check engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1500 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–13

AX

MECHANICAL SYSTEM TESTS

1. PERFORM MECHANICAL SYSTEM TESTS

(a) Measure the stall speed.

The object of this test is to check the overall

performance of the transaxle and engine by

measuring the stall speeds in the D position.

NOTICE:

• Driving test should be done on a paved road

(a nonskid road).

• Perform the test at the normal operating ATF

(Automatic Transmission Fluid) temperature

50 to 80

C (122 to 176F).

• Do not continuously run this test for longer

than 10 seconds.

• To ensure safety, do this test in a wide, clear

level area which provides good traction.

• The stall test should always be carried out in

pairs. One technician should observe the

conditions of wheels or wheel stoppers

outside the vehicle while the other is doing

the test.

(1) Chock the 4 wheels.

(2) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(3) Fully apply the parking brake.

(4) Keep your left foot pressed firmly on the brake

pedal.

(5) Start the engine.

(6) Shift into the D position. Press all the way down

on the accelerator pedal with your right foot.

(7) Quickly read the stall speed at this time.

Stall speed:

2,300 +- 150 rpm

Evaluation:

Problem Possible cause

(a) Stall engine speed is low in D position• Engine power output may be insufficient

• Stator one-way clutch not operating properly

HINT:

If the value is less than the specified value by 600 rpm or more, the

torque converter could be faulty.

(b) Stall engine speed is high in D position• Line pressure is too low

• Forward clutch slipping

• U/D (Underdrive) brake slipping

• U/D (Underdrive) one-way clutch is not operating properly

• No.1 one-way clutch not operating properly

• Improper fluid level

Page 1501 of 3000

AX–14U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

(b) Measure the time lag.

(1) When the shift lever is shifted while the engine is

idling, there will be a certain time lapse or lag

before the shock can be felt. This is used for

checking the condition of the clutch and brake.

NOTICE:

• Perform the test at the normal operating

ATF (Automatic Transmission Fluid)

temperature: 50 to 80

C (122 to 176F).

• Be sure to allow 1 minute interval between

tests.

• Perform the test three times, and measure

the time lags. Calculate the average value

of the three time lags.

• When conducting stall test, do not

continue more than 10 seconds.

(2) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(3) Fully apply the parking brake.

(4) Start and warm up the engine and check idle

speed.

Idle speed:

approx. 700 rpm (In N position and A/C

OFF)

(5) Shift the lever from N to D position. Using a stop

watch, measure the time from when the lever is

shifted until the shock is felt.

Time lag:

N

D less than 1.2 seconds

(6) In the same way, measure the time lag for N

R.

Time lag:

N

R less than 1.5 seconds

Evaluation (If N

D or N R time lag is longer than the specified):

Problem Possible cause

N

D time lag is longer• Line pressure is too low

• Forward clutch worn

• No.1 one-way clutch is not operating properly

• U/D (Underdrive) one-way clutch is not operating

• U/D (Underdrive) brake worn

N

R time lag is longer• Line pressure is too low

• Reverse clutch worn

• 1st and reverse brake worn

• U/D (Underdrive) brake worn

Page 1502 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–15

AX

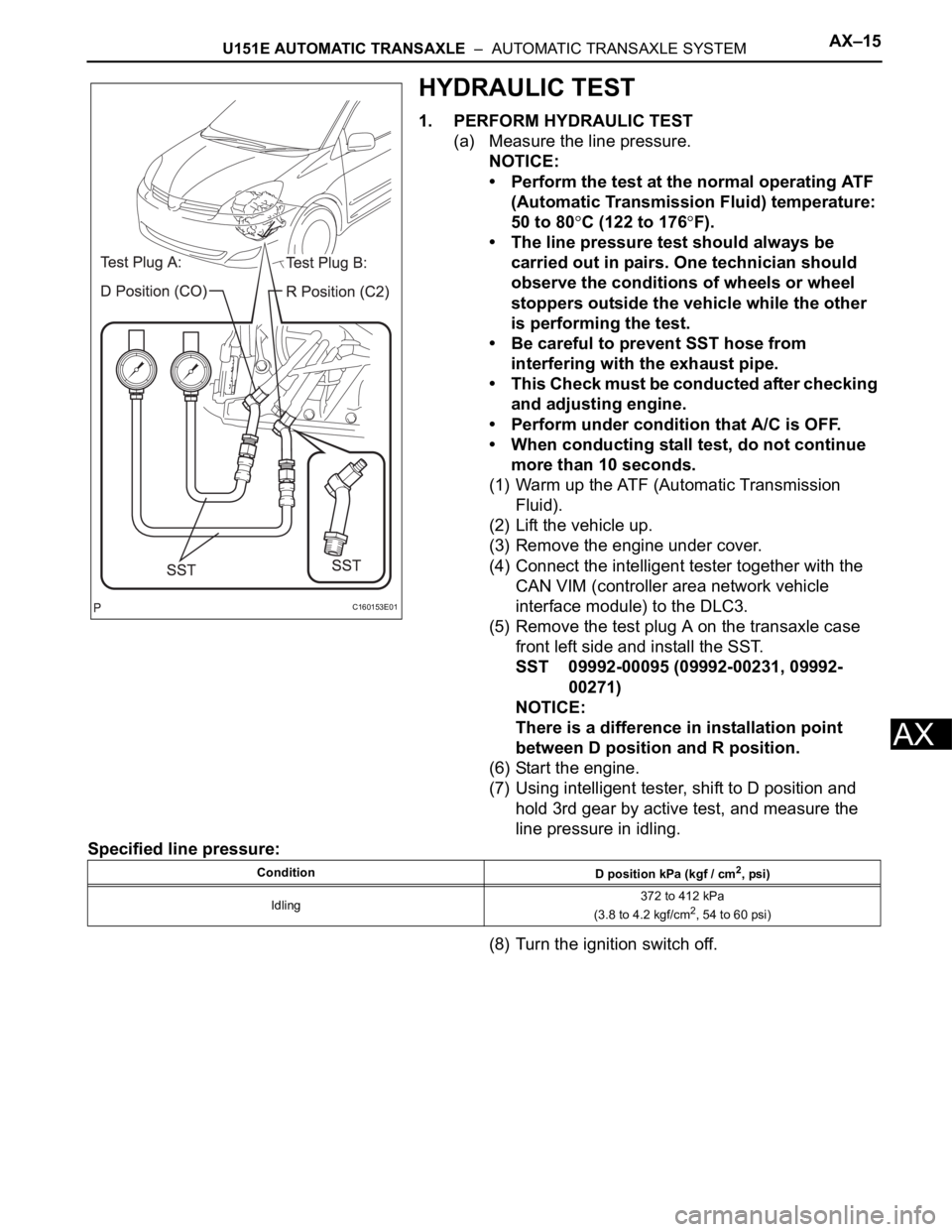

HYDRAULIC TEST

1. PERFORM HYDRAULIC TEST

(a) Measure the line pressure.

NOTICE:

• Perform the test at the normal operating ATF

(Automatic Transmission Fluid) temperature:

50 to 80

C (122 to 176F).

• The line pressure test should always be

carried out in pairs. One technician should

observe the conditions of wheels or wheel

stoppers outside the vehicle while the other

is performing the test.

• Be careful to prevent SST hose from

interfering with the exhaust pipe.

• This Check must be conducted after checking

and adjusting engine.

• Perform under condition that A/C is OFF.

• When conducting stall test, do not continue

more than 10 seconds.

(1) Warm up the ATF (Automatic Transmission

Fluid).

(2) Lift the vehicle up.

(3) Remove the engine under cover.

(4) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(5) Remove the test plug A on the transaxle case

front left side and install the SST.

SST 09992-00095 (09992-00231, 09992-

00271)

NOTICE:

There is a difference in installation point

between D position and R position.

(6) Start the engine.

(7) Using intelligent tester, shift to D position and

hold 3rd gear by active test, and measure the

line pressure in idling.

Specified line pressure:

(8) Turn the ignition switch off.

C160153E01

Condition

D position kPa (kgf / cm2, psi)

Idling372 to 412 kPa

(3.8 to 4.2 kgf/cm

2, 54 to 60 psi)

Page 1503 of 3000

AX–16U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

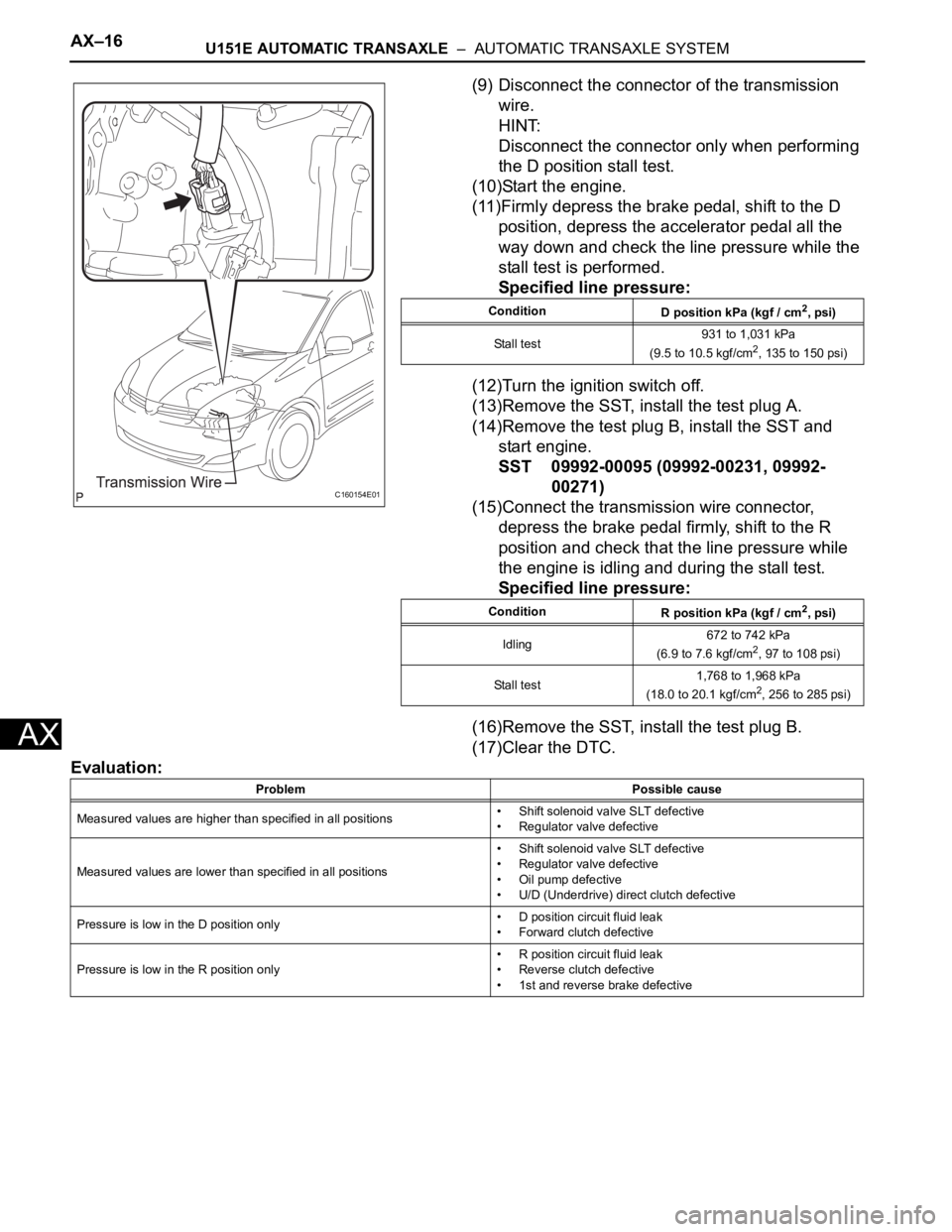

(9) Disconnect the connector of the transmission

wire.

HINT:

Disconnect the connector only when performing

the D position stall test.

(10)Start the engine.

(11)Firmly depress the brake pedal, shift to the D

position, depress the accelerator pedal all the

way down and check the line pressure while the

stall test is performed.

Specified line pressure:

(12)Turn the ignition switch off.

(13)Remove the SST, install the test plug A.

(14)Remove the test plug B, install the SST and

start engine.

SST 09992-00095 (09992-00231, 09992-

00271)

(15)Connect the transmission wire connector,

depress the brake pedal firmly, shift to the R

position and check that the line pressure while

the engine is idling and during the stall test.

Specified line pressure:

(16)Remove the SST, install the test plug B.

(17)Clear the DTC.

Evaluation:

C160154E01

Condition

D position kPa (kgf / cm2, psi)

Stall test931 to 1,031 kPa

(9.5 to 10.5 kgf/cm

2, 135 to 150 psi)

Condition

R position kPa (kgf / cm

2, psi)

Idling672 to 742 kPa

(6.9 to 7.6 kgf/cm

2, 97 to 108 psi)

Stall test1,768 to 1,968 kPa

(18.0 to 20.1 kgf/cm

2, 256 to 285 psi)

Problem Possible cause

Measured values are higher than specified in all positions• Shift solenoid valve SLT defective

• Regulator valve defective

Measured values are lower than specified in all positions• Shift solenoid valve SLT defective

• Regulator valve defective

• Oil pump defective

• U/D (Underdrive) direct clutch defective

Pressure is low in the D position only• D position circuit fluid leak

• Forward clutch defective

Pressure is low in the R position only• R position circuit fluid leak

• Reverse clutch defective

• 1st and reverse brake defective

Page 1507 of 3000

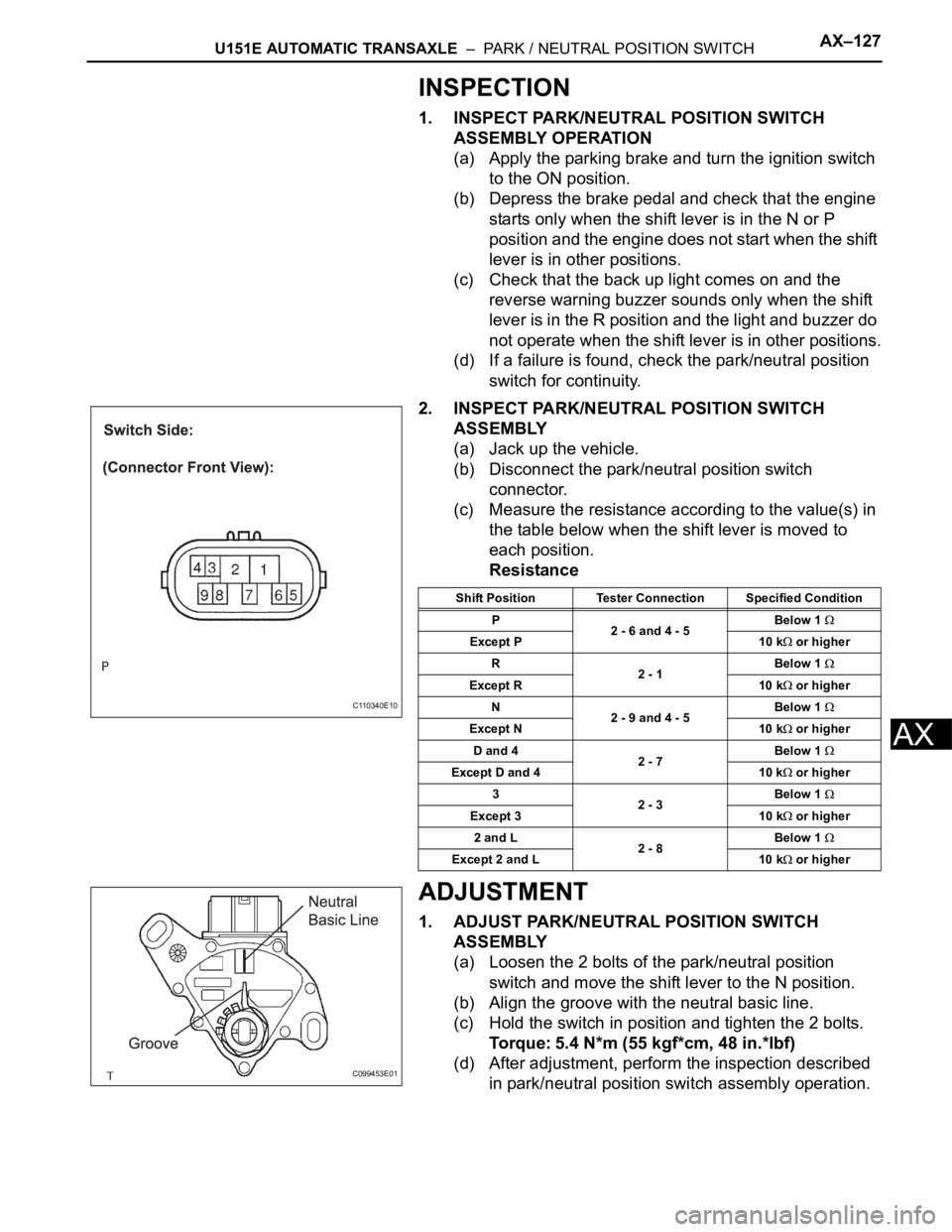

U151E AUTOMATIC TRANSAXLE – PARK / NEUTRAL POSITION SWITCHAX–127

AX

INSPECTION

1. INSPECT PARK/NEUTRAL POSITION SWITCH

ASSEMBLY OPERATION

(a) Apply the parking brake and turn the ignition switch

to the ON position.

(b) Depress the brake pedal and check that the engine

starts only when the shift lever is in the N or P

position and the engine does not start when the shift

lever is in other positions.

(c) Check that the back up light comes on and the

reverse warning buzzer sounds only when the shift

lever is in the R position and the light and buzzer do

not operate when the shift lever is in other positions.

(d) If a failure is found, check the park/neutral position

switch for continuity.

2. INSPECT PARK/NEUTRAL POSITION SWITCH

ASSEMBLY

(a) Jack up the vehicle.

(b) Disconnect the park/neutral position switch

connector.

(c) Measure the resistance according to the value(s) in

the table below when the shift lever is moved to

each position.

Resistance

ADJUSTMENT

1. ADJUST PARK/NEUTRAL POSITION SWITCH

ASSEMBLY

(a) Loosen the 2 bolts of the park/neutral position

switch and move the shift lever to the N position.

(b) Align the groove with the neutral basic line.

(c) Hold the switch in position and tighten the 2 bolts.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

(d) After adjustment, perform the inspection described

in park/neutral position switch assembly operation.

C110340E10

Shift Position Tester Connection Specified Condition

P

2 - 6 and 4 - 5Below 1

Except P 10 k or higher

R

2 - 1Below 1

Except R 10 k or higher

N

2 - 9 and 4 - 5Below 1

Except N 10 k or higher

D and 4

2 - 7Below 1

Except D and 4 10 k or higher

3

2 - 3Below 1

Except 3 10 k or higher

2 and L

2 - 8Below 1

Except 2 and L 10 k or higher

C099453E01

Page 1517 of 3000

AX–20U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

MONITOR DRIVE PATTERN

1. MONITOR DRIVE PATTERN FOR ECT TEST

(a) Perform this drive pattern as one method to

simulate the detection conditions of the ECT

malfunctions. (The DTCs may not be detected due

the actual driving conditions. And some codes may

not be detected through this drive pattern.)

HINT:

Preparation for driving

• Warm up the engine sufficiently. (Engine coolant

temperature is 60

C (140F) or higher)

• Drive the vehicle when the atmospheric

temperature is -10

C (14F) or higher.

(Malfunction is not detected when the

atmospheric temperature is less than -10

C

(14

F))

Driving note

• Drive the vehicle through all gears.

Stop

1st 2nd 3rd 4th 5th 5th

(lock-up ON).

• Repeat the above driving pattern three times or

more.

NOTICE:

• The monitor status can be checked using the

OBD II scan tool or intelligent tester. When

using the intelligent tester, monitor status

can be found in the "ENHANCED OBD II /

DATA LIST" or under "CARB OBD II".

• In the event that the drive pattern must be

interrupted (possibly due to traffic conditions

or other factors), the drive pattern can be

resumed and, in most cases, the monitor can

be completed.

• Perform this drive pattern on a level road as

much as possible and strictly observe the

posted speed limits and traffic laws while

driving.

Page 1524 of 3000

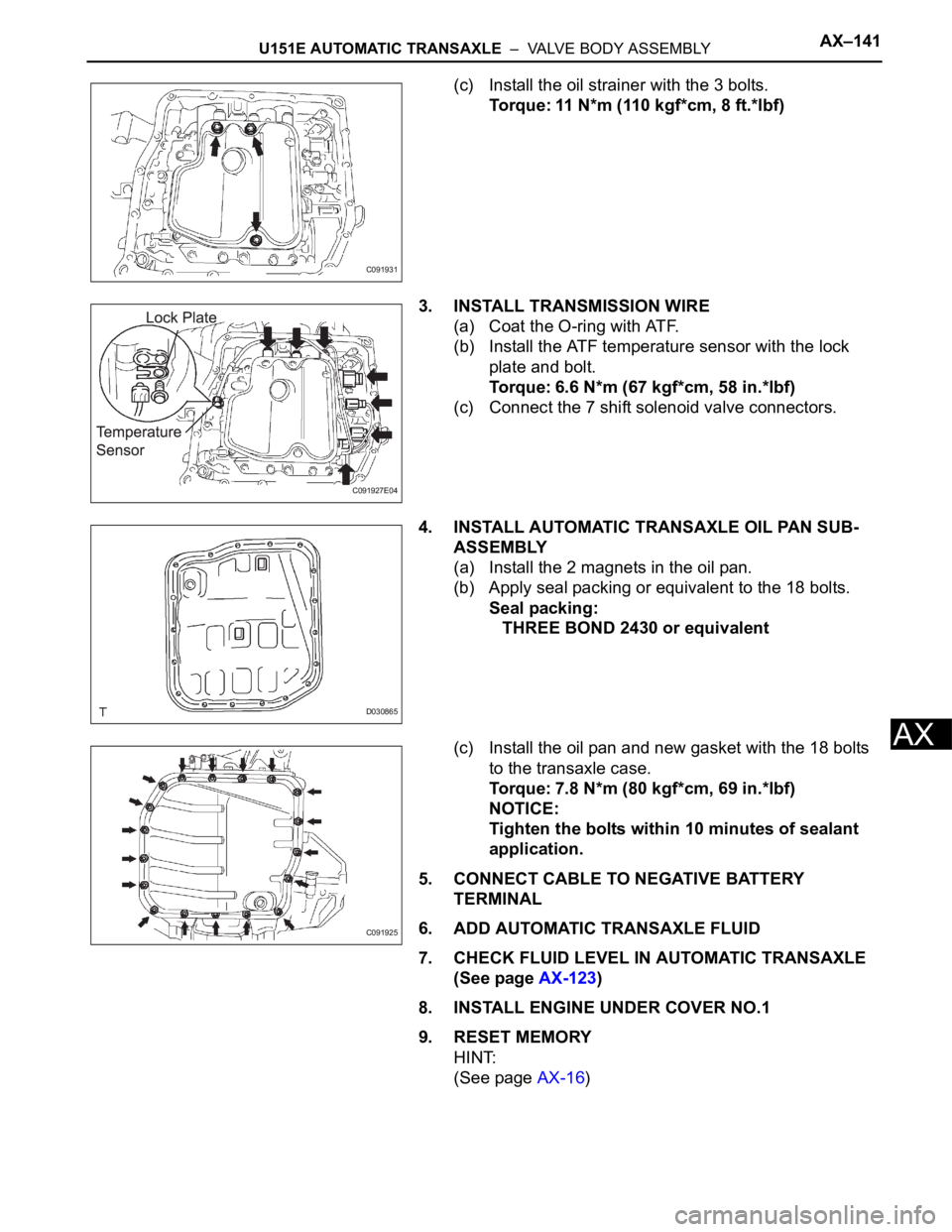

U151E AUTOMATIC TRANSAXLE – VALVE BODY ASSEMBLYAX–141

AX

(c) Install the oil strainer with the 3 bolts.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

3. INSTALL TRANSMISSION WIRE

(a) Coat the O-ring with ATF.

(b) Install the ATF temperature sensor with the lock

plate and bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf)

(c) Connect the 7 shift solenoid valve connectors.

4. INSTALL AUTOMATIC TRANSAXLE OIL PAN SUB-

ASSEMBLY

(a) Install the 2 magnets in the oil pan.

(b) Apply seal packing or equivalent to the 18 bolts.

Seal packing:

THREE BOND 2430 or equivalent

(c) Install the oil pan and new gasket with the 18 bolts

to the transaxle case.

Torque: 7.8 N*m (80 kgf*cm, 69 in.*lbf)

NOTICE:

Tighten the bolts within 10 minutes of sealant

application.

5. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

6. ADD AUTOMATIC TRANSAXLE FLUID

7. CHECK FLUID LEVEL IN AUTOMATIC TRANSAXLE

(See page AX-123)

8. INSTALL ENGINE UNDER COVER NO.1

9. RESET MEMORY

HINT:

(See page AX-16)

C091931

C091927E04

D030865

C091925

Page 1525 of 3000

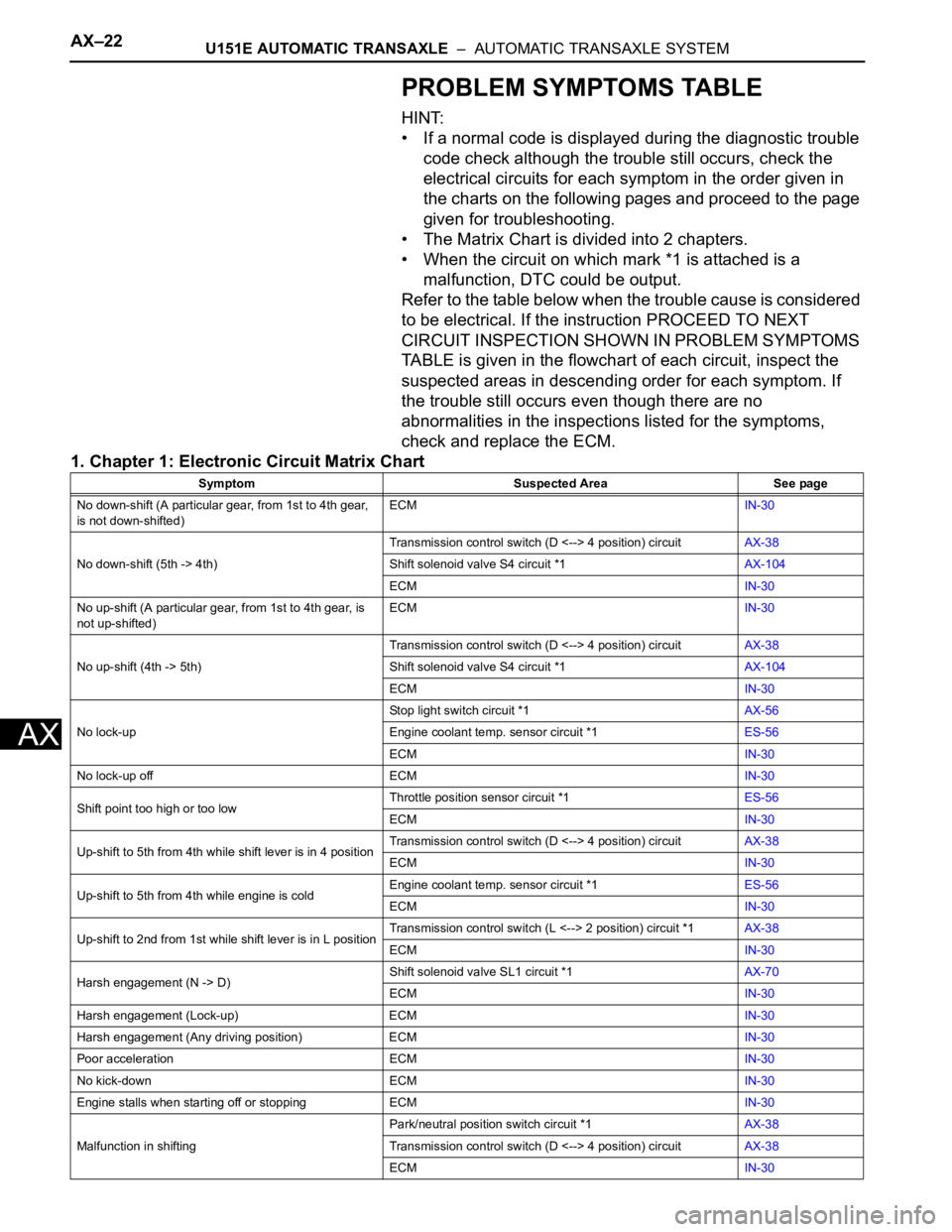

AX–22U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

PROBLEM SYMPTOMS TABLE

HINT:

• If a normal code is displayed during the diagnostic trouble

code check although the trouble still occurs, check the

electrical circuits for each symptom in the order given in

the charts on the following pages and proceed to the page

given for troubleshooting.

• The Matrix Chart is divided into 2 chapters.

• When the circuit on which mark *1 is attached is a

malfunction, DTC could be output.

Refer to the table below when the trouble cause is considered

to be electrical. If the instruction PROCEED TO NEXT

CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS

TABLE is given in the flowchart of each circuit, inspect the

suspected areas in descending order for each symptom. If

the trouble still occurs even though there are no

abnormalities in the inspections listed for the symptoms,

check and replace the ECM.

1. Chapter 1: Electronic Circuit Matrix Chart

Symptom Suspected Area See page

No down-shift (A particular gear, from 1st to 4th gear,

is not down-shifted)ECMIN-30

No down-shift (5th -> 4th)Transmission control switch (D <--> 4 position) circuitAX-38

Shift solenoid valve S4 circuit *1AX-104

ECMIN-30

No up-shift (A particular gear, from 1st to 4th gear, is

not up-shifted)ECMIN-30

No up-shift (4th -> 5th)Transmission control switch (D <--> 4 position) circuitAX-38

Shift solenoid valve S4 circuit *1AX-104

ECMIN-30

No lock-upStop light switch circuit *1AX-56

Engine coolant temp. sensor circuit *1ES-56

ECMIN-30

No lock-up off ECMIN-30

Shift point too high or too lowThrottle position sensor circuit *1ES-56

ECMIN-30

Up-shift to 5th from 4th while shift lever is in 4 positionTransmission control switch (D <--> 4 position) circuitAX-38

ECMIN-30

Up-shift to 5th from 4th while engine is coldEngine coolant temp. sensor circuit *1ES-56

ECMIN-30

Up-shift to 2nd from 1st while shift lever is in L positionTransmission control switch (L <--> 2 position) circuit *1AX-38

ECMIN-30

Harsh engagement (N -> D)Shift solenoid valve SL1 circuit *1AX-70

ECMIN-30

Harsh engagement (Lock-up) ECMIN-30

Harsh engagement (Any driving position) ECMIN-30

Poor acceleration ECMIN-30

No kick-down ECMIN-30

Engine stalls when starting off or stopping ECMIN-30

Malfunction in shiftingPark/neutral position switch circuit *1AX-38

Transmission control switch (D <--> 4 position) circuitAX-38

ECMIN-30

Page 1542 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–29

AX

DIAGNOSIS SYSTEM

1. DESCRIPTION

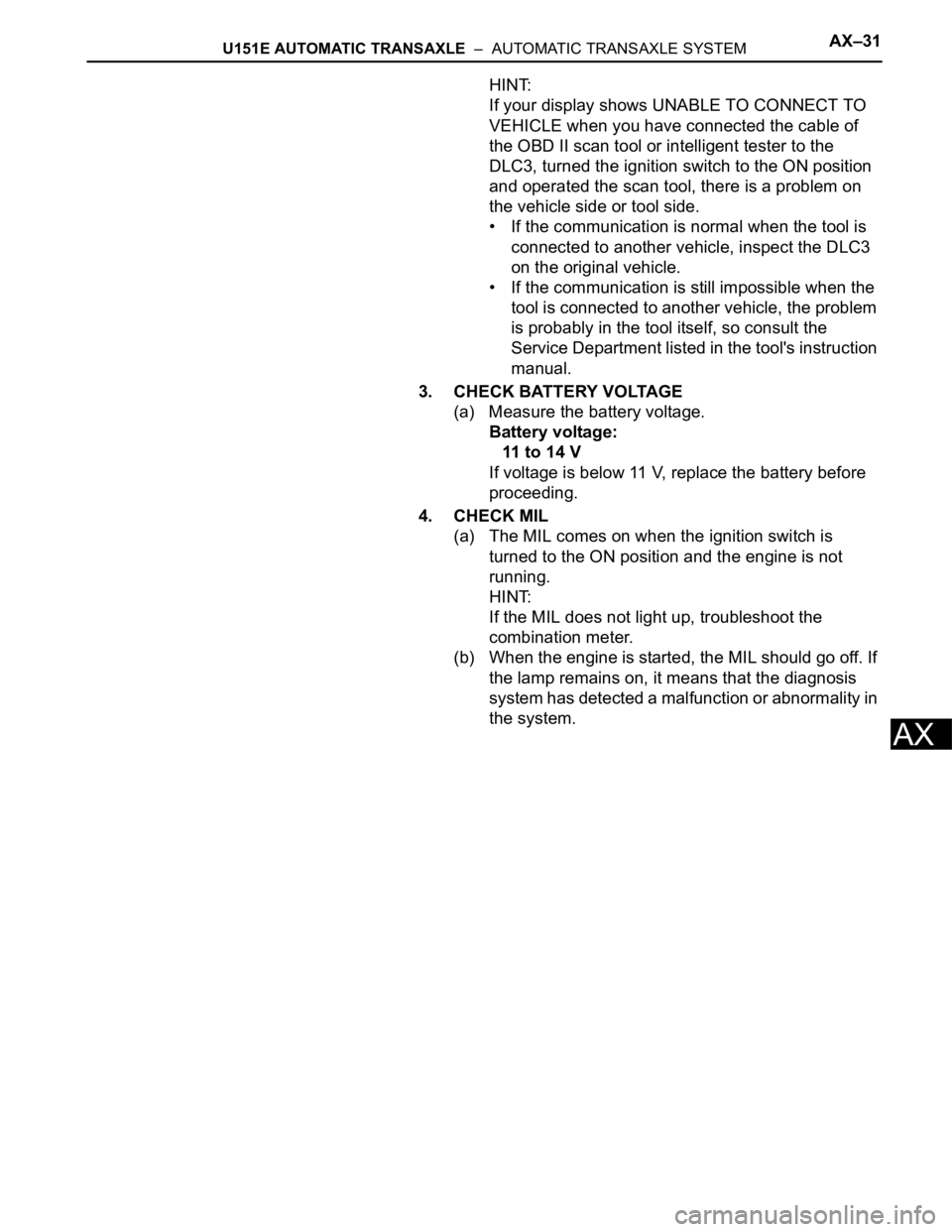

(a) When troubleshooting OBD II vehicles, the only

difference from the usual troubleshooting procedure

is to connect an OBD II scan tool complying with

SAE J1987 or a intelligent tester to the vehicle, and

read off various data output from the vehicle's ECM.

(b) OBD II regulations require that the vehicle's on-

board computer illuminate the Malfunction Indicator

Lamp (MIL) on the instrument panel when the

computer detects a malfunction in the computer

itself or in the drive system components whic h affect

the vehicle emissions. In addition to illuminating the

MIL when a malfunction is detected, the applicable

DTCs prescribed by SAE J2012 are recorded in the

ECM memory (See page AX-35).

If the malfunction does not occur in 3 consecutive

trips, the MIL goes off but the DTCs remain in the

ECM memory.

(c) To check the DTCs, connect the OBD II scan tool or

intelligent tester to the DLC3 of the vehicle. The

OBD II scan tool or intelligent tester also enables

you to erase the DTCs and check freeze frame data

and various forms of engine data (For operating

instructions, see the instruction book).

(d) The DTCs include SAE controlled codes and

Manufacturer controlled codes. SAE controlled

codes must be set as prescribed by the SAE, while

Manufacturer controlled codes can be set freely by

a manufacturer within the prescribed limits (See

page AX-35).

(e) The diagnosis system operates in "normal mode"

during the normal vehicle use. In normal mode, "2-

trip detection logic" is used to ensure accurate

detection of malfunction. "Check mode" is also

available to technicians as an option. In check

mode, "1-trip detection logic" is used for simulating

malfunction symptoms and increasing the system's

ability to detect malfunctions, including intermittent

malfunction.

(f) *2 trip detection logic: When a malfunction is first

detected, the malfunction is temporarily stored in

the ECM memory (1st trip). If the ignition switch is

turned off and then turned to the ON position again,

and same malfunction is detected again, the MIL will

illuminate.

FI00534

C159873E01

Page 1544 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–31

AX

HINT:

If your display shows UNABLE TO CONNECT TO

VEHICLE when you have connected the cable of

the OBD II scan tool or intelligent tester to the

DLC3, turned the ignition switch to the ON position

and operated the scan tool, there is a problem on

the vehicle side or tool side.

• If the communication is normal when the tool is

connected to another vehicle, inspect the DLC3

on the original vehicle.

• If the communication is still impossible when the

tool is connected to another vehicle, the problem

is probably in the tool itself, so consult the

Service Department listed in the tool's instruction

manual.

3. CHECK BATTERY VOLTAGE

(a) Measure the battery voltage.

Battery voltage:

11 to 14 V

If voltage is below 11 V, replace the battery before

proceeding.

4. CHECK MIL

(a) The MIL comes on when the ignition switch is

turned to the ON position and the engine is not

running.

HINT:

If the MIL does not light up, troubleshoot the

combination meter.

(b) When the engine is started, the MIL should go off. If

the lamp remains on, it means that the diagnosis

system has detected a malfunction or abnormality in

the system.