TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 2261 of 3000

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEMTW–19

TW

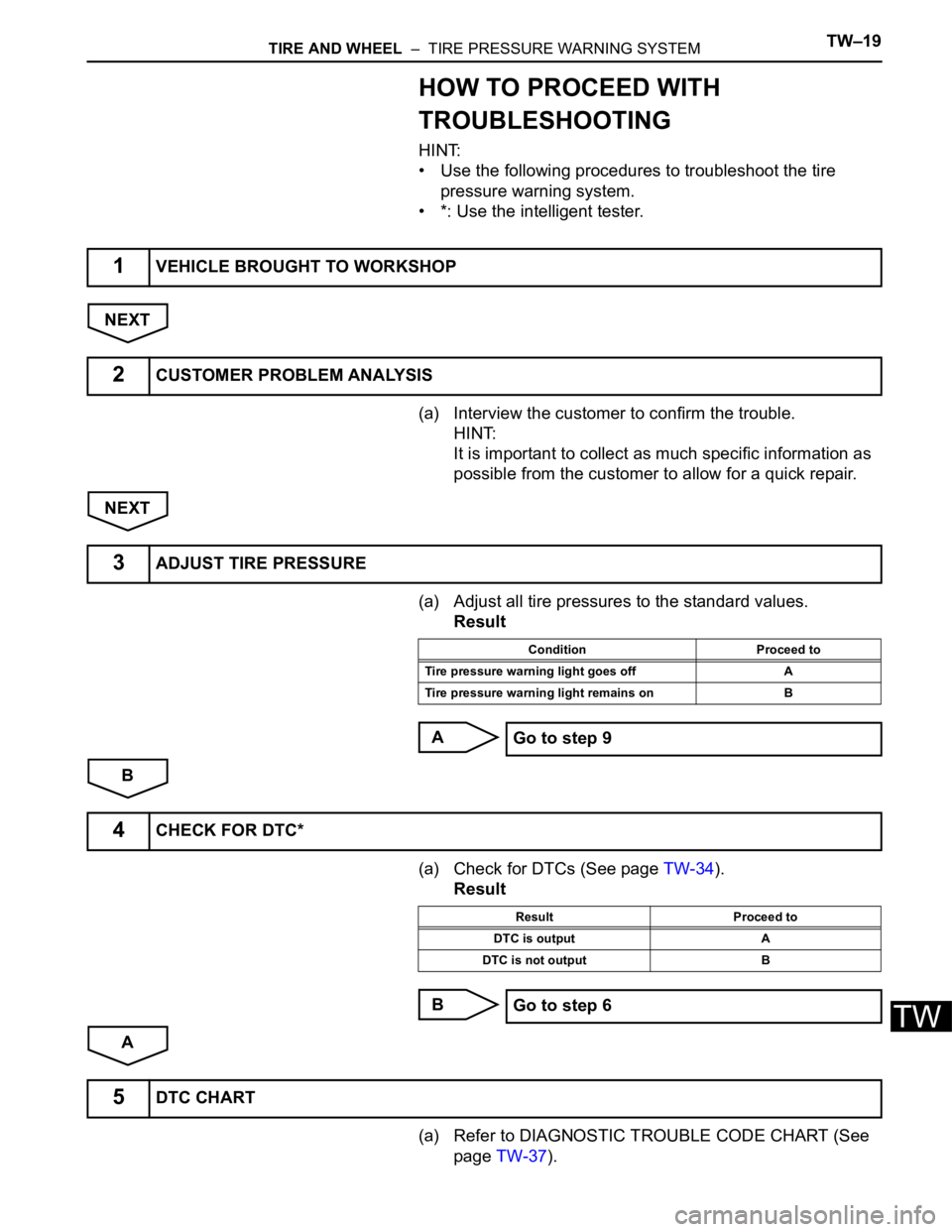

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

• Use the following procedures to troubleshoot the tire

pressure warning system.

• *: Use the intelligent tester.

NEXT

(a) Interview the customer to confirm the trouble.

HINT:

It is important to collect as much specific information as

possible from the customer to allow for a quick repair.

NEXT

(a) Adjust all tire pressures to the standard values.

Result

A

B

(a) Check for DTCs (See page TW-34).

Result

B

A

(a) Refer to DIAGNOSTIC TROUBLE CODE CHART (See

page TW-37).

1VEHICLE BROUGHT TO WORKSHOP

2CUSTOMER PROBLEM ANALYSIS

3ADJUST TIRE PRESSURE

Condition Proceed to

Tire pressure warning light goes off A

Tire pressure warning light remains on B

Go to step 9

4CHECK FOR DTC*

Result Proceed to

DTC is output A

DTC is not output B

Go to step 6

5DTC CHART

Page 2262 of 3000

TW–20TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

TW

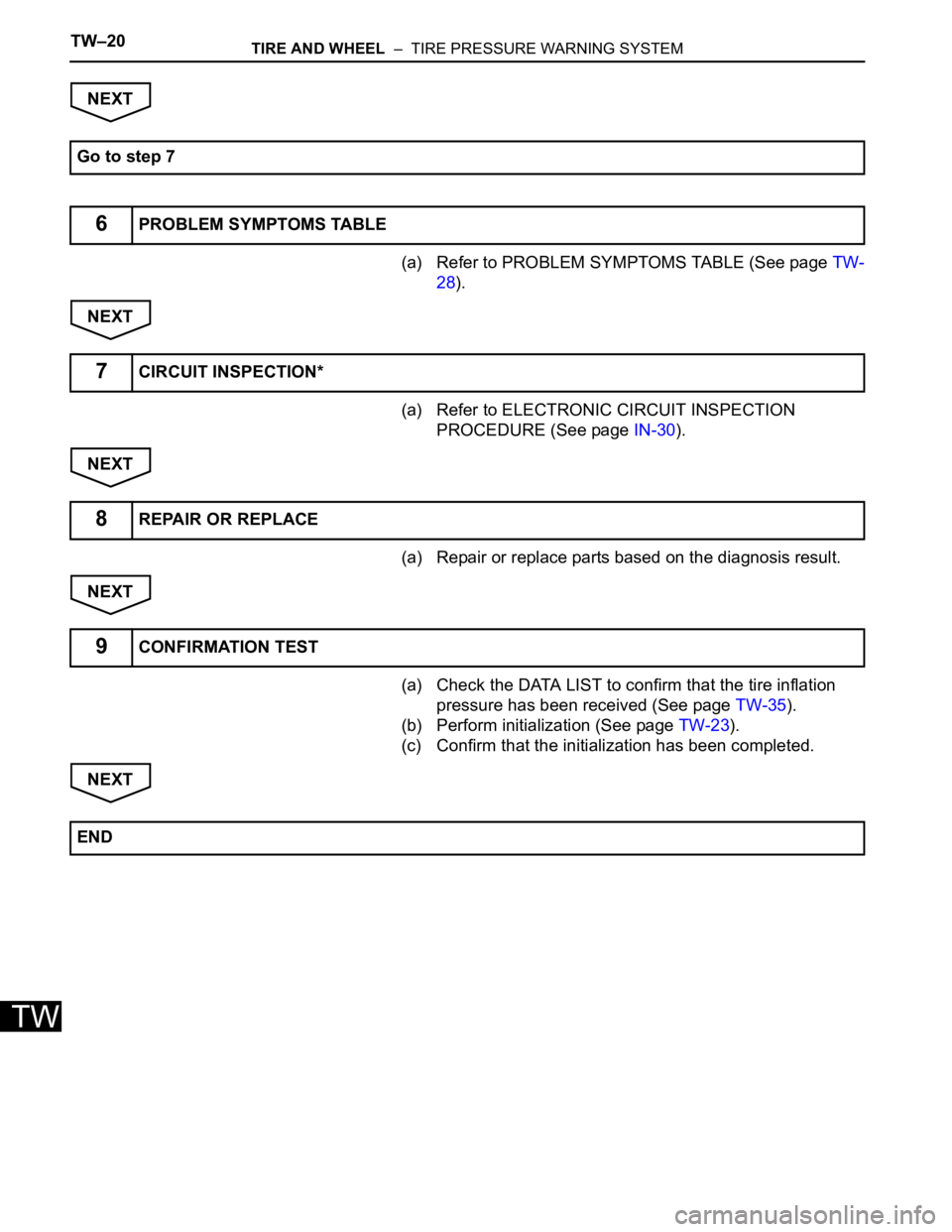

NEXT

(a) Refer to PROBLEM SYMPTOMS TABLE (See page TW-

28).

NEXT

(a) Refer to ELECTRONIC CIRCUIT INSPECTION

PROCEDURE (See page IN-30).

NEXT

(a) Repair or replace parts based on the diagnosis result.

NEXT

(a) Check the DATA LIST to confirm that the tire inflation

pressure has been received (See page TW-35).

(b) Perform initialization (See page TW-23).

(c) Confirm that the initialization has been completed.

NEXT Go to step 7

6PROBLEM SYMPTOMS TABLE

7CIRCUIT INSPECTION*

8REPAIR OR REPLACE

9CONFIRMATION TEST

END

Page 2263 of 3000

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEMTW–25

TW

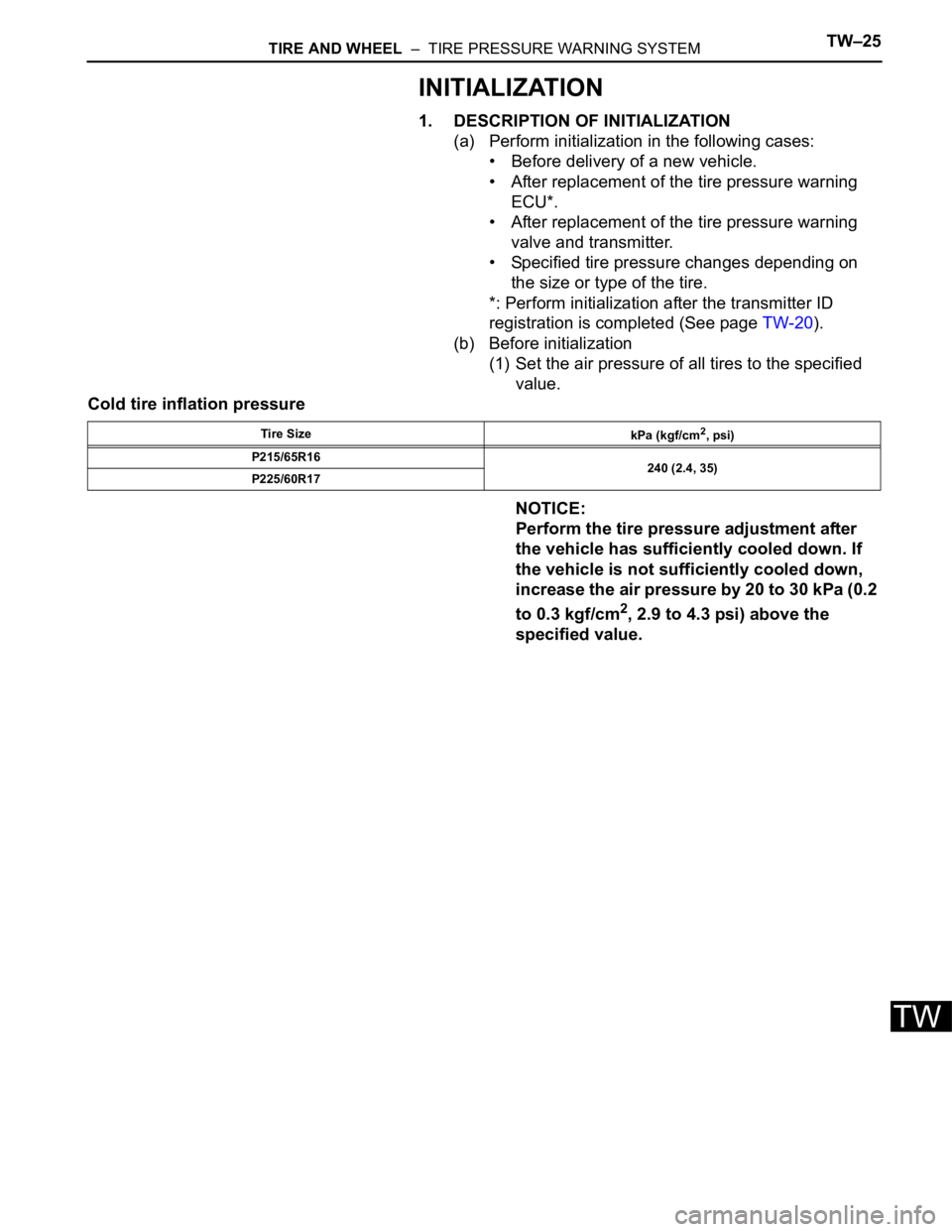

INITIALIZATION

1. DESCRIPTION OF INITIALIZATION

(a) Perform initialization in the following cases:

• Before delivery of a new vehicle.

• After replacement of the tire pressure warning

ECU*.

• After replacement of the tire pressure warning

valve and transmitter.

• Specified tire pressure changes depending on

the size or type of the tire.

*: Perform initialization after the transmitter ID

registration is completed (See page TW-20).

(b) Before initialization

(1) Set the air pressure of all tires to the specified

value.

Cold tire inflation pressure

NOTICE:

Perform the tire pressure adjustment after

the vehicle has sufficiently cooled down. If

the vehicle is not sufficiently cooled down,

increase the air pressure by 20 to 30 kPa (0.2

to 0.3 kgf/cm

2, 2.9 to 4.3 psi) above the

specified value.

Tire Size

kPa (kgf/cm2, psi)

P215/65R16

240 (2.4, 35)

P225/60R17

Page 2264 of 3000

TW–26TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

TW

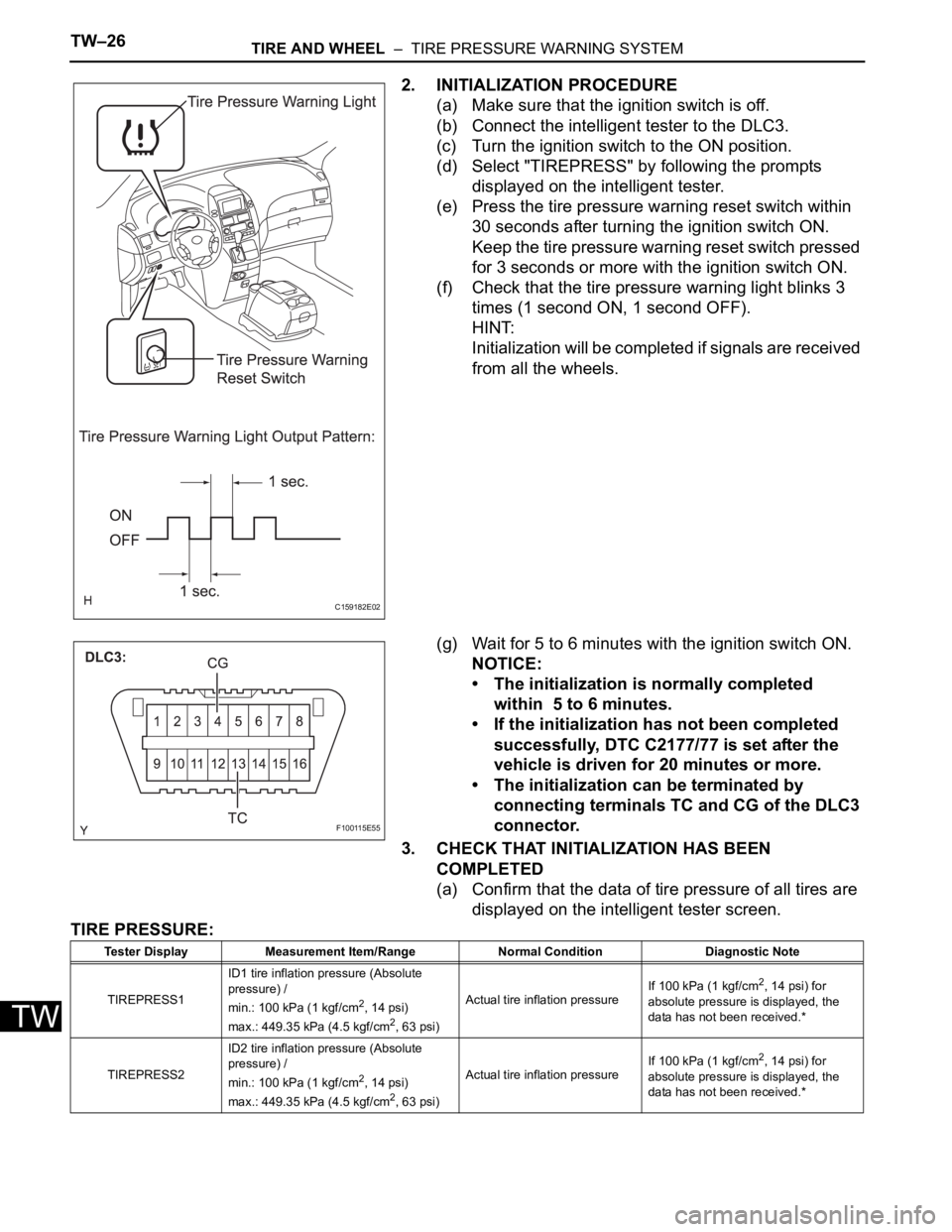

2. INITIALIZATION PROCEDURE

(a) Make sure that the ignition switch is off.

(b) Connect the intelligent tester to the DLC3.

(c) Turn the ignition switch to the ON position.

(d) Select "TIREPRESS" by following the prompts

displayed on the intelligent tester.

(e) Press the tire pressure warning reset switch within

30 seconds after turning the ignition switch ON.

Keep the tire pressure warning reset switch pressed

for 3 seconds or more with the ignition switch ON.

(f) Check that the tire pressure warning light blinks 3

times (1 second ON, 1 second OFF).

HINT:

Initialization will be completed if signals are received

from all the wheels.

(g) Wait for 5 to 6 minutes with the ignition switch ON.

NOTICE:

• The initialization is normally completed

within 5 to 6 minutes.

• If the initialization has not been completed

successfully, DTC C2177/77 is set after the

vehicle is driven for 20 minutes or more.

• The initialization can be terminated by

connecting terminals TC and CG of the DLC3

connector.

3. CHECK THAT INITIALIZATION HAS BEEN

COMPLETED

(a) Confirm that the data of tire pressure of all tires are

displayed on the intelligent tester screen.

TIRE PRESSURE:

C159182E02

F100115E55

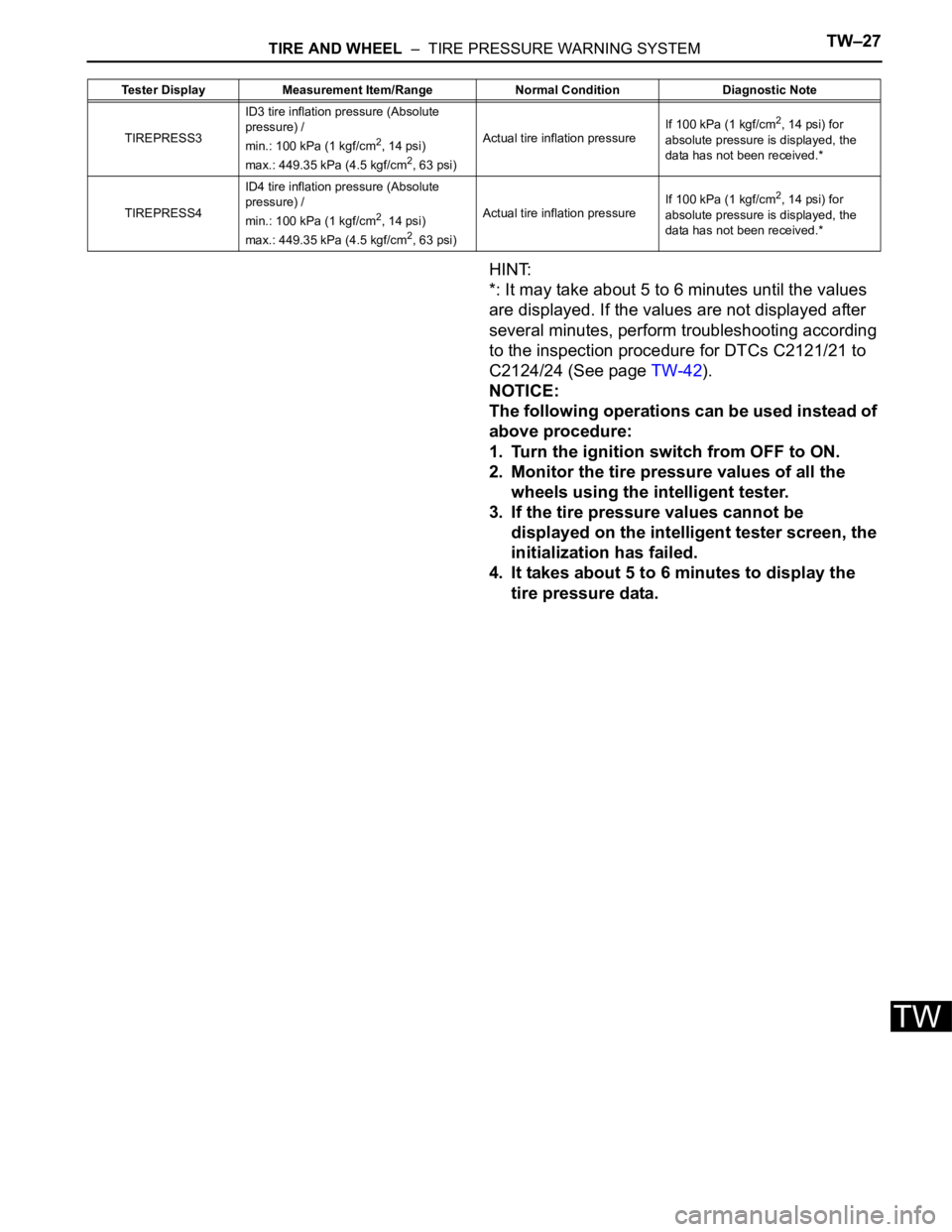

Tester Display Measurement Item/Range Normal Condition Diagnostic Note

TIREPRESS1ID1 tire inflation pressure (Absolute

pressure) /

min.: 100 kPa (1 kgf/cm

2, 14 psi)

max.: 449.35 kPa (4.5 kgf/cm2, 63 psi)Actual tire inflation pressureIf 100 kPa (1 kgf/cm

2, 14 psi) for

absolute pressure is displayed, the

data has not been received.*

TIREPRESS2ID2 tire inflation pressure (Absolute

pressure) /

min.: 100 kPa (1 kgf/cm

2, 14 psi)

max.: 449.35 kPa (4.5 kgf/cm2, 63 psi)Actual tire inflation pressureIf 100 kPa (1 kgf/cm

2, 14 psi) for

absolute pressure is displayed, the

data has not been received.*

Page 2265 of 3000

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEMTW–27

TW

HINT:

*: It may take about 5 to 6 minutes until the values

are displayed. If the values are not displayed after

several minutes, perform troubleshooting according

to the inspection procedure for DTCs C2121/21 to

C2124/24 (See page TW-42).

NOTICE:

The following operations can be used instead of

above procedure:

1. Turn the ignition switch from OFF to ON.

2. Monitor the tire pressure values of all the

wheels using the intelligent tester.

3. If the tire pressure values cannot be

displayed on the intelligent tester screen, the

initialization has failed.

4. It takes about 5 to 6 minutes to display the

tire pressure data.

TIREPRESS3ID3 tire inflation pressure (Absolute

pressure) /

min.: 100 kPa (1 kgf/cm2, 14 psi)

max.: 449.35 kPa (4.5 kgf/cm2, 63 psi)Actual tire inflation pressureIf 100 kPa (1 kgf/cm

2, 14 psi) for

absolute pressure is displayed, the

data has not been received.*

TIREPRESS4ID4 tire inflation pressure (Absolute

pressure) /

min.: 100 kPa (1 kgf/cm

2, 14 psi)

max.: 449.35 kPa (4.5 kgf/cm2, 63 psi)Actual tire inflation pressureIf 100 kPa (1 kgf/cm

2, 14 psi) for

absolute pressure is displayed, the

data has not been received.* Tester Display Measurement Item/Range Normal Condition Diagnostic Note

Page 2266 of 3000

TW–40TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

TW

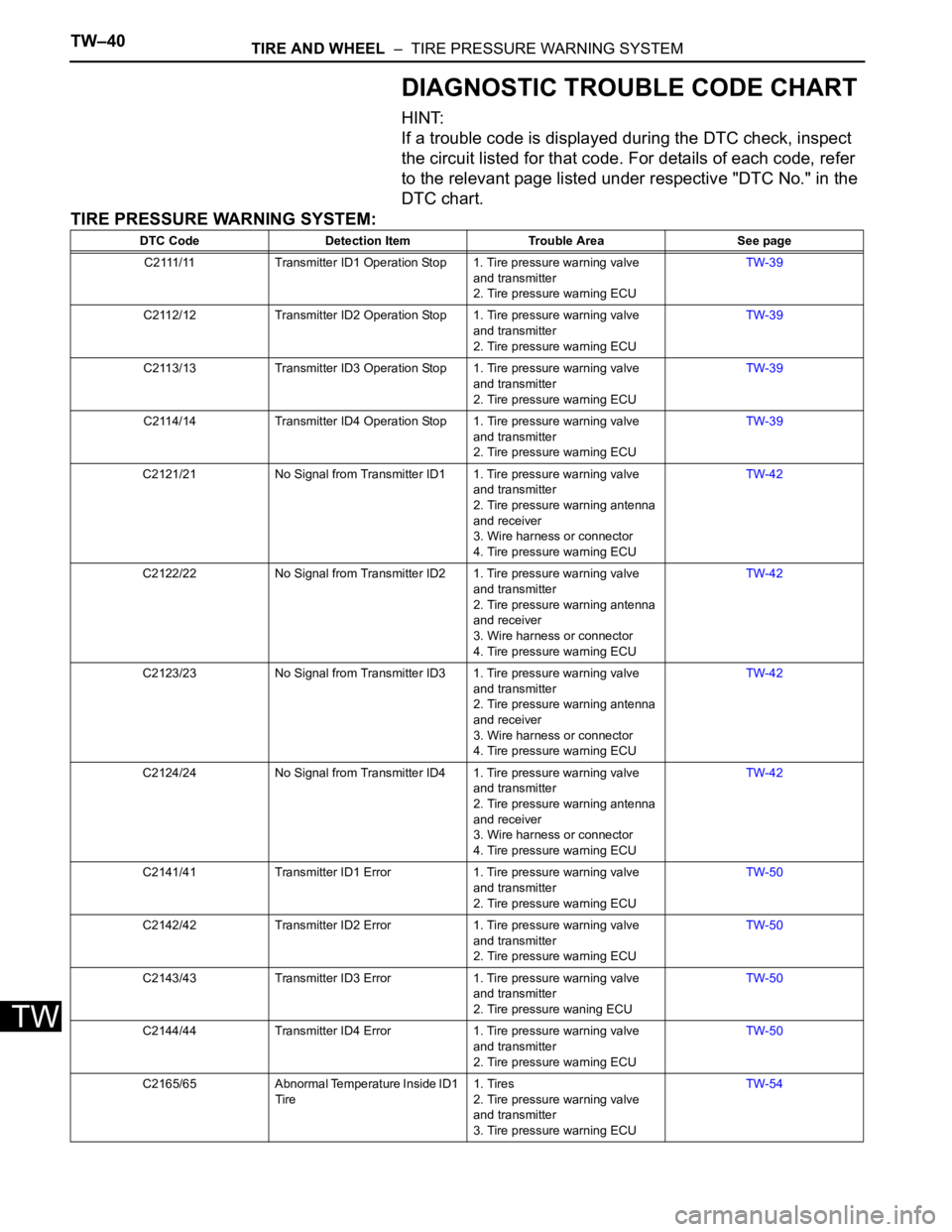

DIAGNOSTIC TROUBLE CODE CHART

HINT:

If a trouble code is displayed during the DTC check, inspect

the circuit listed for that code. For details of each code, refer

to the relevant page listed under respective "DTC No." in the

DTC chart.

TIRE PRESSURE WARNING SYSTEM:

DTC Code Detection Item Trouble Area See page

C2111/11 Transmitter ID1 Operation Stop 1. Tire pressure warning valve

and transmitter

2. Tire pressure warning ECUTW-39

C2112/12 Transmitter ID2 Operation Stop 1. Tire pressure warning valve

and transmitter

2. Tire pressure warning ECUTW-39

C2113/13 Transmitter ID3 Operation Stop 1. Tire pressure warning valve

and transmitter

2. Tire pressure warning ECUTW-39

C2114/14 Transmitter ID4 Operation Stop 1. Tire pressure warning valve

and transmitter

2. Tire pressure warning ECUTW-39

C2121/21 No Signal from Transmitter ID1 1. Tire pressure warning valve

and transmitter

2. Tire pressure warning antenna

and receiver

3. Wire harness or connector

4. Tire pressure warning ECUTW-42

C2122/22 No Signal from Transmitter ID2 1. Tire pressure warning valve

and transmitter

2. Tire pressure warning antenna

and receiver

3. Wire harness or connector

4. Tire pressure warning ECUTW-42

C2123/23 No Signal from Transmitter ID3 1. Tire pressure warning valve

and transmitter

2. Tire pressure warning antenna

and receiver

3. Wire harness or connector

4. Tire pressure warning ECUTW-42

C2124/24 No Signal from Transmitter ID4 1. Tire pressure warning valve

and transmitter

2. Tire pressure warning antenna

and receiver

3. Wire harness or connector

4. Tire pressure warning ECUTW-42

C2141/41 Transmitter ID1 Error 1. Tire pressure warning valve

and transmitter

2. Tire pressure warning ECUTW-50

C2142/42 Transmitter ID2 Error 1. Tire pressure warning valve

and transmitter

2. Tire pressure warning ECUTW-50

C2143/43 Transmitter ID3 Error 1. Tire pressure warning valve

and transmitter

2. Tire pressure waning ECUTW-50

C2144/44 Transmitter ID4 Error 1. Tire pressure warning valve

and transmitter

2. Tire pressure warning ECUTW-50

C2165/65 Abnormal Temperature Inside ID1

Tire1. Tires

2. Tire pressure warning valve

and transmitter

3. Tire pressure warning ECUTW-54

Page 2267 of 3000

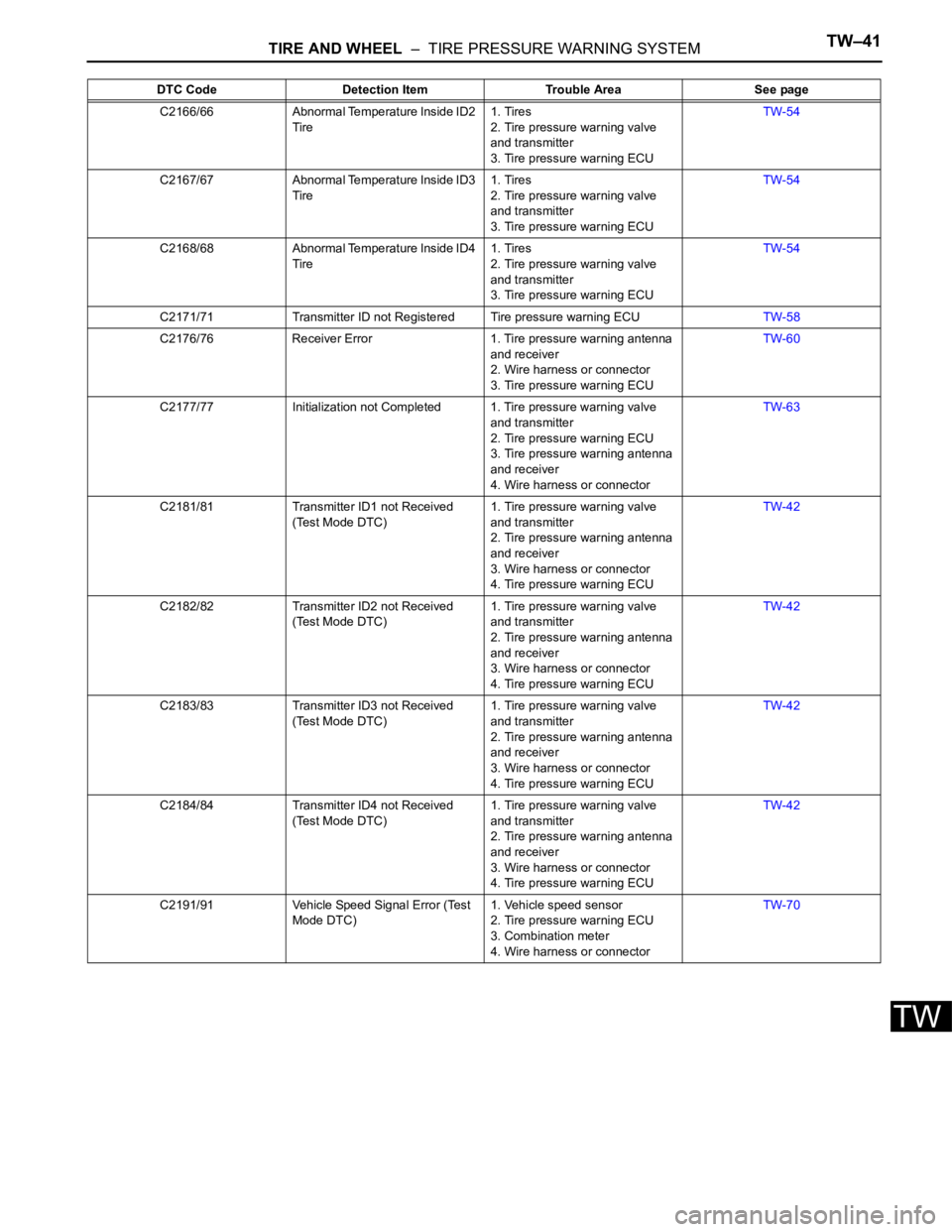

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEMTW–41

TW

C2166/66 Abnormal Temperature Inside ID2

Tire1. Tires

2. Tire pressure warning valve

and transmitter

3. Tire pressure warning ECUTW-54

C2167/67 Abnormal Temperature Inside ID3

Tire1. Tires

2. Tire pressure warning valve

and transmitter

3. Tire pressure warning ECUTW-54

C2168/68 Abnormal Temperature Inside ID4

Tire1. Tires

2. Tire pressure warning valve

and transmitter

3. Tire pressure warning ECUTW-54

C2171/71 Transmitter ID not Registered Tire pressure warning ECUTW-58

C2176/76 Receiver Error 1. Tire pressure warning antenna

and receiver

2. Wire harness or connector

3. Tire pressure warning ECUTW-60

C2177/77 Initialization not Completed 1. Tire pressure warning valve

and transmitter

2. Tire pressure warning ECU

3. Tire pressure warning antenna

and receiver

4. Wire harness or connectorTW-63

C2181/81 Transmitter ID1 not Received

(Test Mode DTC)1. Tire pressure warning valve

and transmitter

2. Tire pressure warning antenna

and receiver

3. Wire harness or connector

4. Tire pressure warning ECUTW-42

C2182/82 Transmitter ID2 not Received

(Test Mode DTC)1. Tire pressure warning valve

and transmitter

2. Tire pressure warning antenna

and receiver

3. Wire harness or connector

4. Tire pressure warning ECUTW-42

C2183/83 Transmitter ID3 not Received

(Test Mode DTC)1. Tire pressure warning valve

and transmitter

2. Tire pressure warning antenna

and receiver

3. Wire harness or connector

4. Tire pressure warning ECUTW-42

C2184/84 Transmitter ID4 not Received

(Test Mode DTC)1. Tire pressure warning valve

and transmitter

2. Tire pressure warning antenna

and receiver

3. Wire harness or connector

4. Tire pressure warning ECUTW-42

C2191/91 Vehicle Speed Signal Error (Test

Mode DTC)1. Vehicle speed sensor

2. Tire pressure warning ECU

3. Combination meter

4. Wire harness or connectorTW-70 DTC Code Detection Item Trouble Area See page

Page 2268 of 3000

TW–10TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

TW

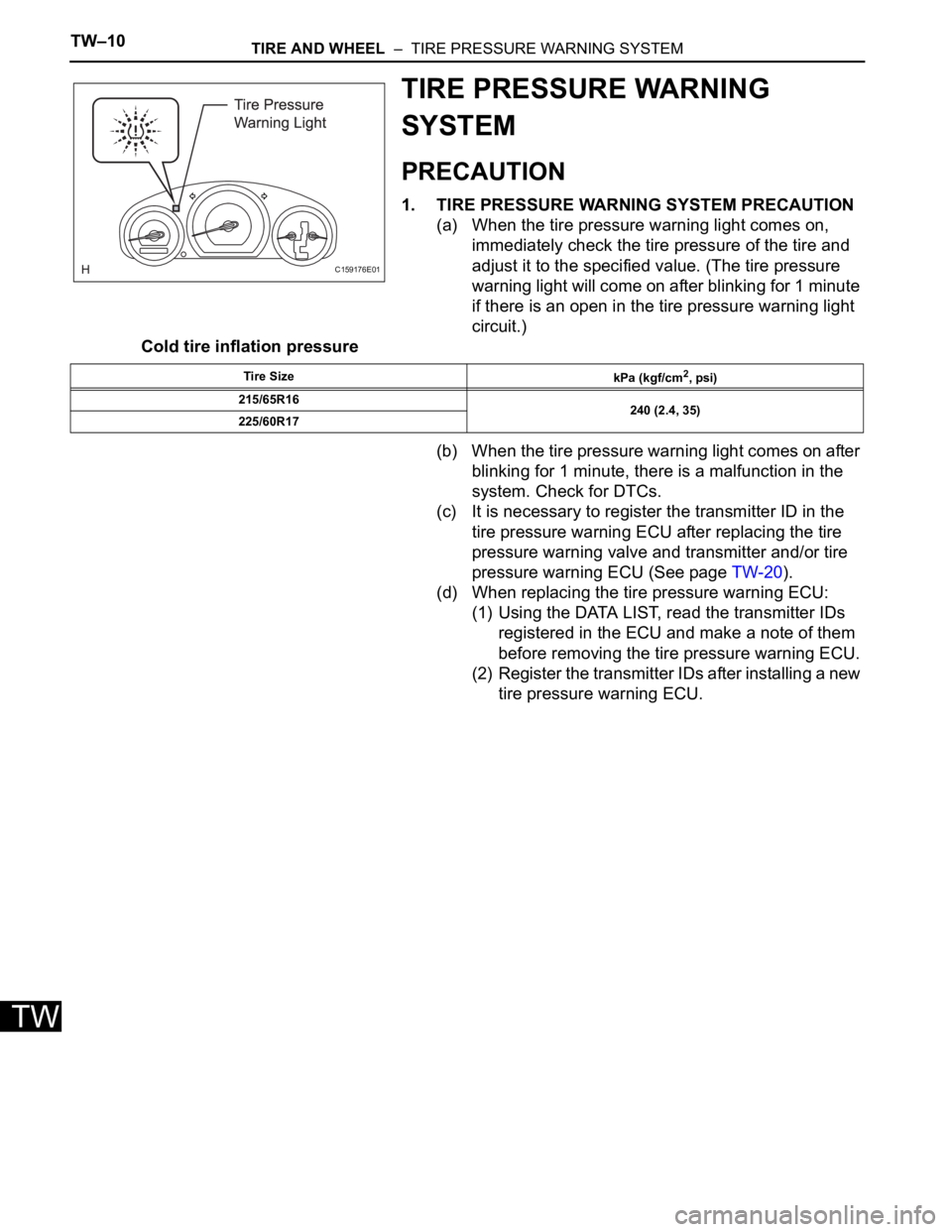

TIRE PRESSURE WARNING

SYSTEM

PRECAUTION

1. TIRE PRESSURE WARNING SYSTEM PRECAUTION

(a) When the tire pressure warning light comes on,

immediately check the tire pressure of the tire and

adjust it to the specified value. (The tire pressure

warning light will come on after blinking for 1 minute

if there is an open in the tire pressure warning light

circuit.)

Cold tire inflation pressure

(b) When the tire pressure warning light comes on after

blinking for 1 minute, there is a malfunction in the

system. Check for DTCs.

(c) It is necessary to register the transmitter ID in the

tire pressure warning ECU after replacing the tire

pressure warning valve and transmitter and/or tire

pressure warning ECU (See page TW-20).

(d) When replacing the tire pressure warning ECU:

(1) Using the DATA LIST, read the transmitter IDs

registered in the ECU and make a note of them

before removing the tire pressure warning ECU.

(2) Register the transmitter IDs after installing a new

tire pressure warning ECU.

C159176E01

Tire Size

kPa (kgf/cm2, psi)

215/65R16

240 (2.4, 35)

225/60R17

Page 2269 of 3000

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEMTW–11

TW

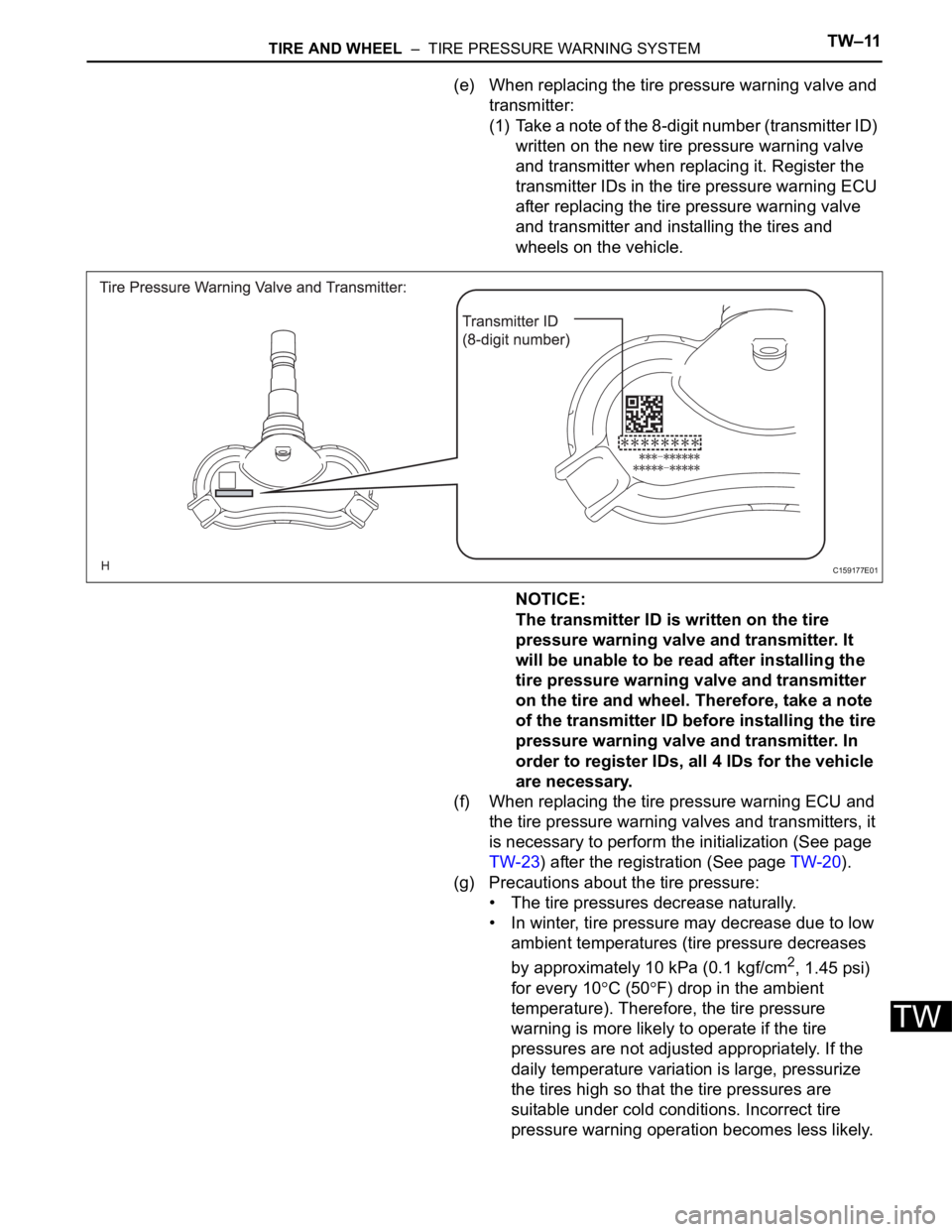

(e) When replacing the tire pressure warning valve and

transmitter:

(1) Take a note of the 8-digit number (transmitter ID)

written on the new tire pressure warning valve

and transmitter when replacing it. Register the

transmitter IDs in the tire pressure warning ECU

after replacing the tire pressure warning valve

and transmitter and installing the tires and

wheels on the vehicle.

NOTICE:

The transmitter ID is written on the tire

pressure warning valve and transmitter. It

will be unable to be read after installing the

tire pressure warning valve and transmitter

on the tire and wheel. Therefore, take a note

of the transmitter ID before installing the tire

pressure warning valve and transmitter. In

order to register IDs, all 4 IDs for the vehicle

are necessary.

(f) When replacing the tire pressure warning ECU and

the tire pressure warning valves and transmitters, it

is necessary to perform the initialization (See page

TW-23) after the registration (See page TW-20).

(g) Precautions about the tire pressure:

• The tire pressures decrease naturally.

• In winter, tire pressure may decrease due to low

ambient temperatures (tire pressure decreases

by approximately 10 kPa (0.1 kgf/cm

2, 1.45 psi)

for every 10

C (50F) drop in the ambient

temperature). Therefore, the tire pressure

warning is more likely to operate if the tire

pressures are not adjusted appropriately. If the

daily temperature variation is large, pressurize

the tires high so that the tire pressures are

suitable under cold conditions. Incorrect tire

pressure warning operation becomes less likely.

C159177E01

Page 2270 of 3000

TW–12TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

TW

2. IN CASE OF TIRE AND WHEEL REPLACEMENT

(a) When tires and wheels are replaced, always ensure

that each transmitter ID is correctly registered.

3. IN CASE OF REPLACEMENT OF TIRE PRESSURE

WARNING ECU, TIRE PRESSURE WARNING VALVE

AND TRANSMITTER, OR TIRE(S) WITH DIFFERENT

TIRE PRESSURE

(a) Initialize the tire pressure warning system after any

of the following is performed:

• Replacing the tire pressure warning ECU or the

tire pressure warning valve and transmitter.

• Installing tire(s) which require different tire

pressure.

• Changing the tire inflation pressure by changing

traveling speed or load weight, etc.

HINT:

The tire pressure warning system will not operate

properly if it is not initialized (See page TW-23).

4. FAIL-SAFE FUNCTION

(a) When a system malfunction occurs in the tire

pressure warning system, the tire pressure warning

light comes on after blinking for 1 minute and

informs the driver of the system failure.

(b) The result of this diagnosis is stored in the tire

pressure warning ECU.

5. CHECK TIRE PRESSURE AFTER REPAIRS

(a) After repairs, confirm that the actual tire pressures

are displayed in DATA LIST (See page TW-35).