check engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1306 of 3000

LU–142GR-FE LUBRICATION – OIL PUMP

LU

(d) Check the body clearance.

(1) Using a feeler gauge, measure the clearance

between the timing chain cover and driven

rotor, as shown in the illustration.

Body clearance

If the body clearance is greater than the

maximum, replace the timing chain cover.

REASSEMBLY

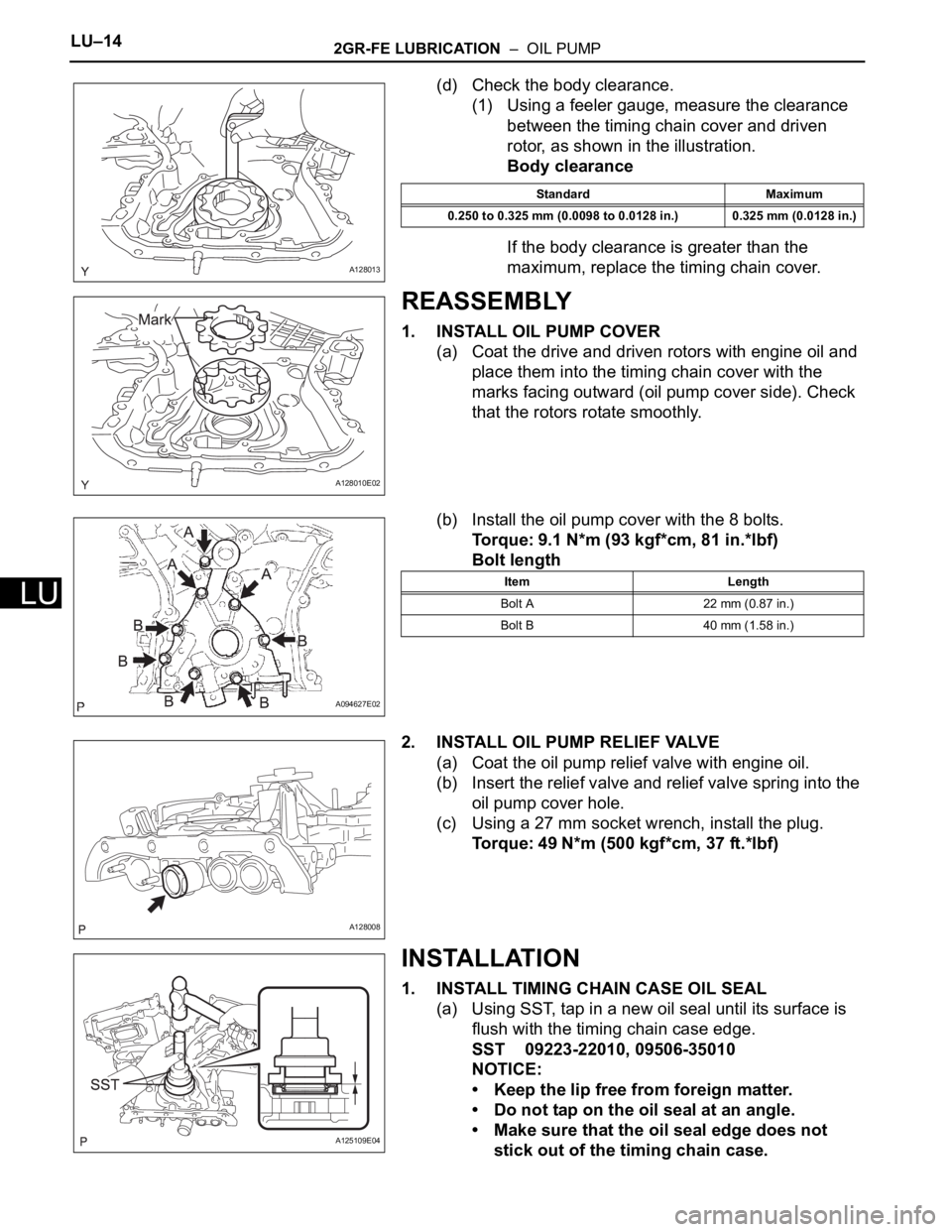

1. INSTALL OIL PUMP COVER

(a) Coat the drive and driven rotors with engine oil and

place them into the timing chain cover with the

marks facing outward (oil pump cover side). Check

that the rotors rotate smoothly.

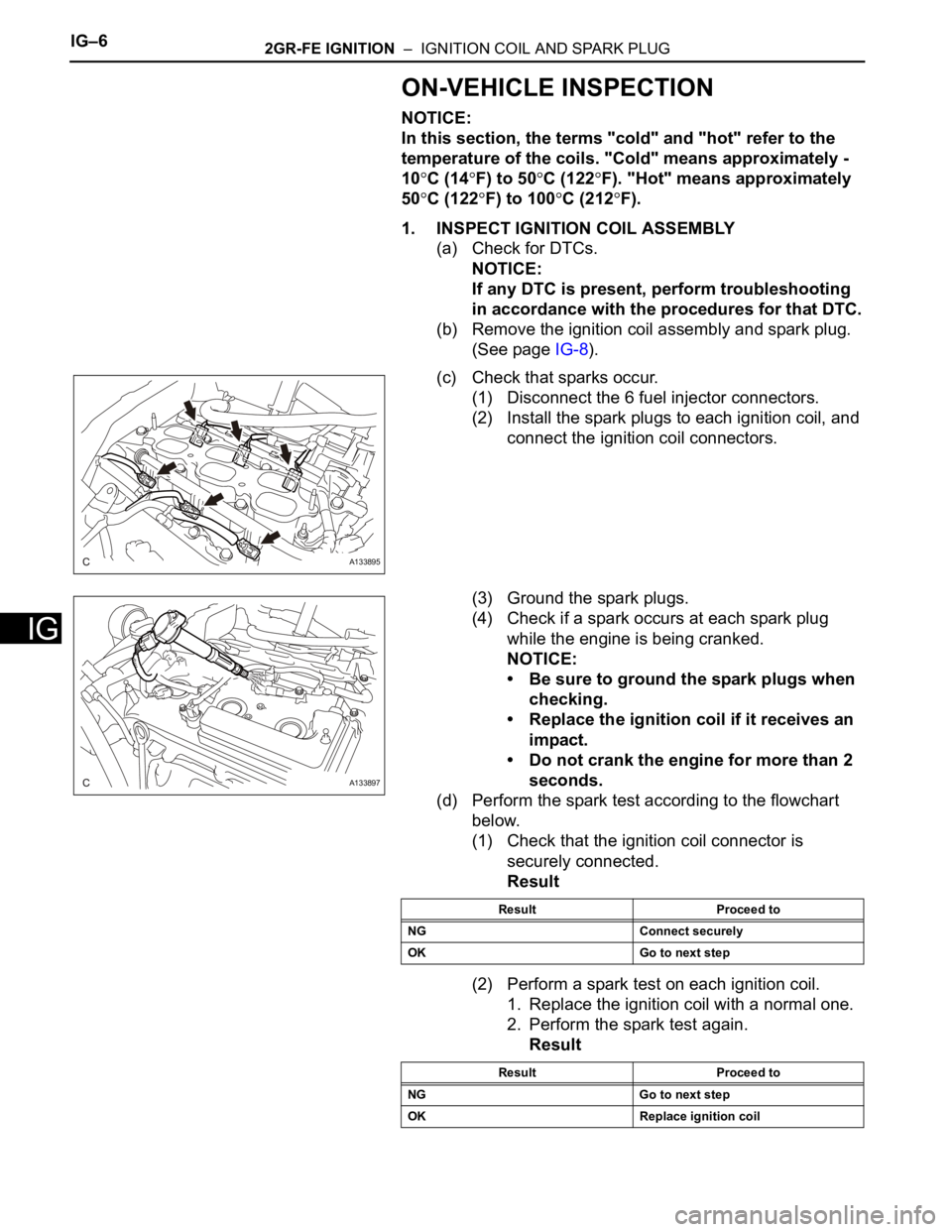

(b) Install the oil pump cover with the 8 bolts.

Torque: 9.1 N*m (93 kgf*cm, 81 in.*lbf)

Bolt length

2. INSTALL OIL PUMP RELIEF VALVE

(a) Coat the oil pump relief valve with engine oil.

(b) Insert the relief valve and relief valve spring into the

oil pump cover hole.

(c) Using a 27 mm socket wrench, install the plug.

Torque: 49 N*m (500 kgf*cm, 37 ft.*lbf)

INSTALLATION

1. INSTALL TIMING CHAIN CASE OIL SEAL

(a) Using SST, tap in a new oil seal until its surface is

flush with the timing chain case edge.

SST 09223-22010, 09506-35010

NOTICE:

• Keep the lip free from foreign matter.

• Do not tap on the oil seal at an angle.

• Make sure that the oil seal edge does not

stick out of the timing chain case.

A128013

Standard Maximum

0.250 to 0.325 mm (0.0098 to 0.0128 in.) 0.325 mm (0.0128 in.)

A128010E02

A094627E02

Item Length

Bolt A 22 mm (0.87 in.)

Bolt B 40 mm (1.58 in.)

A128008

A125109E04

Page 1315 of 3000

IG–62GR-FE IGNITION – IGNITION COIL AND SPARK PLUG

IG

ON-VEHICLE INSPECTION

NOTICE:

In this section, the terms "cold" and "hot" refer to the

temperature of the coils. "Cold" means approximately -

10

C (14F) to 50C (122F). "Hot" means approximately

50

C (122F) to 100C (212F).

1. INSPECT IGNITION COIL ASSEMBLY

(a) Check for DTCs.

NOTICE:

If any DTC is present, perform troubleshooting

in accordance with the procedures for that DTC.

(b) Remove the ignition coil assembly and spark plug.

(See page IG-8).

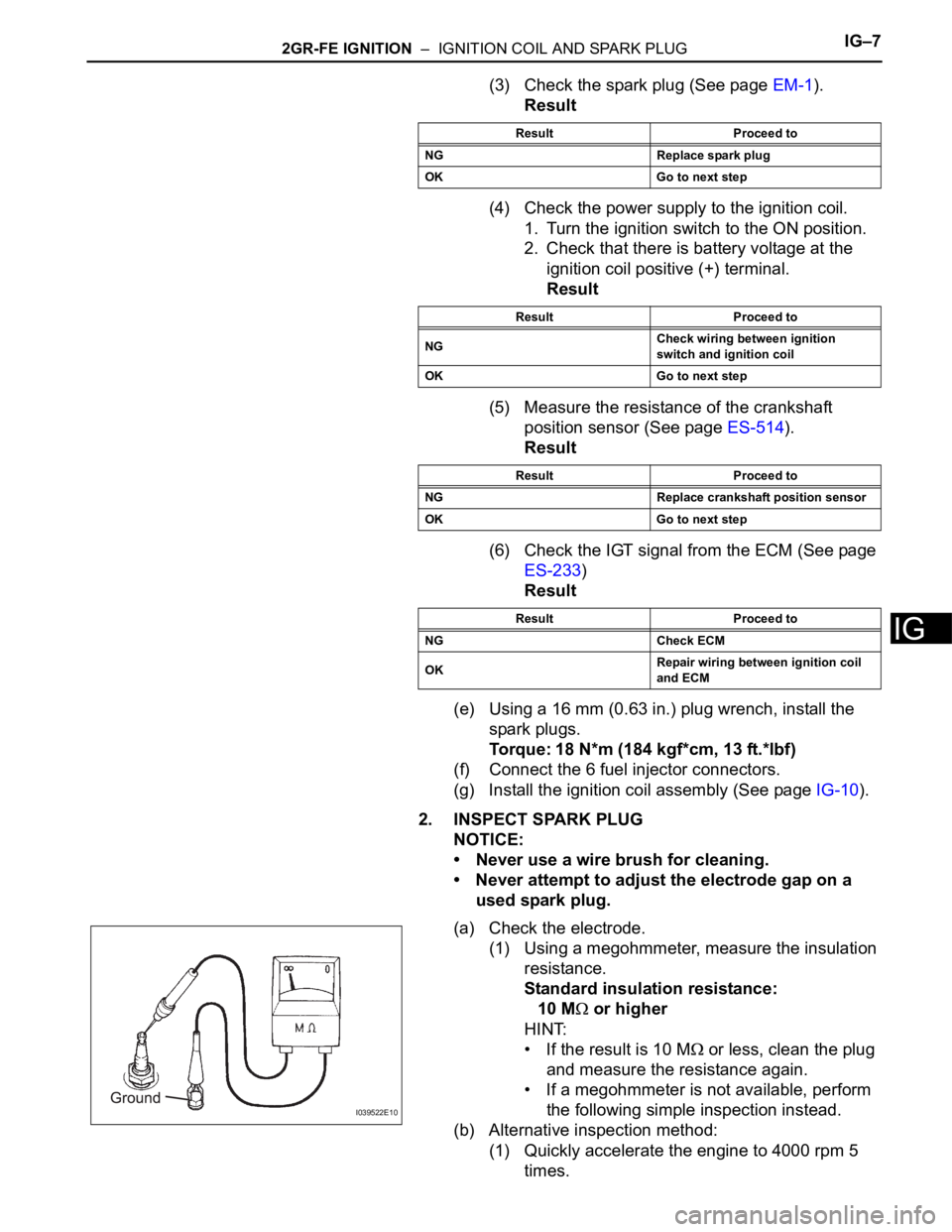

(c) Check that sparks occur.

(1) Disconnect the 6 fuel injector connectors.

(2) Install the spark plugs to each ignition coil, and

connect the ignition coil connectors.

(3) Ground the spark plugs.

(4) Check if a spark occurs at each spark plug

while the engine is being cranked.

NOTICE:

• Be sure to ground the spark plugs when

checking.

• Replace the ignition coil if it receives an

impact.

• Do not crank the engine for more than 2

seconds.

(d) Perform the spark test according to the flowchart

below.

(1) Check that the ignition coil connector is

securely connected.

Result

(2) Perform a spark test on each ignition coil.

1. Replace the ignition coil with a normal one.

2. Perform the spark test again.

Result

A133895

A133897

Result Proceed to

NG Connect securely

OK Go to next step

Result Proceed to

NG Go to next step

OK Replace ignition coil

Page 1316 of 3000

2GR-FE IGNITION – IGNITION COIL AND SPARK PLUGIG–7

IG

(3) Check the spark plug (See page EM-1).

Result

(4) Check the power supply to the ignition coil.

1. Turn the ignition switch to the ON position.

2. Check that there is battery voltage at the

ignition coil positive (+) terminal.

Result

(5) Measure the resistance of the crankshaft

position sensor (See page ES-514).

Result

(6) Check the IGT signal from the ECM (See page

ES-233)

Result

(e) Using a 16 mm (0.63 in.) plug wrench, install the

spark plugs.

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

(f) Connect the 6 fuel injector connectors.

(g) Install the ignition coil assembly (See page IG-10).

2. INSPECT SPARK PLUG

NOTICE:

• Never use a wire brush for cleaning.

• Never attempt to adjust the electrode gap on a

used spark plug.

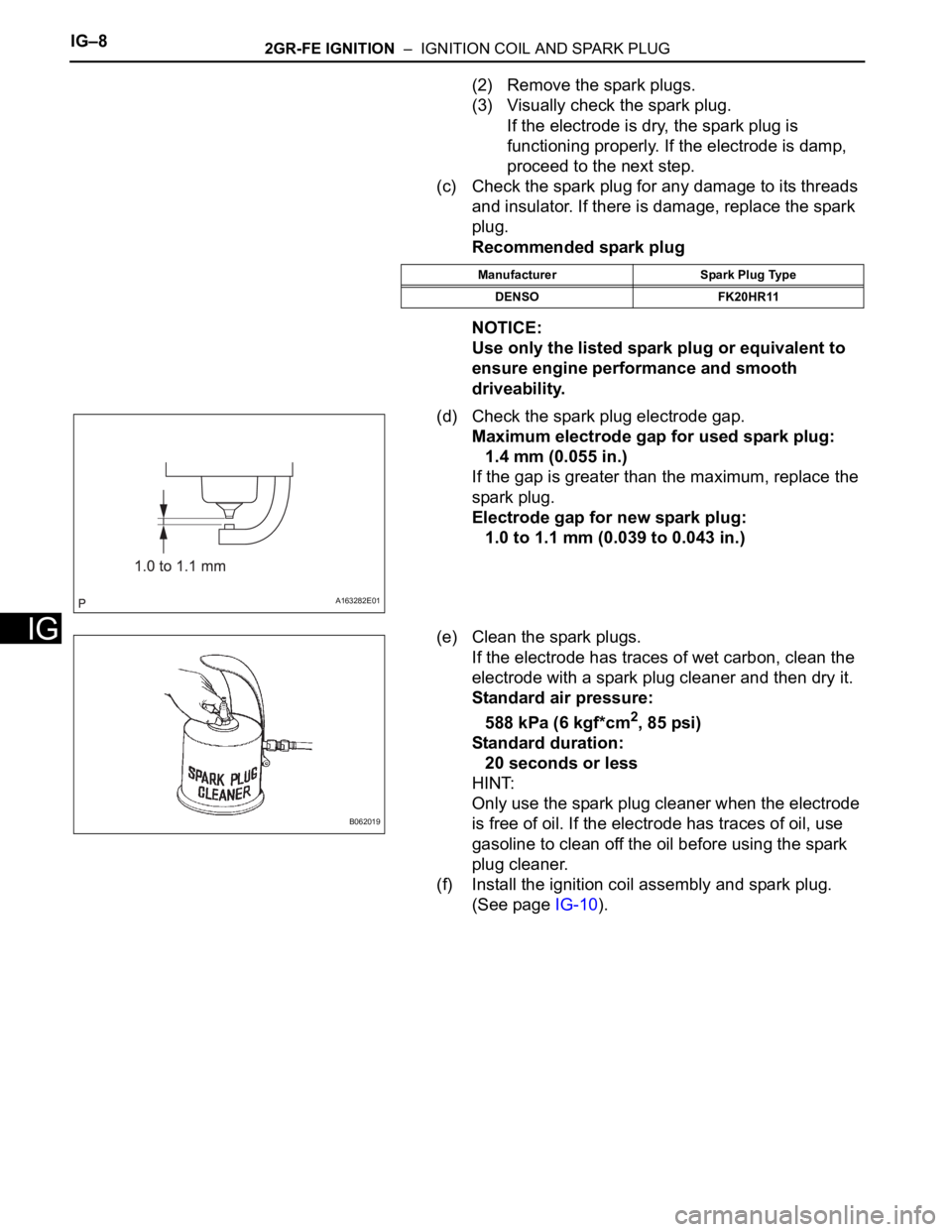

(a) Check the electrode.

(1) Using a megohmmeter, measure the insulation

resistance.

Standard insulation resistance:

10 M

or higher

HINT:

• If the result is 10 M

or less, clean the plug

and measure the resistance again.

• If a megohmmeter is not available, perform

the following simple inspection instead.

(b) Alternative inspection method:

(1) Quickly accelerate the engine to 4000 rpm 5

times.

Result Proceed to

NG Replace spark plug

OK Go to next step

Result Proceed to

NGCheck wiring between ignition

switch and ignition coil

OK Go to next step

Result Proceed to

NG Replace crankshaft position sensor

OK Go to next step

Result Proceed to

NG Check ECM

OKRepair wiring between ignition coil

and ECM

I039522E10

Page 1317 of 3000

IG–82GR-FE IGNITION – IGNITION COIL AND SPARK PLUG

IG

(2) Remove the spark plugs.

(3) Visually check the spark plug.

If the electrode is dry, the spark plug is

functioning properly. If the electrode is damp,

proceed to the next step.

(c) Check the spark plug for any damage to its threads

and insulator. If there is damage, replace the spark

plug.

Recommended spark plug

NOTICE:

Use only the listed spark plug or equivalent to

ensure engine performance and smooth

driveability.

(d) Check the spark plug electrode gap.

Maximum electrode gap for used spark plug:

1.4 mm (0.055 in.)

If the gap is greater than the maximum, replace the

spark plug.

Electrode gap for new spark plug:

1.0 to 1.1 mm (0.039 to 0.043 in.)

(e) Clean the spark plugs.

If the electrode has traces of wet carbon, clean the

electrode with a spark plug cleaner and then dry it.

Standard air pressure:

588 kPa (6 kgf*cm

2, 85 psi)

Standard duration:

20 seconds or less

HINT:

Only use the spark plug cleaner when the electrode

is free of oil. If the electrode has traces of oil, use

gasoline to clean off the oil before using the spark

plug cleaner.

(f) Install the ignition coil assembly and spark plug.

(See page IG-10).

Manufacturer Spark Plug Type

DENSO FK20HR11

A163282E01

B062019

Page 1341 of 3000

CH–62GR-FE CHARGING – CHARGING SYSTEM

CH

ON-VEHICLE INSPECTION

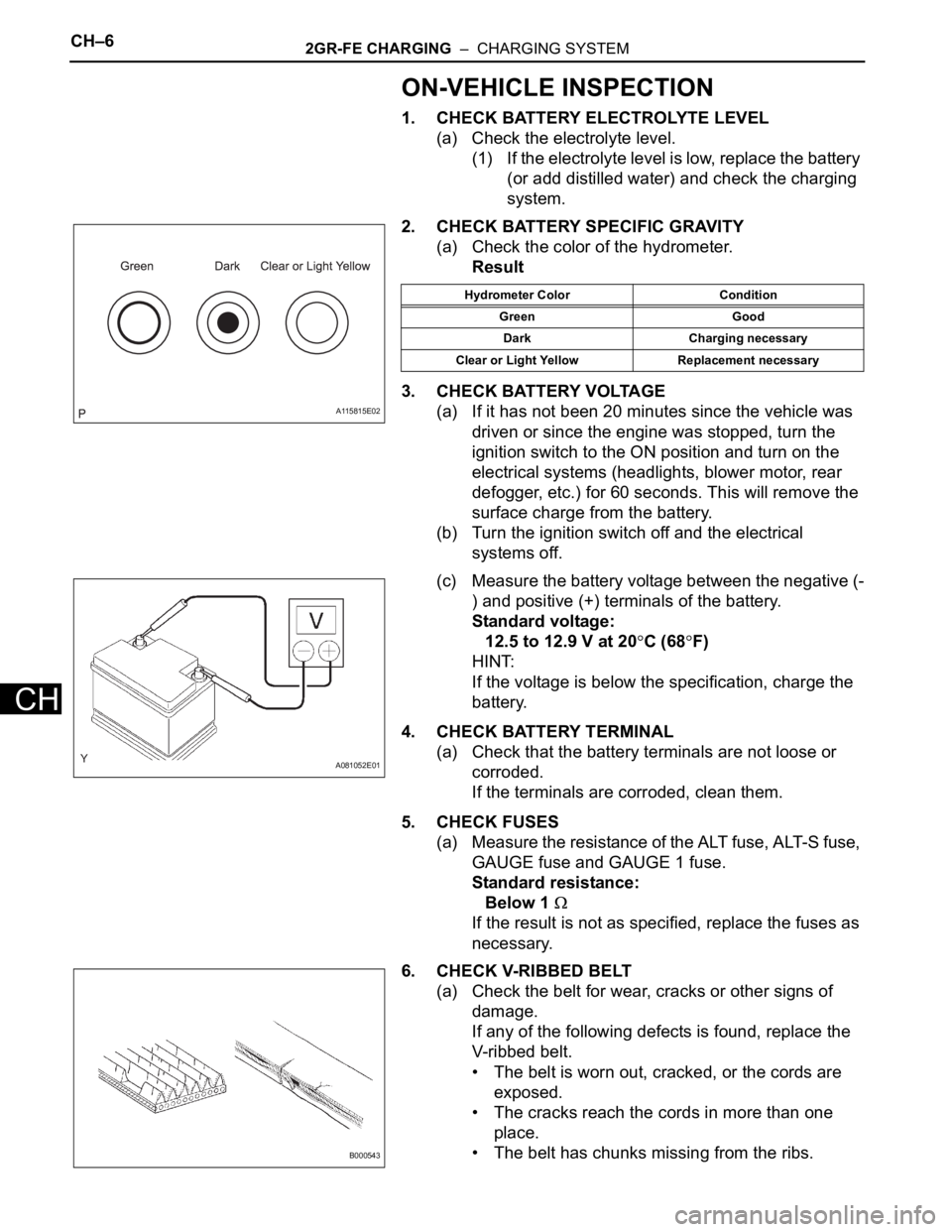

1. CHECK BATTERY ELECTROLYTE LEVEL

(a) Check the electrolyte level.

(1) If the electrolyte level is low, replace the battery

(or add distilled water) and check the charging

system.

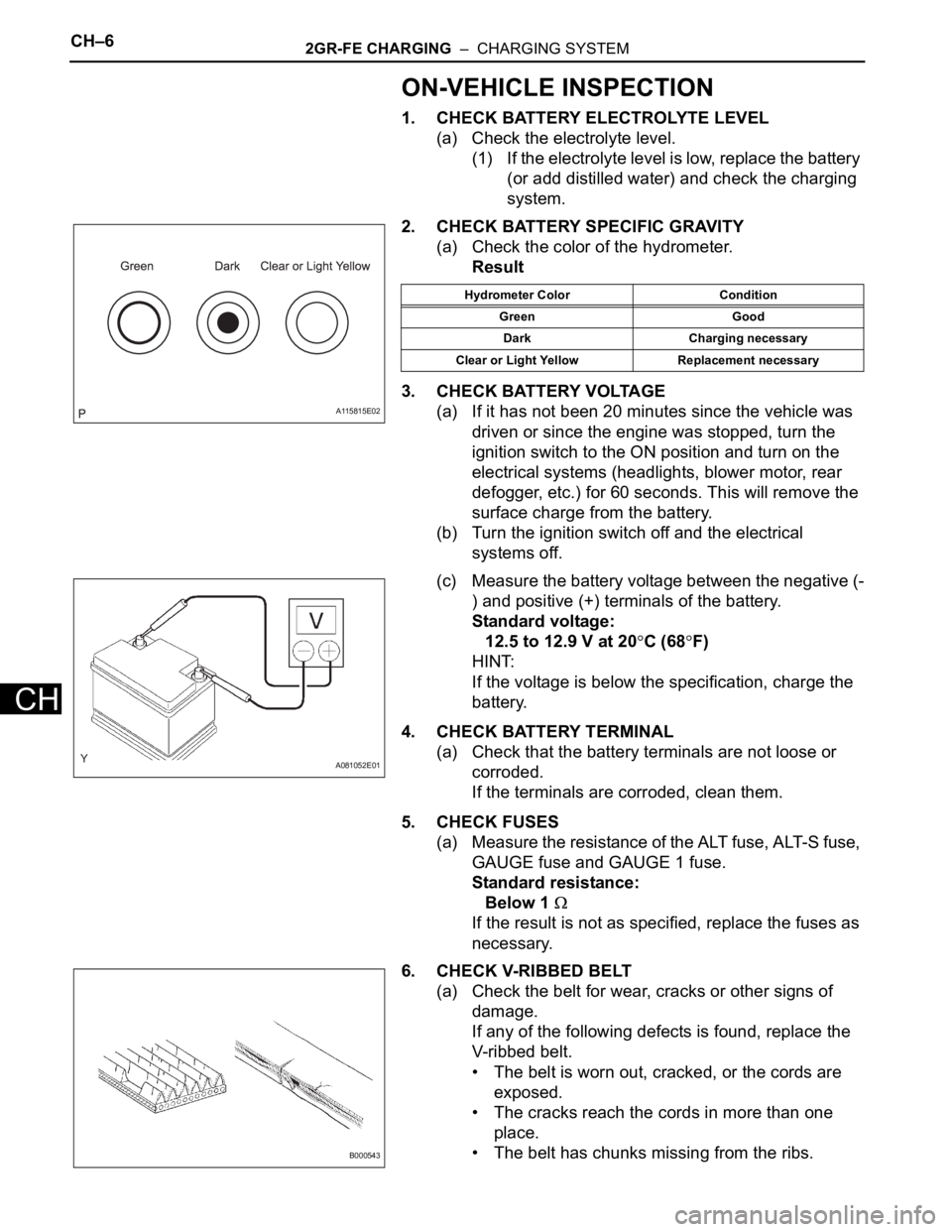

2. CHECK BATTERY SPECIFIC GRAVITY

(a) Check the color of the hydrometer.

Result

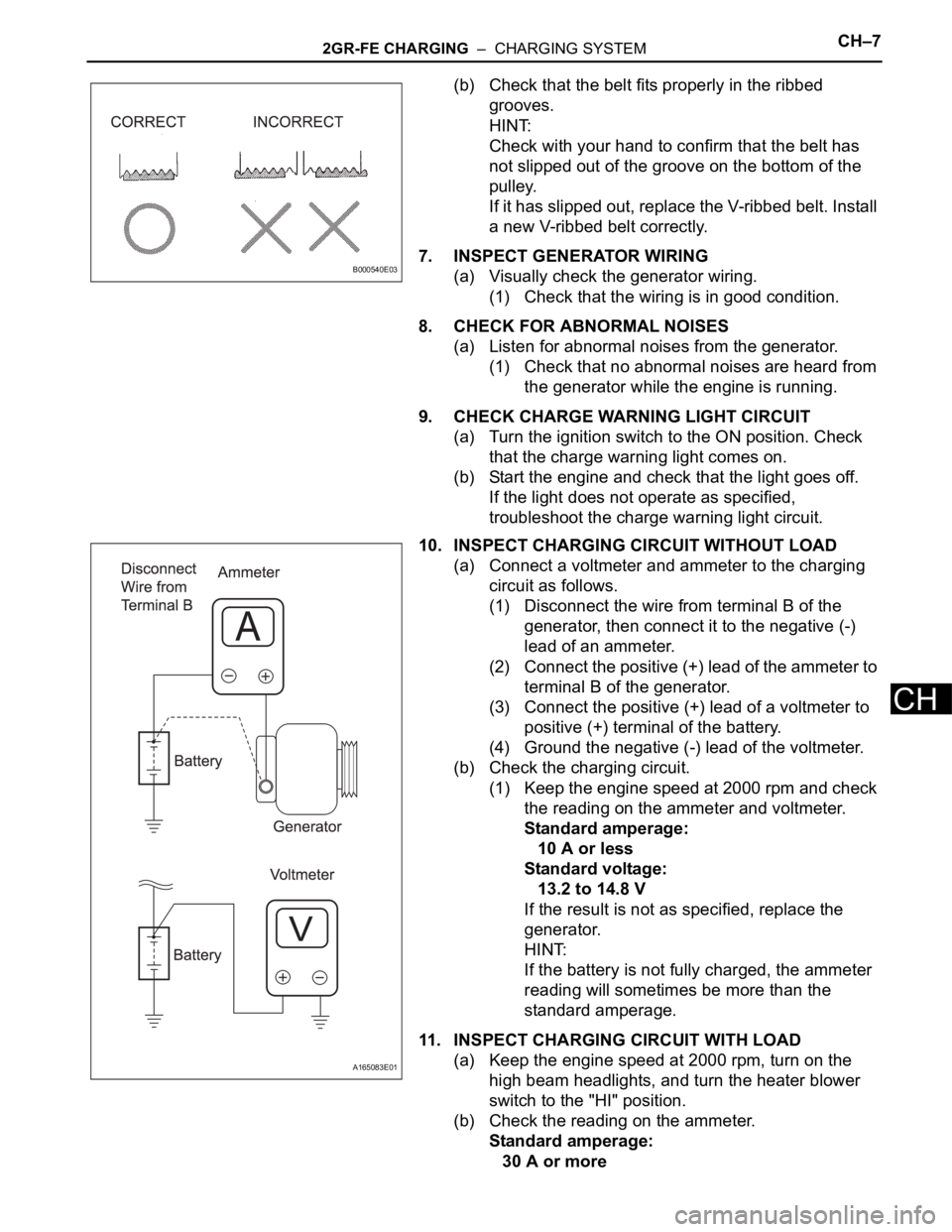

3. CHECK BATTERY VOLTAGE

(a) If it has not been 20 minutes since the vehicle was

driven or since the engine was stopped, turn the

ignition switch to the ON position and turn on the

electrical systems (headlights, blower motor, rear

defogger, etc.) for 60 seconds. This will remove the

surface charge from the battery.

(b) Turn the ignition switch off and the electrical

systems off.

(c) Measure the battery voltage between the negative (-

) and positive (+) terminals of the battery.

Standard voltage:

12.5 to 12.9 V at 20

C (68F)

HINT:

If the voltage is below the specification, charge the

battery.

4. CHECK BATTERY TERMINAL

(a) Check that the battery terminals are not loose or

corroded.

If the terminals are corroded, clean them.

5. CHECK FUSES

(a) Measure the resistance of the ALT fuse, ALT-S fuse,

GAUGE fuse and GAUGE 1 fuse.

Standard resistance:

Below 1

If the result is not as specified, replace the fuses as

necessary.

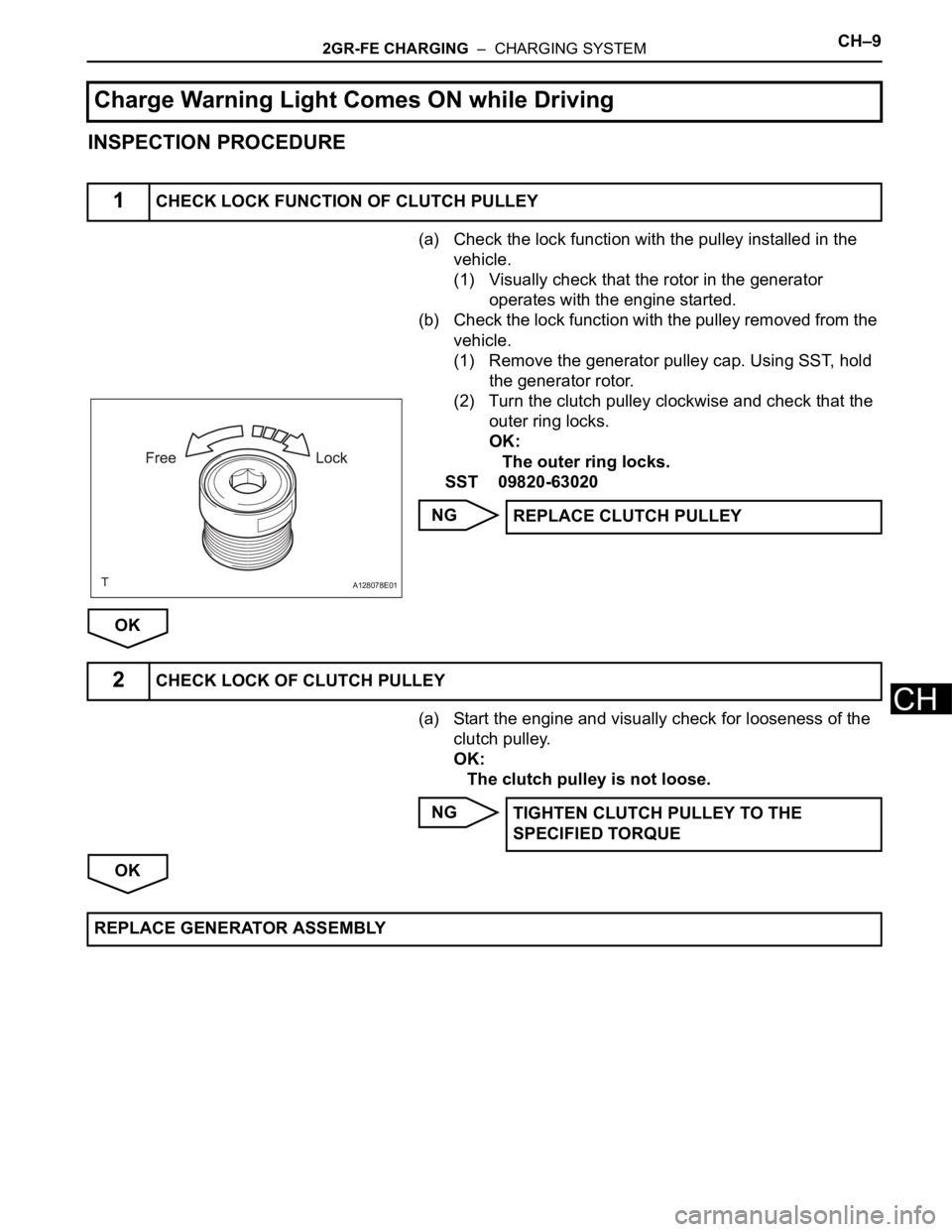

6. CHECK V-RIBBED BELT

(a) Check the belt for wear, cracks or other signs of

damage.

If any of the following defects is found, replace the

V-ribbed belt.

• The belt is worn out, cracked, or the cords are

exposed.

• The cracks reach the cords in more than one

place.

• The belt has chunks missing from the ribs.

A115815E02

Hydrometer Color Condition

Green Good

Dark Charging necessary

Clear or Light Yellow Replacement necessary

A081052E01

B000543

Page 1342 of 3000

2GR-FE CHARGING – CHARGING SYSTEMCH–7

CH

(b) Check that the belt fits properly in the ribbed

grooves.

HINT:

Check with your hand to confirm that the belt has

not slipped out of the groove on the bottom of the

pulley.

If it has slipped out, replace the V-ribbed belt. Install

a new V-ribbed belt correctly.

7. INSPECT GENERATOR WIRING

(a) Visually check the generator wiring.

(1) Check that the wiring is in good condition.

8. CHECK FOR ABNORMAL NOISES

(a) Listen for abnormal noises from the generator.

(1) Check that no abnormal noises are heard from

the generator while the engine is running.

9. CHECK CHARGE WARNING LIGHT CIRCUIT

(a) Turn the ignition switch to the ON position. Check

that the charge warning light comes on.

(b) Start the engine and check that the light goes off.

If the light does not operate as specified,

troubleshoot the charge warning light circuit.

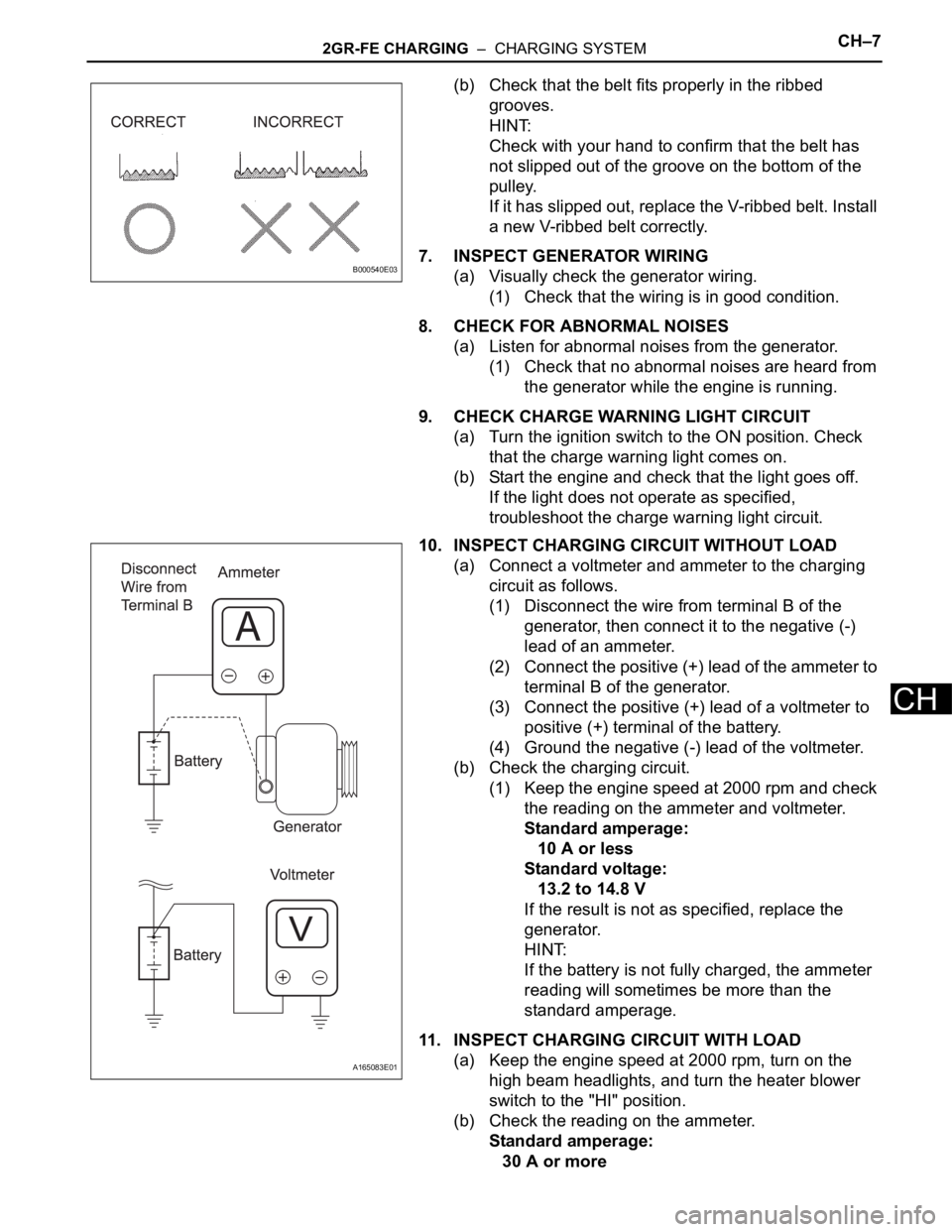

10. INSPECT CHARGING CIRCUIT WITHOUT LOAD

(a) Connect a voltmeter and ammeter to the charging

circuit as follows.

(1) Disconnect the wire from terminal B of the

generator, then connect it to the negative (-)

lead of an ammeter.

(2) Connect the positive (+) lead of the ammeter to

terminal B of the generator.

(3) Connect the positive (+) lead of a voltmeter to

positive (+) terminal of the battery.

(4) Ground the negative (-) lead of the voltmeter.

(b) Check the charging circuit.

(1) Keep the engine speed at 2000 rpm and check

the reading on the ammeter and voltmeter.

Standard amperage:

10 A or less

Standard voltage:

13.2 to 14.8 V

If the result is not as specified, replace the

generator.

HINT:

If the battery is not fully charged, the ammeter

reading will sometimes be more than the

standard amperage.

11. INSPECT CHARGING CIRCUIT WITH LOAD

(a) Keep the engine speed at 2000 rpm, turn on the

high beam headlights, and turn the heater blower

switch to the "HI" position.

(b) Check the reading on the ammeter.

Standard amperage:

30 A or more

B000540E03

A165083E01

Page 1344 of 3000

2GR-FE CHARGING – CHARGING SYSTEMCH–9

CH

INSPECTION PROCEDURE

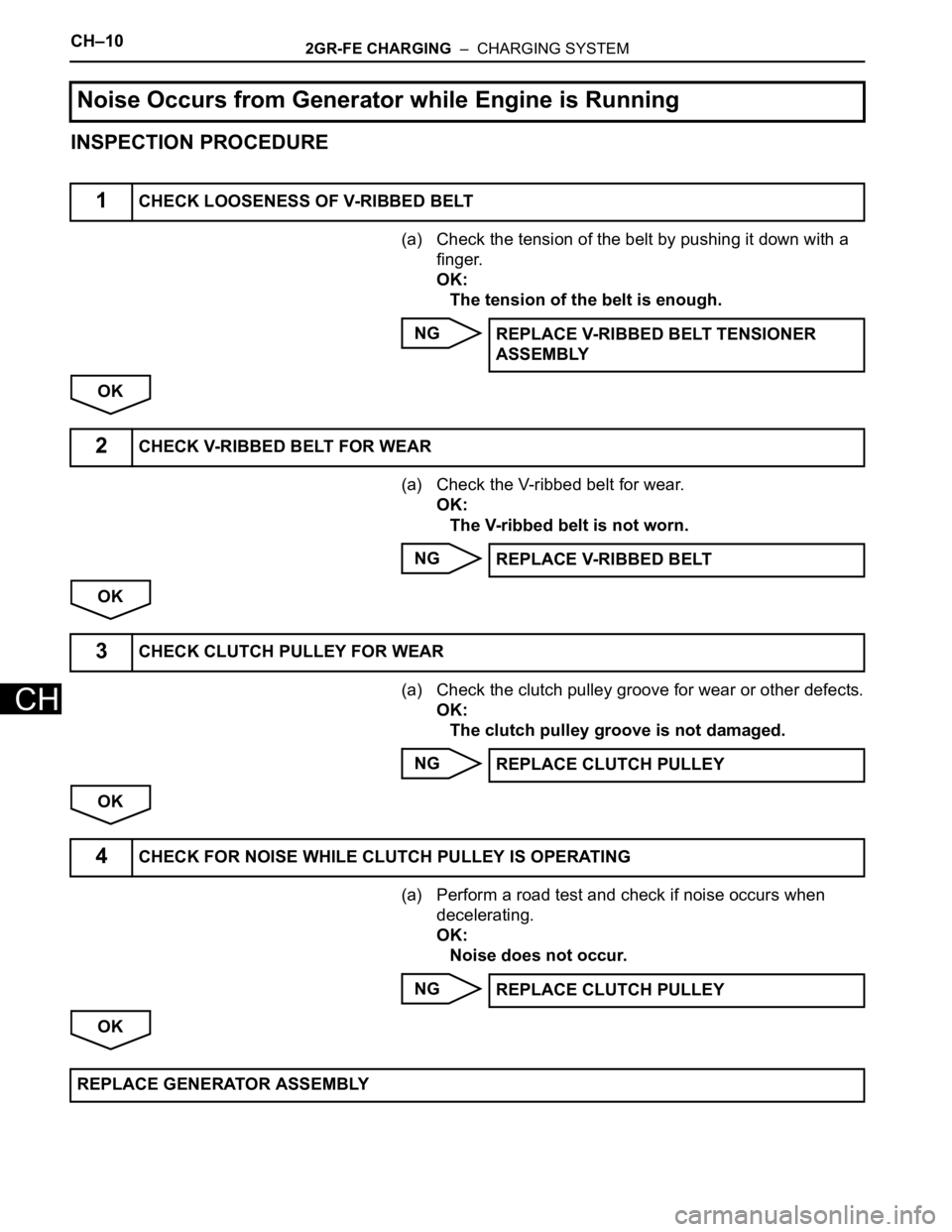

(a) Check the lock function with the pulley installed in the

vehicle.

(1) Visually check that the rotor in the generator

operates with the engine started.

(b) Check the lock function with the pulley removed from the

vehicle.

(1) Remove the generator pulley cap. Using SST, hold

the generator rotor.

(2) Turn the clutch pulley clockwise and check that the

outer ring locks.

OK:

The outer ring locks.

SST 09820-63020

NG

OK

(a) Start the engine and visually check for looseness of the

clutch pulley.

OK:

The clutch pulley is not loose.

NG

OK

Charge Warning Light Comes ON while Driving

1CHECK LOCK FUNCTION OF CLUTCH PULLEY

A128078E01

REPLACE CLUTCH PULLEY

2CHECK LOCK OF CLUTCH PULLEY

TIGHTEN CLUTCH PULLEY TO THE

SPECIFIED TORQUE

REPLACE GENERATOR ASSEMBLY

Page 1345 of 3000

CH–102GR-FE CHARGING – CHARGING SYSTEM

CH

INSPECTION PROCEDURE

(a) Check the tension of the belt by pushing it down with a

finger.

OK:

The tension of the belt is enough.

NG

OK

(a) Check the V-ribbed belt for wear.

OK:

The V-ribbed belt is not worn.

NG

OK

(a) Check the clutch pulley groove for wear or other defects.

OK:

The clutch pulley groove is not damaged.

NG

OK

(a) Perform a road test and check if noise occurs when

decelerating.

OK:

Noise does not occur.

NG

OK

Noise Occurs from Generator while Engine is Running

1CHECK LOOSENESS OF V-RIBBED BELT

REPLACE V-RIBBED BELT TENSIONER

ASSEMBLY

2CHECK V-RIBBED BELT FOR WEAR

REPLACE V-RIBBED BELT

3CHECK CLUTCH PULLEY FOR WEAR

REPLACE CLUTCH PULLEY

4CHECK FOR NOISE WHILE CLUTCH PULLEY IS OPERATING

REPLACE CLUTCH PULLEY

REPLACE GENERATOR ASSEMBLY

Page 1346 of 3000

CH–62GR-FE CHARGING – CHARGING SYSTEM

CH

ON-VEHICLE INSPECTION

1. CHECK BATTERY ELECTROLYTE LEVEL

(a) Check the electrolyte level.

(1) If the electrolyte level is low, replace the battery

(or add distilled water) and check the charging

system.

2. CHECK BATTERY SPECIFIC GRAVITY

(a) Check the color of the hydrometer.

Result

3. CHECK BATTERY VOLTAGE

(a) If it has not been 20 minutes since the vehicle was

driven or since the engine was stopped, turn the

ignition switch to the ON position and turn on the

electrical systems (headlights, blower motor, rear

defogger, etc.) for 60 seconds. This will remove the

surface charge from the battery.

(b) Turn the ignition switch off and the electrical

systems off.

(c) Measure the battery voltage between the negative (-

) and positive (+) terminals of the battery.

Standard voltage:

12.5 to 12.9 V at 20

C (68F)

HINT:

If the voltage is below the specification, charge the

battery.

4. CHECK BATTERY TERMINAL

(a) Check that the battery terminals are not loose or

corroded.

If the terminals are corroded, clean them.

5. CHECK FUSES

(a) Measure the resistance of the ALT fuse, ALT-S fuse,

GAUGE fuse and GAUGE 1 fuse.

Standard resistance:

Below 1

If the result is not as specified, replace the fuses as

necessary.

6. CHECK V-RIBBED BELT

(a) Check the belt for wear, cracks or other signs of

damage.

If any of the following defects is found, replace the

V-ribbed belt.

• The belt is worn out, cracked, or the cords are

exposed.

• The cracks reach the cords in more than one

place.

• The belt has chunks missing from the ribs.

A115815E02

Hydrometer Color Condition

Green Good

Dark Charging necessary

Clear or Light Yellow Replacement necessary

A081052E01

B000543

Page 1347 of 3000

2GR-FE CHARGING – CHARGING SYSTEMCH–7

CH

(b) Check that the belt fits properly in the ribbed

grooves.

HINT:

Check with your hand to confirm that the belt has

not slipped out of the groove on the bottom of the

pulley.

If it has slipped out, replace the V-ribbed belt. Install

a new V-ribbed belt correctly.

7. INSPECT GENERATOR WIRING

(a) Visually check the generator wiring.

(1) Check that the wiring is in good condition.

8. CHECK FOR ABNORMAL NOISES

(a) Listen for abnormal noises from the generator.

(1) Check that no abnormal noises are heard from

the generator while the engine is running.

9. CHECK CHARGE WARNING LIGHT CIRCUIT

(a) Turn the ignition switch to the ON position. Check

that the charge warning light comes on.

(b) Start the engine and check that the light goes off.

If the light does not operate as specified,

troubleshoot the charge warning light circuit.

10. INSPECT CHARGING CIRCUIT WITHOUT LOAD

(a) Connect a voltmeter and ammeter to the charging

circuit as follows.

(1) Disconnect the wire from terminal B of the

generator, then connect it to the negative (-)

lead of an ammeter.

(2) Connect the positive (+) lead of the ammeter to

terminal B of the generator.

(3) Connect the positive (+) lead of a voltmeter to

positive (+) terminal of the battery.

(4) Ground the negative (-) lead of the voltmeter.

(b) Check the charging circuit.

(1) Keep the engine speed at 2000 rpm and check

the reading on the ammeter and voltmeter.

Standard amperage:

10 A or less

Standard voltage:

13.2 to 14.8 V

If the result is not as specified, replace the

generator.

HINT:

If the battery is not fully charged, the ammeter

reading will sometimes be more than the

standard amperage.

11. INSPECT CHARGING CIRCUIT WITH LOAD

(a) Keep the engine speed at 2000 rpm, turn on the

high beam headlights, and turn the heater blower

switch to the "HI" position.

(b) Check the reading on the ammeter.

Standard amperage:

30 A or more

B000540E03

A165083E01