check engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1254 of 3000

CO–82GR-FE COOLING – COOLANT

CO

(j) Bleed air from the cooling system.

(1) Warm up the engine until the thermostat opens.

While the thermostat is open, circulate the

coolant for several minutes.

HINT:

The thermostat open timing can be confirmed

by squeezing the inlet radiator hose by hand,

and checking when the engine coolant starts to

flow inside the hose.

(2) Maintain the engine speed at 2500 to 3000

rpm.

(3) Squeeze the inlet and outlet radiator hoses

several times by hand to bleed air.

CAUTION:

When squeezing the radiator hoses:

• Wear protective gloves.

• Be careful as the radiator hoses are hot.

• Keep your hands away from the radiator

fan.

NOTICE:

• Make sure that the radiator reservoir still

has some coolant in it.

• If the coolant temperature gauge

indicates an excessive temperature, turn

off the engine and let it cool.

• If there is not enough coolant, the engine

may overheat or be seriously damaged.

• If the radiator reservoir does not have

enough coolant, perform the following: 1)

stop the engine, 2) wait until the coolant

has cooled down, and 3) add coolant

until the coolant is filled to the FULL line.

(k) Stop the engine and wait until the engine coolant

cools down.

(l) Add engine coolant to the FULL line on the radiator

reservoir.

5. INSPECT FOR COOLANT LEAK (See page CO-1)

6. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-63)

7. INSTALL NO. 1 ENGINE UNDER COVER (See page

EM-63)

Page 1264 of 3000

CO–462GR-FE COOLING – RADIATOR

CO

24. INSTALL BATTERY (See page EM-59)

25. INSTALL NO. 2 AIR CLEANER INLET (See page EM-

60)

26. ADD ENGINE COOLANT (See page CO-7)

27. INSPECT FOR COOLANT LEAK (See page CO-1)

28. ADD AUTOMATIC TRANSAXLE FLUID

29. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

30. INSTALL NO. 1 ENGINE UNDER COVER (See page

EM-63)

31. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-63)

32. VEHICLE PREPARATION FOR HEADLIGHT AIM

ADJUSTMENT (See page LI-71)

33. PREPARATION FOR HEADLIGHT AIMING (Using a

tester) (See page LI-71)

34. PREPARATION FOR HEADLIGHT AIMING (Using a

screen) (See page LI-72)

35. HEADLIGHT AIMING INSPECTION (See page LI-74)

36. HEADLIGHT AIMING ADJUSTMENT (See page LI-75)

37. VEHICLE PREPARATION FOR FOG LIGHT AIM

ADJUSTMENT (w/ Fog Light) (See page LI-82)

38. PREPARATION FOR FOG LIGHT AIMING (Using a

screen) (w/ Fog Light) (See page LI-83)

39. FOG LIGHT AIMING INSPECTION (w/ Fog Light) (See

page LI-84)

40. FOG LIGHT AIMING ADJUSTMENT (w/ Fog Light)

(See page LI-85)

Page 1291 of 3000

CO–462GR-FE COOLING – RADIATOR

CO

24. INSTALL BATTERY (See page EM-59)

25. INSTALL NO. 2 AIR CLEANER INLET (See page EM-

60)

26. ADD ENGINE COOLANT (See page CO-7)

27. INSPECT FOR COOLANT LEAK (See page CO-1)

28. ADD AUTOMATIC TRANSAXLE FLUID

29. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

30. INSTALL NO. 1 ENGINE UNDER COVER (See page

EM-63)

31. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-63)

32. VEHICLE PREPARATION FOR HEADLIGHT AIM

ADJUSTMENT (See page LI-71)

33. PREPARATION FOR HEADLIGHT AIMING (Using a

tester) (See page LI-71)

34. PREPARATION FOR HEADLIGHT AIMING (Using a

screen) (See page LI-72)

35. HEADLIGHT AIMING INSPECTION (See page LI-74)

36. HEADLIGHT AIMING ADJUSTMENT (See page LI-75)

37. VEHICLE PREPARATION FOR FOG LIGHT AIM

ADJUSTMENT (w/ Fog Light) (See page LI-82)

38. PREPARATION FOR FOG LIGHT AIMING (Using a

screen) (w/ Fog Light) (See page LI-83)

39. FOG LIGHT AIMING INSPECTION (w/ Fog Light) (See

page LI-84)

40. FOG LIGHT AIMING ADJUSTMENT (w/ Fog Light)

(See page LI-85)

Page 1292 of 3000

2GR-FE LUBRICATION – OIL PUMPLU–13

LU

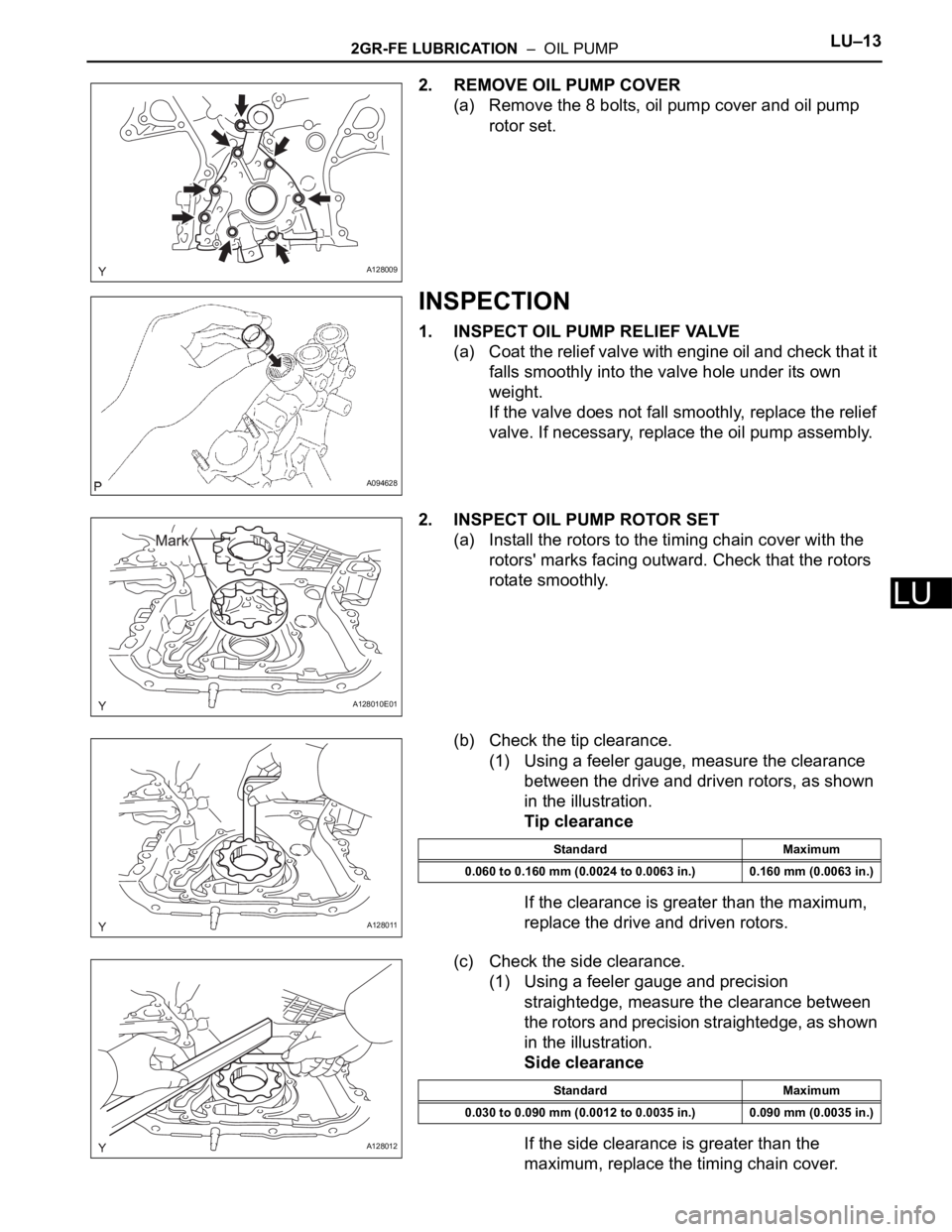

2. REMOVE OIL PUMP COVER

(a) Remove the 8 bolts, oil pump cover and oil pump

rotor set.

INSPECTION

1. INSPECT OIL PUMP RELIEF VALVE

(a) Coat the relief valve with engine oil and check that it

falls smoothly into the valve hole under its own

weight.

If the valve does not fall smoothly, replace the relief

valve. If necessary, replace the oil pump assembly.

2. INSPECT OIL PUMP ROTOR SET

(a) Install the rotors to the timing chain cover with the

rotors' marks facing outward. Check that the rotors

rotate smoothly.

(b) Check the tip clearance.

(1) Using a feeler gauge, measure the clearance

between the drive and driven rotors, as shown

in the illustration.

Tip clearance

If the clearance is greater than the maximum,

replace the drive and driven rotors.

(c) Check the side clearance.

(1) Using a feeler gauge and precision

straightedge, measure the clearance between

the rotors and precision straightedge, as shown

in the illustration.

Side clearance

If the side clearance is greater than the

maximum, replace the timing chain cover.

A128009

A094628

A128010E01

A128011

Standard Maximum

0.060 to 0.160 mm (0.0024 to 0.0063 in.) 0.160 mm (0.0063 in.)

A128012

Standard Maximum

0.030 to 0.090 mm (0.0012 to 0.0035 in.) 0.090 mm (0.0035 in.)

Page 1293 of 3000

LU–142GR-FE LUBRICATION – OIL PUMP

LU

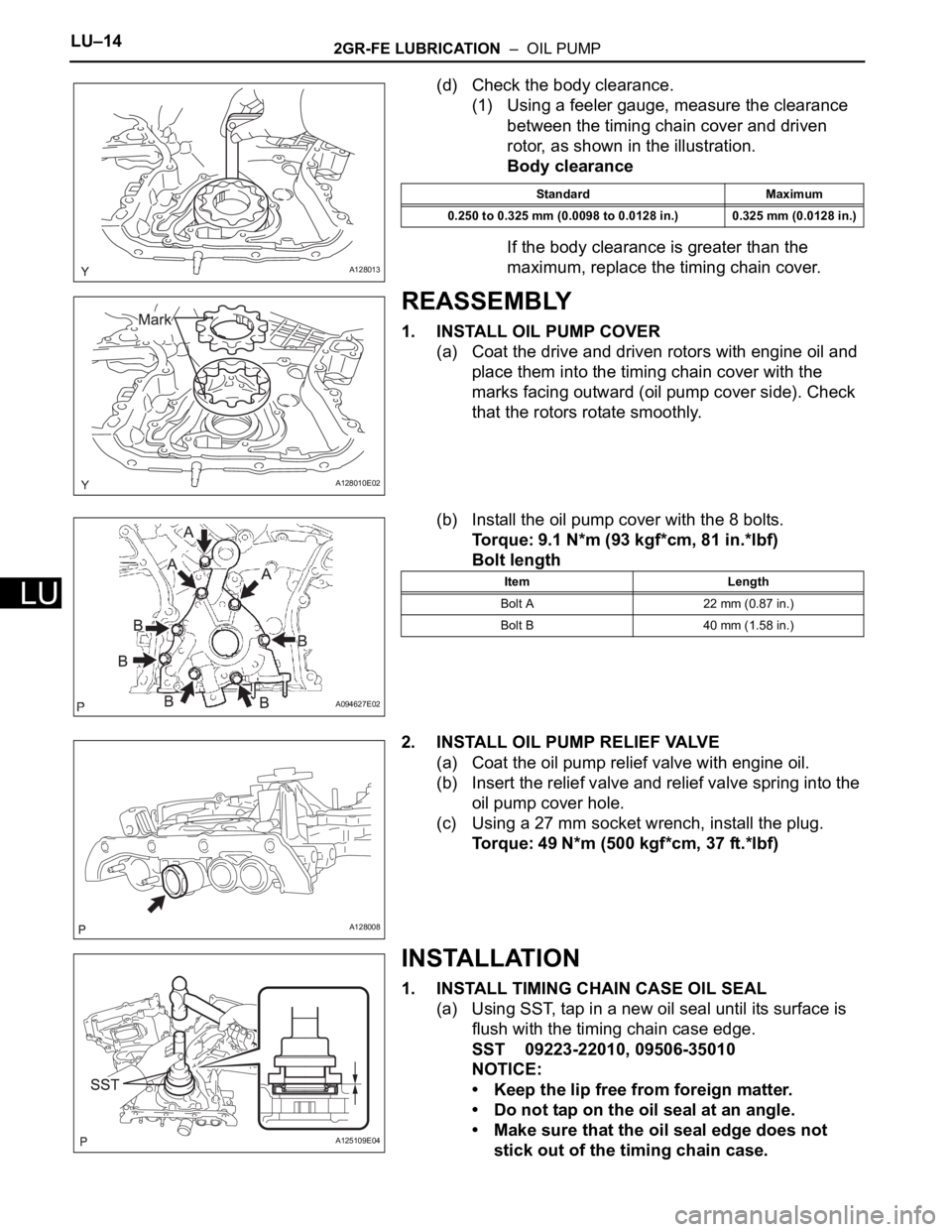

(d) Check the body clearance.

(1) Using a feeler gauge, measure the clearance

between the timing chain cover and driven

rotor, as shown in the illustration.

Body clearance

If the body clearance is greater than the

maximum, replace the timing chain cover.

REASSEMBLY

1. INSTALL OIL PUMP COVER

(a) Coat the drive and driven rotors with engine oil and

place them into the timing chain cover with the

marks facing outward (oil pump cover side). Check

that the rotors rotate smoothly.

(b) Install the oil pump cover with the 8 bolts.

Torque: 9.1 N*m (93 kgf*cm, 81 in.*lbf)

Bolt length

2. INSTALL OIL PUMP RELIEF VALVE

(a) Coat the oil pump relief valve with engine oil.

(b) Insert the relief valve and relief valve spring into the

oil pump cover hole.

(c) Using a 27 mm socket wrench, install the plug.

Torque: 49 N*m (500 kgf*cm, 37 ft.*lbf)

INSTALLATION

1. INSTALL TIMING CHAIN CASE OIL SEAL

(a) Using SST, tap in a new oil seal until its surface is

flush with the timing chain case edge.

SST 09223-22010, 09506-35010

NOTICE:

• Keep the lip free from foreign matter.

• Do not tap on the oil seal at an angle.

• Make sure that the oil seal edge does not

stick out of the timing chain case.

A128013

Standard Maximum

0.250 to 0.325 mm (0.0098 to 0.0128 in.) 0.325 mm (0.0128 in.)

A128010E02

A094627E02

Item Length

Bolt A 22 mm (0.87 in.)

Bolt B 40 mm (1.58 in.)

A128008

A125109E04

Page 1298 of 3000

2GR-FE LUBRICATION – ENGINE OIL COOLERLU–21

LU

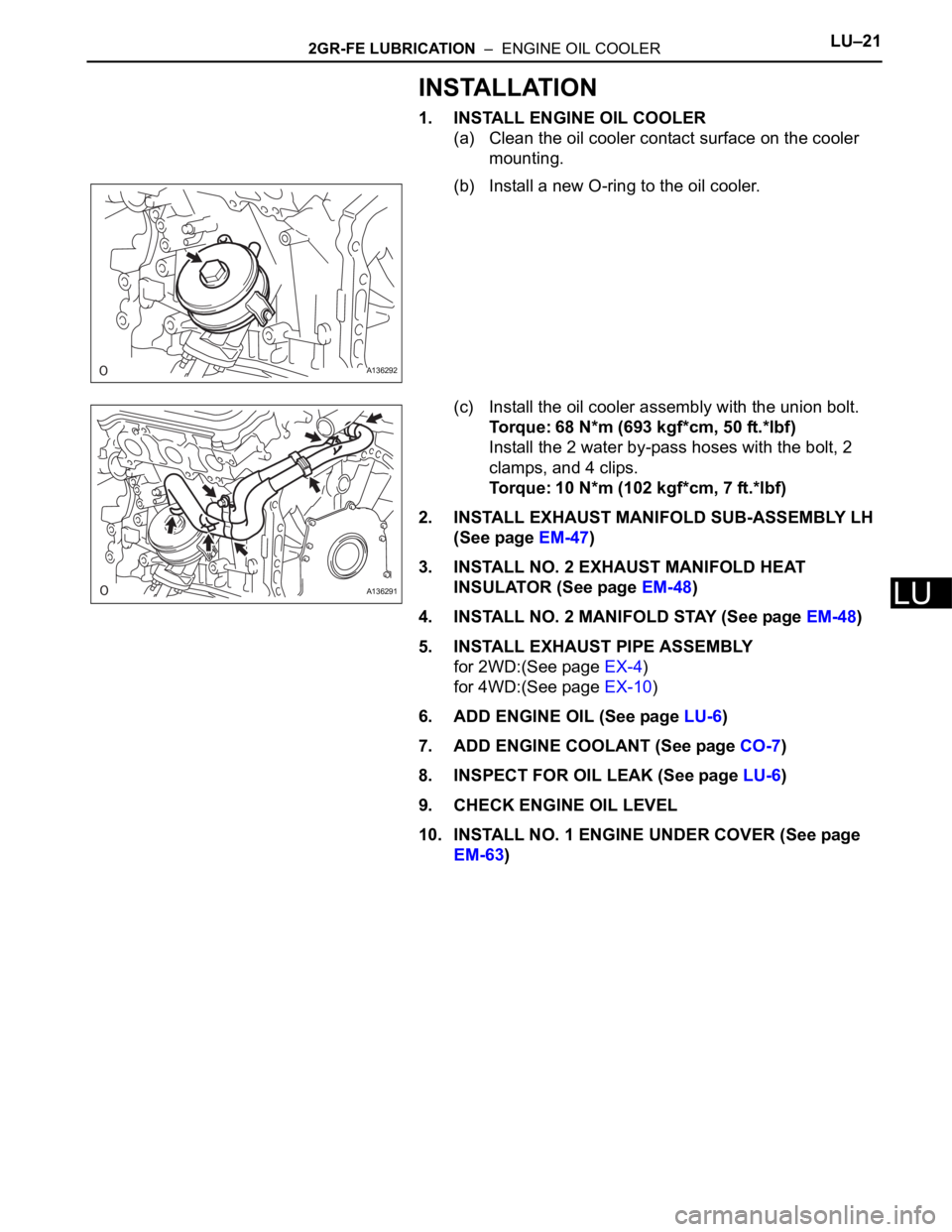

INSTALLATION

1. INSTALL ENGINE OIL COOLER

(a) Clean the oil cooler contact surface on the cooler

mounting.

(b) Install a new O-ring to the oil cooler.

(c) Install the oil cooler assembly with the union bolt.

Torque: 68 N*m (693 kgf*cm, 50 ft.*lbf)

Install the 2 water by-pass hoses with the bolt, 2

clamps, and 4 clips.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

2. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY LH

(See page EM-47)

3. INSTALL NO. 2 EXHAUST MANIFOLD HEAT

INSULATOR (See page EM-48)

4. INSTALL NO. 2 MANIFOLD STAY (See page EM-48)

5. INSTALL EXHAUST PIPE ASSEMBLY

for 2WD:(See page EX-4)

for 4WD:(See page EX-10)

6. ADD ENGINE OIL (See page LU-6)

7. ADD ENGINE COOLANT (See page CO-7)

8. INSPECT FOR OIL LEAK (See page LU-6)

9. CHECK ENGINE OIL LEVEL

10. INSTALL NO. 1 ENGINE UNDER COVER (See page

EM-63)

A136292

A136291

Page 1299 of 3000

2GR-FE LUBRICATION – LUBRICATION SYSTEMLU–1

LU

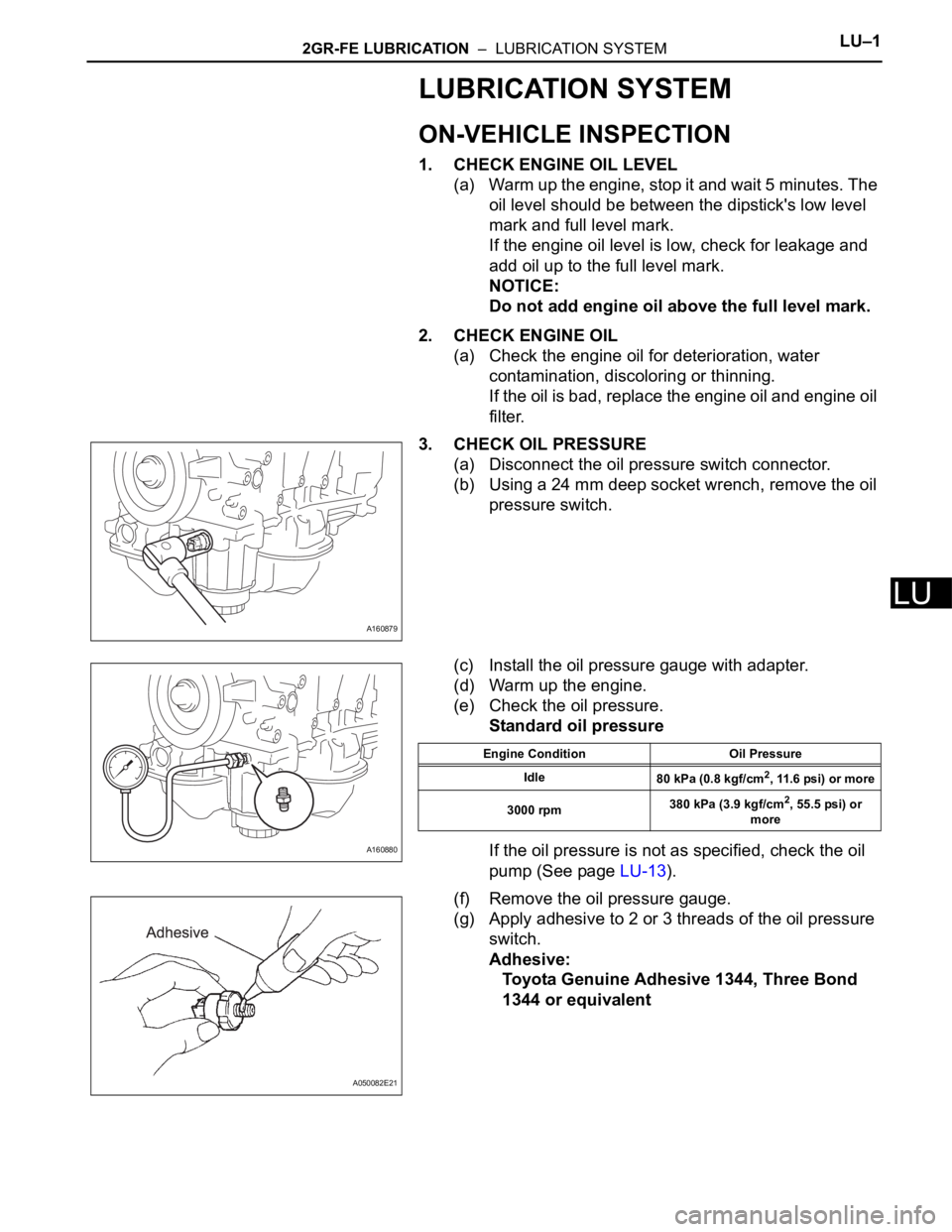

LUBRICATION SYSTEM

ON-VEHICLE INSPECTION

1. CHECK ENGINE OIL LEVEL

(a) Warm up the engine, stop it and wait 5 minutes. The

oil level should be between the dipstick's low level

mark and full level mark.

If the engine oil level is low, check for leakage and

add oil up to the full level mark.

NOTICE:

Do not add engine oil above the full level mark.

2. CHECK ENGINE OIL

(a) Check the engine oil for deterioration, water

contamination, discoloring or thinning.

If the oil is bad, replace the engine oil and engine oil

filter.

3. CHECK OIL PRESSURE

(a) Disconnect the oil pressure switch connector.

(b) Using a 24 mm deep socket wrench, remove the oil

pressure switch.

(c) Install the oil pressure gauge with adapter.

(d) Warm up the engine.

(e) Check the oil pressure.

Standard oil pressure

If the oil pressure is not as specified, check the oil

pump (See page LU-13).

(f) Remove the oil pressure gauge.

(g) Apply adhesive to 2 or 3 threads of the oil pressure

switch.

Adhesive:

Toyota Genuine Adhesive 1344, Three Bond

1344 or equivalent

A160879

A160880

Engine Condition Oil Pressure

Idle

80 kPa (0.8 kgf/cm

2, 11.6 psi) or more

3000 rpm380 kPa (3.9 kgf/cm

2, 55.5 psi) or

more

A050082E21

Page 1300 of 3000

LU–22GR-FE LUBRICATION – LUBRICATION SYSTEM

LU

(h) Using a 24 mm deep socket wrench, install the oil

pressure switch.

Torque: 15 N*m (153 kgf*cm, 11 ft.*lbf)

NOTICE:

Do not start the engine within 1 hour after

installation.

(i) Connect the oil pressure switch connector.

(j) Check for engine oil leaks.

A160879

Page 1304 of 3000

LU–62GR-FE LUBRICATION – OIL AND OIL FILTER

LU

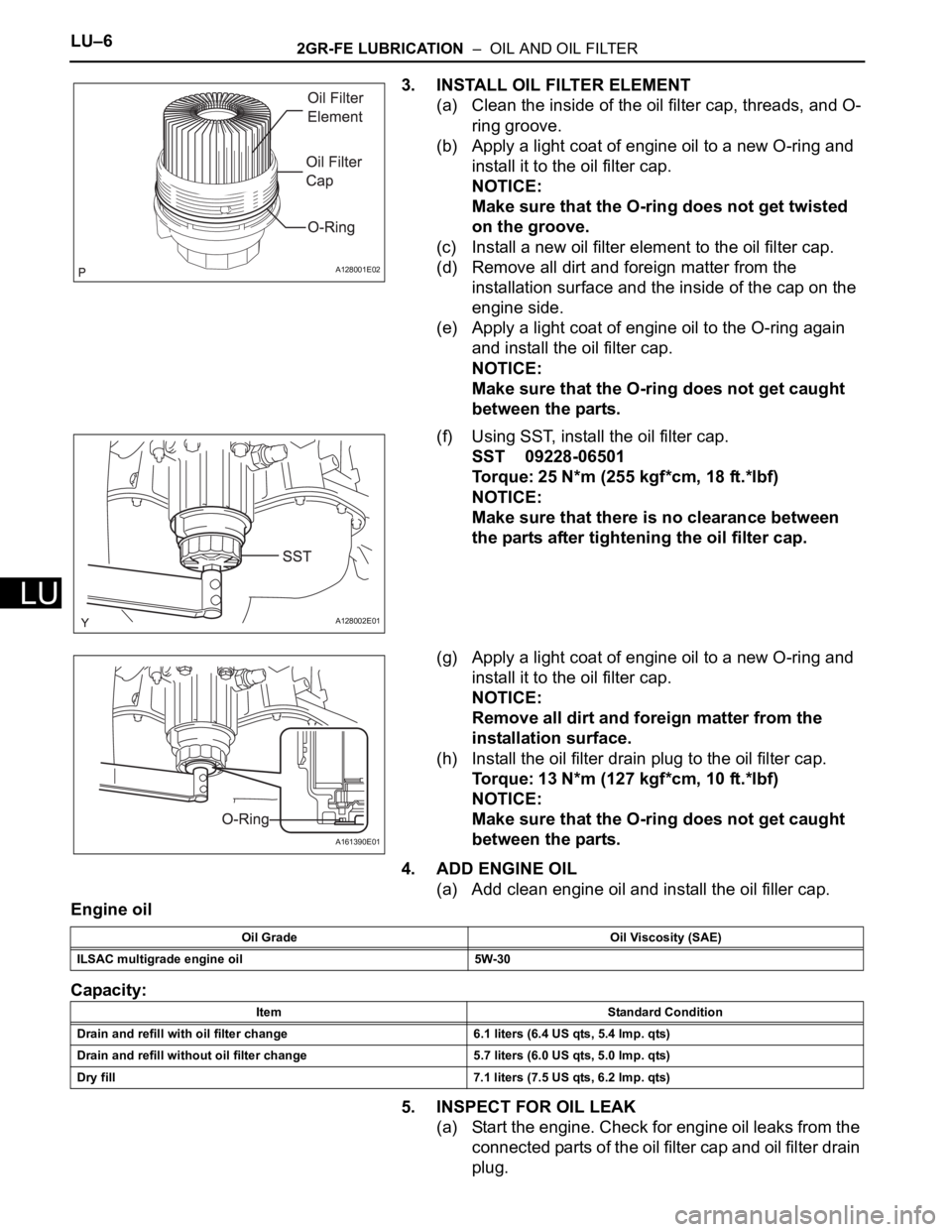

3. INSTALL OIL FILTER ELEMENT

(a) Clean the inside of the oil filter cap, threads, and O-

ring groove.

(b) Apply a light coat of engine oil to a new O-ring and

install it to the oil filter cap.

NOTICE:

Make sure that the O-ring does not get twisted

on the groove.

(c) Install a new oil filter element to the oil filter cap.

(d) Remove all dirt and foreign matter from the

installation surface and the inside of the cap on the

engine side.

(e) Apply a light coat of engine oil to the O-ring again

and install the oil filter cap.

NOTICE:

Make sure that the O-ring does not get caught

between the parts.

(f) Using SST, install the oil filter cap.

SST 09228-06501

Torque: 25 N*m (255 kgf*cm, 18 ft.*lbf)

NOTICE:

Make sure that there is no clearance between

the parts after tightening the oil filter cap.

(g) Apply a light coat of engine oil to a new O-ring and

install it to the oil filter cap.

NOTICE:

Remove all dirt and foreign matter from the

installation surface.

(h) Install the oil filter drain plug to the oil filter cap.

Torque: 13 N*m (127 kgf*cm, 10 ft.*lbf)

NOTICE:

Make sure that the O-ring does not get caught

between the parts.

4. ADD ENGINE OIL

(a) Add clean engine oil and install the oil filler cap.

Engine oil

Capacity:

5. INSPECT FOR OIL LEAK

(a) Start the engine. Check for engine oil leaks from the

connected parts of the oil filter cap and oil filter drain

plug.

A128001E02

A128002E01

A161390E01

Oil Grade Oil Viscosity (SAE)

ILSAC multigrade engine oil 5W-30

Item Standard Condition

Drain and refill with oil filter change 6.1 liters (6.4 US qts, 5.4 lmp. qts)

Drain and refill without oil filter change 5.7 liters (6.0 US qts, 5.0 lmp. qts)

Dry fill 7.1 liters (7.5 US qts, 6.2 lmp. qts)

Page 1305 of 3000

2GR-FE LUBRICATION – OIL PUMPLU–13

LU

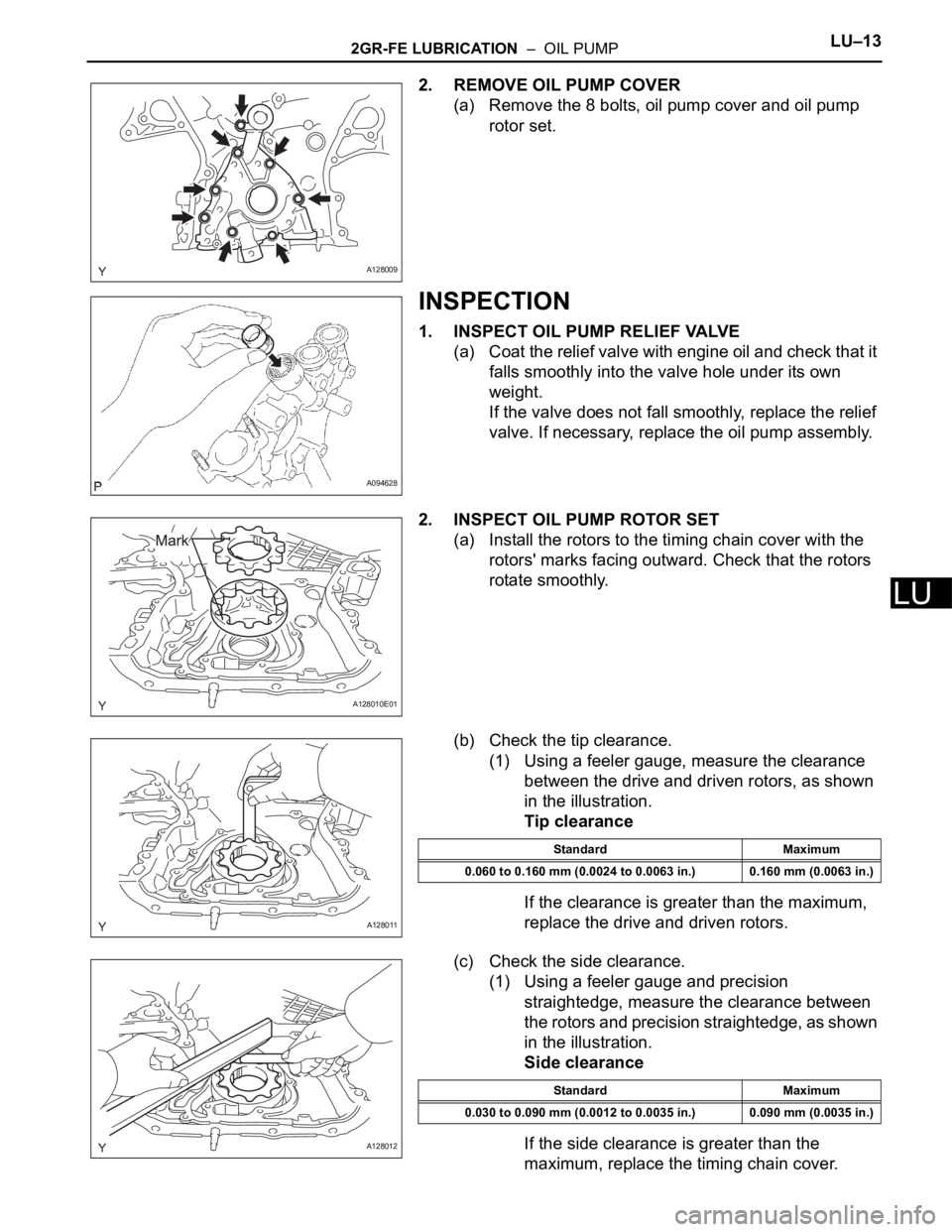

2. REMOVE OIL PUMP COVER

(a) Remove the 8 bolts, oil pump cover and oil pump

rotor set.

INSPECTION

1. INSPECT OIL PUMP RELIEF VALVE

(a) Coat the relief valve with engine oil and check that it

falls smoothly into the valve hole under its own

weight.

If the valve does not fall smoothly, replace the relief

valve. If necessary, replace the oil pump assembly.

2. INSPECT OIL PUMP ROTOR SET

(a) Install the rotors to the timing chain cover with the

rotors' marks facing outward. Check that the rotors

rotate smoothly.

(b) Check the tip clearance.

(1) Using a feeler gauge, measure the clearance

between the drive and driven rotors, as shown

in the illustration.

Tip clearance

If the clearance is greater than the maximum,

replace the drive and driven rotors.

(c) Check the side clearance.

(1) Using a feeler gauge and precision

straightedge, measure the clearance between

the rotors and precision straightedge, as shown

in the illustration.

Side clearance

If the side clearance is greater than the

maximum, replace the timing chain cover.

A128009

A094628

A128010E01

A128011

Standard Maximum

0.060 to 0.160 mm (0.0024 to 0.0063 in.) 0.160 mm (0.0063 in.)

A128012

Standard Maximum

0.030 to 0.090 mm (0.0012 to 0.0035 in.) 0.090 mm (0.0035 in.)