IGNITION – IGNITION COIL AND SPARK PLUGIG–7

IG

(3) Check the spark plug (See page EM-1).

Result

(4) Check the power supply to the ignition coil.

1. Turn the ignition switch to the ON position.

2. Check that there is battery voltage at the

ignition coil positive (+) terminal.

Result

(5) Measure the resistance of the crankshaft

position sensor (See page ES-514).

Result

(6) Check the IGT signal from the ECM (See page

ES-233)

Result

(e) Using a 16 mm (0.63 in.) plug wrench, install the

spark plugs.

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

(f) Connect the 6 fuel injector connectors.

(g) Install the ignition coil assembly (See page IG-10).

2. INSPECT SPARK PLUG

NOTICE:

• Never use a wire brush for cleaning.

• Never attempt to adjust the electrode gap on a

used spark plug.

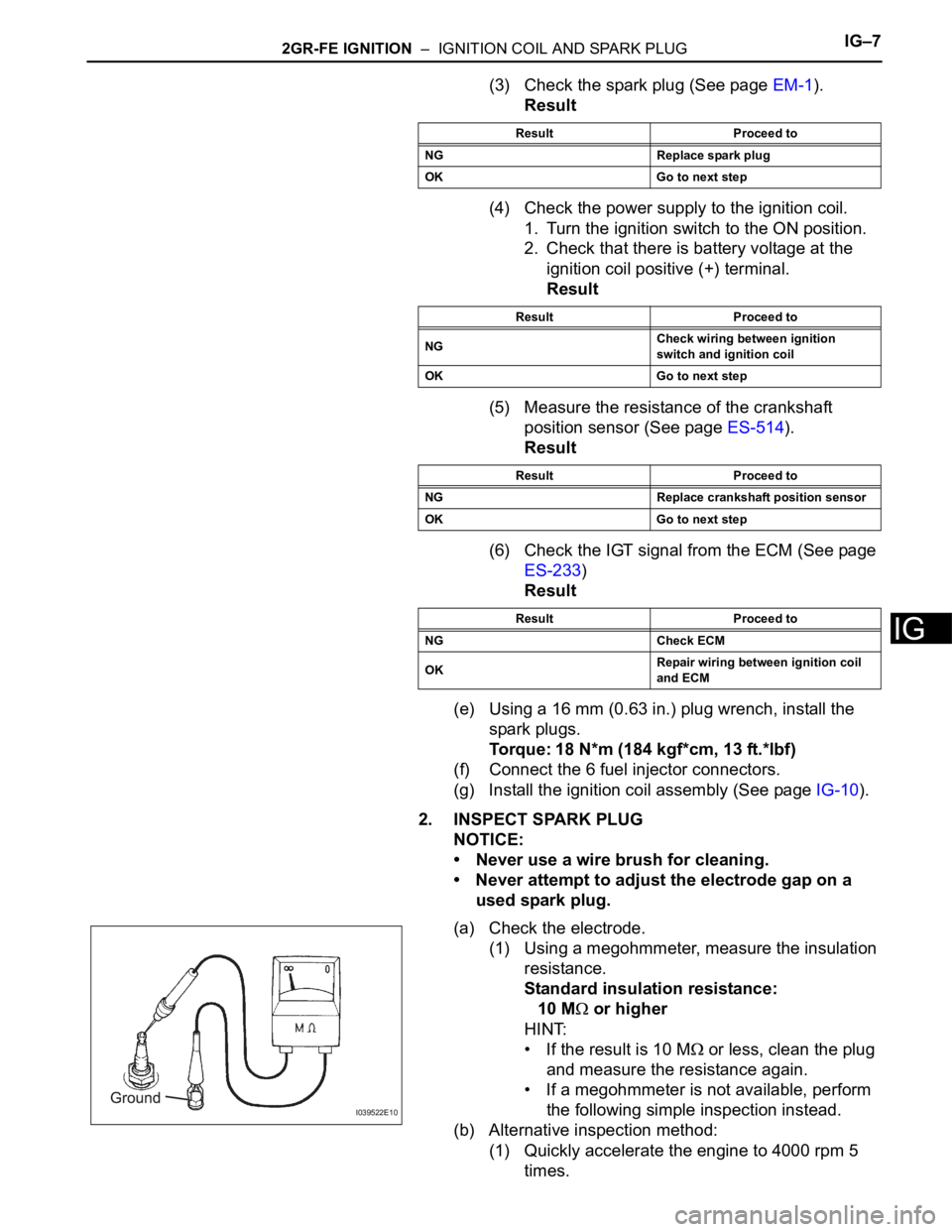

(a) Check the electrode.

(1) Using a megohmmeter, measure the insulation

resistance.

Standard insulation resistance:

10 M

or higher

HINT:

• If the result is 10 M

or less, clean the plug

and measure the resistance again.

• If a megohmmeter is not available, perform

the following simple inspection instead.

(b) Alternative inspection method:

(1) Quickly accelerate the engine to 4000 rpm 5

times.

Result Proceed to

NG Replace spark plug

OK Go to next step

Result Proceed to

NGCheck wiring between ignition

switch and ignition coil

OK Go to next step

Result Proceed to

NG Replace crankshaft position sensor

OK Go to next step

Result Proceed to

NG Check ECM

OKRepair wiring between ignition coil

and ECM

I039522E10

Page 82 of 3000

IG–82GR-FE IGNITION – IGNITION COIL AND SPARK PLUG

IG

(2) Remove the spark plugs.

(3) Visually check the spark plug.

If the electrode is dry, the spark plug is

functioning properly. If the electrode is damp,

proceed to the next step.

(c) Check the spark plug for any damage to its threads

and insulator. If there is damage, replace the spark

plug.

Recommended spark plug

NOTICE:

Use only the listed spark plug or equivalent to

ensure engine performance and smooth

driveability.

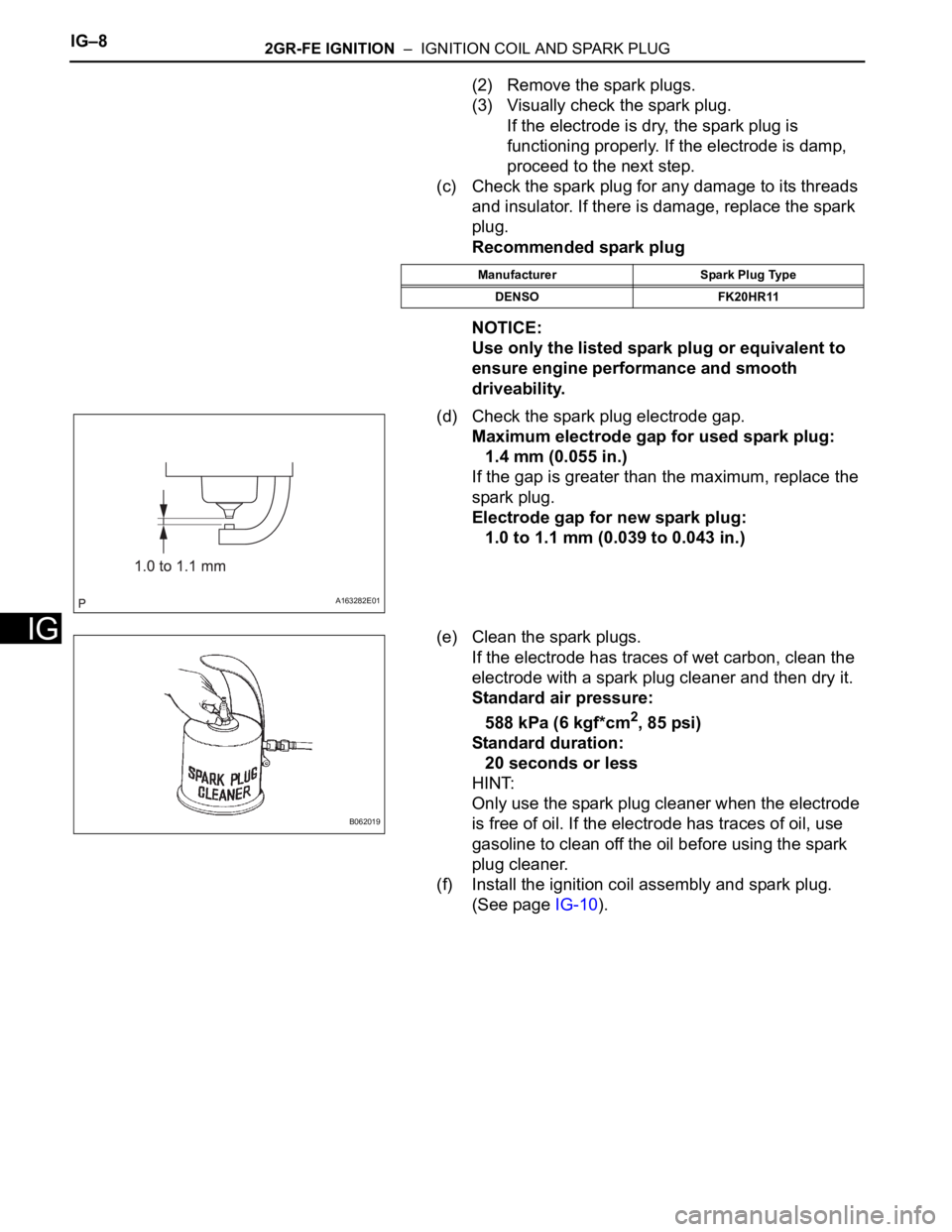

(d) Check the spark plug electrode gap.

Maximum electrode gap for used spark plug:

1.4 mm (0.055 in.)

If the gap is greater than the maximum, replace the

spark plug.

Electrode gap for new spark plug:

1.0 to 1.1 mm (0.039 to 0.043 in.)

(e) Clean the spark plugs.

If the electrode has traces of wet carbon, clean the

electrode with a spark plug cleaner and then dry it.

Standard air pressure:

588 kPa (6 kgf*cm

2, 85 psi)

Standard duration:

20 seconds or less

HINT:

Only use the spark plug cleaner when the electrode

is free of oil. If the electrode has traces of oil, use

gasoline to clean off the oil before using the spark

plug cleaner.

(f) Install the ignition coil assembly and spark plug.

(See page IG-10).

Manufacturer Spark Plug Type

DENSO FK20HR11

A163282E01

B062019

Page 93 of 3000

AX–166U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLY

AX

INSTALLATION

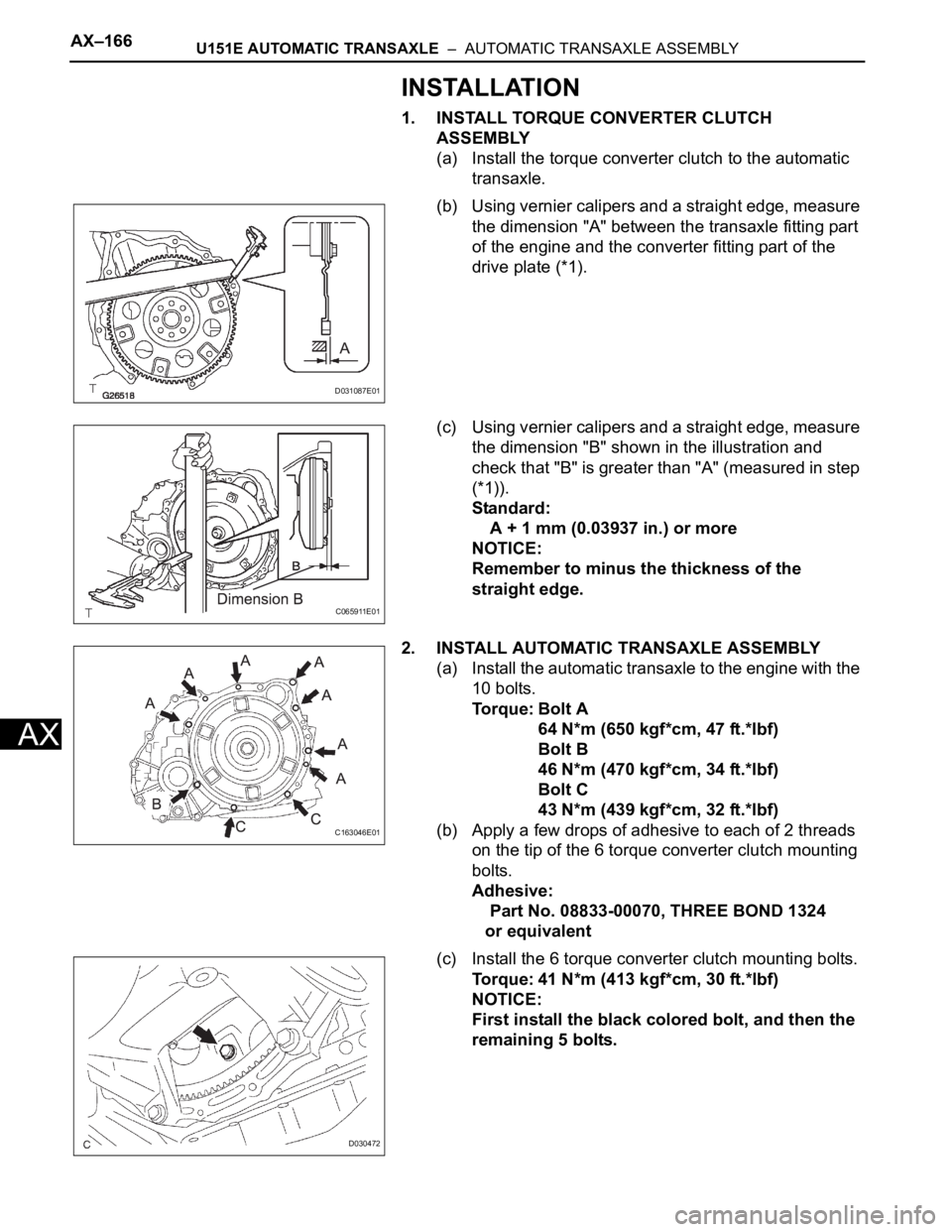

1. INSTALL TORQUE CONVERTER CLUTCH

ASSEMBLY

(a) Install the torque converter clutch to the automatic

transaxle.

(b) Using vernier calipers and a straight edge, measure

the dimension "A" between the transaxle fitting part

of the engine and the converter fitting part of the

drive plate (*1).

(c) Using vernier calipers and a straight edge, measure

the dimension "B" shown in the illustration and

check that "B" is greater than "A" (measured in step

(*1)).

Standard:

A + 1 mm (0.03937 in.) or more

NOTICE:

Remember to minus the thickness of the

straight edge.

2. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY

(a) Install the automatic transaxle to the engine with the

10 bolts.

Torque: Bolt A

64 N*m (650 kgf*cm, 47 ft.*lbf)

Bolt B

46 N*m (470 kgf*cm, 34 ft.*lbf)

Bolt C

43 N*m (439 kgf*cm, 32 ft.*lbf)

(b) Apply a few drops of adhesive to each of 2 threads

on the tip of the 6 torque converter clutch mounting

bolts.

Adhesive:

Part No. 08833-00070, THREE BOND 1324

or equivalent

(c) Install the 6 torque converter clutch mounting bolts.

Torque: 41 N*m (413 kgf*cm, 30 ft.*lbf)

NOTICE:

First install the black colored bolt, and then the

remaining 5 bolts.

D031087E01

C065911E01

C163046E01

D030472

Page 103 of 3000

AX–168U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLY

AX

INSTALLATION

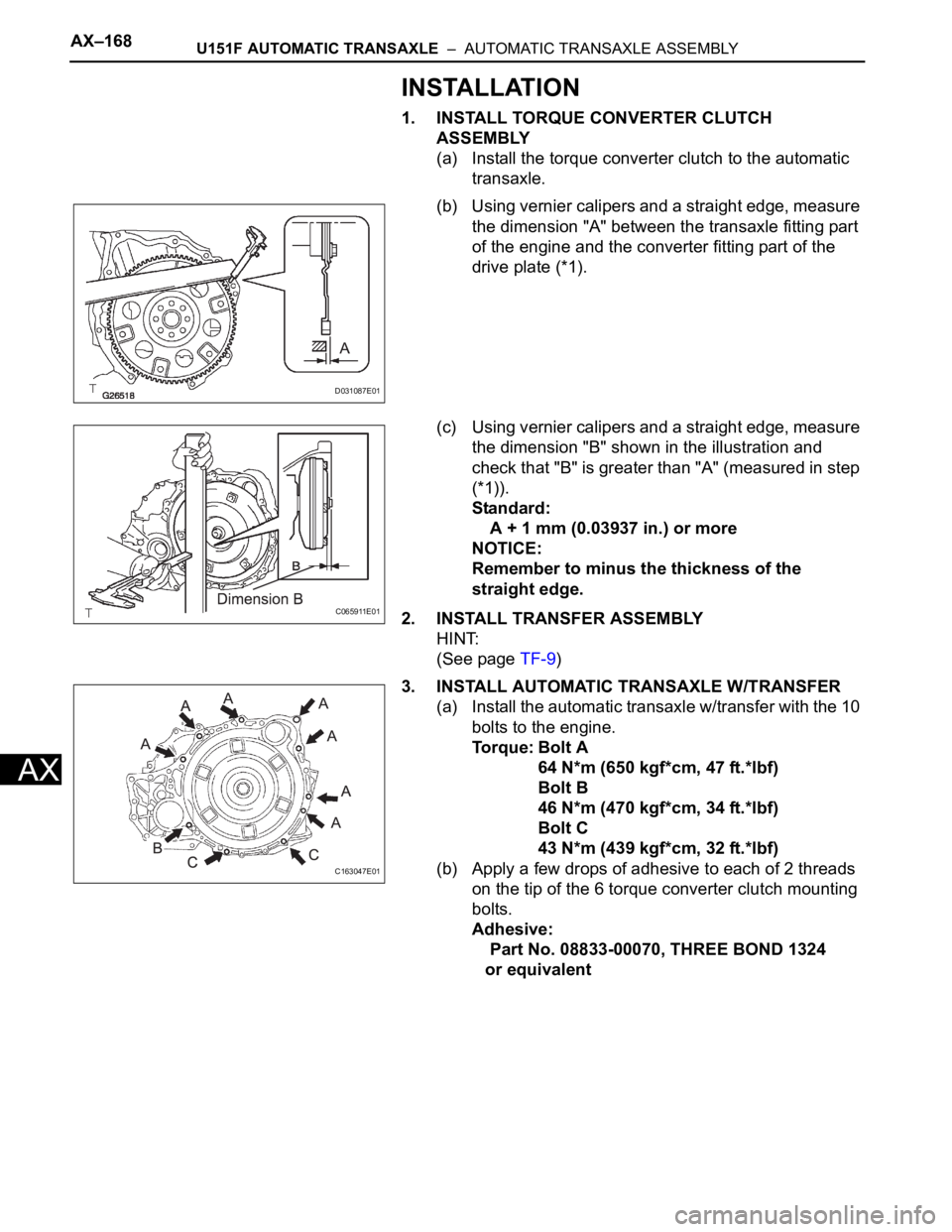

1. INSTALL TORQUE CONVERTER CLUTCH

ASSEMBLY

(a) Install the torque converter clutch to the automatic

transaxle.

(b) Using vernier calipers and a straight edge, measure

the dimension "A" between the transaxle fitting part

of the engine and the converter fitting part of the

drive plate (*1).

(c) Using vernier calipers and a straight edge, measure

the dimension "B" shown in the illustration and

check that "B" is greater than "A" (measured in step

(*1)).

Standard:

A + 1 mm (0.03937 in.) or more

NOTICE:

Remember to minus the thickness of the

straight edge.

2. INSTALL TRANSFER ASSEMBLY

HINT:

(See page TF-9)

3. INSTALL AUTOMATIC TRANSAXLE W/TRANSFER

(a) Install the automatic transaxle w/transfer with the 10

bolts to the engine.

To r q u e : B o l t A

64 N*m (650 kgf*cm, 47 ft.*lbf)

Bolt B

46 N*m (470 kgf*cm, 34 ft.*lbf)

Bolt C

43 N*m (439 kgf*cm, 32 ft.*lbf)

(b) Apply a few drops of adhesive to each of 2 threads

on the tip of the 6 torque converter clutch mounting

bolts.

Adhesive:

Part No. 08833-00070, THREE BOND 1324

or equivalent

D031087E01

C065911E01

C163047E01

Page 107 of 3000

TRANSFER – TRANSFER ASSEMBLYTF–9

TF

INSTALLATION

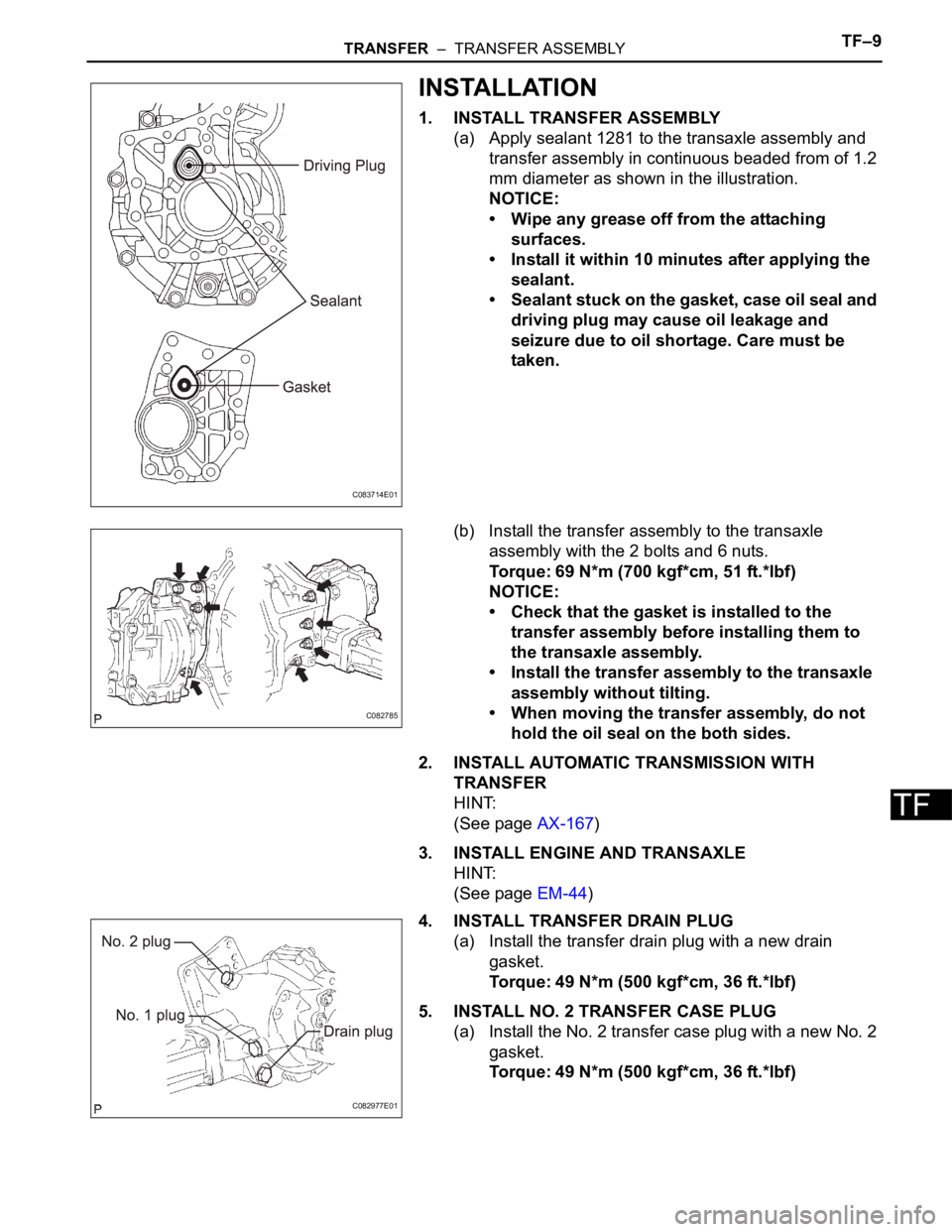

1. INSTALL TRANSFER ASSEMBLY

(a) Apply sealant 1281 to the transaxle assembly and

transfer assembly in continuous beaded from of 1.2

mm diameter as shown in the illustration.

NOTICE:

• Wipe any grease off from the attaching

surfaces.

• Install it within 10 minutes after applying the

sealant.

• Sealant stuck on the gasket, case oil seal and

driving plug may cause oil leakage and

seizure due to oil shortage. Care must be

taken.

(b) Install the transfer assembly to the transaxle

assembly with the 2 bolts and 6 nuts.

Torque: 69 N*m (700 kgf*cm, 51 ft.*lbf)

NOTICE:

• Check that the gasket is installed to the

transfer assembly before installing them to

the transaxle assembly.

• Install the transfer assembly to the transaxle

assembly without tilting.

• When moving the transfer assembly, do not

hold the oil seal on the both sides.

2. INSTALL AUTOMATIC TRANSMISSION WITH

TRANSFER

HINT:

(See page AX-167)

3. INSTALL ENGINE AND TRANSAXLE

HINT:

(See page EM-44)

4. INSTALL TRANSFER DRAIN PLUG

(a) Install the transfer drain plug with a new drain

gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

5. INSTALL NO. 2 TRANSFER CASE PLUG

(a) Install the No. 2 transfer case plug with a new No. 2

gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

C083714E01

C082785

C082977E01

Page 180 of 3000

BC–4BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

TEST MODE PROCEDURE

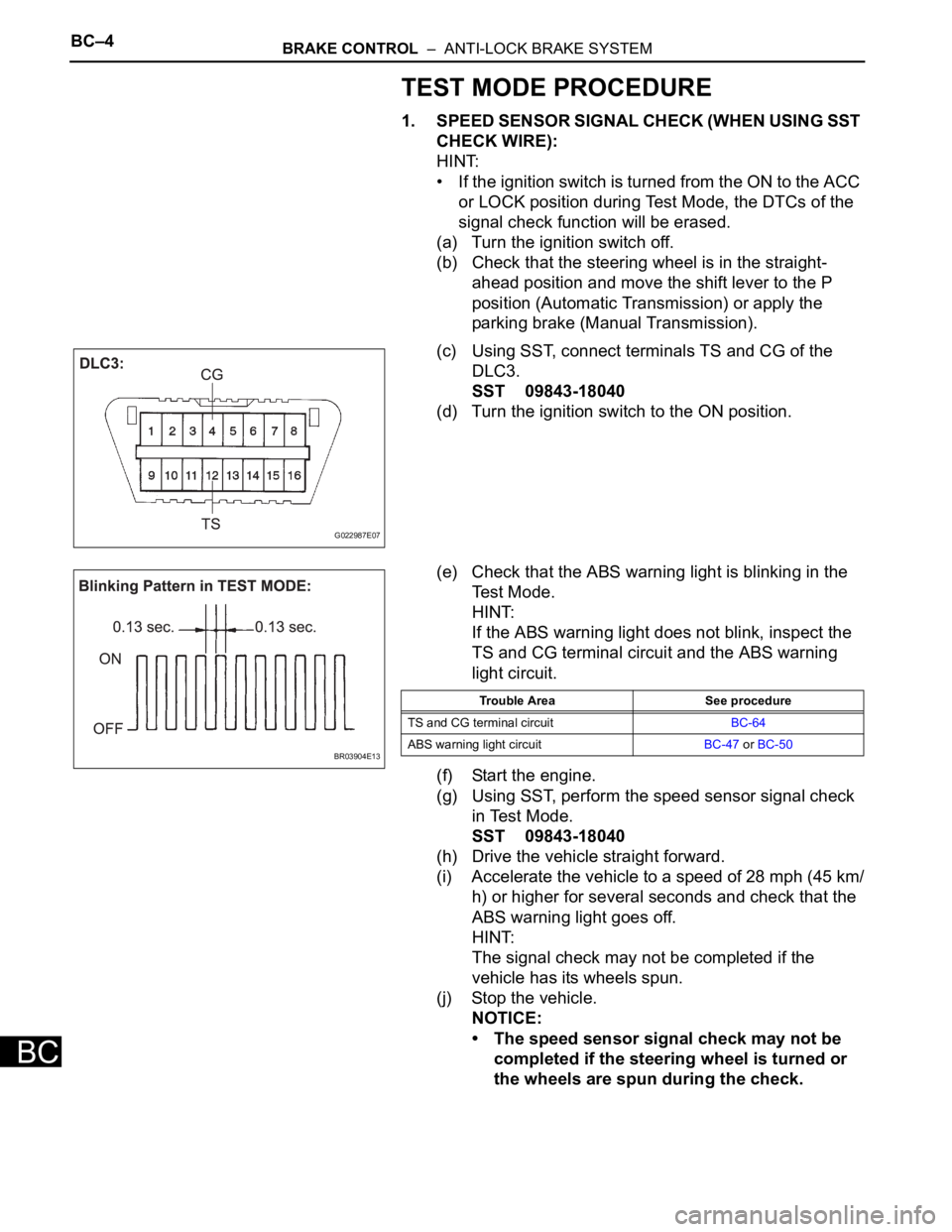

1. SPEED SENSOR SIGNAL CHECK (WHEN USING SST

CHECK WIRE):

HINT:

• If the ignition switch is turned from the ON to the ACC

or LOCK position during Test Mode, the DTCs of the

signal check function will be erased.

(a) Turn the ignition switch off.

(b) Check that the steering wheel is in the straight-

ahead position and move the shift lever to the P

position (Automatic Transmission) or apply the

parking brake (Manual Transmission).

(c) Using SST, connect terminals TS and CG of the

DLC3.

SST 09843-18040

(d) Turn the ignition switch to the ON position.

(e) Check that the ABS warning light is blinking in the

Test Mode.

HINT:

If the ABS warning light does not blink, inspect the

TS and CG terminal circuit and the ABS warning

light circuit.

(f) Start the engine.

(g) Using SST, perform the speed sensor signal check

in Test Mode.

SST 09843-18040

(h) Drive the vehicle straight forward.

(i) Accelerate the vehicle to a speed of 28 mph (45 km/

h) or higher for several seconds and check that the

ABS warning light goes off.

HINT:

The signal check may not be completed if the

vehicle has its wheels spun.

(j) Stop the vehicle.

NOTICE:

• The speed sensor signal check may not be

completed if the steering wheel is turned or

the wheels are spun during the check.

G022987E07

BR03904E13

Trouble Area See procedure

TS and CG terminal circuitBC-64

ABS warning light circuitBC-47 or BC-50

Page 183 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–7

BC

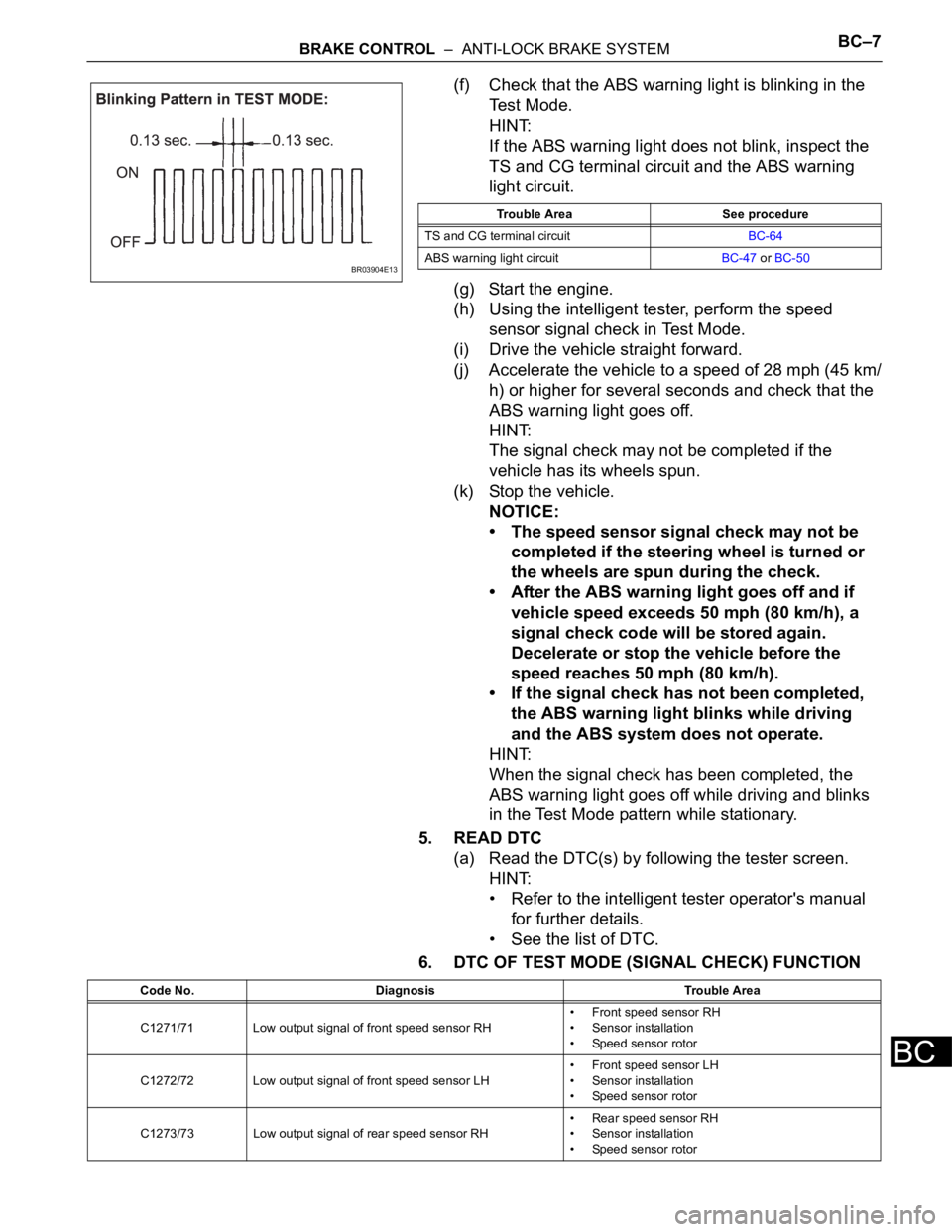

(f) Check that the ABS warning light is blinking in the

Test Mode.

HINT:

If the ABS warning light does not blink, inspect the

TS and CG terminal circuit and the ABS warning

light circuit.

(g) Start the engine.

(h) Using the intelligent tester, perform the speed

sensor signal check in Test Mode.

(i) Drive the vehicle straight forward.

(j) Accelerate the vehicle to a speed of 28 mph (45 km/

h) or higher for several seconds and check that the

ABS warning light goes off.

HINT:

The signal check may not be completed if the

vehicle has its wheels spun.

(k) Stop the vehicle.

NOTICE:

• The speed sensor signal check may not be

completed if the steering wheel is turned or

the wheels are spun during the check.

• After the ABS warning light goes off and if

vehicle speed exceeds 50 mph (80 km/h), a

signal check code will be stored again.

Decelerate or stop the vehicle before the

speed reaches 50 mph (80 km/h).

• If the signal check has not been completed,

the ABS warning light blinks while driving

and the ABS system does not operate.

HINT:

When the signal check has been completed, the

ABS warning light goes off while driving and blinks

in the Test Mode pattern while stationary.

5. READ DTC

(a) Read the DTC(s) by following the tester screen.

HINT:

• Refer to the intelligent tester operator's manual

for further details.

• See the list of DTC.

6. DTC OF TEST MODE (SIGNAL CHECK) FUNCTION

BR03904E13

Trouble Area See procedure

TS and CG terminal circuitBC-64

ABS warning light circuitBC-47 or BC-50

Code No. Diagnosis Trouble Area

C1271/71 Low output signal of front speed sensor RH• Front speed sensor RH

• Sensor installation

• Speed sensor rotor

C1272/72 Low output signal of front speed sensor LH• Front speed sensor LH

• Sensor installation

• Speed sensor rotor

C1273/73 Low output signal of rear speed sensor RH• Rear speed sensor RH

• Sensor installation

• Speed sensor rotor

Page 243 of 3000

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEMEI–3

EI

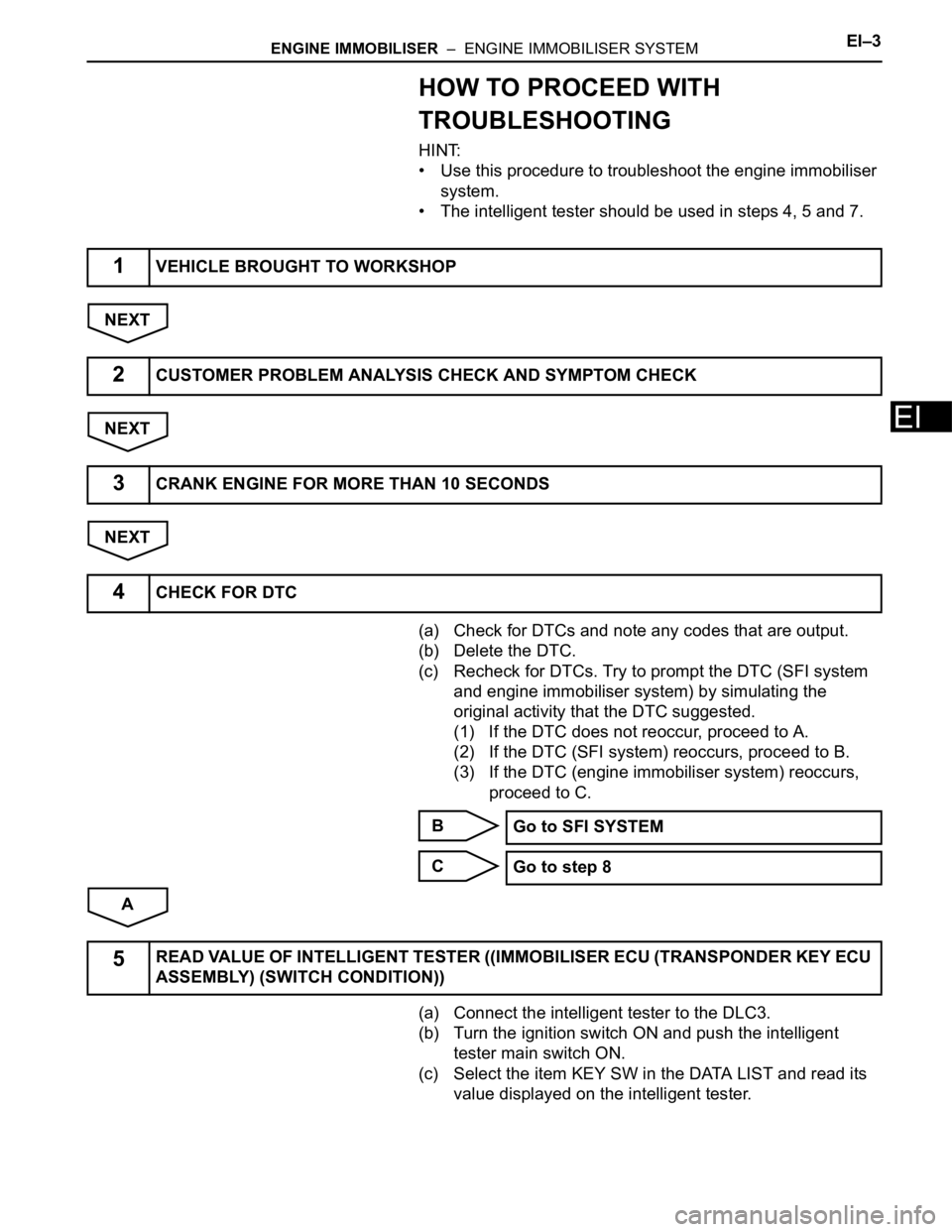

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

• Use this procedure to troubleshoot the engine immobiliser

system.

• The intelligent tester should be used in steps 4, 5 and 7.

NEXT

NEXT

NEXT

(a) Check for DTCs and note any codes that are output.

(b) Delete the DTC.

(c) Recheck for DTCs. Try to prompt the DTC (SFI system

and engine immobiliser system) by simulating the

original activity that the DTC suggested.

(1) If the DTC does not reoccur, proceed to A.

(2) If the DTC (SFI system) reoccurs, proceed to B.

(3) If the DTC (engine immobiliser system) reoccurs,

proceed to C.

B

C

A

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch ON and push the intelligent

tester main switch ON.

(c) Select the item KEY SW in the DATA LIST and read its

value displayed on the intelligent tester.

1VEHICLE BROUGHT TO WORKSHOP

2CUSTOMER PROBLEM ANALYSIS CHECK AND SYMPTOM CHECK

3CRANK ENGINE FOR MORE THAN 10 SECONDS

4CHECK FOR DTC

Go to SFI SYSTEM

Go to step 8

5READ VALUE OF INTELLIGENT TESTER ((IMMOBILISER ECU (TRANSPONDER KEY ECU

ASSEMBLY) (SWITCH CONDITION))

Page 312 of 3000

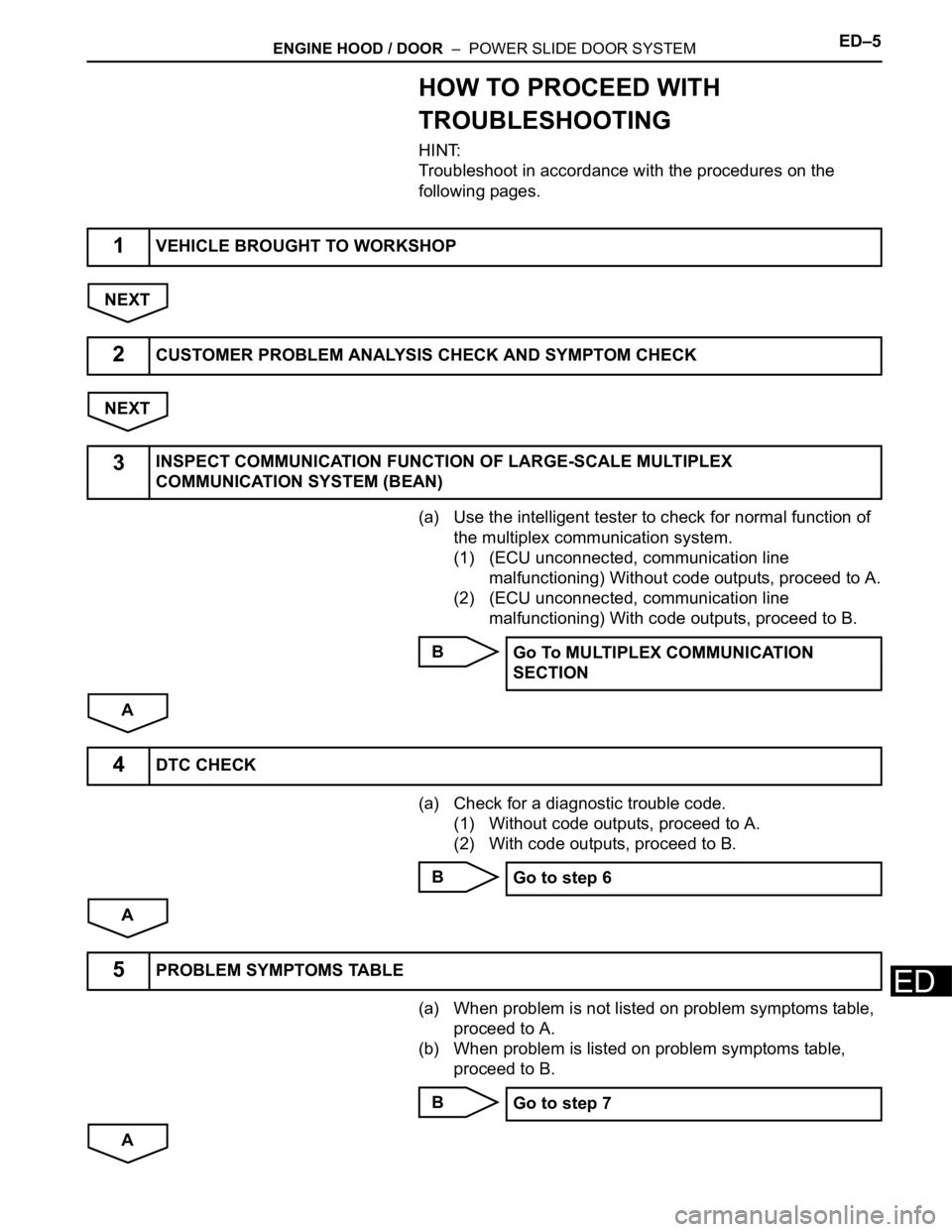

ENGINE HOOD / DOOR – POWER SLIDE DOOR SYSTEMED–5

ED

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

Troubleshoot in accordance with the procedures on the

following pages.

NEXT

NEXT

(a) Use the intelligent tester to check for normal function of

the multiplex communication system.

(1) (ECU unconnected, communication line

malfunctioning) Without code outputs, proceed to A.

(2) (ECU unconnected, communication line

malfunctioning) With code outputs, proceed to B.

B

A

(a) Check for a diagnostic trouble code.

(1) Without code outputs, proceed to A.

(2) With code outputs, proceed to B.

B

A

(a) When problem is not listed on problem symptoms table,

proceed to A.

(b) When problem is listed on problem symptoms table,

proceed to B.

B

A

1VEHICLE BROUGHT TO WORKSHOP

2CUSTOMER PROBLEM ANALYSIS CHECK AND SYMPTOM CHECK

3INSPECT COMMUNICATION FUNCTION OF LARGE-SCALE MULTIPLEX

COMMUNICATION SYSTEM (BEAN)

Go To MULTIPLEX COMMUNICATION

SECTION

4DTC CHECK

Go to step 6

5PROBLEM SYMPTOMS TABLE

Go to step 7

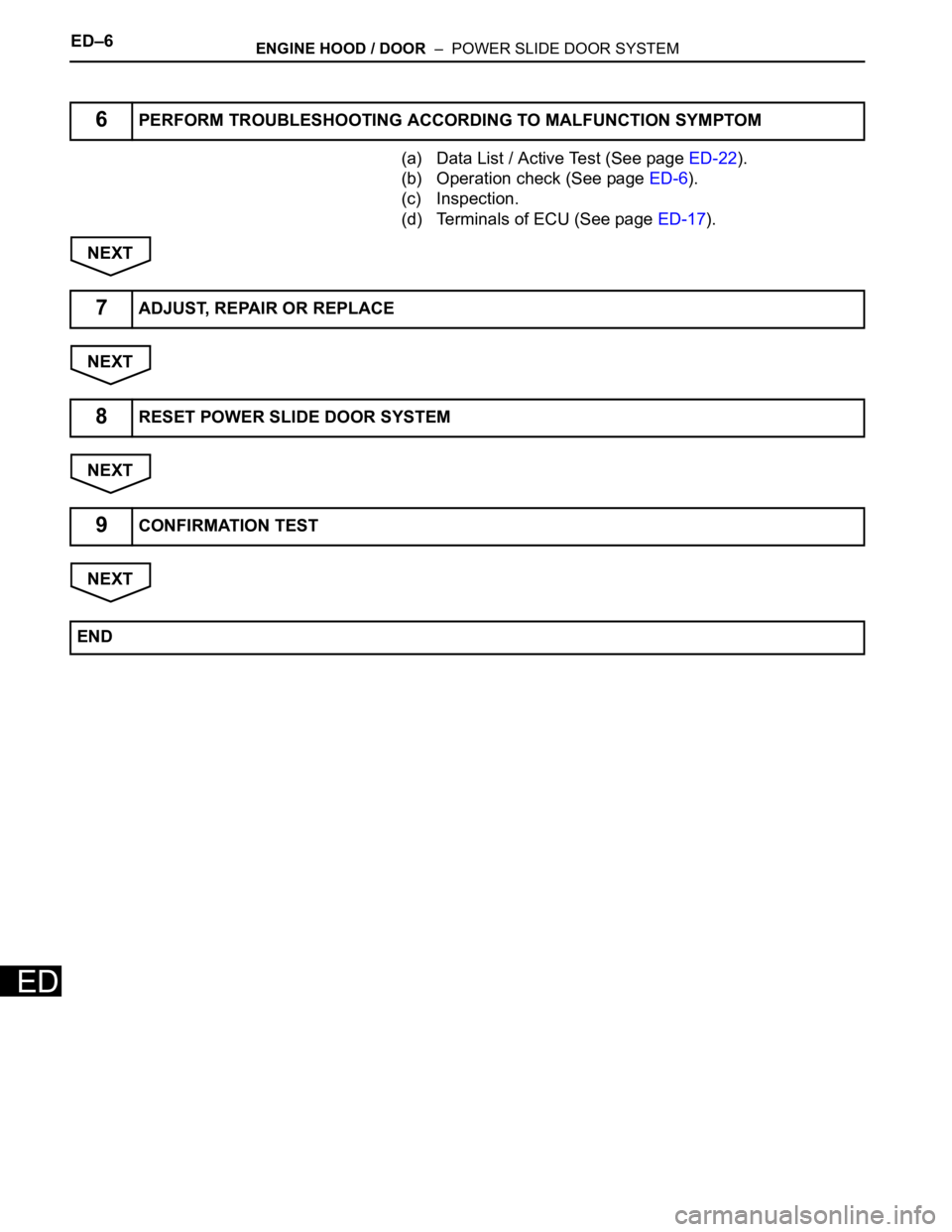

Page 313 of 3000

ED–6ENGINE HOOD / DOOR – POWER SLIDE DOOR SYSTEM

ED

(a) Data List / Active Test (See page ED-22).

(b) Operation check (See page ED-6).

(c) Inspection.

(d) Terminals of ECU (See page ED-17).

NEXT

NEXT

NEXT

NEXT

6PERFORM TROUBLESHOOTING ACCORDING TO MALFUNCTION SYMPTOM

7ADJUST, REPAIR OR REPLACE

8RESET POWER SLIDE DOOR SYSTEM

9CONFIRMATION TEST

END