wheel TOYOTA SIENNA 2007 Service Service Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 980 of 3000

EM–62GR-FE ENGINE MECHANICAL – DRIVE BELT

EM

REMOVAL

1. REMOVE FRONT WHEEL RH

2. REMOVE FRONT FENDER APRON SEAL RH (See

page EM-26)

3. REMOVE V-RIBBED BELT

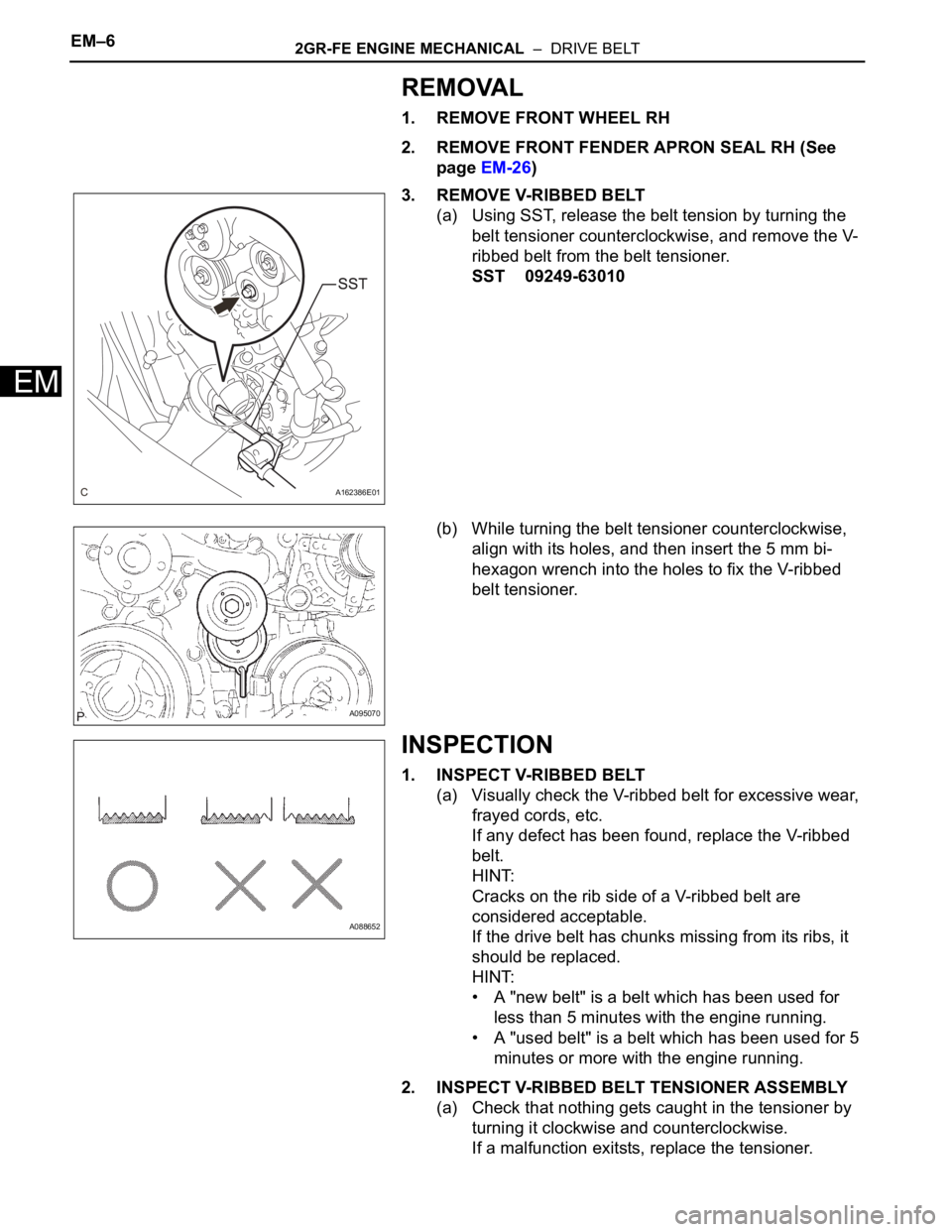

(a) Using SST, release the belt tension by turning the

belt tensioner counterclockwise, and remove the V-

ribbed belt from the belt tensioner.

SST 09249-63010

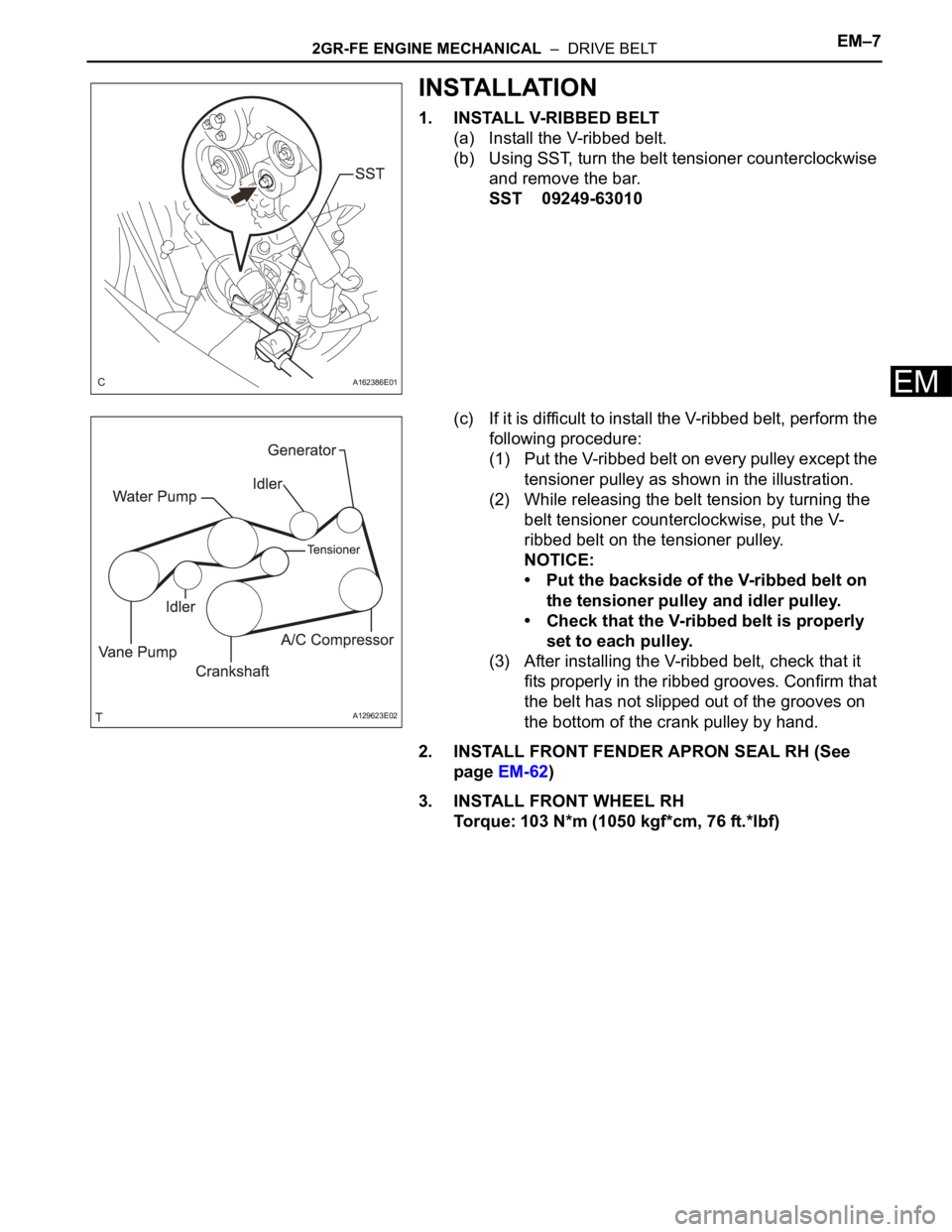

(b) While turning the belt tensioner counterclockwise,

align with its holes, and then insert the 5 mm bi-

hexagon wrench into the holes to fix the V-ribbed

belt tensioner.

INSPECTION

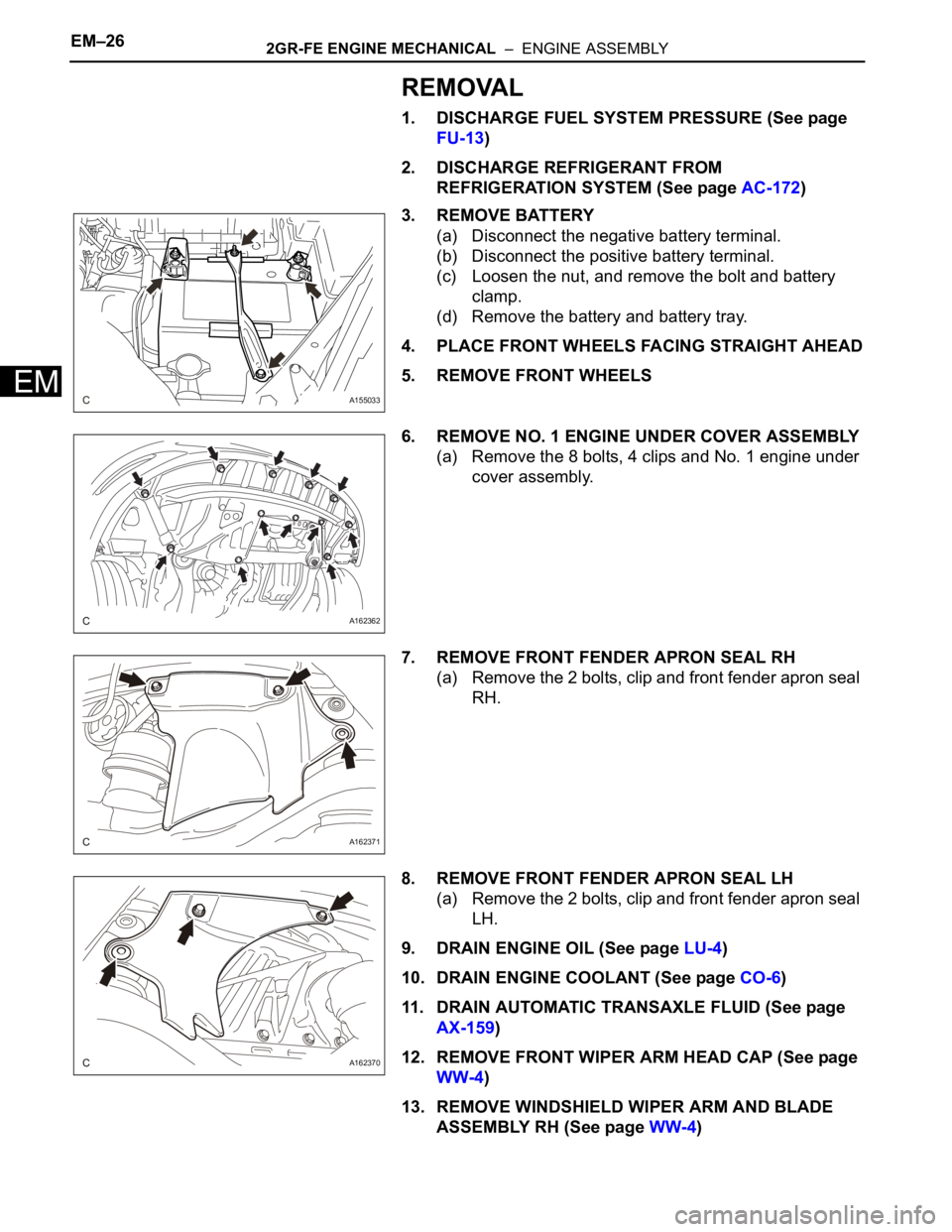

1. INSPECT V-RIBBED BELT

(a) Visually check the V-ribbed belt for excessive wear,

frayed cords, etc.

If any defect has been found, replace the V-ribbed

belt.

HINT:

Cracks on the rib side of a V-ribbed belt are

considered acceptable.

If the drive belt has chunks missing from its ribs, it

should be replaced.

HINT:

• A "new belt" is a belt which has been used for

less than 5 minutes with the engine running.

• A "used belt" is a belt which has been used for 5

minutes or more with the engine running.

2. INSPECT V-RIBBED BELT TENSIONER ASSEMBLY

(a) Check that nothing gets caught in the tensioner by

turning it clockwise and counterclockwise.

If a malfunction exitsts, replace the tensioner.

A162386E01

A095070

A088652

Page 981 of 3000

2GR-FE ENGINE MECHANICAL – DRIVE BELTEM–7

EM

INSTALLATION

1. INSTALL V-RIBBED BELT

(a) Install the V-ribbed belt.

(b) Using SST, turn the belt tensioner counterclockwise

and remove the bar.

SST 09249-63010

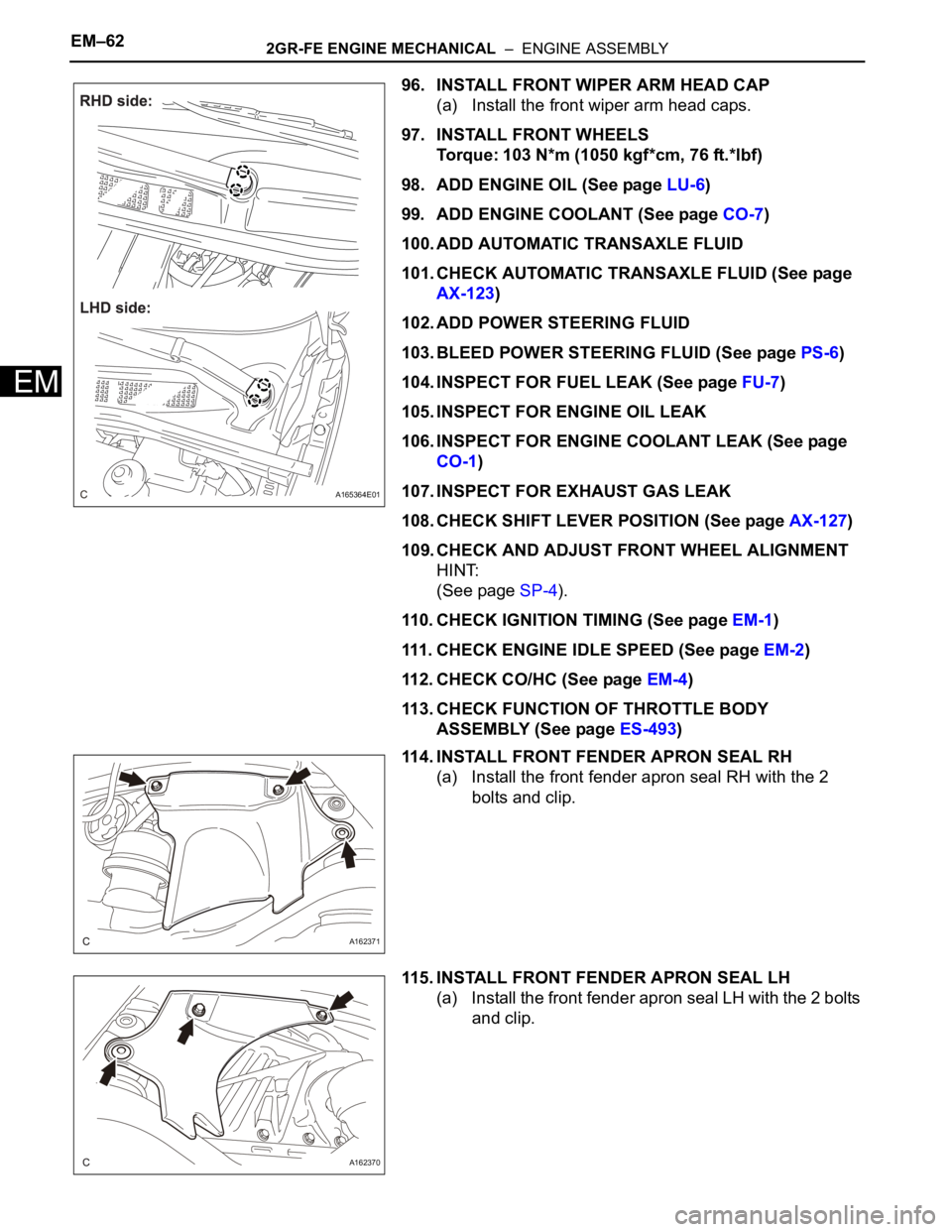

(c) If it is difficult to install the V-ribbed belt, perform the

following procedure:

(1) Put the V-ribbed belt on every pulley except the

tensioner pulley as shown in the illustration.

(2) While releasing the belt tension by turning the

belt tensioner counterclockwise, put the V-

ribbed belt on the tensioner pulley.

NOTICE:

• Put the backside of the V-ribbed belt on

the tensioner pulley and idler pulley.

• Check that the V-ribbed belt is properly

set to each pulley.

(3) After installing the V-ribbed belt, check that it

fits properly in the ribbed grooves. Confirm that

the belt has not slipped out of the grooves on

the bottom of the crank pulley by hand.

2. INSTALL FRONT FENDER APRON SEAL RH (See

page EM-62)

3. INSTALL FRONT WHEEL RH

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

A162386E01

A129623E02

Page 985 of 3000

EM–262GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE (See page

FU-13)

2. DISCHARGE REFRIGERANT FROM

REFRIGERATION SYSTEM (See page AC-172)

3. REMOVE BATTERY

(a) Disconnect the negative battery terminal.

(b) Disconnect the positive battery terminal.

(c) Loosen the nut, and remove the bolt and battery

clamp.

(d) Remove the battery and battery tray.

4. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

5. REMOVE FRONT WHEELS

6. REMOVE NO. 1 ENGINE UNDER COVER ASSEMBLY

(a) Remove the 8 bolts, 4 clips and No. 1 engine under

cover assembly.

7. REMOVE FRONT FENDER APRON SEAL RH

(a) Remove the 2 bolts, clip and front fender apron seal

RH.

8. REMOVE FRONT FENDER APRON SEAL LH

(a) Remove the 2 bolts, clip and front fender apron seal

LH.

9. DRAIN ENGINE OIL (See page LU-4)

10. DRAIN ENGINE COOLANT (See page CO-6)

11. DRAIN AUTOMATIC TRANSAXLE FLUID (See page

AX-159)

12. REMOVE FRONT WIPER ARM HEAD CAP (See page

WW-4)

13. REMOVE WINDSHIELD WIPER ARM AND BLADE

ASSEMBLY RH (See page WW-4)

A155033

A162362

A162371

A162370

Page 1021 of 3000

EM–622GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

96. INSTALL FRONT WIPER ARM HEAD CAP

(a) Install the front wiper arm head caps.

97. INSTALL FRONT WHEELS

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

98. ADD ENGINE OIL (See page LU-6)

99. ADD ENGINE COOLANT (See page CO-7)

100. ADD AUTOMATIC TRANSAXLE FLUID

101. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

102. ADD POWER STEERING FLUID

103. BLEED POWER STEERING FLUID (See page PS-6)

104. INSPECT FOR FUEL LEAK (See page FU-7)

105. INSPECT FOR ENGINE OIL LEAK

106. INSPECT FOR ENGINE COOLANT LEAK (See page

CO-1)

107. INSPECT FOR EXHAUST GAS LEAK

108. CHECK SHIFT LEVER POSITION (See page AX-127)

109. CHECK AND ADJUST FRONT WHEEL ALIGNMENT

HINT:

(See page SP-4).

110. CHECK IGNITION TIMING (See page EM-1)

111. CHECK ENGINE IDLE SPEED (See page EM-2)

112. CHECK CO/HC (See page EM-4)

113. CHECK FUNCTION OF THROTTLE BODY

ASSEMBLY (See page ES-493)

114. INSTALL FRONT FENDER APRON SEAL RH

(a) Install the front fender apron seal RH with the 2

bolts and clip.

115. INSTALL FRONT FENDER APRON SEAL LH

(a) Install the front fender apron seal LH with the 2 bolts

and clip.

A165364E01

A162371

A162370

Page 1240 of 3000

CO–182GR-FE COOLING – THERMOSTAT

CO

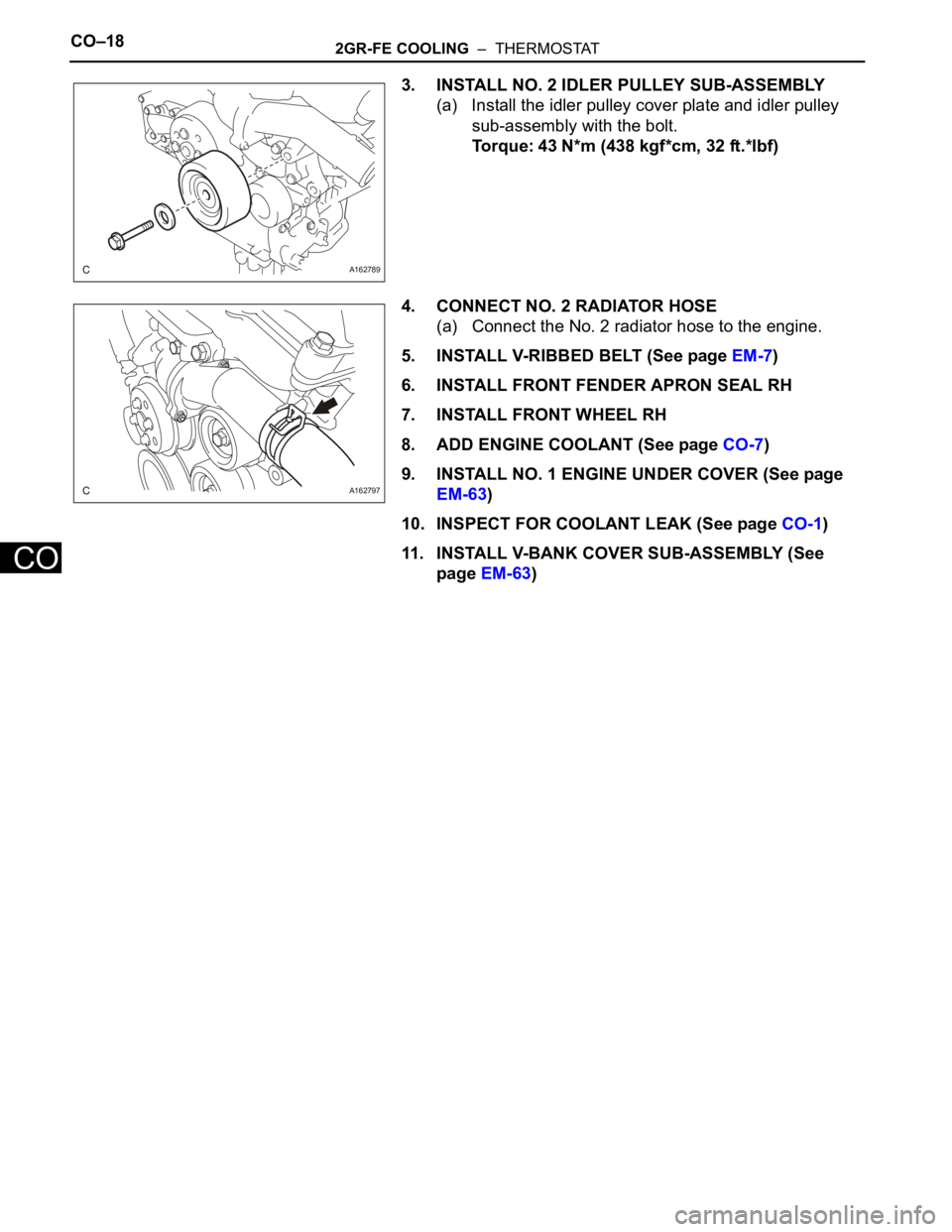

3. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY

(a) Install the idler pulley cover plate and idler pulley

sub-assembly with the bolt.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

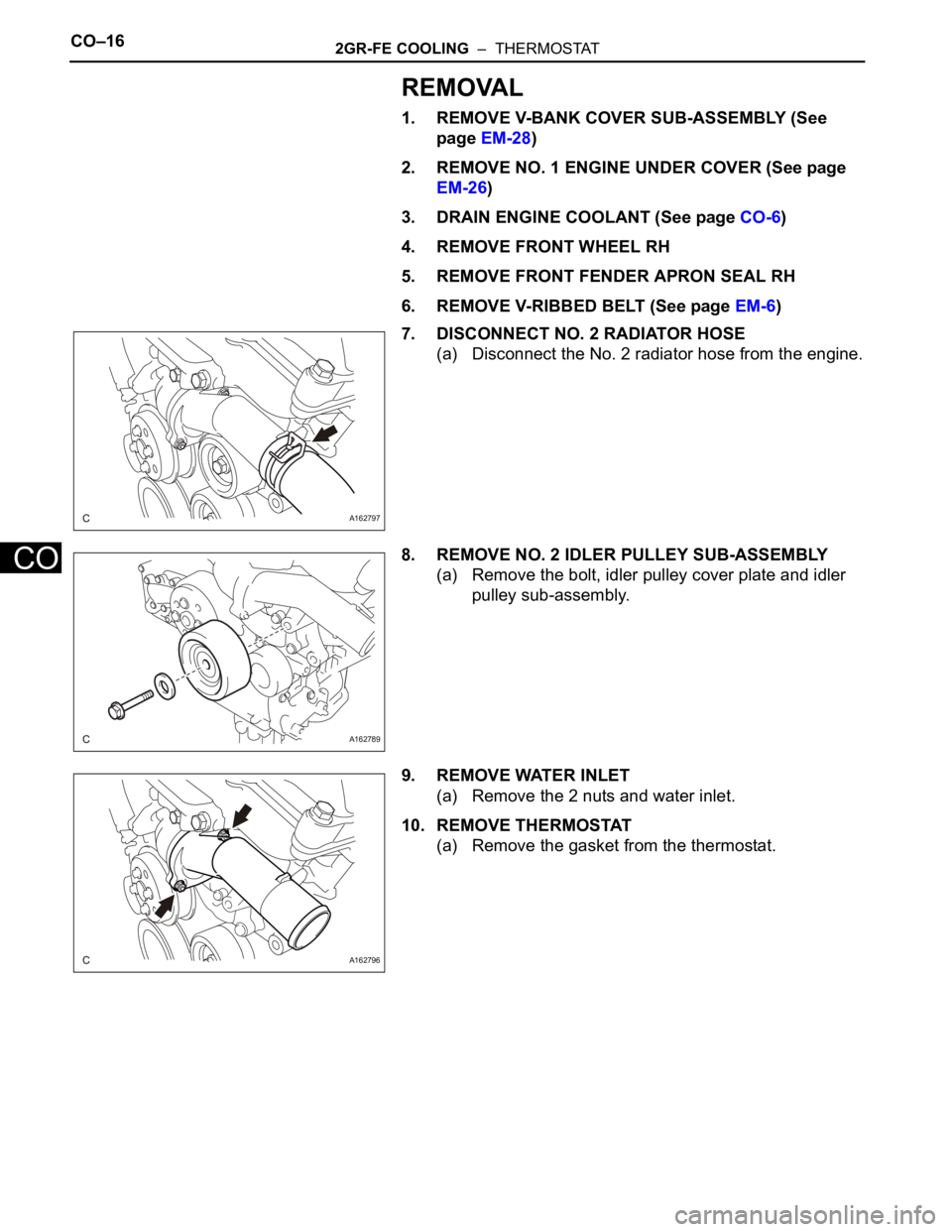

4. CONNECT NO. 2 RADIATOR HOSE

(a) Connect the No. 2 radiator hose to the engine.

5. INSTALL V-RIBBED BELT (See page EM-7)

6. INSTALL FRONT FENDER APRON SEAL RH

7. INSTALL FRONT WHEEL RH

8. ADD ENGINE COOLANT (See page CO-7)

9. INSTALL NO. 1 ENGINE UNDER COVER (See page

EM-63)

10. INSPECT FOR COOLANT LEAK (See page CO-1)

11. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-63)

A162789

A162797

Page 1270 of 3000

CO–162GR-FE COOLING – THERMOSTAT

CO

REMOVAL

1. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

2. REMOVE NO. 1 ENGINE UNDER COVER (See page

EM-26)

3. DRAIN ENGINE COOLANT (See page CO-6)

4. REMOVE FRONT WHEEL RH

5. REMOVE FRONT FENDER APRON SEAL RH

6. REMOVE V-RIBBED BELT (See page EM-6)

7. DISCONNECT NO. 2 RADIATOR HOSE

(a) Disconnect the No. 2 radiator hose from the engine.

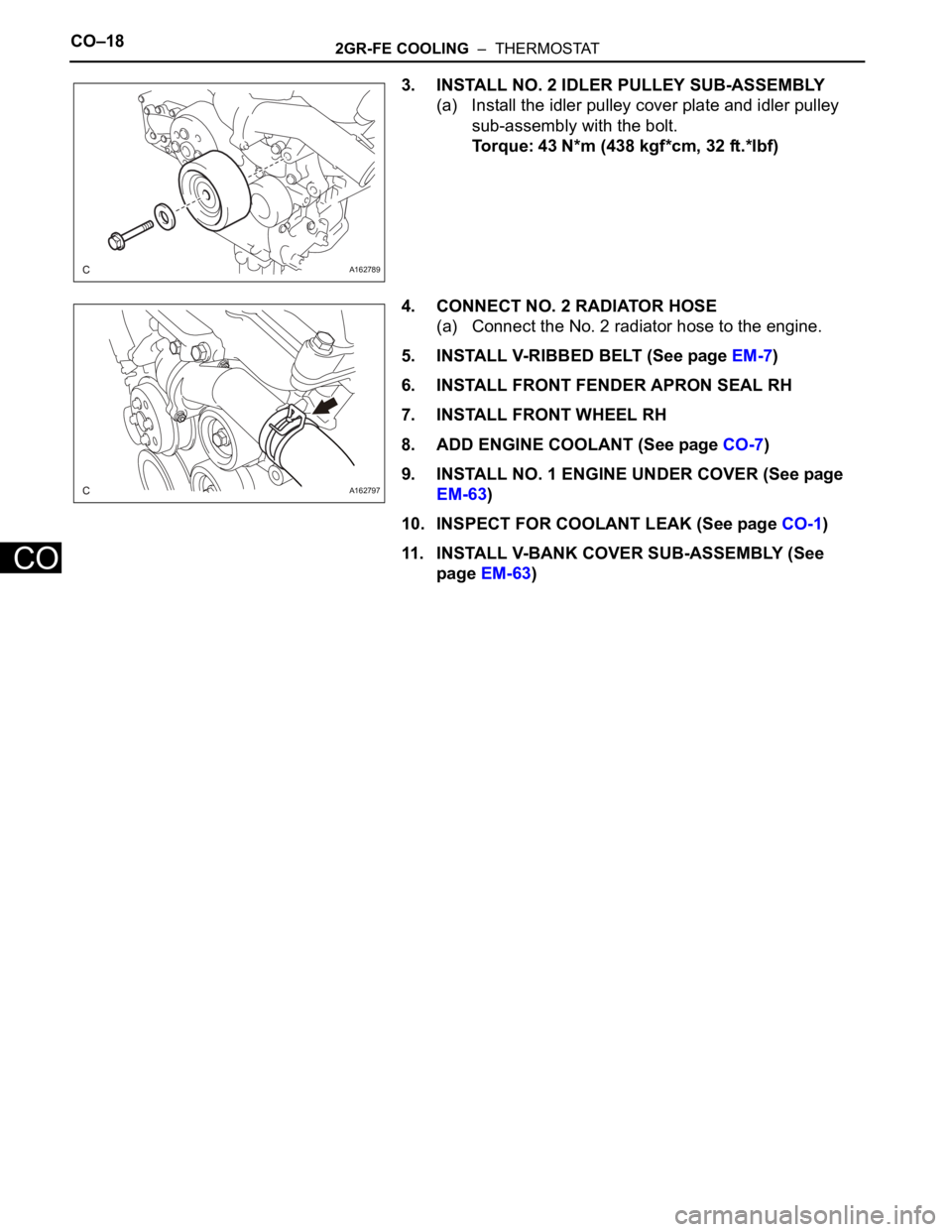

8. REMOVE NO. 2 IDLER PULLEY SUB-ASSEMBLY

(a) Remove the bolt, idler pulley cover plate and idler

pulley sub-assembly.

9. REMOVE WATER INLET

(a) Remove the 2 nuts and water inlet.

10. REMOVE THERMOSTAT

(a) Remove the gasket from the thermostat.

A162797

A162789

A162796

Page 1272 of 3000

CO–182GR-FE COOLING – THERMOSTAT

CO

3. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY

(a) Install the idler pulley cover plate and idler pulley

sub-assembly with the bolt.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

4. CONNECT NO. 2 RADIATOR HOSE

(a) Connect the No. 2 radiator hose to the engine.

5. INSTALL V-RIBBED BELT (See page EM-7)

6. INSTALL FRONT FENDER APRON SEAL RH

7. INSTALL FRONT WHEEL RH

8. ADD ENGINE COOLANT (See page CO-7)

9. INSTALL NO. 1 ENGINE UNDER COVER (See page

EM-63)

10. INSPECT FOR COOLANT LEAK (See page CO-1)

11. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-63)

A162789

A162797

Page 1339 of 3000

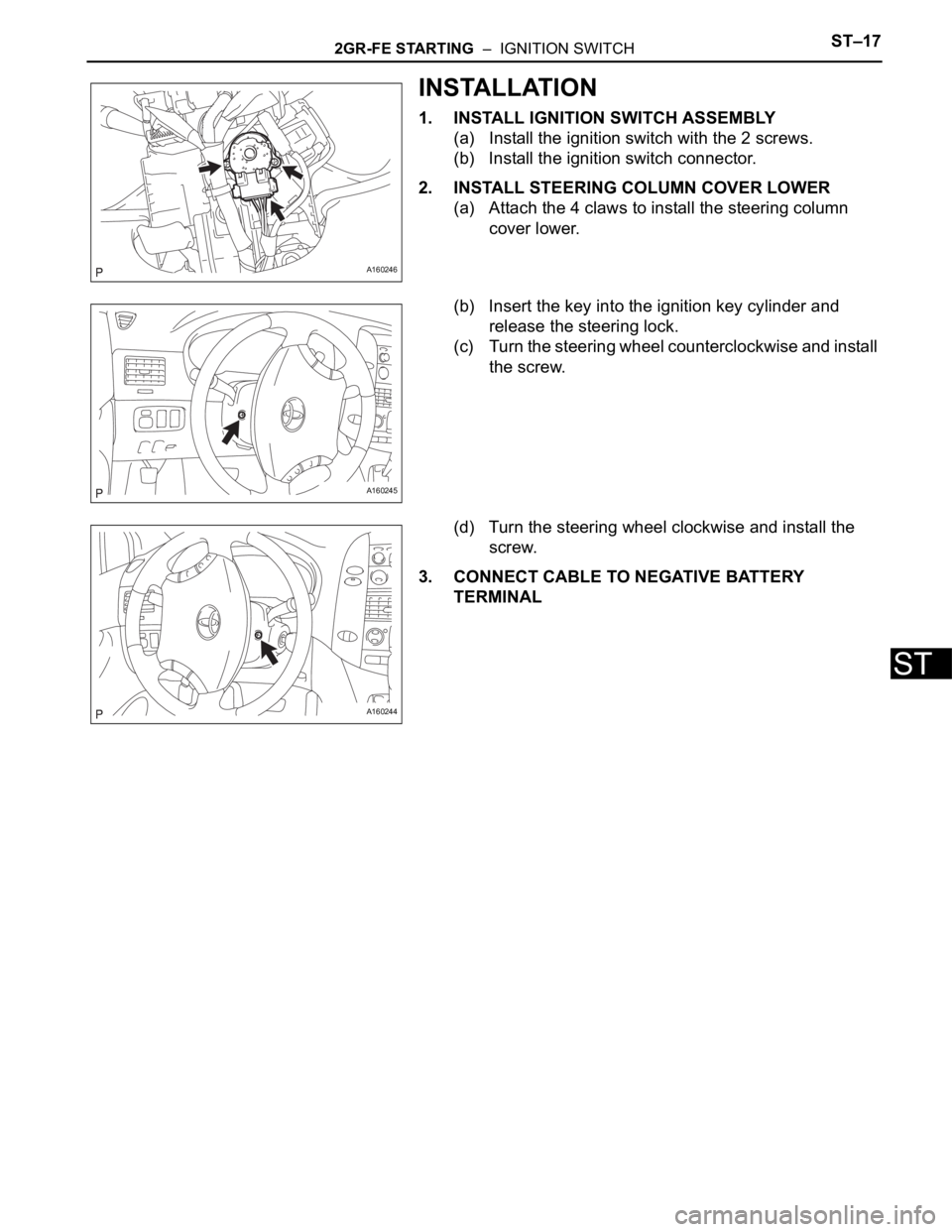

ST–162GR-FE STARTING – IGNITION SWITCH

ST

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

2. REMOVE STEERING COLUMN COVER LOWER

(a) Insert the key into the ignition key cylinder and

release the steering lock.

(b) Turn the steering wheel clockwise to gain access to

the screw and remove the screw.

(c) Turn the steering wheel counterclockwise to gain

access to the screw and remove the screw.

(d) Detach the 4 claws, and remove the steering

column cover lower.

3. REMOVE IGNITION SWITCH ASSEMBLY

(a) Disconnect the ignition switch connector.

(b) Remove the 2 screws and ignition switch.

INSPECTION

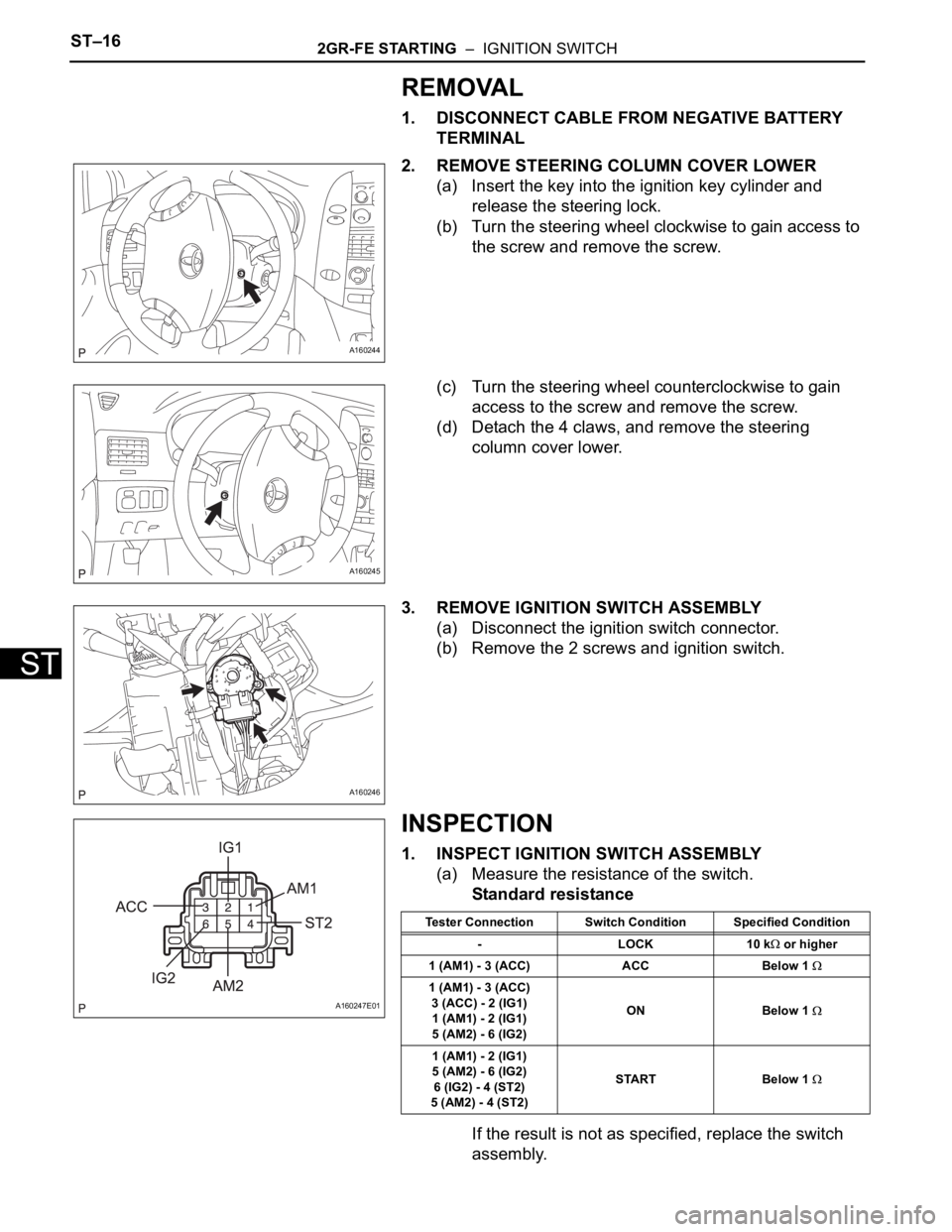

1. INSPECT IGNITION SWITCH ASSEMBLY

(a) Measure the resistance of the switch.

Standard resistance

If the result is not as specified, replace the switch

assembly.

A160244

A160245

A160246

A160247E01

Tester Connection Switch Condition Specified Condition

-LOCK10 k

or higher

1 (AM1) - 3 (ACC) ACC Below 1

1 (AM1) - 3 (ACC)

3 (ACC) - 2 (IG1)

1 (AM1) - 2 (IG1)

5 (AM2) - 6 (IG2)ON Below 1

1 (AM1) - 2 (IG1)

5 (AM2) - 6 (IG2)

6 (IG2) - 4 (ST2)

5 (AM2) - 4 (ST2)START Below 1

Page 1340 of 3000

2GR-FE STARTING – IGNITION SWITCHST–17

ST

INSTALLATION

1. INSTALL IGNITION SWITCH ASSEMBLY

(a) Install the ignition switch with the 2 screws.

(b) Install the ignition switch connector.

2. INSTALL STEERING COLUMN COVER LOWER

(a) Attach the 4 claws to install the steering column

cover lower.

(b) Insert the key into the ignition key cylinder and

release the steering lock.

(c) Turn the steering wheel counterclockwise and install

the screw.

(d) Turn the steering wheel clockwise and install the

screw.

3. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

A160246

A160245

A160244

Page 1351 of 3000

CH–162GR-FE CHARGING – GENERATOR

CH

REMOVAL

1. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

2. REMOVE FRONT WHEEL RH

3. REMOVE NO. 1 ENGINE UNDER COVER (See page

EM-26)

4. REMOVE FRONT FENDER APRON SEAL RH (See

page EM-26)

5. DRAIN ENGINE COOLANT (See page CO-6)

6. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

7. REMOVE BATTERY (See page EM-26)

8. REMOVE FRONT BUMPER ASSEMBLY (See page

ET-3)

9. REMOVE FRONT BUMPER ENERGY ABSORBER

10. REMOVE NO. 1 AIR CLEANER INLET (See page EM-

28)

11. DISCONNECT RADIATOR RESERVE TANK HOSE OR

PIPE (See page CO-28)

12. DISCONNECT NO. 1 RADIATOR HOSE (See page CO-

28)

13. DISCONNECT NO. 2 RADIATOR HOSE (See page CO-

29)

14. REMOVE HOOD LOCK RELEASE LEVER

PROTECTOR (See page CO-29)

15. REMOVE HOOD LOCK ASSEMBLY (See page CO-29)

16. REMOVE HOOD LOCK SUPPORT SUB-ASSEMBLY

(See page CO-29)

17. DISCONNECT COOLING FAN ECU CONNECTOR

(See page CO-30)

18. REMOVE RADIATOR UPPER SUPPORT SUB-

ASSEMBLY (See page CO-30)

19. DISCONNECT NO. 2 OIL COOLER OUTLET TUBE

SUB-ASSEMBLY (See page CO-31)

20. REMOVE HEADLIGHT ASSEMBLY RH (See page LI-

69)

21. REMOVE RADIATOR SIDE DEFLECTOR RH (See

page CO-31)

22. REMOVE HEADLIGHT BRACKET RH (See page CO-

32)

23. REMOVE PRESSURE FEED TUBE ASSEMBLY (See

page CO-32)